Mine Backfilling in the Permafrost, Part II: Effect of Declining Curing Temperature on the Short-Term Unconfined Compressive Strength of Cemented Paste Backfills

Abstract

:1. Introduction

2. Characterization of Materials and Methodology

2.1. Characteristic of Tailings, Binder, and Mixing Water

2.2. Mixture Preparation and Thermal Curing Conditions

2.3. UCS Determination

3. Results

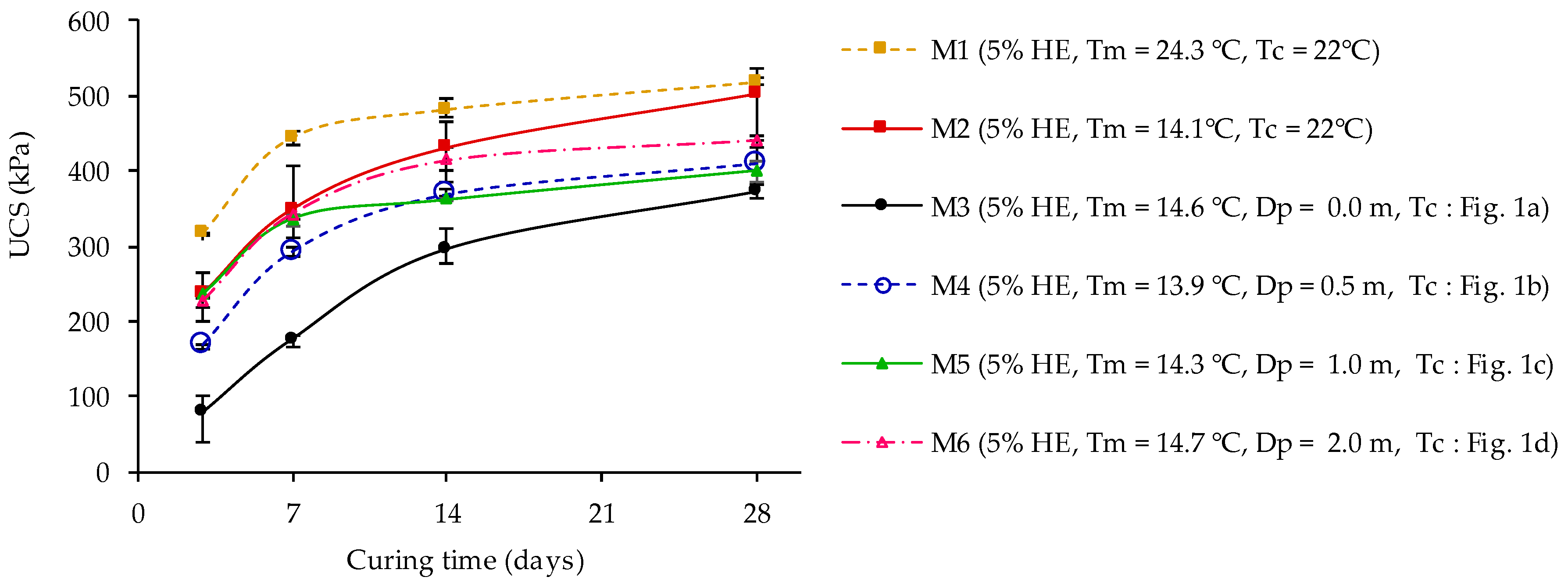

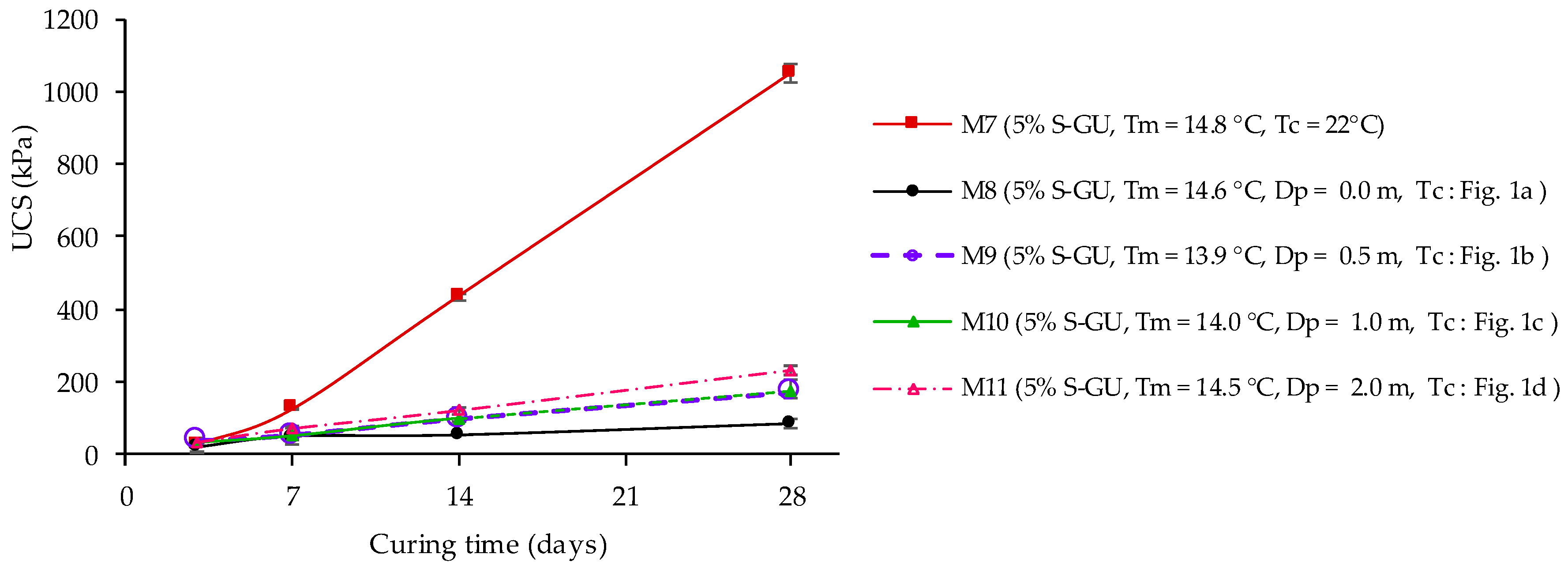

3.1. Effect of Declining Curing Temperature on the UCS

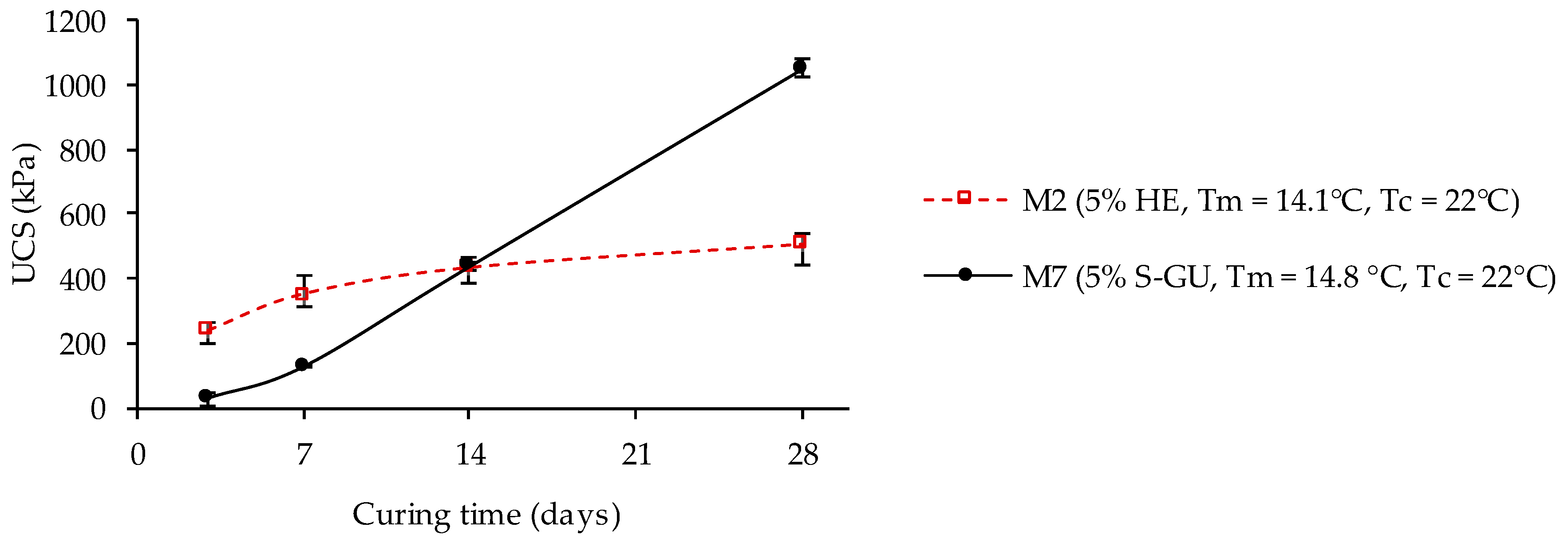

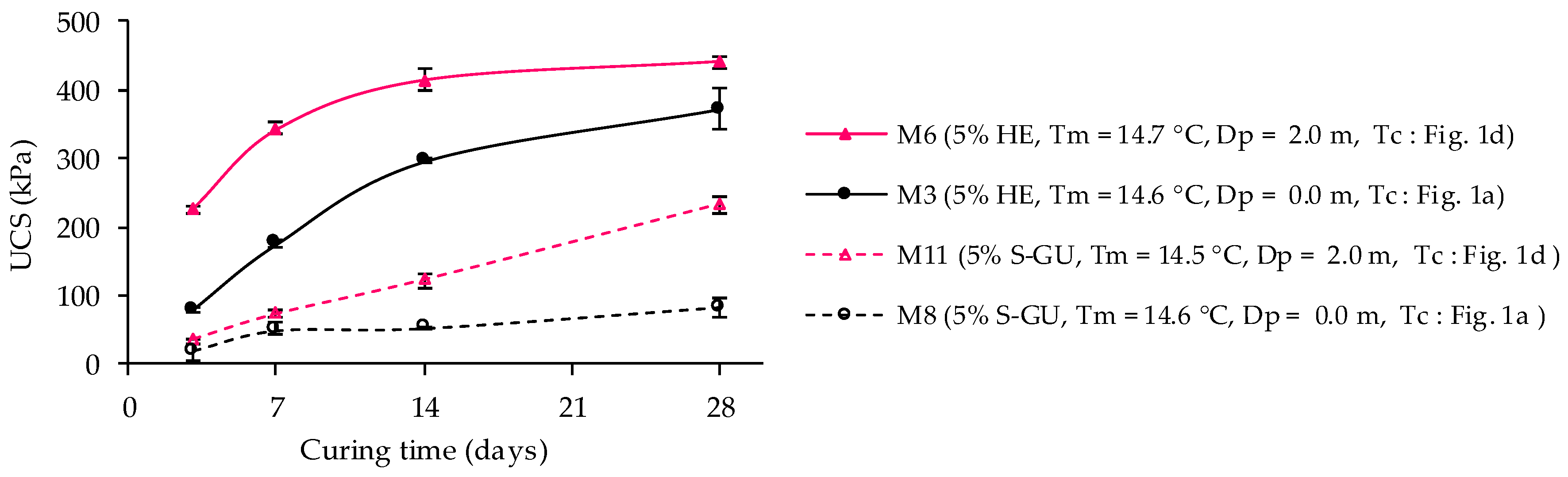

3.2. Effect of Binder Type on the UCS of CPB Cured under Declining Temperature

3.3. Effect of Cement Content on the UCS of CPB Curing under Decreasing Temperature

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hassani, F.; Archibald, J. Mine Backfill; CD-ROM; CIM: Montreal, QC, Canada, 1998. [Google Scholar]

- Sheshpari, M. A review of underground mine backfilling methods with emphasis on cemented paste backfill. Electron. J. Geotech. Eng. 2015, 20, 5183–5208. [Google Scholar]

- Zhang, J.; Li, M.; Taheri, A.; Zhang, W.; Wu, Z.; Song, W. Properties and Application of Backfill Materials in Coal Mines in China. Minerals 2019, 9, 53. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M.; Bussière, B. Mechanical behaviour of cemented paste backfill. In Proceedings of the 53th Canadian Geotechnical Conference, Geotechnical Engineering at the Dawn of the Third Millennium, Montreal, QC, Canada, 15–18 October 2000; Volume 1, pp. 373–380. [Google Scholar]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Brackebusch, F.W. Basics of paste backfill systems. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 3, 122A. [Google Scholar]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Compos. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Landriault, D.; Verburg, R.; Cincilla, W.; Welch, D. Paste technology for Underground Backfill and Surface Tailings Disposal Applications; Short Course Notes, Canadian Institute of Mining and Metallurgy, Technical Workshop; Canadian Institute of Mining and Metallurgy: Montreal, QC, Canada, 1997; Volume 27, p. 1997. [Google Scholar]

- Belem, T.; Benzaazoua, M. An overview on the use of paste backfill technology as a ground support method in cut-and-fill mines. In Proceedings of the 5th International Symposium on Ground Support in Mining and Underground Construction, Perth, Australia, 28–30 September 2004; Villaescusa, E., Potvin, Y., Eds.; CRC Press: Boca Raton, FL, USA, 2004; pp. 28–30. [Google Scholar]

- Fourie, A.B.; Helinski, M.; Fahey, M. Using effective stress theory to characterize the behaviour of backfill. In Proceedings of the Minefill Conference, Montreal, QC, Canada, 29 April–2 May 2007; Volume 29. [Google Scholar]

- Mitchell, R.J.; Olsen, R.S.; Smith, J.D. Model studies on cemented tailings used in mine backfill. Can. Geotech. J. 1982, 19, 14–28. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and Application of Underground Mine Paste Backfill Technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Thompson, B.D.; Bawden, W.F.; Grabinsky, M.W. In situ measurements of cemented paste backfill at the Cayeli Mine. Can. Geotech. J. 2012, 49, 755–772. [Google Scholar] [CrossRef]

- Ouattara, D.; Belem, T.; Mbonimpa, M.; Yahia, A. Effect of superplasticizers on the consistency and unconfined compressive strength of cemented paste backfills. Constr. Build. Mater. 2018, 181, 59–72. [Google Scholar] [CrossRef]

- Ouattara, D.; Mbonimpa, M.; Yahia, A.; Belem, T. Assessment of rheological parameters of high density cemented paste backfill mixtures incorporating superplasticizers. Constr. Build. Mater. 2018, 190, 294–307. [Google Scholar] [CrossRef]

- Ouattara, D.; Yahia, A.; Mbonimpa, M.; Belem, T. Effects of superplasticizer on rheological properties of cemented paste backfills. Int. J. Miner. Process. 2017, 161, 28–40. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Deng, J.; Ke, B. Effects of Superplasticizer on the Hydration, Consistency, and Strength Development of Cemented Paste Backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef]

- Bandopadhyay, S.; Izaxon, V. Ice-cemented backfill for underground support in arctic mines. In Proceedings of the SME Annual Meeting, Denver, CO, USA, 6 February 2004. [Google Scholar]

- Cluff, D.L.; Kazakidis, V. Frozen Baclfill Mix Formulations and Process for Use Thereof in Underground Mining Applications. U.S. Pat. Appl. Publ. US 2012/0114429 A1, 10 May 2012. [Google Scholar]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress–strain behaviour of cemented paste backfill in compression. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Li, H.; Yang, H.; Chang, C.; Sun, X. Experimental Investigation on Compressive Strength of Frozen Soil versus Strain Rate. J. Cold Reg. Eng. 2001, 15, 125–133. [Google Scholar] [CrossRef]

- Nasir, O.; Fall, M. Coupling binder hydration, temperature and compressive strength development of underground cemented paste backfill at early ages. Tunn. Undergr. Space Technol. 2010, 25, 9–20. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Bussière, B.; Benzaazoua, M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills. Cem. Concr. Compos. 2011, 33, 702–715. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Hassani, F.; Mohammadian, A.; Abbasy, F. Numerical modeling of thawing in frozen rocks of underground mines caused by backfilling. Int. J. Rock Mech. Min. 2011, 48, 1068–1076. [Google Scholar] [CrossRef]

- Beya, F.K.; Mbonimpa, M.; Belem, T.; Li, L.; Kalonji, K.; Benzaazoua, M.; Ouellet, S. Mine backfilling in the permafrost, Part I: Numerical prediction of thermal curing conditions within the cemented paste backfill matrix. Minerals 2019, 9, 165. [Google Scholar] [CrossRef]

- Beya, F.K. Étude du Transfert de chaleur dans les remblais en pâte cimentés curant sous les conditions aux frontières des chantiers miniers dans le pergélisol. Master’s Thesis, UQAT—École Polytechnique de Montréal, Montreal, QC, Canada, 2016. [Google Scholar]

- Han, F.S. Geotechnical Behaviour of Frozen Mine Backfills. Master’s Thesis, Université d’Ottawa/University of Ottawa, Ottawa, ON, Canada, 2011. [Google Scholar]

- Evirgen, B.; Onur, M.I.; Tuncan, M.; Tuncan, A. Determination of the Freezing Effect on Unconfined Compression Strength and Permeability of Saturated Granular Soils. Int. J. GEOMATE 2015, 8, 1283–1287. [Google Scholar] [CrossRef]

- Li, H.; Zhu, Y.; Pan, W. Uniaxial compressive strength of saturated frozen silt. In Proceedings of the 8th International Conference on Permafrost, Zürich, Switzerland, 21–25 July 2003; pp. 679–684. [Google Scholar]

- ASTM. C150-07 Standard Specification for Portland Cement; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Sivakugan, N.; Veenstra, R.; Naguleswaran, N. Underground Mine Backfilling in Australia Using Paste Fills and Hydraulic Fills. Int. J. Geosynth. Ground Eng. 2015, 1, 18. [Google Scholar] [CrossRef]

- Tariq, A.; Yanful, E.K. A review of binders used in cemented paste tailings for underground and surface disposal practices. J. Eniron. Manag. 2013, 131, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Soltani, A.; Taheri, A.; Karakus, M.; Deng, A. Application of Slag–Cement and Fly Ash for Strength Development in Cemented Paste Backfills. Minerals 2019, 9, 22. [Google Scholar] [CrossRef]

- Hivon, E.G.; Sego, D.C. Distribution of saline permafrost in the Northwest Territories, Canada. Can. Geotech. J. 1993, 30, 506–514. [Google Scholar] [CrossRef]

- Williams, J.R. Ground Water in the Permafrost Regions of Alaska; US Government Printing Office: Washington, DC, USA, 1970.

- Kalonji, K. Étude des propriétés rhéologiques et du transport du remblai cimenté en pâte en condition nordique. Master’s Thesis, UQAT—École Polytechnique de Montréal, Montreal, QC, Canada, 2016. [Google Scholar]

- COMSOL Multiphysics. Heat Transfer Module User’s Guide; COMSOL: Burlington, MA, USA, 2015; Volume 5.2. [Google Scholar]

- Benzaazoua, M.; Belem, T.; Bussière, B. Chemical aspect of sulfurous paste backfill mixtures. Cem. Concr. 2002, 32, 1133–1134. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B.; Alp, I.; Deveci, H. Effect of properties of tailings and binder on the short-and long-term strength and stability of cemented paste backfill. Mater. Lett. 2005, 59, 3703–3709. [Google Scholar] [CrossRef]

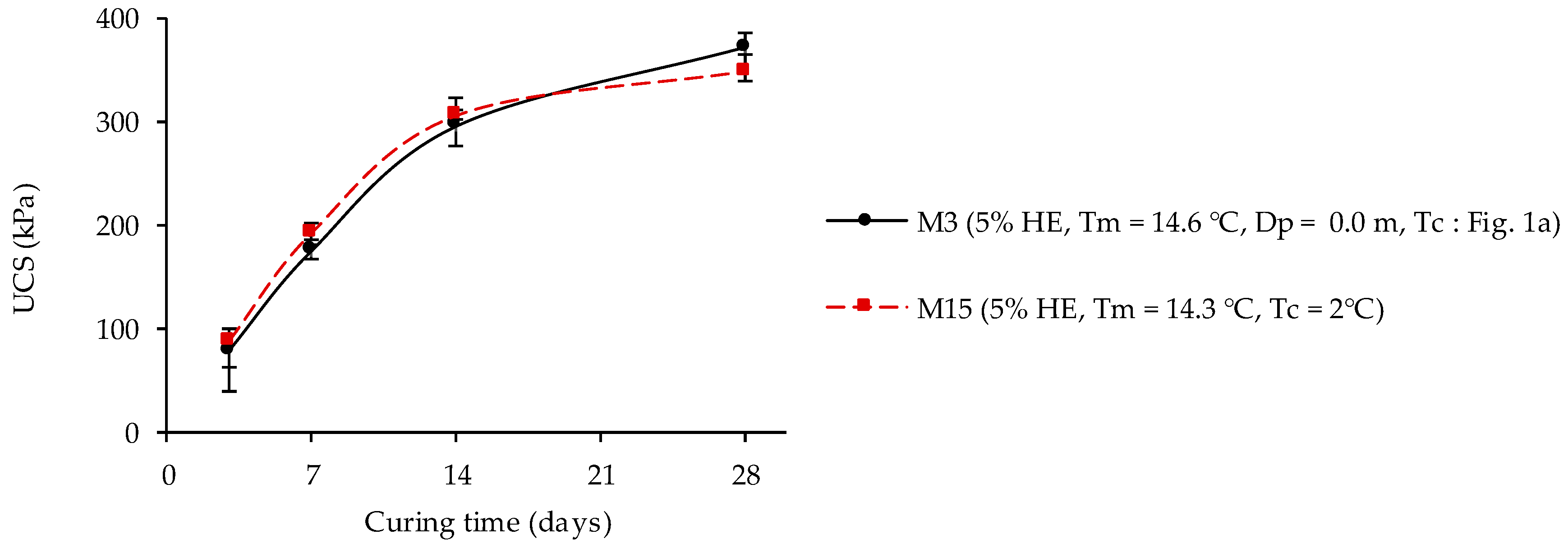

| Mixtures | Binder Type | Bw (%) | Temperature at the End of the Mixing Tm (°C) | Distance to the Interface Dp (m) | Target and Applied Curing Temperature |

|---|---|---|---|---|---|

| M1 | HE | 5 | 24.3 | - | 22 ± 1 °C |

| M2 | HE | 5 | 14.1 | 22 ± 1 °C | |

| M3 | HE | 5 | 14.6 | 0.0 | see Figure 1a |

| M4 | HE | 5 | 13.9 | 0.5 | see Figure 1b |

| M5 | HE | 5 | 14.3 | 1.0 | see Figure 1c |

| M6 | HE | 5 | 14.7 | 2.0 | see Figure 1d |

| M7 | S-GU | 5 | 14.8 | 22 ± 1 °C | |

| M8 | S-GU | 5 | 14.6 | 0.0 | see Figure 1a |

| M9 | S-GU | 5 | 13.9 | 0.5 | see Figure 1b |

| M10 | S-GU | 5 | 14.0 | 1.0 | see Figure 1c |

| M11 | S-GU | 5 | 14.5 | 2.0 | see Figure 1d |

| M12 | HE | 3 | 14.8 | - | 22 ± 1 °C |

| M13 | HE | 3 | 14.4 | 0.0 | see Figure 1a |

| M14 | HE | 3 | 14.0 | 2.0 | see Figure 1d |

| M15 | HE | 5 | 14.3 | - | 2 ± 1 °C |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mbonimpa, M.; Kwizera, P.; Belem, T. Mine Backfilling in the Permafrost, Part II: Effect of Declining Curing Temperature on the Short-Term Unconfined Compressive Strength of Cemented Paste Backfills. Minerals 2019, 9, 172. https://doi.org/10.3390/min9030172

Mbonimpa M, Kwizera P, Belem T. Mine Backfilling in the Permafrost, Part II: Effect of Declining Curing Temperature on the Short-Term Unconfined Compressive Strength of Cemented Paste Backfills. Minerals. 2019; 9(3):172. https://doi.org/10.3390/min9030172

Chicago/Turabian StyleMbonimpa, Mamert, Parrein Kwizera, and Tikou Belem. 2019. "Mine Backfilling in the Permafrost, Part II: Effect of Declining Curing Temperature on the Short-Term Unconfined Compressive Strength of Cemented Paste Backfills" Minerals 9, no. 3: 172. https://doi.org/10.3390/min9030172

APA StyleMbonimpa, M., Kwizera, P., & Belem, T. (2019). Mine Backfilling in the Permafrost, Part II: Effect of Declining Curing Temperature on the Short-Term Unconfined Compressive Strength of Cemented Paste Backfills. Minerals, 9(3), 172. https://doi.org/10.3390/min9030172