Surface Organic Modification of CaCO3-TiO2 Composite Pigment

Abstract

:1. Introduction

2. Methods

2.1. Raw Materials

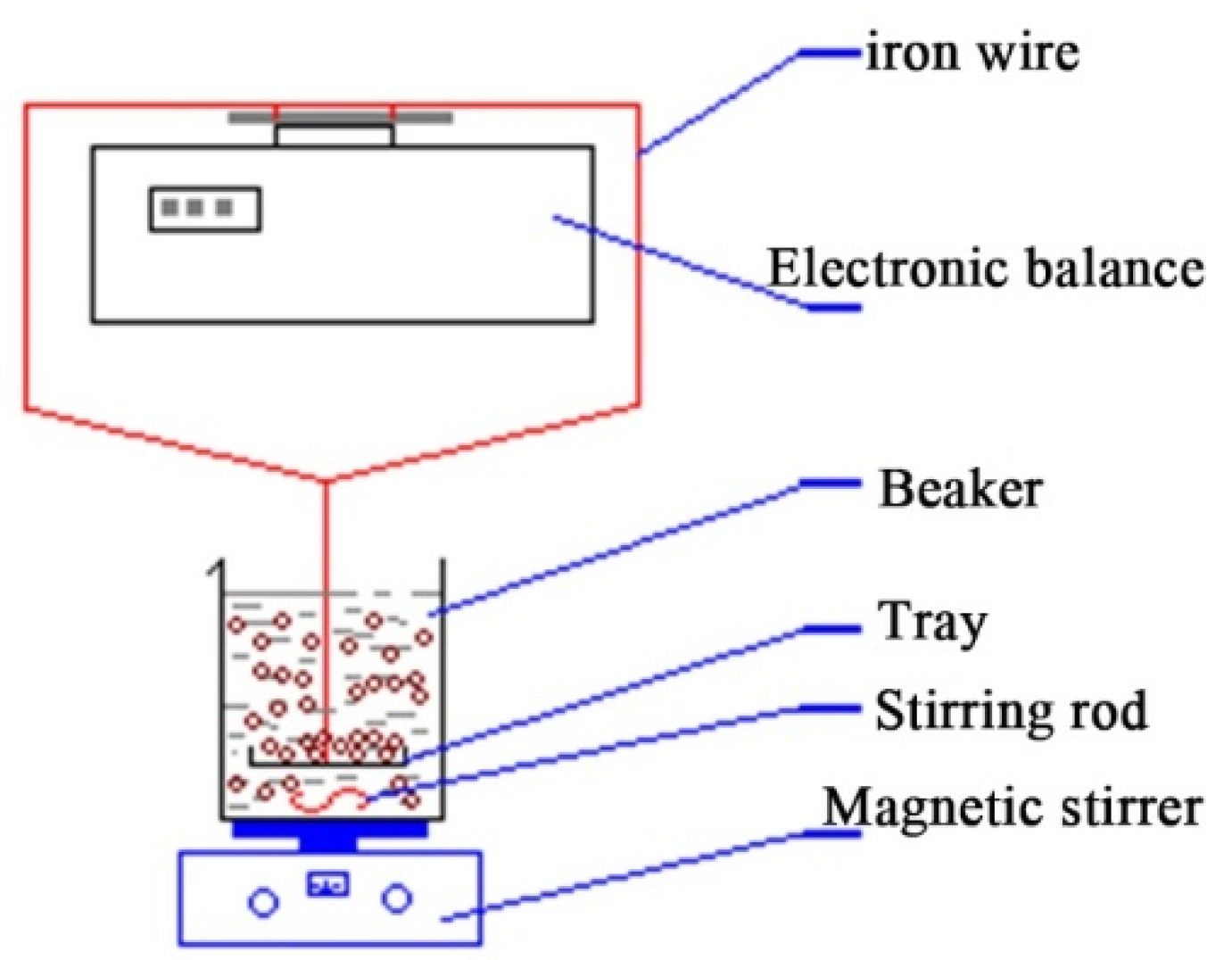

2.2. Modification Method

2.3. Property Test of Modified CaCO3-TiO2

3. Results and Discussion

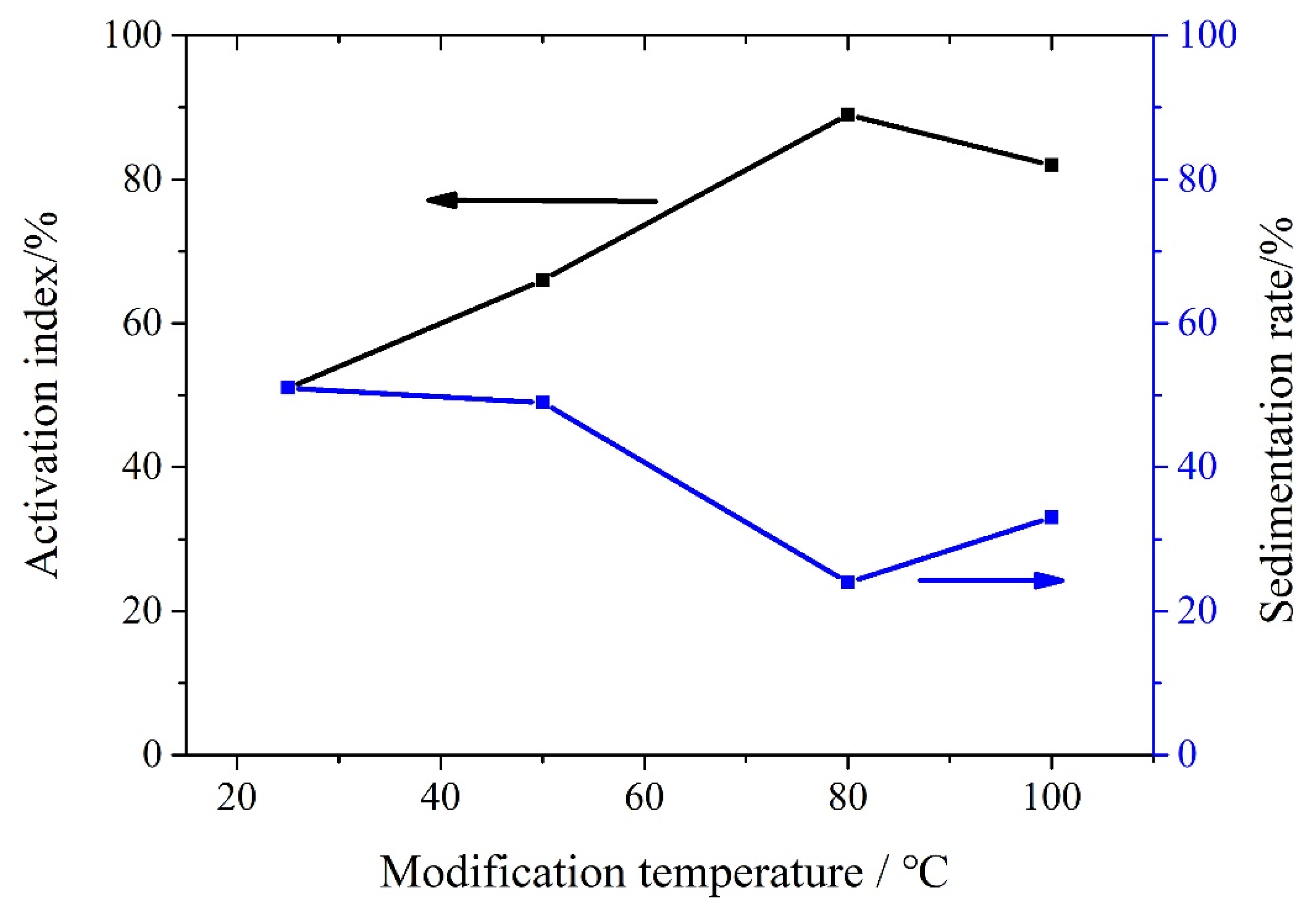

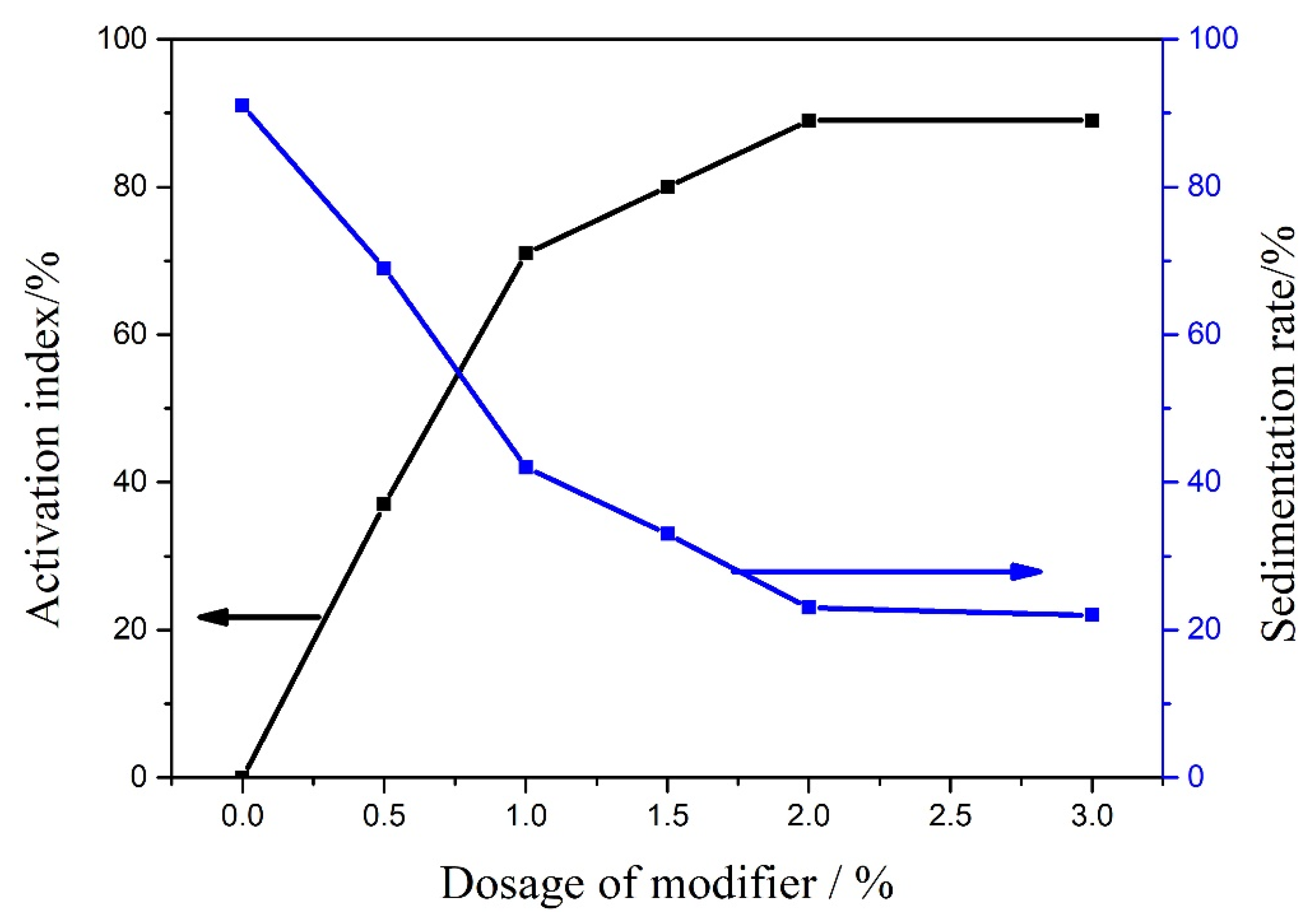

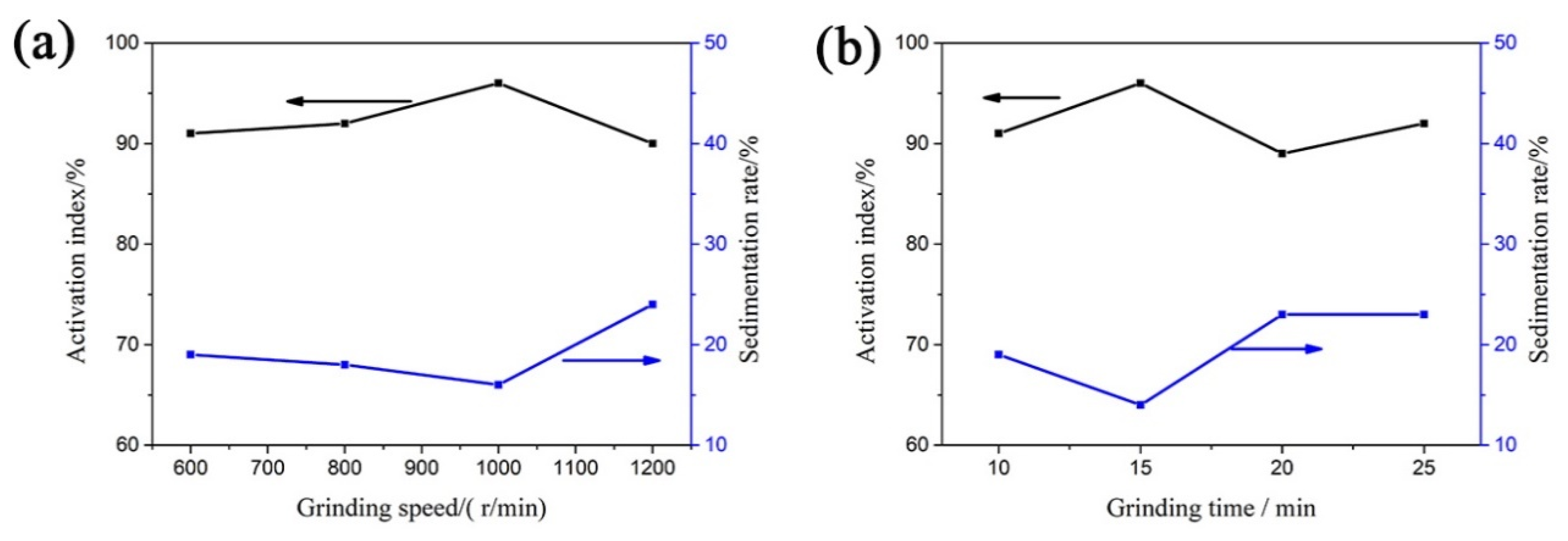

3.1. Influences of Modification Conditions on the Activation Index and Sedimentation Rate of CaCO3-TiO2

3.1.1. Influences of Modification Temperature

3.1.2. Influences of Modifier Dosage

3.1.3. Influences of the Mechanical Strength in Grinding

3.2. Properties of Modified CaCO3-TiO2

3.2.1. Pigment Properties of Modified CaCO3-TiO2

3.2.2. Dispersion Properties

3.2.3. Particle Characteristics

3.3. Change in Surface Free Energy of CaCO3-TiO2 after Modification

3.3.1. Wetting Contact Angle of CaCO3-TiO2

3.3.2. Calculation of Surface Free Energy

3.4. Binding Properties between CaCO3-TiO2 and Modifier

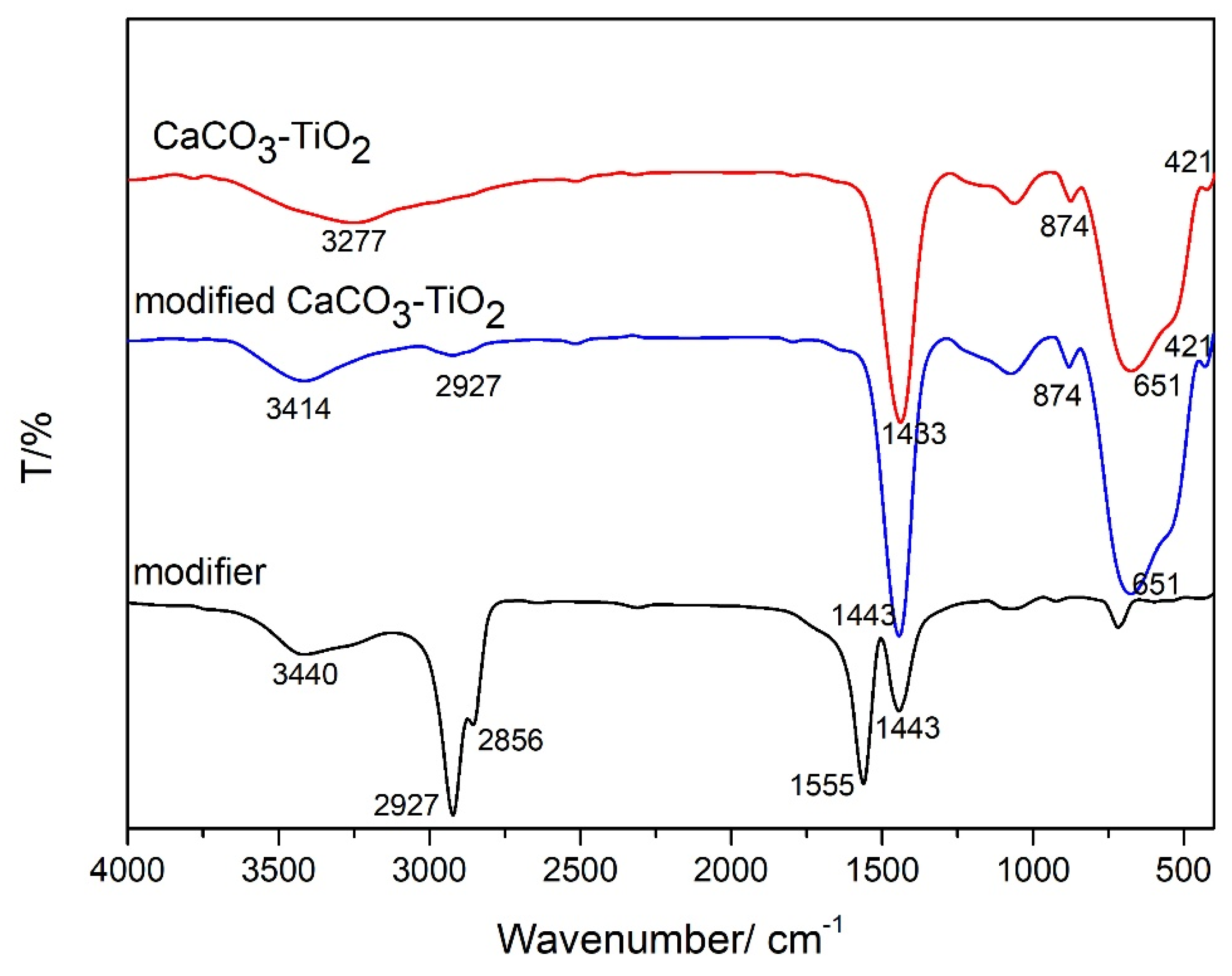

3.4.1. Infrared Spectral Analysis

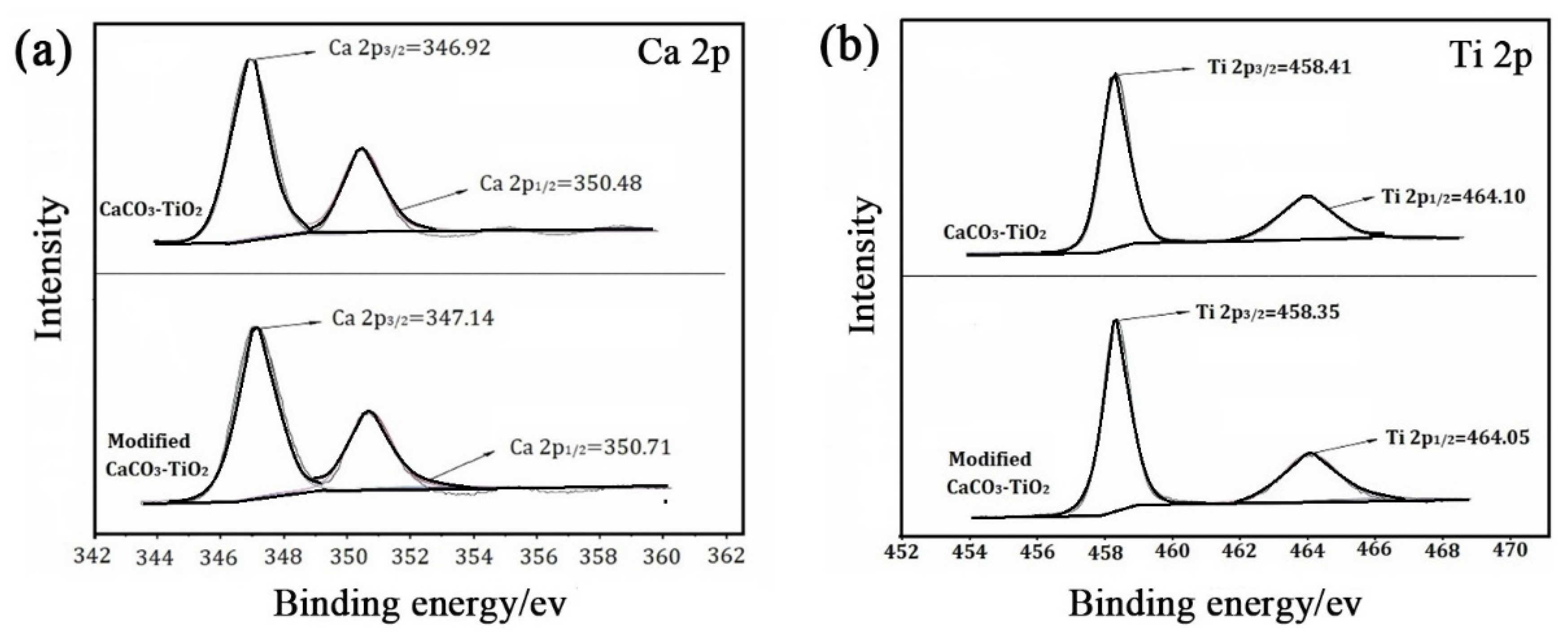

3.4.2. XPS Analysis

3.4.3. Surface Organic Modification Model of CaCO3-TiO2

4. Conclusions

- (1)

- The surface organic modification of CaCO3-TiO2 was carried out by the wet mechanical grinding method with sodium stearate as the modifier. The modification temperature, dosage of modifier, and mechanical strength in grinding are the important factors of the activation index and sedimentation rate of CaCO3-TiO2. After modification, the hydrophilic surface of CaCO3-TiO2 was converted into a hydrophobic surface. The activation index of CaCO3-TiO2 in aqueous medium reached 97% and the water wetting contact angle reached 114.9° under 1.5 wt % SS. The dispersibility of modified CaCO3-TiO2 in ethanol and kerosene was significantly improved.

- (2)

- The calculation results of the surface free energy showed that after the modification, the properties of polar components on the surface of CaCO3-TiO2 were masked, whereas the organic non-polar properties of SS were displayed, thus changing the dispersion behaviors of CaCO3-TiO2. When the dosage of SS was 1.5%, the γs value decreased from 74.2 mJ/m2 to 11.6 mJ/m2.

- (3)

- Modification leads to a significant improvement in the pigment properties of CaCO3-TiO2. The hiding power of CaCO3-TiO2 dropped from 19.6 g/m2 to 16.9 g/m2 under 1.5 wt % SS and 16.7 g/m2 under 2 wt % SS after modification.

- (4)

- The modifier was chemisorbed on the surface of particles. The binding of the modifier with CaCO3-TiO2 was mainly induced by the dehydroxylation of RCOOH and hydroxyl groups on the TiO2 surface.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Q.; Yu, Z.; Xie, X.; Mai, Y. Crystallization and impact energy of polypropylene/CaCO3 nanocomposites with nonionic modifier. Polymer 2004, 45, 5985–5994. [Google Scholar] [CrossRef]

- Hu, Z.; Zen, X.; Gong, J.; Deng, Y. Water resistance improvement of paper by superhydrophobic modification with microsized CaCO3, and fatty acid coating. Colloid Surf. A 2009, 351, 65–70. [Google Scholar] [CrossRef]

- Tao, H.; He, Y.; Zhao, X. Preparation and characterization of calcium carbonate–titanium dioxide core–shell (CaCO3 @TiO2) nanoparticles and application in the papermaking industry. Powder Technol. 2015, 283, 308–314. [Google Scholar] [CrossRef]

- Zhang, L. Preparation of nanosized anatase TiO2-coated kaolin composites and their pigmentary properties. Powder Technol. 2009, 196, 122–125. [Google Scholar]

- Gao, Q.; Wu, X.; Xia, Z.; Fan, Y. Coating mechanism and near-infrared reflectance property of hollow fly ash bead/TiO2 composite pigment. Powder Technol. 2017, 305, 433–439. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Liu, Y.; Zhang, Y.; Qu, J.; Qi, T. Preparation and mechanism of TiO2-coated illite composite pigments. Dyes Pigments 2014, 108, 84–92. [Google Scholar] [CrossRef]

- Li, Z.; Huang, C.; Guo, L.; Cui, L.; Zhou, B. Mass production and application of TiO2@CaCO3 composites in interior emulsion coatings. Colloid Surf. A 2016, 498, 98–105. [Google Scholar] [CrossRef]

- Sun, S.; Ding, H.; Hou, X.; Chen, D.; Yu, S.; Zhou, H.; Chen, Y. Effects of organic modifiers on the properties of TiO2-coated CaCO3 composite pigments prepared by the hydrophobic aggregation of particles. Appl. Surf. Sci. 2018, 456, 923–931. [Google Scholar] [CrossRef]

- Morsy, F.; El-Sherbiny, S.; Hassan, M.; Mohammed, H. Modification and evaluation of Egyptian kaolinite as pigment for paper coating. Powder Technol. 2014, 264, 430–438. [Google Scholar] [CrossRef]

- Zhou, H.; Sun, S.; Ding, H. Surface organic modification of TiO2 powder and relevant Characterization. Adv. Mater. Sci. Eng. 2017, 2017, 9562612. [Google Scholar] [CrossRef]

- Lin, J.; Siddiqui, J.A.; Ottenbrite, R.M. Surface modification of inorganic oxide particles with silane coupling agent and organic dyes. Polym. Adv. Technol. 2001, 12, 285–292. [Google Scholar] [CrossRef]

- Bagwe, R.P.; Hilliard, L.R.; Tan, W. Surface Modification of silica nanoparticles to reduce aggregation and nonspecific binding. Langmuir 2006, 22, 4357–4362. [Google Scholar] [CrossRef]

- Jiang, D.; Xu, Y.; Hou, B.; Wu, D.; Sun, Y. Synthesis of visible light-activated TiO2 photocatalyst via surface organic modification. J. Solid State Chem. 2007, 180, 1787–1791. [Google Scholar] [CrossRef]

- Palaniandy, S.; Azizli, K.A.M. Mechanochemical effects on talc during fine grinding process in a jet mill. Int. J. Miner. Process. 2009, 92, 22–33. [Google Scholar] [CrossRef]

- Romeis, S.; Schmidt, J.; Peukert, W. Mechanochemical aspects in wet stirred media milling. Int. J. Miner. Process. 2016, 156, 24–31. [Google Scholar] [CrossRef]

- Ding, H.; Lu, S.C.; Deng, Y.X.; Du, G.X. Mechano-activated surface modification of calcium carbonate in wet stirred mill and its properties. Trans. Nonferrous Met. Soc. 2007, 17, 1100–1104. [Google Scholar] [CrossRef]

- Ding, H.; Lu, S.; Du, G. Surface modification of wollastonite by themechano-activated method and its properties. Int. J. Miner. Metall. Mater. 2011, 18, 83–88. [Google Scholar] [CrossRef]

- Sun, S.; Ding, H.; Hou, X. Preparation of CaCO3-TiO2 composite particles and their pigment properties. Materials 2018, 11, 1131. [Google Scholar] [CrossRef]

- Ding, H. Surface Modification of Powder and Its Application; Tsinghua University Press: Beijing, China, 2013. [Google Scholar]

- Luo, Z.; Zhu, J.F.; Tang, L.G.; Zhao, Y.M.; Guo, J.; Zuo, W.; Chen, S.L. Fluidization characteristics of magnetite powder after hydrophobic surface modification. Int. J. Miner. Process. 2010, 94, 166–171. [Google Scholar] [CrossRef]

- GB/T5211.15-2014, General Methods of Test for Pigments and Extenders; Standards Press of China: Beijing, China, 2014.

- HG/T3851-2006, Covering Power Determination of Dyestuff; National Development and Reform Commission: Beijing, China, 2006.

- Qiu, G.; Hu, Y.; Wang, D. Interactions between Particles and Flotation of Fine Particles; Central South University Press: Chnagsha, China, 1993. [Google Scholar]

- Farahat, M.; Hirajima, T.; Sasaki, K. Adhesion of Ferroplasma acidiphilum onto pyrite calculated from the extended DLVO theory using the van Oss-Good-Chaudhury approach. J. Colloid Interface Sci. 2010, 349, 594–601. [Google Scholar] [CrossRef]

- Fowkes, F.M. Determination of interfacial tensions, contact angles, and dispersion forces in surfaces by assuming additivity of intermolecular interactions in surfaces. J. Phys. Chem. 1962, 66, 382. [Google Scholar] [CrossRef]

- Li, Z.; Giese, R.F.; Vanoss, C.J.; Yvon, J.; Cases, J. The surface thermodynamic properties of talc treated with octadecylamine. J. Colloid Interface Sci. 1993, 156, 279–284. [Google Scholar] [CrossRef]

- Legodi, M.A.; Waal, D.D.; Potgieter, J.H.; Potgieter, S.S. Rapid determination of CaCO3 in mixtures utilising FT-IR spectroscopy. Miner. Eng. 2001, 14, 1107–1111. [Google Scholar] [CrossRef]

- Tran, H.V.; Tran, L.D.; Vu, H.D.; Thai, H. Facile surface modification of nanoprecipitated calcium carbonate by adsorption of sodium stearate in aqueous solution. Colloid Surf. A 2010, 366, 95–103. [Google Scholar] [CrossRef]

- Akple, M.S.; Low, J.; Qin, Z.; Liu, S. Nitrogen-doped TiO2 microsheets with enhanced visible light photocatalytic activity for CO2 reduction. Chin. J. Catal. 2015, 36, 2127–2134. [Google Scholar] [CrossRef]

- Bezrodna, T.; Puchkovska, G.; Shymanovska, V.; Baran, J.; Ratajczak, H. IR-analysis of H-bonded H2O on the pure TiO2 surface. J. Mol. Struct. 2004, 700, 175–181. [Google Scholar] [CrossRef]

- Perrin, D.D. Stability Constants of Metal-Ion-Complexes; Pergamon Press: Oxford, UK, 1979. [Google Scholar]

| Performance Indicators | Content of ~2 μm Fraction % | Whiteness % | Density (g/m3) | Oil Absorption (g/100 g) | Hiding Power (g/m2) | pH Value of Suspension |

|---|---|---|---|---|---|---|

| 92.5 | 94.5 | 3.1 | 21.9 | 19.6 | 6.8–9.5 |

| Samples | Oil Absorption (g/100 g) | Hiding Power (g/m2) | Whiteness (%) |

|---|---|---|---|

| Unmodified CaCO3-TiO2 | 21.9 | 19.6 | 94.5 |

| Modified CaCO3-TiO2-1.5% | 16.4 | 16.9 | 94.2 |

| Modified CaCO3-TiO2-2% | 16.3 | 16.7 | 92.5 |

| Samples | Water | Glycerol | Hexane |

|---|---|---|---|

| Unmodified CaCO3-TiO2 | 1.4 | 15.6 | 81.5 |

| Modified CaCO3-TiO2-0.5% | 70.5 | 73.0 | 75.0 |

| Modified CaCO3-TiO2-1.5% | 114.9 | 104.6 | 56.7 |

| Solvents | γL | γLLW | γL+ | γL− |

|---|---|---|---|---|

| Water | 72.8 | 21.8 | 25.5 | 25.5 |

| Glycerol | 64.0 | 34.0 | 3.9 | 57.5 |

| Hexane | 18.4 | 18.4 | 0 | 0 |

| Samples | γs | γsLW | γsAB | γs+ | γs− |

|---|---|---|---|---|---|

| Unmodified CaCO3-TiO2 | 74.2 | 6.1 | 68.2 | 18.9 | 61.3 |

| Modified CaCO3-TiO2-0.5% | 28.1 | 7.3 | 20.8 | 4.2 | 25.7 |

| Modified CaCO3-TiO2-1.5% | 11.6 | 11.0 | 0.60 | 0.20 | 0.50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Ding, H.; Zha, Y.; Chen, W.; Xu, Z. Surface Organic Modification of CaCO3-TiO2 Composite Pigment. Minerals 2019, 9, 112. https://doi.org/10.3390/min9020112

Sun S, Ding H, Zha Y, Chen W, Xu Z. Surface Organic Modification of CaCO3-TiO2 Composite Pigment. Minerals. 2019; 9(2):112. https://doi.org/10.3390/min9020112

Chicago/Turabian StyleSun, Sijia, Hao Ding, Yanpeng Zha, Wanting Chen, and Zhuoqun Xu. 2019. "Surface Organic Modification of CaCO3-TiO2 Composite Pigment" Minerals 9, no. 2: 112. https://doi.org/10.3390/min9020112

APA StyleSun, S., Ding, H., Zha, Y., Chen, W., & Xu, Z. (2019). Surface Organic Modification of CaCO3-TiO2 Composite Pigment. Minerals, 9(2), 112. https://doi.org/10.3390/min9020112