Abstract

Feldspar minerals are essential ingredients for the glass and ceramic-glass industries. The potassium element found in certain proportions in the composition of K-feldspar minerals has a fundamental function in the growth of plants. The production of potassium fertilizers is mostly made from the soluble minerals, which are located in lakes. Despite having a huge area of use in the agriculture industry, the reserves of these salts are limited and not evenly distributed in the earth’s crust. Due to the high availability of feldspar reserves in the earth’s crust, the production of potential potassium salts can provide a wide range of social and economic benefits. In this study, potassium extraction from a feldspar ore, which contained microcline, albite, muscovite, and quartz, was studied using chloridizing (CaCl2) roasting followed by leaching. Direct leaching experiments were also performed on the sample by adapting various solvents. To emphasize the importance of roasting before the dissolution process, different parameters such as particle size, roasting temperature, and duration, as well as the feldspar/CaCl2 ratio, were tested. Under the optimum conditions (i.e., −106 microns, 850 Co, 60 minutes, 1:1.5 feldspar:CaCl2), 99% of the potassium was successfully extracted from the ore feed.

1. Introduction

Potassium is the seventh most abundant element in the world and it has a significant function in the growth of plants with nitrogen and phosphorus [1]. In agricultural areas, potassium is analyzed at certain intervals, and potassium addition is made according to analysis results. Worldwide, potash (K2O) fertilizers are produced from soluble reserves, and two main compounds are used as the potash source. The first one is potassium chloride (KCl), and the known minerals of this compound are sylvite (KCl) and carnallite (KMgCl3·6(H2O)). The second source is potassium sulphate (K2SO4), and it is mostly found as kainite (MgSO4·KCl·3(H2O)) and leonite (K2Mg(SO4)2·4(H2O)). All of those minerals are mostly found in salt lake deposits. For some specific fruits and vegetables, potassium sulphate can only be used due to their sensitivity to chloride. However, potassium sulphate is not as commonly used as potassium chloride. Thus, potassium sulphate is mostly produced from potassium chloride by reacting it with sulphuric acid.

Feldspars, as a potential potassium resource, are the most common rock forming minerals and constitute about 60% of the earth’s crust [2]. The general formula of feldspars is XAl(1−2)Si(3−2)O(8), where X can alter as Na, K, and Ca. The feldspar group has nearly 20 recognized members but only two of them (sodium and potassium feldspars) are used commercially. When the Na2O content in feldspar is more than 7%, it is classified as sodium feldspar, and it is named as potassium feldspar when the K2O content is above 10%. These two feldspars are the most important inputs in the glass industry, and 70% of these feldspars are commercially used in this sector [3]. The impurities that affect the use of feldspars in industry are iron and titanium oxides, thus very important economic and technological benefits can be achieved by decreasing the contents of these impurities.

As a potential potash source, K bearing feldspars could be processed with a heat treatment followed by water leaching. This process might present an alternative potash production source and value-added products can be produced from the feldspars. Despite having deep background information, there is still no plant that produces potash from feldspars. Most of the studies carried out on this subject did not conduct an economic evaluation. However, this situation can be re-evaluated using today’s technologies. Similar studies related to this topic are explained below.

In the last century, the studies on the production of potash from feldspar mainly involved roasting and then water dissolution. Nayak et al. reported that 65% of the potassium could be dissolved from 13% K2O bearing rock with roasting at 850–900 °C together with MgSO4+CaCO3 at a ratio of 1:0.7:3 to feldspar, with the feldspar having a grain size under 63 microns [4]. Zhang et al. [5] claimed that when feldspar:CaCl2:NaCl roasted together at a ratio of 1.8:1.1:0.6 at 800 °C for 1 hour, the potassium extraction reached 95.5%, starting from 14.81% K2O bearing feldspar with a grain size under 70 microns. Xie et al. [6] stated that 84.7% potassium recovery was obtained from 9.3% K2O bearing feldspar, minus 45 microns feldspar ore with CaCl2, by roasting at 800 °C for 1 hour. Jena et al. [7] showed that 99.6% potassium from 5.4% potassium bearing nepheline syenite was extracted with the addition of CaCl2 (45% weight to the feed) at a roasting temperature of 900 °C and 15 minutes mechanical activation. Pradhan et al. investigated the effect of NaCl, CaCl2, Na2CO3, BaCl2, and Ca(OH)2 on potassium extraction from feldspar ore that was ground to a grain size below 74 microns. The roasting temperature and duration were selected as 900 °C and 1 hour, respectively. They achieved 36% and 28% potassium recovery from 9.8% K2O bearing feldspar using CaCl2 and NaCl [8]. Yuan et al. reported that 91% potassium recovery could be achieved from 13.3% K2O bearing feldspar under 50 microns particle size when the roasting temperature was adjusted to 900 °C, and roasting took place for 40 minutes in a dry nitrogen atmosphere with the addition of 1:1.5 CaCl2 to the feldspar [9]. Orosco and Ruiz indicated that 93% potassium recovery from 10.43% potassium bearing feldspar could be achieved with the addition of 1:1 MgCl2 to the feldspar and roasting at 900 °C [10]. Kumanan et al. announced 90% potassium recovery from 8% K2O bearing feldspar below 70 microns with the addition of 1:8 CaCl2 to potassium feldspar at a roasting temperature of 900 °C, for an 8-hour duration [11]. Jena et al. reached 92.8% potassium recovery from 10.89% K2O bearing feldspar with the addition of the same amount of NaCl and phosphogypsum at a roasting temperature of 900 °C, for a 1-hour duration [12]. Jena et al. also showed that 85% of potassium could be dissolved from 5.4% K2O bearing nepheline syenite ground below 150 microns with the addition of 20% charcoal and 30% CaCl2 by weight, using microwave roasting at 900 W for 8 minutes at 727 °C [13].

In this study, potassium extraction from feldspar ore was studied using chloridizing (CaCl2) roasting followed by leaching, and the variable parameters such as solvent type and particle size were investigated by extensively adapting the calcination temperature–duration correlation for the first time. In this study, systematic analyses using calcium chloride for the production of potassium salts from potassium feldspar ore containing high muscovite were performed using potassium chloride at much lower temperatures, shorter times, and with a lesser amount of calcium chloride.

2. Experimental Studies

2.1. Material and Characterization

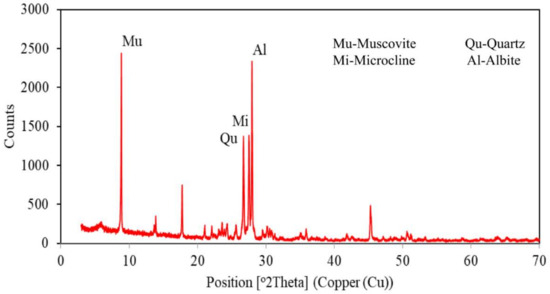

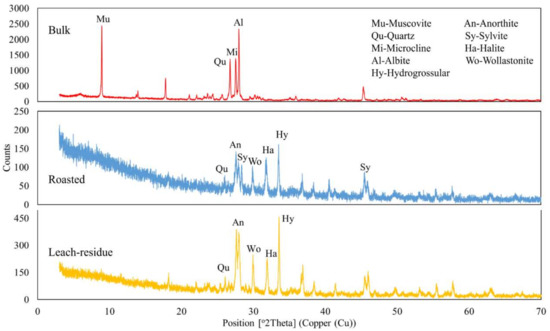

The potassium feldspar sample obtained from the Buzlukdagi Region, Kırşehir, Turkey was used in the experimental studies. The chemical content of the sample was determined using the inductively coupled plasma (ICP) method, and the results are given in Table 1. X-ray diffraction analysis was conducted using a Cu X-ray sourced Panalytical X’Pert Pro diffractometer. Figure 1 shows the XRD analysis results. According to the results, the dominant minerals were K-Feldspar, albite, muscovite, albite, and quartz.

Table 1.

Chemical analysis results of the sample.

Figure 1.

X-Ray Diffraction (XRD) patterns of the sample.

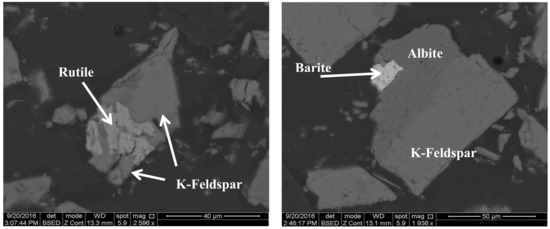

Scanning electron microscope (SEM-BSE) analysis using the Bruker 5010 SDD (Billerica, MA, USA) device showed the presence of K-feldspar in the ore (Figure 2).

Figure 2.

Backscattered electrons (BSE) images of the sample.

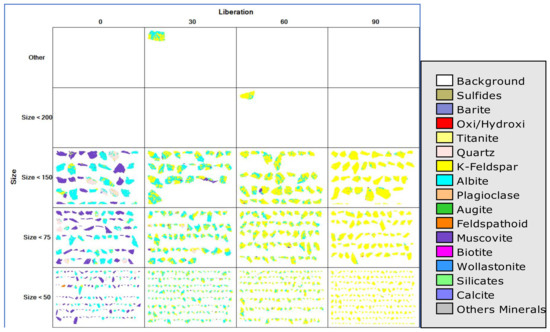

Mineral liberalization analysis was performed with a FEI MLA 650F (Hillsboro, OR, USA). According to liberation analysis shown in Figure 3, K-feldspar is liberated below 200 µm with liberation degree of about 75%.

Figure 3.

Image analysis of the sample.

2.2. Beneficiation Methods

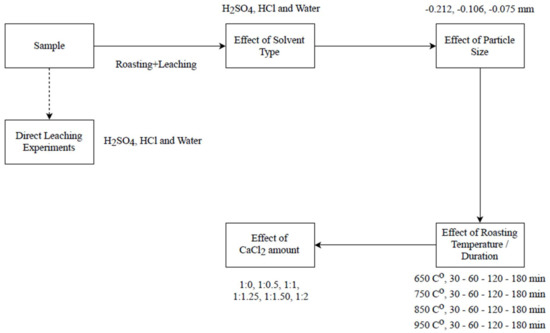

The laboratory type ceramic mill with alumina balls was used for grinding the representative ore sample from 2 mm to below 212 μm, 106 μm, and 74 μm. In direct leaching experiments, 20% purity hydrochloric acid and 95% purity sulphuric acid from VWR Chemicals were used. Pure granular anhydrous calcium chloride obtained from Carlo Erba Reagents was ground in an agate mortar and mixed uniformly to different size groups of K-feldspar samples based on a certain ratio. Thereafter, 7.5 g of mixture was added to each porcelain crucible and the roasting tests were performed in a muffle furnace at elevated temperatures using 30 g of mixture. After weighing the roasted samples, 15 g were separated and used in a dissolution process. Leaching experiments were carried out on pulp with a 10% solid ratio at 60 °C temperature for 2 hours. The pulp was mixed using a magnetic stirrer at 500 rpm. Liquid/solid separation was performed using a lab scale vacuum filter with blue ribbon filter papers. The filtered cake was dried at 70 °C for around 24 hours. Ion contents of the pregnant solutions was analyzed by the atomic adsorption spectrometry (AAS) method using the Varian AA240FS device (Palo Alto, CA, USA). Figure 4 presents the flowsheet of the experimental study.

Figure 4.

General flowsheet of the experimental studies.

3. Results

3.1. Direct Leaching Experiments

The possibilities of extracting potassium in the feldspar’s composition were investigated by direct leaching and roasting, followed by the leaching process. The results from two different methods were compared according to the obtained dissolution data. Alumina content was monitored to understand the dissolution mechanism, that is, whether it occurred random or selectively. We chose an 8 M acid concentration and 90 °C leaching temperature. Although very high amounts of acid were used, the dissolution recoveries remained at very low levels after 2 hours of leaching (Table 2). The increase in dissolution time might have been increased and the dissolution recovery values could have been enhanced to some extent, but it was very difficult to achieve the desired high recovery rates without the roasting process. Similar to our findings, Kumanan et al. reached only 16% potassium extraction at a 90 °C temperature and 10 M H2SO4 concentration [11].

Table 2.

K and Al recoveries after direct leaching experiments.

3.2. The Roasting Followed by Leaching

The result showed that in the direct dissolution experiments, even applying very high concentrations of acids, the ore did not respond to direct leaching. Therefore, the necessity of roasting emerged. In the roasting experiments, the effect of solvent type, particle size, roasting temperature/duration, and the amount of CaCl2 were investigated.

3.2.1. Effect of Solvent Type

HCl, H2SO4, and water were used as solvents to investigate the effect of various types of solvents on the potassium extraction of roasted products. The roasting temperature and duration were chosen as 750 °C and 120 minutes, respectively. The particle size of the feed was below 106 µm, and the feldspar:CaCl2 ratio was adjusted to 1:1.5. Given the emerging problem of gelation from using vacuum filtration, the centrifugation method was used in the dewatering process. The results are given in Table 3.

Table 3.

The effect of solvent type on K and Al dissolution after the roasting process.

Table 3 clearly shows that HCl provides the highest potassium extraction rate by 76.4%, while water only dissolves 52.6% of the potassium because of the formation of KCl during roasting, based on the below equations:

KAlSi3O8 + 4HCl + 4H2O = AlCl3 + 3H4SiO4 + KCl

4KAlSi3O8 + 22H2O = Al4Si4O10(OH)8 + 8H4SiO4 + 4KOH

Water was used as the solvent in the subsequent experiments, since potassium was only selectively obtained in the solution made with water.

3.2.2. Effect of Particle Size

The effect of particle size on potassium extraction was investigated using three different fractions (−212, −106, and −75 µm). The roasting tests were managed at the optimized values of 750 °C temperature and for 120 minutes roasting time. CaCl2 addition was kept similar to the previous experiment. Water was used as the solvent. The results in Table 4 show that the particle size had no significant effect on potassium dissolution.

Table 4.

Effect of particle size on potassium recovery.

Similar to our findings, Jena et al. [13] stated that only a 10% increase in potassium dissolution efficiency was achieved when the feeding size was reduced from 210 microns to 75 microns, at a roasting temperature of 900 °C and duration of 60 minutes. The reason for the increase obtained at 75 microns was that the sample had been sufficiently decomposed by the roasting process. With the implementation of this method, the roasting costs will increase to some extent, but shorter milling operations will significantly reduce the milling costs. According to the results given in Table 4, −212 µm was considered to be the most suitable particle size. However, it was observed that increasing the particle size caused adhesion between the particles. Some amount of adhesion was detected in the grains below 106 µm (Figure 5), but it was removed from the container in which it was attached without much effort. Therefore, a −106 µm fraction was selected as the optimum for the following tests.

Figure 5.

(a) CaCl2 + K-Feldspar mixture before roasting. (b) CaCl2 + K-Feldspar mixture after roasting.

3.2.3. Effect of Roasting Temperature and Duration

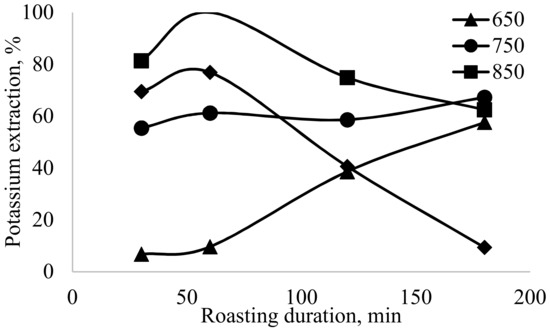

Roasting is the most critical step of potassium extraction from potassium feldspar. Two main parameters, that is, temperature and roasting duration, impact the success of the process. In this experiment, first, the feldspar:CaCl2 ratio was kept constant at 1:1.5, and then, the leaching tests were performed at a 10% solid in pulp ratio, 60 °C pulp temperature, and a 2 hour leaching time. Figure 6 shows the results of the dissolution experiments in which the sample was roasted at temperatures of 650, 750, 850, and 950 °C and for 30, 60, 120, and 180 minutes.

Figure 6.

Potassium extraction recoveries of the roasted sample at different temperature values and durations.

Researchers who conducted similar potassium extraction studies stated that the highest recoveries were obtained at 800 °C [5,6] and 900 °C [4,7,8,10,11,13]. Yuan et al. [9] observed a decrease in the potassium yields at elevated temperatures, similar to the findings of this study. Figure 6 shows that the highest potassium extraction was obtained at an 850 °C roasting temperature and at a 60 minutes roasting time.

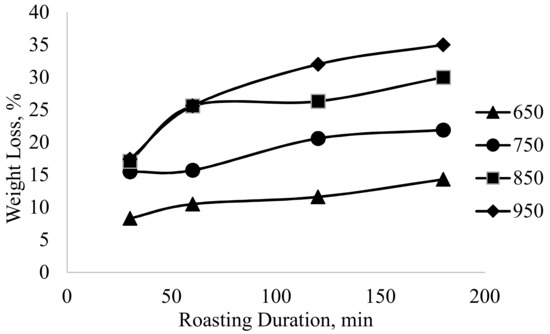

Despite the melting point of CaCl2 being 772 °C, the activation of KCl starts at around 650 °C after 60 minutes. The dissolution curve of the roasted sample at 750 °C did not change much and had an almost linear line for all durations (Figure 6). The extraction value of the roasted sample at 950 °C was lower than the roasted sample at 850 °C for all the duration values. This recovery reduction between 850 and 950 °C could be explained by mass losses during the roasting process (Figure 7).

Figure 7.

Mass losses at the roasting.

As seen in Figure 7, it is observed that the mass losses increase as the temperature increases. It is also known that the boiling point of pure sodium and potassium elements is 882 °C and 759 °C, respectively. It can be said that the decrease in potassium extraction rates for long periods and temperatures depends on the evaporation of alkalis. It would not be correct to associate mass loss directly with recovery because of the humidity. As mentioned in the materials section, the experiments were conducted using anhydrous granular CaCl2, and it was ground in an agate mortar before mixing. When it is being ground, CaCl2 captures humidity from the air. Even after keeping it for 30 seconds under room conditions, there were observable water drops occurring around it. Thus, some of this mass loss was related to humidity. Therefore, XRD analysis was performed on the leach cakes of each roasting temperature at a 60-minute duration scale.

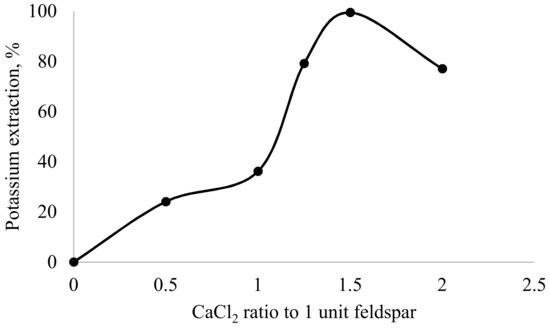

3.2.4. Effect of the CaCl2 Amount

The effect of the feldspar:CaCl2 ratio was investigated under the optimized roasting temperature and duration (850 °C and 60 minutes). Our previous findings showed that potassium in feldspar can be completely dissolved at a 1:1.5 feldspar:CaCl2 ratio. As suggested by Yuan et al. [9] the following equation can explain the possible transition:

CaCl2(s,l) + 2KAlSi3O8(s) = CaAl2Si2O8 + 4SiO2(s) + 2KCl(s,l)

Equation (3) expresses that CaCl2 salt replaces with K of the microcline and forms calcium aluminum silicate, which is another feldspar (anorthite). The reaction shows that the CaCl2 amount must be high enough to activate all of the potassium in the microcline structure for the highest recovery. Therefore, the effect of the CaCl2 amount was investigated at different feldspar:CaCl2 ratios (1:0, 1:0.5, 1:1, 1:1.25, 1:1.5, and 1:2). Figure 8 illustrates that there is a sharp increase after the 1:1 ratio and the highest extraction was achieved at a 1:1.5 CaCl2 ratio.

Figure 8.

Effect of the CaCl2 amount.

Jena et al. [12] prepared a feed with a 1:0.8 CaCl2:nepheline syenite ratio for the mechanical activation process, and they reached a 99.6% potassium extraction. Yuan et al. [9] achieved a 91.8% potassium extraction value after combining CaCl2 with feldspar at a ratio of 1:1.5. Although the transformation of microcline is shown in Equation (3), the ore in this study also contained albite and muscovite. The formula of muscovite (KAl2Si3AlO10(OH)2) is somewhat similar to microcline (KAlSi3O9); however, the decomposition temperatures between them are different. In addition, as understood from the sodium extraction values, a part of the calcium in CaCl2 consumes albite and NaCl salt is formed. To see these transformations, XRD analysis was also applied to the roasted product and the leaching cake. The XRD analysis results in Figure 9 show the formations of bulk, roasted and leach residue comparatively.

Figure 9.

XRD patterns of bulk, roasted and leach residue.

Figure 9 reveals that after the roasting process, anorthite, halite, sylvite, wollastonite, and hydrogrossular were formed from the raw ore. The transformation of the minerals was thought to be as follows: (i) microcline was converted to sylvite and anorthite, (ii) albite was converted to halite and anorthite, (iii) silica (SiO2) was converted to wollastonite, and (iv) muscovite was converted to hydrogrossular, which is a mineral series in the garnet group. The transition of microcline to anorthite and quartz was found in the literature. For example, Jena et al. [14] used pyrophillite mine waste containing 52% muscovite, 30% pyrophyllite, and 13% microcline. They observed almandine formation after roasting with CaCl2, which is a member of the garnet group, and the chemical formula was Fe2+3Al2(SiO4)3. Moreover, 75% by weight CaCl2 was added to the fed ore and a potassium dissolution efficiency of over 80% was obtained [14]. According to these results, it was understood that microcline consumed too much CaCl2 and converted to a garnet group mineral series, hydrogrossular, with the chemical formula of Ca3Al2(SiO4)3-x(OH)4x, with (OH) partly replacing (SiO4), where the value of x determines whether it is grossular, hibschite, or katoite. From an economic point of view, the increase in muscovite content promotes the consumption of CaCl2 and almost 100% potassium extraction was achieved. Therefore, patterns in both the roasted product and leach residue showed that a high portion of halite remained in the leach residue as a result of the solid/liquid separation or leaching conditions.

4. Conclusions

Potassium, which is a key component in the agriculture and ceramic-glass industries, is expected to be produced at a global volume of nearly 43 million tons in 2019 [15]. Therefore, the production of high value added products from potential potassium resources has received increased attention. In the scope of this study, K-feldspar was used as an alternative source and a series of experiments were performed to extract potassium in an efficient way.

Feldspar ore mainly consists of microcline, albite, and muscovite with a 9.69% K2O total content. The potential of potassium production from this ore, as a source of potash for the agricultural industry, was investigated using roasting followed by a leaching process. The experimental studies showed that leaching without roasting did not result in potassium extraction from feldspar. Thus, roasting followed by a leaching method was applied. Since water is economic and selective for salty compounds, it was chosen as the solvent. The optimum particle size was found to be −106 µm because −212 µm showed powerful adhesion. The roasting time was investigated in detail and the highest potassium extraction was obtained at 850 °C for 60 minutes. The optimum feldspar:CaCl2 ratio was found to be 1:1.5, and 99.8% of the potassium was successfully extracted from the representative potassium feldspar ore.

Although roasting feldspar with CaCl2 has been investigated in many studies, this study’s approach was novel in terms of expressing the correlation between roasting duration and temperature. A more particular achievement of this study was that potassium extraction of a feldspar ore with a high impurity content was achieved.

On the other hand, it should be noted that the roasting process is an energy intensive process. The occurrence of the substitution reaction between feldspar and additives such as CaCl2 requires relatively high temperatures. As the mechanism of this reaction was revealed properly, alternative methods to initiate the reaction should be investigated in further studies. In this concept; low roasting temperature, fewer and more cost-effective additives, and/or various techniques to apply external force on the sample could be the essential topics.

Author Contributions

M.O.K. and M.T.S. conceived and designed the experiments; all researchers performed the experiments and analyzed the data; M.O.K., M.T.S. and F.B. wrote the paper.

Funding

This research was funded by The Scientific and Technological Research Council of Turkey (TUBITAK), Project No: 218M107.

Acknowledgments

The authors would like to express their sincere thanks and appreciation to The Scientific and Technological Research Council of Turkey (Project No: 218M107) for the financial support, and to BS Invest Co. for kindly providing the feldspar samples.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Scherer, H.W.; Mengel, K.; Dittmar, H.; Drach, M.; Vosskamp, R.; Trenkel, M.E.; Gutser, R.; Steffens, G.; Czikkely, V.; Niedermaier, T.; et al. Fertilizers. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2002. [Google Scholar]

- Rao, J.R.; Nayak, R.; Suryanarayana, A. Feldspar for potassium, fertilizers, catalysts and cement. Asian J. Chem. 1998, 10, 690–706. [Google Scholar]

- Ahmed, M.M.; Ibrahim, G.A.; Rizk, A.M.E.; Mahmoud, N.A. Reduce the iron content in Egyptian feldspar ore of Wadi Zirib for industrial applications. Int. J. Min. Eng. Miner. Process. 2016, 5, 25–34. [Google Scholar]

- Nayak, R.; Rao, J.R.; Suryanarayana, A.; Nayak, B.B. A Process for Extraction of Potassium from Feldspar. Indian Patent No. 217121, 31 March 2008. [Google Scholar]

- Zhang, H.; Sun, D.S.; Bao, H. The extraction of potassium from feldspar by molten salt leaching method with composite additives. Adv. Mater. Res. 2012, 524, 1136–1139. [Google Scholar] [CrossRef]

- Xie, H.; Wang, Y.; Ju, Y.; Liang, B.; Zhu, J.; Zhang, R.; Xie, L.; Liu, T.; Zhou, X.; Zeng, H.; et al. Simultaneous mineralization of CO2 and recovery of soluble potassium using earth-abundant potassium feldspar. Chin. Sci. Bull. 2013, 58, 128–132. [Google Scholar] [CrossRef]

- Jena, S.K.; Dhawan, N.; Rao, D.S.; Misra, P.K.; Mishra, B.K.; Das, B. Studies on extraction of potassium values from nepheline syenite. Int. J. Miner. Process. 2014, 133, 13–22. [Google Scholar] [CrossRef]

- Pradhan, G.K.; Singh, Y.P.; Dhawan, N. Silicate Rocks-A potash source for fertilizers. In Proceedings of the India International Science Festival-Young Scientists’ Meet, Delhi, India, 4–8 December 2015; pp. 1–9. [Google Scholar]

- Yuan, B.; Li, C.; Liang, B.; Lü, L.; Yue, H.; Sheng, H.; Ye, L.; Xie, H. Extraction of potassium from K-feldspar via the CaCl2 calcination route. Chin. J. Chem. Eng. 2015, 23, 1557–1564. [Google Scholar] [CrossRef]

- Orosco, P.; del Carmen Ruiz, M. Potassium chloride production by microcline chlorination. Thermochim. Acta 2015, 613, 108–112. [Google Scholar] [CrossRef]

- Kumanan, M.; Sathya, G.; Nandakumar, V.; Berchmans, L.J. Extraction of potash from K-Feldspar mineral by acid and molten salt leaching processes. IASET Int. J. Metall. Mater. Chem. Eng. 2016, 7, 1–10. [Google Scholar]

- Jena, S.K.; Misra, P.K.; Das, B. Studies on extraction of potassium from feldspar by roast-leach method using phosphogypsum and sodium chloride. Min. Process. Extr. Metall. 2016, 37, 323–332. [Google Scholar] [CrossRef]

- Jena, S.K.; Dhawan, N.; Rath, S.S.; Rao, D.S.; Das, B. Investigation of microwave roasting for potash extraction from nepheline syenite. Sep. Purif. Technol. 2016, 161, 104–111. [Google Scholar] [CrossRef]

- Jena, S.K.; Dhawan, N.; Rao, D.S.; Misra, P.K.; Das, B. Extraction of potash values from pyrophyllite mine waste. Sep. Sci. Technol. 2015, 51, 269–277. [Google Scholar] [CrossRef]

- Jasinski, S.M. Potash. In United States Geological Survey Minerals Yearbook; U.S. Geological Survey: Reston, VA, USA, 2017; pp. 128–129. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).