1. Introduction

Typically, automobile scrap is recycled via remelting in an electric arc furnace (EAF) [

1]. In the EAF, the high temperatures and the atmospheric conditions result in the production of a dust, which contains not only numerous elements, but also has a complex mineralogy. About one to two percent of the charge is converted into dust [

2]. This dust contains significant amounts of metallic values such as zinc, iron and lead [

3]. However, as a result of the presence of the heavy metals, the dust is considered to be a hazardous waste. The mechanisms of formation of the dust have been extensively studied and mainly involve metal evaporation followed by oxidation in the atmosphere above the bath and also by ejection of slag particulates from bursting gas bubbles at the slag-gas interface [

4,

5,

6]. Consequently, the majority of the elements in the dust are oxidised [

5,

7]. Moreover, low-density slag additives, such as calcium oxide, can be entrained in the dust [

8].

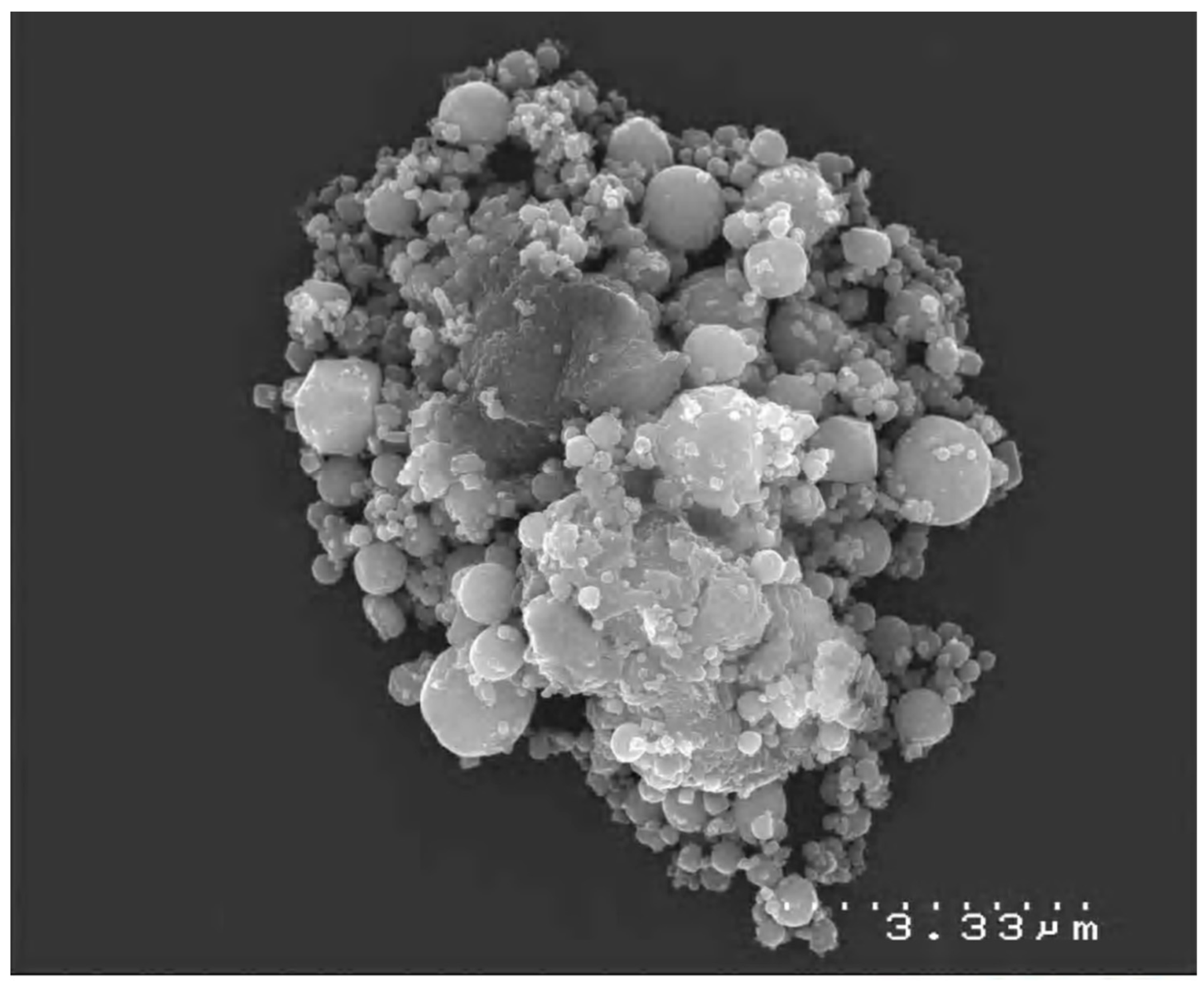

Figure 1 shows a Scanning Electron Micrograph of a typical dust and it can be seen that it consists of agglomerates of extremely fine irregular and spherical particles.

The dust analysis and mineralogy are highly variable since they depend upon the scrap composition, the additives and the steelmaking practice [

9,

10,

11,

12,

13,

14]. Usually, the major components are zinc and iron, followed by calcium [

15]. Additionally, numerous other elements, such as lead, copper, nickel, magnesium, manganese, aluminum and silicon, are present, as well as some alkali metals, such as sodium and potassium, and also chlorine, fluorine and sulphur [

2,

3]. Although the majority of the species are oxides, there are also silicates and sulphates and small amounts of sulphides, chlorides, fluorides and in some cases, minor amounts of some elements in metallic form. The zinc is present primarily as zincite (ZnO), followed by franklinite (ZnFe

2O

4), while the iron can exist as hematite (Fe

2O

3), magnetite (Fe

3O

4), wustite (FeO) and in some cases metallic iron [

1,

16,

17].

There are three main options for dealing with the dust: (1) disposal in a landfill, (2) recycle to the steelmaking process, and (3) recovery of the valuable metals [

18,

19]. Disposal is not an attractive option, and recycling has operational difficulties and limitations. Currently, more than half of the electric arc furnace (EAF) dust produced worldwide is still sent to a landfill [

20]. The dust contains approximately seven percent of the world’s zinc production [

21]. Zinc is of considerable economic value, followed by lead, iron and potentially copper and nickel. Numerous dust processing routes have been devised and tested to recover the metal values [

18,

22,

23]. However, for several reasons, the recycling processes have had limited success. Firstly, a viable process needs to be able to accommodate the variable composition of the dust. Secondly, from an environmental perspective, a large number of elements, including, copper and nickel need to be accounted for. Thirdly, halides such as chlorine can have deleterious effects on the recycling process and must be removed. Finally, the economics of any given recycling process are limited by the relatively restricted local supply of dust, constrained product markets and also variations in metal prices [

24].

Generally, high-temperature metal recovery (HTMR) and/or low-temperature aqueous processing routes have been utilised to recover some metal values. Typically, in the HTMR or pyrometallurgical processes, various energy sources, reactor types and reductants are utilised. The objective is to recover both the zinc and the lead, and in some cases, the iron and other metals, and produce a residue that can be disposed of. Normally, the lead and zinc are reduced, vaporised and collected as an oxidised condensate, as for example in the Waelz rotary kiln process [

22,

25,

26]. In the commercial pyrometallurgical processes, such as the Waelz kiln, the zinc in the dust is collected with some lead, iron and chlorine as a crude zinc oxide, known as Waelz Oxide (WZO) [

22]. However, this process has limitations with respect to both the maximum zinc recovery of about 90% and also the recovery of other metals, such as nickel and copper, which remain with the iron. Consequently, it would be advantageous to identify and investigate alternative pyrometallurgical processing routes for the recovery of the metal values in the dust. These processes should not only extract the majority of the metals, but also produce them in a form such that they can be recovered.

The objective of the present research was to investigate the sulphation of electric arc furnace dust from a thermodynamic perspective and to determine the optimum conditions for the recovery of the metal values. Firstly, the equilibrium reactions involved in the process are discussed. Secondly, the literature is reviewed with regards the sulphation of zinc oxide-bearing materials. Thirdly, a thermodynamic model is developed using HSC® Chemistry 7.1 (Outotec, Espoo, Finland) and the effects of operating variables are evaluated. Finally, the optimum conditions are determined and alternative reagents are evaluated.

5. Results and Discussion

5.1. Selective Sulphation

In the sulphation process for EAF dust, not only is the zinc oxide sulphated, but also those oxides that form more stable sulphates than zinc oxide. Consequently, as a first approximation, the overall reaction can be described as follows:

Thus, for the current dust composition and also including the small amount of alumina, the stoichiometric requirements are 0.68 kmole SO2/100 kg of dust and 0.34 kmole O2/100 kg of dust.

Figure 3 shows the behaviours of the zinc-containing species for the stoichiometric addition. At low temperatures, the majority of the zinc is present as zinc sulphate, with the remainder being zinc ferrite and a small amount of zinc silicate. Therefore, for these conditions, the conversion to zinc sulphate is not complete, as some zinc oxide remains as relatively stable zinc ferrite. The amount of zinc sulphate reaches a maximum at about 800 °C and here the percent conversion of zinc oxide to zinc sulphate is about eighty-five percent. Thereafter, the amount of zinc sulphate begins to decline as the amount of zinc ferrite increases and also zinc oxide begins to form in increasing amounts.

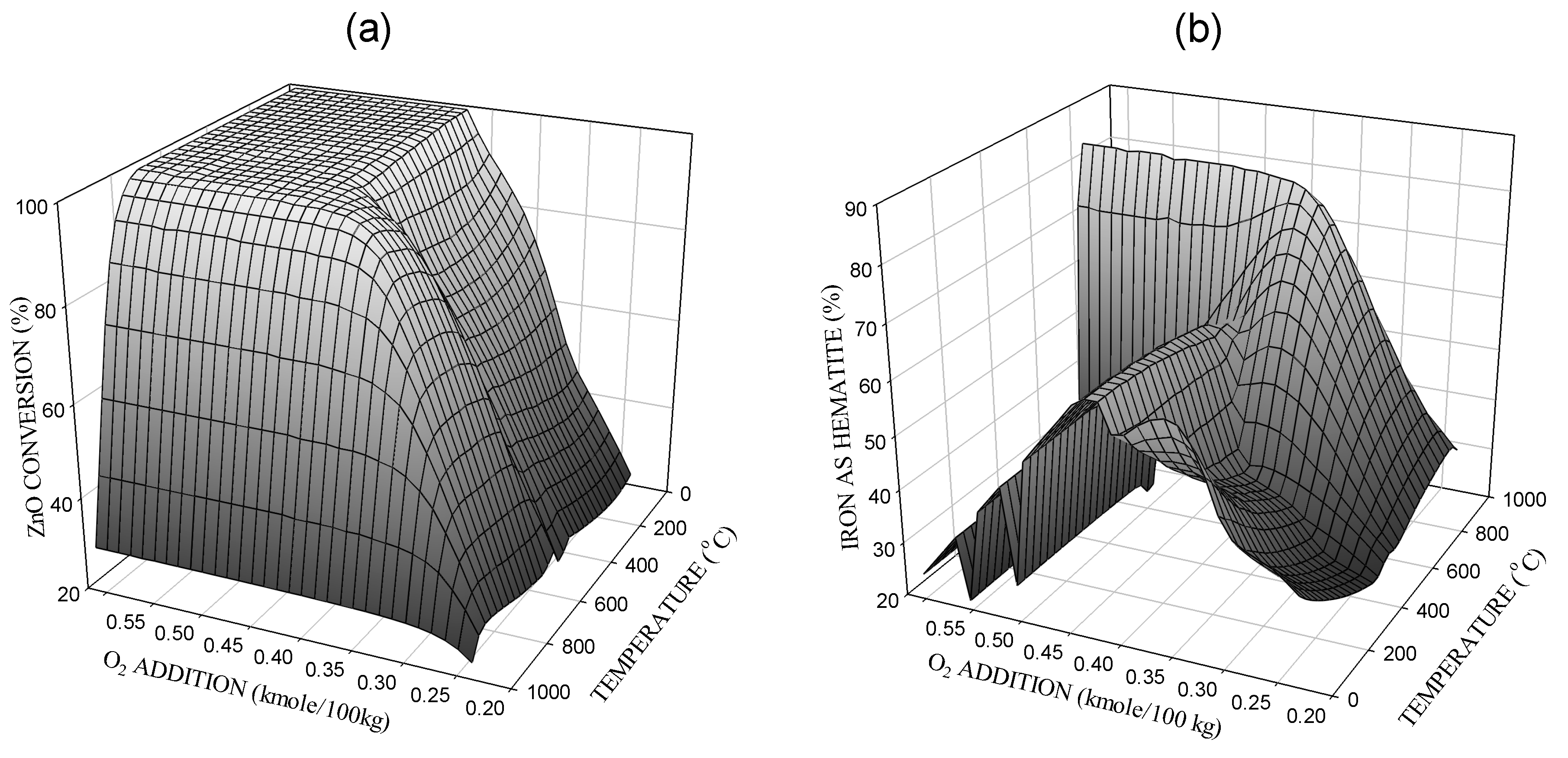

To increase the percent conversion of zinc oxide to zinc sulphate and also to maximise the amount of hematite formed, different conditions for the sulphation process were investigated. The amounts of oxygen were varied both below and above the stoichiometric value, while maintaining a constant sulphur dioxide to oxygen molar ratio of two. The percent conversion of zinc oxide to zinc sulphate is shown in

Figure 4a as a function of both the oxygen addition and the temperature. Zinc sulphate conversions approaching one hundred percent can be achieved at low temperatures and oxygen additions of over 0.45 kmole/100 kg of dust and sulphur dioxide additions of over 0.9 kmole/100 kg of dust. Thus, oxygen and sulphur dioxide additions considerably in excess of the stoichiometric values are required. Above about 800 °C, the percent conversion drops precipitously. At lower additions, the percent conversion is not a strong function of temperature below about 800 °C, but thereafter it drops again rapidly.

Figure 4b shows the amount of iron as hematite for the same conditions as in

Figure 4a. In contrast to zinc sulphate, the amount of hematite is a complex function of both the temperature and the amounts of the reagent gases. At low temperatures, the amount of hematite is low at both low and high additions of the reagent gases. A peak in the amount of hematite is observed at an oxygen addition of 0.45 kmole/ 100 kg of dust (sulphur dioxide addition of 0.9 kmole/100 kg of dust), but the maximum amount of hematite is only about sixty two percent. The highest amount of hematite of about eighty three percent, occurs for oxygen additions above 0.45 kmole/100 kg and sulphur dioxide additions of 0.9 kmole/100 kg of dust and over a very narrow temperature range, centred on about 800 °C. Although the sulphur dioxide to oxygen ratio under these conditions is two to one, the reagent additions required are above those where the zinc sulphate conversion is a maximum as shown in

Figure 4a and also at these temperatures the stability of zinc sulphate is decreasing.

From the above discussion, it can be concluded that for the constant molar ratio of sulphur dioxide to oxygen of two, the majority of the zinc oxide can be converted into zinc sulphate; however, not all of the iron is present as hematite. This deviation of the model from the stoichiometric predictions can be attributed in part to the assumption in the model of the formation of a sulphate phase, consisting of an ideal mixture of all the various metal sulphates. Under such conditions, the activity coefficient of each metal sulphate is unity, and thus the activities of all the various sulphate species are equivalent to their mole fractions. There is very little information in the literature regarding the solubilities of the various metal sulphates in each other and also the activities of metal sulphates in solid solutions. Since the various metal sulphates are considered part of the sulphate phase, then their activities are substantially lower than unity, particularly if their concentration is low. Therefore, the formation of metal sulphates with a low activity will be favoured, and in particular, some ferrous and/or ferric sulphate would be expected to form, which lowers the amount of iron converted to hematite. Thus, alternative conditions need to be established to not only maintain the high conversion of zinc oxide to zinc sulphate, but also to further maximise the amount of hematite retained.

Figure 5a,b shows the equilibrium amounts of both the zinc and the iron-containing species, respectively, as a function of the oxygen addition for the sulphur dioxide addition of 0.68 kmole/100 kg of dust and at a temperature of 600 °C. Also included in each plot are the equilibrium amounts of sulphur dioxide and oxygen. As the oxygen addition increases above about 0.1 kmole/100 kg of dust, the amounts of zinc ferrite, zinc oxide, zinc silicate and sulphur dioxide decrease. Oxygen is totally consumed to produce metal sulphates up to the oxygen addition of 0.4 kmole/100 kg of dust. For the case of the iron-containing species, the amounts of magnetite and zinc ferrite decrease, while the amount of hematite increases. Ferrous sulphate increases up to an oxygen addition of about 0.35 kmoles/100 kg of dust, and then begins to decrease rapidly and as a result, the amount of hematite increases rapidly. Simultaneously, ferric sulphate begins to form. It is noteworthy, that at the temperatures of interest for the sulphation process, both ferrous and ferric sulphate coexist in equilibrium with unreacted hematite. Consequently, above an oxygen addition of about 0.4 kmole/100 kg of dust, the equilibrium species are zinc sulphate, hematite, and the ferrous and ferric sulphates in about equal amounts. Although the conversion of zinc oxide to zinc sulphate is essentially complete, the presence of some ferrous and ferric sulphates somewhat limits the amount of iron that can be retained as hematite. The conversion of zinc oxide and the proposed reaction temperature of 600 °C are close to the experimental values obtained by other researchers [

28,

33].

5.2. Behaviour of Other Elements

In addition to zinc and iron, the behaviours of the other elements during the sulphation process are of interest.

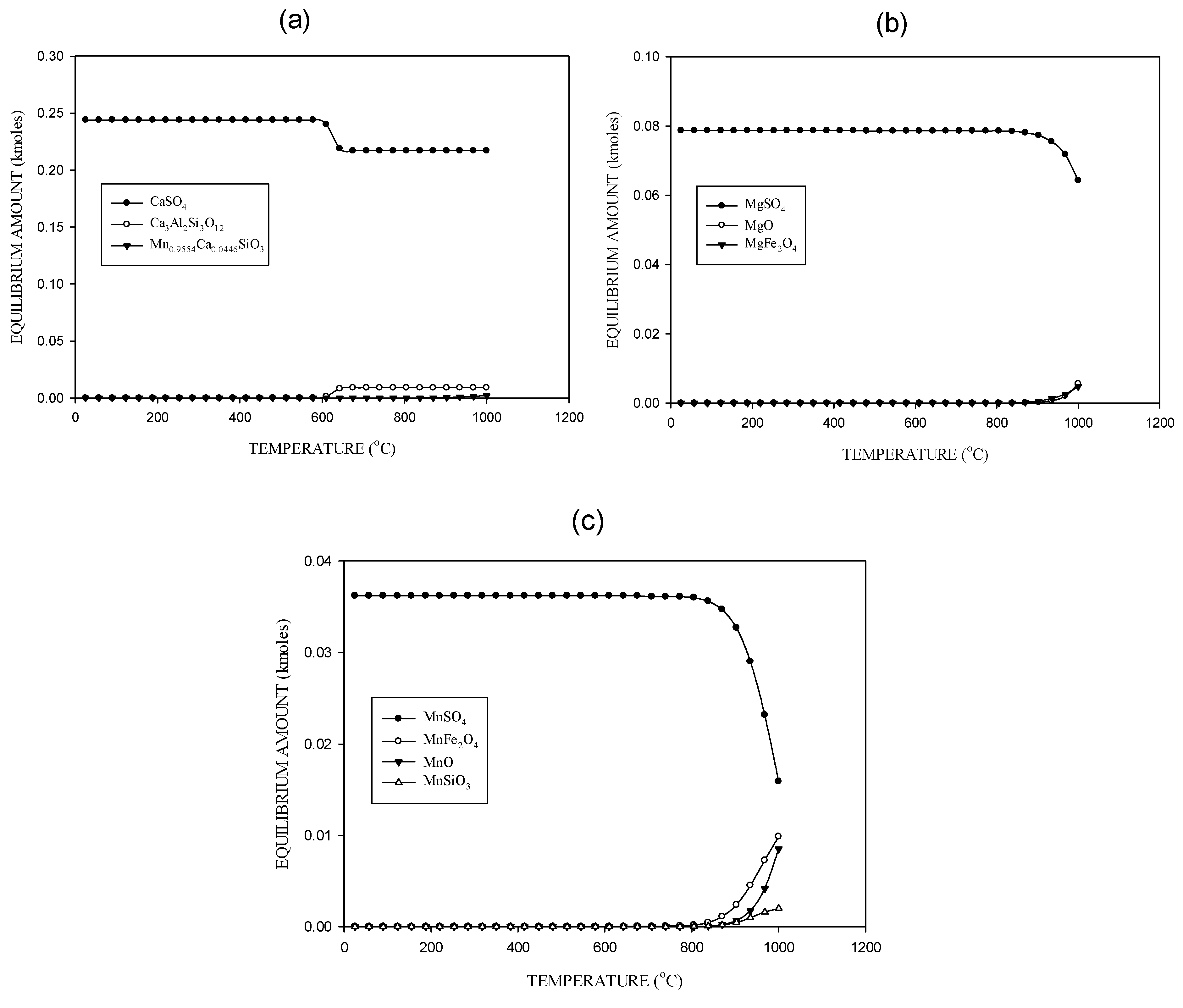

Figure 6a–c shows the equilibrium amounts of the calcium, magnesium and manganese-containing species as a function of temperature, respectively, for a sulphur dioxide addition of 0.68 kmole/100 kg of dust and 0.4 kmole of oxygen/100 kg of dust. These three elements behave similarly, with the metal sulphate being stable over most of the temperature range, but decomposing at higher temperatures. Here, calcium forms calcium aluminium silicate, magnesium forms magnesium oxide and magnesium ferrite, and manganese forms manganese oxide, manganese ferrite and manganese silicate.

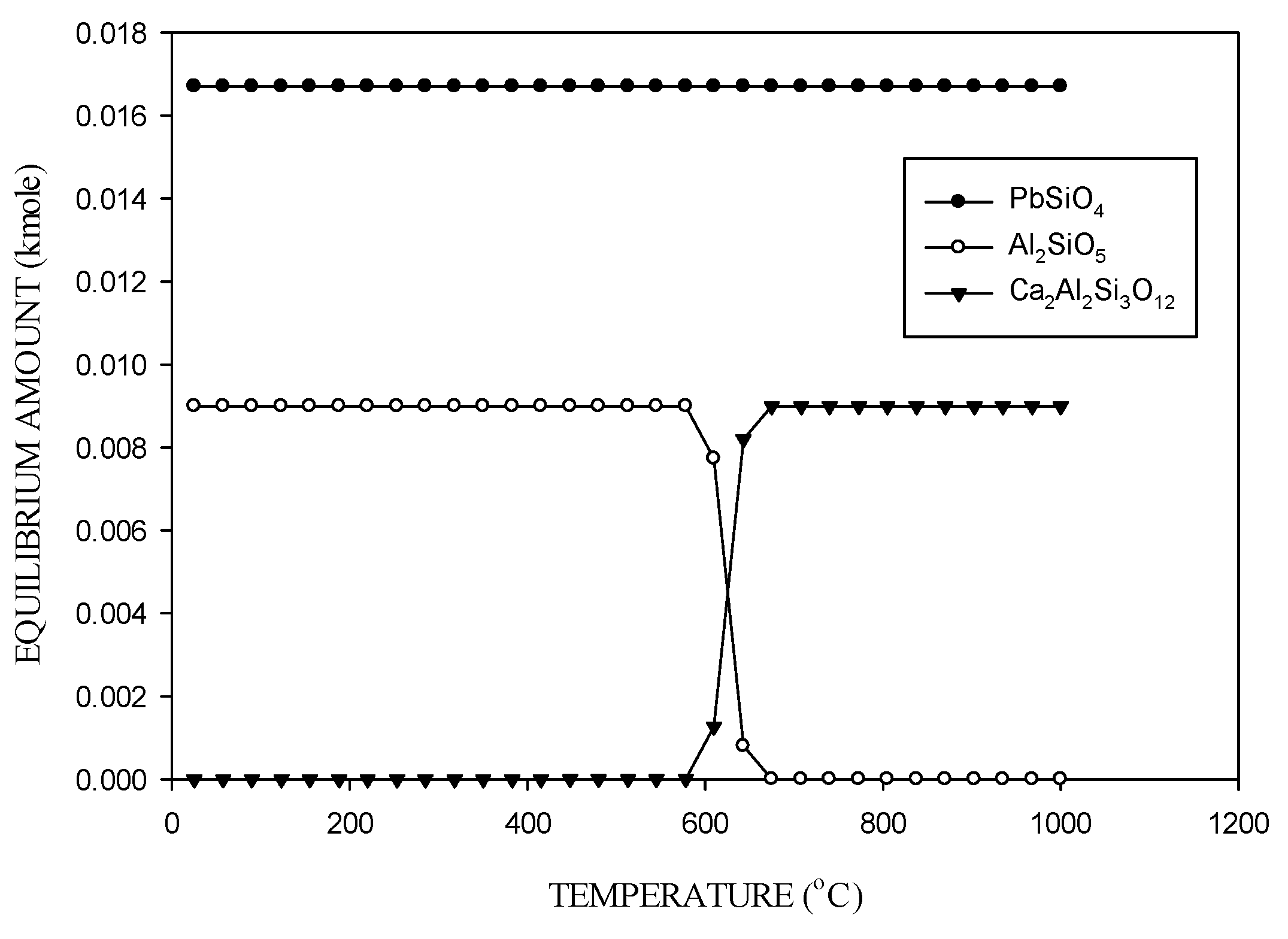

The behaviours of aluminium and lead are shown in

Figure 7 for the same conditions. Lead is not sulphated and exists as only lead orthosilicate across the whole temperature range. Similarly, aluminium does not form a sulphate and exists as aluminium silicate at low temperatures and calcium aluminium silicate at high temperatures.

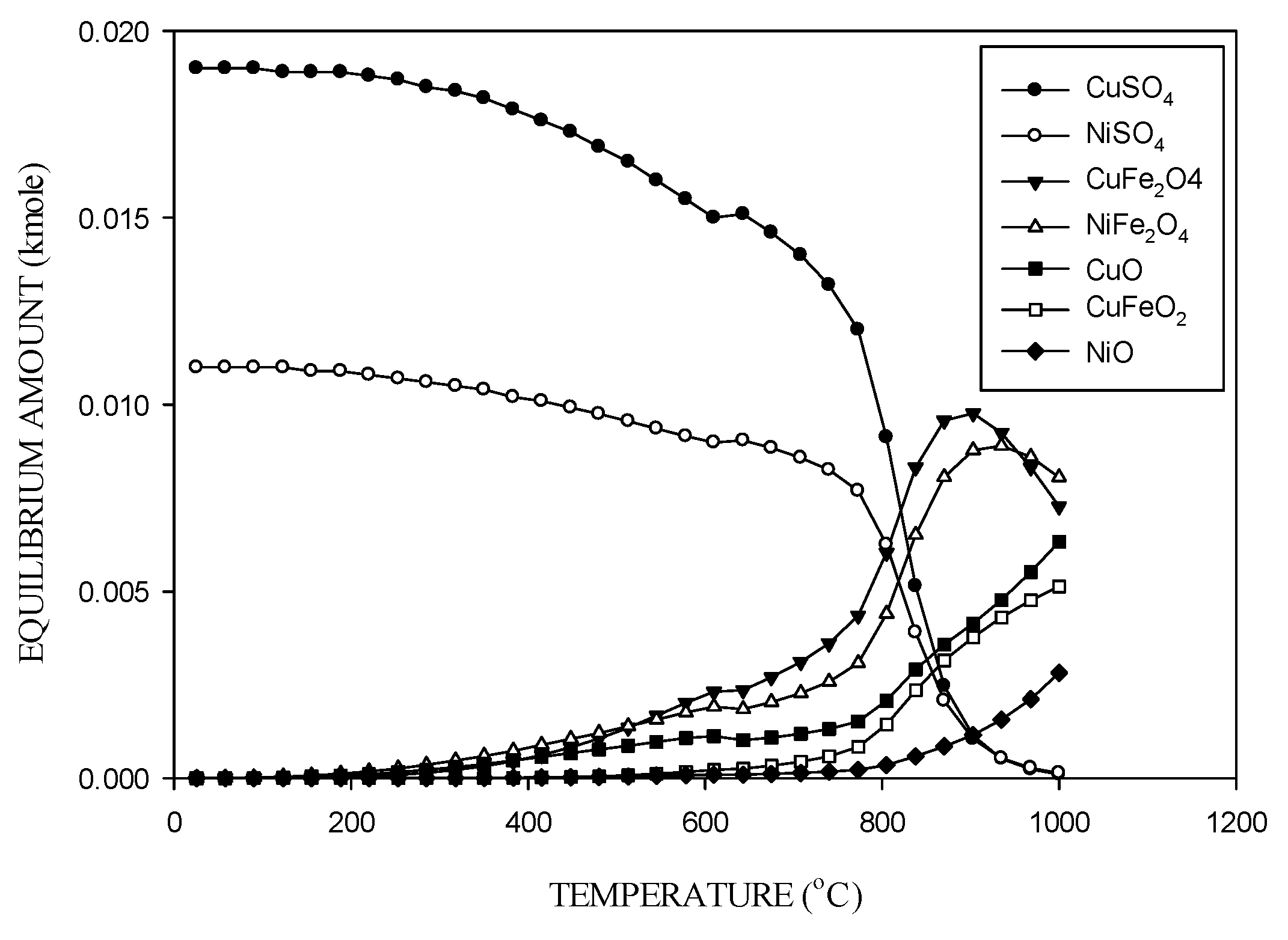

As shown in

Figure 8, copper and nickel behave in a similar manner. Both the copper and nickel sulphates are stable at room temperature, but their amounts decrease slowly with increasing temperature, and then more rapidly at about 600 °C, before disappearing at about 1000 °C. As the temperature increases, the copper and nickel ferrites form in increasing amounts, as well as the copper and nickel oxides. At 900 °C, the amounts of the ferrites reach a maximum before decreasing, and subsequently, the amounts of the nickel and copper oxides continue to increase. The amounts of copper and nickel sulphates could be increased by adding additional sulphur dioxide and oxygen, but this would also result in an increase in the amounts of the iron sulphates.

5.3. Gas Composition

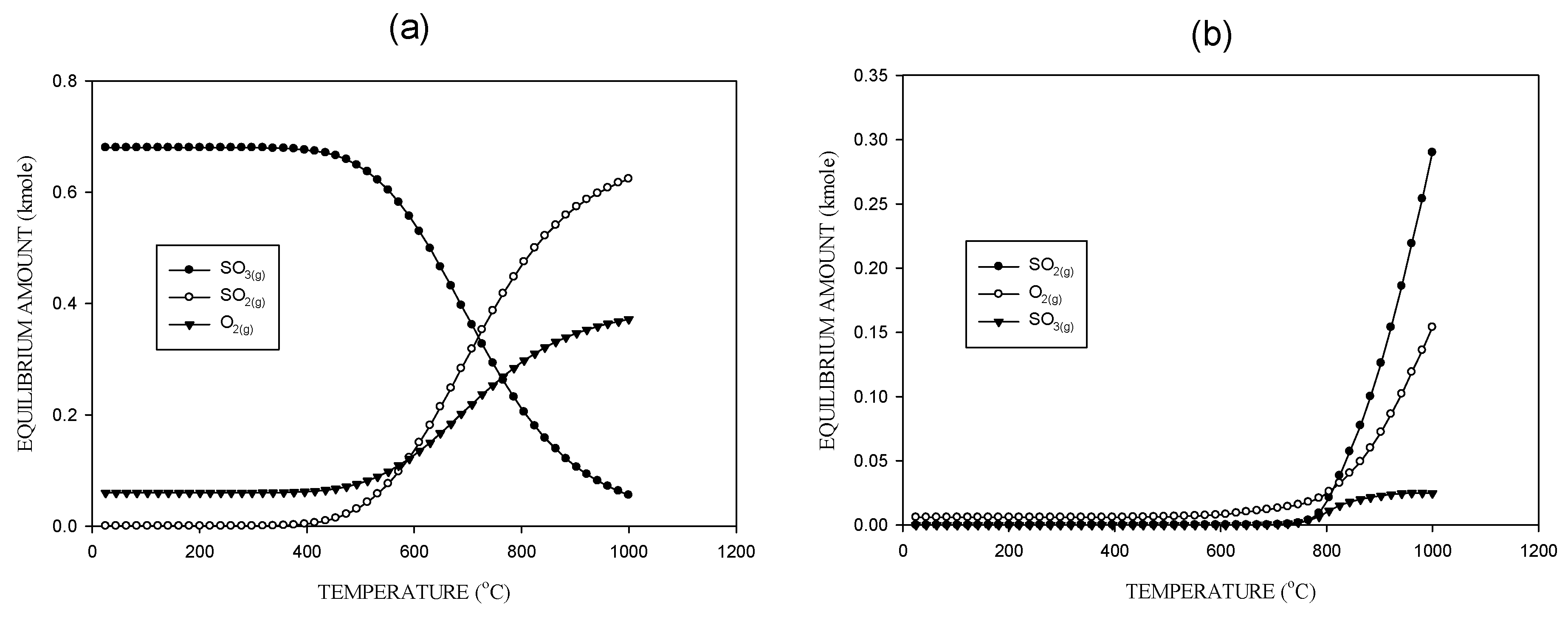

The gas composition as a function of temperature in the absence of condensed species for the sulphur dioxide addition of 0.68 kmole/100 kg of dust and 0.4 kmole of oxygen/100 kg of dust is shown in

Figure 9a.

Here it can be seen that at low temperatures, sulphur trioxide is the predominant reacting species and any available sulphur dioxide is combined with oxygen. As discussed previously, there is a small amount of oxygen that is unreacted. Above about 400 °C, the sulphur trioxide becomes unstable and the amounts of sulphur dioxide and oxygen increase slowly, and then more rapidly, with increasing temperature. By about 1000 °C, the amount of sulphur trioxide has decreased to very low levels.

Figure 9b shows the gas composition for the same conditions, but in the presence of the condensed species. In this case, at low temperatures, the sulphur trioxide has reacted with the metal oxides to produce metal sulphates. Therefore, below about 600 °C, the small amount of unreacted oxygen comprises the majority of the gas phase. At about 600 °C, the amount of oxygen begins to increase slowly and then more rapidly above 700 °C. Sulphur dioxide begins to form at about 600 °C and increases rapidly again at 700 °C. These increases in oxygen and sulphur dioxide are mainly due to the decomposition of the metal sulphates with increasing temperature. Also, at 700 °C, the amount of sulphur trioxide begins to increase before levelling off at about 900 °C. Here it becomes relatively unstable in comparison to both sulphur dioxide and oxygen.

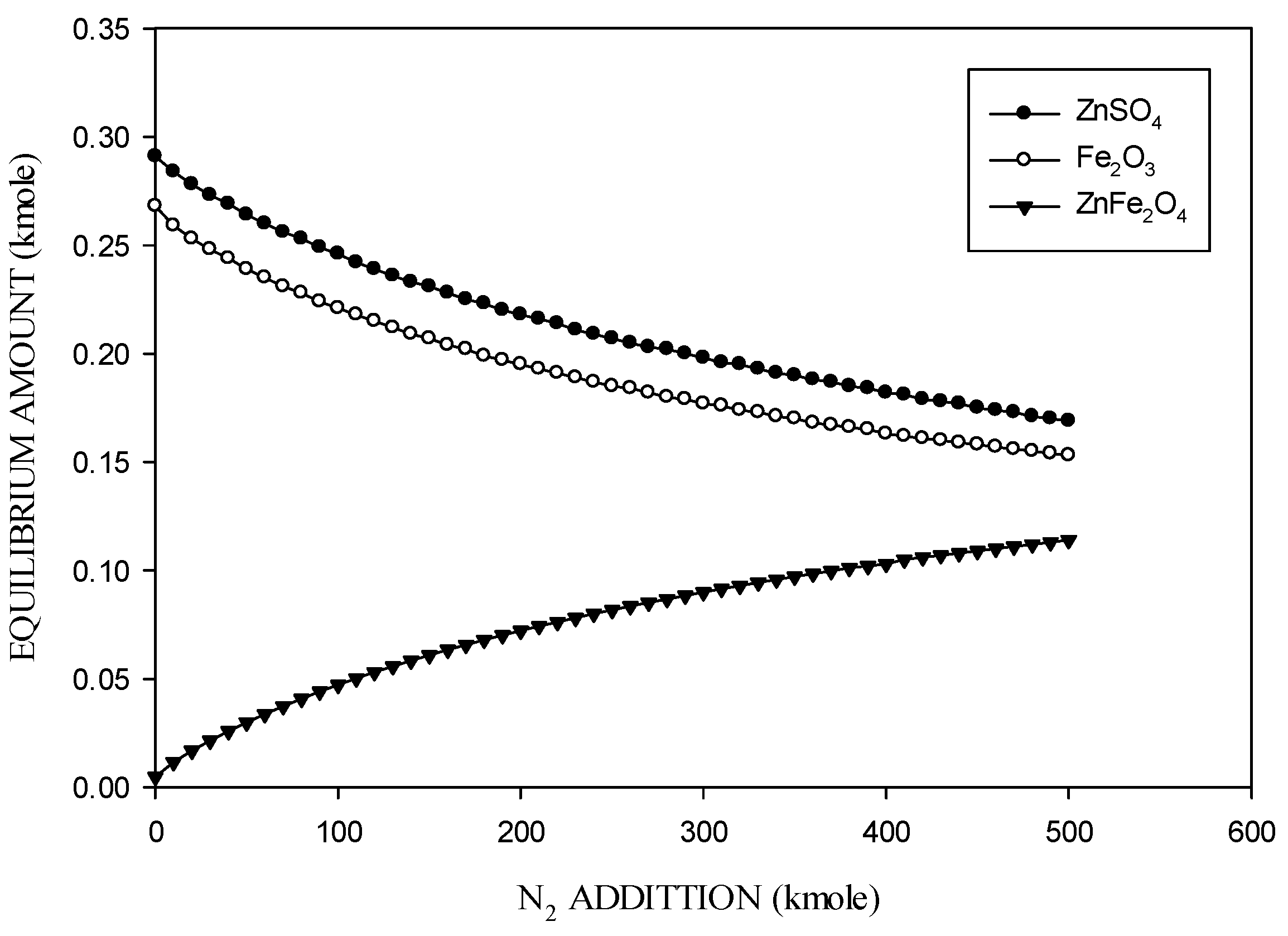

Figure 10 shows the equilibrium amounts of zinc sulphate, hematite and zinc ferrite as a function of the amount of nitrogen in the system at 600 °C. With increasing nitrogen, the partial pressures of the reacting gases are reduced in the gas phase and this lowers the stability of zinc sulphate and thus the conversion to zinc sulphate is reduced. More of the iron oxide is retained as zinc ferrite, and thus the amount of hematite is reduced. Thus, nitrogen or inert gases present in the system will reduce both the conversion of zinc oxide and the amount of hematite.

Based on the previous discussion, it can be noted that although the sulphur dioxide addition is close to the stoichiometric requirement as given by reaction (9), the oxygen addition is considerably in excess. Some sulphur dioxide is consumed to produce the copper, nickel and iron sulphates, which are not accounted for by reaction (9). This additional sulphur dioxide is generated by the oxidation of the copper and nickel sulphides, originally present in the as-received dust. The formation of ferrous and ferric sulphates requires additional oxygen. Also, oxygen is consumed to produce lead orthosilicate, and furthermore, there is a small amount of oxygen in the gas phase.

5.4. Alternative Reagents

In addition to sulphur dioxide and oxygen, there are other potential sulphating reagents such as: sulphur plus oxygen, ferrous sulphate plus oxygen, ferric sulphate and finally pyrite plus oxygen. The reactions of these species with zinc oxide to form zinc sulphate can described as follows:

Assuming the other components in the dust behave as described previously, then the stoichiometric requirements for each reagent for the sulphation of zinc oxide were determined to be equivalent to the previously determined values of 0.68 kmole of SO2/100 kg of dust and 0.4 kmole of O2/100 kg of dust.

Figure 11 shows the conversion of zinc to zinc sulphate as a function of temperature for the various reagents. Generally, the behaviours of each reagent are similar, and for the proposed reaction temperature of 600 °C, the zinc conversions are close to one hundred percent for all the reagents. The temperatures at which zinc sulphate begins to decompose are to some degree dissimilar for each reagent, reflecting the somewhat differing equilibrium conditions at the higher temperatures. The addition of ferrous sulphate, ferric sulphate and pyrite would all increase the amount of iron oxide in the reaction products.

6. Conclusions

(1) Predominance area diagrams were calculated for the Fe-Zn-O-S system at both 600 °C and 700 °C, which showed that zinc sulphate can coexist with hematite. For this system, and for a process operating in air, the equilibrium pSO2 would be between about 10−3 and 10−6 atm at 600 °C and between about 10−1 and 10−4 atm at 700 °C. Additionally, a thermodynamic model was developed using the Equilibrium Module of HSC® Chemistry 7.1 to investigate the sulphation of a typical electric arc furnace dust. Three phases were utilised and forty-one species were considered to be stable. Within each phase, the species were assumed to behave ideally. Using this model, the equilibrium amounts of the reaction products could be determined as a function of three variables: sulphur dioxide, oxygen and temperature.

(2) The optimum conditions for the maximum conversion of zinc oxide to zinc sulphate while maintaining the iron as hematite were determined. These were found to be: a temperature of 600 °C, and sulphur dioxide and oxygen additions were close to the predicted stoichiometric requirements for the selected dust. Almost one hundred percent of the zinc could be converted into zinc sulphate, and about ninety-five percent of the iron was retained as hematite. Some iron was converted to both ferrous and ferric sulphates. Both copper and nickel were only partially converted to their respective sulphates.

(3) In the absence of condensed phases and at low temperatures, oxygen and sulphur dioxide combined to form sulphur trioxide. Thus, sulphur trioxide can be considered to be the predominant gaseous reacting species for the formation of the metal sulphates. As the temperature increased above about 400 °C, sulphur trioxide became unstable and sulphur dioxide and oxygen were produced in increasing amounts. In the presence of condensed phases, the sulphur trioxide was consumed to produce metal sulphates. Consequently, sulphur dioxide and oxygen were not generated until the sulphates decomposed at temperatures above about 600 °C.

(4) In addition to sulphur dioxide and oxygen, the following reagents were evaluated: sulphur plus oxygen, ferrous sulphate plus oxygen, ferric sulphate and pyrite plus oxygen. In general, all of these reagents could be utilised for the sulphation of electric arc furnace dust with recoveries approaching one hundred percent at 600 °C. From a thermodynamic perspective, they represent different sources of sulphur and oxygen. At higher temperatures, the decomposition of zinc sulphate occurred over slightly dissimilar temperature ranges due to the differing equilibrium compositions of the reaction products.

(5) This process offers several potential advantages over the current pyrometallurgical or hydrometallurgical processes for the treatment of EAF dust. Firstly, the sulphation reactions can be carried out at low temperature, using low-cost reagents. Secondly, the iron remains as iron oxide, and since the zinc sulphate is soluble in aqueous solutions, the zinc can be efficiency separated from the iron. Some copper and nickel can be sulphated and could also be recovered in aqueous solutions. The recovery of these metals could be increased by adding more sulphur dioxide and oxygen, but this would result in the formation of additional iron sulphate.