Strength Development and Microstructure Evolution of Cemented Tailings Backfill Containing Different Binder Types and Contents

Abstract

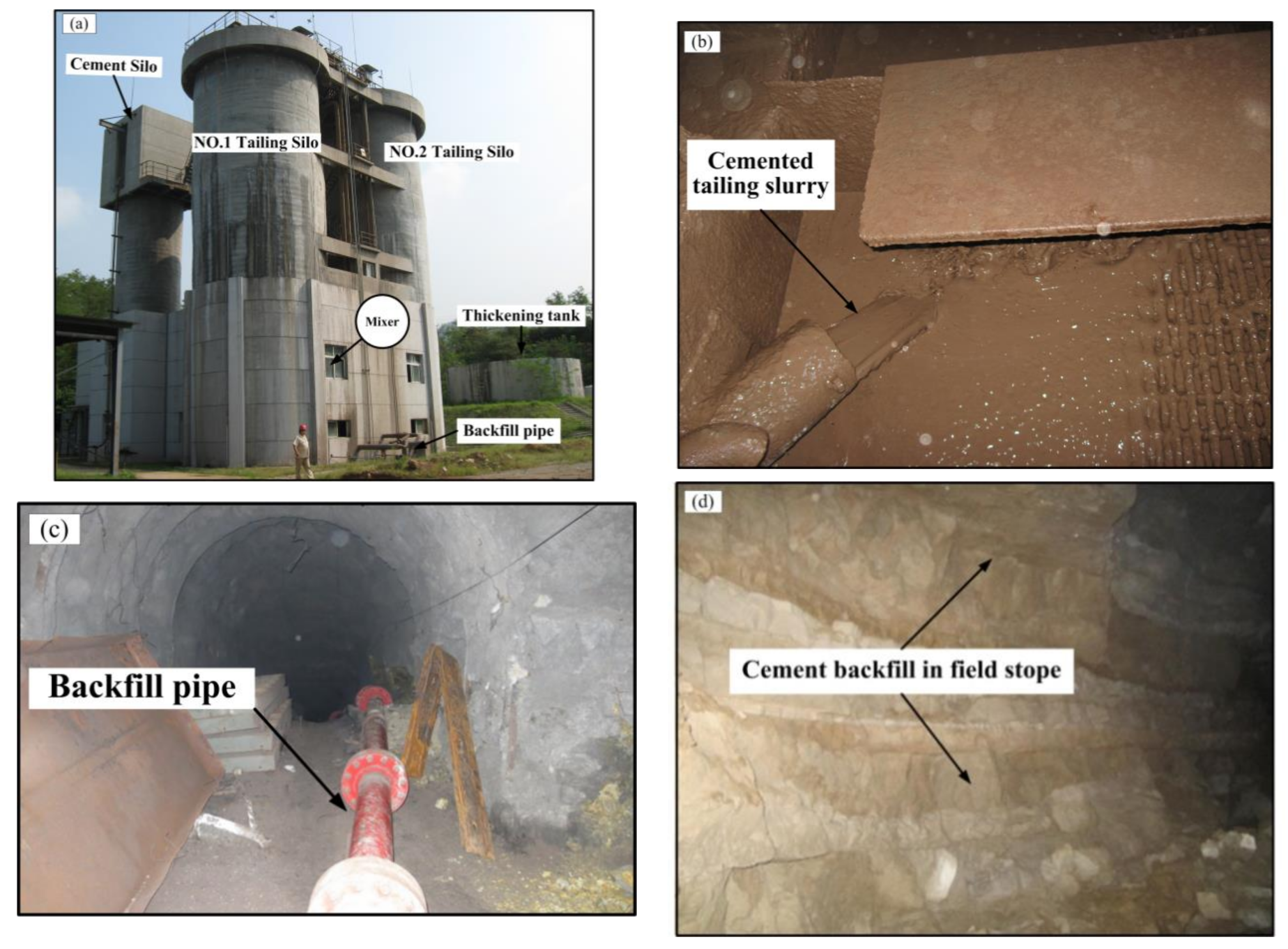

:1. Introduction

2. Materials and Methods

2.1. Tailings Materials

2.2. Binders

2.3. Water

2.4. Cemented Tailings Backfill Preparation

2.5. Mechanical Tests

2.6. Microstructure Analysis

3. Results and Discussion

3.1. The Strength Development of the CTB

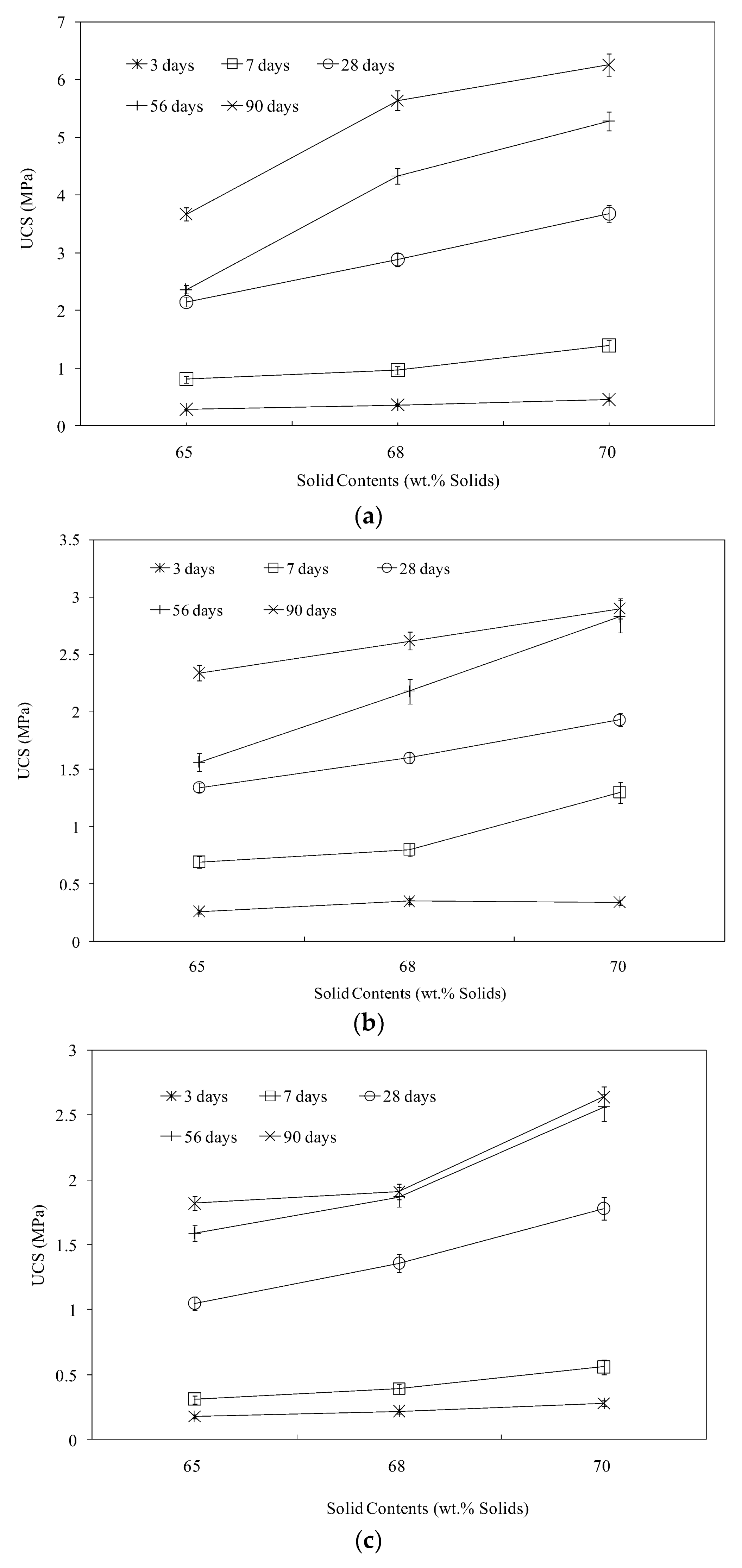

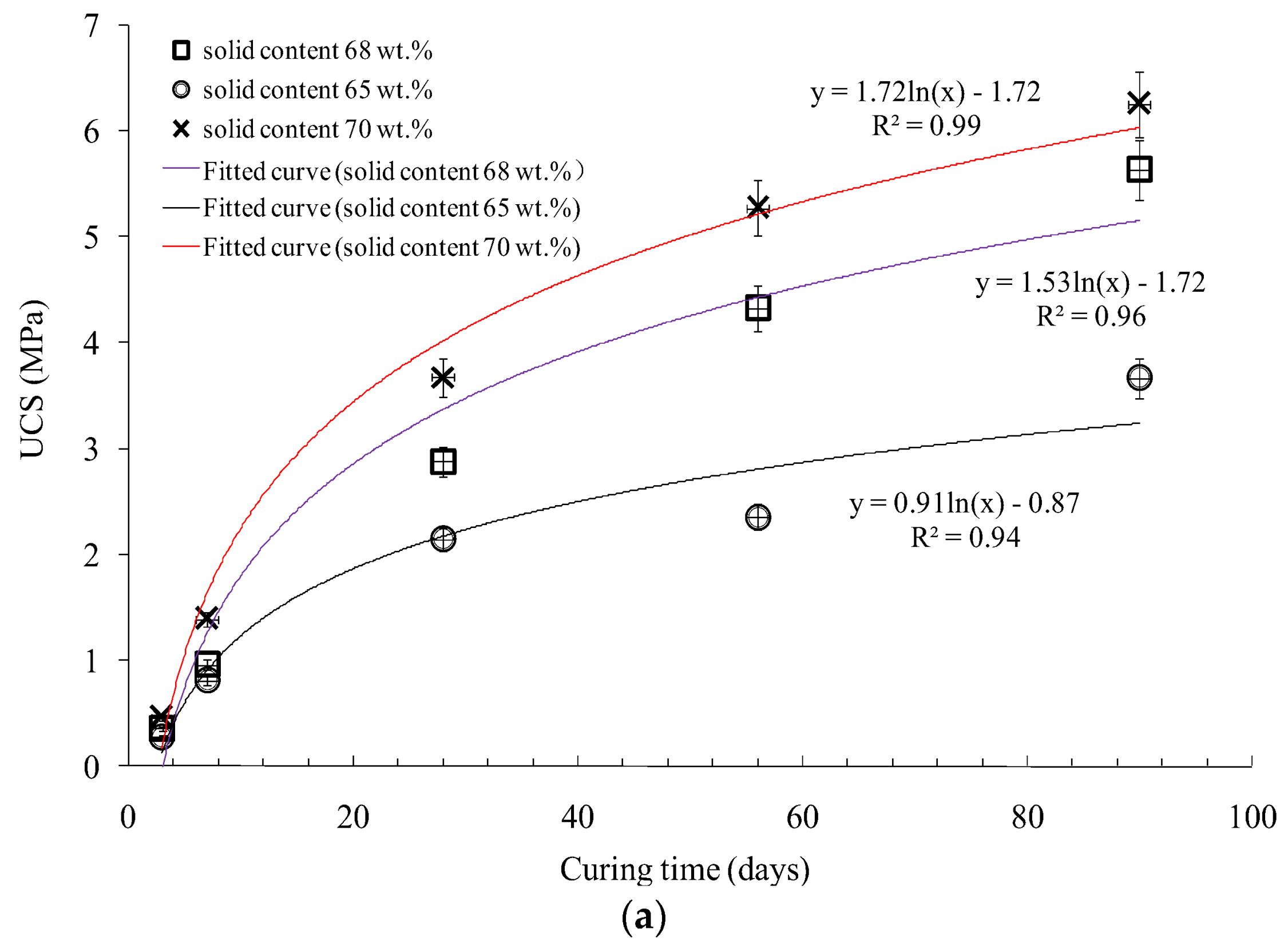

3.1.1. The Effect of Solid Content

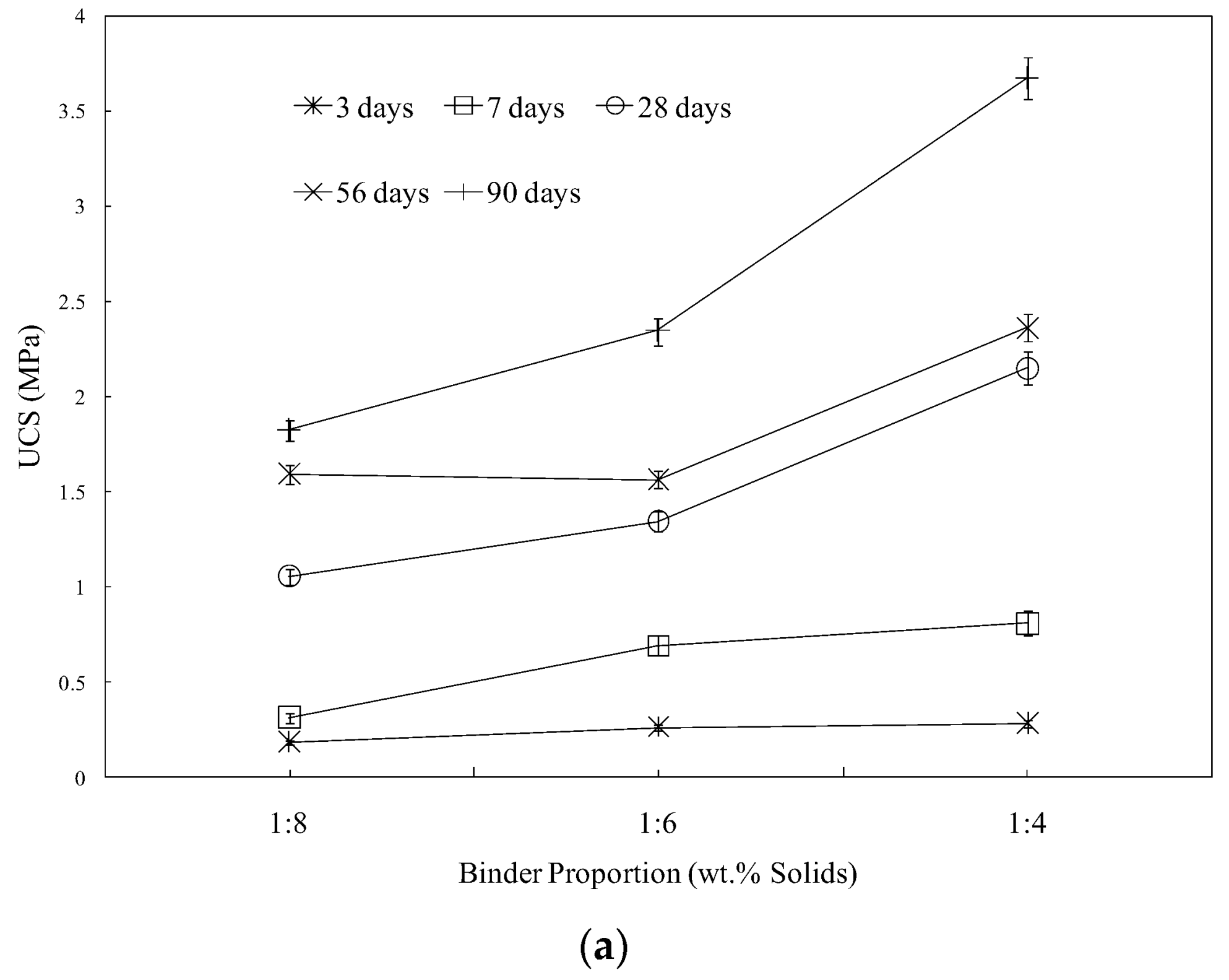

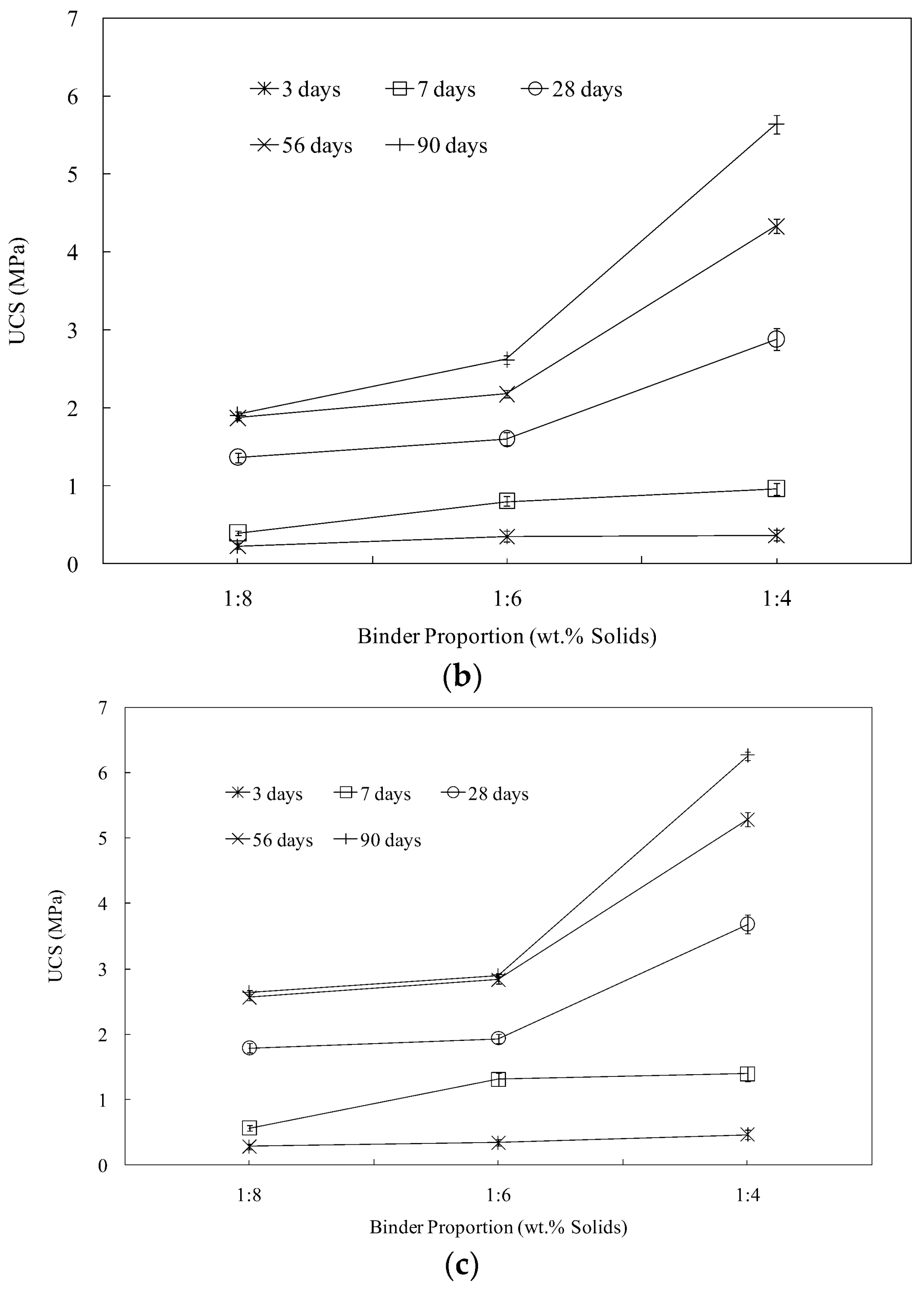

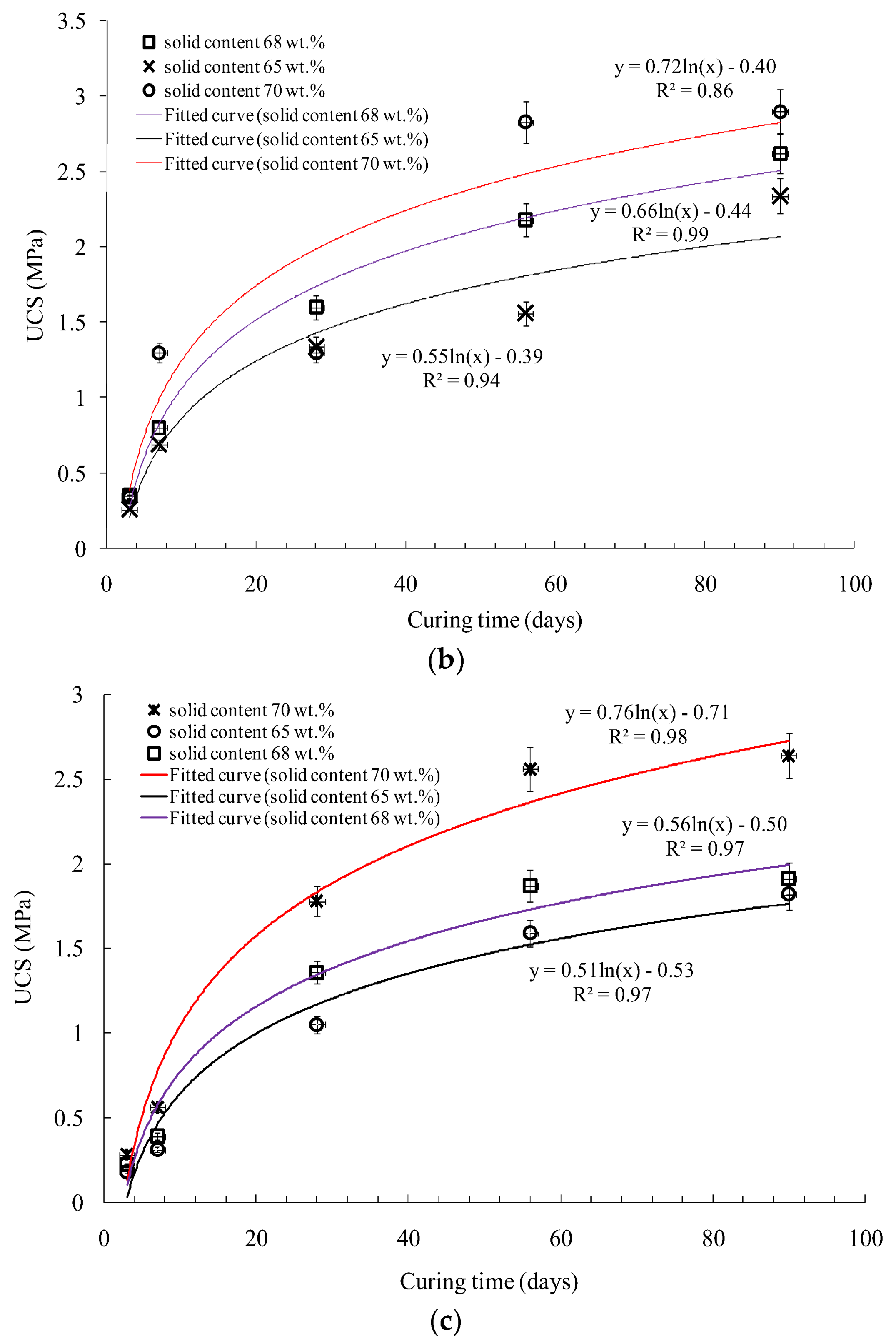

3.1.2. The Effect of the Binder Content

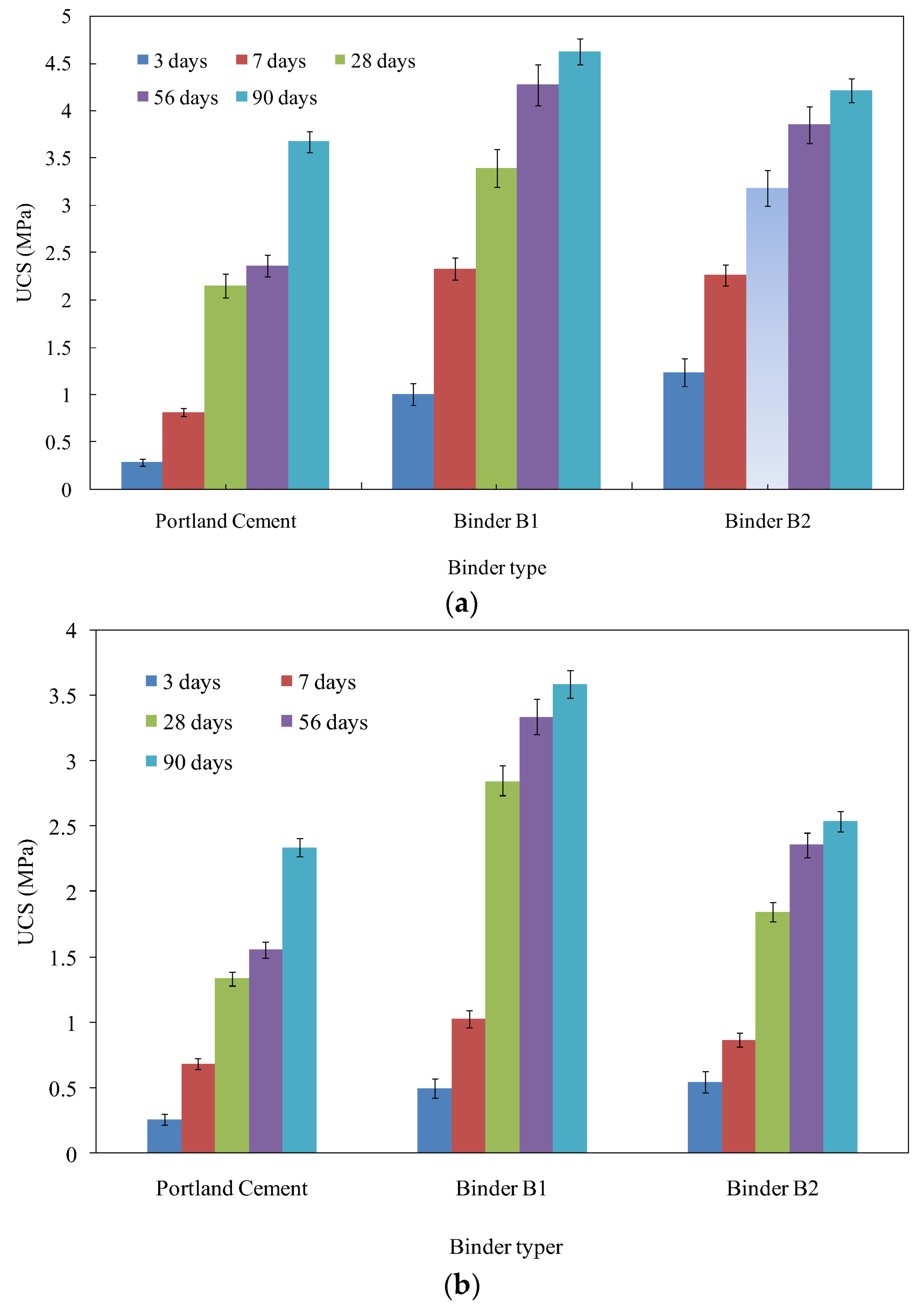

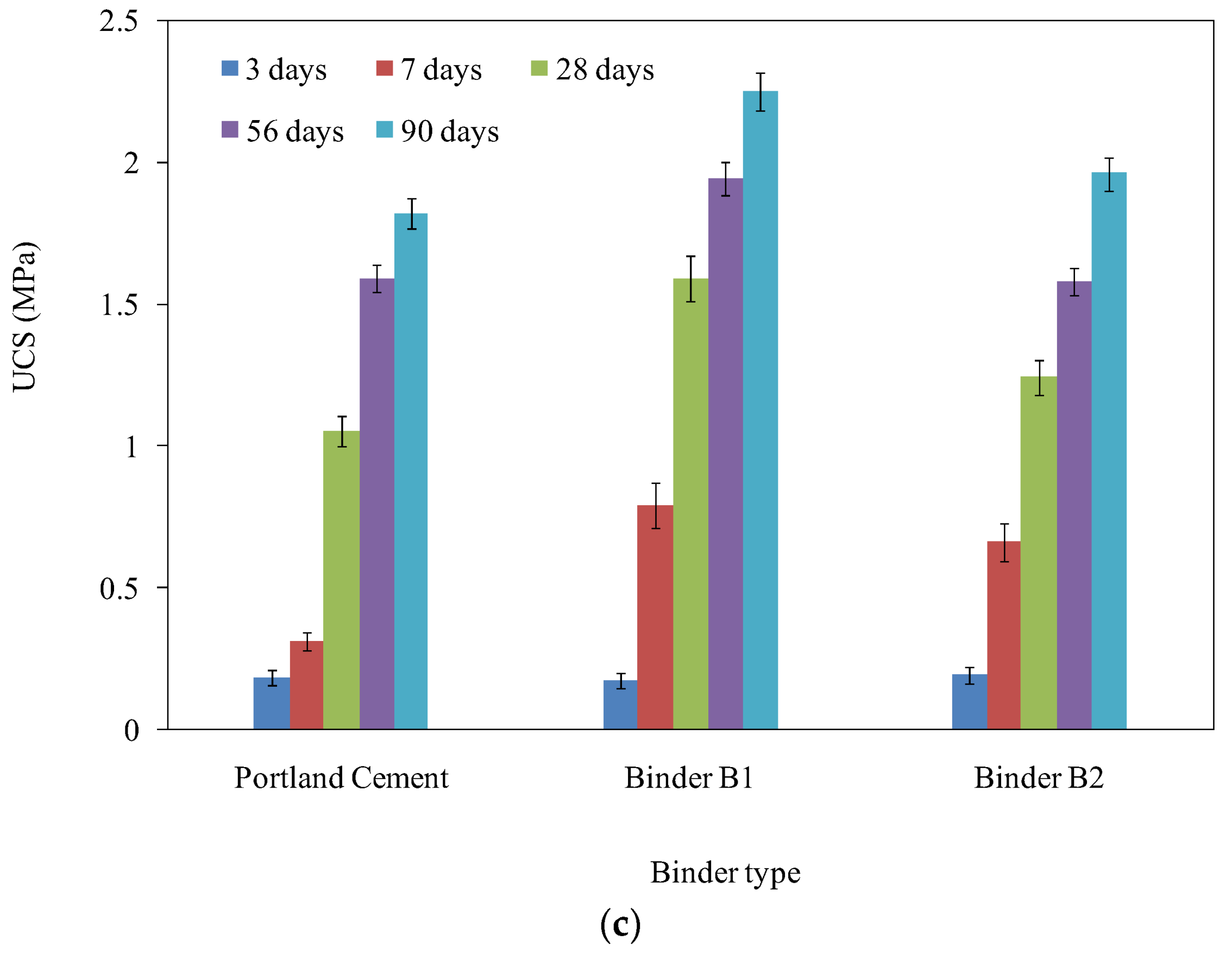

3.1.3. The Effect of the Binder Type

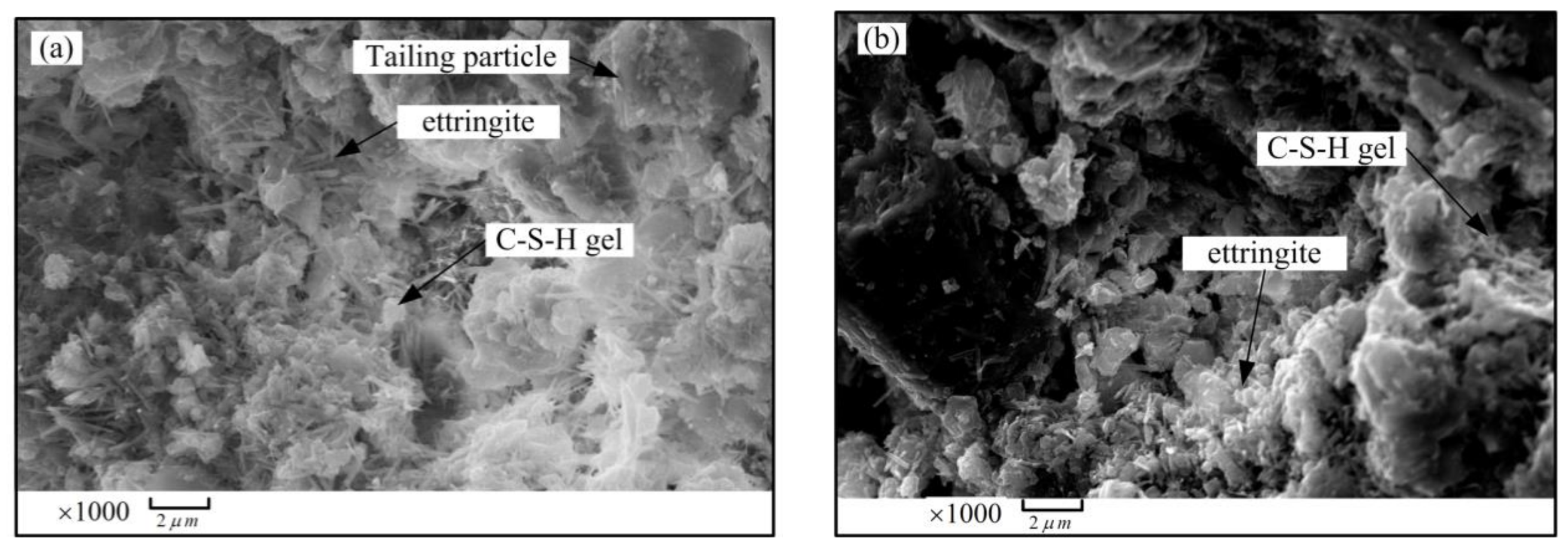

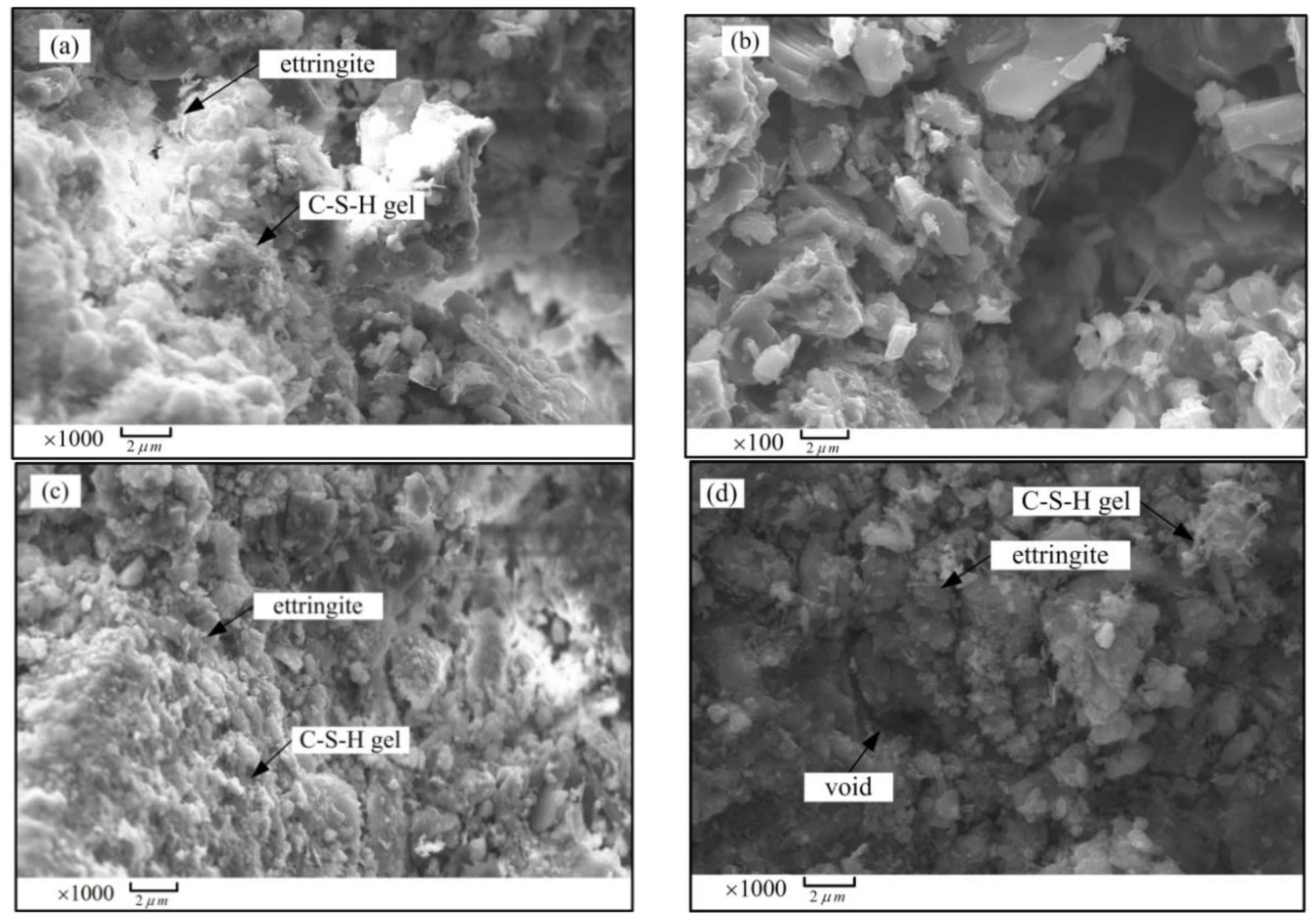

3.2. The Microstructure Evolution of CTB

3.3. Discussion on the Strength Development Model of CTB

4. Conclusions

- (1)

- The solid content and binder content tests clearly show that an increase in the strength acquisition of cemented tailings backfill are caused by the increase of solid content and cement dosage. The binder content plays an important role in the mechanical behavior of CTB. The paper also highlights the effect of the binder type on the performance of cement backfill. The different binders correspond to different strength for a given tailings. Up to 3 days curing time, the Binder B1 has more advantages than Binder B2 and Portland cement. However, when the curing period is over 3 days, Binder B2 is more suitable for this backfill than Binder B1 and Portland cement.

- (2)

- The genre and form mode of hydration products in CTB were strongly affected by the hydration process, which is affected by the binder type and content along with the curing time. At an early curing time (i.e., from 0 to 3 days) the cement hydration is weak, there are mainly portlandite and calcium silicate hydrated gels (C–S–H) dispersing within their matrix, and the UCS can reach to 0.5 MPa. After 28 days of curing time, the structure of hydration products becomes denser, contributing to the cohesion of cement backfill matrix. Hence, the CTB developed a UCS of approximate 3.6 MPa. Over 90 days of curing time, SEM micrographs show that cemented backfill grains are evenly dispersed within their matrix. The voids between the coarse particles of the original tailings are filled with ultrafine articles and cement hydrates, and the hydration reaction almost accomplished completely, developing a good compressive strength.

- (3)

- The paper shows that UCS and curing time is in a logarithmic relationship within 90 days of curing time. Tests are executed to determine the fitted coefficient, and the correlation coefficients of the fitted curves are almost higher than 95%. It indicates that the function can accurately describe the strength development of CTB within 90 days curing time.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, S.; Xue, X.; Liu, R.; Jin, Z. Current situation and prospect of the comprehensive utilization of mining tailings. Min. Metall. Eng. 2005, 25, 44–47. (In Chinese) [Google Scholar]

- Aldhafeeri, Z.; Fall, M.; Pokharel, M.; Pouramini, Z. Temperature dependence of the reactivity of cemented paste backfill. Appl. Geochem. 2016, 72, 10–19. [Google Scholar] [CrossRef]

- Dold, B. Submarine tailings disposal (STD)—A review. Minerals 2014, 4, 642–666. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikki, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikki, B.; Alp, I.; Deveci, H. Effect of properties of tailings and binder on the short and long-term strength and stability of cemented paste backfill. Mater. Lett. 2005, 59, 3703–3709. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M. Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization. Cem. Concr. Res. 2005, 35, 301–314. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Gonzalo, S.; Fourie, A.; James, D. Cyclic Shear Response of Cemented Paste Backfill. Geotech. Geoenviron. Eng. 2017, 143, 1–11. [Google Scholar]

- Yin, S.; Wu, A.; Hu, K.; Wang, Y.; Zhang, Y. The effect of solid components on the rheological and mechanical properties of cemented paste backfill. Miner. Eng. 2012, 35, 61–66. [Google Scholar] [CrossRef]

- Yi, X.; Ma, G.; Fourie, A. Compressive behaviour of fibre-reinforced cemented paste backfill. Geotext. Geomembr. 2015, 43, 207–215. [Google Scholar] [CrossRef]

- Sun, W.; Wu, A.; Hou, K. Real-time observation of meso-fracture process in backfill body during mine subsidence using X-ray CT under uniaxial compressive conditions. Constr. Build. Mater. 2016, 113, 153–162. [Google Scholar] [CrossRef]

- Yilmaz, E.; Benzaazoua, M.; Belem, T. Effect of curing under pressure on compressive strength development of cemented paste backfill. Miner. Eng. 2009, 22, 772–785. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill. Eng. Geol. 2014, 168, 23–37. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Specimen size effect on strength behavior of cemented paste backfills subjected to different placement conditions. Eng. Geol. 2015, 185, 52–62. [Google Scholar] [CrossRef]

- Fall, M.; Pokharel, M. Coupled effect of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement paste backfill. Compos. Concr. Mater. 2010, 32, 819–828. [Google Scholar] [CrossRef]

- Ercikdi, B.; Kesimal, A.; Cihangir, F. Cemented paste backfill of sulphide-rich tailings: Importance of binder type and dosage. Cem. Concr. Compos. 2009, 31, 268–274. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B.; Alp, I.; Yumlu, M.; Ozdemir, B. Laboratory testing of cemented paste backfill. Turk. Min. J. 2002, 41, 11–20. [Google Scholar]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B.; Alp, I.; Yumlu, M.; Ozdemir, B. Paste backfill technology in underground mining: A case study. Turk.J. Earth Sci. Rev. 2003, 16, 45–53. [Google Scholar]

- Yilmaz, E.; Kesimal, A.; Ercikdi, B. Evaluation of acid producing sulphidic mine tailings as a paste backfill. Turk. J. Earth Sci. Rev. 2004, 17, 11–19. [Google Scholar]

- Yilmaz, E.; Belem, T.; Benzaazoua, M.; Kesimal, A.; Ercikdi, B. Evaluation of the strength properties of deslimed tailings paste backfill. Miner. Res. Eng. 2007, 12, 129–144. [Google Scholar]

- Yilmaz, E. Investigating the Hydrogeotechnical and Microstructural Properties of Cemented Paste Backfills Using the Versatile CUAPS Apparatus. Ph.D. Thesis, Université du Québec en Abitibi-Témiscamingue UQAT, Rouyn-Noranda, QC, Canada, 2010; pp. 1–388. [Google Scholar]

- Landriault, D. Paste Backfill Mix Design for Canadian Underground Hard Rock Mining. In Proceedings of the 97th Annual General Meeting of the CIM Rock Mechanics and Strata Control Session, Halifax, NS, Canada, 14–18 March 1995; pp. 652–663. [Google Scholar]

- Amaratunga, L.; Yaschyshyn, D. Development of a high modulus paste fill using fine gold mill tailings, Geotechnology. Geol. Eng. 1997, 15, 205–219. [Google Scholar]

- Fall, M.; Samb, S. Pore structure of cemented tailings materials under natural or accidental thermal loads. Mater. Charact. 2008, 59, 598–605. [Google Scholar] [CrossRef]

- Fall, M.; Celestin, J.C.; Pokharel, M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng. Geol. 2010, 114, 397–413. [Google Scholar] [CrossRef]

- Grice, T. Underground mining with backfill. In Proceedings of the 2nd Annual Summit, Mine Tailings Disposal Systems, Australasian Institute of Mining and Metallurgy, Brisbane, Australia, 24–25 November 1998; p. 14. [Google Scholar]

- Orejarena, L.; Fall, M. Artificial neural network based modeling of the coupled effect of sulphate and temperature on the strength of cemented paste backfill. Can. J. Civ. Eng. 2011, 38, 100–109. [Google Scholar] [CrossRef]

- ASTM. Standard Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM C39-96; ASTM: West Conshohochen, PA, USA, 2001. [Google Scholar]

- Benzaazoua, M.; Belem, T.; Bussiere, B. Chemical factors that influence the performance of mine sulphidic paste backfill. Cem. Concr. Res. 2002, 32, 1133–1144. [Google Scholar] [CrossRef]

- Fall, M.; Pokharel, M. Strength development and sorptivity of tailings shotcrete under various thermal and chemical loads. Can. J. Civ. Eng. 2011, 38, 772–784. [Google Scholar]

- Fall, M.; Brackebusch, F. Basics of paste backfill system. Eng. Min. J. 1994, 46, 1175–1178. [Google Scholar]

- Claude, J.; Célestin, H.; Fall, M. Thermal conductivity of cemented paste backfill material and factors affecting it. Int. J. Min. Reclam. Environ. 2009, 23, 274–290. [Google Scholar]

- Xu, W.; Du, J.; Song, W. Experiment on the mechanism of consolidating backfill body of extra-fine grain unclassified tailings and cementitious materials. Rock Soil Mech. 2013, 34, 2295–2302. (In Chinese) [Google Scholar]

- Xu, W.; Tian, X.; Qiu, Y. Experiment of the resistivity characteristic of cemented backfill mass during the whole consolidation process. J. China Univ. Min. Tech. 2017, 46, 265–272. (In Chinese) [Google Scholar]

- Hekal, E.; Kishar, E.; Mostafa, H. Magnesium sulfate attack on hardened blended cement pastes under different circumstances. Cem. Concr. Res. 2002, 32, 1421–1427. [Google Scholar] [CrossRef]

| Compound | SiO2 | TFe | SFe | CaO | FeO | Al2O3 | MgO | S | Loss-on-Ignition | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Tailings (wt %) | 26.30 | 10.79 | 20.02 | 12.45 | 10.90 | 6.07 | 5.55 | 1.32 | 6.60 | 100 |

| Particle Size (μm) | 20 | 45 | 75 | 106 | 150 | 180 | 200 |

|---|---|---|---|---|---|---|---|

| Cumulative passing (%) | 53.7 | 67.5 | 78.7 | 86.1 | 93.9 | 97.1 | 100 |

| Item | Specific Gravity | Bulk Density (t/m3) | Porosity (%) | Specific Surface Area (m2/m3) |

|---|---|---|---|---|

| Tailings | 3.20 | 1.47 | 57.00 | 640,000 |

| Portland Cement | 3.10 | 1.30 | 58.06 | 582,000 |

| Binder B1 | 3.34 | 1.52 | 53.60 | 756,000 |

| Binder B2 | 3.42 | 1.48 | 55.20 | 680,000 |

| Compound | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | K2O | Na2O | NaOH |

|---|---|---|---|---|---|---|---|---|

| Binder B1 (%) | 52.40 | 29.10 | 1.26 | 10.30 | 5.32 | 0.98 | 0.65 | - |

| Binder B2 (%) | 48.84 | 23.77 | 2.34 | 19.05 | 4.03 | 1.26 | 0.71 | 5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Cao, P.; Tian, M. Strength Development and Microstructure Evolution of Cemented Tailings Backfill Containing Different Binder Types and Contents. Minerals 2018, 8, 167. https://doi.org/10.3390/min8040167

Xu W, Cao P, Tian M. Strength Development and Microstructure Evolution of Cemented Tailings Backfill Containing Different Binder Types and Contents. Minerals. 2018; 8(4):167. https://doi.org/10.3390/min8040167

Chicago/Turabian StyleXu, Wenbin, Peiwang Cao, and Mingming Tian. 2018. "Strength Development and Microstructure Evolution of Cemented Tailings Backfill Containing Different Binder Types and Contents" Minerals 8, no. 4: 167. https://doi.org/10.3390/min8040167

APA StyleXu, W., Cao, P., & Tian, M. (2018). Strength Development and Microstructure Evolution of Cemented Tailings Backfill Containing Different Binder Types and Contents. Minerals, 8(4), 167. https://doi.org/10.3390/min8040167