CFD Simulation of Pipeline Transport Properties of Mine Tailings Three-Phase Foam Slurry Backfill

Abstract

:1. Introduction

2. Materials and Methods

2.1. Foam Slurry Materials

2.1.1. Constituent Materials

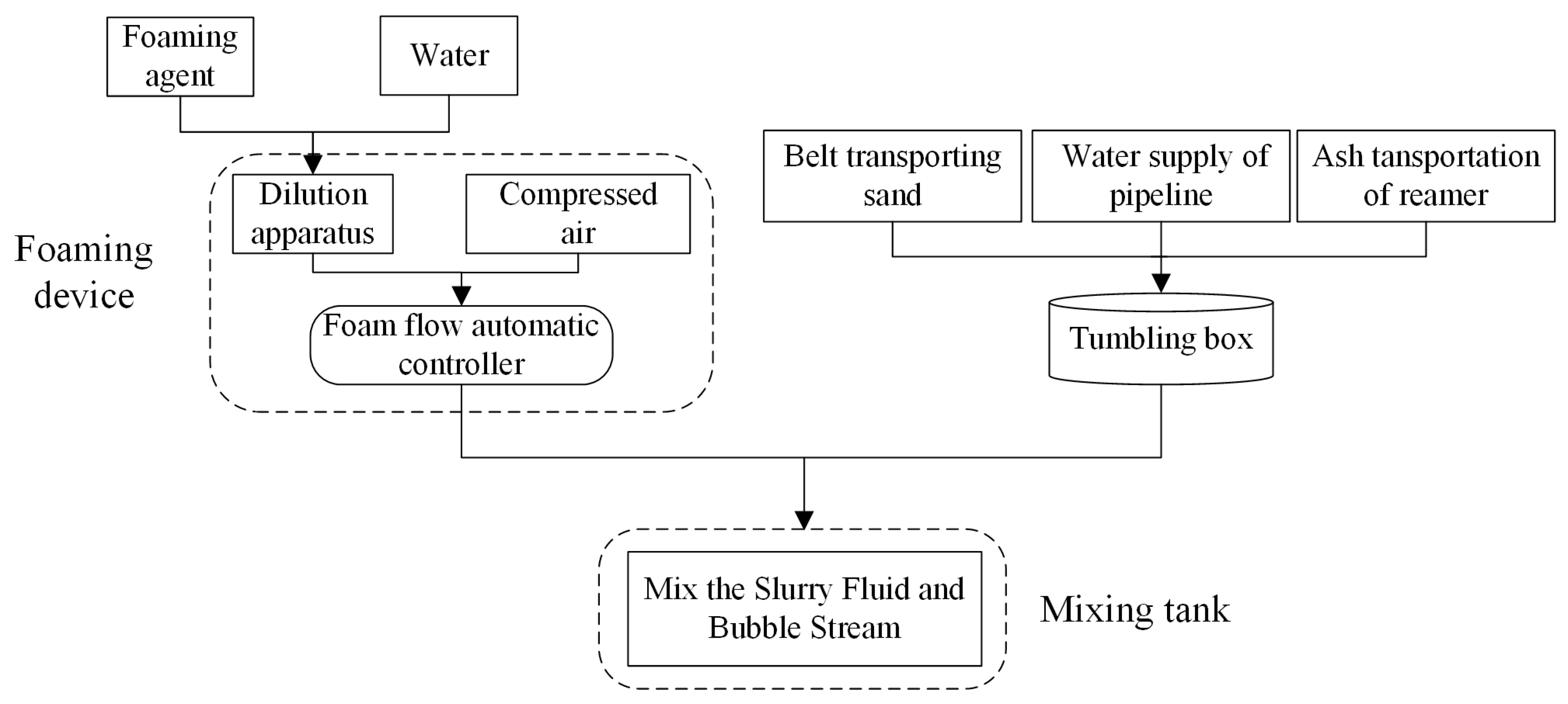

2.1.2. Manufacturing Process

- Foam preparation: A special foaming agent is fully mixed with water according to a given dilution ratio to generate foam. Then, the diluted liquid is loaded into a foaming gun along with compressed air at a certain pressure to prepare a standard-density foam.

- Cement slurry preparation: Cement, tailings, and water are mixed according to given proportions to prepare the cement slurry.

- TFSB preparation: The premade cement slurry and standard-density foam are mixed in a given proportion to prepare the TFSB.

2.2. Test Methods

2.2.1. Rheological Test

2.2.2. Slump Tests

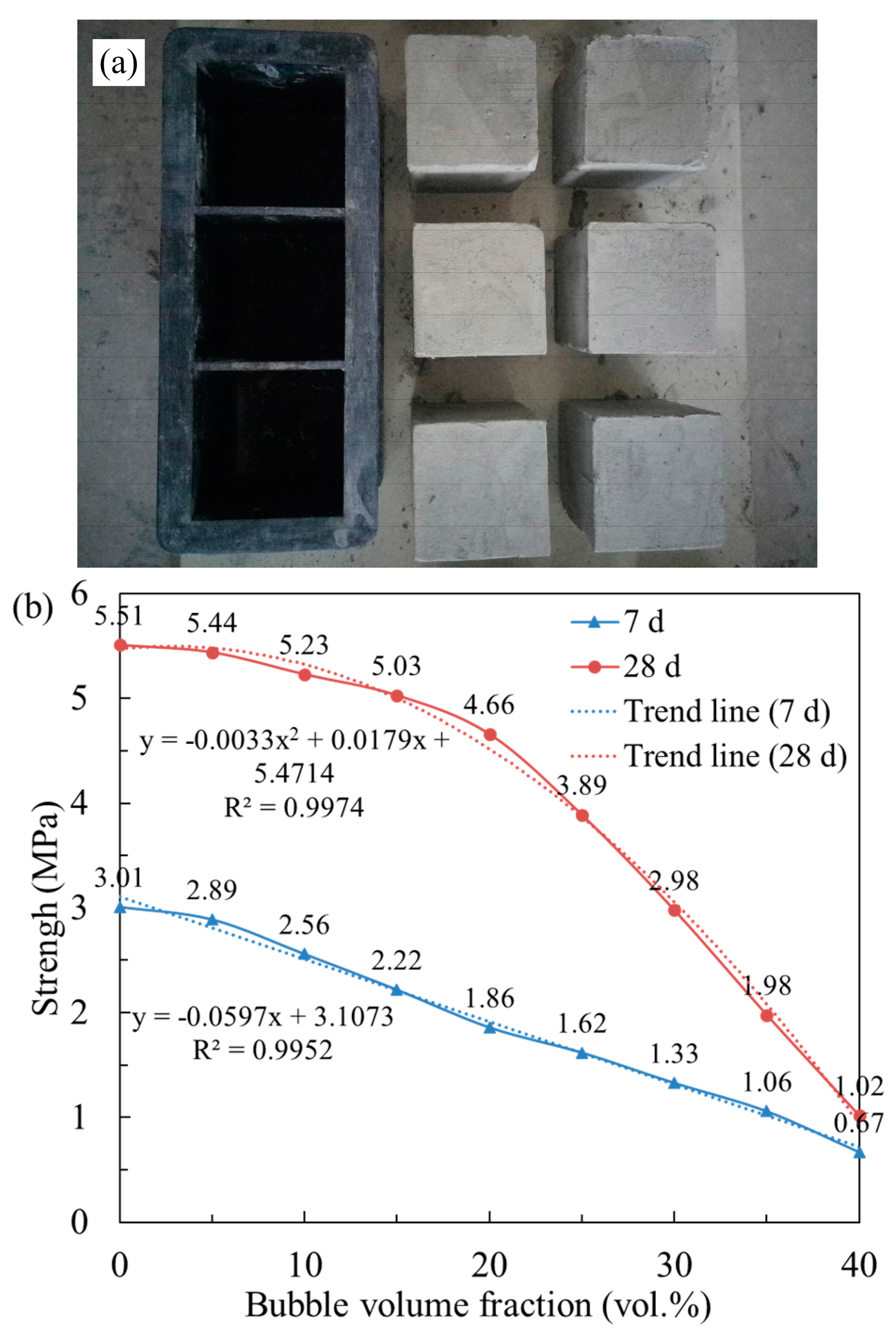

2.2.3. Strength Tests

2.3. CFD Simulation

2.3.1. Governing Conservation Equations

2.3.2. Flow State

2.3.3. Boundary Conditions

- (1)

- At the walls: the wall is stationary and no-slip.

- (2)

- At the pipe inlet, the velocity (v) function given below is used at the inlet face [28]:where is the slurry flow backfilling ability (m3/h), is the diameter of the backfill pipe (m), the value of which is 0.102 m, is a constant, and the value is 1.1. Thus, when the backfilling ability is 60 m3/h, the slurry velocity is 2.24 m/s.

- (3)

- At the pipe outlet, the outflow function is used at the outlet face.

- (4)

- In the calculation domain, a gravity field is applied, and the standard atmospheric pressure (1 bar) is used as the reference to atmospheric pressure.

3. Results and Discussion

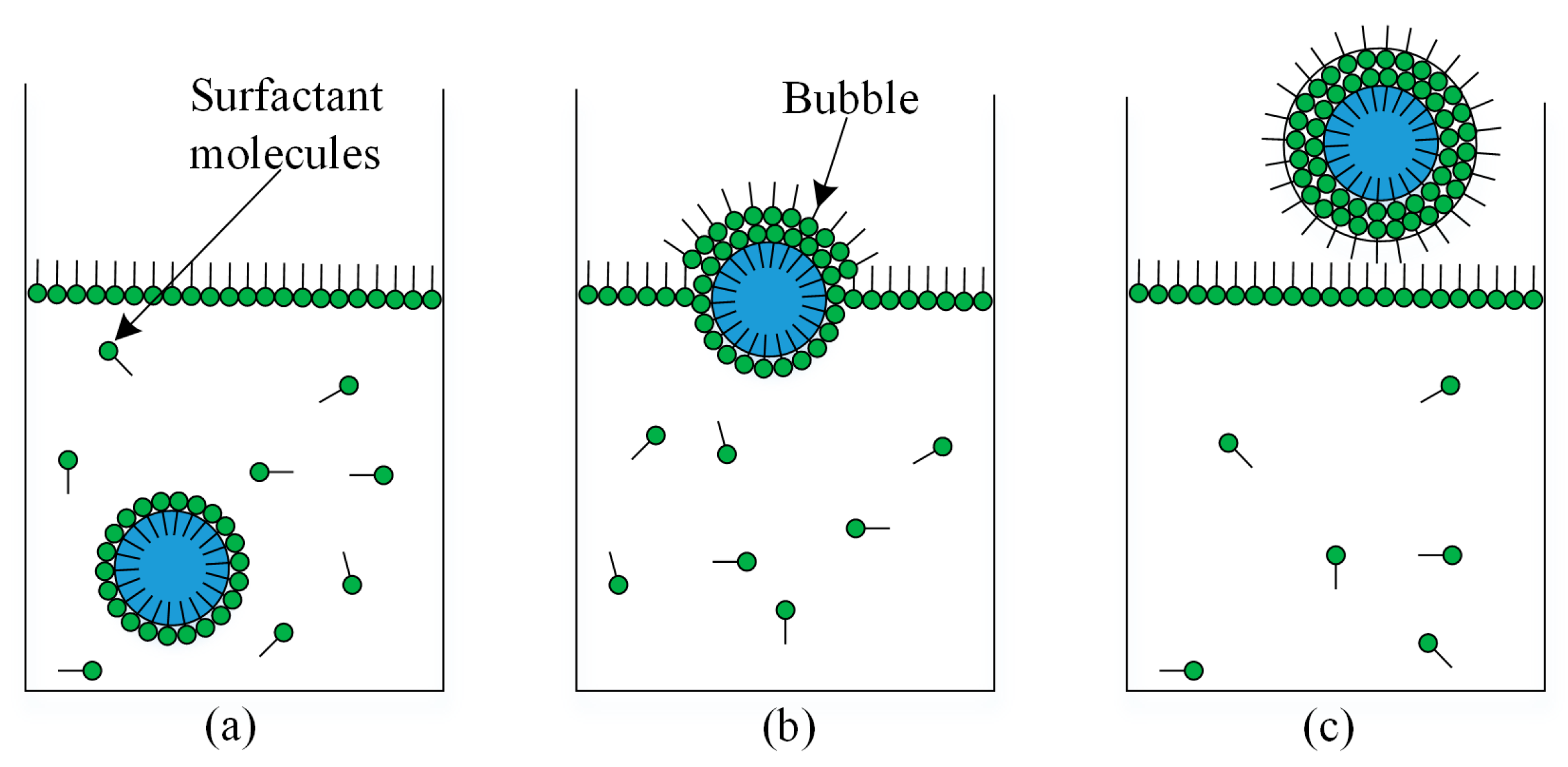

3.1. Foam Formation Characteristics

3.2. Test Results Analyses

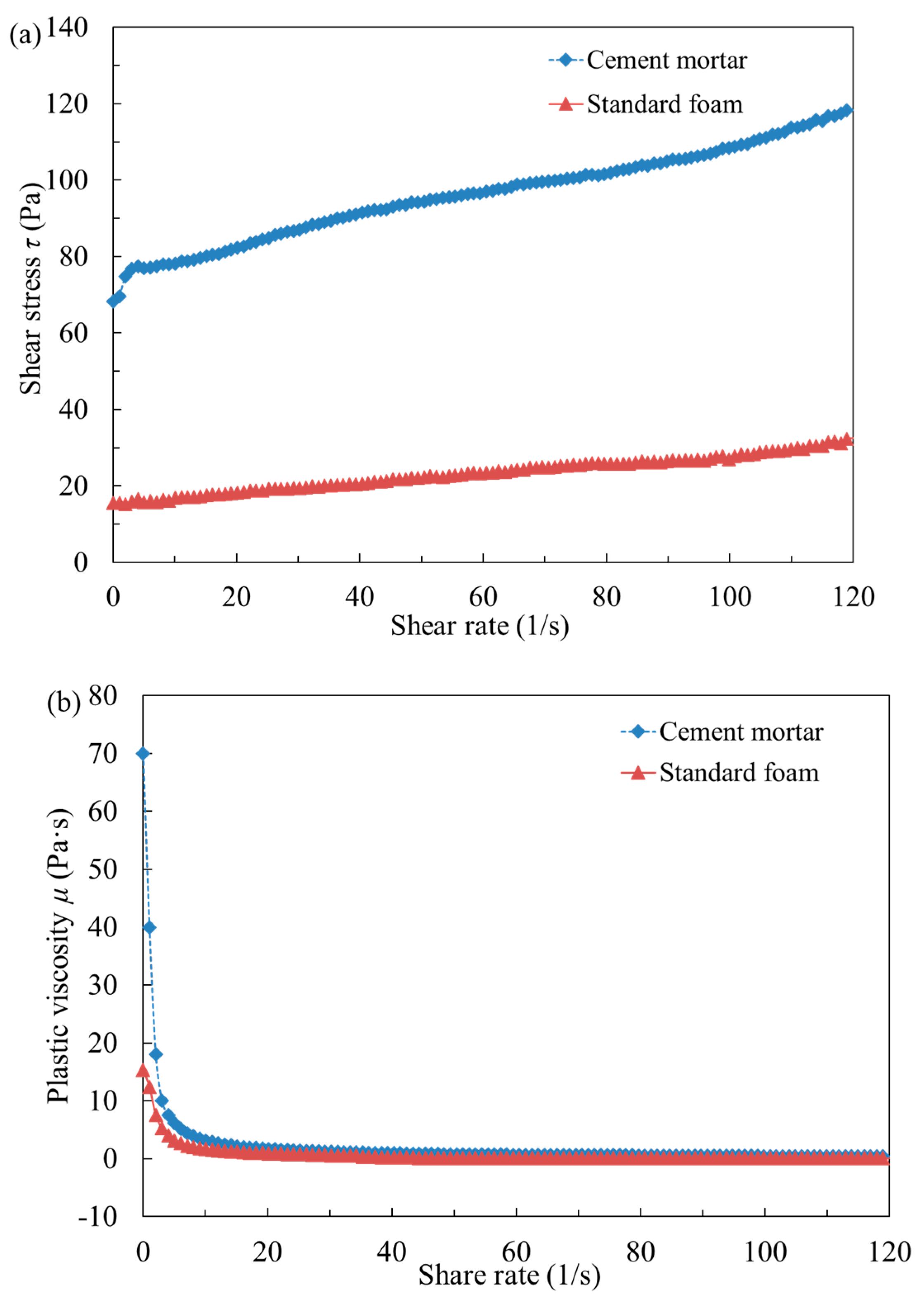

3.2.1. Rheological Properties

3.2.2. Slump

3.2.3. Strength

3.3. Effect of Bubble Volume Fraction

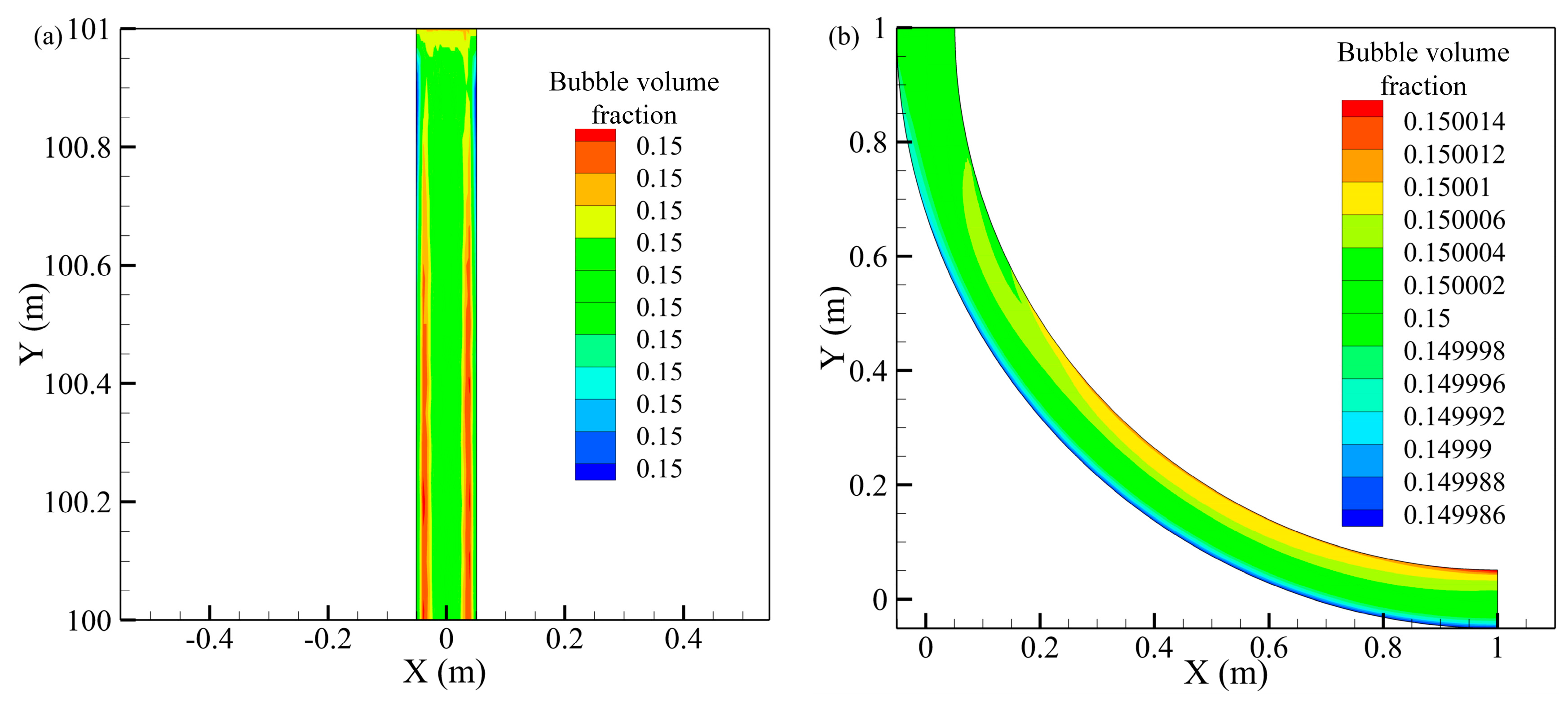

3.3.1. Foam Phase

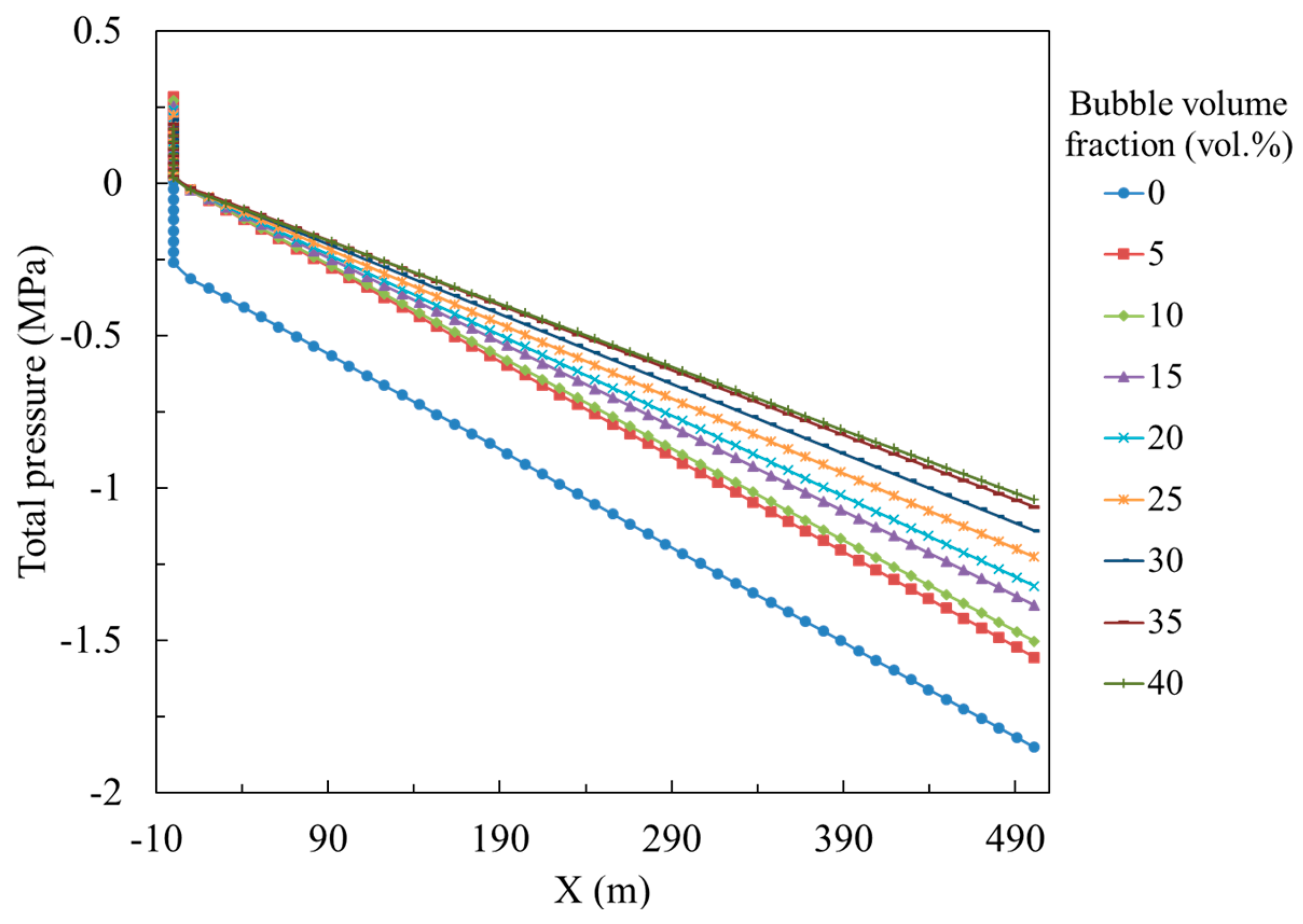

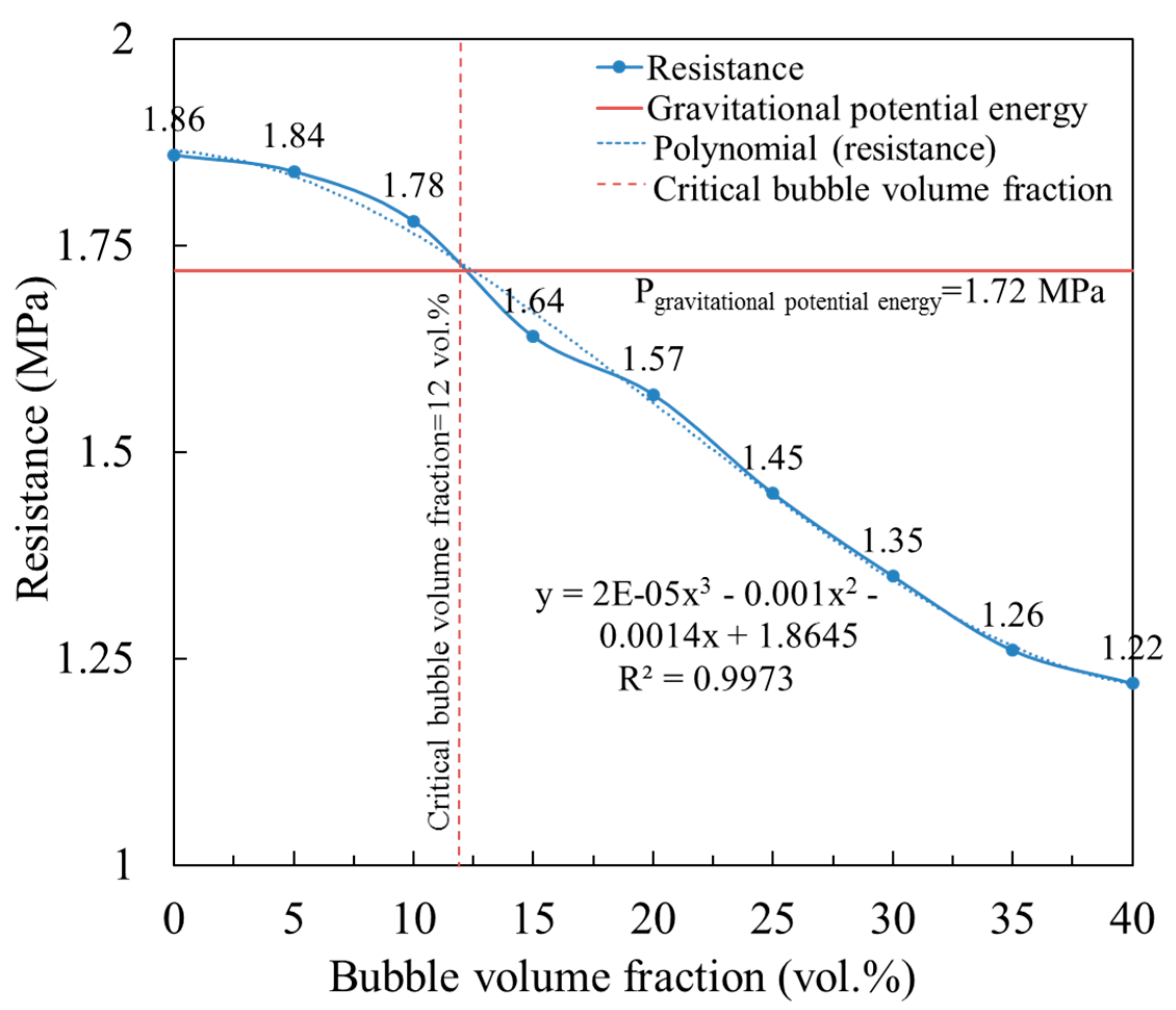

3.3.2. Pressure

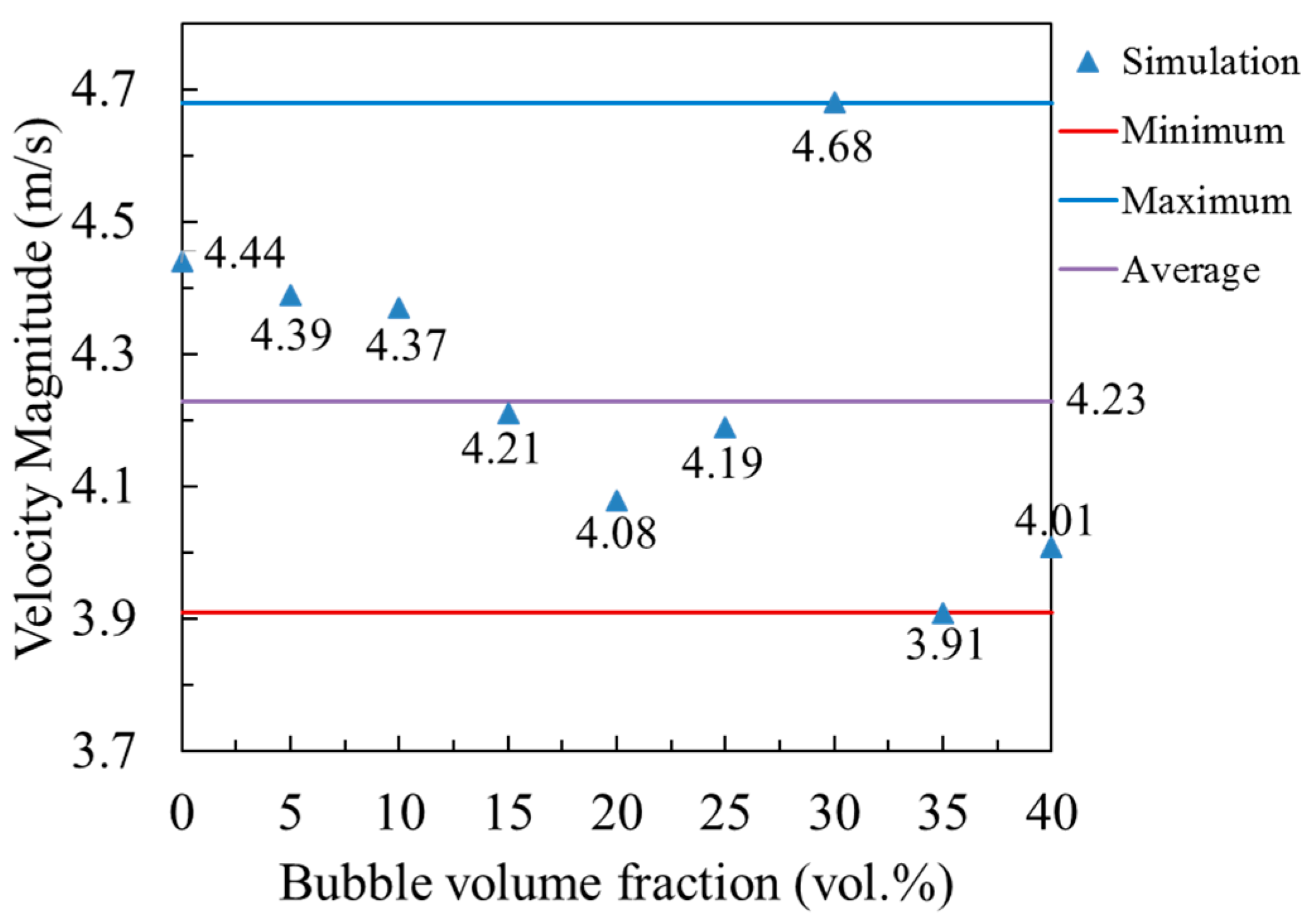

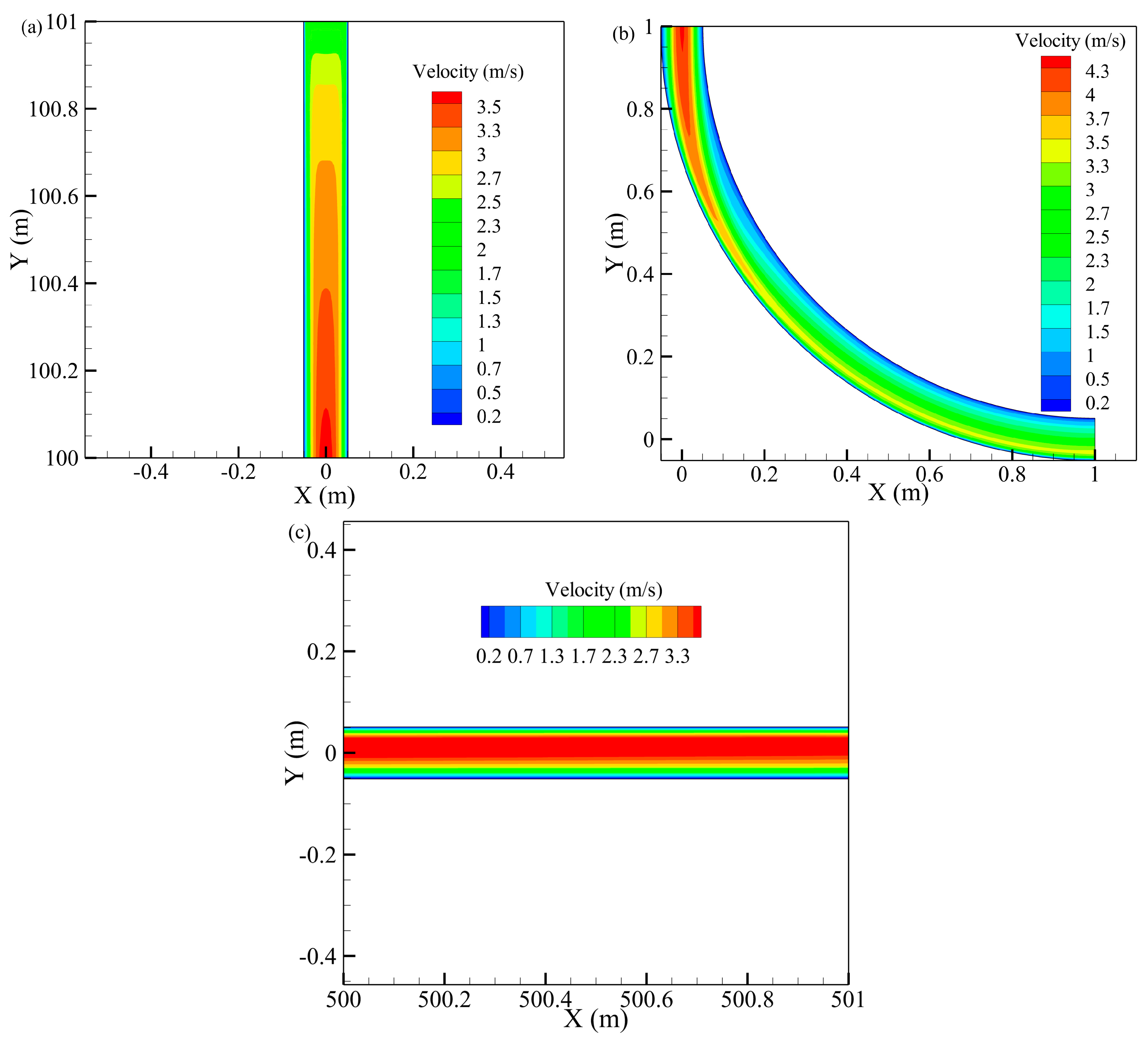

3.3.3. Velocity

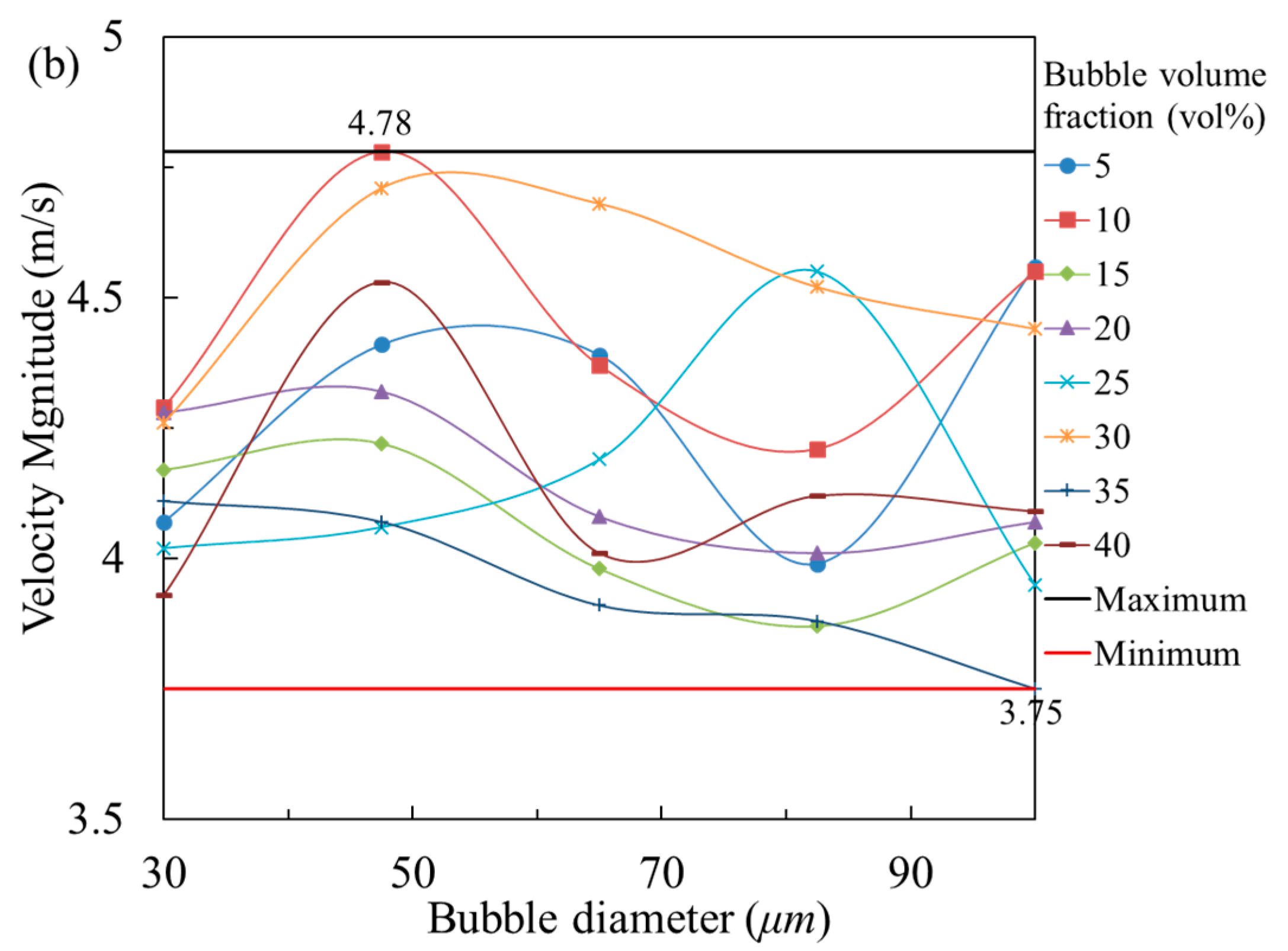

3.4. Effect of Bubble Diameter

3.5. Industrial Applications

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, S.; Wang, X.M. Fly-ash-based magnetic coagulant for rapid sedimentation of electronegative slimes and ultrafine tailings. Powder Technol. 2016, 303, 20–26. [Google Scholar] [CrossRef]

- Liang, C.; Fall, M. Multiphysics modeling of arching effects in fill mass. Comput Geotech. 2017, 83, 114–131. [Google Scholar]

- Wu, D.; Yang, B.G.; Liu, Y.C. Transportability and pressure drop of fresh cemented coal gangue-fly ash backfill (CGFB) slurry in pipe loop. Powder Technol. 2015, 284, 218–224. [Google Scholar] [CrossRef]

- Chen, Q.S.; Zhang, Q.L.; Wang, X.M.; Xiao, C.C.; Hu, Q. A hydraulic gradient model of paste-like crude tailings backfill slurry transported by a pipeline system. Environ. Earth Sci. 2016, 75. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Chen, Q.S.; Wang, X.M. Cemented Backfilling Technology of Paste-Like Based on Aeolian Sand and Tailings. Minerals 2016, 6, 132. [Google Scholar] [CrossRef]

- Belem, T.; Fourie, A.B.; Fahey, M. Time-dependent failure criterion for cemented paste backfills. Richard Jewell and Andy Fourie. In Proceedings of the 13th International Seminar on Paste and Thickened Tailings, Perth: Australian Centre for Geomechanics, Australian, 3–6 May 2010; pp. 147–162. [Google Scholar]

- Grabinsky, M.W. In situ monitoring for ground trothing paste backfill design. In Proceedings of the 13th International Seminar on Paste and Thickened Tailings, Toronto, ON, Canada, 3–6 May 2010; pp. 85–98. [Google Scholar]

- Zhou, J.; Li, X.B.; Mitri, H.S. Classification of rockburst in undergroud projects: Comparison of ten supervised learning methods. J. Comput. Civ. Eng. 2016, 30, 04016003. [Google Scholar] [CrossRef]

- Ju, F.; Zhang, J.X.; Zhang, Q. Vertical transportation system of solid material for backfilling coal mining technology. Int. J. Min. Sci. Technol. 2012, 22, 41–45. [Google Scholar] [CrossRef]

- Wu, D.; Sun, G.H.; Liu, Y.C. Modeling the thermo-hydro-chemical behavior of cemented coal gangue-fly ash backfill. Constr. Build. Mater. 2016, 111, 658–662. [Google Scholar] [CrossRef]

- Marradi, A.; Pinori, U.; Betti, G. The use of lightweight materials in road embankment construction. Proc. Soc. Behav. Sci. 2012, 53, 1000–1009. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Su, X.P.; Tan, W.; Yang, S.Y.; Guo, W.J. The application value of foam mortar filling body. Met. Mine 2013, 10, 40–42. (In Chinese) [Google Scholar]

- Chen, Z.P.; Zhai, S.H.; Gao, X.; Dong, L. Research on the mechanical prosperities of foam mortar backfill and its application. Met. Mine 2010, 8, 7–10. (In Chinese) [Google Scholar]

- Zhang, W. Evaluation of effect of viscosity changes on bubble size in a mechanical flotation cell. Trans. Nonferrous Met. Soc. China 2014, 24, 2964–2968. [Google Scholar] [CrossRef]

- Yan, K.L.; Sun, C.Y.; Chen, J.; Chen, L.T.; Shen, D.J.; Liu, B.; Jia, M.L.; Niu, M.; Lv, Y.N.; Li, N.; et al. Flow characteristics and rheological properties of natural gas hydrate slurry in the presence of anti-agglomerant in a flow loop apparatus. Chem. Eng. Sci. 2014, 106, 99–108. [Google Scholar] [CrossRef]

- Bakshi, A.; Altantzis, C.; Bates, R.B.; Ghoniem, A.F. Study of the effect of reactor scale on fluidization hydrodynamics using fine-grid CFD simulations based on the two-fluid model. Powder Technol. 2016, 299, 185–198. [Google Scholar] [CrossRef]

- Bisognin, P.C.; Fusco, J.M.; Soares, C. Heat transfer in fluidized beds with immersed surface: Effect of geometric parameters of surface. Powder Technol. 2016, 297, 401–408. [Google Scholar] [CrossRef]

- Eesa, M.; Barigou, M. CFD analysis of viscous non-Newtonian flow under the influence of a superimposed rotational vibration. Comput. Fluids 2008, 37, 24–34. [Google Scholar] [CrossRef]

- Shannag, M.J. Characteristics of lightweight concrete containing mineral admixtures. Constr. Build. Mater. 2011, 25, 658–662. [Google Scholar] [CrossRef]

- Chen, Z.P. A New Type of High Efficient Foaming AGENT for Geotechnical Engineering. Chinese Patent ZL 200610033825.9, 27 February 2006. [Google Scholar]

- GB/T18046-2008 (MOD, ASTM C989M). In Ground Granulated Blast Furnace Slag Used for Cement and Concrete; General Administration of Quality Supervision, Inspection and Quarantine of PR China: Beijing, China, 2008.

- Gao, J.; Fourie, A. Spread is better: An investigation of the mini-slump test. Miner. Eng. 2015, 71, 120–132. [Google Scholar] [CrossRef]

- B.F Inc. Fluent User’s Guide; Fluent Incorporated: Lebanon, NH, USA, 2010. [Google Scholar]

- Hata, K.; Masuzaki, S. Critical heat fluxes of sub cooled water flow boiling in a short vertical tube at high liquid Reynolds number. Nucl. Eng. Des. 2010, 240, 3145–3157. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.Z.; Zhou, J.; Chen, Q.S.; Yang, C. Feasibility of Recycling Ultrafine Leaching Residue by Backfill: Experimental and CFD Approaches. Minerals 2017, 7, 54. [Google Scholar] [CrossRef]

- Zhao, G.H. Simulating and Experiment Research of Resistance Characteristics of coal-Water-Slurry. Master’s Thesis, Southeast University, Nanjing, China, 2007. (In Chinese). [Google Scholar]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl. Math. Model. 2014, 38, 3467–3484. [Google Scholar] [CrossRef]

- Yang, J.; Wang, X.M.; Zhang, Q.L.; Ke, Y.X. Pipeline transportation properties of high viscosity sulfur-content filling slurry in three-phase flow. Chin. J. Nonferrous Met. 2015, 25, 1049–1055. (In Chinese) [Google Scholar]

- Zhang, J.S.; Wang, C.Z.; Huang, L.X.; Qang, B.Q. Foam Concrete, 1st ed.; Harbin Institute of Technology Press: Harbin, China, 2016. [Google Scholar]

- Nambiar, E.K.K.; Ramamurthy, K. Sorption characteristics of foam concrete. Cem. Concr. Res. 2007, 37, 1341–1347. [Google Scholar] [CrossRef]

- Bingham, E.C. Fluidity and Plasticity; McGraw-Hill: New York, NY, USA, 1922. [Google Scholar]

- Gopala, V.R.; Nijeholt, J.A.L.À.; Bakker, P.; Haverkate, B. Development and validation of a CFD model predicting the backfill process of a nuclear waste gallery. Nucl. Eng. Des. 2011, 241, 2508–2518. [Google Scholar] [CrossRef]

- Slottee, J.S. Update on the application of paste thickeners for tailings disposal-mine paste backfill. In Proceedings of the International Seminar on Paste and Thickened Tailings, Cape Town, South Africa, 31 March–2 April 2004. [Google Scholar]

- Liu, G.S.; Li, L.; Yang, X.C.; Guo, L.J. A numerical analysis of the stress distribution in backfilled stopes considering interfaces between backfill and rock walls. Int. J. Geomech. 2017, 17, 06016014-1–06016014-9. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.Z.; Zhou, J.; Qiu, X.Y.; Lin, X.F. CFD simulation of transportation properties of W type and long distance pipeline for foam slurry backfilling. Chin. J. Nonferrous Met. 2016, 26, 1782–1793. (In Chinese) [Google Scholar]

- Beltrán, J.P.; Ceci, P.; Miguez, P.; Casali, P. Construction of slurry pipelines. Proc. Eng. 2016, 138, 27–130. [Google Scholar] [CrossRef]

- Xiao, H.L. Study on the Performance of Foaming Agents Applied to the Foamed Concrete. Master’s Thesis, Zhejiang University, Zhejiang, China, 2011. (In Chinese). [Google Scholar]

| Fluid Type | Yield Stress τ0 (Pa) | Plastic Viscosity μ (Pa·s) |

|---|---|---|

| Cement slurry | 68.23 | 0.41 |

| Standard foam | 15.54 | 0.08 |

| Fluid Type | Cement-to-Sand Ratio | Mass Fraction (wt %) | Density (kg/m3) | Bubble Volume Fraction (vol %) | Bubble Diameter (μm) | Yield Stress τ0 (Pa) | Plastic Viscosity μ (Pa·s) |

|---|---|---|---|---|---|---|---|

| Cement slurry | 1:5 | 70 | 1750 | * | * | 68.23 | 0.41 |

| Standard foam | * | * | 50 | 0–40 | 30–100 | 15.54 | 0.08 |

| Studied Case | Bubble Volume Fraction (vol %) | Plastic Viscosity μ (Pa·s) | Relative Error (%) | |

|---|---|---|---|---|

| Theoretical Calculation | Simulation | |||

| 1 | 0 | 0.4100 | 0.4116 | 0.39 |

| 2 | 5 | 0.3935 | 0.3902 | 0.19 |

| 3 | 10 | 0.3770 | 0.3690 | 0.24 |

| 4 | 15 | 0.3605 | 0.3491 | 0.17 |

| 5 | 20 | 0.3440 | 0.3287 | 0.21 |

| 6 | 25 | 0.3275 | 0.3080 | 0.14 |

| 7 | 30 | 0.3110 | 0.2878 | 0.25 |

| 8 | 35 | 0.2945 | 0.2667 | 0.05 |

| 9 | 40 | 0.2780 | 0.2462 | 0.05 |

| Studied Case | Bubble Volume Fraction (vol %) | Inlet Pressure (MPa) | Outlet Pressure (MPa) | Resistance (MPa) | Average Resistance (kPa/m) | Gravitational Potential Energy (MPa) | Self-Flowing Transport |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 0.0044 | -1.86 | 1.86 | 3.09 | 1.72 | No |

| 2 | 5 | 0.28 | -1.56 | 1.84 | 3.06 | 1.72 | No |

| 3 | 10 | 0.27 | -1.51 | 1.78 | 2.96 | 1.72 | No |

| 4 | 15 | 0.25 | -1.39 | 1.64 | 2.73 | 1.72 | Yes |

| 5 | 20 | 0.24 | -1.33 | 1.57 | 2.60 | 1.72 | Yes |

| 6 | 25 | 0.22 | -1.23 | 1.45 | 2.42 | 1.72 | Yes |

| 7 | 30 | 0.21 | -1.14 | 1.35 | 2.25 | 1.72 | Yes |

| 8 | 35 | 0.19 | -1.07 | 1.26 | 2.09 | 1.72 | Yes |

| 9 | 40 | 0.18 | -1.04 | 1.22 | 2.02 | 1.72 | Yes |

| Studied Case | Bubble Volume Fraction (vol %) | Elbow | Pipe | W (%) | ||

|---|---|---|---|---|---|---|

| Resistance (MPa) | Average Resistance kPa/m) | Resistance (MPa) | Average Resistance (kPa/m) | |||

| 1 | 0 | 0.0086 | 5.46 | 1.86 | 3.09 | 43.41 |

| 2 | 5 | 0.0083 | 5.30 | 1.84 | 3.06 | 42.26 |

| 3 | 10 | 0.0077 | 4.88 | 1.78 | 2.96 | 39.34 |

| 4 | 15 | 0.0074 | 4.74 | 1.64 | 2.73 | 42.41 |

| 5 | 20 | 0.0070 | 4.46 | 1.57 | 2.60 | 41.70 |

| 6 | 25 | 0.0066 | 4.19 | 1.45 | 2.42 | 42.24 |

| 7 | 30 | 0.0062 | 3.94 | 1.35 | 2.25 | 42.89 |

| 8 | 35 | 0.0056 | 3.59 | 1.26 | 2.09 | 41.78 |

| 9 | 40 | 0.0051 | 3.24 | 1.22 | 2.02 | 37.65 |

| Goaf Number | Density (kg/m3) | Bubble Volume Fraction (vol %) | Strength (MPa) | |

|---|---|---|---|---|

| 7 days | 28 days | |||

| S01 | 1496 | 16 | 1.21 | 2.33 |

| N02 | 1402 | 19 | 1.20 | 2.17 |

| S05 | 1533 | 12 | 1.38 | 2.38 |

| Project Specifications | Conventional Cement Slurry | TFSB |

|---|---|---|

| Cement consumption (kg/m3) | 288 | 240 |

| Foam agent consumption (kg/m3) | 0 | 0.14 |

| Unit cost ($/m3) | 14.4 | 12.84 |

| Cost savings ($/m3) | 1.56 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Zhou, J.; Chen, Q.; Shi, X.; Gou, Y. CFD Simulation of Pipeline Transport Properties of Mine Tailings Three-Phase Foam Slurry Backfill. Minerals 2017, 7, 149. https://doi.org/10.3390/min7080149

Chen X, Zhou J, Chen Q, Shi X, Gou Y. CFD Simulation of Pipeline Transport Properties of Mine Tailings Three-Phase Foam Slurry Backfill. Minerals. 2017; 7(8):149. https://doi.org/10.3390/min7080149

Chicago/Turabian StyleChen, Xin, Jian Zhou, Qiusong Chen, Xiuzhi Shi, and Yonggang Gou. 2017. "CFD Simulation of Pipeline Transport Properties of Mine Tailings Three-Phase Foam Slurry Backfill" Minerals 7, no. 8: 149. https://doi.org/10.3390/min7080149

APA StyleChen, X., Zhou, J., Chen, Q., Shi, X., & Gou, Y. (2017). CFD Simulation of Pipeline Transport Properties of Mine Tailings Three-Phase Foam Slurry Backfill. Minerals, 7(8), 149. https://doi.org/10.3390/min7080149