Sustainable Reuse of Mine Tailings and Waste Rock as Water-Balance Covers

Abstract

:1. Introduction

2. Materials and Methods

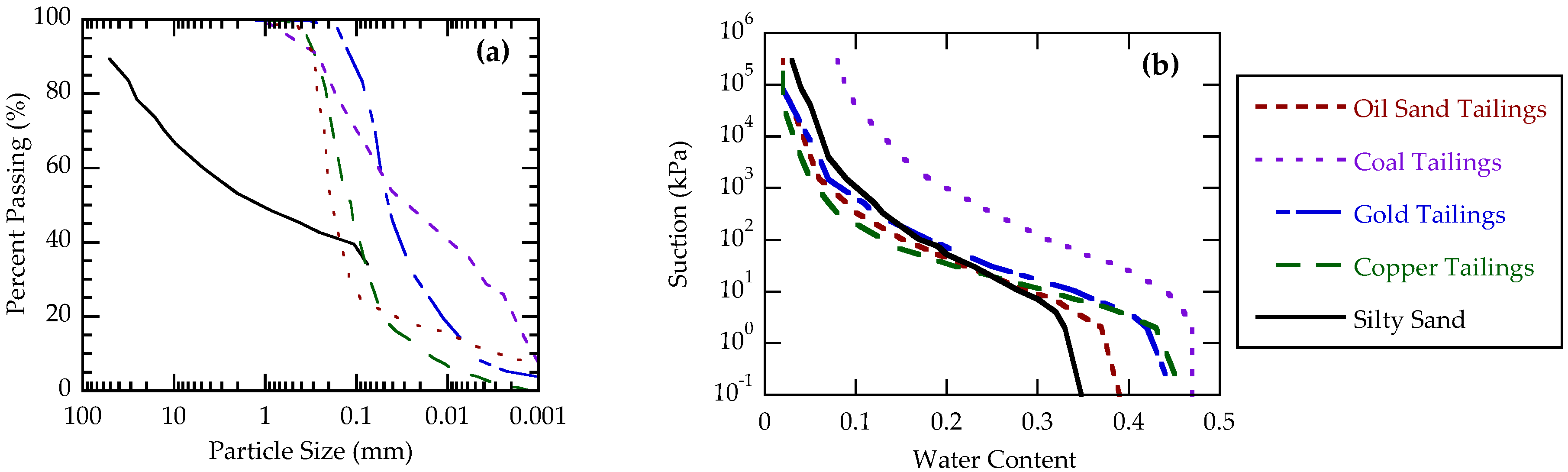

2.1. Soils and Mine Tailings

2.2. Water Balance Cover Design and Modeling

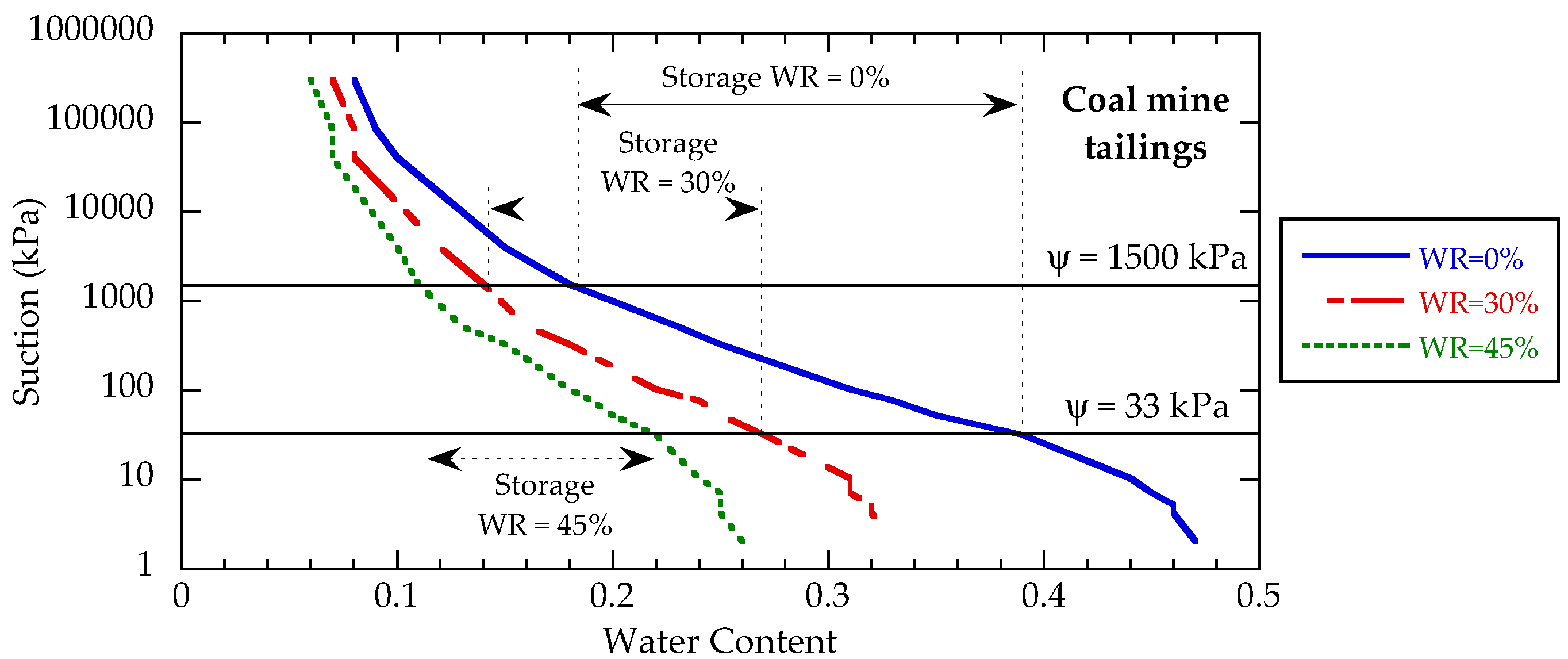

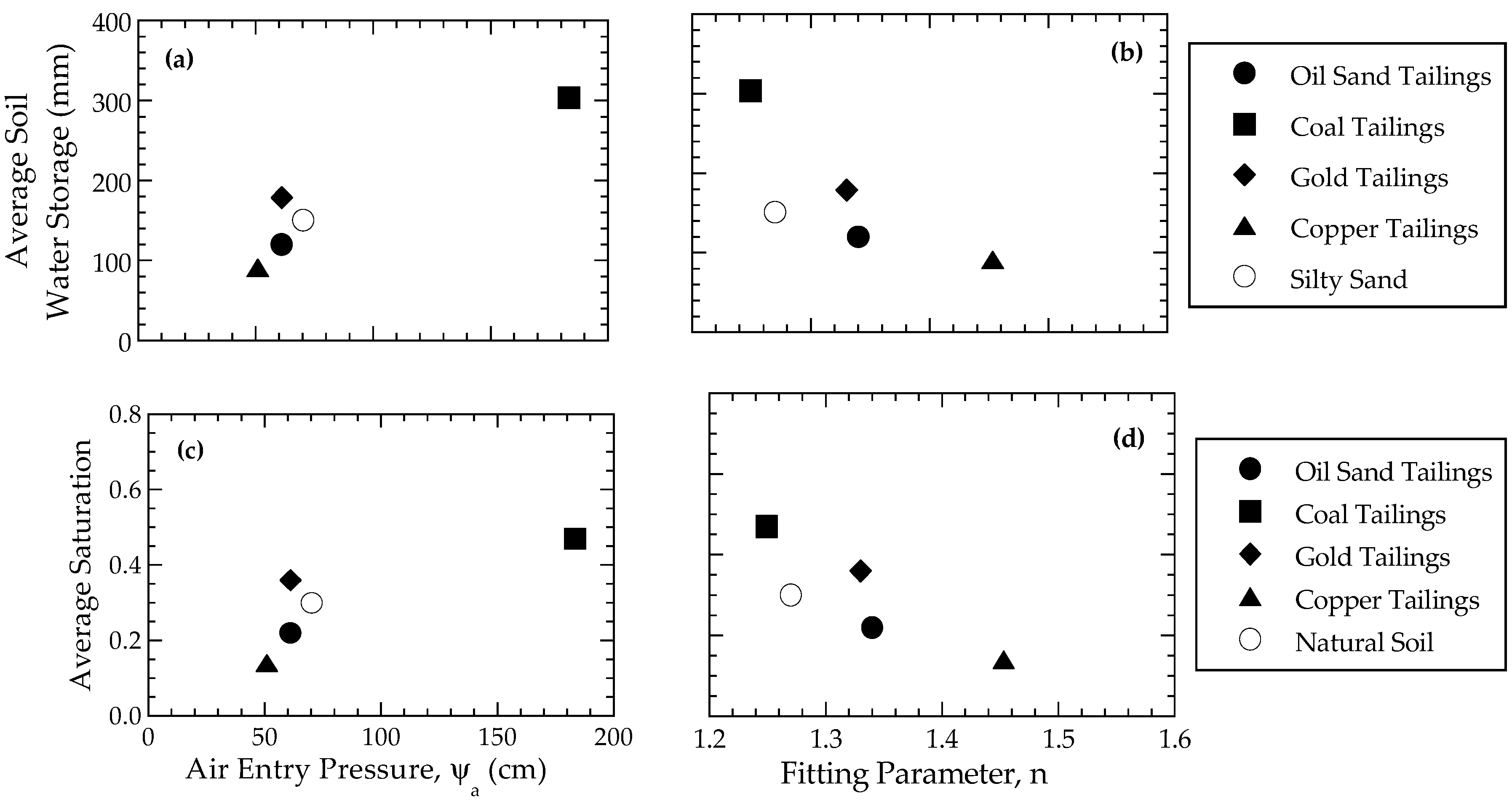

2.2.1. Storage Assessment

2.2.2. Water-Balance Modeling

2.2.3. Test Site, Vegetation Characteristics, and Meteorological Data

2.2.4. Boundary and Initial Conditions

2.3. Water-Balance Covers Composed of Mine Waste

3. Results

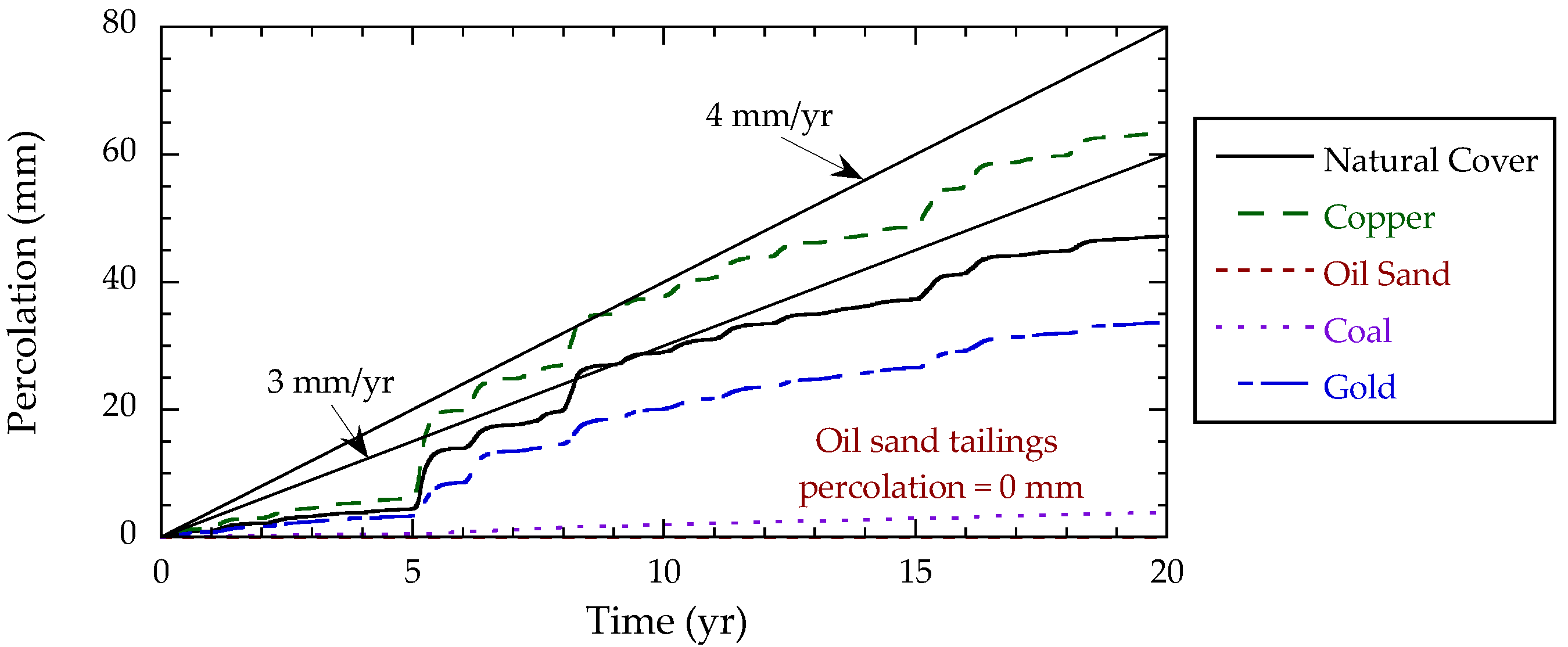

3.1. Fixed Storage Layer Thickness Composed of Mine Tailings

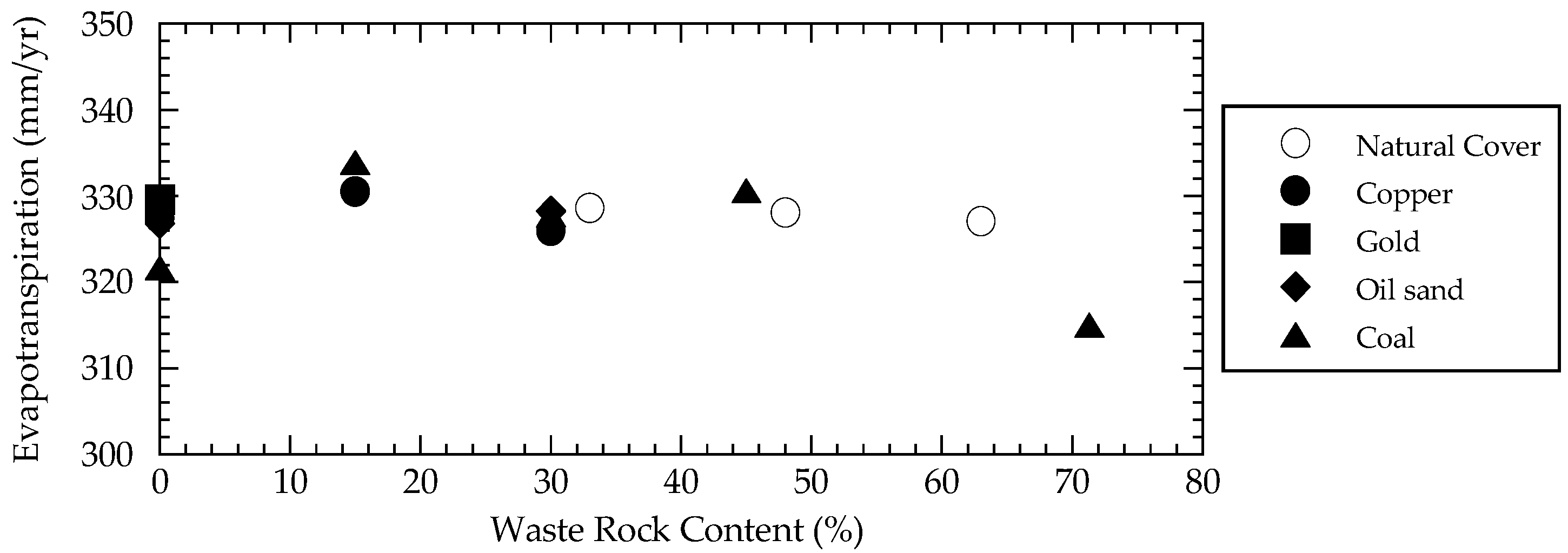

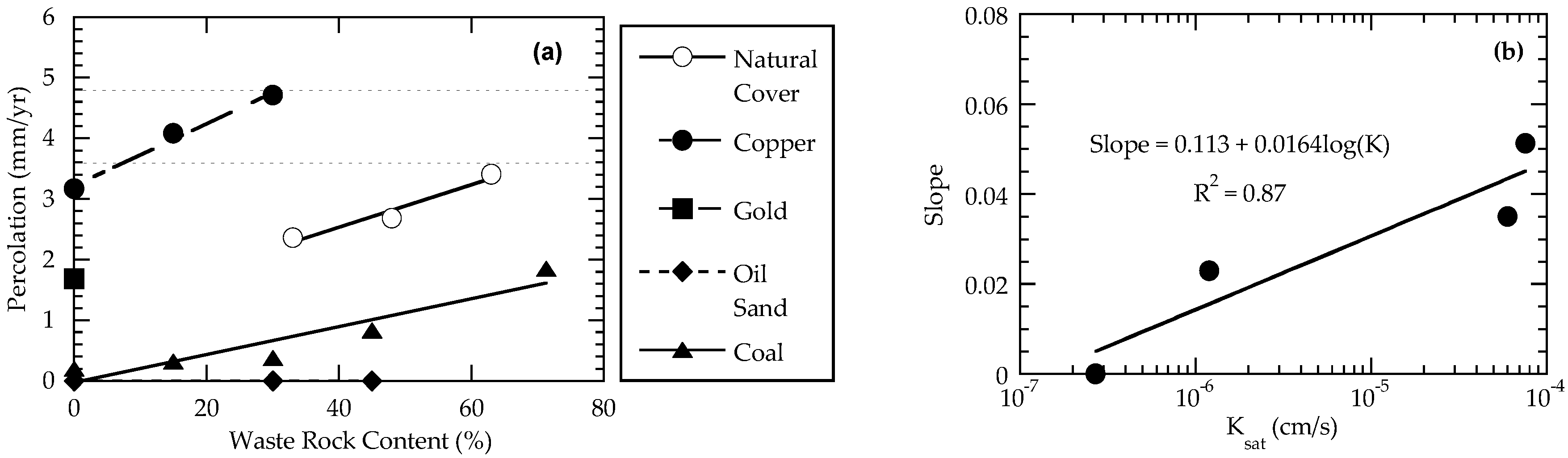

3.2. Fixed Storage Layer Thickness Composed of Tailings and Waste Rock

3.3. Adjusted Storage Layer Thickness Composed of Tailings and Waste Rock

3.4. Contribution to the Circular Economy and Mining Sustainability

4. Conclusions

- Percolation rates for WBCs simulated with hard rock mine tailings met the prescribed percolation rate of the Natural Cover (i.e., 4 mm/year). Lower percolation rates were representative of tailings with higher clay content and lower hydraulic conductivity (ks).

- Evapotranspiration and percolation increased and runoff decreased with an increase in ks of the storage layer. Storage layers with larger ks results in faster infiltration through the cover (percolation) and faster transfer of water out of the soil via evapotranspiration.

- Addition of waste rock to WBCs increased percolation when the storage layer thickness was fixed due to reduced storage capacity. The effect of waste rock addition was more pronounced in WBCs that included tailings with higher ks.

- Two methods were presented to redesign the storage layer thickness in a WBC that includes mixed WR&T: Method 1—redesign for the constant available storage and Method 2—redesign for the constant void volume. Both methods yielded similar WBC thicknesses and similar percolation rates that compared favorable to the percolation rate with no waste rock.

- Reuse of mixed WR&T in on-site WBCs provides an opportunity to enhance mine site sustainability via reduced costs associated the acquisition of raw materials required for closure as well as reduced waste volumes requiring storage.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Resource Conservation and Recovery Act (RCRA); Publication Law 94-580; 94th United States Congress: Washington, DC, USA, 1976.

- Albright, W.H.; Benson, C.H.; Waugh, W.J. Water Balance Covers for Waste Containment: Principles and Practice; American Society of Civil Engineers: Reston, VA, USA, 2010. [Google Scholar]

- Meer, S.R.; Benson, C.H. Hydraulic conductivity of geosynthetic clay liners exhumed from landfill final covers. J. Geotech. Geoenviron. 2007, 133, 550–563. [Google Scholar] [CrossRef]

- Albright, W.H.; Benson, C.H.; Gee, G.W.; Abichou, T.; McDonald, E.V.; Tyler, S.W.; Rock, S.A. Field performance of a compacted clay landfill final cover at a humid site. J. Geotech. Geoenviron. 2006, 132, 1393–1403. [Google Scholar] [CrossRef]

- Khire, M.V.; Benson, C.H.; Bosscher, P.J. Capillary barriers: Design variables and water balance. J. Geotech. Geoenviron. 2010, 126, 695–708. [Google Scholar] [CrossRef]

- Zornberg, J.G.; LaFountain, L.; Caldwell, J.A. Analysis and design of evapotranspirative cover for hazardous waste landfill. J. Geotech. Geoenviron. 2003, 129, 427–438. [Google Scholar] [CrossRef]

- Albright, W.H.; Benson, C.H.; Gee, G.W.; Roesler, A.C.; Abichou, T.; Apiwantragoon, P.; Lyles, B.F.; Rock, S.A. Field water balance of landfill final covers. J. Environ. Qual. 2004, 33, 2317–2332. [Google Scholar] [CrossRef] [PubMed]

- Malusis, M.A.; Benson, C.H. Lysimeters versus water-content sensors for performance monitoring of alternative earthen final covers. In Unsaturated Soils 2006, Proceedings of the Fourth International Conference on Unsaturated Soils, Carefree, AZ, USA, 2–6 April 2006; American Society of Civil Engineers: Reston, VA, USA, 2006; pp. 741–752. [Google Scholar]

- Bussiere, B. Colloquium 2004: Hydrogeotechnical properties of hard rock tailings from metal mines and emerging geoenvironmental disposal approaches. Can. Geotech. J. 2007, 44, 1019–1052. [Google Scholar] [CrossRef]

- Blight, G. Geotechnical Engineering for Mine Waste Storage Facilities; Taylor & Francis: London, UK, 2009. [Google Scholar]

- Aubertin, M.; Ricard, J.F.; Chapuis, R.P. A predictive model for the water retention curve: Application to tailings from hard-rock mines. Can. Geotech. J. 1998, 35, 55–69. [Google Scholar] [CrossRef]

- Qiu, Y.; Sego, D.C. Laboratory properties of mine tailings. Can. Geotech. J. 2001, 38, 183–190. [Google Scholar] [CrossRef]

- Williams, D.J.; Wilson, G.W.; Panidis, C. Waste rock and tailings mixtures as a possible seal for potentially acide forming waste rock. In 6th International Conference on Acid Rock Drainage; The Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2003; Volume 400, pp. 427–435. [Google Scholar]

- Bussière, B.; Aubertin, M. Clean tailings as cover material for preventing acid mine drainage: An in situ experiment. In Proceedings of Sudbury; Laurentian University: Sudbury, ON, Canada, 1999; Volume 99, pp. 19–28. [Google Scholar]

- Bossé, B.; Bussière, B.; Hakkou, R.; Maqsoud, A.; Benzaazoua, M. Assessment of phosphate limestone wastes as a component of a store-and-release cover in a semiarid climate. Mine Water Environ. 2013, 32, 152–167. [Google Scholar] [CrossRef]

- Bossé, B.; Bussière, B.; Hakkou, R.; Maqsoud, A.; Benzaazoua, M. Field experimental cells to assess hydrogeological behaviour of store-and-release covers made with phosphate mine waste. Can. Geotech. J. 2015, 52, 1255–1269. [Google Scholar] [CrossRef]

- Wickland, B.E.; Wilson, G.W. Self-weight consolidation of mixtures of mine waste rock and tailings. Can. Geotech. J. 2005, 42, 327–339. [Google Scholar] [CrossRef]

- Jehring, M.M.; Bareither, C.A. Tailings composition effects on shear strength behavior of co-mixed mine waste rock and tailings. Acta Geotech. 2016, 11, 1147–1166. [Google Scholar] [CrossRef]

- Wickland, B.E.; Wilson, G.W.; Wijewickreme, D. Hydraulic conductivity and consolidation response of mixtures of mine waste rock and tailings. Can. Geotech. J. 2010, 47, 472–485. [Google Scholar] [CrossRef]

- Kabambi, A.K.; Bussière, B.; Demers, I. Hydrogeological Behaviour of Covers with Capillary Barrier Effects Made of Mining Materials. Geotech. Geol. Eng. 2017, 35, 1199–1220. [Google Scholar] [CrossRef]

- Benson, C.H.; Bareither, C.A. Designing water balance covers for sustainable waste containment: Transitioning state of the art to state of the practice. In Geotechnical Engineering State of the Art and Practice: Keynote Lectures from GeoCongress 2012; American Society of Civil Engineering: Reston, VA, USA, 2012; pp. 1–33. [Google Scholar]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Benson, C.H.; Sawangsuriya, A.; Trzebiatowski, B.; Albright, W.H. Postconstruction changes in the hydraulic properties of water balance cover soils. J. Geotech. Geoenviron. 2007, 133, 349–359. [Google Scholar] [CrossRef]

- Bareither, C.A.; Foley, J.C.; Benson, C.H. Using surrogate meteorological data to predict the hydrology of a water balance cover. J. Geotech. Geoenviron. 2015, 142, 1–16. [Google Scholar] [CrossRef]

- Benson, C.H. Modeling unsaturated flow and atmospheric interactions. In Theoretical and Numerical Unsaturated Soil Mechanics; Springer: Berlin, Germany, 2007; pp. 187–201. [Google Scholar]

- Ogorzalek, A.S.; Bohnhoff, G.L.; Shackelford, C.D.; Benson, C.H.; Apiwantragoon, P. Comparison of field data and water-balance predictions for a capillary barrier cover. J. Geotech. Geoenviron. 2008, 134, 470–486. [Google Scholar] [CrossRef]

- Bohnhoff, G.L.; Ogorzalek, A.S.; Benson, C.H.; Shackelford, C.D.; Apiwantragoon, P. Field data and water-balance predictions for a monolithic cover in a semiarid climate. J. Geotech. Geoenviron. 2009, 135, 333–348. [Google Scholar] [CrossRef]

- Fayer, M.J. UNSAT-H Version 3.0: Unsaturated Soil Water and Heat Flow Model. Theory, User Manual, and Examples; Pacific Northwest National Laboratory: Richland, WA, USA, 2000. [Google Scholar]

- Khire, M.V.; Benson, C.H.; Bosscher, P.J. Water balance modeling of earthen final covers. J. Geotech. Geoenviron. 1997, 123, 744–754. [Google Scholar] [CrossRef]

- Penman, H.L. Natural evaporation from open water, bare soil and grass. Proc. Soc. Lond. A Math. Phys. Eng. Sci. 1948, 193, 120–145. [Google Scholar] [CrossRef]

- Schaap, M.G.; Leij, F.J. Improved prediction of unsaturated hydraulic conductivity with the Mualem-van Genuchten model. Soil Sci. Soc. Am. J. 2000, 64, 843–851. [Google Scholar] [CrossRef]

- Roesler, A.C.; Benson, C.H.; Albright, W.H. Field Hydrology and Model Predictions for Final Covers in the Alternative Cover Assessment Program-2002; Geo Engineering Report; University of Wisconsin-Madison: Madison, WI, USA, 2002; pp. 2–8. [Google Scholar]

- Bareither, C.A.; Benson, C. Evaluation of Bouwer-Rice large-particle correction procedure for soil water characteristic curves. Geotech. Test. J. 2013, 36, 680–694. [Google Scholar] [CrossRef]

- Shelley, T.L.; Daniel, D.E. Effect of gravel on hydraulic conductivity of compacted soil liners. J. Geotech. Eng. 1993, 119, 54–68. [Google Scholar] [CrossRef]

- Bouwer, H.; Rice, R.C. Renovation of wastewater at the 23rd Avenue rapid infiltration project. J. Water Pollut. Control Fed. 1984, 56, 76–83. [Google Scholar]

- Gorakhki, M.H.; Bareither, C.A. Unconfined compressive strength of synthetic and natural mine tailings amended with fly ash and cement. J. Geotech. Geoenviron. Eng. 2017, 143, 1–14. [Google Scholar] [CrossRef]

- Lottermoser, B.G. Recycling, reuse and rehabilitation of mine wastes. Elements 2011, 7, 405–410. [Google Scholar] [CrossRef]

- McLellan, B.C.; Corder, G.D.; Giurco, D.; Green, S. Incorporating sustainable development in the design of mineral processing operations–Review and analysis of current approaches. J. Clean. Prod. 2009, 17, 1414–1425. [Google Scholar] [CrossRef] [Green Version]

- McLellan, B.C.; Corder, G.D.; Ali, S.H. Sustainability of rare earths—An overview of the state of knowledge. Minerals 2013, 3, 304–317. [Google Scholar] [CrossRef]

- Corder, G.D. Insights from case studies into sustainable design approaches in the minerals industry. Miner. Eng. 2015, 76, 47–57. [Google Scholar] [CrossRef]

| Soil | θs | θr | α, 1/cm | n | Ψa (cm) | Sand (%) | Silt (%) | Clay (%) | ks (cm/s) (Actual) | ks (cm/s) (Modified) | Ropt |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Top Soil | 0.50 | 0.00 | 0.0049 | 1.33 | 205.76 | -- | -- | -- | 2.8 × 10−6 | 2.8 × 10−5 | - |

| Silty-Sand | 0.35 | 0.00 | 0.0142 | 1.27 | 70.27 | 34 | -- | -- | 6.0 × 10−5 | 6.0 × 10−4 | 2.01 |

| Copper | 0.46 | 0.01 | 0.0196 | 1.453 | 50.99 | 69 | 30 | 1 | 7.6 × 10−5 | 7.6 × 10−4 | 2.43 |

| Gold | 0.45 | 0.00 | 0.0163 | 1.33 | 61.18 | 23.5 | 71.5 | 5 | 4.3 × 10−5 | 4.3 × 10−4 | 2.38 |

| Coal | 0.47 | 0.04 | 0.0054 | 1.249 | 183.50 | 35 | 39 | 26 | 1.2 × 10−6 | 1.2 × 10−5 | 2.49 |

| Oil Sand a | 0.39 | 0.00 | 0.0167 | 1.34 | 61.18 | 67 | 24 | 9 | 2.7 × 10−7 | 2.7 × 10−6 | 2.16 |

| Soil/Tailings | Waste Rock Content (%) | Modeling Condition | Storage Layer Height (mm) | Percolation Rate (mm/year) |

|---|---|---|---|---|

| Coal mine tailings | 0 | - | 1220 | 0.200 |

| 30 | Fixed height | 1220 | 0.260 | |

| 30 | Adjusted height-Method 1 | 1810 | 0.135 | |

| 30 | Adjusted height-Method 2 | 1740 | 0.135 | |

| 45 | Fixed height | 1220 | 0.830 | |

| 45 | Adjusted height-Method 1 | 2390 | 0.075 | |

| 45 | Adjusted height-Method 2 | 2220 | 0.075 | |

| Copper mine tailings | 0 | - | 1220 | 3.17 |

| 30 | Fixed height | 1220 | 4.71 | |

| 30 | Adjusted height-Method 2 | 1770 | 3.36 | |

| 45 | Adjusted height-Method 2 | 2350 | 3.09 |

| Simulated Water Balance Cover | Evapo- Transpiration (mm/year) | Runoff (mm/year) | Average Soil Water Storage (mm) | Average Saturation Degree (%) | Percolation (mm/year) |

|---|---|---|---|---|---|

| Natural Cover | 328.6 | 0.215 | 151.6 | 30.3 | 2.36 |

| Copper Tailings | 327.4 | 0.185 | 91.1 | 18.3 | 3.17 |

| Gold Tailings | 329.6 | 0.18 | 144.1 | 28.9 | 1.69 |

| Coal Tailings | 325.6 | 0.18 | 303.7 | 60.9 | 0.20 |

| Oil Sand Tailings | 314.9 | 2.17 | 120.4 | 24.1 | 0.00 |

| Soil/Tailings | Waste Rock (%) | Runoff (mm/year) | Evapotranspiration (mm/year) | Percolation (mm/year) | Average Soil Water Storage (mm) | Average Saturation Degree (%) |

|---|---|---|---|---|---|---|

| Natural Cover | 33 | 0.215 | 328.6 | 2.36 | 151.1 | 30 |

| 48 | 0.170 | 328.1 | 2.69 | 139.4 | 32 | |

| 63 | 0.190 | 327.1 | 3.41 | 112.8 | 30 | |

| Copper Tailings | 0 | 0.185 | 327.4 | 3.17 | 91.1 | 14 |

| 15 | 0.180 | 330.5 | 4.08 | 80.3 | 15 | |

| 30 | 0.180 | 325.9 | 4.71 | 75.3 | 16 | |

| Oil Sand Tailings | 0 | 2.170 | 314.9 | 0.00 | 120.4 | 22 |

| 30 | 2.140 | 328.3 | 0.00 | 93.5 | 23 | |

| 45 | 1.040 | 301.0 | 0.00 | 71.8 | 24 | |

| Coal Tailings | 0 | 0.180 | 321.7 | 0.20 | 303.7 | 47 |

| 15 | 0.190 | 333.9 | 0.32 | 274.0 | 49 | |

| 30 | 0.320 | 317.8 | 0.26 | 212.4 | 45 | |

| 45 | 0.265 | 328.9 | 0.83 | 215.0 | 55 | |

| 71.3 | 0.525 | 315.0 | 1.85 | 124.4 | 52 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gorakhki, M.H.; Bareither, C.A. Sustainable Reuse of Mine Tailings and Waste Rock as Water-Balance Covers. Minerals 2017, 7, 128. https://doi.org/10.3390/min7070128

Gorakhki MH, Bareither CA. Sustainable Reuse of Mine Tailings and Waste Rock as Water-Balance Covers. Minerals. 2017; 7(7):128. https://doi.org/10.3390/min7070128

Chicago/Turabian StyleGorakhki, Mohammad H., and Christopher A. Bareither. 2017. "Sustainable Reuse of Mine Tailings and Waste Rock as Water-Balance Covers" Minerals 7, no. 7: 128. https://doi.org/10.3390/min7070128

APA StyleGorakhki, M. H., & Bareither, C. A. (2017). Sustainable Reuse of Mine Tailings and Waste Rock as Water-Balance Covers. Minerals, 7(7), 128. https://doi.org/10.3390/min7070128