1. Background and Challenge

In the field of industrial project management, formal integration of occupational health (OHS) risk evaluation and monitoring has been found inadequate, indeed absent in many cases [

1,

2,

3]. Problems affecting the safety and reliability of industrial processes are common manifestations of this inadequacy. This situation is generally due to poor knowledge of OHS principles in business organizations and among project team members [

4].

Although risk management tools are put to good use in many industrial sectors, many major projects have run into difficulty because of a failure to integrate OHS (

Table 1). Industrial projects often contain hidden risks that can lead to poor decision-making. Several types of OHS risks potentially exist, and these change in frequency and gravity depending on the dynamic context. Despite the level of hazards, the literature is not unanimous on the subject of risk management processes that organizations should put in place. In spite of the heightened risks and uncertainties associated with such projects, the number of published studies on the systematic management of risks as a whole remains small [

1,

2,

5]. Among the reasons cited for this situation are gaps in the data and knowledge that would be required in order to identify and evaluate correctly all of the risks involved. The complexity of some projects introduces additional constraints on the consideration of OHS in the management of potential risks [

6,

7].

Table 1.

Examples of major industrial accidents.

Table 1.

Examples of major industrial accidents.

| Date | Location | Accident | Potential Cause | Consequences |

|---|

| 2014 | Manisa, Turkey | Explosion in the Soma mine | Detection failure of carbon monoxide gas | 301 deaths |

| 2013 | Texas, USA | Explosion in a fertilizer manufacturing plant | Storage problems of chemical substances | 14 deaths and 200 injured |

| 2012 | State of Falcon, Venezuela | Fire at the Amuay refinery | Storage problems of chemical substances | 48 deaths |

| 2010 | Copiapó, Chile | Collapse of the copper and gold mine in San José | Lack of reinforcement; poor decision-making | 33 miners trapped underground rescued after 69 days |

| 2010 | Gulf of Mexico, USA | Explosion on the off-shore oil-drilling platform Deepwater Horizon | Poor decision-making | 11 deaths, vast environmental damage |

| 2010 | Connecticut, USA | Explosion at an electrical power plant | Storage problems of chemical substances | 5 deaths, 12 injured |

This article puts into perspective the complexity of the challenge of integrating OHS into industrial project risk management. This challenge will be more understood once its principal aspects have been clearly defined. Given the interdisciplinary nature of the problem, research in this field must start with this exercise. A conceptual and methodological approach is proposed to guide future research focused on meeting this challenge. The approach is based on applying multi-disciplinary research modes to a complex industrial context in order to identify all scenarios likely to contain threats to humans or the environment. A case study is used to illustrate the potential of the proposed approach for application and its contribution to meeting the challenge of taking OHS into consideration. On-site researchers were able to develop a new approach that helped mining companies to achieve successful integration of OHS into expansion projects.

This article is organized as follows: Methodological considerations and the terminology used throughout the article are presented in

Section 2. The principal elements taken into consideration in our analysis of the challenge of integrating OHS into industrial project management are described in

Section 3. Examples of potential research questions and the most relevant objectives are provided in

Section 4. The proposed methodological approach is described in detail in

Section 5. A case study is summarized in

Section 6. The limitations of the concepts proposed and various recommendations are discussed in

Section 7.

2. Methodological Considerations and Terminology

We began by narrowing our focus to the four principal problematic aspects of integrating OHS into risk management in the context of industrial projects, based on a systematic examination of the literature and noting interactions that also appear to be aspects of the problem. We then set guidelines to orient the research towards innovative solutions that are compatible with the major aspects. This framework is intended to orient researchers, as well as to provide a more precise definition of the concepts and, thus, delimit our contribution to solving this complex and multi-faceted problem.

We emphasize the industrial context in our analysis of projects, risks, good OHS practices and management thereof. The Oxford dictionary (2014) provides the following first meaning of the term “industry”: (1) economic activity concerned with the processing of raw materials and manufacture of goods in factories. The work in [

8] defines industry as follows: (1) the activities and trades that as a whole produce wealth through the processing of raw materials, exploitation of mines, use of energy sources, and so on; (2) any economic activity organized on a large scale (entertainment industry spectacle, heavy industry, light industry, automobile industry, textile, industry,

etc.).

The term “phase” is often used in descriptions of processes of project management or risk management. One dictionary definition of this term is any of the successive aspects of a phenomenon or of an evolving action [

8]. In this article, it shall refer to a pre-determined period of a process. The term “stage” refers to any of a plurality of categories of activity (or tasks) that occur in succession within a phase of the process under study.

3. Principal Aspects of the Challenge

The challenge of integrating OHS into industrial project risk management will be more clearly understood once its principal aspects have been defined. Given the interdisciplinary nature of the problem, research in this field must start with this exercise. We have used a systematic approach to identifying the elements that must be taken into consideration, as well as the interactions and interdependencies that are also aspects of the problem under study.

It is clear that integration of OHS into project management involves challenges that must be approached using a variety of disciplines (technological, managerial and sociological). For our purposes, it must be emphasized that elements of project management and of OHS may influence each other. Since we are attempting to integrate “OHS risk” into “industrial project management”, it is important to view the risk management component from both perspectives and to specify the type of industrial project under consideration. In order to refine further the focus of our study, we examine time as a constraint on the integration of OHS into the project risk management process. The importance of this aspect becomes clear when the sequential and cyclical character of project management and risk management processes are considered. Finally, integration of OHS must be studied in a context involving industrial businesses or partnerships. The organizational aspect thereby becomes an additional element to take into consideration in the description of the challenge under study.

These elements show the challenge of the presence of several elements that may influence the integration of OHS into the project risk management process (project management, risk management, OHS risk and organization). Risk identification, a very important phase in the process, is influenced by the management of these elements and their integration. Neglect of a factor will hide potential dangers and bias the final results.

Figure 1 summarizes the four principal elements of the challenge of integrating OHS into industrial project risk management. The links between these elements represent possible influences, which, in turn, represent a variety of constraints on the integration of OHS. We thus provide a systemic and macroscopic view of the aspects that we have taken into consideration throughout the description of the proposed methodological approach.

In the sub-sections that follow, we shall attempt to clarify these elements in order to formulate research questions and general research hypotheses, to construct a conceptual framework and propose techniques of data collection and analysis for researchers interested in meeting the challenge of solving this problem.

Figure 1.

The four principal aspects of the OHS integration challenge.

Figure 1.

The four principal aspects of the OHS integration challenge.

3.1. Project Management

Various worldwide organizations provide a framework for defining good practice in project management. These organizations oversee the application of managerial principles and the development of their communities of practitioners (training and certification). Among the best-known organizations in this area, we must cite the Project Management Institute (PMI) and the International Project Management Association (IPMA). Founded in 1965, the IPMA is the oldest project management association and is currently represented in more than 50 countries [

9]. The PMI currently has about 600,000 members worldwide representing 185 countries [

10]. Members of these organizations are active in numerous sectors, including mining, manufacturing, the petrochemical industry, the pharmaceutical industry, telecommunications, financial services, health services, consulting services in management, organization and engineering, construction, policing and defense.

The PMBOK

® Guide [

11] is generally recognized as the most comprehensive reference on best practices in the field of project management. This document is a collection of knowledge that is essential for managing a project, regardless of the nature and the field of the project (PMI, 2008a). The know-how compiled in the PMBOK

® Guide is grouped into nine chapters covering the following aspects of project management: (1) integration; (2) content; (3) delays; (4) costs; (5) quality; (6) human resources; (7) communication; (8) risks; and (9) supply.

The Project Management Institute defines a project as an organized effort undertaken in order to create a unique product, service or result. The temporary nature of projects implies a determined beginning and an end [

11]. Project management is an exercise undertaken in order to organize and facilitate the execution of a complex task that is intended to provide deliverables according to objectives specified by a client. Corriveau and Larose define project management as a managerial approach to specifying, designing and overseeing a project mandated to a team assembled to bring suitable expertise to the project and to carry it out [

12]. The PMI has defined the basic concept of project management in terms of the utilization of knowledge, skills, tools and techniques to organize activities in order to meet the requirements of a project [

11]. For our purposes, a project and its management are considered as an ensemble of temporary efforts undertaken by one or more teams in order to bring about a specific transformation of an organization and thereby improve performance or one or more processes, products or services [

13].

The lifecycle of a project is defined as the entire sequence of the phases (whether overlapping or not) of the project as a whole [

11]. The PMBOK

® Guide [

11] describes several types of project lifecycles that are compatible with PMI management methods. Lifecycles vary depending on the industrial sector, the technology used and sometimes on the uniqueness of the organization.

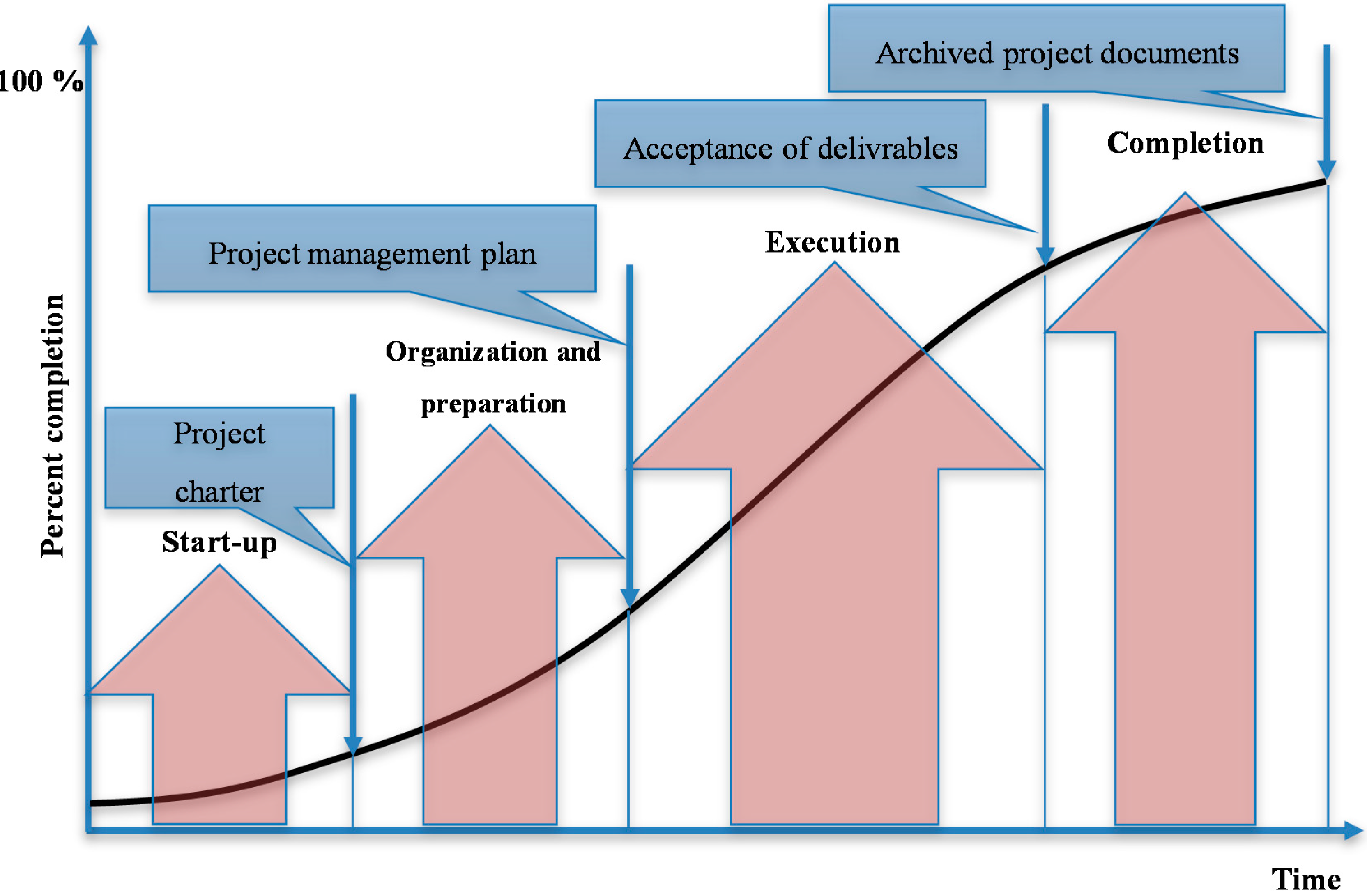

Figure 2 illustrates the lifecycle of a typical project comprising four phases: (1) start-up; (2) organization and preparation; (3) execution of the planned activities; and (4) completion.

The management of a project is often subject to the influence of several factors, both endogenous (internal) and exogenous (external to the project). These factors make the achieving of objectives more complex by imposing constraints on essential activities (e.g., risk management) for undeterminable periods of time. The following factors in particular should be noted [

13,

14]:

Project complexity (scale, duration, budget, number of activities, number of suppliers or sub-contractors, etc.)

Variety within the project (diversity of teams, experience, skills, geographical location of actors, management methods and tools used, etc.)

Interdependencies within the project (between individual actors, between teams, relationships, organizational environment, etc.)

Industrial or business context (cooperation, competition, work environment, legal and regulatory framework, culture, etc.)

Figure 2.

Lifecycle of a project. Adapted from the PMBOK

® Guide [

11].

Figure 2.

Lifecycle of a project. Adapted from the PMBOK

® Guide [

11].

Project management is also subject to influence by uncertainties present throughout the project lifecycle. The work in [

15] has summarized several uncertainties as a function of project phase, the consequences of which we shall examine in terms of erroneous resource availability estimates and specifications for deliverables.

According to the PMBOK

® Guide [

11], the influence of stakeholders (clients, sub-contractors, suppliers, users, public, government,

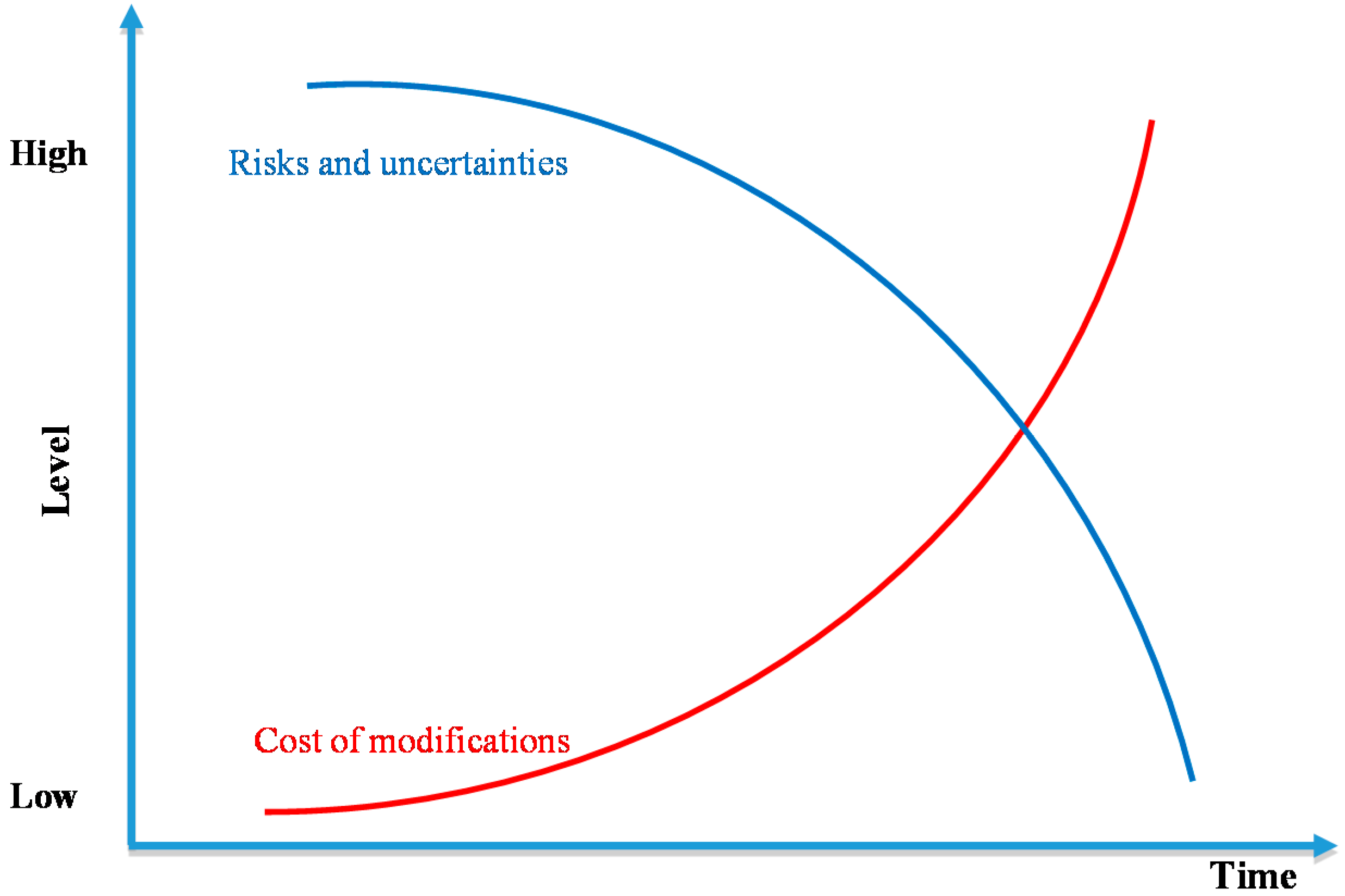

etc.), risks and uncertainties is greatest at the beginning of a project and decreases as the project advances (

Figure 3). “A project at its inception is necessarily vague, disorganized and dysfunctional” [

12]. It is therefore wise to seek to eliminate or control as many risks and uncertainties as possible right from the beginning of an industrial project.

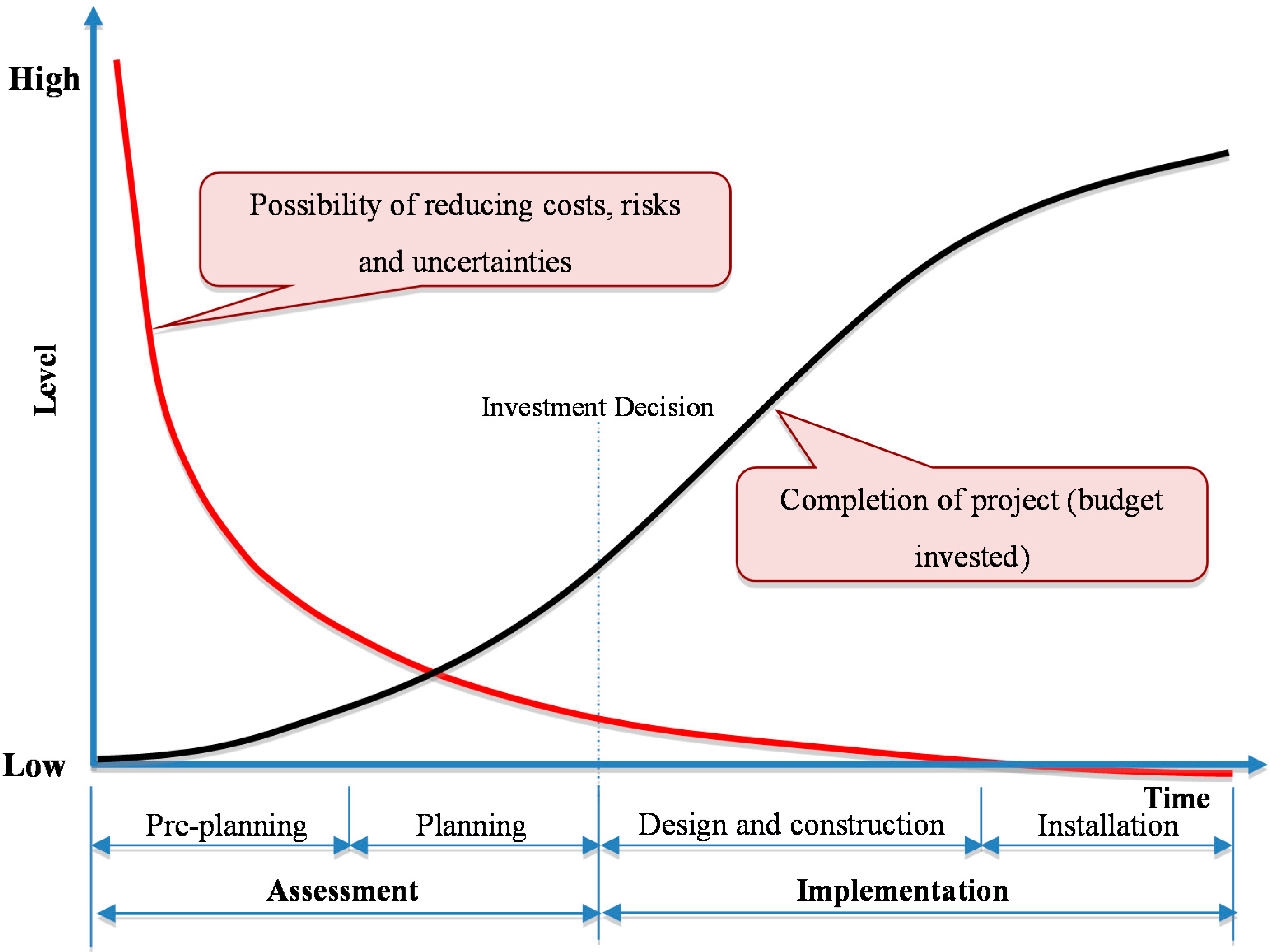

Figure 4 shows in more detail the importance of eliminating risk at the beginning of a project. It is important at this point to define the “beginning of a project” in terms of the pre-determined phases of the project. Although

Figure 4 shows a slight difference in the division and designation of the phases compared to

Figure 2, it shows more clearly the true meaning of the expression “beginning of the project”. The greatest reduction in costs, risks and uncertainties is achievable during the evaluation period (the pre-planning and planning phases). The work in [

16] notes that proper evaluation of risks at this point makes it possible to avoid disastrous consequences. We therefore define the beginning of a project as the evaluation period represented in

Figure 4. This includes all of the activities involved in clarifying (logical framework, pre-feasibility and feasibility studies and specification document) and planning the project.

Figure 3.

Progression of risks and uncertainties and the cost of modifications, according to the PMBOK

® Guide [

11].

Figure 3.

Progression of risks and uncertainties and the cost of modifications, according to the PMBOK

® Guide [

11].

Figure 4.

Control of project factors (costs, risks and uncertainties). Adapted from [

16].

Figure 4.

Control of project factors (costs, risks and uncertainties). Adapted from [

16].

3.2. Risk Management

Risk management has been described as “the adoption of financial, technological and organizational measures designed to modify the relationship between the turbulence of an environment and the variability of the results obtained therein” [

17]. Risk management is based essentially on analysis and evaluation of all of the relevant information available.

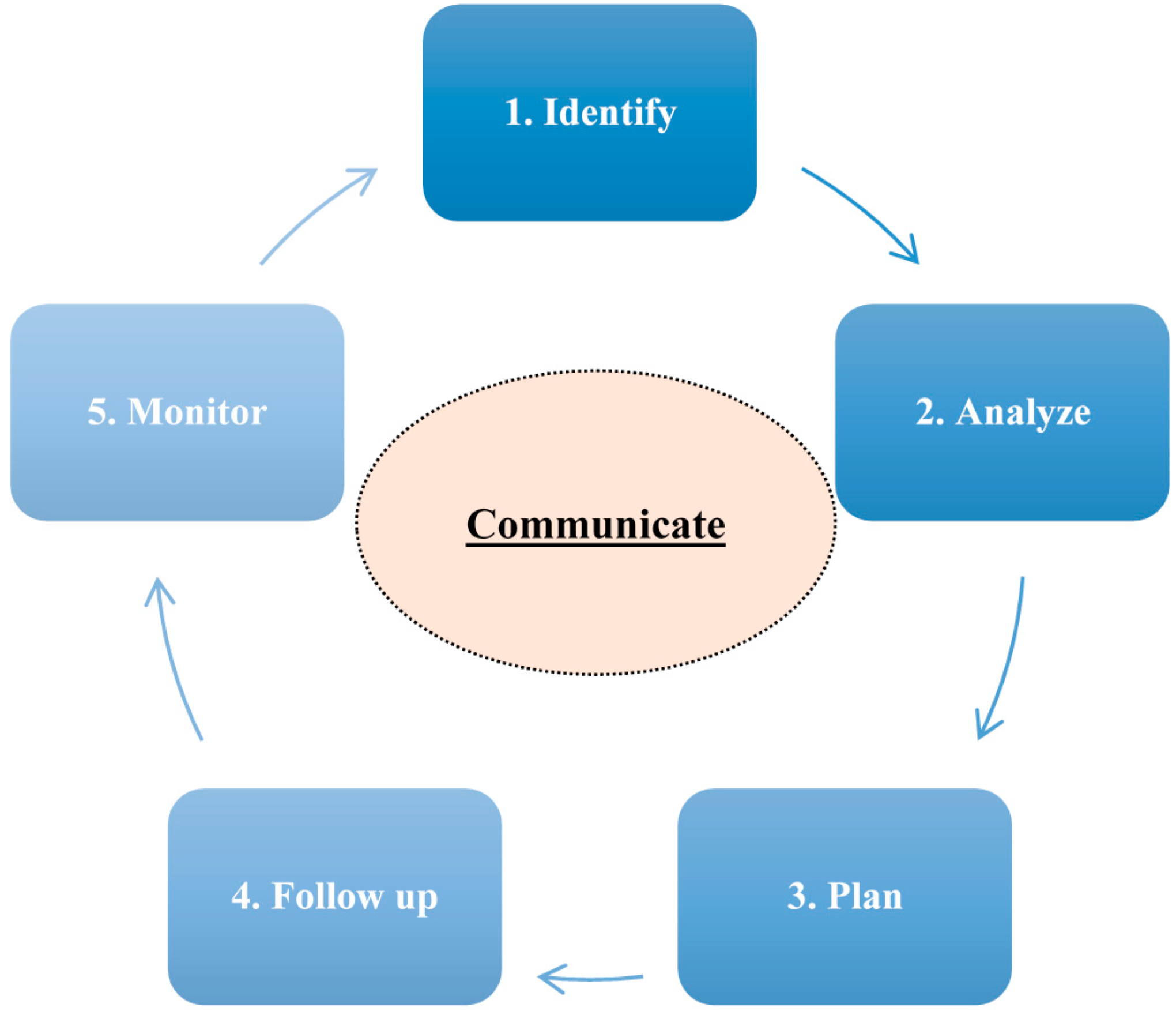

A common risk management process, as represented by the Software Engineering Institute (SEI), is shown in

Figure 5 [

18]. This process is carried out essentially in five phases: (1) risk identification (discovering or enumerating risks); (2) risk analysis (evaluation); (3) planning (risk control); (4) follow-up (of the actions implemented); and (5) monitoring (of the effectiveness of the measures taken). It should be noted that communication remains an essential element throughout the risk management process.

Figure 5.

A typical risk management process. Adapted from [

18].

Figure 5.

A typical risk management process. Adapted from [

18].

Integrated risk management is defined as a coordinated ensemble of activities carried out in an organization in order to identify, measure, evaluate and modify both the probability of occurrence of certain events having an impact on one or more entities and the impact of such events on these entities [

19].

Figure 6 lists the factors that contribute to the success of a project risk management initiative and also shows the difficulties and constraints that need to be taken into consideration when integrating risk management into a project management process.

Figure 6.

Factors that contribute to successful risk management. Based on [

20].

Figure 6.

Factors that contribute to successful risk management. Based on [

20].

Risk management is based on evaluation and utilization of all of the information available in the organization under study. Throughout the risk management process, it is necessary to analyze the available information as a whole before deciding on corrective or preventive actions. Well-founded and unbiased factual information makes it possible to avoid making poor decisions that could put human lives in danger [

21].

In order for an action to be truly preventive or corrective, hazards must be identified first on the basis of rigorous analysis of information or data. This analysis inevitably collides with reality and with constraints on the selection of sources of information of various types (financial, economic, operational,

etc.). In addition, risk analysis is often delegated to a team made up of individuals from different backgrounds and cultures (personal, organizational, risk tolerance,

etc.), who will have to collaborate in order to meet common objectives. The team members will not likely have the same expertise or the same vocabulary and will therefore have difficulty understanding each other [

22].

Industrial project management is based generally on purely technical and scientific skills. Project managers, engineers and designers concern themselves with known technical risks and tend to neglect risks affecting OHS (among others), due to lack of knowledge, to time constraints or to technical and economic constraints [

23].

Since risk management is the task of one or more human beings who hire other human beings to analyze hazards associated with systems, processes or projects, which, in turn, involve other human beings, the sociological perspective is indispensable. Human interactions and influences must be taken into consideration in any risk management process. The task is interdisciplinary, and the management team must therefore be multi-disciplinary.

Other constraints on risk management will be present, such as delays in obtaining responses to tenders, competition, the shortening of industrial project lifecycles and limitations on the availability of human resources and materials. These put the team under pressure to oversimplify the studies in order to complete the risk analysis on time and on budget.

3.3. OHS Risks

Taking OHS into consideration is now generally regarded as financially justified, and most high-level decision-makers acknowledge that neglecting it ultimately causes economic growth to slow down [

24]. Legislation in Québec has made it mandatory to take OHS into consideration and specifies that any factor or condition known to threaten human life be eliminated at its source. Regulatory measures worldwide have led to improvements in project management paradigms in a wide variety of fields. A good example of this is integration of OHS into risk management in construction projects [

25]. Through application of various codes of ethics (e.g., of the Québec order of professional engineers [

26]), engineers are now “the first line of defense in the effort to contain and prevent risks. Furthermore, they have an ethical and legal obligation to concern themselves with the safety of the installations, processes and products that they design and use” [

27].

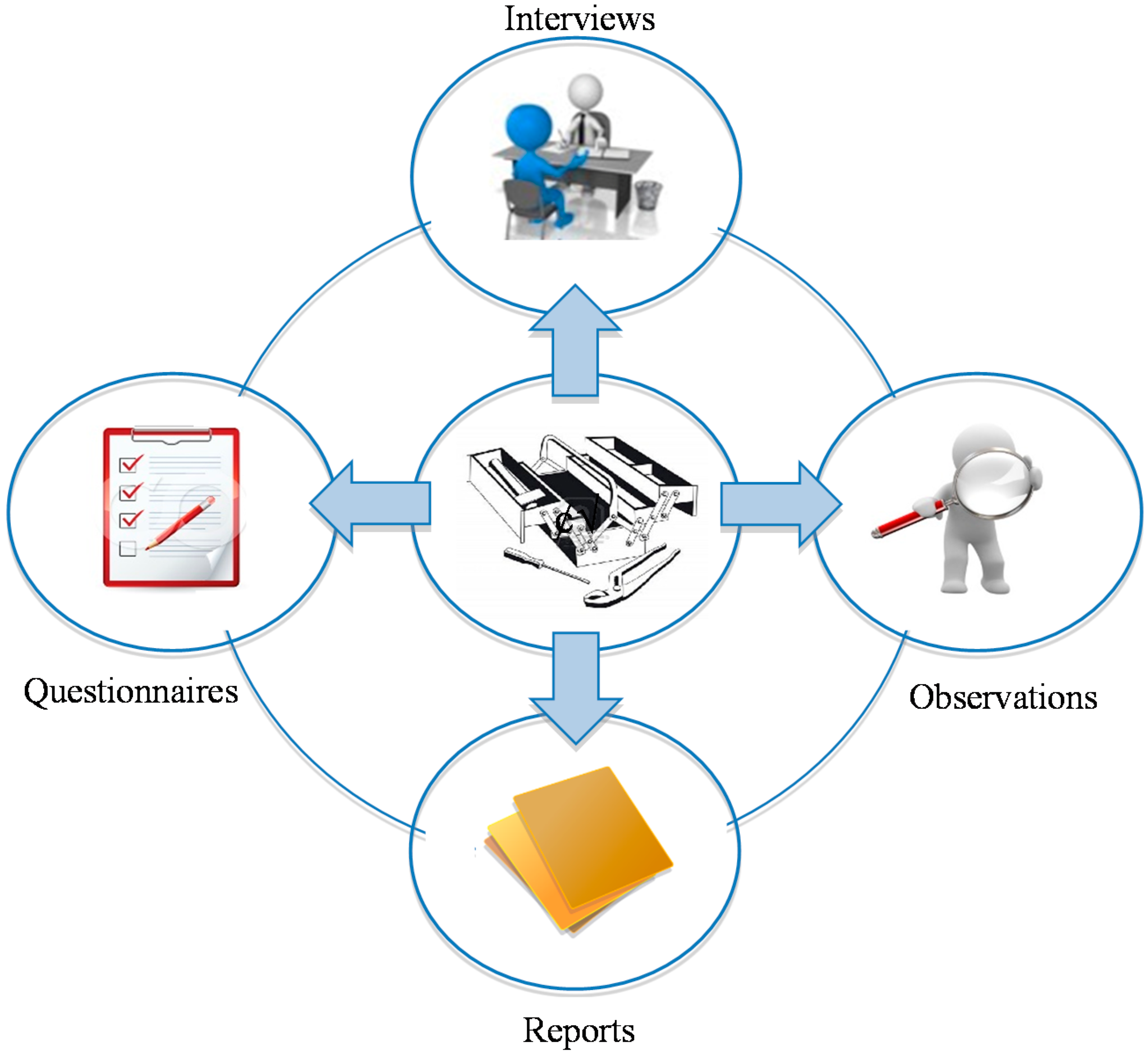

In order to analyze properly the OHS risks associated with an industrial project, all potential hazards must be taken into consideration. Due to the complex nature of these risks, their enumeration and evaluation will require that the company or corporation use sociological research tools (e.g., observation, interviews and surveys). However, organizations do not always have the means to recruit external experts for the purpose of such evaluations. In addition, the choice and utilization of these tools are also subject to various constraints and require rigorous adherence to procedures, which practitioners sometimes neglect.

3.4. The Organization

The objectives of a project are of course derived from the current business strategy of the company. The project team remains subject to the direct and indirect relationships that its members have within the hierarchy and with the existing departments and services. The company or corporation is therefore the first determinant of the universe within which the project unfolds. The work in [

12] describes the influence of three typical corporate structures on project management. However, they consider the “matrix-type” structure to be the best adapted and capable of eliminating the drawbacks associated with the so-called “functional” structure and the “project” structure.

Project management or risk management may suffer a drop in quality when tasks are out-sourced or one or more team members come from other organizations. Some researchers have examined the impact of sub-contracting on managerial effectiveness [

6,

28]. According to the PMBOK

® Guide, organizational culture and corporate style and structure have a strong influence on the manner in which projects are managed and, hence, on successful achievement of the objectives [

11].

We wish to emphasize here that we have attempted to take into consideration these different facets of the research problem in developing a conceptual framework intended to guide researchers in their efforts to find ways of improving the integration of OHS into industrial project management. The principal elements represented in

Figure 1 should be the subject of more focused discussions based on the nature of the project and the industrial sector.

4. Recognizing Relevant Research Questions and Objectives

In order to orient future research towards the stated goal, we propose research questions based on the four principal elements derived from the central theme. We shall begin by justifying the integration of OHS into industrial projects in general and then in specific sectors (construction, petrochemical, mining, metallurgy, manufacturing, aerospace, nuclear, engineering,

etc.). The relevance and importance of taking OHS into consideration stems principally from the limitations and deficiencies identified in the findings of published research [

1,

6,

7,

29,

30]. The previously described four principal elements of the problem were identified through preliminary readings that must be completed by careful examination of the literature of reference. Since the subject area is vast, themes, questions and objectives for future research must be specific and stated in clear, unambiguous language.

The challenge described above raises questions, such as the following:

How to integrate OHS into project risk management and achieve simultaneous evaluation of all of the risks identified.

How to adapt and test new approaches to project risk management in the context of a particular industrial sector.

Is it possible to build knowledge bases that encompass most of the hazards and threats not taken into consideration systematically in industrial project risk management?

The goal of future research focused on this challenge must be to develop solutions that integrate OHS systemically into industrial project risk management. This integration must allow evaluation of all potential risks identified (which differ in nature) with minimal difficulty. It will require generally some adaptation and transposition of existing tools (those that are generalizable), as well as the creation of other risk evaluation techniques, to be included in overall approaches to risk management.

The proposed approach features a practical framework consisting of several tools that in fact have been already adopted in a partial and unsystematic way. The work offers a comprehensive and organized approach. To identify the maximum of scenarios, researchers and practitioners must use all proposed tools following the predefined steps. An establishment of a common framework for researcher and practitioners may improve risk management and especially can lead to verifiable and comparable results, which is currently impossible to do. This proposal will also improve the regulatory and normative framework related to risk management in the mining sector.

Three orientations that must guide any solution conceptualization effort require emphasis:

A multi-criteria mode of thought allowing the consideration of all of the components of the four principal elements of the challenge (the project management approach, the risk management process, OHS and organizational aspects).

Active participation of the stakeholders (industrial partners and sub-contractors) and project team members (design, construction, operation, OHS, environment and maintenance); this participation must not be limited to managerial and technical members of the project team.

A framework of study that favors continued improvement and is compatible with the management paradigms recognized in each sector and country. Convergence with current paradigms, laws and regulations is an important aspect that must be taken into consideration.

5. Proposed Methodological Approach

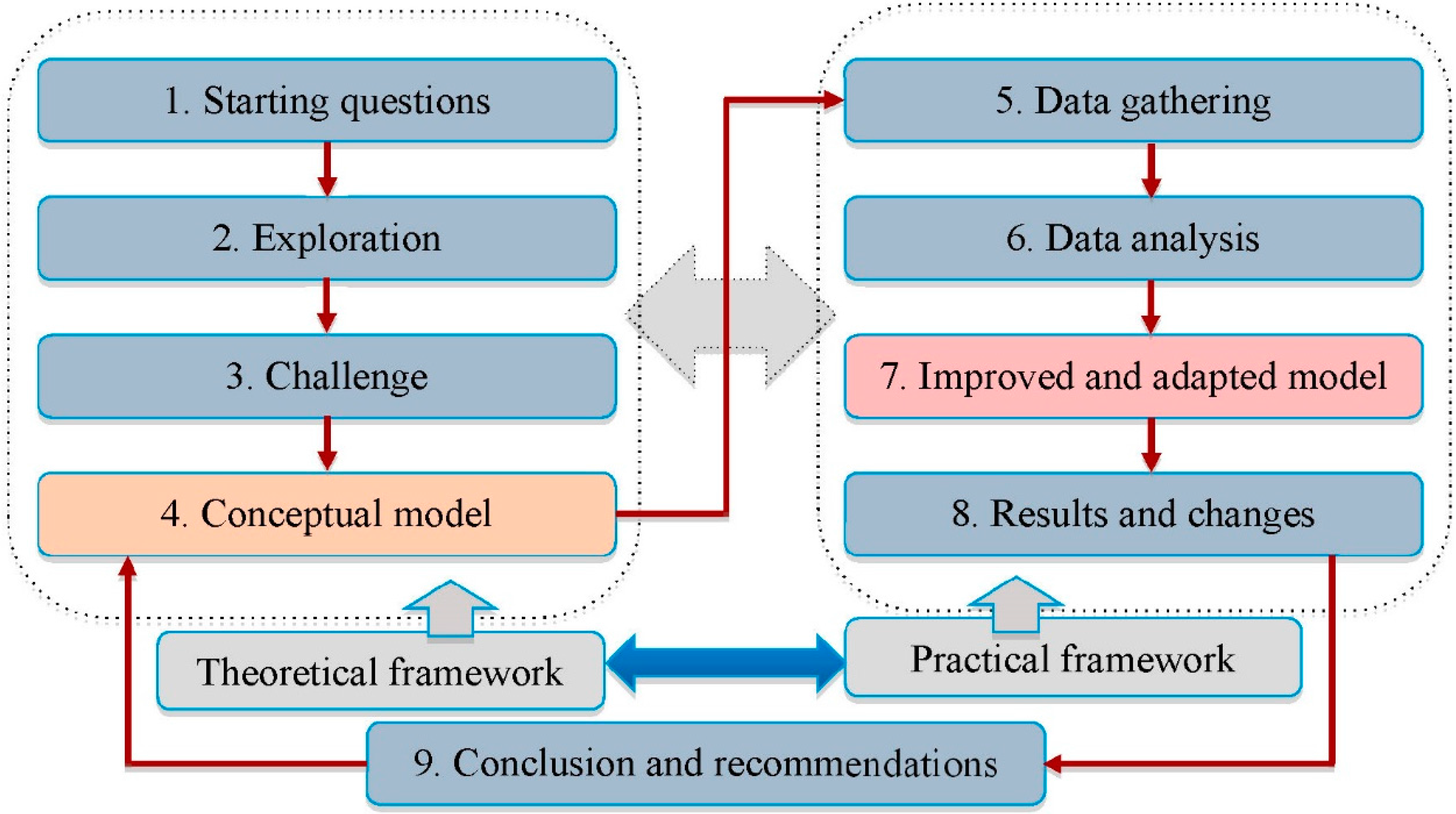

Figure 7 summarizes the proposed methodological approach, including the various steps for conducting any partnered research method intended to integrate OHS into the management of industrial project risks.

To begin with, the approach features a theoretical framework consisting of the following steps: (1) statement of the underlying questions; (2) examination of the literature; (3) description of the challenge; and (4) development of the conceptual model. It then provides a practical framework consisting of the following steps: (5) data gathering; (6) data analysis; (7) implementation of an adapted and improved conceptual model; (8) description of results and of changes; and, finally, (9) conclusion and recommendations; which allow recapitulation and evaluation of the changes brought about by implementing the solutions and then adjustment of the theoretical conceptual model for future generalization.

In order to place the proposed methodological approach in its context, we take into consideration the four principal elements of the challenge as mentioned above (

Section 3). The practical framework allows researchers to evaluate the conceptual model by applying it in a specific industrial context and measuring the appreciation of the solutions thus brought thereto. The businesses involved benefit from the research results by improving conditions and eliminating problems. Such improvements come about by influencing culture, business practices or even the behavior of managerial staff and workers.

The conceptual model must include a formal system and a system of thought. The formal system is composed of fundamental ensembles (logical and mathematical). In most cases, risk is evaluated in terms of its probability of existing and the impact (negative) of the occurrence associated with it. The system of thought includes cognitive and behavioral structures. This is to make sure that sociological aspects are not neglected in the modeling of the concept to be studied in sociotechnical and dynamic business environments.

Figure 7.

Proposed methodological approach.

Figure 7.

Proposed methodological approach.

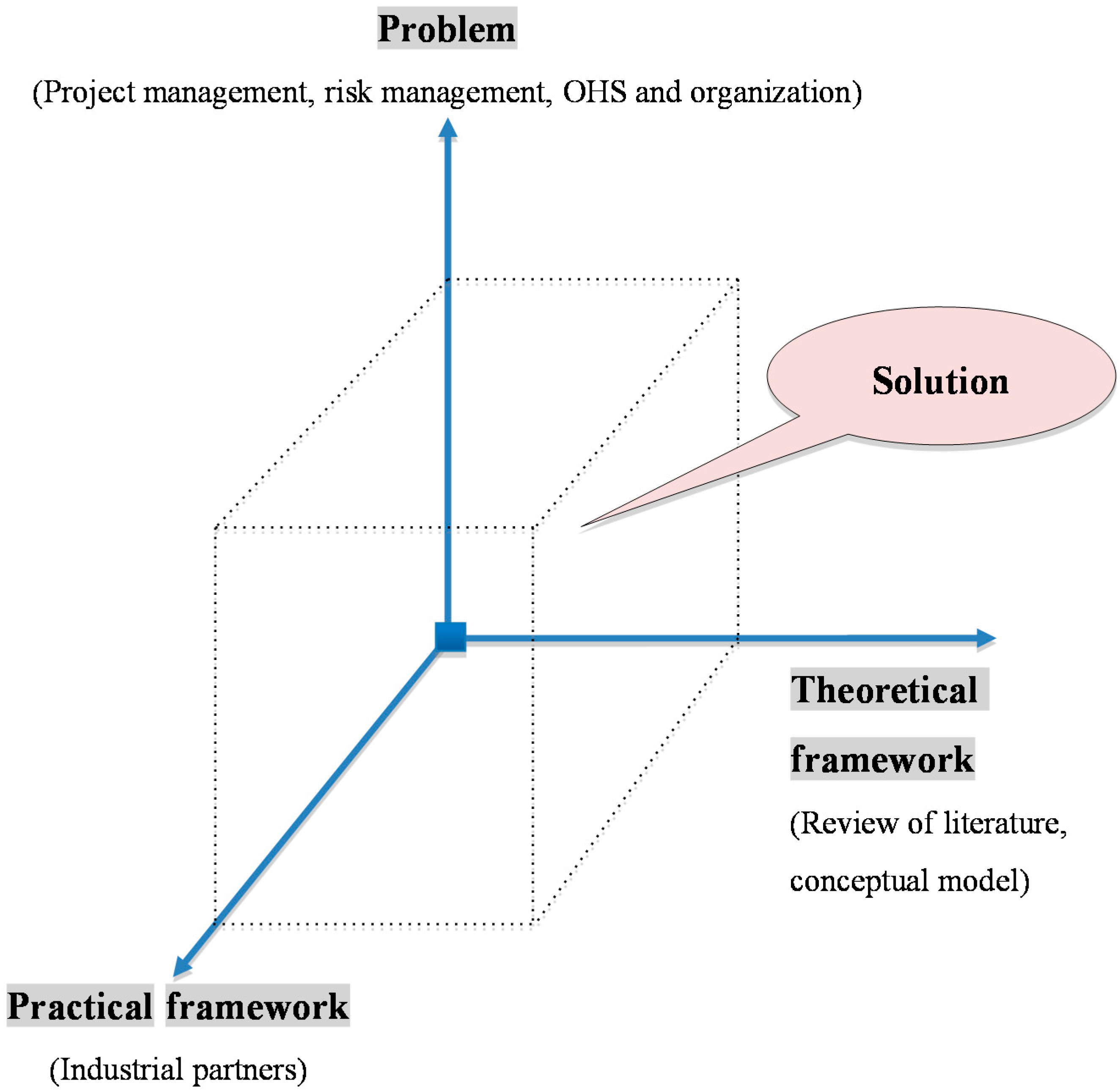

5.1. From the Idea to the Concept: The Dimensions of the Solution

The research must take place in a specific industrial setting. It must begin with a theoretical framework (examination of the literature and development of the conceptual model). The theoretical framework is based essentially on findings published in the literature and on exploration of the structured practices of numerous industries with regard to integration of OHS. During this first part, the researchers must acquire an understanding of the current state of OHS integration into industrial project risk management in order to propose improvements. The second part of the research completes the theoretical framework by providing the understanding of how the business of the industrial partners works, the nature of their activities and their organizational structure. Improvements to be achieved by implementing one or more solutions adapted to constraints (which may be several) in the field are then proposed.

In order to specify the scope of the solution envisaged, we may summarize it in terms of three dimensions. The first dimension shows the theoretical framework, which combines the literature search and the development of the conceptual model. The theory is based on case studies in several industries. The second dimension represents the practical framework of involvement of the industrial partners. The third dimension combines the four principal elements involved in the interactions to take into consideration in the study (project management, risk management, OHS, the business). The proposed solution must therefore reflect the three dimensions mentioned above (

Figure 8).

Figure 8.

The dimensions of the solution.

Figure 8.

The dimensions of the solution.

5.2. From the Concept to the Field: Action Research

The study must be designed to answer questions raised by the theory, but also those expressed by the industrial partners. In addition, it can be ascertained easily whether or not the presence of researchers has any effect on practices in the field. Action research is certainly one approach that should be considered.

The approach being proposed to researchers converges with the definition provided by [

31], which describes action research as an approach to fundamental research that is borne of the convergence of the “will to change” with a “research intention”. The work in [

32] has defined action research as an approach that is “focused on solving real-life problems. Action research is research in which the participants and the researchers together generate knowledge through collaborative processes” (p. 251). Action research leads to the construction of a solution that takes into consideration an interactive world, perceived as an ensemble of dependent purposes with coherent relationships [

33,

34].

Action research is viewed in terms of various groupings of components [

35]. Defined by [

36], the first of these groupings contains two components: (1) the proper dosage of research and action; and (2) the nature of the intervention. A second grouping [

37] defines research action that depends on several factors, including the proximity to the field and the number of actors involved. Another grouping [

38] distinguishes action research on the basis of participation: (1) research on the action, but without action; (2) the actor presents the problem, and the researcher proposes solutions; and (3) all actors are totally committed to the research. Yet another grouping [

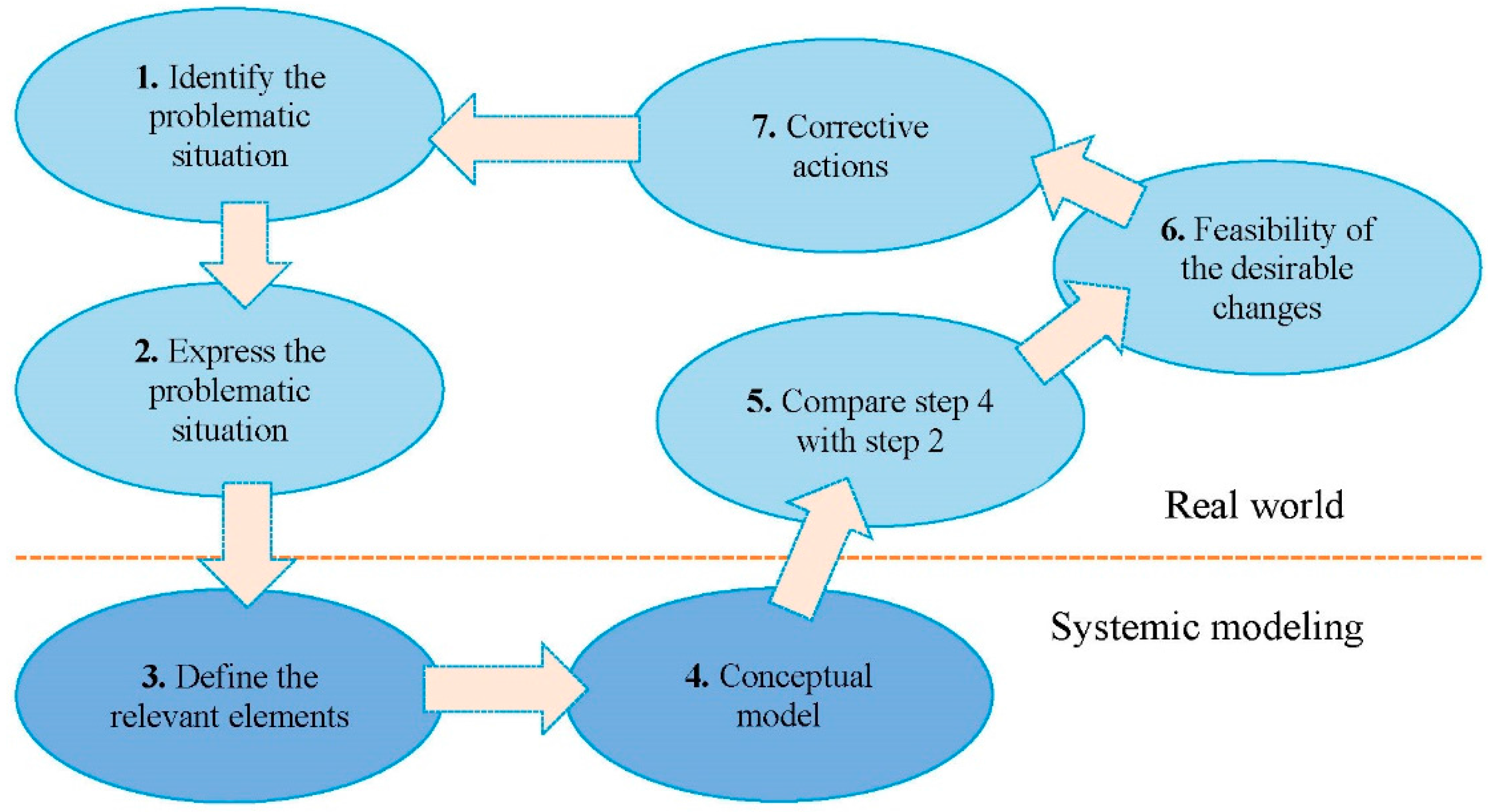

39] comprises five types of action research, of which we shall consider only the soft systems methodology.

In order to ensure proper use of an action research, five criteria must be met simultaneously [

40]. The research must be: (1) grounded in the real world; (2) reduced to application on a limited scale; (3) focused on changing groups and environments (through the action) according to objectives set at the beginning of the project; (4) designed from the outset to yield results that may be generalized; and (5) borrow tools used in other disciplines (rules, paradigms, data gathering tools,

etc.).

For our purposes, the preferred type of research action is a cross between the groupings of [

38] and [

39]. The industrial partner presents the problem, and the researchers propose solutions according to a conceptual model built around a theoretical framework. For example, the problem appears to be the lack of a simple, effective and well-adapted tool for integrating OHS into risk management and the absence of techniques for evaluating the impact of OHS incidents on the project and on the business. In order to propose better-adapted means, we chose soft systems methodology as a framework [

41].

Soft systems methodology is an approach composed of seven steps [

41,

42,

43]. These steps rely on the human activity systems concept in order to define the challenge and propose changes or transformations (

Figure 9):

Figure 9.

The steps involved in the soft systems methodology. Adapted from [

43].

Figure 9.

The steps involved in the soft systems methodology. Adapted from [

43].

Step 1, observe the problematic situation, that is the problem in an unstructured context. At this point, we seek to identify and understand the elements associated directly with the problem, in order to describe the problematic situation overall.

Step 2, express the problematic situation, that is state the knowledge acquired through observation. The description must be in terms understood by all groups involved.

-

Step 3, define the relevant elements. The purpose of this step is to define and conceptualize the system of thought that is best suited to solving the problem. The perspectives that will serve as a grounding for the conceptualization are chosen at this point.

-

Step 4, develop the conceptual model, using the definitions obtained in the preceding step (image of reality). The design of this model must be based on the problematic situation as described in Step 2.

Step 5, compare the results of Steps 4 and 2, that is the conceptual model with the actual situation, and evaluate the resemblance. Identify deficiencies in the actual situation that are addressed in the conceptual model. The model may be adapted and improved at this stage.

Step 6, study the feasibility of suitable changes, that is define them and estimate their potential impact on the problematic situation.

Step 7, implement actions that will improve the problematic situation, that is bring about the changes described in Step 6.

The soft systems methodology is preferred because of its systemic concept in which the system under study is considered as a set of elements in dynamic interaction and organized to achieve a goal [

44]. The work in [

45] describes this systemic approach as “gathering and organizing knowledge in order to help to solve complex problems of the effective universe” (p. 6)

. Due to its flexibility, soft systems methodology allows researchers to adapt more effectively to the constraints of the dynamic environments that characterize human activity systems.

6. Implementation and Results: The Case of Two Goldmines in Quebec (Canada)

The goal of the research was essentially to integrate OHS into risk management in mining projects in Québec. In the course of this work, an interdisciplinary and practical approach to risk management was developed and implemented in two Québec mining companies. The methodological approach proposed in this article was followed.

In order to achieve the goal, the researchers adopted a partnered research approach. They began by verifying the relevance of the initial questions by examining published studies [

1]. Having completed the review of the literature, they then elucidated the challenge in terms of industrial projects in general. They then constructed a conceptual model of an approach previously proposed [

29] using general research hypotheses, on the basis of the principal elements of the challenge as described above (

Section 3). As they progressed, they adapted and improved the reference model through action research involving both industrial partners [

6,

7,

30]. In doing so, they evaluated the conceptual model developed by gathering and using data and assessing the improvements. The businesses used the research results to improve situations and eliminate problems based on the identification of hazards and ranking of risks.

Based on the review of the literature, the first portion of the study provided a summary of the extent to which OHS risks are taken into consideration in industrial project management practices [

1,

29] and an overview of tools, methods and approaches developed or adapted for this purpose. The importance of identifying OHS risks associated with industrial projects and adequate planning of their management was thus demonstrated. The researchers then added the perspective of the mining industry and exposed the importance of systematic integration of OHS into the management of projects in this sector [

6,

7,

29,

30]. The need for innovative solutions adapted to allow OHS risks to be taken into consideration throughout the project lifecycle was thus demonstrated. Such solutions took into consideration several factors associated with this industry, such as the complexity of projects, the dynamic character of mines, the dominance of human input in mining operations, the evolution of technologies and equipment and the emergence of new mining companies in a highly effervescent economic context.

The conceptual model was then developed in order to evaluate all potential risks associated with an industrial project, including OHS [

29]. Using the new “concentration of hazards” concept and multi-criteria evaluation, the new approach developed was applied to identifying hazards and calculating their concentrations relative to each undesirable event identified. The concentration factor gives more realism to the weight factor for perturbation by each “family of hazards” associated with undesirable events. The hazards concentration concept thus combines the weighting of the potential for a family of hazards to perturb a state and its hazard concentration. Evaluators are thus no longer required to consider identified hazards as entities having the same influence.

The presence of researchers at the site made it possible for them to carry out the steps involved in developing the practical framework as outlined in

Figure 7 and thereby to propose to the scientific community and to practitioners an approach to integrating OHS into risk management in mining projects. Not limited to theoretical modeling and simulation of a single case [

29], this approach should be implemented in an industrial context in a manner that allows measurement of its relevance by concrete assessment of the effectiveness of the solutions brought forth [

6,

7].

Undertaken in a new open-pit goldmine, their first mandate allowed the researchers to adapt the proposed approach to the context of a mining start-up project [

6]. Based on analysis of incidents and accidents, interviews and partnered observation, an OHS database listing 200 hazards was constituted in the course of this mandate, which proved helpful to experts responsible for risk management in this mine. They were able to confirm the presence of many of these hazards (also identified in other studies); they identified reinforcing effects between families of hazards; and they were able to rank all of the potential risks identified by the teams concerned.

Under a second mandate, the researchers completed the preceding work and improved the proposed approach based on their observations in an established commercially-viable underground goldmine [

7]. At this stage, the risk evaluation and ranking method evolved further. The conversion of “concentration of hazards” to probabilities was replaced with a direct estimate of risk as a function of these concentrations. A new notion called “perturbation weighting” was added during the comparison of hazards. A step of risk management mission planning was added to the approach in order to make it compliant with the majority of project management paradigms. In addition, the OHS database was adapted to the underground mining context. This evolutionary database listed about 250 hazards identified in the underground mine. A more extensive evaluation of risks was carried out using the preliminary portrait of mining project risks [

30], which was adapted to the particularities of the mining company and the phase of the project underway.

Following the principles described in the present article, the researchers developed a new approach that allowed integration of OHS into management of either mining project. This was based essentially on the selection of complementary data-gathering tools that maximized the information extraction achievable over a relatively short time period.

This allowed convergence of OHS considerations with all operations of the mining companies involved. Several OHS problems were solved rapidly through the collaborative and interdisciplinary work conducted by the teams. The work contributed to the progressive implementation of an evolutionary OHS database with potential for generalization to other mines in Quebec. The new tools developed make it possible to evaluate simultaneously and quickly practically all project risks and to avoid neglecting various potential threats to the project. Such extensive evaluation of risks can only help managers to make more enlightened and well-founded decisions.

7. Limitations and Recommendations

It is important to emphasize that the proposed methodological approach and its underlying concepts have been applied to two mining companies in Quebec, which has one of the most developed and regulated frameworks for OHS in industrial mining in the world. The mining sector also represents a very particular industrial culture, and mining companies are highly unique sociotechnical systems. There are thus limits on the generalization of the concepts described in this article. The extent to which the adopted action research methodology can be generalized is also limited, given the influence of the culture of the business involved on the results thus obtained [

35]. The research therefore should be expanded to other industries in order to bring improvements to the model proposed initially.

8. Conclusion

In the field of industrial project management, formal integration of occupational health and safety risk evaluation and follow-up has been found inadequate, indeed absent in some cases. Attributable primarily to inadequate knowledge of OHS in the organization and among project team members, this deficiency has a direct impact on the safety and reliability of industrial processes. In spite of the high degree of risk and uncertainty inherent in several types of industrial projects, the number of studies on systematic risk management remains small.

This article proposes conceptual and methodological approaches designed to orient future research focused on integrating OHS into industrial project risk management. A multi-disciplinary approach capable of considering all imaginable scenarios that put human wellbeing and environmental integrity in harm’s way in complex industrial situations is envisaged.

In spite of its limitations, the proposed approach has been used to solve the problem of OHS integration in the cases of two mining projects in Québec. Thanks to an action research intervention, OHS was taken into consideration in all operations of the two mining companies involved. It thus now appears possible to evaluate simultaneously practically all project risks and thus avoid neglecting possible threats to projects.