Thin-Section Petrography in the Use of Ancient Ceramic Studies

Abstract

1. Introduction

2. Materials Sampled, Methods and Implementations

2.1. Archaeological Ceramics

2.2. History of Research

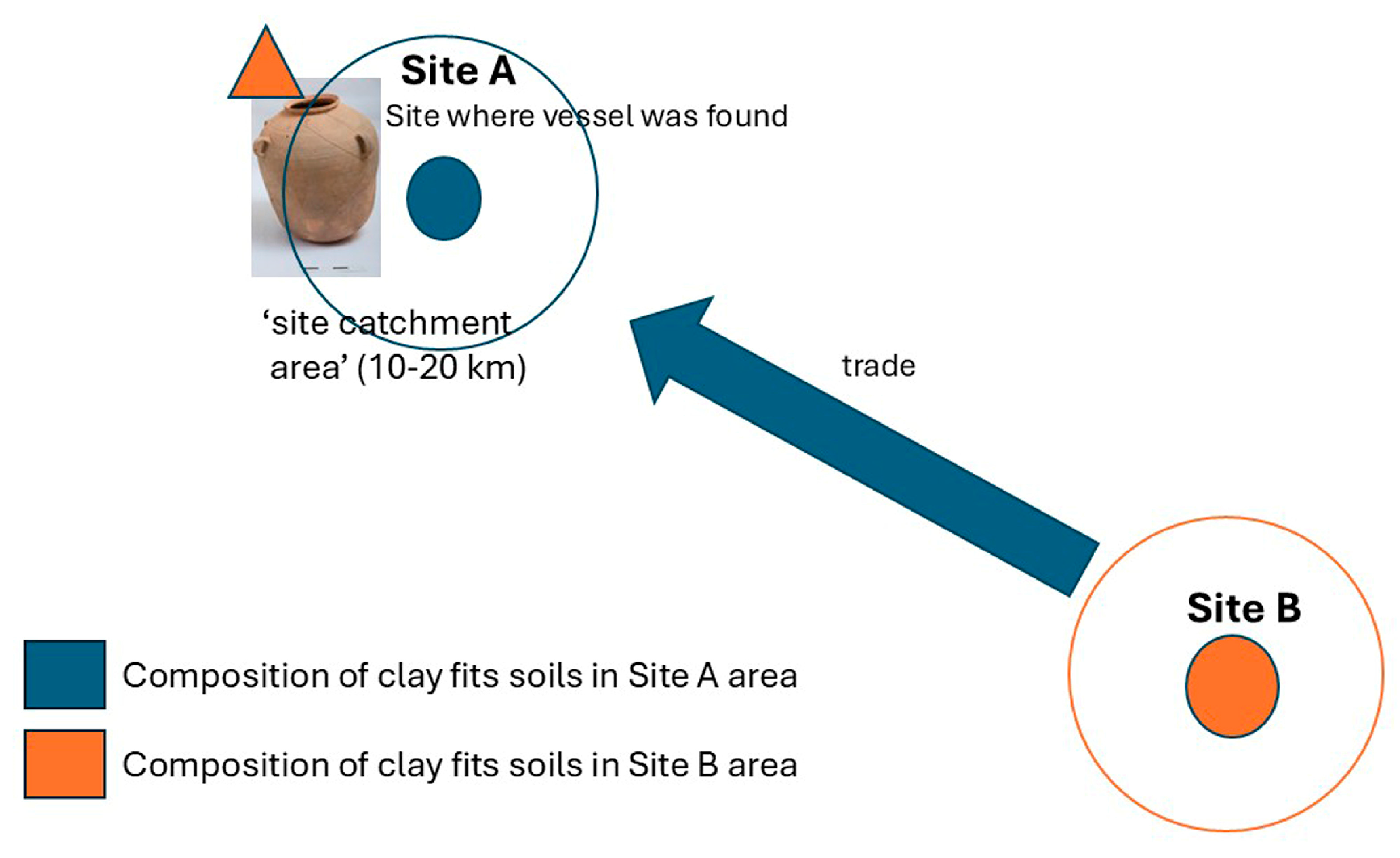

2.3. Provenancing

- a.

- Differences within a single vessel or artifact (Sv)

- b.

- Differences within the same clay source (Scs)

- c.

- Difference between clay sources (with possibly two categories: intra-regional Sr, and inter-regional Sir). A clear detection of clay sources would be when Sir > Sr >> Scs >> Sv.

2.4. Reconstruction of Ancient Potters’ Technology

3. Selected Case Studies

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Quinn, P.S. Ceramic Petrography: The Interpretation of Archaeological Pottery and Related Artifacts in Thin Section; Archaeopress: Oxford, UK, 2013. [Google Scholar]

- Garfinkel, Y. Neolithic and Chalcolithic Pottery of the Southern Levant; Qedem 39; Hebrew University: Jerusalem, Israel, 1999. [Google Scholar]

- Vandiver, P.B.; Soffer, O.; Klima, B.; Svoboda, J. The origins of ceramic technology at Dolni Věstonice, Czechoslovakia. Science 1989, 246, 1002–1008. [Google Scholar] [CrossRef]

- Arnold, D.E. Ceramic Theory and Cultural Process; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Rice, P.M. Pottery Analysis: A Sourcebook; University of Chicago Press: Chicago, IL, USA, 1987. [Google Scholar]

- Goren, Y.; Finkelstein, I.; Na’aman, N. Inscribed in Clay: Provenance Study of the Amarna Tablets and Other Ancient Near Eastern Texts; Monograph Series 23 (Emery and Claire Yass Publications in Archaeology); Tel Aviv University: Tel Aviv, Israel, 2004. [Google Scholar]

- Nodarou, E.; Frederick, C.; Hein, A. Another (Mud)Brick in the Wall: Scientifiic Analysis of Bronze Age Earthen Construction Materials from East Crete. J. Archaeol. Sci. 2008, 35, 2997–3015. [Google Scholar] [CrossRef]

- Evely, D.; Hein, A.; Nodarou, E. Crucibles from Palaikastro, East Crete: Insights into Metallurgical Technology in the Aegean Late Bronze Age. J. Archaeol. Sci. 2012, 39, 1821–1836. [Google Scholar] [CrossRef]

- Quinn, P.S. Thin Section Petrography, Geochemistry and Scanning Electron Microscopy of Archaeological Ceramics; Archaeopress: Oxford, UK, 2022. [Google Scholar]

- Fouque, F. Santorin et Ses Eruptions; The Johns Hopkins University Press: Baltimore, MD, USA, 1879. (English translation published 1999). [Google Scholar]

- Shepard, A.O. Rio Grande Glaze Paint Ware: A Study Illustrating the Place of Technological Analysis in Archaeological Research; Publication 526, Contributions to Archaeology 39; Carnegie Institution of Washington: Washington, DC, USA, 1942. [Google Scholar]

- Shepard, A.O. Ceramics for the Archaeologist; Carnegie Institution of Washington: Washington, DC, USA, 1956. [Google Scholar]

- Matson, F.R. (Ed.) Ceramic Ecology: An Approach to the Study of Early Cultures of the Near East. In Ceramics and Man; Aldine Publishing Company: Chicago, IL, USA, 1965; pp. 202–217. [Google Scholar]

- Middleton, A.; Freestone, I. (Eds.) Recent Developments in Ceramic Petrology; Occasional Paper 81; British Museum: London, UK, 1991. [Google Scholar]

- Bishop, R.L.; Rands, R.L.; Holley, G.P. Ceramic Composition Analysis in Archaeological Perspective. Adv. Archaeol. Method Theory 1982, 5, 275–325. [Google Scholar]

- Bennett, W.J., Jr.; Blakely, J.A.; Brinkmann, R.; Vitaliano, C.J. The Provenance Postulate: Thought on the Use of Physical and Chemical Data in the Study of Ceramic Materials. In Analysis and Publication of Ceramics; Blakely, J.A., Bennett, W.J., Eds.; B.A.R. International Series 551; Archaeopress: Oxford, UK, 1989; pp. 31–44. [Google Scholar]

- Poole, A.B.; Sims, I. Concrete Petrography: A Handbook of Investigative Techniques; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Shahack-Gross, R. Herbivorous Livestock Dung: Formation, Taphonomy, Methods for Identification, and Archaeological Significance. J. Archaeol. Sci. 2011, 38, 205–218. [Google Scholar] [CrossRef]

- Whitbread, I.K. A Proposal for the Systematic Description of Thin Sections towards the Study of Ancient Ceramic Technology. In Proceedings of the 25th International Symposium on Archaeometry; Maniatis, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 1989; pp. 127–138. [Google Scholar]

- Whitbread, I.K. Greek Transport Amphorae: A Petrological and Archaeological Study; Fitch Laboratory Occasional Paper 4; British School at Athens: Athens, Greece, 1995. [Google Scholar]

- Quinn, P.S. (Ed.) Interpreting Silent Artefacts: Petrographic Approaches to Archaeological Ceramics; Archaeopress: Oxford, UK, 2009. [Google Scholar]

- Adams, A.E.; MacKenzie, W.S.; Guildford, C. Atlas of Sedimentary Rocks Under the Microscope; Longman: Essex, UK, 1984. [Google Scholar]

- Ben-Shlomo, D.; Bouzaglou, L. The Production of Cooking Pots in Iron Age Judah: A Multi Analytical Technological Study; Ariel University Institute of Archaeology Monograph Series; Ariel University Press: Ariel, Israel, 2025. [Google Scholar]

- Ben-Shlomo, D. The Iron Age Pottery of Jerusalem: A Typological and Technological Study; Ariel University Institute of Archaeology Monograph Series 2; Ariel University Press: Ariel, Israel, 2019. [Google Scholar]

- Roux, V. Ceramic Manufacture: The Chaîne Opératoire Approach. In The Oxford Handbook of Archaeological Ceramic Analysis; Hunt, A., Ed.; Oxford University Press: Oxford, UK, 2017; pp. 101–113. [Google Scholar]

- Skibo, J.M.; Schiffer, M.B.; Kenneth, C.R. Organic-Tempered Pottery: An Experimental Study. Am. Antiq. 1989, 54, 122–146. [Google Scholar] [CrossRef]

- Gauss, W.; Kiriatzi, E. Pottery Production and Supply at Bronze Age Kolonna, Aegina: An Integrated Archaeological and Scientiic Study of a Ceramic Landscape; Verlag der Österreichischen Akademie der Wissenschaften: Vienna, Austria, 2011. [Google Scholar]

- Amicone, S.; Morandi, L.F.; Gur-Arieh, S. ‘Seeing Shit’: Assessing the Visibility of Dung Tempering in Ancient Pottery Using an Experimental Approach. Environ. Archaeol. 2020, 26, 423–438. [Google Scholar] [CrossRef]

- Martin, M.A.S.; Eliyahu-Behar, A.; Anenburg, M.; Goren, Y.; Finkelstein, I. Iron IIA Slag-Tempered Pottery in the Negev Highlands, Israel. J. Archaeol. Sci. 2013, 40, 3777–3792. [Google Scholar] [CrossRef]

- Shoval, S.; Gaft, M.; Beck, P.; Kirsh, Y. Thermal Behavior of Limestone and Monocrystalline Calcite Tempers during Firing and Their Use in Ancient Vessels. J. Therm. Anal. 1993, 40, 263–273. [Google Scholar] [CrossRef]

- Tite, M.; Kilikoglou, V.; Vekinis, G. Strength, Toughness and Thermal Shock Resistance of Ancient Ceramics, and Their Influence on Technological Choice. Archaeometry 2001, 43, 301–324. [Google Scholar] [CrossRef]

- Whitbread, I.K. The Characterization of Agrillaceous Inclusions in Ceramic Thin Sections. Archaeometry 1986, 28, 79–88. [Google Scholar] [CrossRef]

- Courty, M.A.; Roux, V. Identification of Wheel Throwing on the Basis of Ceramic Surface Features and Microfabrics. J. Archaeol. Sci. 1995, 22, 17–50. [Google Scholar] [CrossRef]

- Matson, F.R. A Study of Temperatures Used in Firing Ancient Mesopotamian Pottery. In Science and Archaeology; Brill, R.H., Ed.; MIT Press: Cambridge, MA, USA, 1971; pp. 65–79. [Google Scholar]

- Mommsen, H.; Kreuser, A.; Weber, J. A Method of Grouping Pottery by Chemical Composition. Archaeometry 1988, 30, 47–57. [Google Scholar] [CrossRef]

- Day, P.M.; Kiriatzi, E.; Tsolakidou, A.; Kilikoglou, V. Group Therapy: A Comparison between Analyses by NAA and Thin Section Petrography of Early Bronze Age Pottery from Central and East Crete. J. Archaeol. Sci. 1999, 26, 1025–1036. [Google Scholar] [CrossRef]

- Miškolciová, L.; Slavíček, K.; Adameková, K.; Všianský, D.; Roupcová, P.; Štulířová, J.; Gebel, H.G.K. Archaeometric Insights into Pre-pottery Neolithic Clay Technologies at Ba`ja, Jordan: Distinguishing Three Types of Clay Objects. Archaeol. Anthropol. Sci. 2025, 17, 159. [Google Scholar] [CrossRef]

- Porat, N. An Egyptian Colony in Southern Palestine during the Late Predynastic/Early Dynastic Period. In Proceedings of the Nile Delta in Transition: 4th–3rd Millennium B.C., Cairo, Egypt, 21–24 October 1990; pp. 433–440. [Google Scholar]

- Greenberg, R.; Porat, N. A Third Millennium Levantine Pottery Production Center: Typology, Petrography, and Provenance of the Metallic Ware of Northern Israel and Adjacent Regions. Bull. Am. Sch. Orient. Res. 1996, 301, 5–24. [Google Scholar] [CrossRef]

- Badreshany, K.; Philip, G.; Kennedy, M. The development of integrated regional economies in the Early Bronze Age Levant: New evidence from ‘Combed Ware’ jars. Levant 2019, 52, 160–196. [Google Scholar] [CrossRef]

- Ben-Shlomo, D.; Nodarou, E.; Rutter, J.B. Transport Stirrup Jars from the Southern Levant: New Light on Commodity Exchange in the East Mediterranean. Am. J. Archaeol. 2011, 115, 327–351. [Google Scholar] [CrossRef]

- Lis, B. Aeginetan Cooking Pottery in Central Greece and Its Wider Perspective. In Archaeological Work in Thessaly and Mainland Greece 3; Mazarakis-Ainian, A., Ed.; Ministry of Culture and Sports: Athens, Greece, 2012; pp. 1203–1211. [Google Scholar]

- Gauss, W.; Klebinder-Gauss, G.; Kiriatzi, E.; Pentedeka, A.; Georgakopoulou, M. Aegina: An Important Centre of Production of Cooking Pottery from the Prehistoric to the Historic Era. In Ceramics, Cuisine and Culture: The Archaeology and Science of Kitchen Pottery in the Ancient Mediterranean World; Spataro, M., Villing, A., Eds.; Oxbow: Oxford, UK, 2015; pp. 65–74. [Google Scholar]

- Ben-Shlomo, D.; Bouzaglou, L.; Mommsen, H.; Sterba, J.H. Production Centers of Cooking Pots in Iron Age Judah. Archaeometry 2023, 65, 84–104. [Google Scholar] [CrossRef]

- Hein, A.; Müller, N.S.; Kilikoglou, V. Great Pots on Fire: Thermal Properties of Archaeological Cooking Ware. In Vessels Inside and Outside: Proceedings of the 9th European Meeting on Ancient Ceramics, EMAC 2007; Biró, K.T., Szilágyi, V., Kreiter, A., Eds.; Hungarian National Museum: Budapest, Hungary, 2009; pp. 15–19. [Google Scholar]

- Shoval, S.; Gaft, M.; Beck, P.; Kirsh, Y.; Yadin, E. The Preference of Monocrystalline Calcite Tempers over Limestone Ones in the Preparation of Iron Age Cooking Pots. In Israel Geological Society Annual Meeting; Polishook, B., Ed.; Israel Geological Society: Jerusalem, Israel, 1992; p. 137. [Google Scholar]

- Gabrieli, R.S.; Ben-Shlomo, D.; Walker, B.J. Production and Distribution of Hand-Made Geometric-Painted (HMGP) and Plain Hand-Made Wares of the Mamluk Period: A Case Study from Northern Israel, Jerusalem and Tall Hisban. J. Islam. Archaeol. 2014, 1, 193–229. [Google Scholar]

- Ben-Shlomo, D. Compositional Analysis of Cultic Clay Objects from the Iron Age Southern Levant. Religions 2025, 16, 661. [Google Scholar] [CrossRef]

- Quinn, P.S.; Stringer, L.; Rout, D.; Alexander, T.; Armstrong, A.; Olmstead, S. Petrodatabase: An On-line Database for Ceramic Petrography. J. Archaeol. Sci. 2011, 38, 2491–2496. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben-Shlomo, D. Thin-Section Petrography in the Use of Ancient Ceramic Studies. Minerals 2025, 15, 984. https://doi.org/10.3390/min15090984

Ben-Shlomo D. Thin-Section Petrography in the Use of Ancient Ceramic Studies. Minerals. 2025; 15(9):984. https://doi.org/10.3390/min15090984

Chicago/Turabian StyleBen-Shlomo, David. 2025. "Thin-Section Petrography in the Use of Ancient Ceramic Studies" Minerals 15, no. 9: 984. https://doi.org/10.3390/min15090984

APA StyleBen-Shlomo, D. (2025). Thin-Section Petrography in the Use of Ancient Ceramic Studies. Minerals, 15(9), 984. https://doi.org/10.3390/min15090984