Study on Grinding Optimization of Cassiterite Polymetallic Sulfide Ore Based on Single-Factor Test Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Grinding Technical Efficiency

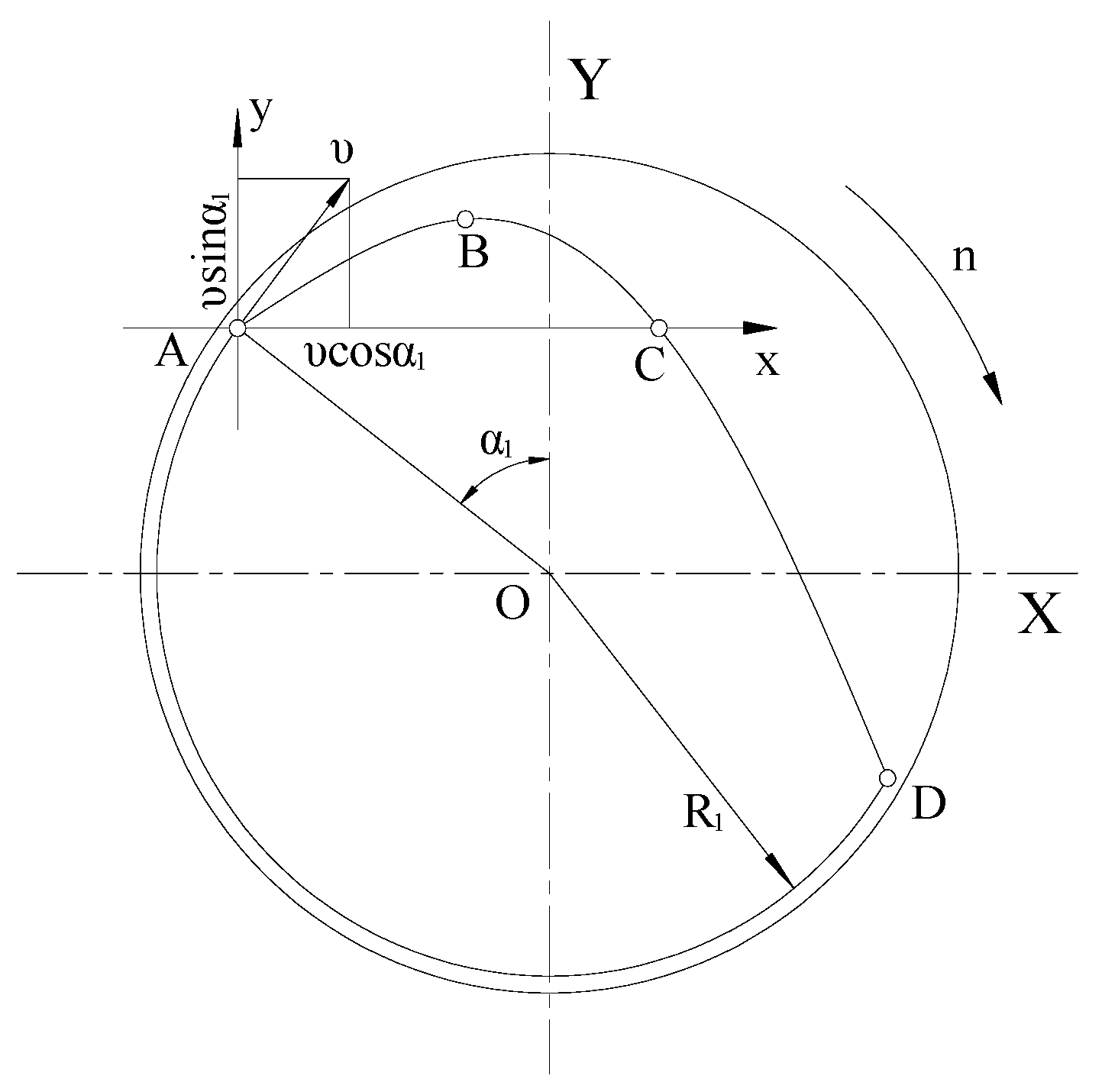

2.2.2. Mill Rotational Rate

2.2.3. Grinding Test

3. Results and Discussion

3.1. Effect of Grinding Time

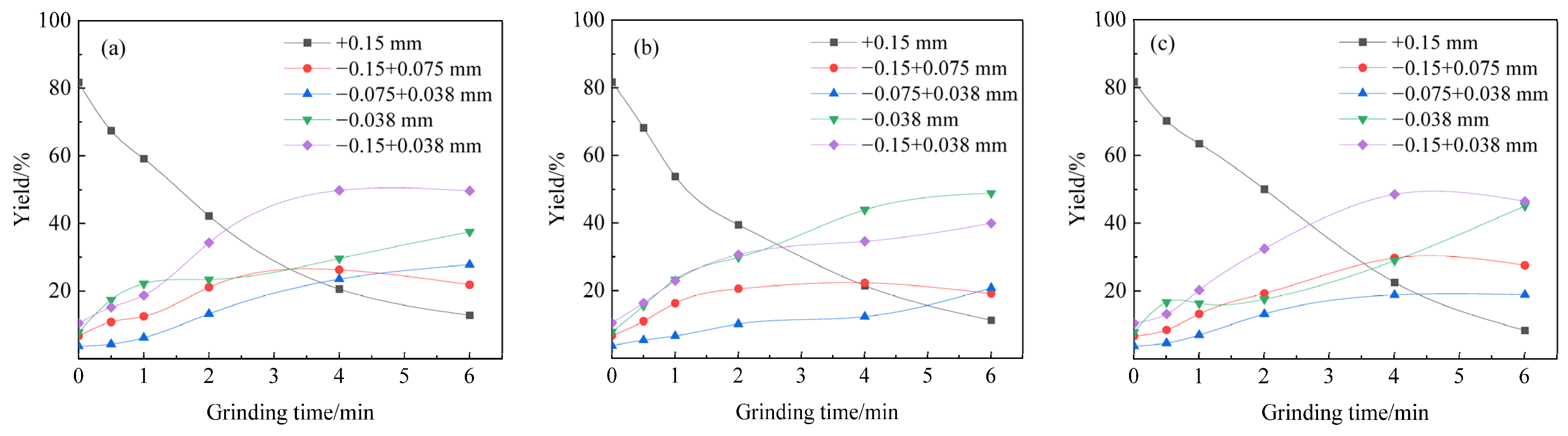

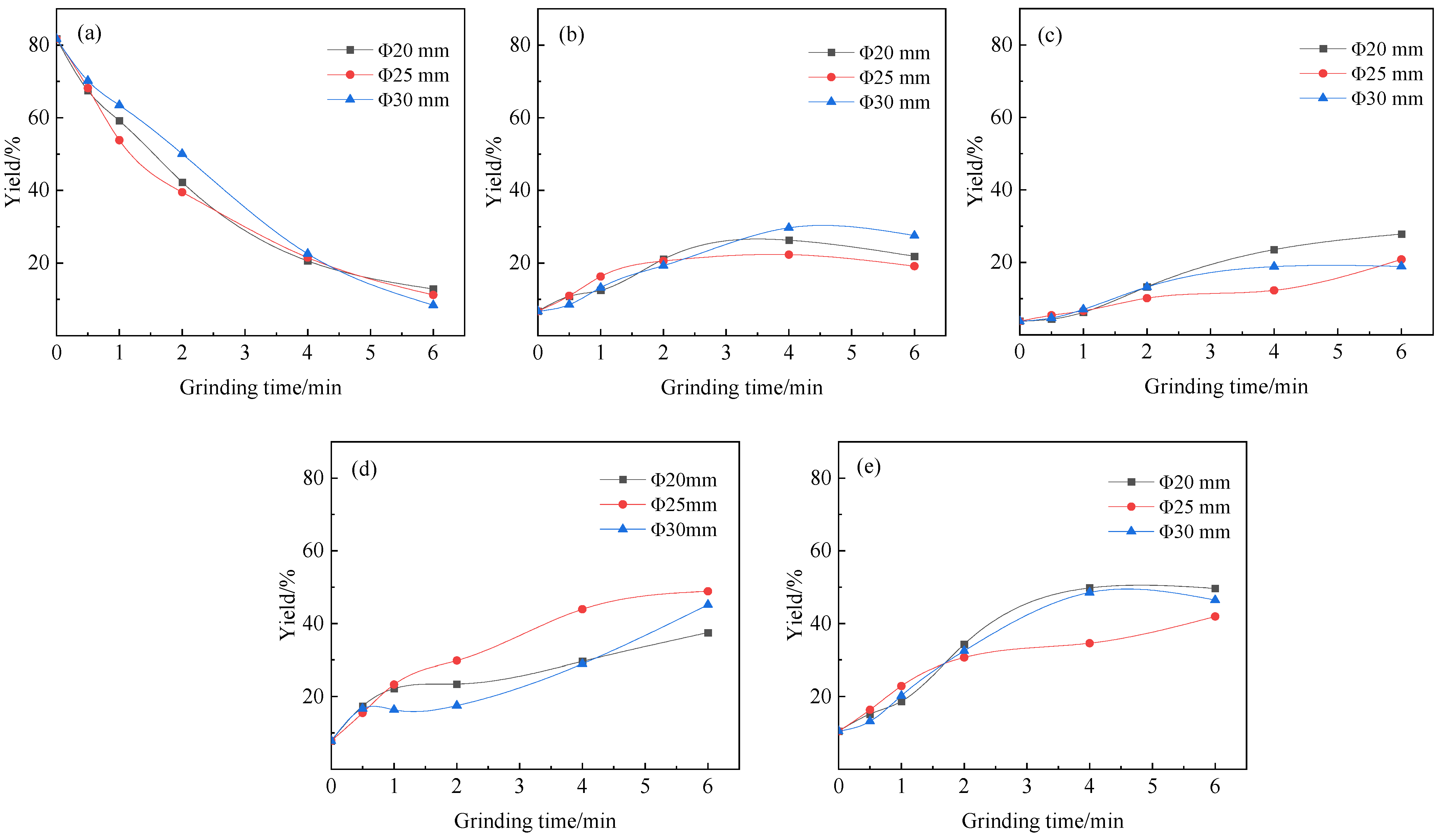

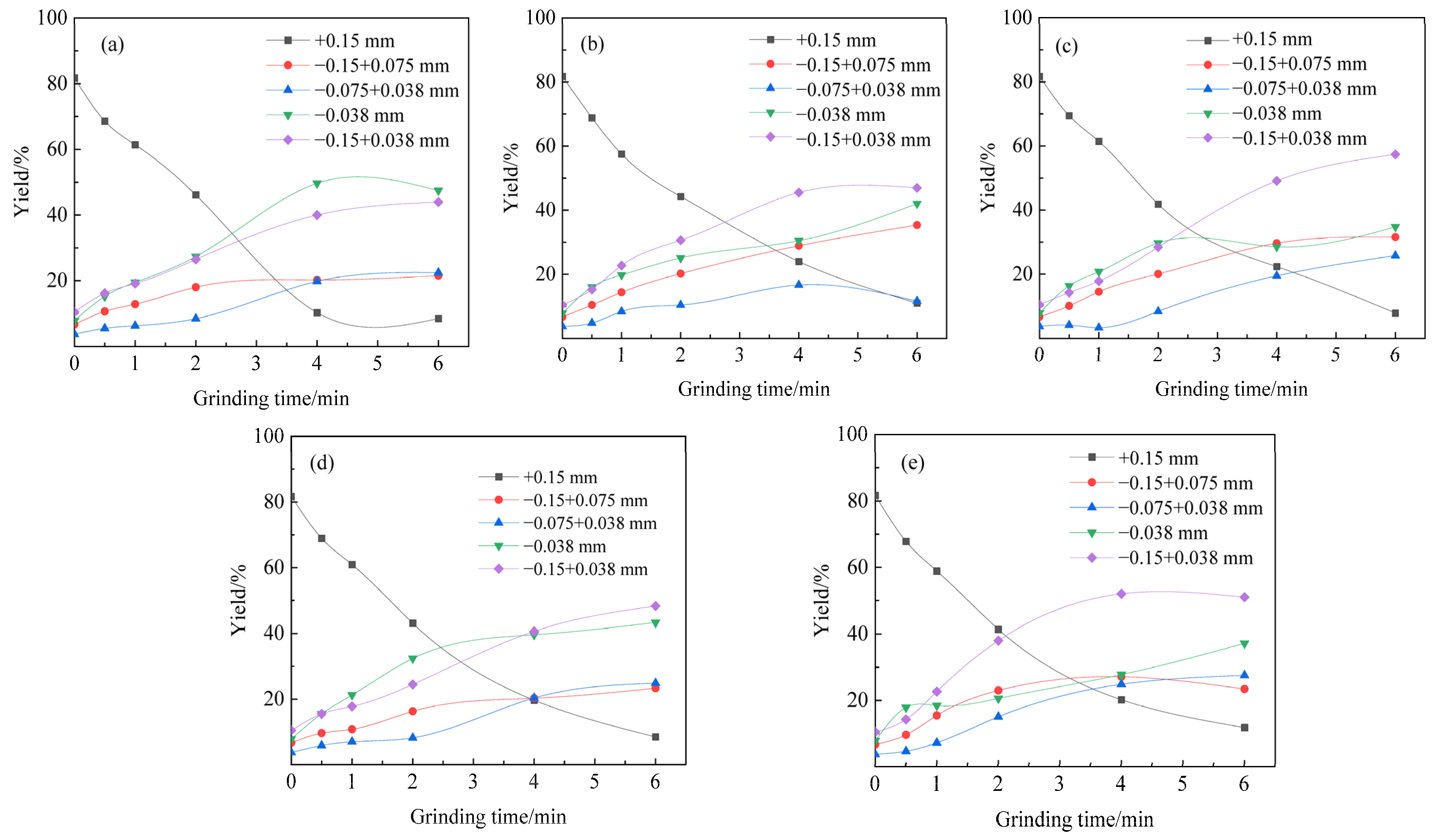

3.1.1. Effect of Grinding Time Under the Condition of Single Media

Effect of Grinding Time on the Particle Size Distribution of Grinding Products

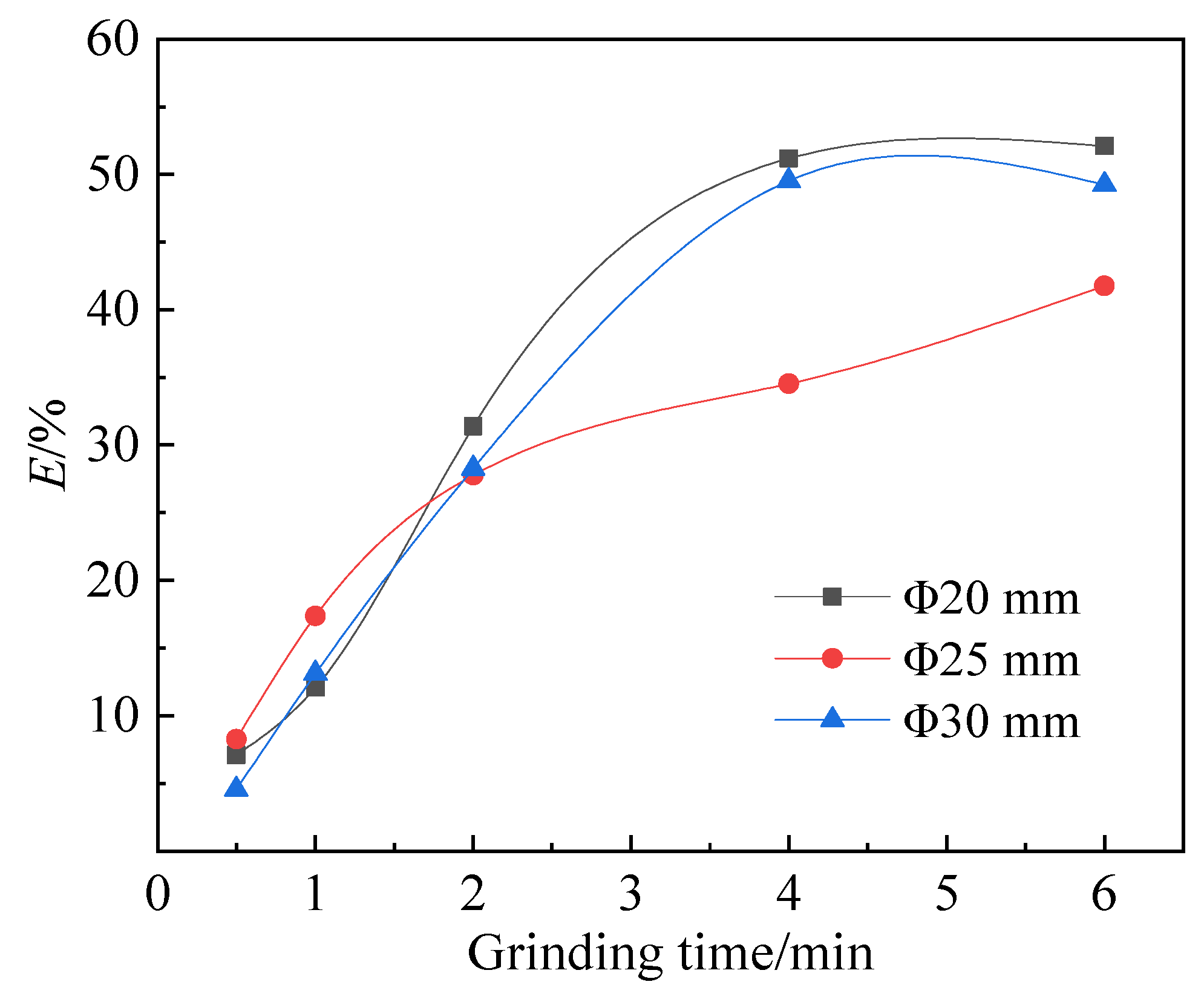

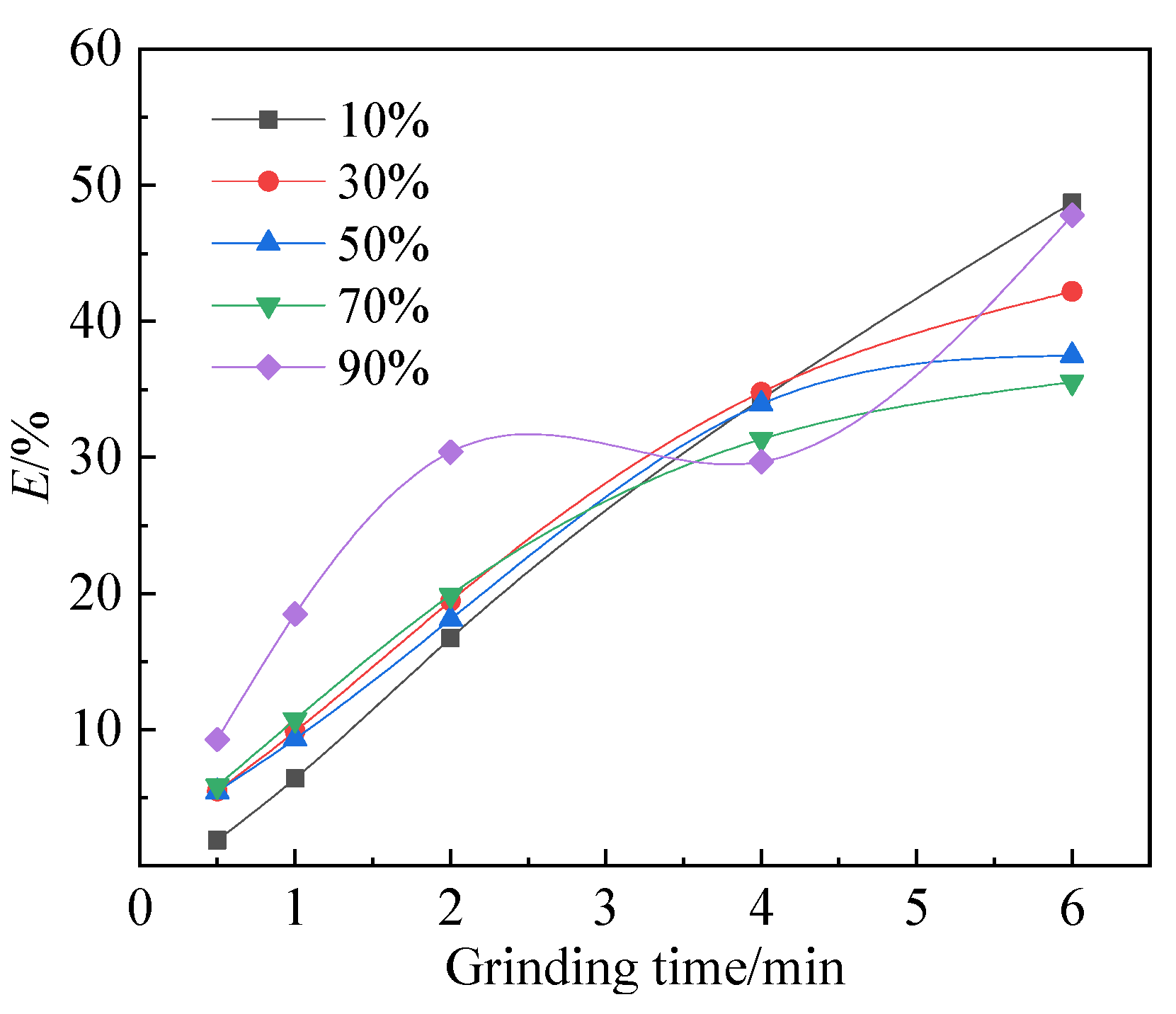

Effect of Grinding Time on Grinding Technical Efficiency

3.1.2. Effect of Grinding Time Under Different Combinations of Media

Effect of Grinding Time on the Particle Size Composition of Grinding Products

- (1)

- Grinding test results of steel ball combination of Φ20 mm and Φ25 mm

- (2)

- Grinding test results of the steel ball combination of Φ20 mm and Φ30 mm

Effect of Grinding Time on Grinding Technical Efficiency

- (1)

- Grinding test results of steel balls combinations of Φ20 mm and Φ25 mm

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

3.2. Effect of Mill Rotational Rate

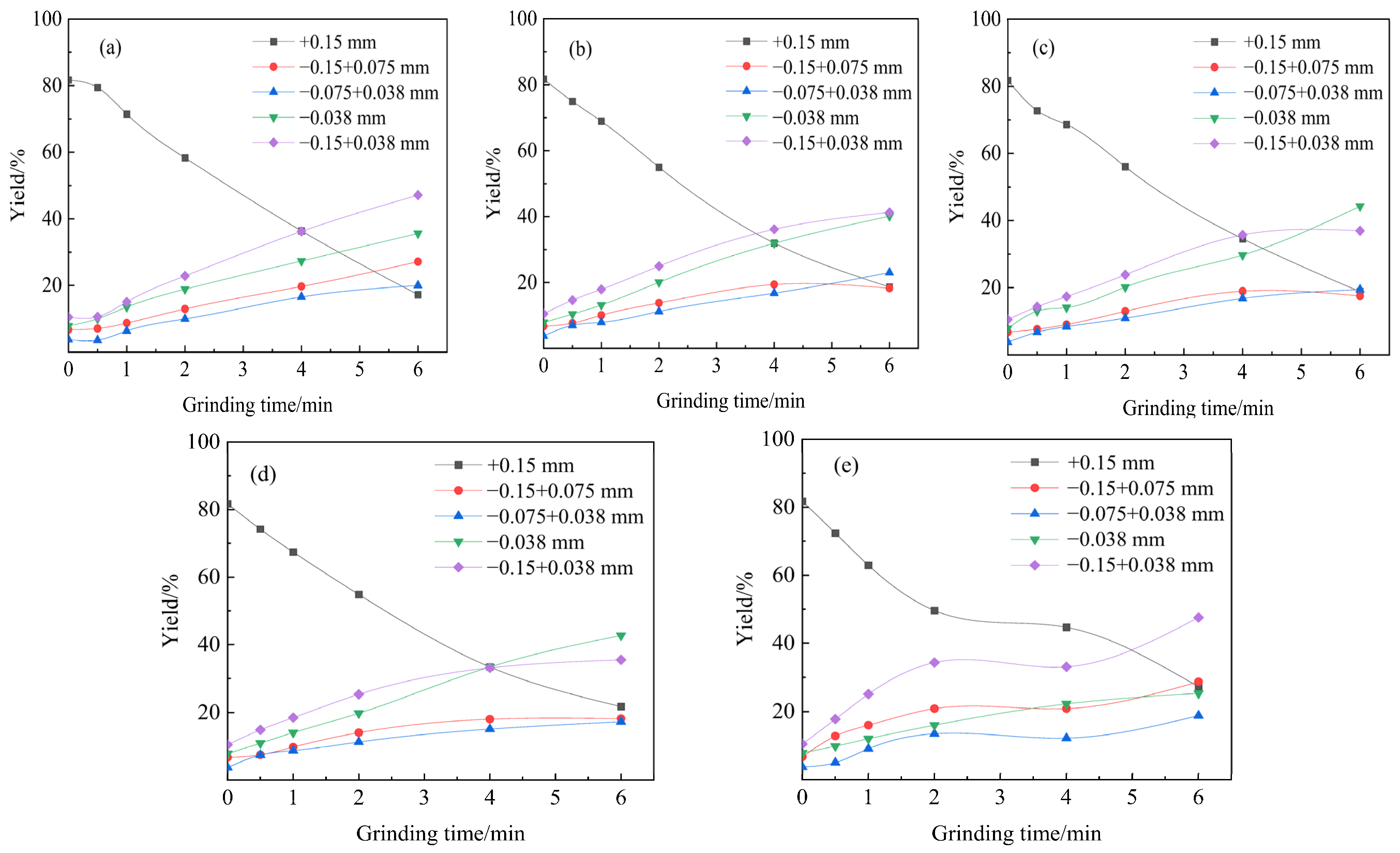

3.2.1. Effect of Mill Rotational Rate Under the Single Media

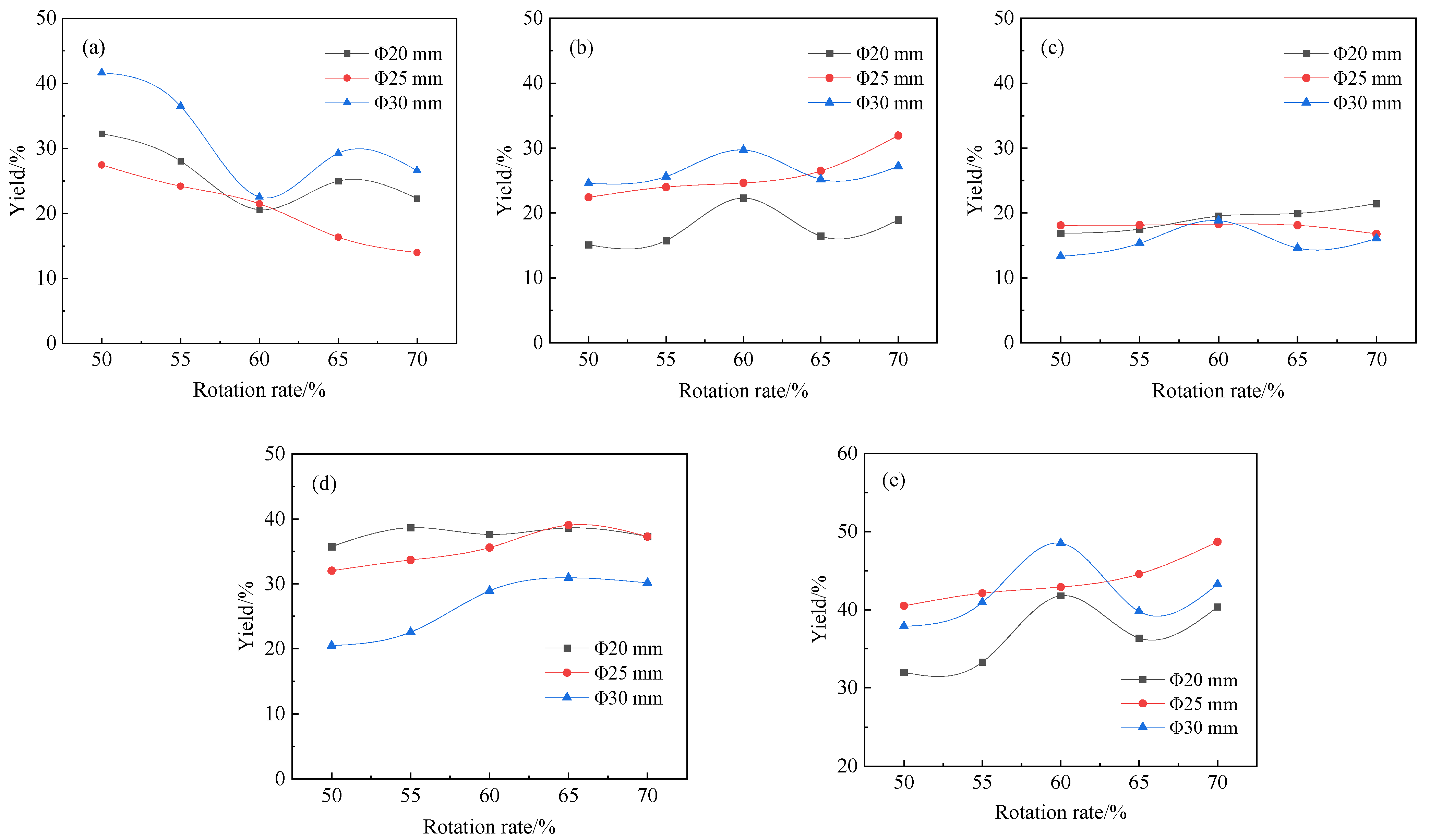

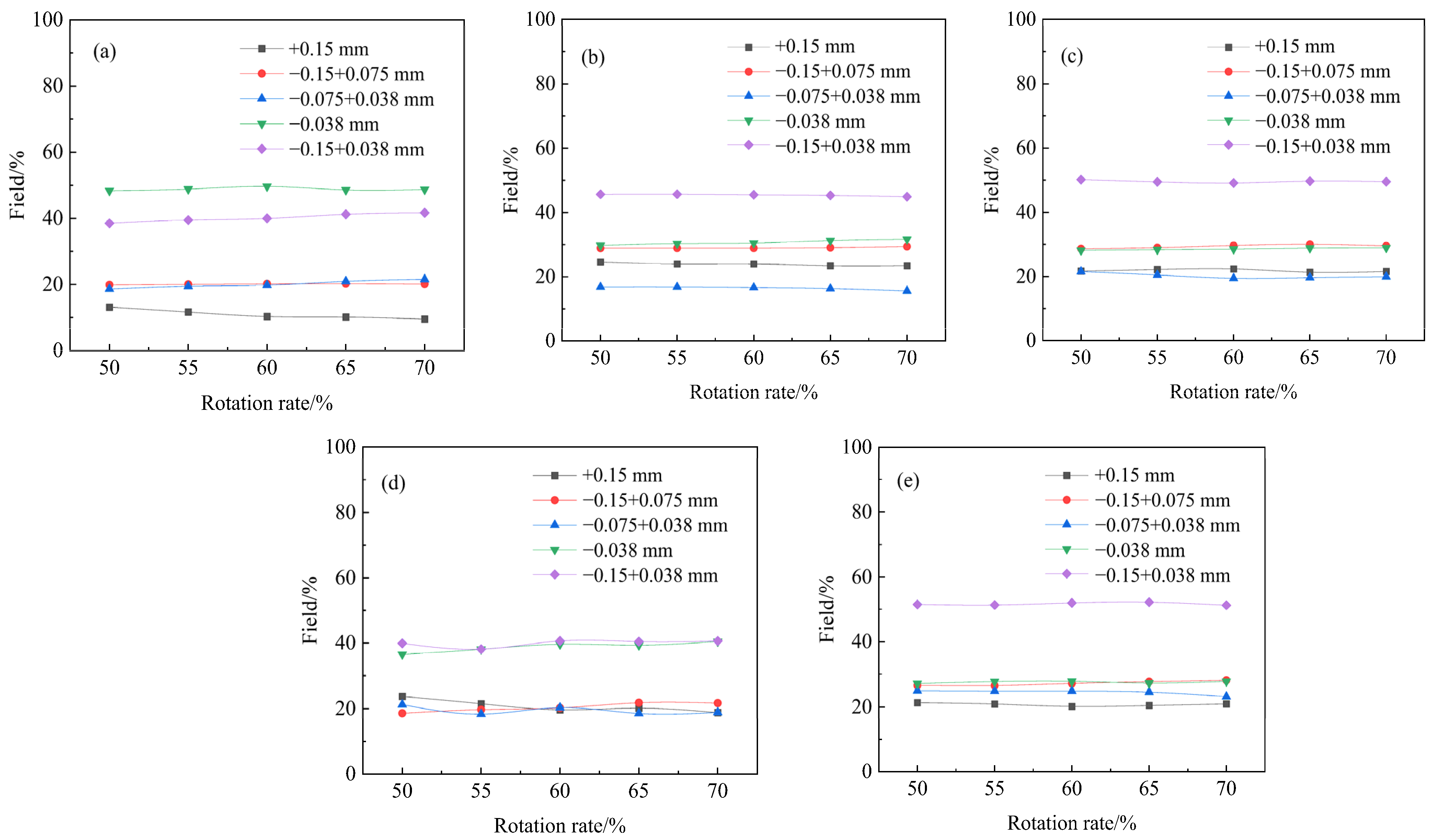

Effect of Mill Rotational Rate on the Particle Size Composition of Grinding Products

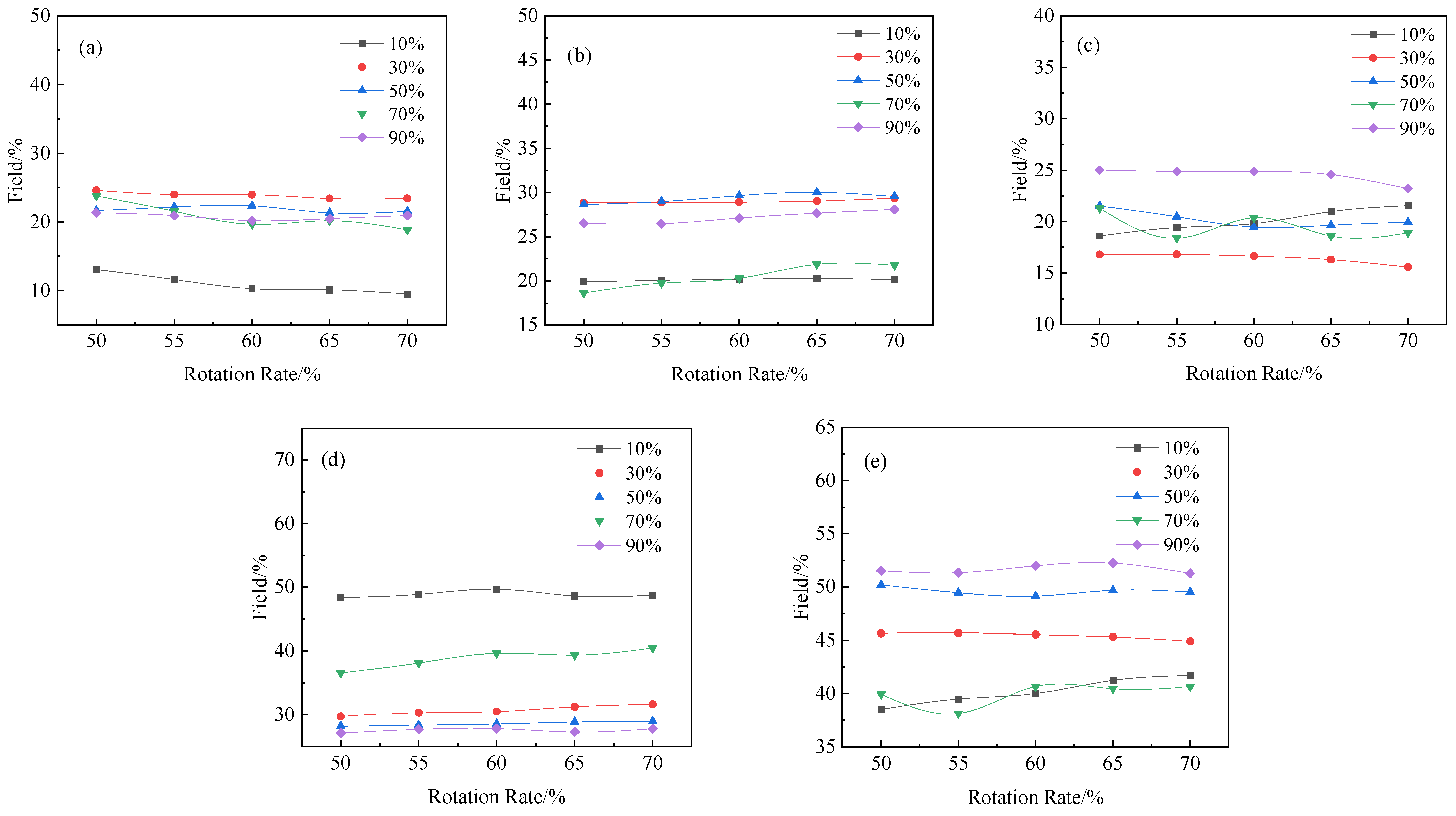

Effect of Mill Rotational Rate on Grinding Technical Efficiency

3.2.2. Effect of Mill Rotational Rate Under the Different Media Combinations

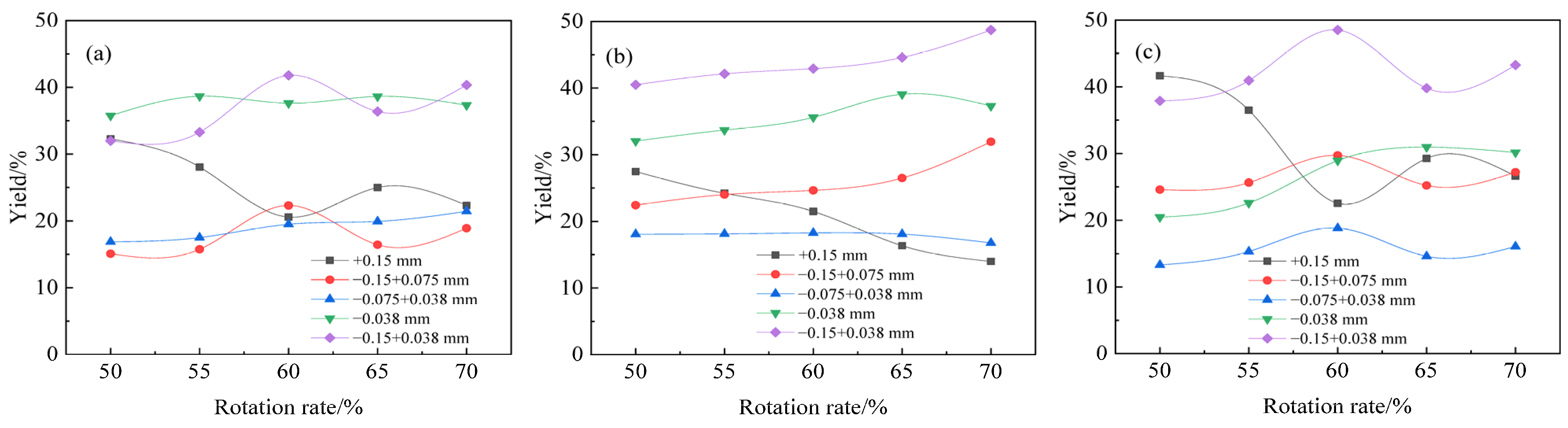

Effect of Mill Rotational Rate on the Particle Size Composition of Grinding Products

- (1)

- Grinding test results of steel ball combinations of Φ20 mm and Φ25 mm

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

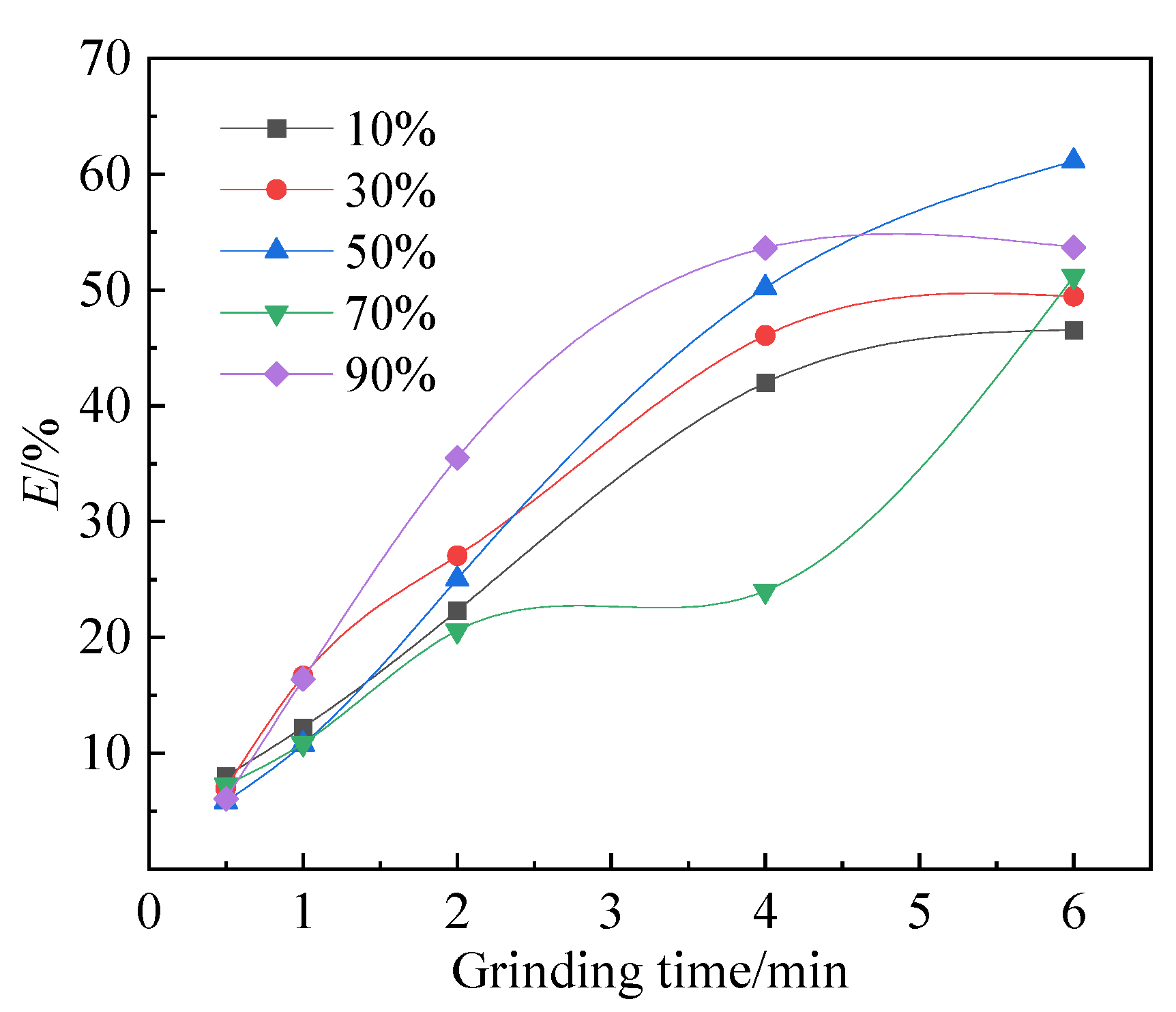

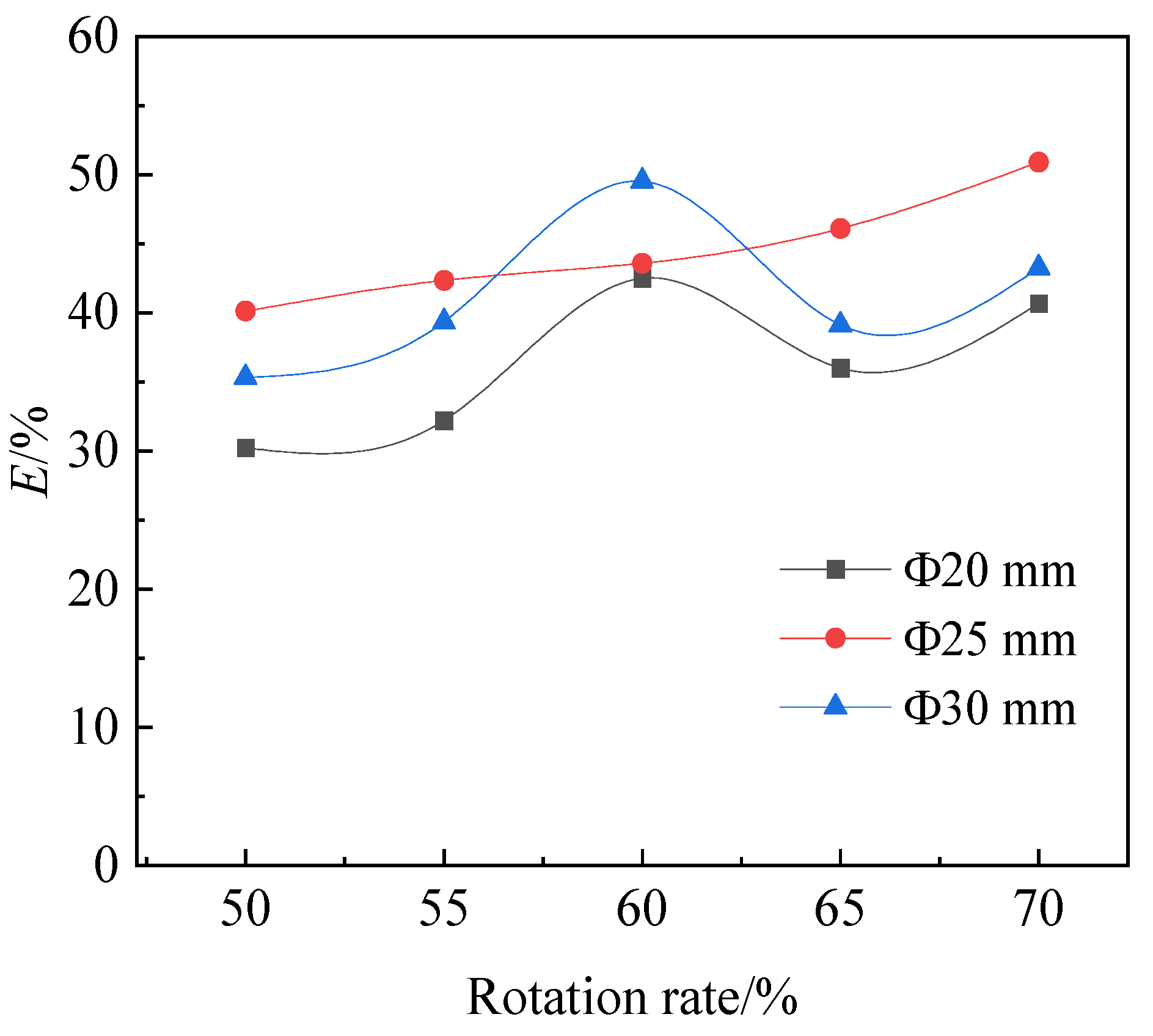

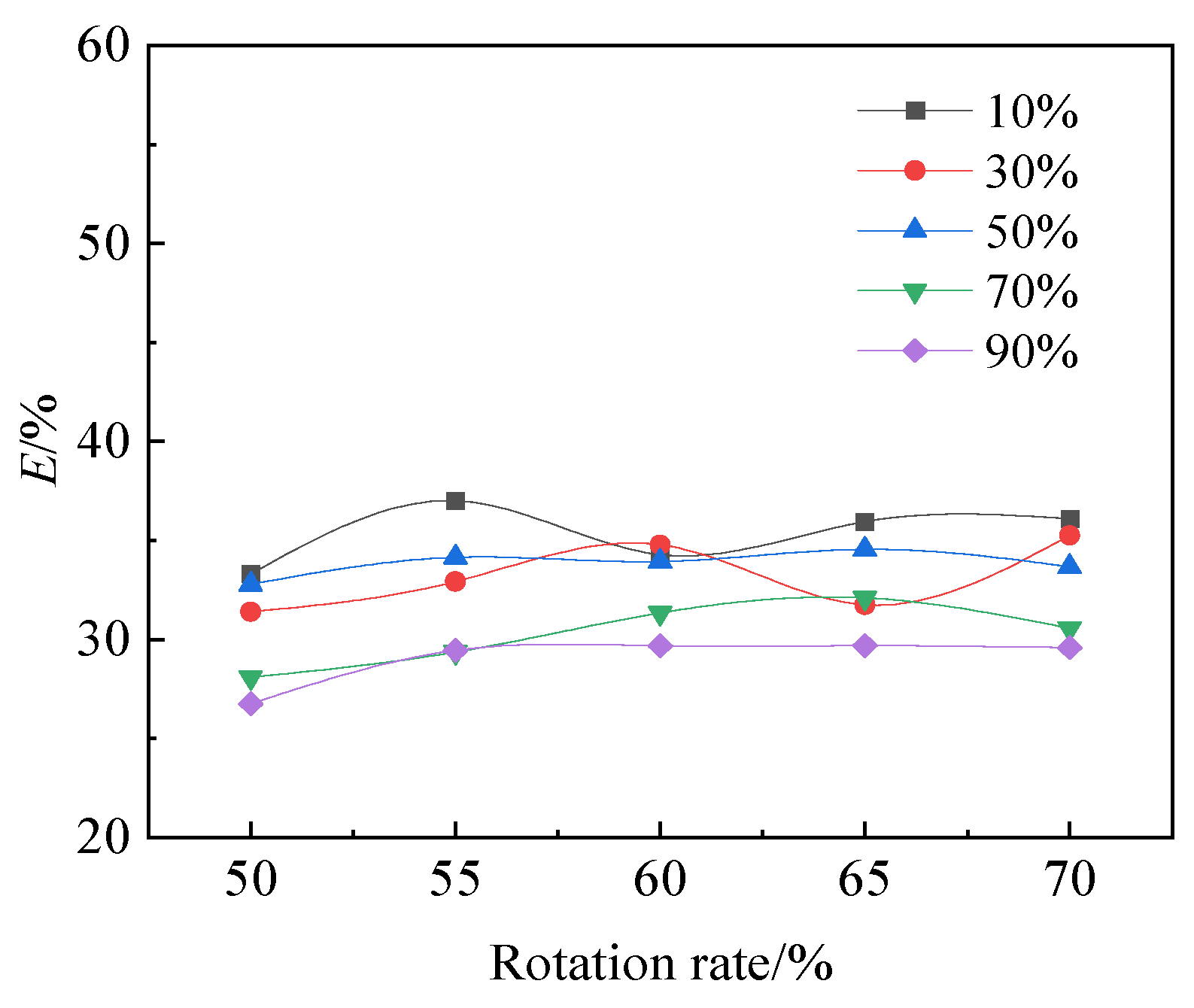

Effect of Mill Rotational Rate on the Grinding Technical Efficiency

- (1)

- Based on the grinding test data in Section 3.2.2 The effect of mill rotational rate on the particle size composition of grinding products, the corresponding grinding technical efficiency can be calculated by using Equation (2), and the results are shown in Figure 19.

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

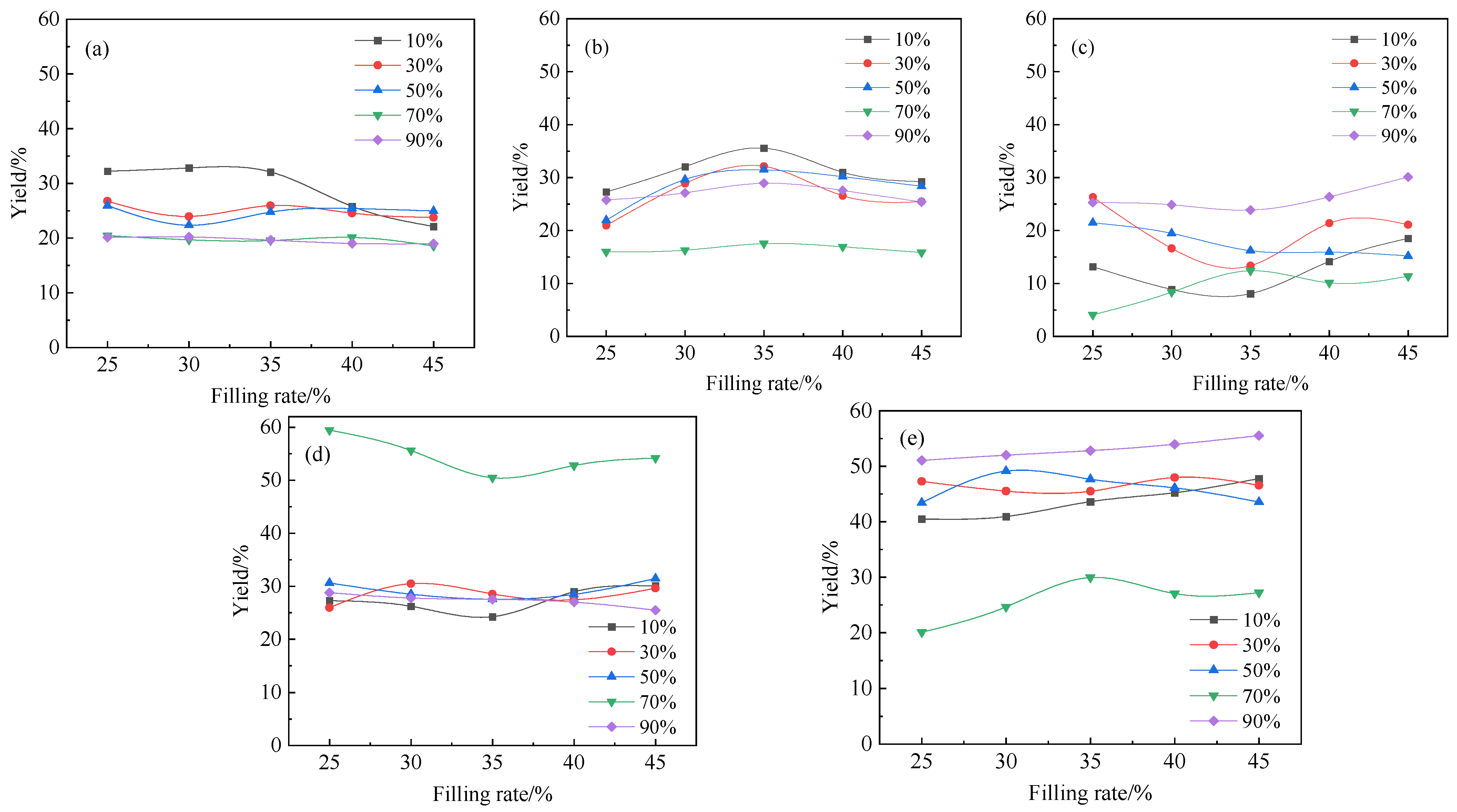

3.3. Effect of Mill Filling Rate

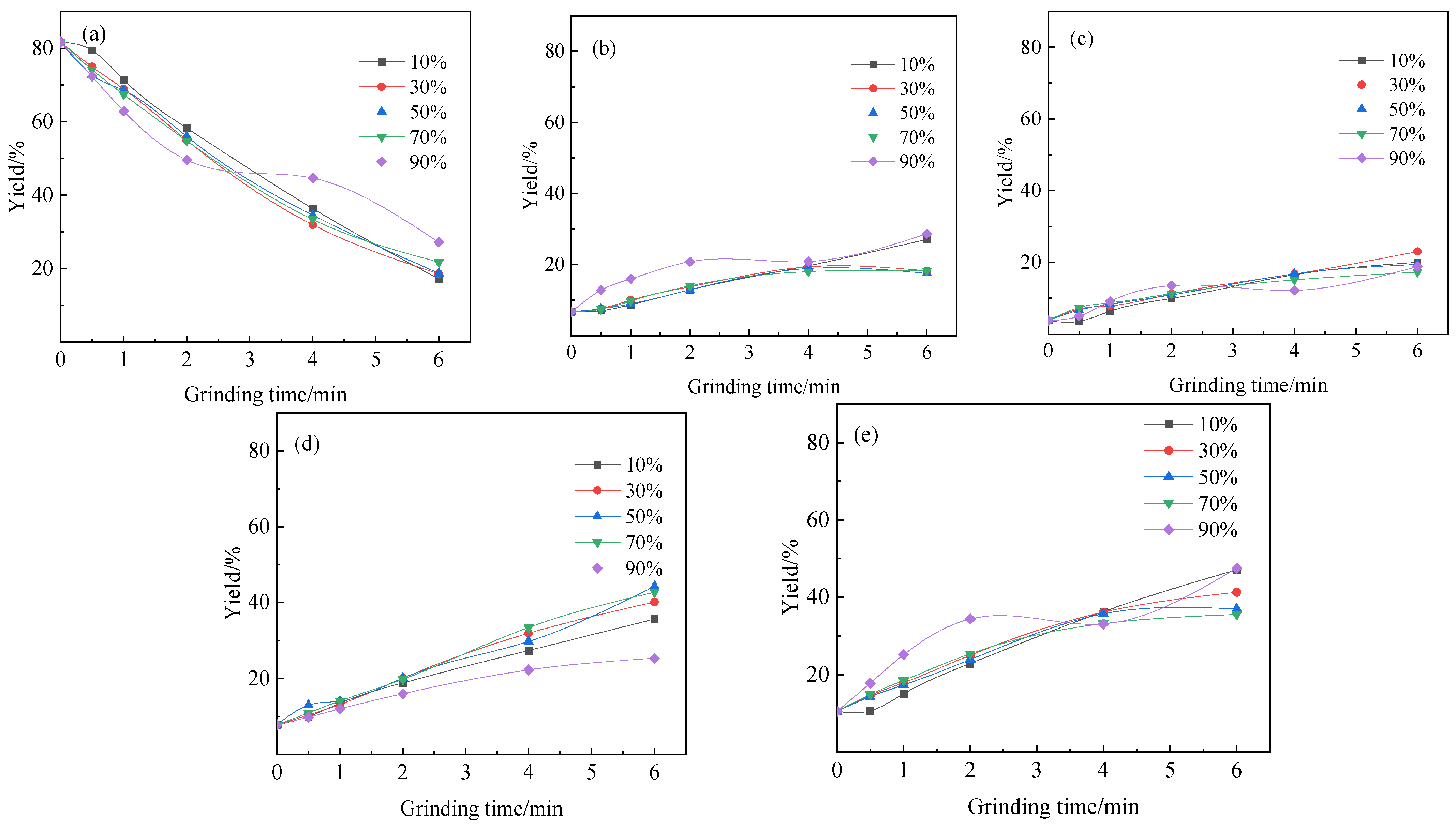

3.3.1. Effect of Mill Filling Rates Under the Single Media

Effect of Mill Filling Rate on the Particle Size Composition of Grinding Products

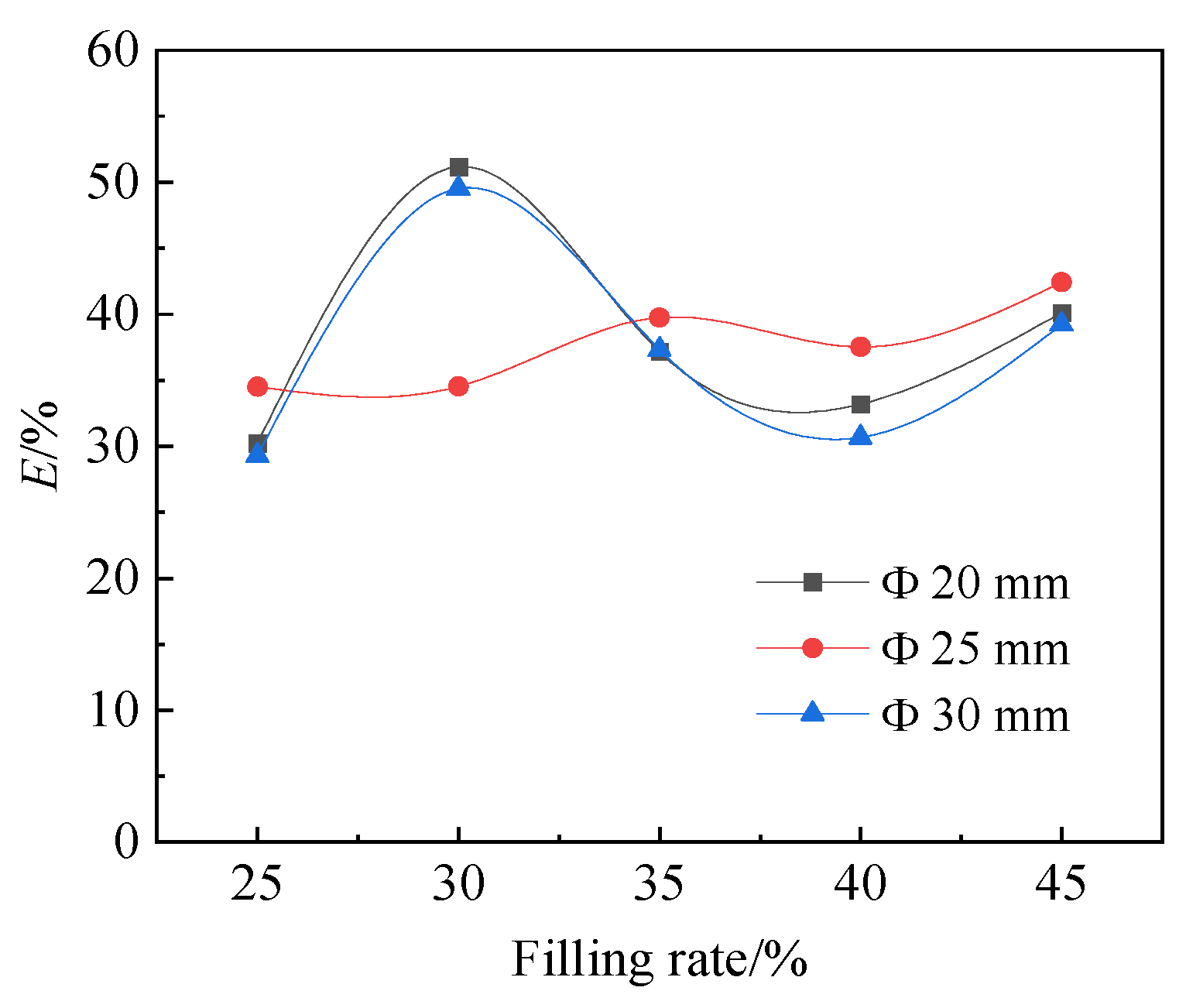

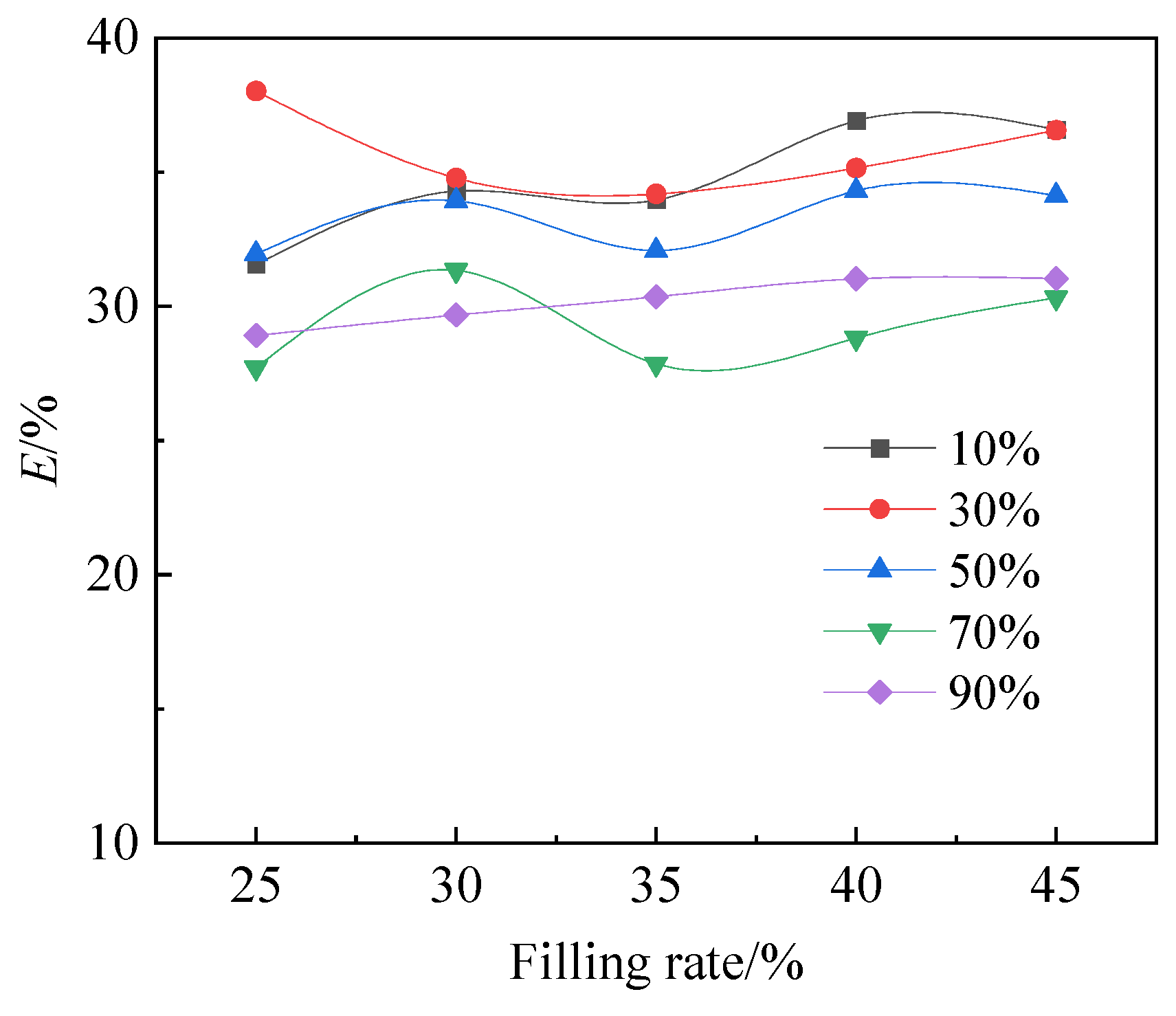

Effect of Mill Filling Rate on the Grinding Technical Efficiency

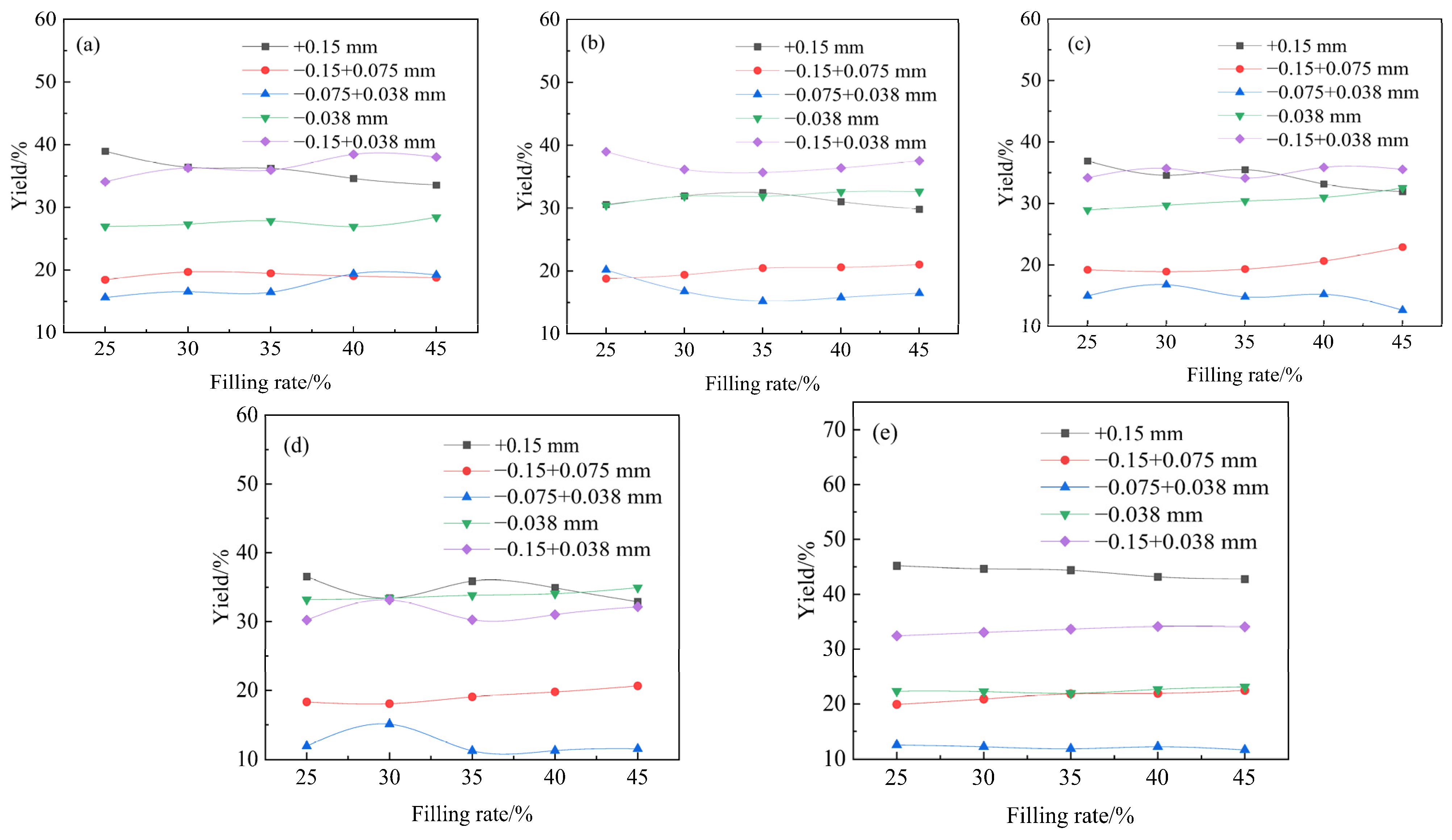

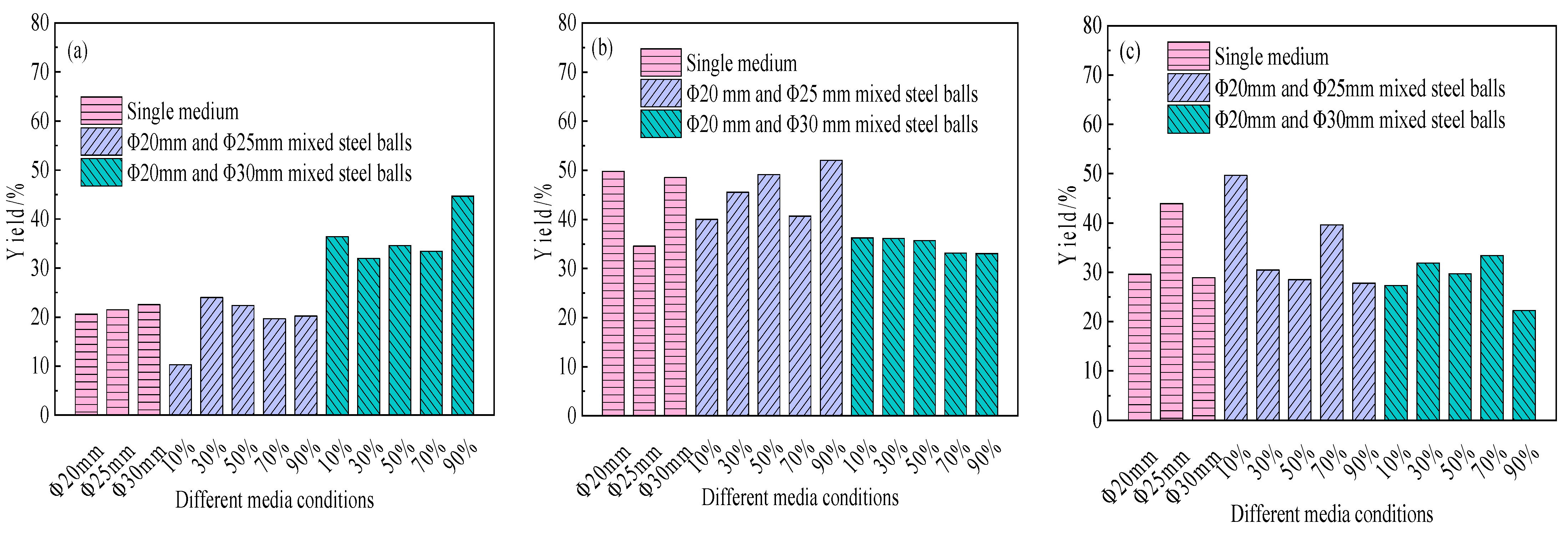

3.3.2. Effect of Mill Filling Rates on the Different Media Combinations

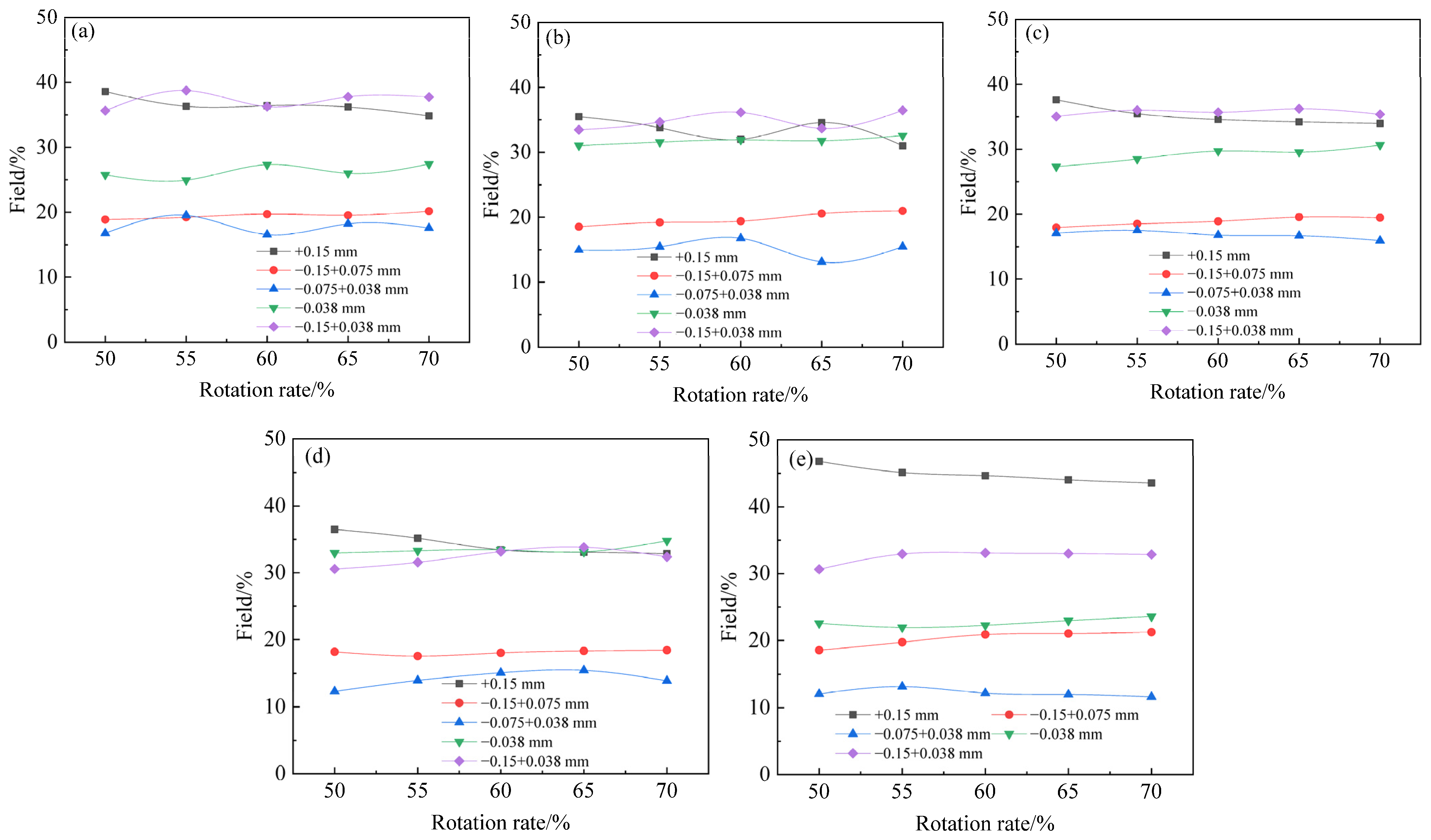

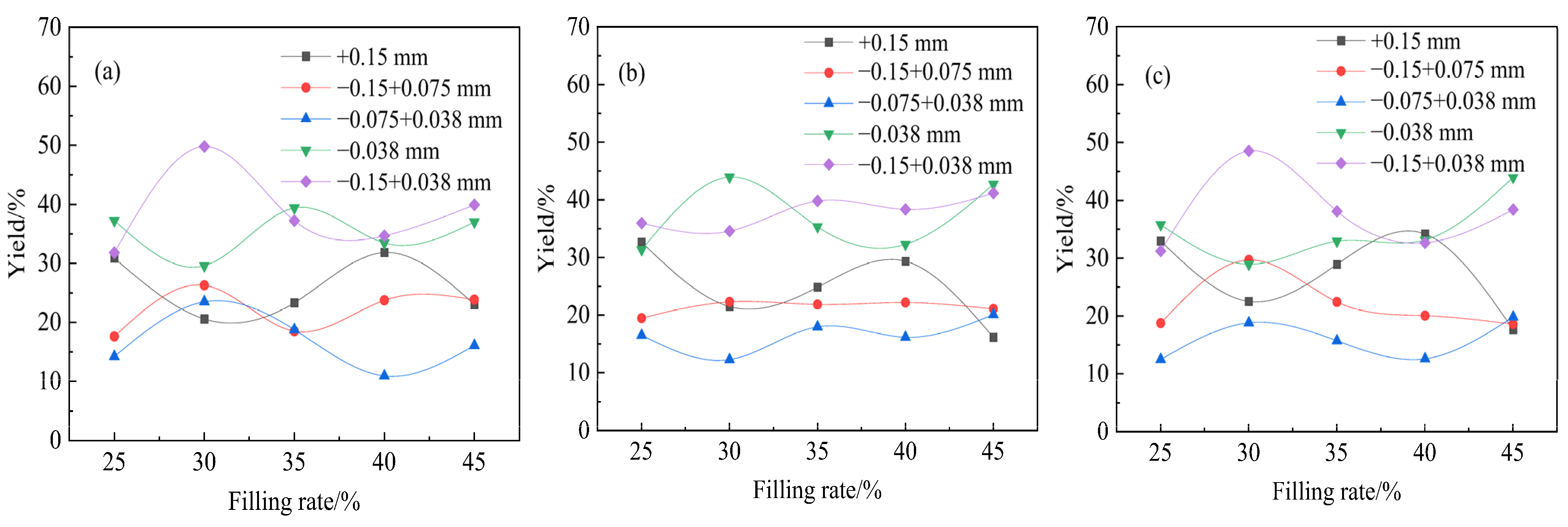

Effect of Mill Filling Rate on the Particle Size Composition of Grinding Products

- (1)

- Grinding test results of steel ball combinations of Φ20 mm and Φ25 mm

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

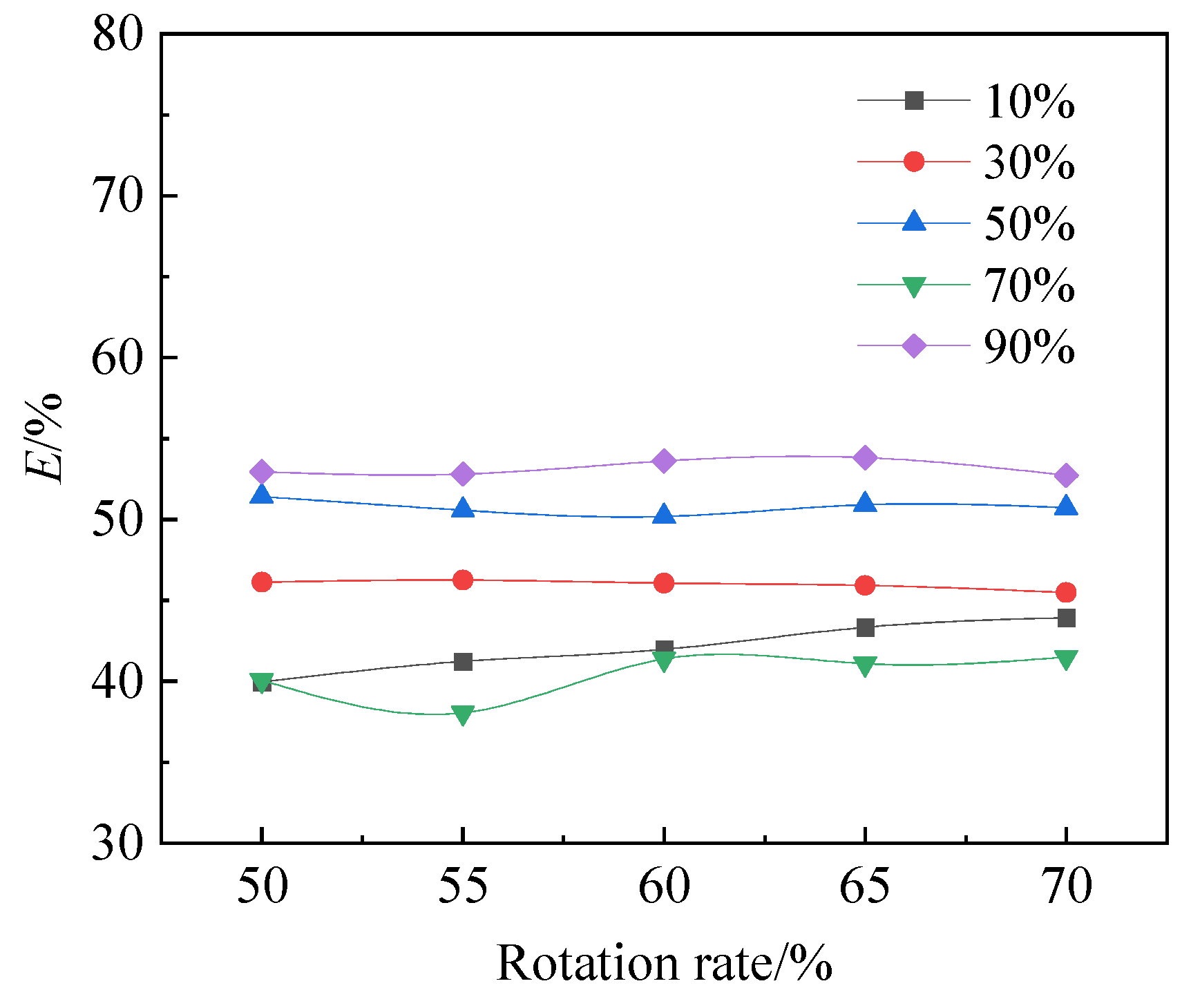

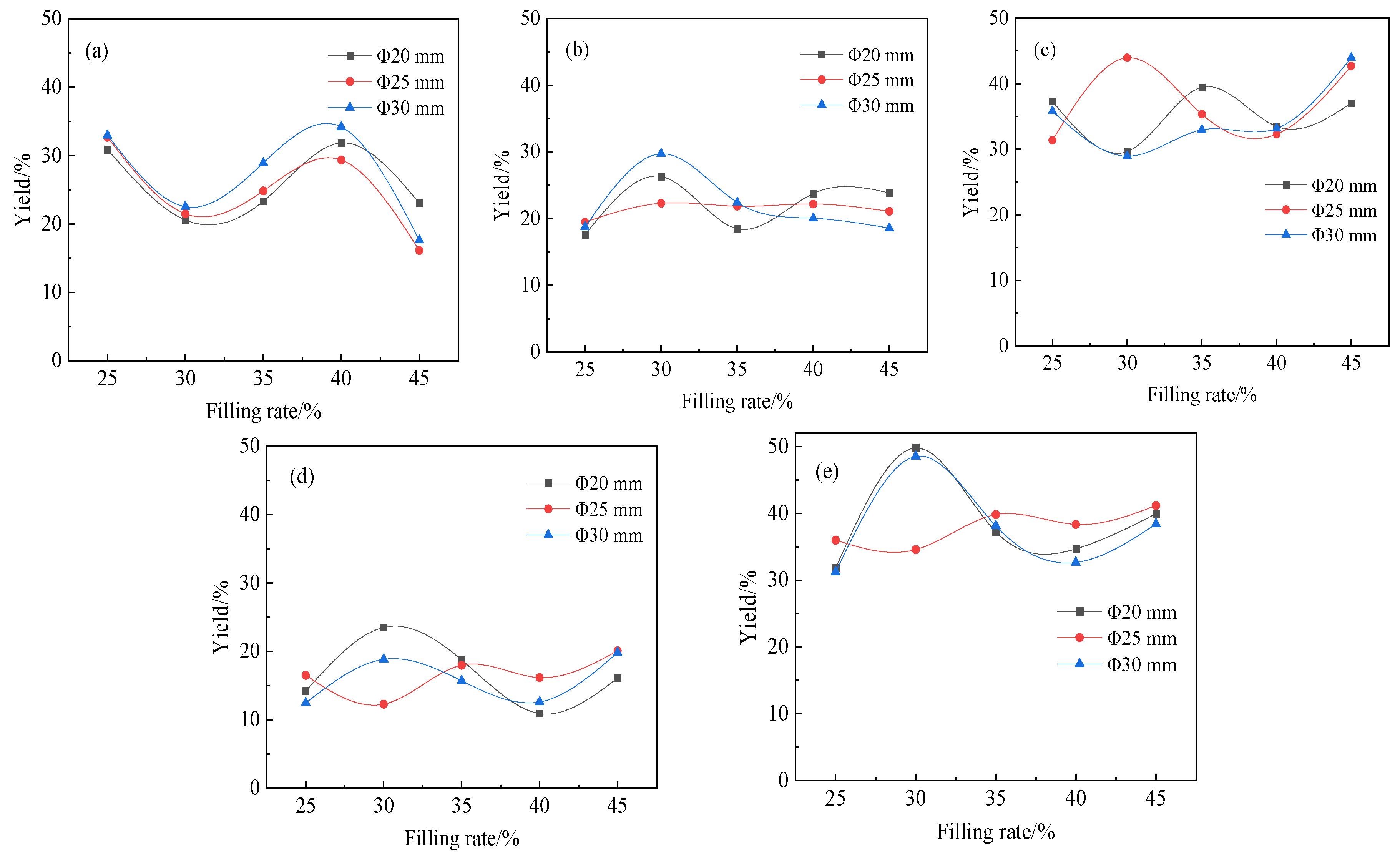

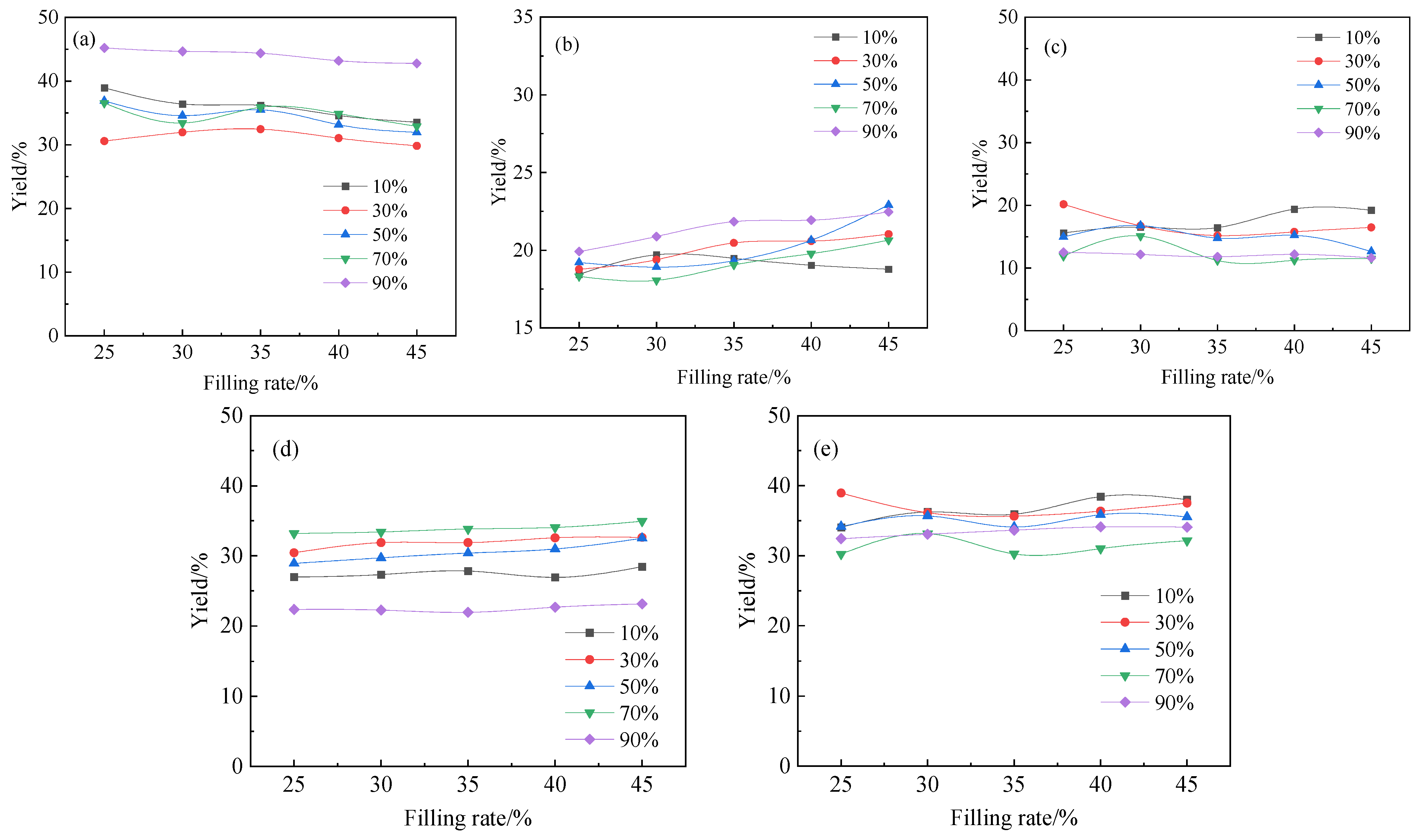

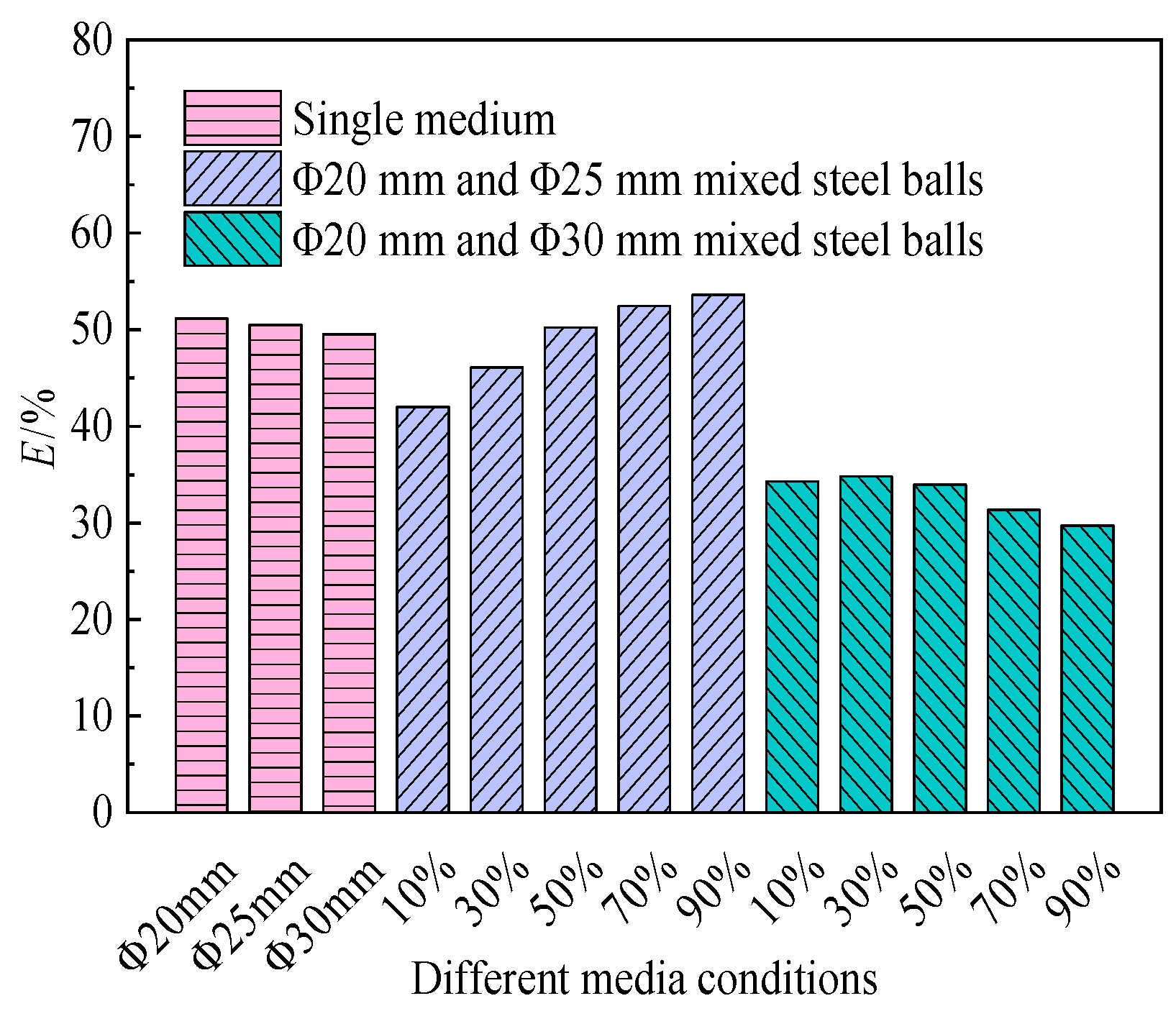

Effect of Mill Filling Rate on the Grinding Technical Efficiency

- (1)

- Grinding Test Results of Steel Ball Combinations of Φ20 mm and Φ25 mm

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

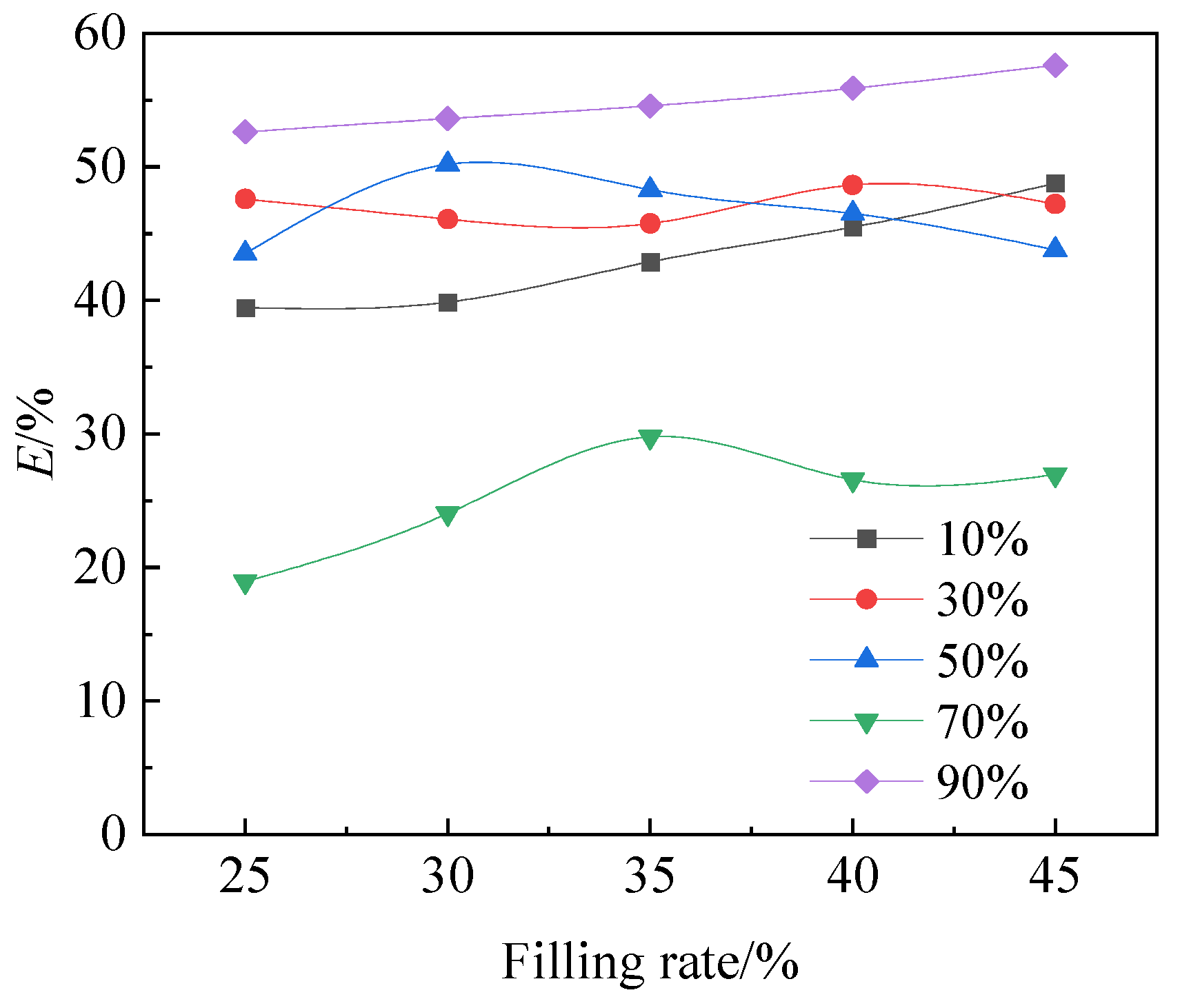

3.4. Comparative Study of Grinding Test Results Under the Single Media and the Different Media Combinations

4. Conclusions

- (1)

- Grinding time has a significant effect on the particle size distribution of the grinding products. Regardless of whether the media size of the single or the combination of two different sizes is used. The yield of qualified particle size (−0.15 + 0.038 mm) increases with grinding time, but the yield of over-grinding particle size also increases accordingly. After 4 min of grinding, the yield of over-grinding particle size approaches that of the qualified particle size and even exceeds it. Therefore, in the actual grinding process of cassiterite polymetallic sulfide ore, more attention should be paid to reasonable grinding time, and the products of qualified particle size should be expelled in a timely manner to prevent over-grinding. After comprehensive consideration, 4 min is the most appropriate grinding time.

- (2)

- The rotational rate has little effect on the particle size distribution of the grinding products. Under the conditions of the single media. The yield of qualified particle size (−0.15 + 0.038 mm) increases slightly with increasing rotational rate, reaching a maximum at 60%. Under the combination of two media conditions of Φ20 mm and Φ25 mm and Φ20 mm and Φ30 mm, as the rotational rate increases, the yield of coarse particle size decreases, while the yield of qualified size and fine particle size both increases. At the constant rotational rate, the higher the percentage of Φ20 mm steel balls, the better the grinding effect, and the less pronounced the over-grinding phenomenon. Therefore, the rotational rate of 60% is more appropriate.

- (3)

- The filling rate has a significant impact on the particle size distribution of the grinding products. Under the conditions of the single medium. The yield of particle sizes of −0.15 + 0.038 mm increases first and then decreases with increasing filling rate, reaching a maximum at 30%, and the optimal filling rate is 30%. Under the combination conditions of two different media. When the filling rate is constant, the higher the ball percentage, the better the grinding effect and the less obvious the over-grinding phenomenon. After the comprehensive consideration, the filling rate of 35% is considered appropriate.

- (4)

- Under the optimal parameters of grinding operations, the yield of qualified particle size and grinding technical efficiency are used as evaluation indices. Overall, the order of the grinding effect of different media conditions was as follows: steel ball combination of Φ20 mm and Φ25 mm > steel balls of three single sizes > steel ball combination of Φ20 mm and Φ30 mm. Whether in the single media or the mixed media, 20 mm steel balls play a crucial role in the grinding effect on the cassiterite polymetallic sulfide ore. Among them, the best grinding effect is achieved when the media ratios are Φ20 mm and Φ25 mm (the percentage of the Φ20 mm ball is 90%). Therefore, in the actual grinding of cassiterite polymetallic sulfide ore, the reasonable grinding media ratios and selection of ball diameter are crucial for the effective synergy between large and small media to achieve the best grinding efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tian, C.; Gao, P.; Tang, Z. Optimization of grinding parameters and efficient separation of iron and rare earths from poor oxide ores in magnetic separation operation. Powder Technol. 2025, 458, 120962. [Google Scholar] [CrossRef]

- Li, Q.; Wu, L.; Yang, Y.; Gu, G.; Wang, Y. The relationship among pyrite fine grinding by stirred ball mill and tumbling ball mill, the properties of the product and the flotation behavior. Miner. Eng. 2025, 229, 109401. [Google Scholar] [CrossRef]

- Pereira, L.; Kupka, N.; Huu Hoang, D. On the impact of grinding conditions in the flotation of semi-soluble salt-type mineral-containing ores driven by surface or particle geometry effects? Int. J. Min. Sci. Technol. 2023, 33, 855–872. [Google Scholar] [CrossRef]

- Yang, B.; He, J. New insights into selective depression mechanism of Tamarindus indica kernel gum in flotation separation of fluorapatite and calcite. Sep. Purif. Technol. 2025, 354, 128787. [Google Scholar] [CrossRef]

- Akkaya, B.; Toroğlu, İ.; Bilen, M. Studying the effect of different operation parameters on the grinding energy efficiency in laboratory stirred mill. Adv. Powder Technol. 2020, 31, 4517–4525. [Google Scholar] [CrossRef]

- Urbaniak, D.; Kolmasiak, C.; Wylecial, T. Using of fluidized-bed jet mill to a super fine comminution of steel composite. Metalurgij 2015, 54, 201–203. [Google Scholar]

- Krishnaraj, L.; Ravichandran, P.T. Investigation on grinding impact of fly ash particles and its characterization analysis in cement mortar composites. Ain Shams Eng. J. 2019, 10, 267–274. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, S.; Deng, S. Effect of grinding aids on the fracture energy of mica. Met. Mine 2010, 402, 80–84. (In Chinese) [Google Scholar] [CrossRef]

- Wu, N.; Li, S. Test on Copper Separation Process of a Pyrrhotite-type Low-grade Copper Ore. Mod. Min. 2023, 39, 169–172. (In Chinese) [Google Scholar]

- Yang, X.; Hu, G.; Wang, S. Research Progress of Magnesium Removal Technology from Medium and Low Grade Phosphate Rocks. Conserv. Util. Miner. Resour. 2022, 42, 67–73. (In Chinese) [Google Scholar]

- Xue, H.Y.; Lv, G.Z.; Wang, L.; Zhang, T.A. Review of rare earth extraction and product preparation technologies and new thinking for clean utilization. Miner. Eng. 2024, 215, 108796. [Google Scholar] [CrossRef]

- Guo, M.C.; Yang, Y.K.; Yu, S.L. Effects of Grinding Parameters on Galena Particle Size Distribution and Flotation Performance. Minerals 2025, 15, 618. [Google Scholar] [CrossRef]

- Fang, X.; Wu, C.B.; Liao, N.N. Investigating the Influence of Medium Size and Ratio on Grinding Characteristics. Minerals 2024, 14, 875. [Google Scholar] [CrossRef]

- Si, L.; Cao, Y.J.; Fan, G.X. The Effect of Grinding Media on Mineral Breakage Properties of Magnetite Ores. Geofluids 2021, 2021, 1–9. [Google Scholar] [CrossRef]

- Muanpaopong, N.; Davé, R.; Bilgili, E. Application of TUSSIM with a variable Tromp curve for predicting optimal operation of multi-compartment mills with various ball size distributions. Adv. Powder Technol. 2023, 34, 104171. [Google Scholar] [CrossRef]

- Genç, Ö. Effect of ball load and size distribution on grinding and classification performance. Zkg Int. 2015, 68, 40–51. [Google Scholar]

- Ma, S.; Deng, J.; Xing, D.; Zhang, Y.; Ren, J.; Hu, M.; Huang, Y.; Wu, B. Effects of controllable shock wave on particle size characteristics of tin polymetallic ore crushing products. J. Mater. Res. Technol. 2023, 26, 3676–3685. [Google Scholar] [CrossRef]

- Liu, Y.-P.; Ni, P.; Pan, J.-Y.; Su, W.-C.; Albanese, S.; Cui, J.-M.; Cai, Y.-F.; Fan, M.-S.; Cheng, Z.-L. Geochemistry of sulfides from massive carbonate replacement type tin ore at Gaofeng, Dachang orefield: Insights into precipitation conditions and enrichment of critical metals. J. Geochem. Explor. 2025, 275, 107787. [Google Scholar] [CrossRef]

- Liu, S.Q.; Tong, X.; Song, B.X.; Wang, W.P. In Case Study on Beneficiation of Cassiterite-Polymetallic Sulphide Ores. In Proceedings of the 2nd International Conference on Automation, Communication, Architectonics and Materials (ACAM 2012), Hefei, China, 23–24 June 2012; pp. 28–31. [Google Scholar]

- Aikawa, K.; Ito, M.; Segawa, T.; Jeon, S.; Park, I.; Tabelin, C.B.; Hiroyoshi, N. Depression of lead-activated sphalerite by pyrite via galvanic interactions: Implications to the selective flotation of complex sulfide ores. Miner. Eng. 2020, 152, 106367. [Google Scholar] [CrossRef]

- Yang, J.; Shuai, Z.; Zhou, W.; Ma, S. Grinding Optimization of Cassiterite-Polymetallic Sulfide Ore. Minerals 2019, 9, 134. [Google Scholar] [CrossRef]

- Chimwani, N.; Mulenga, F.K.; Hildebrandt, D. Ball size distribution for the maximum production of a narrowly-sized mill product. Powder Technol. 2015, 284, 12–18. [Google Scholar] [CrossRef]

- Cho, H.; Kwon, J.; Kim, K.; Mun, M. Optimum choice of the make-up ball sizes for maximum throughput in tumbling ball mills. Powder Technol. 2013, 246, 625–634. [Google Scholar] [CrossRef]

- Duan, X.X. Crushing and Grinding; Metallurgical Industry Press: Beijing, China, 2012; pp. 204–218. (In Chinese) [Google Scholar]

- Xue, T. Study on Selective Grinding Behavior of Cassiterite Polymetallic Sulfide Ore. Master’s Thesis, Guangxi University, Nanning, China, 2009. (In Chinese). [Google Scholar]

- Wu, B. Research and Practice of Key Benefiction on Dachang Complex Sulfide Minerals of Low-Tin, Lead, Zinc and Iron. Ph.D. Thesis, Central South University, Changsha, China, 2005. (In Chinese). [Google Scholar]

- Li, Q. Research and Practice of Key Benefication on No.100 and No.105 Ore Body of Dachang Tin-Polymetallic Deposit. Ph.D. Thesis, Central South University, Changsha, China, 2007. (In Chinese). [Google Scholar]

- Liu, J.X.; Fan, M. Experimental Research Methods; China University of Mining and Technology Press: Beijing, China, 2006. (In Chinese) [Google Scholar]

- Yang, J.; Deng, X.; Xu, W.; Li, H.; Ma, S. Study on the Grinding Law of Ball Media for Cassiterite–Polymetallic Sulfide Ore. Minerals 2022, 12, 270. [Google Scholar] [CrossRef]

- Shi, Z. Experimental Study on Grinding Law with Ball Medium of Cassiterite-Polymetallic Sulfide Ore. Master’s Thesis, Guangxi University, Nanning, China, 2009. (In Chinese). [Google Scholar]

- Duan, X.X. Selective Grinding and Its Applications; Metallurgical Industry Press: Beijing, China, 1991. (In Chinese) [Google Scholar]

- Duan, X.X. Study on the selective grinding phenomenon of cassiterite. Yunnan Metall. 1981, 17–26+14. [Google Scholar]

- Petrakis, E.; Karmali, V.; Komnitsas, K. Factors affecting nickel upgrade during selective grinding of low-grade limonitic laterites. Miner. Process. Extr. Metall.-Trans. Inst. Min. Metall. 2021, 130, 192–201. [Google Scholar] [CrossRef]

- Deniz, V. A study on the specific rate of breakage of cement materials in a laboratory ball mill. Cem. Concr. Res. 2003, 33, 439–445. [Google Scholar] [CrossRef]

- Nistlaba, N.; Lameck, S. Effects of Grinding Media Shapes on Ball Mill Performance. Master’s Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2006; pp. 1–146. [Google Scholar]

- Kabezya, K.M. The Effect of Ball Size Diameter on Milling Performance. J. Mater. Sci. Eng. 2015, 4, 1–3. [Google Scholar]

- Shin, H.; Lee, S.; Jung, H.S.; Kim, J.B. Effect of ball size and powder loading on the milling efficiency of a laboratory-scale wet ball mill. Ceram. Int. 2013, 39, 8963–8968. [Google Scholar] [CrossRef]

| Mineral | Content/% | Mineral | Content/% | Mineral | Content/% |

|---|---|---|---|---|---|

| native silver | trace | gudmundite | 0.007 | fluorite | 0.002 |

| acanthite | trace | antimony | 0.003 | calcite | 0.010 |

| miargyrite | trace | cervantite | 0.001 | dolomite | 0.005 |

| freibergite | 0.025 | molybdenite | 0.002 | siderite | 0.194 |

| cassiterite | 2.906 | arsenopyrite | 0.458 | siderite | 0.066 |

| stannite | 0.016 | quartz | 0.579 | limonite | 0.286 |

| herzenbergite | 0.004 | muscovite | 0.046 | rutile | 0.008 |

| pyrrhotite | 69.035 | phlogopite | 1.454 | apatite | 0.078 |

| pyrite | 0.544 | feldspar | 0.037 | Other | 0.199 |

| chalcopyrite | 0.126 | sahlite | 0.001 | ||

| sphalerite | 21.011 | kaolin | 0.053 | ||

| jamesonite | 2.806 | tourmaline | 0.038 |

| Chemical component | SiO2 | CaO | Fe2O3 | SO3 | Al2O3 | ZnO | K2O | MgO | Sn |

| Content/% | 5.00 | 17.00 | 24.20 | 33.50 | 1.30 | 12.2 | 0.40 | 0.10 | 0.10 |

| Chemical component | PbO | As2O3 | Sb2O3 | MnO | TiO2 | CuO | Cd | Rb | SrO |

| Content/% | 1.80 | 0.50 | 1.30 | 0.10 | 0 | 0.08 | 0.02 | 0.01 | <0.01 |

| Sizes/mm | Yield/% | Cumulative Yield Under the Screen/% |

|---|---|---|

| −3.35 + 2.36 | 2.65 | 2.65 |

| −2.36 + 1.18 | 26.64 | 29.29 |

| −1.18 + 0.425 | 37.08 | 63.72 |

| −0.425 + 0.15 | 15.34 | 52.42 |

| −0.15 + 0.075 | 6.72 | 22.06 |

| −0.075 + 0.038 | 3.74 | 10.46 |

| −0.038 | 7.83 | 11.57 |

| Sum | 100.00 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Zhu, P.; Deng, X.; Li, H.; Ma, S.; Wang, D. Study on Grinding Optimization of Cassiterite Polymetallic Sulfide Ore Based on Single-Factor Test Method. Minerals 2025, 15, 827. https://doi.org/10.3390/min15080827

Yang J, Zhu P, Deng X, Li H, Ma S, Wang D. Study on Grinding Optimization of Cassiterite Polymetallic Sulfide Ore Based on Single-Factor Test Method. Minerals. 2025; 15(8):827. https://doi.org/10.3390/min15080827

Chicago/Turabian StyleYang, Jinlin, Pengyan Zhu, Xingjian Deng, Hengjun Li, Shaojian Ma, and Dingzheng Wang. 2025. "Study on Grinding Optimization of Cassiterite Polymetallic Sulfide Ore Based on Single-Factor Test Method" Minerals 15, no. 8: 827. https://doi.org/10.3390/min15080827

APA StyleYang, J., Zhu, P., Deng, X., Li, H., Ma, S., & Wang, D. (2025). Study on Grinding Optimization of Cassiterite Polymetallic Sulfide Ore Based on Single-Factor Test Method. Minerals, 15(8), 827. https://doi.org/10.3390/min15080827