Abstract

Cassiterite polymetallic sulfide ore exhibits a complex mineral composition and significant variations in mineral properties, which frequently lead to issues such as the over-grinding of cassiterite and under-grinding of sulfide minerals during the grinding process. These issues consequently impair liberation performance in subsequent beneficiation stages. Among these factors, the grinding media ratios stand as one of the critical factors influencing grinding efficiency. Based on these, the paper adopts the single-factor test method to systematically study the influence law of factors such as grinding time, mill rotational rate, and mill filling rate on the particle size composition of ore grinding products and the grinding technology efficiency under different media conditions; in addition, it is compared with the influence law of different conditions of media ratios on the grinding efficiency of ore. The results show that the optimal parameters of the grinding operation are obtained at the grinding time of 4 min, the mill rotational rate of 60%, and the filling rate of 35%. The grinding time and mill filling rate have a relatively more significant effect on the product particle size distribution, while the effect of the mill rotational rate is relatively less significant. When the parameters of grinding operations are optimal, the yield of qualified particle size and grinding technical efficiency are used as the evaluation indices, respectively. Overall, the order of the grinding effect of different media conditions was as follows: steel ball combination of Φ20 mm and Φ25 mm > steel balls of three single sizes > steel ball combination of Φ20 mm and Φ30 mm. The optimal grinding media ratios are Φ20 mm and Φ25 mm (the percentage of the Φ20 mm ball is 90%). The reasonable media ratios will effectively coordinate the optimal grinding effect between different media. The research results can provide the necessary basic data for the subsequent grinding optimization of cassiterite polymetallic sulfide ores.

1. Introduction

Grinding operations are the process of reducing the particle size of ore by applying mechanical external forces (such as impact and grinding) to the surface of the ore [1,2]. The purpose of grinding operations is to separate useful minerals embedded together from gangue minerals and to reduce the mineral particle size to the size required by the beneficiation plant [3,4]. The particle size distribution of the grinding products has a direct impact on the quality of the mineral processing products. Grinding operations are widely used in mining, metallurgy, chemical engineering, and other industries [5,6,7], and it plays a particularly important role in mineral processing. On the one hand, grinding operations are preparatory work for subsequent separation processes in the dressing plant, providing them with materials of the required particle sizes. On the other hand, the capital construction of grinding operations accounts for about 60% of the construction costs of a dressing plant, while the production costs account for 40–50% of the total costs of a dressing plant [8]. The quality of grinding effectiveness directly affects the performance of subsequent separation operations. Improving the grinding technology, enhancing grinding efficiency, and reducing the consumption of grinding energy are of great significance for the sustainable development of mines.

Mineral resources are crucial lifelines of national economic development. However, as the economy develops, easily mined, easily sorted, and high-grade mineral resources are gradually being depleted. Therefore, there is an urgent need for the efficient recycling and reusing of poor and low-quality resources. The related research work, such as the recovery of low-grade copper ore [9], phosphate ore [10], rare earth ore [11], and other resources has become a hot topic of research. There are significant differences in the properties of the minerals due to the complex composition of low-grade ore. The subsequent separation operations also have different requirements for the particle size, which makes it more complex for the grinding process of ore. This is made more complex for the grinding process of ore and is prone to over-grinding and under-grinding, which is difficult to control. Hence, many experts and scholars have conducted detailed research on the regulation of the grinding particle size. Guo et al. [12] systematically studied the effects of grinding concentrations, media ratios, and filling rates on the particle size distribution of galena products which were finely ground in ball mills. The grinding particle size distribution of galena was optimized, reducing the impact of over-grinding particles smaller than 10 μm on the recovery rate of galena. Xin et al. [13] simulated the influence of medium size and ratio on grinding characteristics based on the Discrete Element Method. It was concluded that under different conditions of media ratios, appropriately increasing the proportion of the small balls can reduce fluctuations in energy consumption. Furthermore, it efficiently improves energy utilization and enhances collision probability, thereby reducing the grinding costs. Si et al. [14] systematically studied the relationship between ball diameters and magnetite liberation degree distributions based on mineral liberation measurements. By comparing the liberation efficiency of magnetite using balls of eight different sizes (i.e., 10 mm, 13 mm, 16 mm, 19 mm, 22 mm, 25 mm, 28 mm, and 32 mm), it was determined that steel balls of 22 mm can provide the optimal liberation degree and the necessary product particle size distribution for magnetite. This shows that the study of the grinding media ratio has an important significance for the precise regulation of the grinding particle size [15,16].

Cassiterite is a major mineral resource in Guangxi, mainly occurring in close association with polymetallic sulfide ores. It exhibits a wide variety of types and complexities, with a relatively high density [17,18]. The commonly used separation methods for cassiterite are gravity concentration as the main method, with flotation and magnetic separation as auxiliary separation methods. Sulfide ores are often recovered by flotation [19,20]. However, cassiterite is brittle and prone to over-grinding, producing a large amount of fine mud. Therefore, the method of gravity concentration is difficult to recover fine-grained cassiterite, which results in a low recovery rate of cassiterite concentrate. Furthermore, employing the flotation process to recover fine-grained cassiterite not only results in a more complex flowsheet but also leads to higher reagent consumption and entails higher economic costs. Sulfide ore exhibits high hardness, making it difficult to grind to a fine size. This leads to losses of valuable components, which will adversely affect key economic indicators of the dressing plant [21]. Therefore, the regulation of the grinding particle size of cassiterite polymetallic sulfide ores is a major problem faced by the workers of mineral processing. Among these, the grinding media ratio is one of the most direct, obvious, and easily achievable effective means that improve grinding efficiency and regulate grinding product particle size [22,23]. Meanwhile, there has been little research on the accurate regulation of the grinding particle size in cassiterite polymetallic sulfide ore. Based on this, this paper takes cassiterite polymetallic sulfide ore as the research object. Focusing on the conditions of grinding media to address the issues of over-grinding and under-grinding in the grinding process of cassiterite polymetallic sulfide ore, the single-factor batch grinding test method was employed. The research results can provide the necessary basic data for the subsequent grinding optimization of cassiterite polymetallic sulfide ores.

2. Materials and Methods

2.1. Materials

The samples were taken from the dressing plant in Guangxi Province, China. A phase analysis and chemical element analysis of the ore are carried out, and the results are shown in Table 1 and Table 2, respectively. Among them, the mineralogical composition of the sample was determined by MLA650 (Mineral Liberation Analyzer), which was produced by FEI Company in Hillsboro, United States and the determination of chemical composition was performed using chemical titration by the Guangxi Metallurgical Research Institute. As can be seen from Table 1, the cassiterite polymetallic sulfide ore is composed of complex minerals, among which the main valuable minerals are pyrrhotite, sphalerite, cassiterite, antimony minerals, silver minerals, etc. The contents of pyrrhotite and sphalerite are up to 90%. The gangue minerals are mainly mica, quartz, calcite, etc. As can be seen from Table 2, the polymetallic complex ore contains iron, zinc, tin, copper, and other metallic elements, among which the important metallic elements of iron and zinc account for 36.4%. The non-metallic elements are mainly sulfur and arsenic, among which the sulfur content is 33.5%, accounting for a relatively high proportion, which indicates that sulfide minerals account for a relatively high proportion in the polymetallic complex ore. The main impurities are CaO and SiO2, with proportions of 17.1% and 5.0%, respectively, which indicates that oxide minerals are the main impurities in the ore. These raw materials are shown in Figure 1.

Table 1.

The results of quantitative mineral detection for complex polymetallic ores.

Table 2.

The analysis results of chemical elements of polymetallic complex ores.

Figure 1.

Photograph of raw materials.

The raw samples of ore were rinsed, naturally air-dried, and crushed by a jaw crusher and a roll crusher. Then, the seven single particle sizes of −3.35 + 2.36 mm, −2.36 + 1.18 mm, −1.18 + 0.425 mm, −0.425 + 0.15 mm, −0.15 + 0.075 mm, −0.075 + 0.038 mm, and −0.038 mm were screened by using a standard sieve. The particle size distribution of the samples is shown in Table 3. To ensure homogeneity of the samples, each particle size sample was blended and divided separately. The samples were prepared and bagged according to the percentage of the mass of each particle size.

Table 3.

Particle size distribution of the samples.

2.2. Methods

2.2.1. Grinding Technical Efficiency

Based on the one-factor batch grinding test, the influence laws of grinding time, rotational rate, and filling rate on the particle size composition of grinding products under different combinations of grinding media were investigated. The transformation law of yield variation in each particle size in the grinding products was scientifically analyzed in the research process, and the grinding technical efficiency index is used to characterize the grinding results. Grinding technical efficiency is the index to evaluate the effect of the grinding process (The greater its value, the better the grinding), referring to the ratio of the yield of qualified size fraction in the grinding products to the yield of more than qualified particles in the feed of ore. The formula for calculating the grinding technical efficiency is as follows [24]:

where γ is the yield of grinding products in less than the upper limit of qualified particle size, %; γ1 is the yield of feed ore in less than the upper limit of qualified particle size, %; γ2 is the yield of over-grinding particle size in the feed of ore, %; γ3 is the yield of over-grinding particle size in the grinding products, %.

In the actual beneficiation production process, the different minerals in the selection method, selection process, and selection of particle size are also different, due to the different physical and chemical properties [25]. The main useful minerals are cassiterite and sulfide ores for cassiterite polymetallic sulfide ores. The sulfide minerals are recovered by flotation, and the suitable size range for recycling is −0.15 + 0.038 mm [21,26,27]. Therefore, for the convenience of research in this paper, the particle sizes of +0.15, −0.15 + 0.038 mm, and −0.038 mm in grinding products of cassiterite polymetallic sulfide ore are regarded as the particle size of under-grinding, qualified particle size, and under-grinding, respectively. According to the relevant data in Table 1, the formula for calculating the grinding technical efficiency can be changed as follows:

2.2.2. Mill Rotational Rate

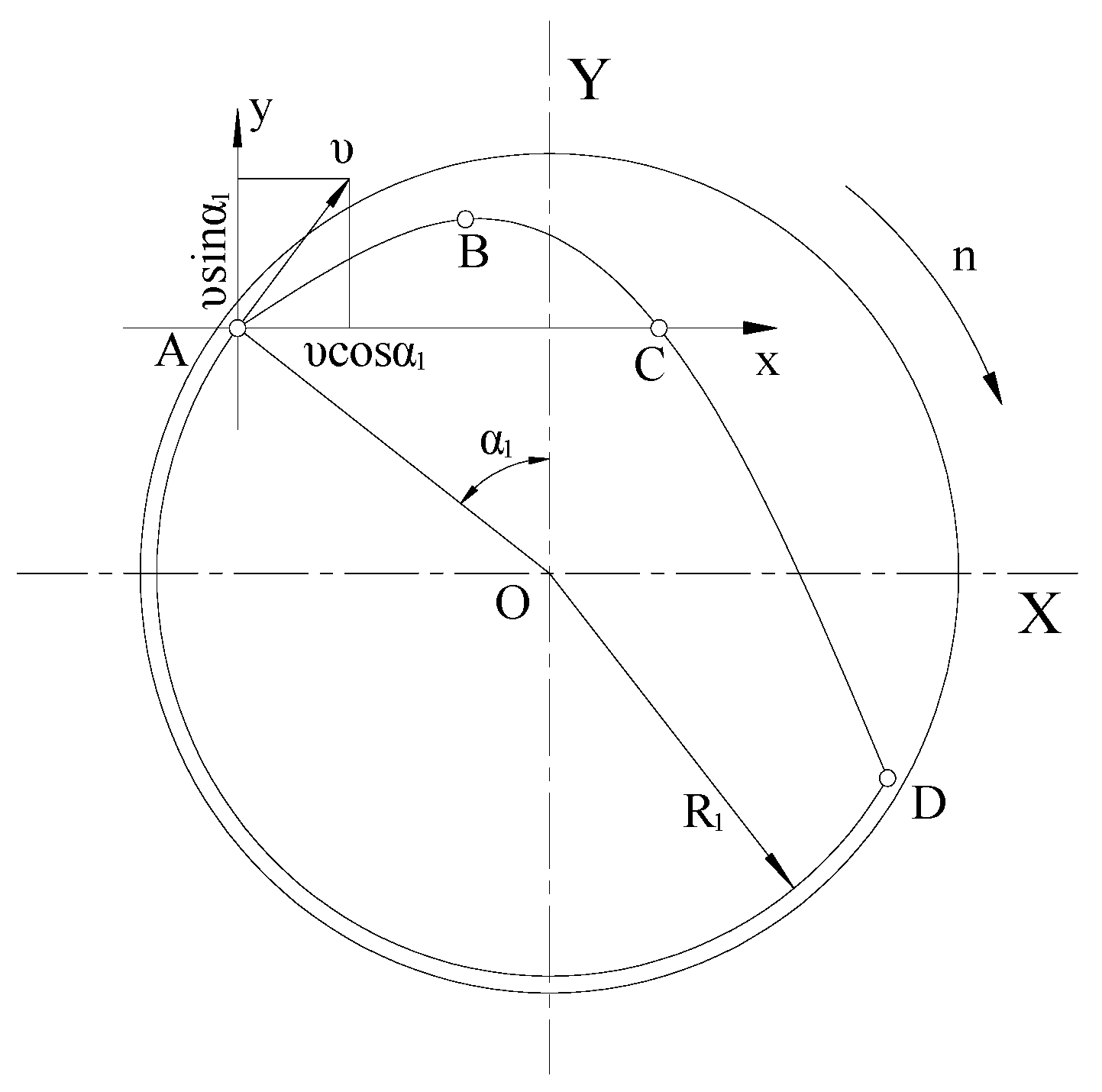

During the grinding process, the factors including rotational rate, filling rate, slurry concentration, mill lining plate and material, media shape and ratio, etc., all affect the movement patterns in that the media are present inside the ball mill. Among these, the most significant ones are the media filling rate and the rotational rate. When other factors remain constant, the movement conditions of the media will change with variations in the rotational rate of the mill. The motion trajectory of the outermost medium in the mill is shown in Figure 2.

Figure 2.

The motion trajectory of the outermost medium.

As can be seen from Figure 2, the medium moves from points A to B, then from points B to C, and finally falls back to point D on the mill lining plate. Now, point A is used as the origin to establish a rectangular coordinate system, and the equation of the trajectory of the outermost medium with radius R1 is shown below [21].

The medium is thrown from points A to B at the same linear velocity v as the mill. The velocity v can be decomposed into the velocity vx parallel to the X-axis and the velocity vy parallel to the Y-axis, respectively:

The medium separates from the lining plate at point A, and the normal component of the gravitational force is equal to the centrifugal force at this point, i.e.,:

This relationship can be determined based on linear velocity and angular velocity. It is displayed as Equation (6).

Substituting it into Equation (6), taking g = 9.8 m/s2, π2 ≈ g, the following can be found:

where it can be seen that the n of actual rotational velocity is directly proportional to cosα1. As n increases, cosα1 also increases, i.e., α1 decreases accordingly. When α1 = 0, cosα1 = 1, the medium rises to the highest point of the cylinder at this time and undergoes centrifugal motion. When the outermost medium undergoes centrifugal motion, the mill enters the critical condition from the throwing to the centrifugal. In actual production, the cylinder radius of the grinding mill is much greater than the radius of the medium. Therefore, from Equation (7), the critical velocity of the mill can be obtained as:

where R is the cylinder radius of the mill; D is the diameter of the mill cylinder.

Based on Equation (8), the formula for calculating this rotational rate can be derived as follows:

where is the rotational rate, %.

2.2.3. Grinding Test

In order to ensure that the test samples are representative and meet the requirements of minimum mass. Based on the empirical equation, test samples were taken, and Equation (10) shown below was used [28]:

where q is the minimum mass of the test sample, kg; d is the maximum particle size in the test sample, mm; k is an empirical coefficient related to the properties of the ore; this coefficient is taken as 1 for cassiterite polymetallic sulfide ore. The maximum particle size of this ore sample is 3.35 mm, which was used in this experiment. According to Equation (10), the minimum mass of the sample is 1.12 kg. Therefore, the amount of ore required for each batch grinding is 1.12 kg.

This method of batch grinding was adopted in this experiment. First, according to the experimental conditions designed for the experiment (mill filling rate, media ratio), these media are placed inside the ball mill. Secondly, a small number of ore samples are placed in a grinding mill for a period of grinding and then washed clean. Then, each 1.12 kg/bag of sample was placed in a mill, and 480 mL of water was added to adjust the required slurry concentration. Finally, the speed of the grinding machine was adjusted using a gearbox and timed with a stopwatch. When the specified time has elapsed, the mill is shut down and the ore sample is washed out with clean water until the water runs clear. After grinding, the experimental samples are dried in the oven and then screened into four particle sizes (+0.15 mm, −0.15 + 0.075 mm, −0.075 + 0.038 mm, and −0.038 mm).

In this experiment, the media ratios are single media (Φ20 mm, Φ25 mm, and Φ30 mm), combination of Φ20 mm &Φ25 mm, and combination of Φ20 mm &Φ30 mm, respectively; the grinding time was selected as 0.5 min, 1 min, 2 min, 4 min, and 6 min, respectively; the rotational rate was selected as 50%, 55%, 60%, 65%, and 70%, respectively; the mill filling rates were selected as 25%, 30%, 35%, 40%, and 45%, respectively [21,25,29,30]; The grinding concentration is 70% throughout. Firstly, under different media conditions, the filling rate (30%) and rotational rate (60%) of this mill are constant, and the optimal grinding time is sought with grinding effect. Secondly, after determining the optimal grinding time (4 min), the optimal rotational rate is sought with grinding effect; at this point, the filling rate (30%) remains unchanged. Thirdly, after determining the optimal rotational rate of this mill (60%), this grinding time remains unchanged (4 min), and the fill rate is sought with the grinding effect. Finally, the grinding effect of different media ratios is compared and analyzed.

3. Results and Discussion

3.1. Effect of Grinding Time

3.1.1. Effect of Grinding Time Under the Condition of Single Media

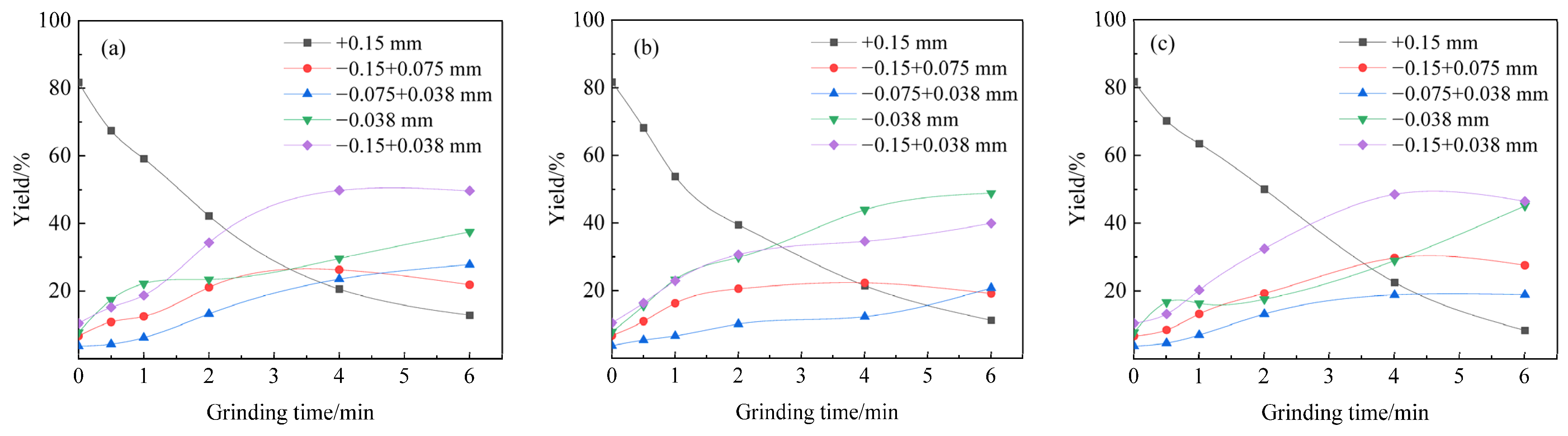

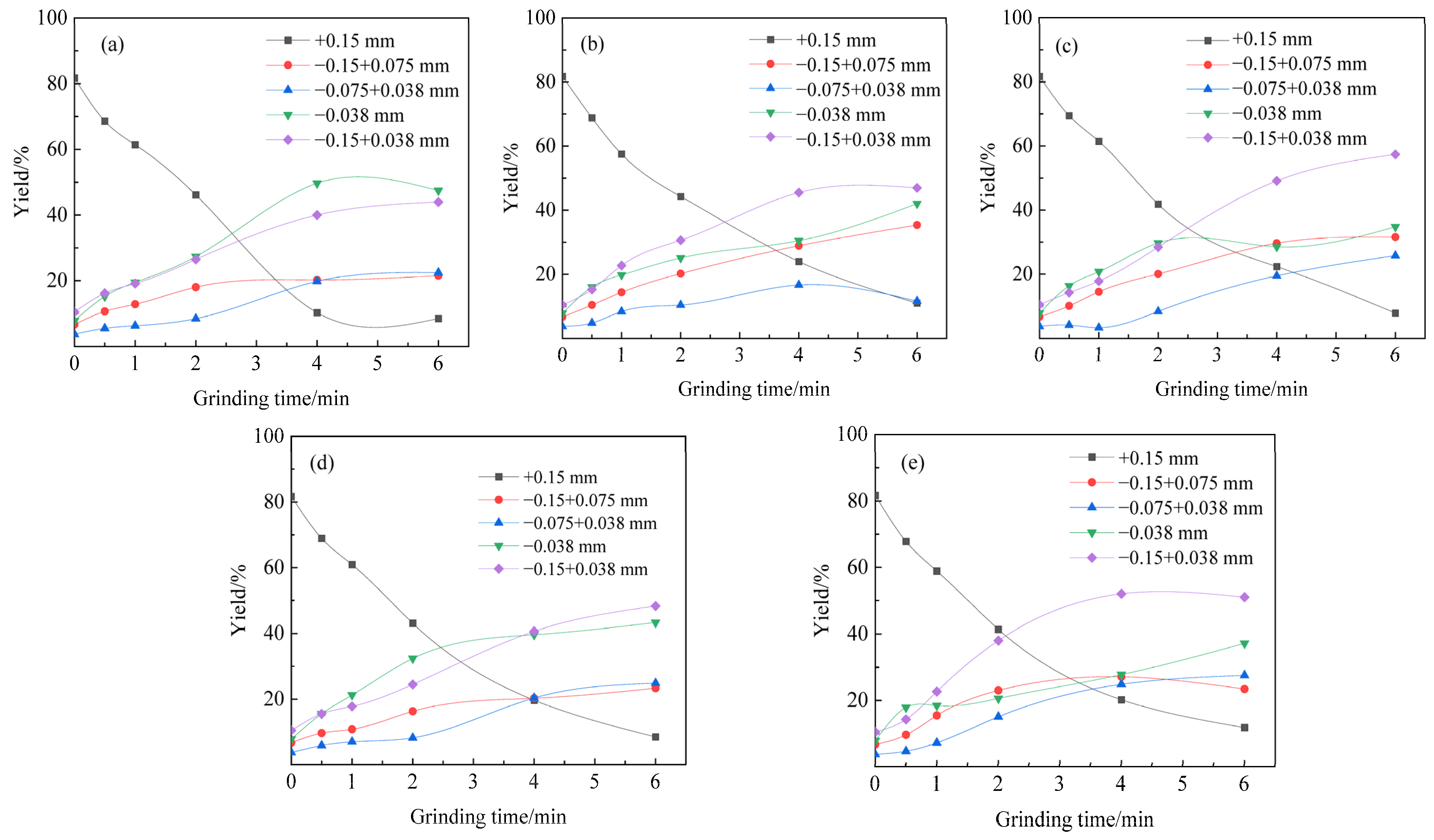

Effect of Grinding Time on the Particle Size Distribution of Grinding Products

The effect of grinding time (0.5 min, 1 min, 2 min, 4 min, and 6 min) on the yield of each particle size in the grinding products was investigated under the three single-size media (the steel balls of Φ20 mm, Φ25 mm, and Φ30 mm) at the grinding concentration of 70%, the filling rate of 30%, and the mill rotational rate of 60%.

From Figure 3a–c, the yield of +0.15 mm particle size decreases rapidly with grinding time for all three single media conditions. The yield of −0.038 mm particle size increases less with the grinding time from 0.5 to 2 min, and increases approximately linearly with the grinding time after 2 min. While the yield of −0.15 + 0.038 mm particle size under the conditions of Φ25 mm steel ball media still increased slowly after 4 min. However, the yield of −0.038 mm particle size increases accordingly, and it exceeds the yield of the −0.15 + 0.038 mm. The reason may be that the ball diameter of Φ20 mm steel ball is small, and the grinding effect of the middle size level is better due to the smaller gap between the balls. The better crushing effect of Φ30 mm steel balls is due to the large ball diameter and strong impact force. In the synthesis of the above analysis, the grinding time of 4 min is more appropriate.

Figure 3.

The effect of grinding time on the yield of different particle sizes in grinding products under the single media ((a): Φ20 mm; (b): Φ25 mm; (c): Φ30 mm).

To further investigate the differences and linkages between the patterns of change in the yields of each particle size in three single media, the dynamic relationships between yield and grinding time of the same particle size under different grinding media conditions are analyzed and compared. The results are shown in Figure 4.

Figure 4.

The effect of grinding time on the yield of particle size in grinding products under different grinding media ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

As can be seen from Figure 4, the trend of the yield of grinding products of each particle size from the three single media with the grinding time is basically the same. The differences are as follows: in the range of 0~4 min for +0.15 mm particle size, the rate of yield decrease is Φ25 mm > Φ20 mm > Φ30 mm; The rate of decline is similar after 4 min. The yield of −0.15 + 0.075 mm particle size increased at the same rate from 0 to 2 min and then slowed down after 2 min, with final yields being Φ30 mm > Φ20 mm > Φ25 mm. The yield growth rate of −0.075 + 0.038 mm particle size is basically the same in the range of 0~2 min, and the growth rate after 2 min is Φ20 mm > Φ30 mm > Φ25 mm. The yield growth rate of −0.038 mm particle size is Φ25 mm > Φ20 mm > Φ30 mm. The yield growth rate of −0.15 + 0.038 mm particle size is smaller in the range of 0~2 min, and this growth rate after 2 min is Φ20 mm > Φ30 mm > Φ25 mm. As can be seen from the above, in the range of grinding time 0~2 min, the three single media have a greater effect on the yield of +0.15 mm (under-grinding particle size) and −0.038 mm (over-grinding particle size), and they have a smaller effect on the yield of −0.15 + 0.038 mm (qualified particle size). At the grinding time greater than 2 min, the three single media have a small effect on the yield of +0.15 mm (under-grinding particle size), and they have a large effect on the yield of −0.15 + 0.038 mm (qualified particle size) and −0.038 mm (over-grinding particle size).

It is possible to find that grinding time has a large effect on the particle size composition of the grinding product through experimental studies of batch grinding under three single media conditions. After analyzing the relationship between the yield of qualified particle size and the change in grinding time, it is concluded that the grinding time of 4 min is more appropriate. In addition, there is also a disparity in how three single media sizes affect the yield of each grain size of the grinding products. When the grinding time is greater than 2 min, the size of the steel ball has a greater effect on the qualified particle size. Therefore, this subsequent study chose a combination of the two media to investigate the effect on the particle size of the grinding product.

Effect of Grinding Time on Grinding Technical Efficiency

Based on the grinding test data in Section 3.1.1 Effect of Grinding Time on the Particle Size Distribution of Grinding Products, the corresponding grinding technical efficiency can be calculated by using Equation (2). The results are shown in Figure 5.

Figure 5.

The effect of grinding time on grinding technical efficiency under different media.

It can be seen from Figure 5 that the effect of grinding time on the grinding technical efficiency is significant. The grinding technical efficiency in 0.5~2 min with the extension of grinding time is approximately linearly increasing in Φ20 mm, Φ30 mm steel ball media conditions. The growth rate of grinding technical efficiency decreases gradually after 2 min, and it reaches a maximum at 4 min and changes slightly after 4 min. Under the condition of Φ25 mm steel ball media, the grinding technical efficiency increased with the extension of grinding time, but the growth rate gradually decreased after 2 min. Therefore, under the three single media conditions, the influence of media size on the grinding technical efficiency is smaller when the grinding time is shorter (0.5–2 min), and the influence is larger after 2 min. This is consistent with the conclusions of the previous study on the particle size composition of the grinding products in Section 3.1.1 Effect of Grinding Time on the Particle Size Distribution of Grinding Products.

In summary, it can be seen that the effect of grinding time on both the particle size composition and the grinding technical efficiency is greater under the single media. In order to further study the effect of grinding time on the particle size composition of grinding products and the grinding technical efficiency under the combinations of different media, the three media of Φ20 mm, Φ25 mm, and Φ30 mm are chosen to be combined. The total ball loading is kept constant by varying the relative content of the two types of steel balls within the media mix. This study investigates the variation rule of the grinding products’ particle size composition and grinding technical efficiency with grinding time under the conditions of the different media combinations.

3.1.2. Effect of Grinding Time Under Different Combinations of Media

Effect of Grinding Time on the Particle Size Composition of Grinding Products

- (1)

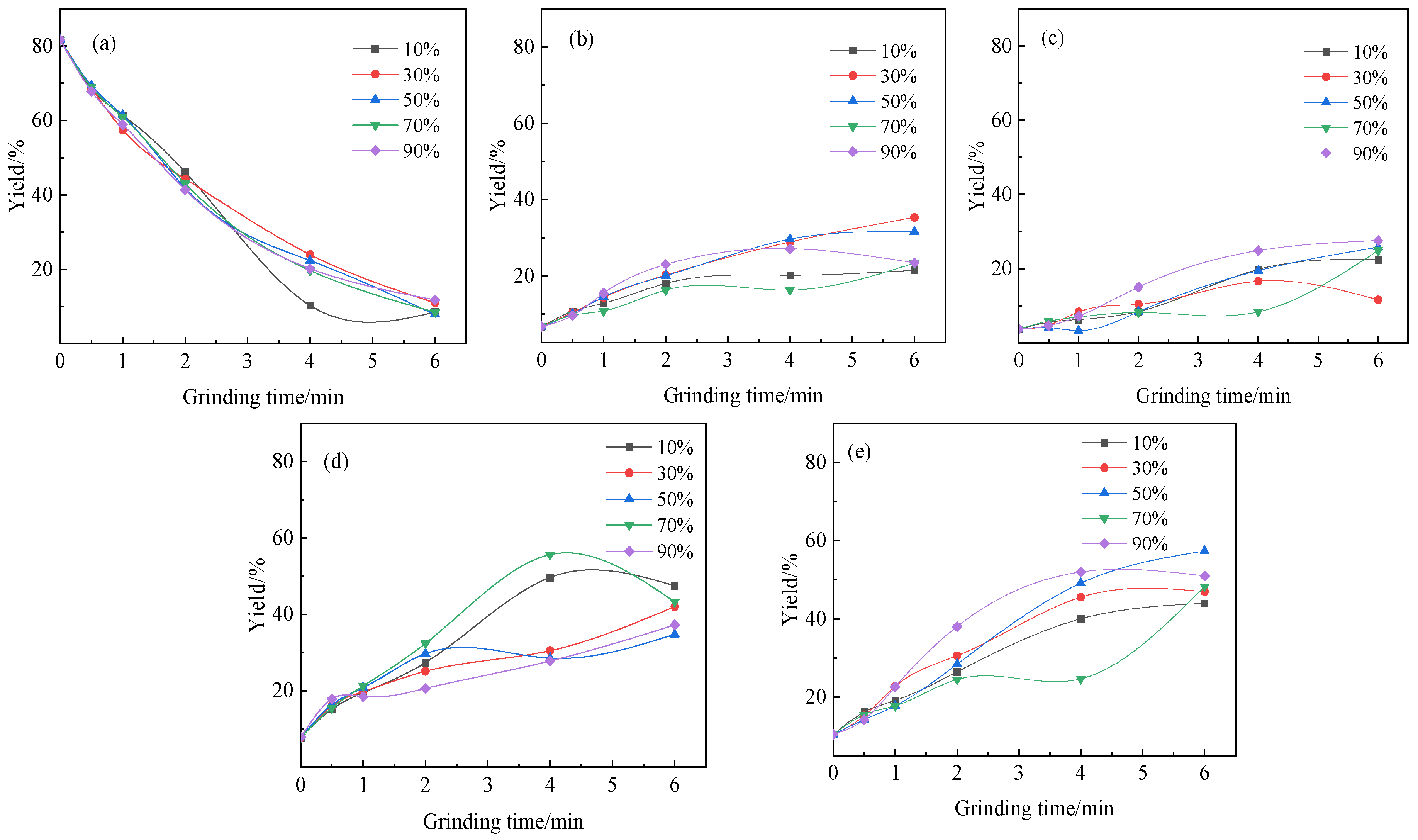

- Grinding test results of steel ball combination of Φ20 mm and Φ25 mm

The test conditions are the same as in Section 3.1.1, and different media combinations are investigated (the percentage of the Φ20 mm ball is 10%, 30%, 50%, 70%, 90%). The effect of grinding time (0.5 min, 1 min, 2 min, 4 min, 6 min) on the yield of each particle size of the grinding products under the conditions of Φ25 mm steel ball content (90%, 70%, 50%, 30%, 10%) was investigated. The results are shown in Figure 6.

Figure 6.

The effect of grinding time on the yield of various particle sizes in the grinding products under different contents of Φ20 mm steel balls ((a): 10%; (b): 30%; (c): 50%; (d): 70%; (e): 90%).

From Figure 6a–e, it can be seen that in the combination of Φ20 mm and Φ25 mm steel balls with different contents of Φ20 mm balls. The yield of +0.15 mm particle size firstly decreases with the increase in grinding time at a faster rate, and the rate slows down after 2 min. The yields of 0.15 + 0.075 mm particle size all increase at a faster rate with grinding time and then slow down after 2 min. The yields of −0.075 + 0.038 mm particle size all increase with grinding time at a slower rate, with the rate accelerating after 2 min. The reason for this may be because the ore particles are inherently friable and achieve better crushing results in a shorter period. It indicates that the content of Φ20 mm steel ball in the combination of Φ20 mm and Φ25 mm has little effect on the yield variation of +0.15 mm, −0.15 + 0.075 mm, and −0.075 + 0.038 mm. Moreover, the yield of −0.038 mm particle size all increased with grinding time. The yield of the qualified particle size of −0.15 + 0.038 mm basically increases with the extension of the grinding time, and it reaches the maximum value at 4 min, which is basically consistent with the law under single media.

To further study the influence of the content of Φ20 mm steel balls in the combination of Φ20 mm and Φ25 mm steel balls on the yield of different particle sizes in ground minerals varying with time. The variation relationship of the yield of a certain particle size with grinding time under different combinations of grinding media was compared and analyzed. The results are shown in Figure 7.

Figure 7.

The effect of grinding time on the yield of a certain particle size in the grinding products under different contents of Φ20 mm steel balls ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

As can be seen in Figure 7, the yield of +0.15 mm particle size decreases with grinding time for all media combinations. The decreasing trend is basically the same, and the reduction rates are all gradually decreasing. This shows that the combination of Φ20 mm and Φ25 mm of steel balls has almost no effect on the yield of +0.15 mm particle size when the ball loading is certain, which is basically the same as the previous rule under a single medium. The yields of −0.15 + 0.075 mm, −0.075 + 0.038 mm, −0.038 mm, and −0.15 + 0.038 mm particle sizes all increased with grinding time. The difference in growth rates is small in the range of 0 to 2 min, and the difference gradually increases after 2 min. This indicates that the effect of Φ20 mm ball content on the yield of −0.15 mm particle size increases with the extension of grinding time for the combination of Φ20 mm and Φ25 mm balls at a certain ball loading. In addition, the ranking by yield of qualified particle size −0.15 + 0.038 mm in the combination is: 90% > 50% > 30% > 10% > 70%. This indicates that the higher the content of Φ20 mm steel balls in the combination, the more favorable the generation of −0.15 + 0.038 mm (qualified particle size).

- (2)

- Grinding test results of the steel ball combination of Φ20 mm and Φ30 mm

As shown in Figure 8a–e, the yield of the +0.15 mm size fraction decreases with prolonged grinding time in all ball mixes consisting of Φ20 mm and Φ30 mm steel balls with varying percentages of Φ20 mm balls. All had good linear characteristics, except for one combination at 90% content. The yields of −0.15 + 0.075 mm, −0.075 + 0.038 mm, −0.038 mm, and −0.15 + 0.038 mm all increased with grinding time. The size relationship of the growth rate is basically −0.15 + 0.038 mm > −0.038 mm > −0.15 + 0.075 mm > −0.075 + 0.038 mm.

Figure 8.

The effect of grinding time on the yield of various particle sizes in the grinding products under different contents of Φ20 mm steel balls ((a): 10%; (b): 30%; (c): 50%; (d): 70%; (e): 90%).

To further investigate the effect of Φ20 mm steel ball content in the combination of Φ20 mm and Φ30 mm on the variation in the yield of a certain particle size in the grinding products with the grinding time, the variation in the yield of a certain particle size with grinding time is comparatively analyzed for different combinations of grinding media, and the results are shown in Figure 9.

Figure 9.

The effect of grinding time on the yield of a certain particle size in the grinding products under different contents of Φ20 mm steel balls ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

From Figure 9a, when the content of Φ20 mm steel balls in the combination of Φ20 mm and Φ30 mm steel ball media is 30%, 50% and 70%, the yield of +0.15 mm particle size decreases with the extension of grinding time. The decreasing trend is basically the same, with the rate of reduction progressively slowing down. When the content of Φ20 mm steel balls in the combination is 10% and 90%, this law will change with the extension of grinding time. It shows that the combinations of Φ20 mm and Φ30 mm steel balls have a certain effect on the yield of +0.15 mm particle size at a certain ball loading. From Figure 9b–e, it can be seen that the yields of −0.15 + 0.075 mm, −0.075 + 0.038 mm, −0.15 + 0.038 mm, and −0.038 mm particle sizes increase with grinding time for all combinations of steel balls. Except for the combination of Φ20 mm steel balls of 90% content, all the other combinations have a small difference in the growth rate in the range of 0~4 min, and this difference gradually increases after 4 min. This indicates that the effect of Φ20 mm steel ball content on the yields of −0.15 + 0.075 mm, −0.075 + 0.038 mm, −0.15 + 0.038 mm, and −0.038 mm particle size increases with grinding time for Φ20 mm and Φ30 mm ball combinations with a certain amount of ball loading.

The batch grinding tests conducted with ball mixes of Φ20 mm and Φ25 mm and Φ20 mm and Φ30 mm steel balls reveal that the influence of grinding time on the yield of each particle size in the grinding products is broadly similar to the patterns observed under the conditions of the single media discussed earlier. That is, the yield of +0.15 mm particle size decreases gradually with grinding time. The particle sizes of −0.15 + 0.038 mm and −0.038 mm increase gradually with grinding time. The difference is that the change rule of the yield of each particle size with grinding time is more linear under the combination of Φ20 mm and Φ30 mm steel balls. In addition, the content of Φ20 mm steel balls in the previous combination had a small effect on the yield of +0.15 mm particle size. The effect on the yield of each particle size of −0.15 mm increases with grinding time. The content of Φ20 mm steel balls in the latter combination had an effect on the yield of +0.15 mm particle size. The effect on the yield of −0.15 mm particle size increases with grinding time.

Effect of Grinding Time on Grinding Technical Efficiency

- (1)

- Grinding test results of steel balls combinations of Φ20 mm and Φ25 mm

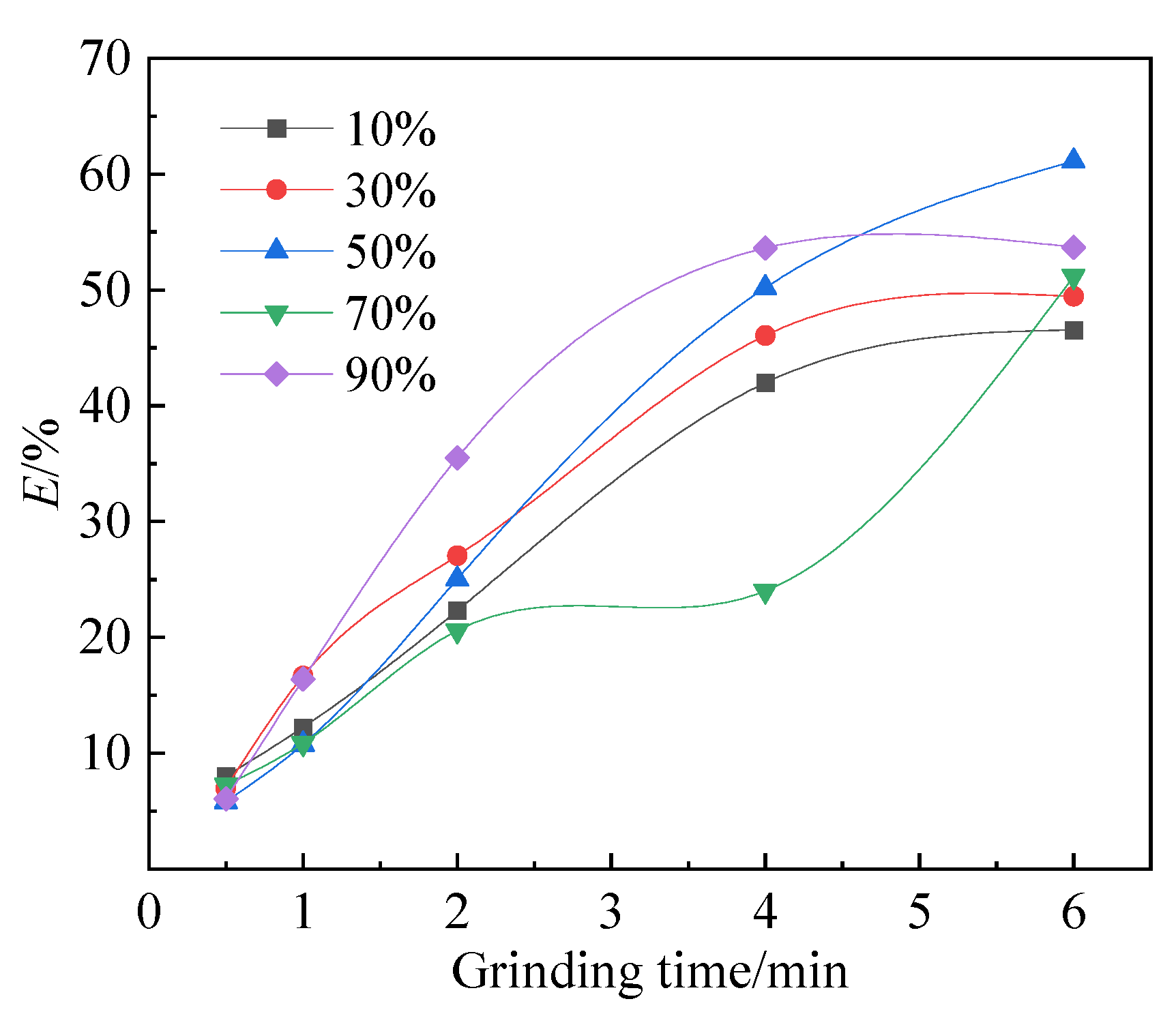

Based on the grinding test data in Section 3.1.2 Effect of Grinding Time on the Particlesize Composition of Grinding Products, the corresponding grinding technical efficiency can be calculated by using Equation (2). The results are shown in Figure 10.

Figure 10.

The effect of grinding time on grinding technical efficiency under different contents of Φ20 mm steel balls.

As can be seen from the figure, the effect of grinding time on grinding technical efficiency is significant, which basically increases rapidly with the extension of grinding time within 0.5~4 min under the combination conditions of all steel balls. Except for the two combinations of Φ20 mm steel ball content of 50% and 70%, the grinding technical efficiency basically reaches the maximum value at 4 min, and the change is very little after that, which is similar to the study results of the previous single media. From the same grinding time in 0.5~4 min, the grinding technical efficiency basically increases with the growth percentage of Φ20 mm steel balls, except for the percentage of 70% steel balls. The grinding technical efficiency basically increases with the percentage of Φ20 mm balls after 4 min, except for the percentages of 50% and 70%.

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

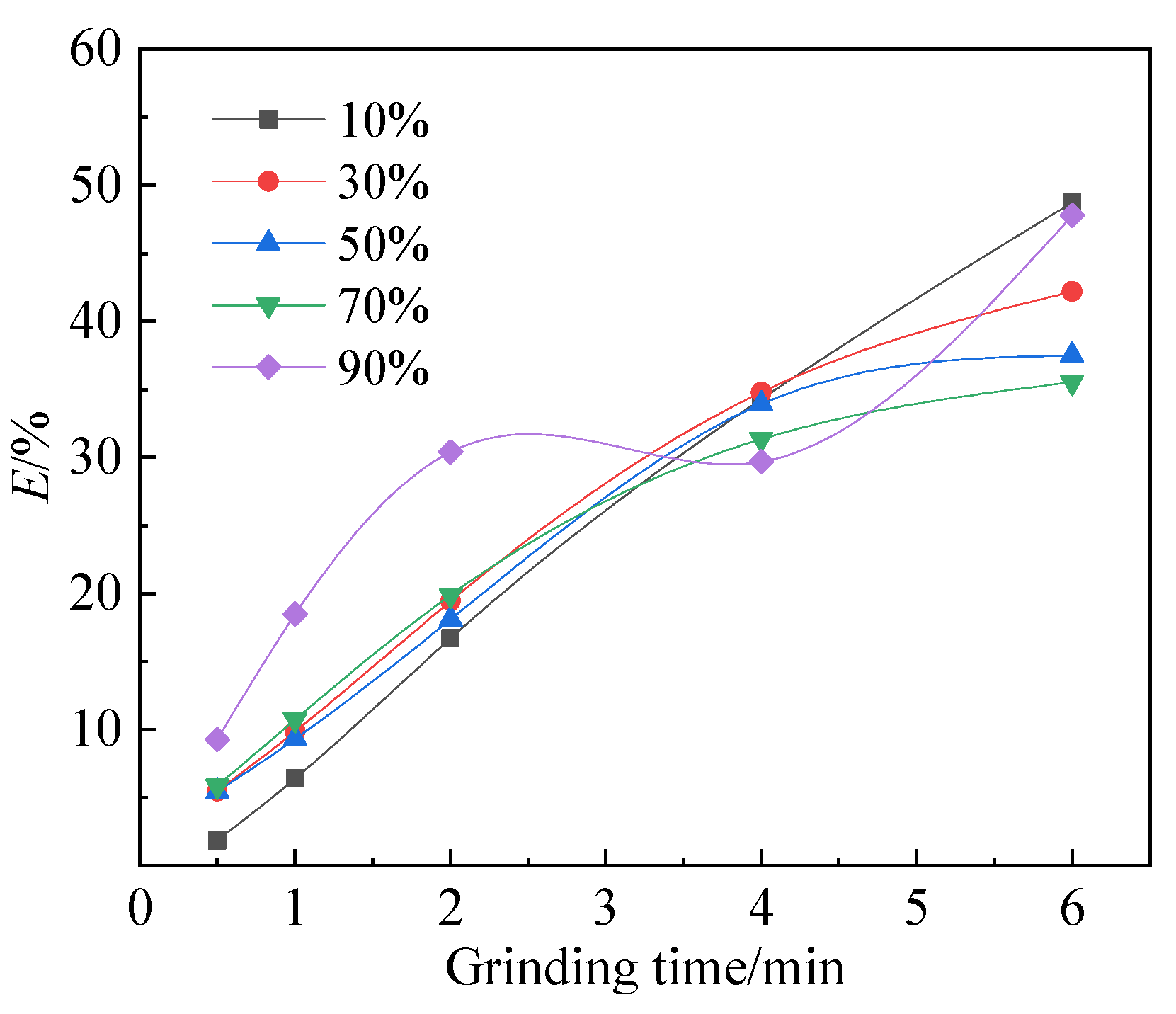

Based on the grinding test data in Section 3.1.2 Effect of Grinding Time on the Particle Size Distribution of Grinding Products, the corresponding grinding technical efficiency can be calculated by using Equation (2). The results are shown in Figure 11.

Figure 11.

The effect of grinding time on grinding technical efficiency under different contents of Φ20 mm steel balls.

As can be seen from Figure 11, the effect of grinding time on the grinding technical efficiency is significant. The grinding technical efficiency under the combinations of all other steel balls increased with the extension of grinding time within 0.5~4 min, except for the percentage of 90%. As the percentage of Φ20 mm steel balls increases, the rate of growth in grinding technical efficiency becomes smaller and smaller after 4 min. In addition, from the same grinding time, the percentage of Φ20 mm steel balls has little effect on the grinding technical efficiency before 4 min of grinding time. When the grinding time is more than 4 min, the percentage of Φ20 mm steel balls has an increasing influence on the grinding technical efficiency.

The effect of grinding time on the grinding technical efficiency of the grinding products is studied the combination of steel balls of Φ20 mm and Φ25 mm and Φ20 mm and Φ30 mm. It can be concluded that the combination of Φ20 mm and Φ25 mm is similar to the change rule of the grinding technical efficiency with grinding time under the condition of single media. All of them increase at a faster rate first, and the rate of growth slows down significantly when the grinding time is 4 min. The combination of Φ20 mm and Φ30 mm steel balls continues to increase after 4 min. In addition, at a certain grinding time, the percentage of Φ20 mm steel balls in the previous combination has a greater effect on the grinding technical efficiency. The latter combination has less impact on the grinding technical efficiency.

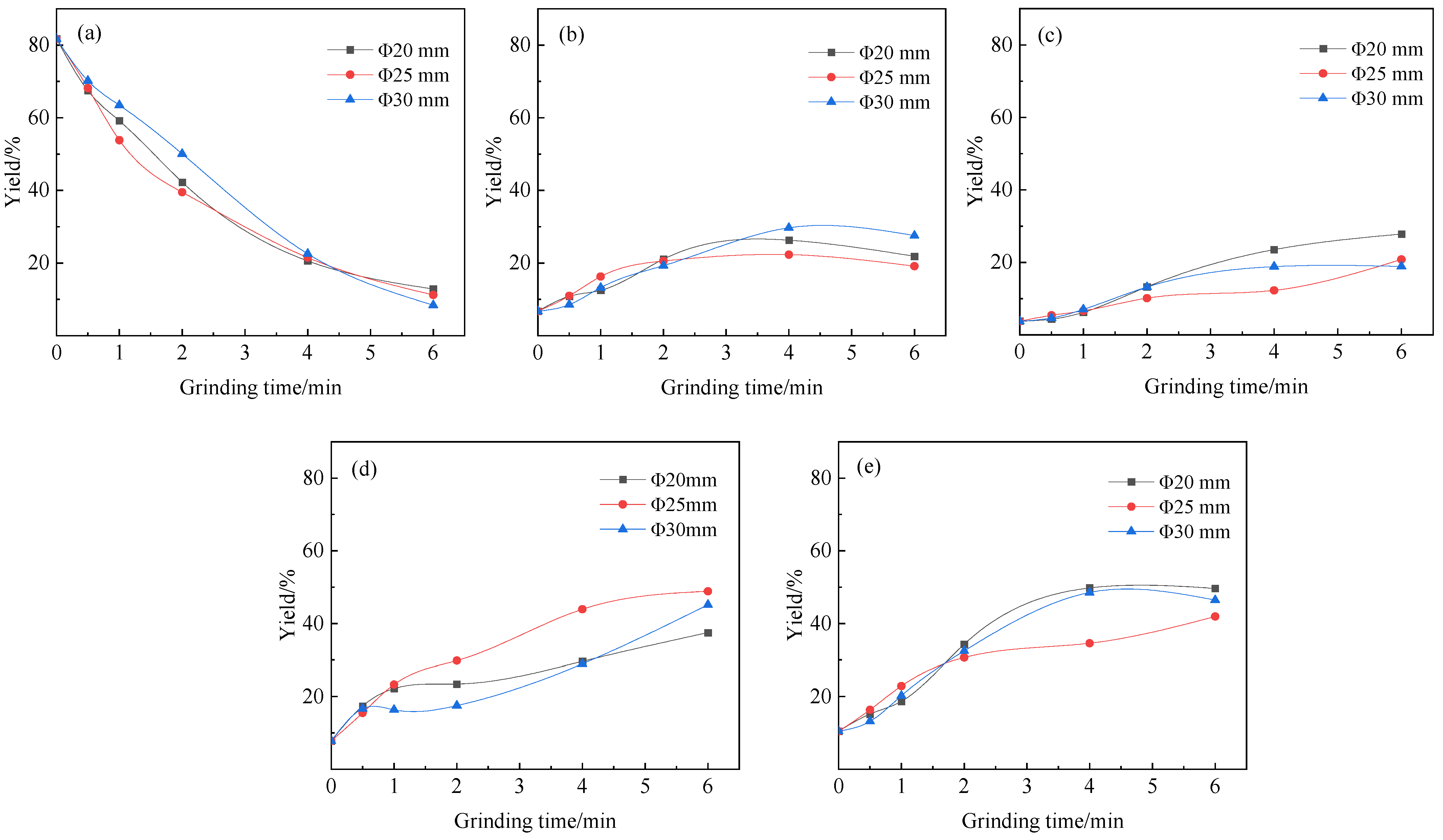

3.2. Effect of Mill Rotational Rate

3.2.1. Effect of Mill Rotational Rate Under the Single Media

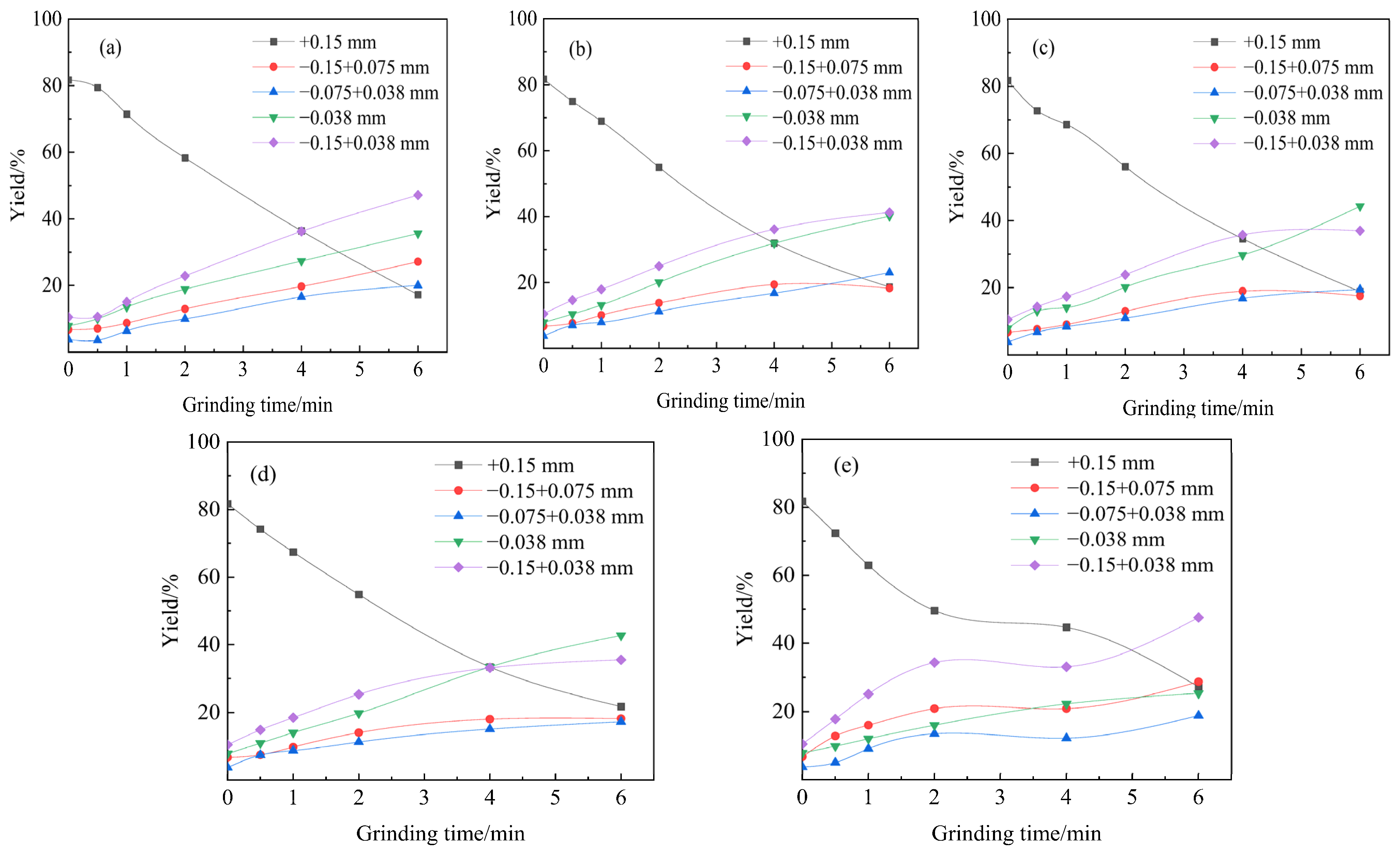

Effect of Mill Rotational Rate on the Particle Size Composition of Grinding Products

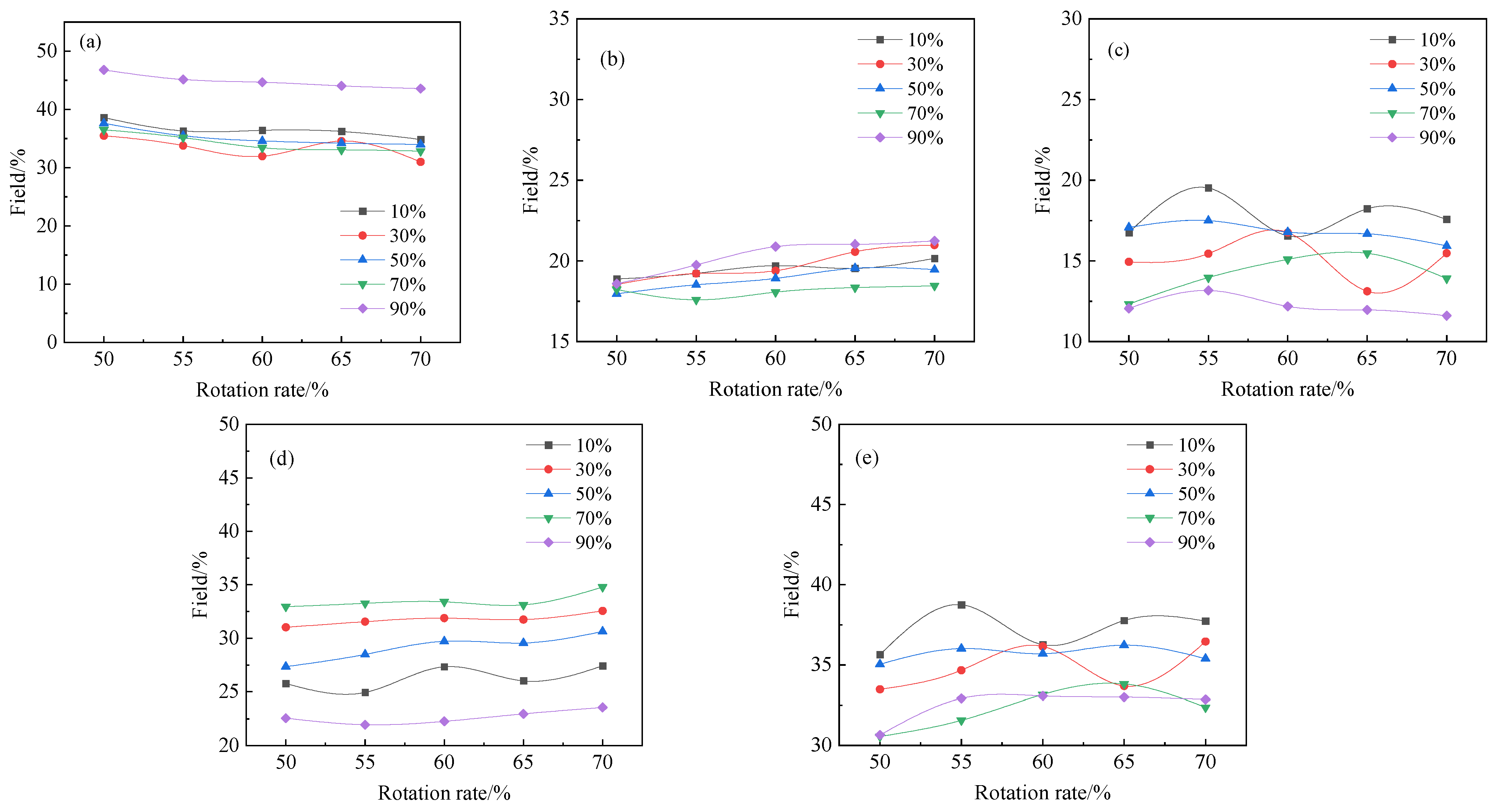

The effect of rotational rate (50%, 55%, 60%, 65%, 70%) on the yield of each particle size in the grinding products is investigated for three single media (the steel balls of Φ20 mm, Φ25 mm, and Φ30 mm) under the concentration of 70%, filling rate of 30%, and grinding time of 4 min. The results are shown in Figure 12.

Figure 12.

The effect of mill rotational rate on the yield of various particle sizes in grinding products under different grinding media ((a): Φ20 mm; (b): Φ25 mm; (c): Φ30 mm).

As shown in Figure 12a–c, the yield of +0.15 mm particle size basically decreases with the increase in grinding rotational rate under the conditions of three single media; the yield of −0.038 mm particle size basically tends to increase with the growth of rotational rate. Differently, under the media conditions of Φ20 mm and Φ30 mm steel balls, the yield of −0.15 + 0.038 mm particle size shows a trend of increasing and then decreasing with the growth of rotational rate. In contrast, under the media condition of Φ25 mm steel ball, the yield of −0.15 + 0.038 mm particle size has been increasing with the growth of the rotational rate. Based on the above analysis, the rotational rate of 60% is more appropriate.

The differences and connections between the patterns of change in the yield of each particle size in three single media were further investigated. The relationship of yield variation with rotational rate for the same particle size was comparatively analyzed under the different conditions of grinding media. The results are shown in Figure 13.

Figure 13.

The effect of mill rotational rate on the yield of particle size in grinding products under different grinding media ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

It can also be seen from Figure 13, when the media of steel balls are Φ20 mm and Φ30 mm, the yield of grinding products for various particle sizes with the change law of the rotational rate is presented in a wave-like pattern, and there are obvious changes at the rotational rate of 60%. The change rule of the yield of each particle size of grinding product with the rotational rate is relatively flat under the conditions of Φ25 mm steel ball media, with certain linear characteristics.

It can be found by the experimental study of grinding under the conditions of three single media; the influence of rotational rate on the particle size composition of grinding products is small; after analyzing the change rule of qualified particle size yield with rotational rate, the optimal rotational rate is 60%. In addition, the variation rule of the yield of each particle size of grinding products with the mill rotational rate is basically similar, which shows fluctuations under the condition of Φ20 mm and Φ30 mm steel balls. The change rule of the yield of each particle size of the grinding products with the rotational rate has certain linear characteristics.

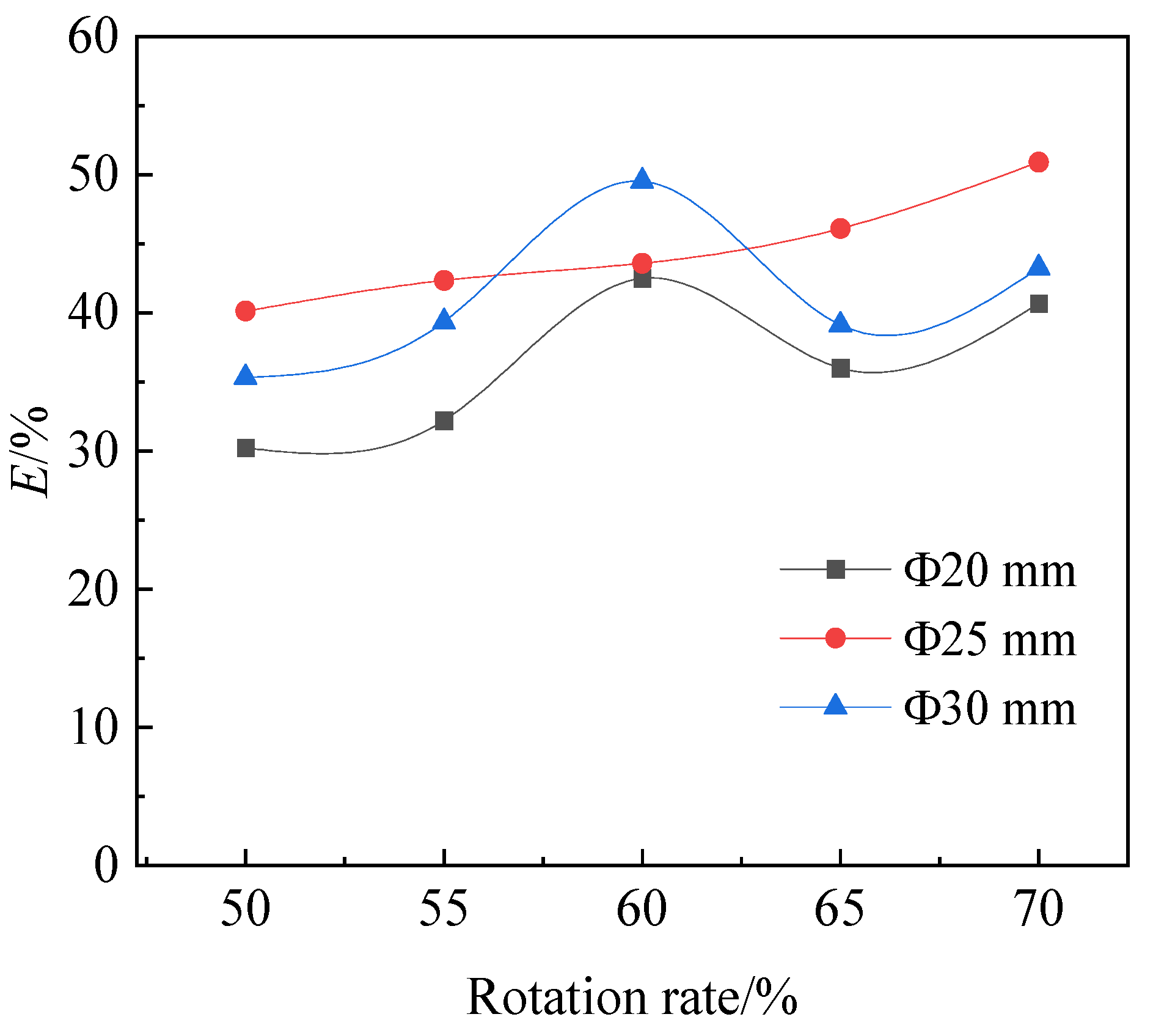

Effect of Mill Rotational Rate on Grinding Technical Efficiency

Based on the grinding test data in Section 3.2.1 Effect of mill rotational rate on the particle size composition of grinding products, the corresponding grinding technical efficiency can be calculated by using Equation (2), and the results are shown in Figure 14.

Figure 14.

The effect of mill rotational rate on grinding technical efficiency under different media.

As can be seen from Figure 14, the rotational rate has an effect on the grinding technical efficiency. Under the media conditions of Φ20 mm and Φ30 mm steel balls, the grinding technical efficiency initially increases with increasing rotational rate, then decreases, and subsequently increases again. The maximum grinding technical efficiency was observed at a rotational rate of 60%. The grinding technical efficiency is increased with the increase in rotation rate under the condition of Φ25 mm steel ball media. This is consistent with the conclusions of the previous study on the yield of −0.15 + 0.038 mm particle size in Effect of Mill Rotational Rate on the Particle Size Composition of Grinding Products.

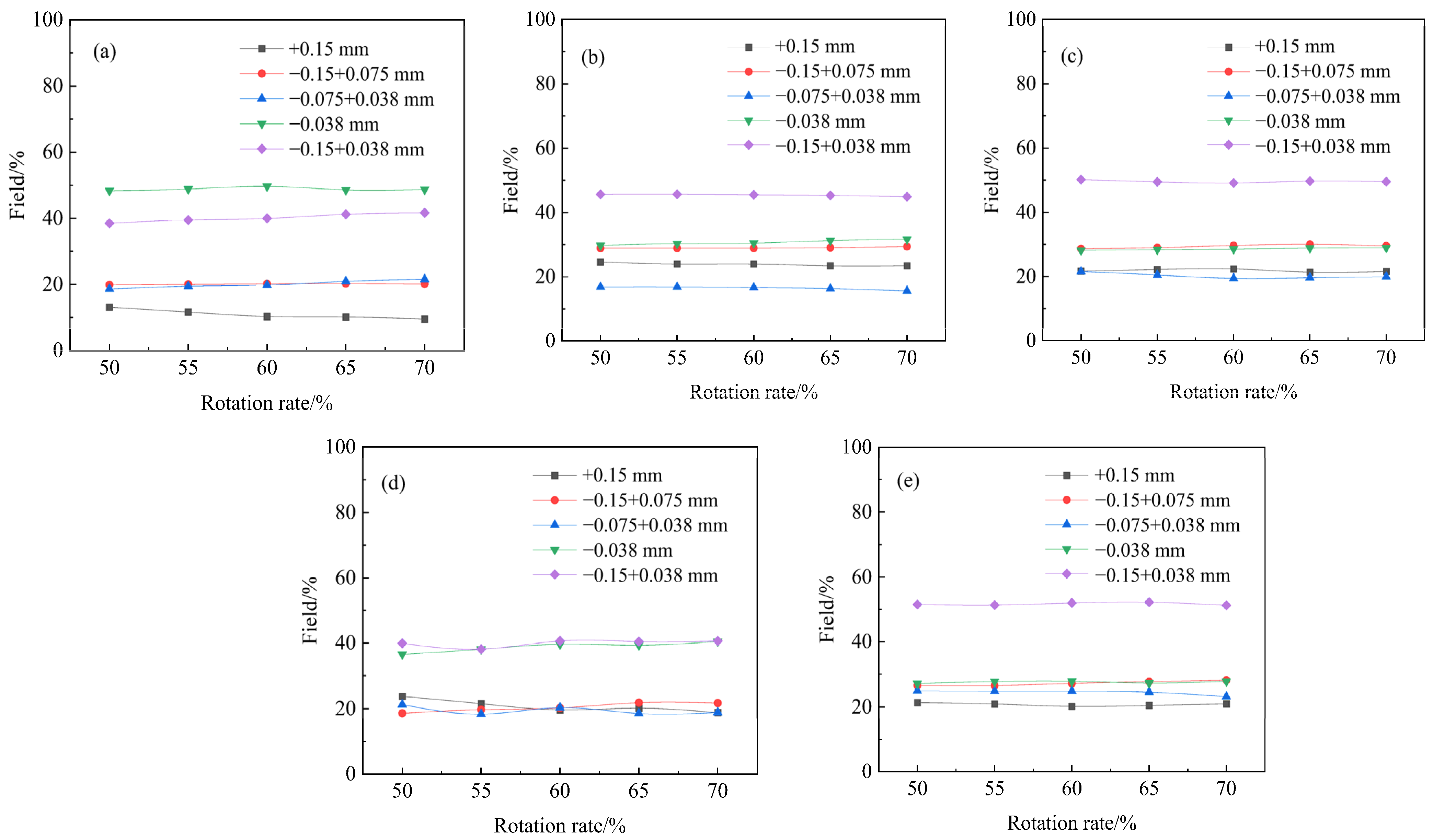

3.2.2. Effect of Mill Rotational Rate Under the Different Media Combinations

Effect of Mill Rotational Rate on the Particle Size Composition of Grinding Products

- (1)

- Grinding test results of steel ball combinations of Φ20 mm and Φ25 mm

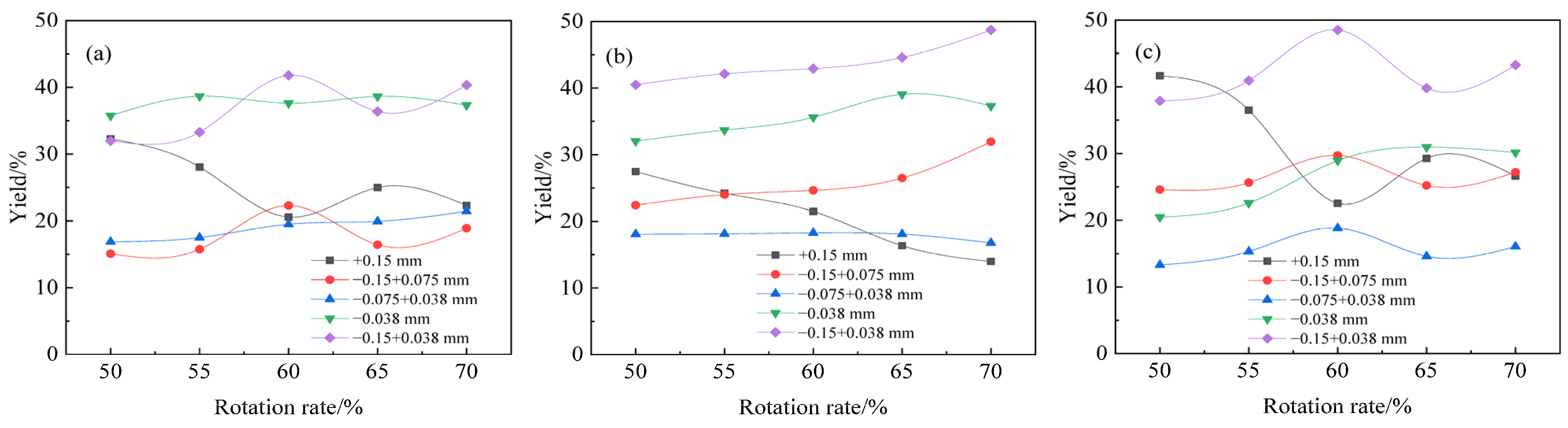

The test conditions are the same as in Section 3.2.1, and the effect of rotational rate (50%, 55%, 60%, 65%, 70%) on the yield of each particle size in the grinding products has been studied under different media combinations (the media combinations of Φ20 mm steel ball in percentages of 10%, 30%, 50%, 70%, 90%). The results are shown in Figure 15.

Figure 15.

The effect of rotation rate on the yield of various particle sizes in the grinding products under different contents of Φ20 mm steel balls ((a): 10%; (b): 30%; (c): 50%; (d): 70%; (e): 90%).

From Figure 15a–e, it can be seen that the variation in yield with increasing rotational rate is basically insignificant for all particle sizes, and all of them have good linear characteristics. It indicates that the rotational rate has a small effect on the yield of each particle size of the grinding products. In addition, as the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ25 mm increased, the relative size of the yield of each particle size within the respective group changed. Initially, the over-grinding particle size (−0.038 mm) constitutes the largest percentage of the grinding products. However, with the extension of grinding time, the qualified particle size (−0.15 +0.038 mm) becomes the predominant component in the grinding products. This indicates that the percentage of Φ20 mm steel balls in the combination has a greater influence on the particle size composition of the grinding products. The effect of Φ20 mm ball percentage in this combination of Φ20 mm and Φ25 mm balls on the variation in the yield of a certain particle size in the grinding products with the rotational rate was further investigated.

The relationship between the variation in a certain particle size yield with rotational rate is comparatively analyzed under the different combinations of grinding media, and the results are shown in Figure 16.

Figure 16.

The effect of rotational rate on the yield of a certain particle size in the grinding products under different contents of Φ20 mm steel balls ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

From Figure 16a–e, it can be seen that the yield of the under-grinding particle size (+0.15 mm) decreases with the increase in the rotational rate at a certain media condition, the yields of the qualified particle size (−0.15 + 0.038 mm) and the over-grinding (−0.038 mm) increase. At a certain rotational rate, as the percentage of Φ20 mm steel balls in the combination increases, the change in the yield of +0.15 mm particle size is smaller; the smaller the yield of −0.038 mm particle size is, the larger the yield of −0.15 + 0.038 mm particle size is. The smaller the phenomenon of overgrinding is, the better the grinding effect is.

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

The test conditions are the same as in Section 3.2.1, and the effect of rotational rate on the yield of each particle size in the grinding products under the combinations of different media is investigated, and the results are shown in Figure 17.

Figure 17.

The effect of rotational rate on the yield of various particle sizes in the grinding products under different contents of Φ20 mm steel balls ((a): 10%; (b): 30%; (c): 50%; (d): 70%; (e): 90%).

Comprehensive analysis of Figure 17a–e shows that the yield of each particle size in the grinding products changes less with the increase in the rotational rate, which indicates that the rotational rate has less influence on the yield of each particle size of the grinding products. In addition, as the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ30 mm increased, as the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ30 mm increases, the relative size of the yield of each particle size within the respective group changes; and the yield of the under-grinding (+0.15 mm) accounts for a larger percentage of the grinding products. This indicates that the combination of Φ20 mm steel balls in percentage has a certain effect on the particle size composition of the grinding products.

In order to further study the effect of Φ20 mm steel ball percentage in the combination of Φ20 mm and Φ30 mm steel balls on the variation in yield of a certain particle size in the grinding products with the rotational rate, the variation in yield of a certain particle with the rotational rate was comparatively analyzed with different combinations of grinding media, and the results are shown in Figure 18.

Figure 18.

The effect of rotational rate on the yield of a certain particle size in the grinding products under different contents of Φ20 mm steel balls ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

As can be seen from Figure 18a–e, at certain media conditions and as the rotational rate increases, the yield of under-grinding particle size (+0.15 mm) decreases, the yields of qualified particle size (−0.15 + 0.038 mm) and over-grinding particle size (−0.038 mm) increase. At a certain rotational rate, the higher the percentage of Φ20 mm steel balls in the combination, the more obvious the phenomenon of over-grinding, and the grinding effect is worse.

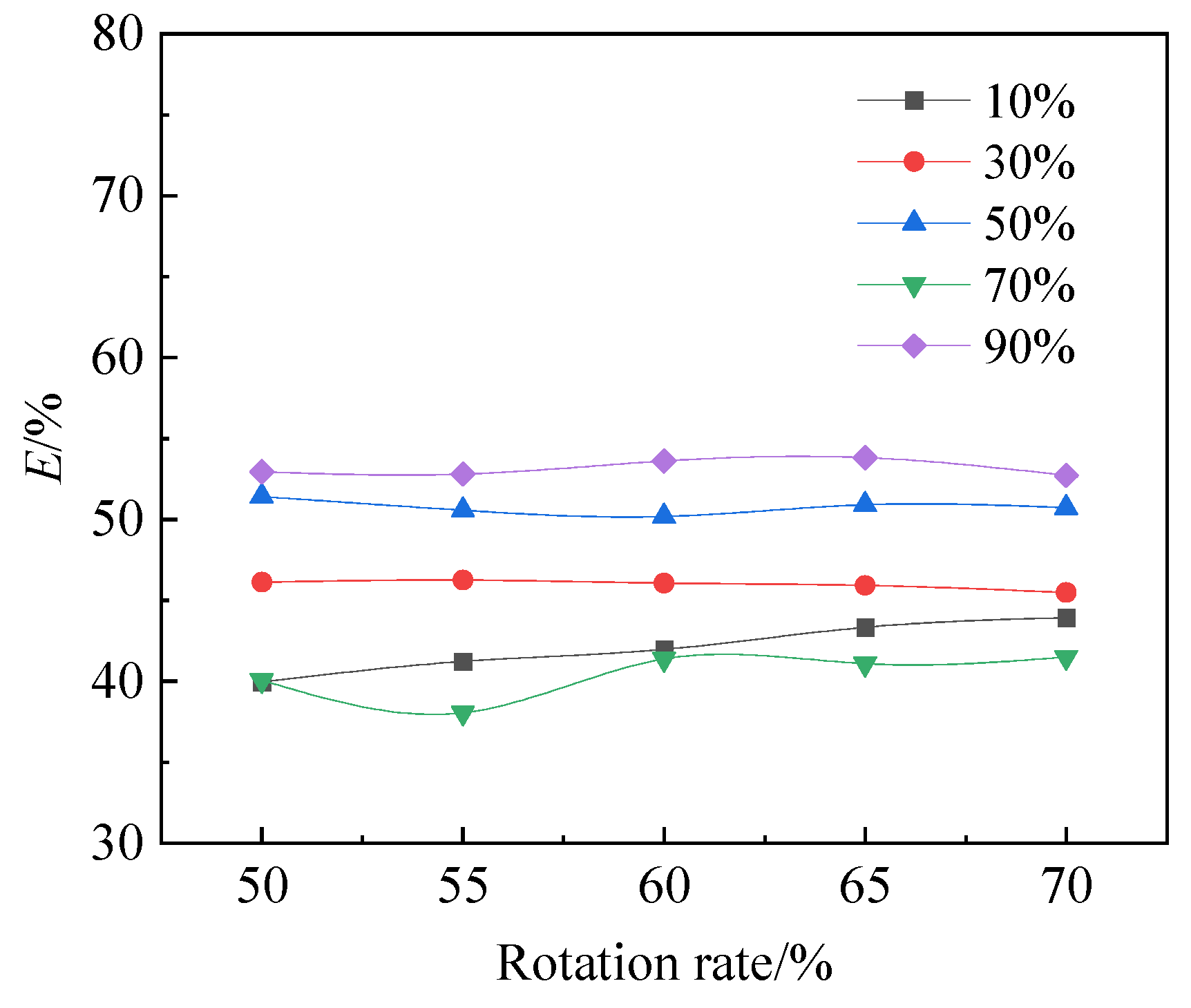

Effect of Mill Rotational Rate on the Grinding Technical Efficiency

Grinding test results of steel ball combinations of Φ20 mm and Φ25 mm

- (1)

- Based on the grinding test data in Section 3.2.2 The effect of mill rotational rate on the particle size composition of grinding products, the corresponding grinding technical efficiency can be calculated by using Equation (2), and the results are shown in Figure 19.

Figure 19. The effect of mill rotation rate on grinding technical efficiency under different contents of Φ20 mm steel balls.

Figure 19. The effect of mill rotation rate on grinding technical efficiency under different contents of Φ20 mm steel balls.

As can be seen from Figure 19, when the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ25 mm is 30%, 50%, and 90%, the effect of rotational rate on the grinding technical efficiency is not significant. When the percentage of Φ20 mm steel balls is 10% and 70%, the rotational rate has a certain effect on the grinding technical efficiency. In addition, when the rotational rate is certain, except for the combination of Φ20 mm steel ball percentage of 70%, the grinding technical efficiency shows an increasing trend with the increase of Φ20 mm steel balls.

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

Based on the grinding test data in Section 3.2.2 Effect of Rotational Rate on the Particle Size Distribution of Ground Products, the corresponding grinding technical efficiency can be calculated using Equation (2). The results are shown in Figure 20.

Figure 20.

The effect of mill rotational rate on grinding technical efficiency under different contents of Φ20 mm steel balls.

As can be seen from Figure 20, when the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ30 mm is 50% and 90%, the effect of rotational rate on the grinding technical efficiency is not significant.

When the percentage of Φ20 mm steel balls is 10%, 30%, 70%, the rotational rate has a certain influence on the grinding technical efficiency. The fluctuations are significant, exhibiting a trend of initially increasing, then decreasing, and subsequently increasing again with increasing mill rotational rate. In addition, when the rotational rate is the same, the grinding technical efficiency basically tends to decrease with the increase of Φ20 mm steel balls in percentage.

By studying the effect of rotational rate on the grinding technical efficiency of the grinding products under the condition combinations of Φ20 mm and Φ25 mm and Φ20 mm and Φ30 mm steel ball, it is concluded that the grinding technical efficiency of the two combinations varies in a small range with the increase in rotational rate. The grinding technical efficiency of the former combination shows an increasing trend with the increase in Φ20 mm ball percentage; the latter combination shows a decreasing trend with the increase in Φ20 mm ball percentage.

3.3. Effect of Mill Filling Rate

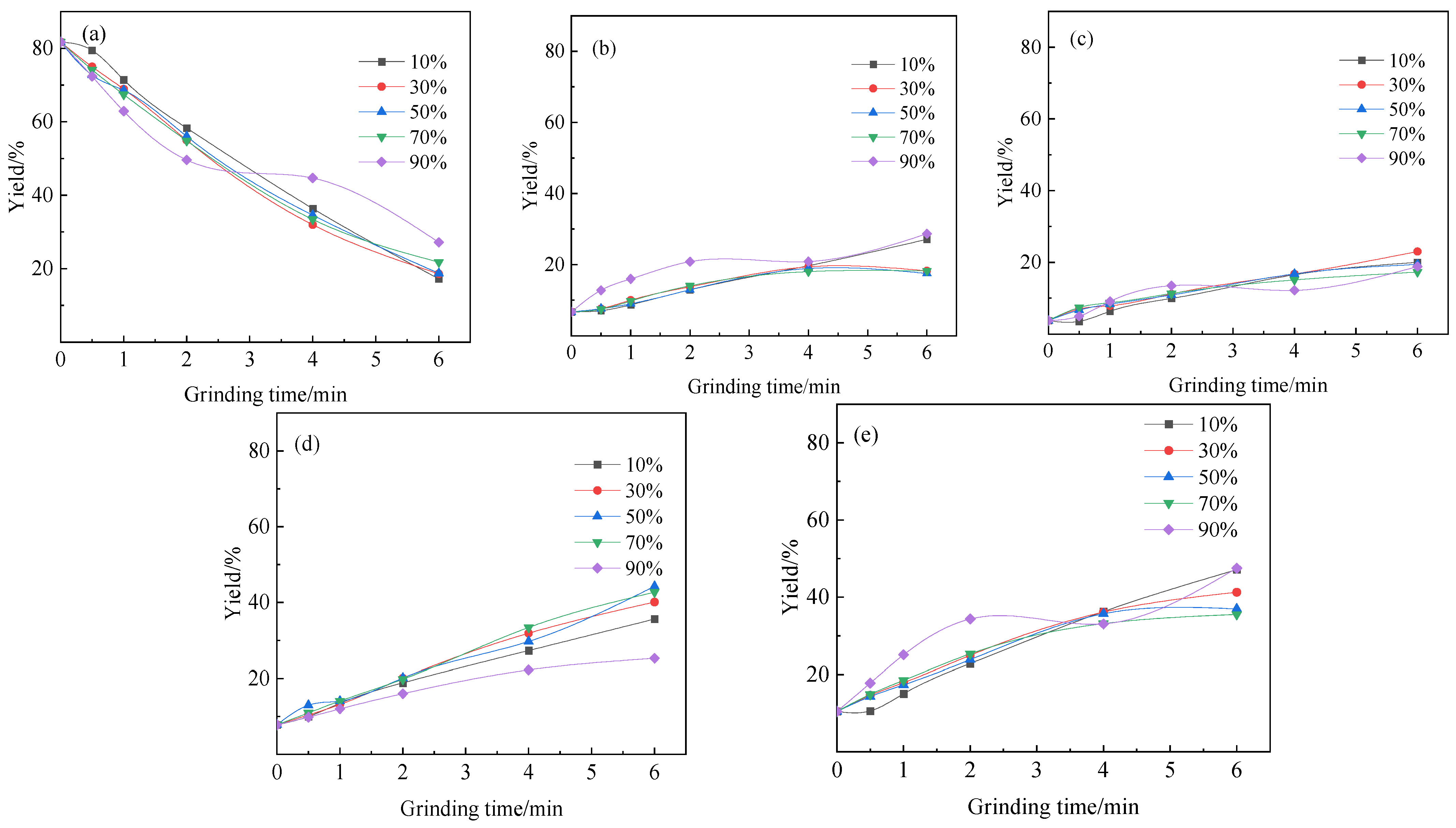

3.3.1. Effect of Mill Filling Rates Under the Single Media

Effect of Mill Filling Rate on the Particle Size Composition of Grinding Products

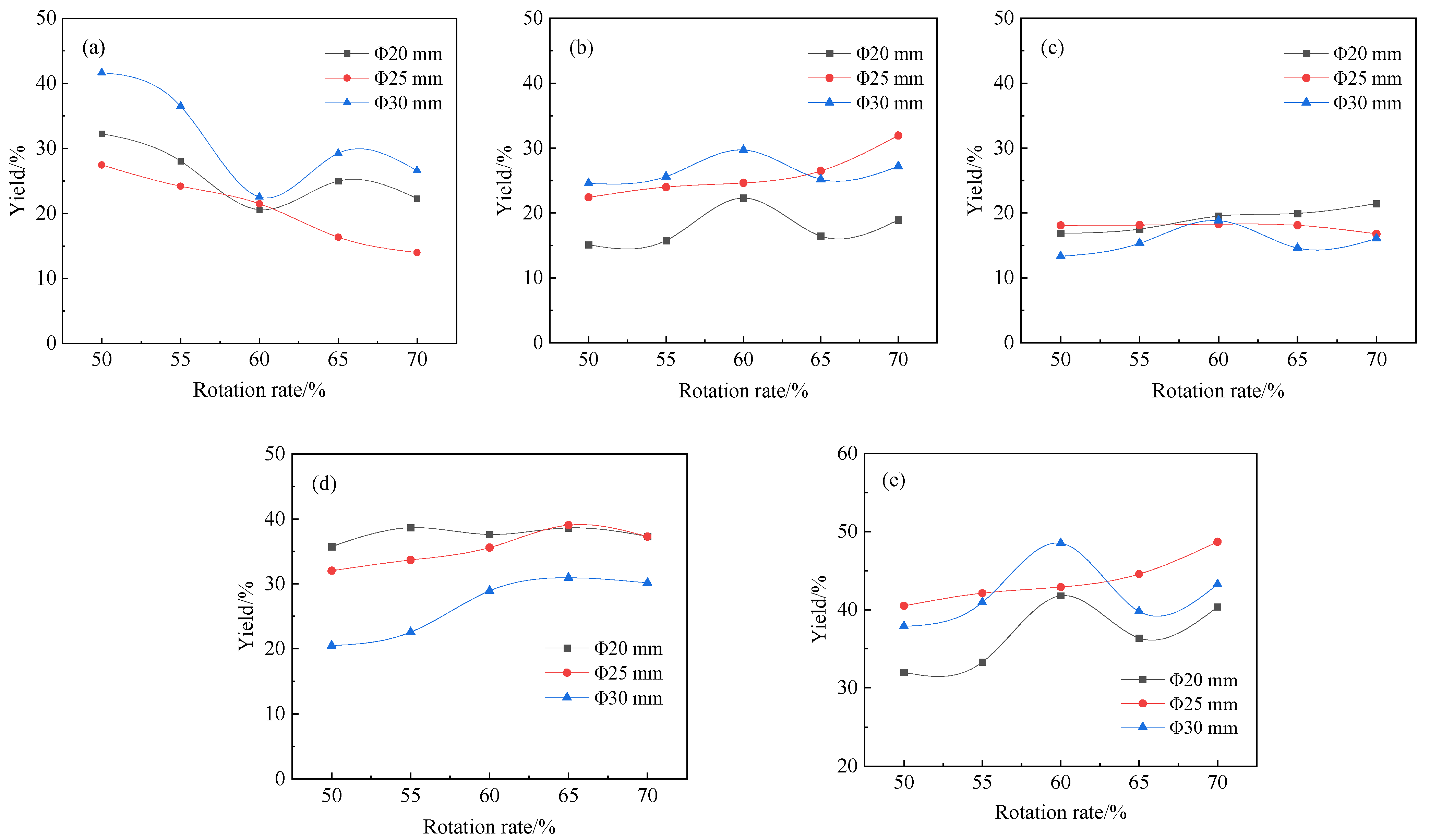

When the grinding concentration was 70%, mill rotation rate was 60%, and grinding time was 4 min, the effect of mill filling rate (25%, 30%, 35%, 40%, and 45%) on the yield of each particle size in the grinding products was investigated under the conditions of three kinds of single media (Φ20 mm, Φ25 mm, and Φ30 mm steel balls), and the results are shown in Figure 21.

Figure 21.

The effect of mill filling rate on the yield of various particle sizes in grinding products under different grinding media ((a): Φ20 mm; (b): Φ25 mm; (c): Φ30 mm).

Based on a comprehensive analysis of Figure 21a–c, it can be observed that under all three single grinding media, the yield of the +0.15 mm particle size generally exhibits an overall trend of initial decrease, followed by an increase, and a subsequent decrease with the increase in filling rate. However, under conditions of steel balls of Φ20 mm and Φ30 mm, the yields of both the −0.15 + 0.038 mm and −0.038 mm particle sizes with increasing mill filling ratio exhibit an initial increase followed by a decrease. In contrast, under the condition of Φ25 mm steel balls, the yields of both the −0.15 + 0.038 mm and −0.038 mm particle sizes generally increase with increasing filling rate.

In order to further study the differences and relationships of the change rule of the yield of each particle size in three single media, the yield of the same particle size in different grinding media conditions is compared and analyzed with the change in filling rate, and the results are shown in Figure 22.

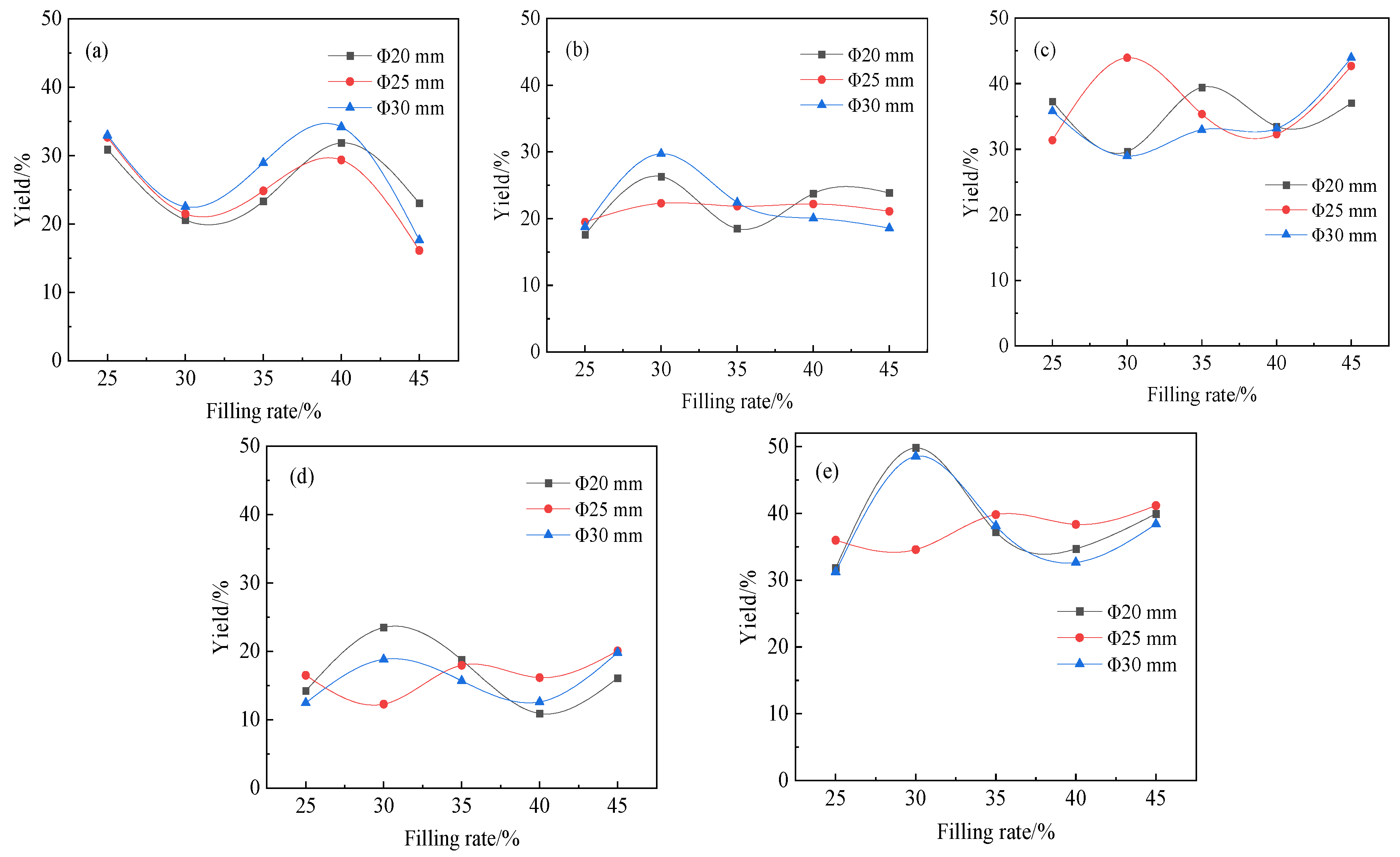

Figure 22.

The effect of mill filling rate on the yield of a certain particle size in grinding products under different grinding media ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

From Figure 22a–e, the effect of filling rate on the yield of each particle size is basically undulating and fluctuating, and the inflection points of the grinding products yield of each particle that changes significantly are at the filling rate of 30% and 40%. It can also be seen that under the single media of Φ20 mm and Φ30 mm steel balls, the variation rule of the yield of each particle size with the filling rate is basically the same, and there is a difference with Φ25 mm steel balls.

Through the grinding experimental study under the conditions of three single media, it can be found that the influence of filling rate on the yield of each particle size of the grinding product is generally of the type of undulating and fluctuating. Under the single media of Φ25 mm steel ball, the variation range of particle size yield of grinding products with the increase in rotational rate is small.

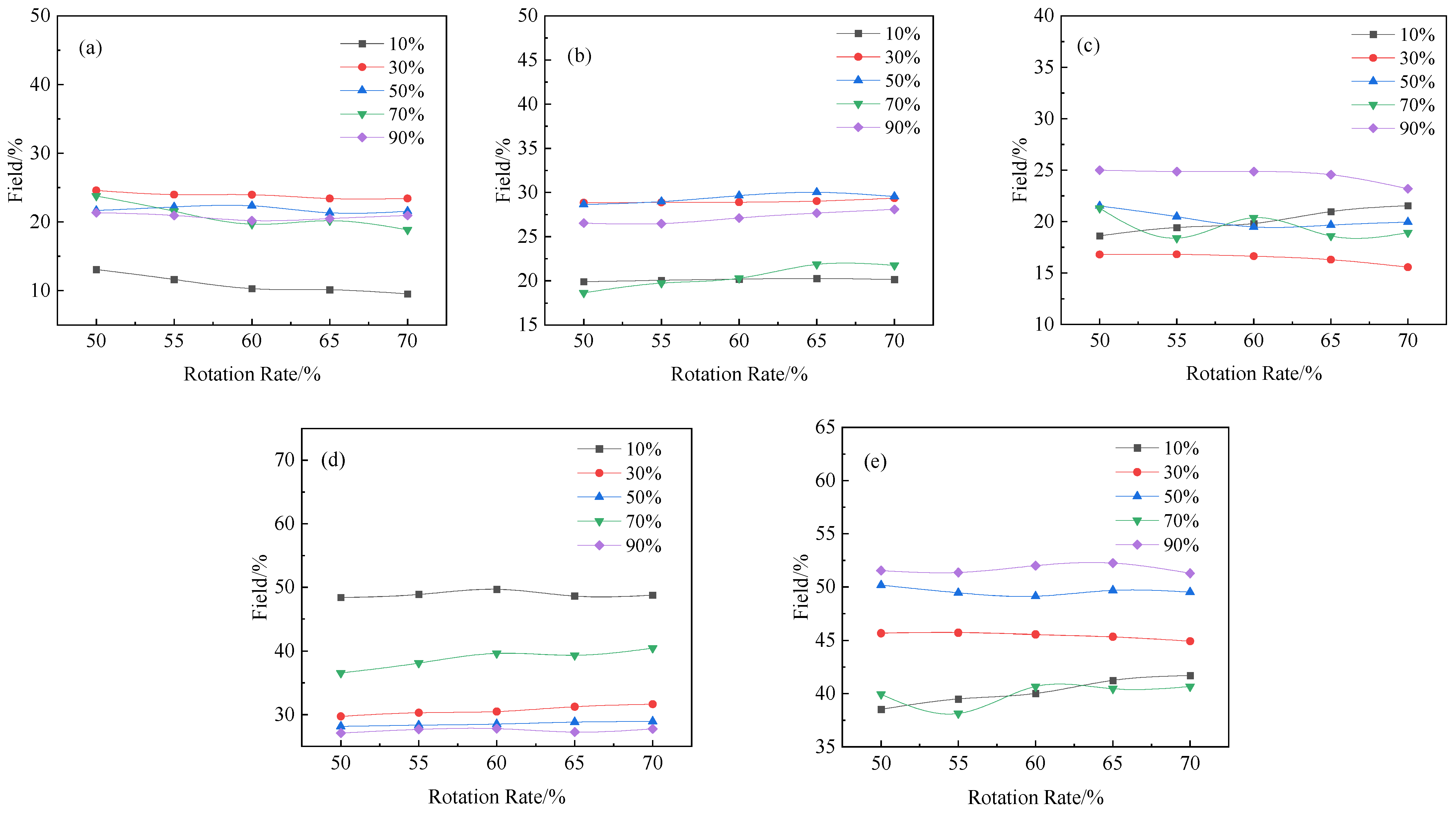

Effect of Mill Filling Rate on the Grinding Technical Efficiency

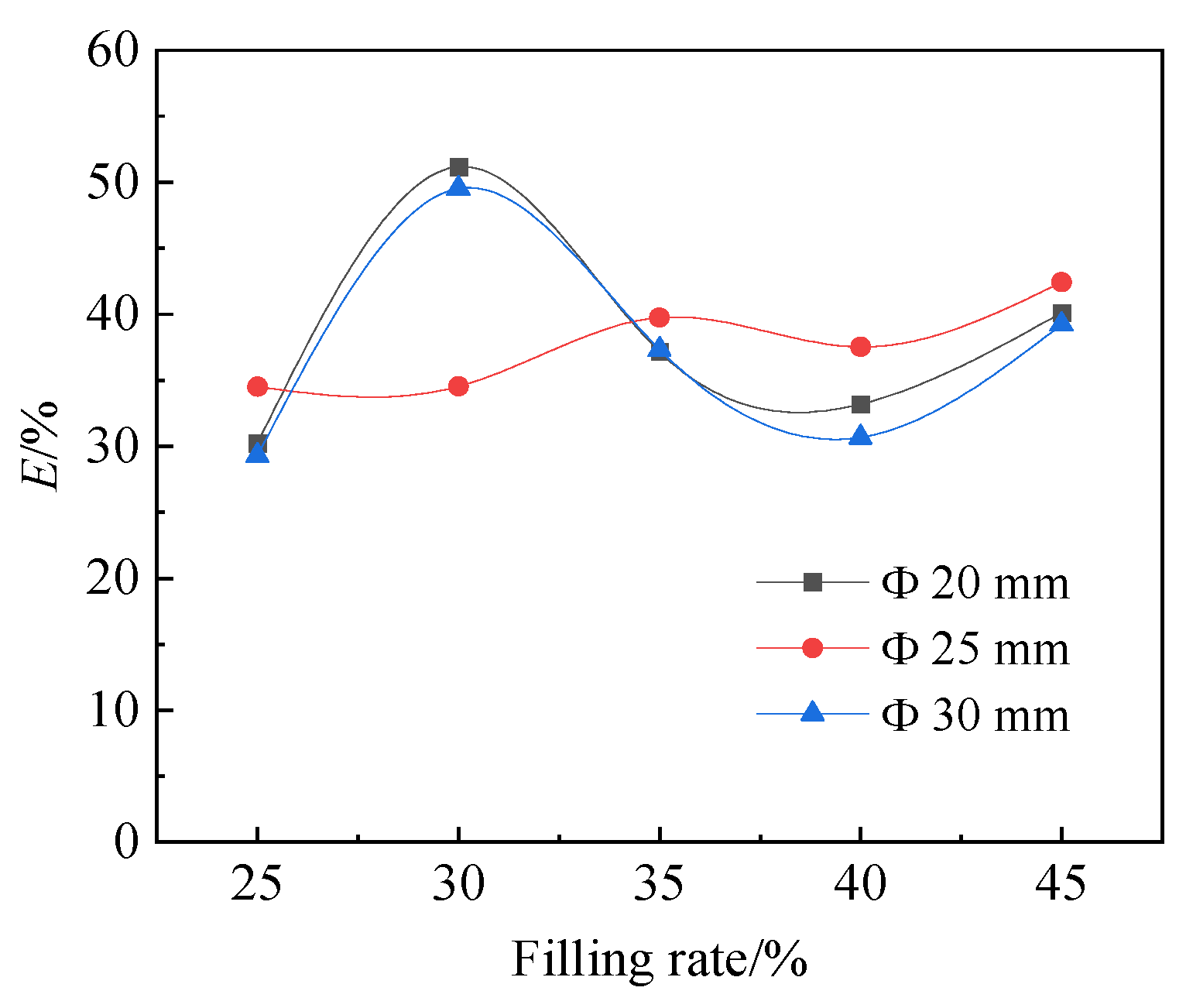

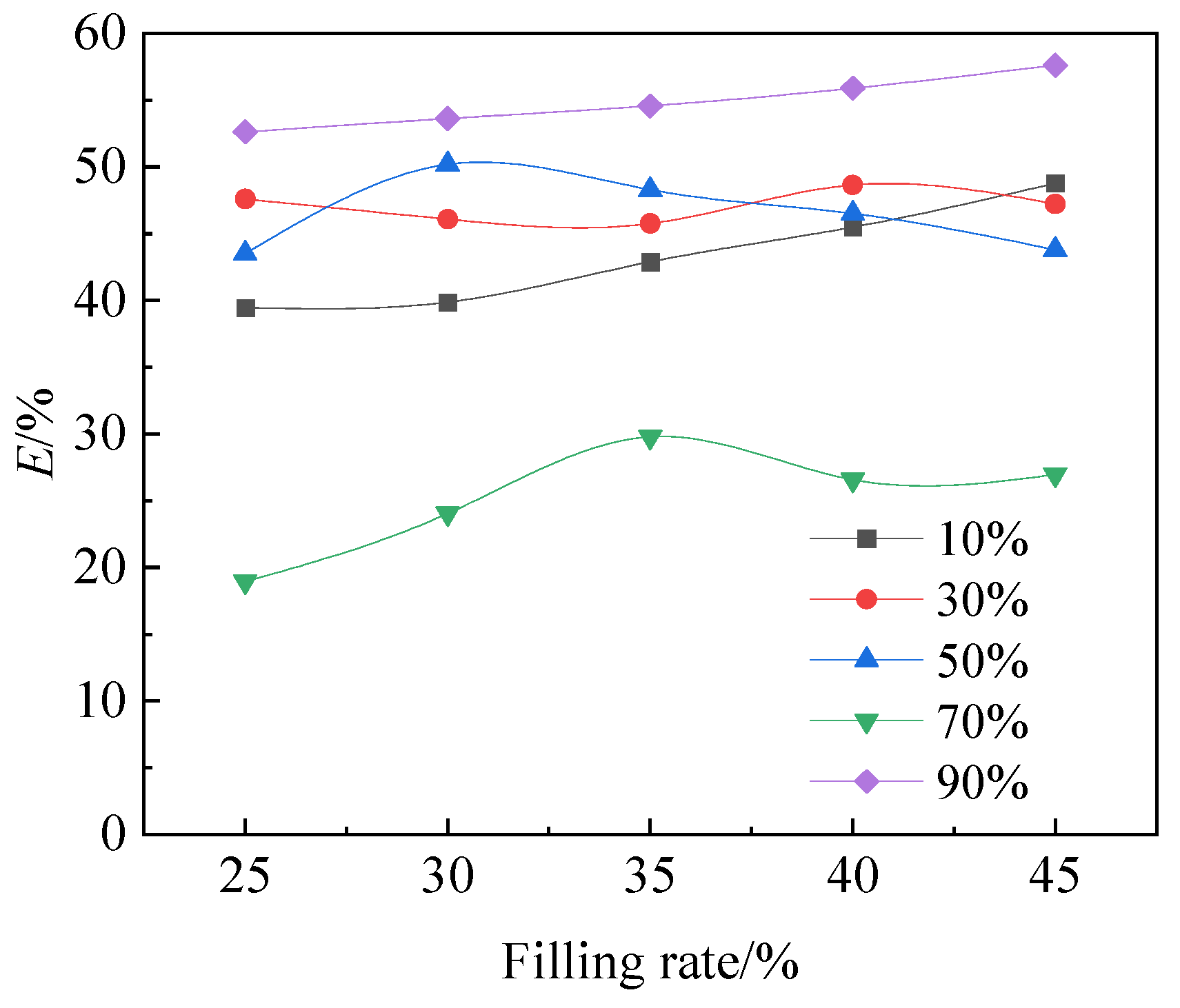

Based on the grinding test data in Section 3.3.1 Effect of Mill Filling Rate on the Particle Size Composition of Grinding Products, the corresponding grinding technical efficiency can be calculated by using Equation (2), and the results are shown in Figure 23.

Figure 23.

The effect of mill filling rate on grinding technical efficiency under different contents of Φ20 mm steel balls.

As can be seen in Figure 23, the effect of the filling rate on the grinding technical efficiency is more significant. Under the conditions of the single grinding media of Φ20 mm and Φ30 mm steel balls, the grinding technical efficiency exhibits a pattern of initial increase, followed by a decrease, and then a subsequent increase with increasing filling rate, reaching its peak at a filling rate of 30%. Under the condition of single grinding media of Φ25 mm steel balls, the grinding technical efficiency also exhibits a pattern of initial increase, followed by a decrease, and then a subsequent increase with increasing filling rate. However, the magnitude of this variation is less pronounced. This is consistent with the conclusions of the previous study in Section 3.3.1 Effect of Mill Filling Rate on the Particle Size Composition of Grinding Products on the yield of −0.15 + 0.038 mm particle size.

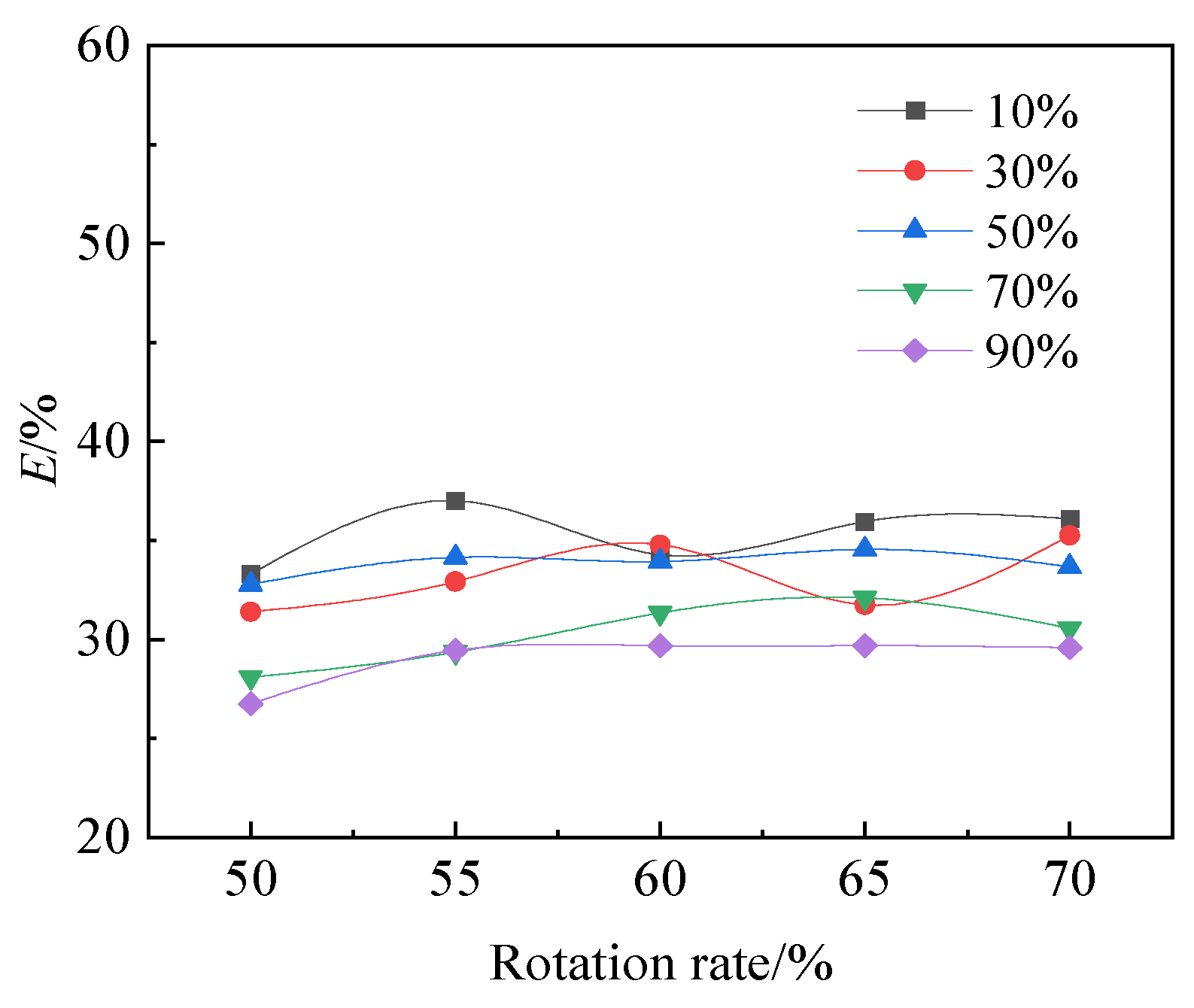

3.3.2. Effect of Mill Filling Rates on the Different Media Combinations

Effect of Mill Filling Rate on the Particle Size Composition of Grinding Products

- (1)

- Grinding test results of steel ball combinations of Φ20 mm and Φ25 mm

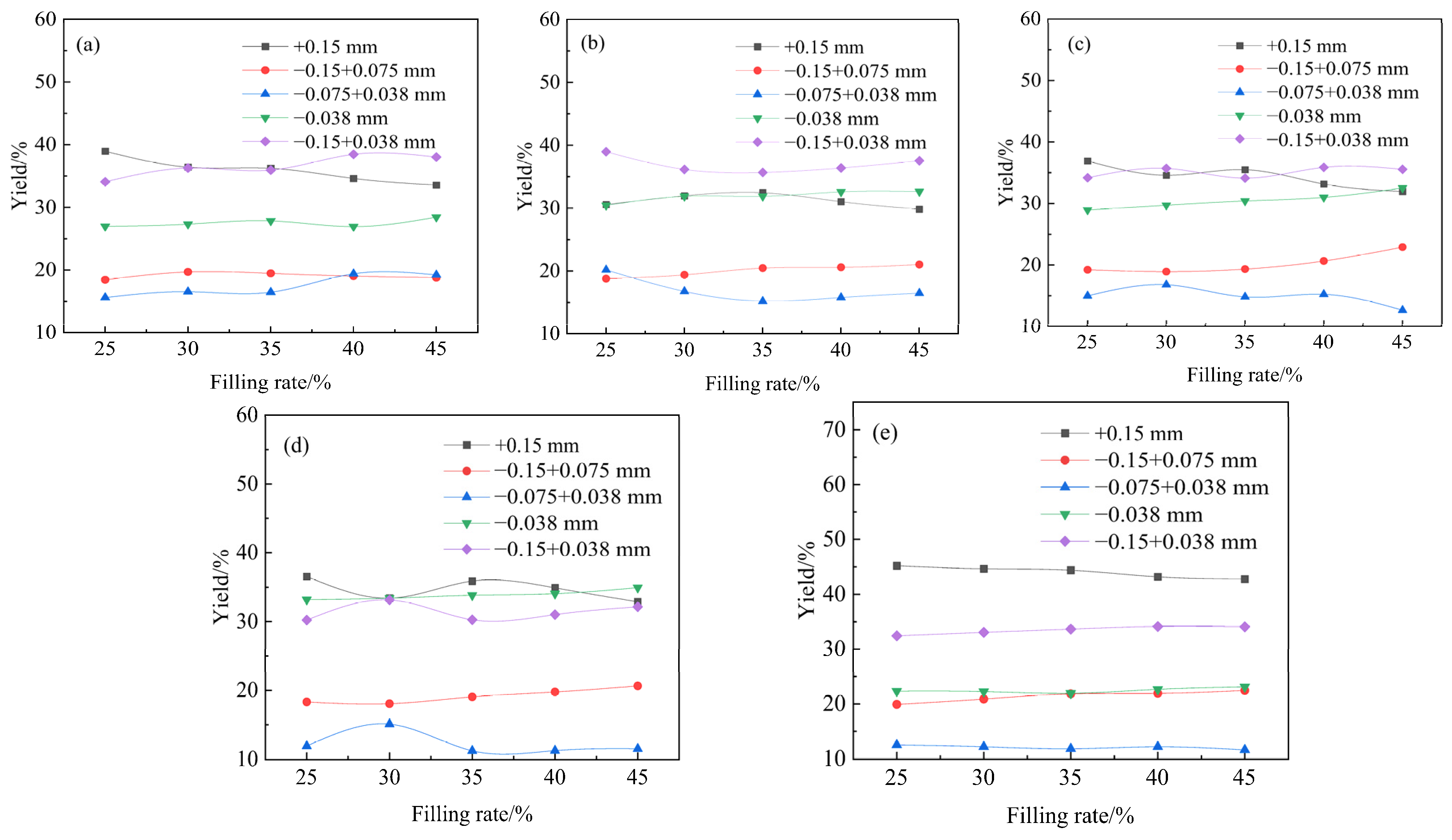

The test conditions were the same as in Section 3.3.1, and the effect of mill filling rate (25%, 30%, 35%, 40%, and 45%) on the yield of each particle size in the grinding products under the different combinations of media (The percentage of Φ20 mm steel balls in the combinations of media is 10%, 30%, 50%, 70%, and 90%) is investigated, and the results are shown in Figure 24.

Figure 24.

The effect of filling rate on the yield of various particle sizes in grinding products under different contents of Φ20 mm steel balls ((a): 10%; (b): 30%; (c): 50%; (d): 70%; (e): 90%).

The comprehensive analysis of Figure 24a–e shows that the yield of all particle sizes basically changes with an increase in the filling rate. It is explained that the filling rate has a certain effect on the yield of each particle size of the grinding products. In addition, as the percentage of Φ20 mm steel balls increases in the combination of Φ20 mm and Φ25 mm steel balls, except for the combination with Φ20 mm steel balls of 70%, under the combination condition of each medium, the particle size distribution of the grinding products shows that the yield of the −0.15 + 0.038 mm particle size is the highest, followed by the −0.038 mm particle size, while the yield of the +0.15 mm particle size is the lowest. It is indicated that the percentage of Φ20 mm steel balls has little effect on the particle size distribution of the grinding products.

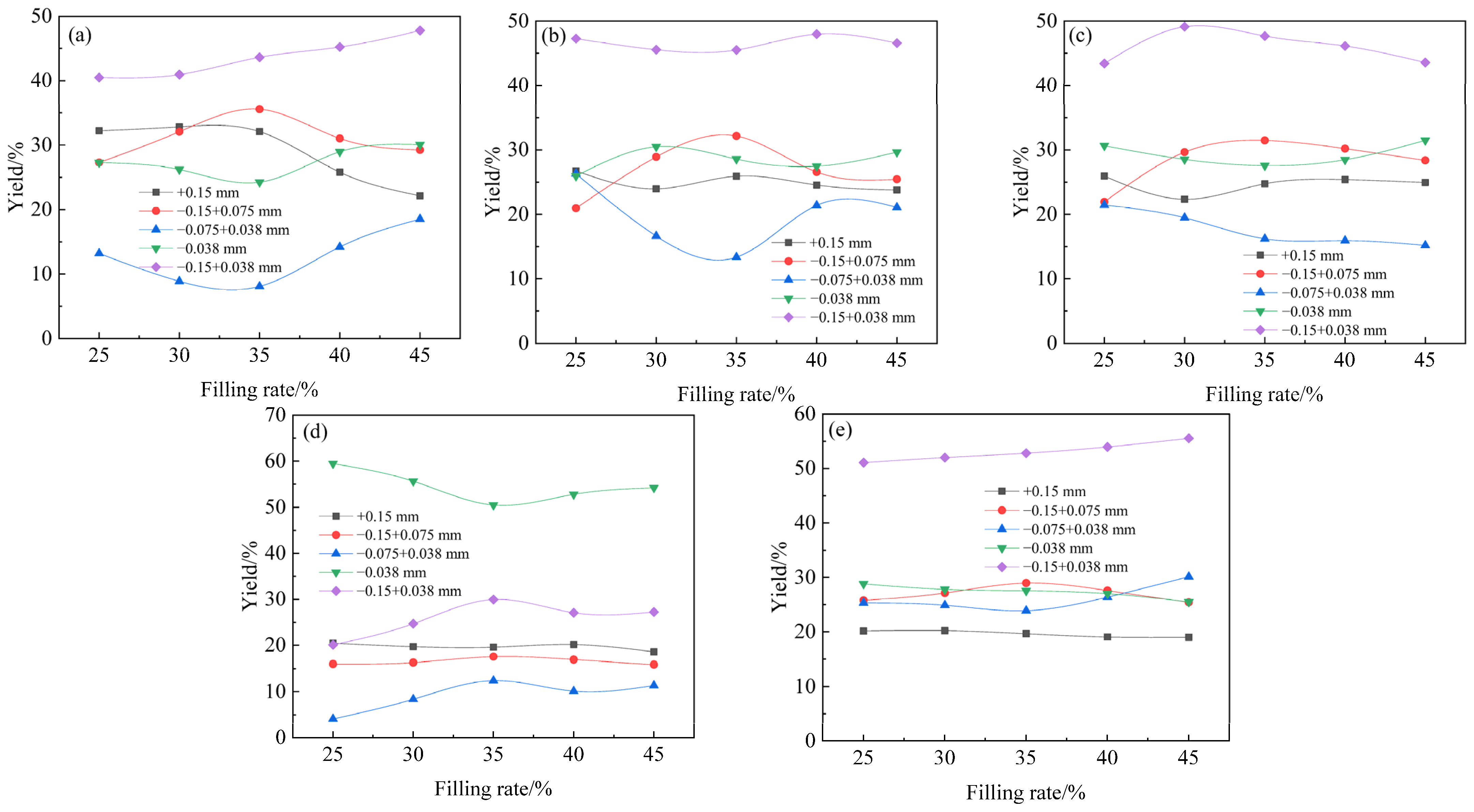

To further investigate the effect of the percentage of Φ20 mm steel balls in a combination of Φ20 mm and Φ25 mm on the yield of a specific particle size in the grinding products as a function of the filling rate, the relationship between the yield of a specific particle size and the filling rate under the combinations of different grinding media was compared and analyzed. The results are shown in Figure 25.

Figure 25.

The effect of filling rate on the yield of a certain particle size in the grinding products under different contents of Φ20 mm steel balls ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

The comprehensive analysis of Figure 25a–e shows that, as the filling rate increases, the yield of under-grinding particle sizes (+0.15 mm) decreases, the yield of qualified particle size (−0.15 + 0.038 mm) increases, while the yield of over-grinding particle size (−0.038 mm) remains essentially unchanged. When the filling rate is constant, the higher the percentage of Φ20 mm steel balls in the combination, the smaller the yield of +0.15 mm particle size; the less pronounced the under-grinding phenomenon, and the better the grinding effect.

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

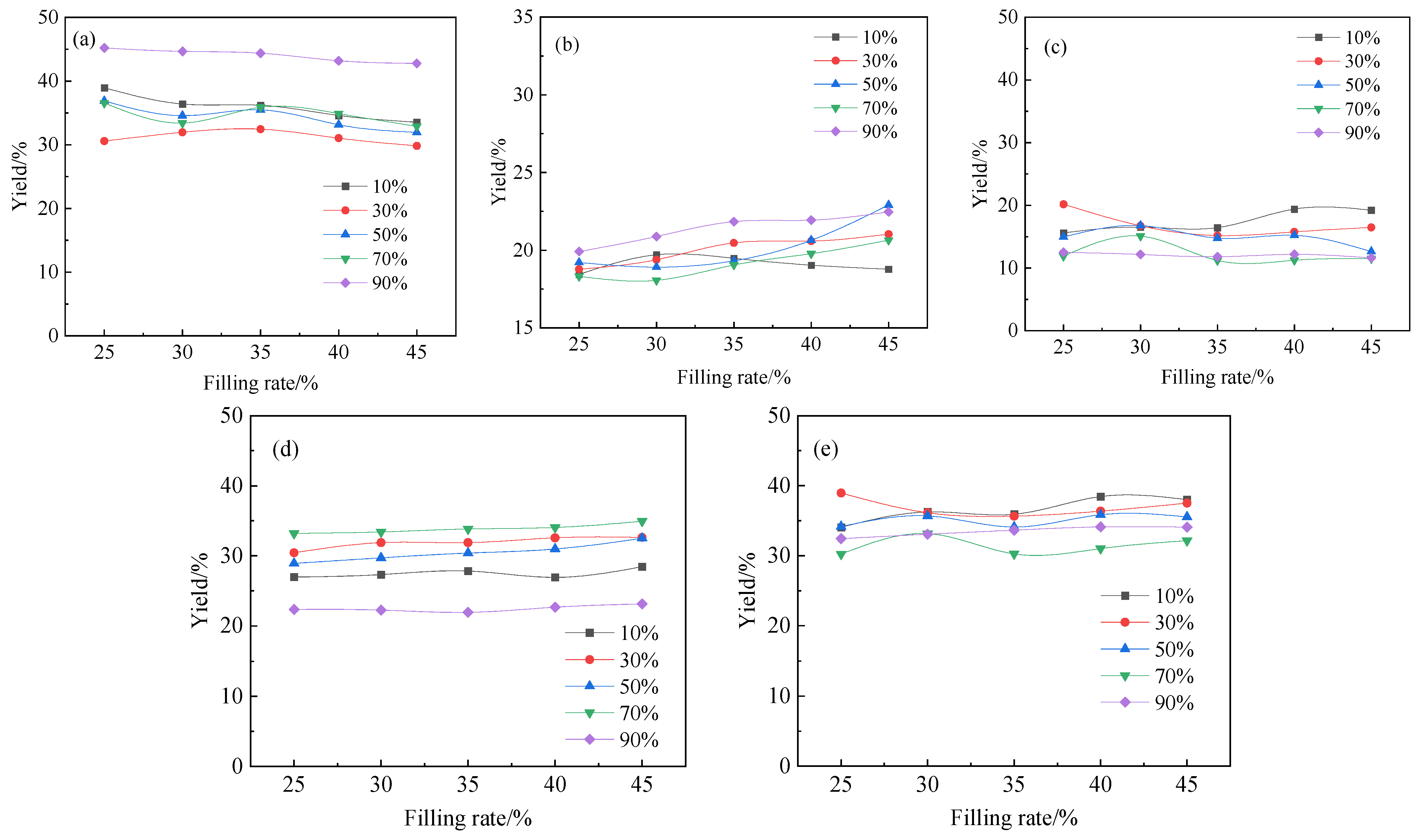

The test conditions are the same as those in Section 3.3.1. This study investigates the effect of the combinations of different media (The percentage of Φ20 mm steel balls in the combination media is 10%, 30%, 50%, 70%, and 90%, respectively.) on the filling rate (5%, 30%, 35%, 40%, 45%) and the yield of each particle size in the grinding products. The results are shown in Figure 26.

Figure 26.

The effect of filling rate on the yield of various particle sizes in grinding products under different contents of Φ20 mm steel balls ((a): 10%; (b): 30%; (c): 50%; (d): 70%; (e): 90%).

As shown in Figure 26a–e, with increasing filling rate, the yield of the +0.15 mm particle size generally decreases, the yield of the −0.15 + 0.038 mm particle size generally increases, and the yield of the −0.038 mm particle size generally increases. This indicates that the filling rate has a significant impact on the yield of each particle size of the grinding products. In addition, as the percentage of Φ20 mm steel balls increases in the combination of Φ20 mm and Φ25 mm steel balls, the composition of the grinding products of each medium combination changes. This indicates that the percentage of Φ20 mm steel balls has a significant impact on the composition of the grinding products.

To further investigate the effect of the percentage of Φ20 mm steel balls in a combination of Φ20 mm and Φ30 mm steel balls on the yield of a specific particle size in the grinding products as a function of the filling rate, the relationship between the yield of a specific particle size and the filling rate under the combinations of different grinding media is compared and analyzed, and the results are shown in Figure 27.

Figure 27.

The effect of filling rate on the yield of a certain particle size in the grinding products under different contents of Φ20 mm steel balls ((a): +0.15 mm; (b): −0.15 + 0.075 mm; (c): −0.075 + 0.038 mm; (d): −0.038 mm; (e): −0.15 + 0.038 mm).

As shown in Figure 27a–e, under the conditions of constant media, as the filling rate increases, the yield of under-grinding particles size (+0.15 mm) decreases, while the yields of qualified particle size (−0.15 + 0.038 mm) and over-grinding particles size (−0.038 mm) generally increase. When the filling rate is constant, the yield of the −0.15 + 0.038 mm particle size decreases as the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ30 mm steel balls increases. The yield of the +0.15 mm and −0.038 mm particle sizes vary complexly with the increase in the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ30 mm.

Through batch grinding tests conducted under conditions combining Φ20 mm and Φ25 mm steel balls and Φ20 mm and Φ30 mm steel balls, it was found that the filling rate has a significant influence on the yield of each particle size of the grinding products. In addition, the percentage of Φ20 mm steel balls in the former combination had little effect on the particle size distribution of the grinding products, while the percentage of Φ20 mm steel balls in the latter combination had a significant effect on the particle size distribution of the grinding products.

Effect of Mill Filling Rate on the Grinding Technical Efficiency

- (1)

- Grinding Test Results of Steel Ball Combinations of Φ20 mm and Φ25 mm

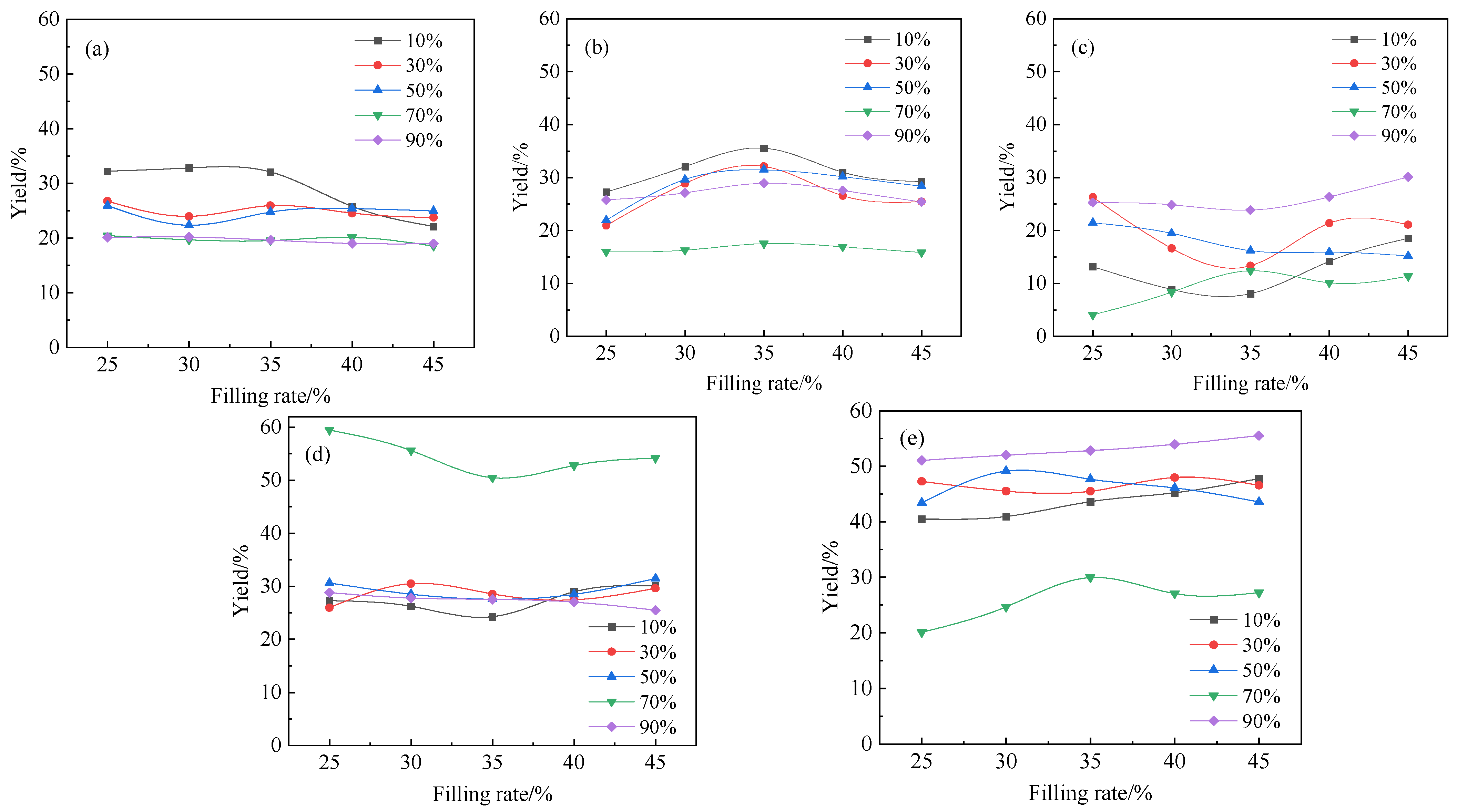

Based on the grinding test data in Section 3.3.2 Effect of mill filling rate on the particle size composition of grinding products, the corresponding grinding technical efficiency can be calculated by using Equation (2), with the results shown in Figure 28.

Figure 28.

The effect of mill filling rate on grinding technical efficiency under different contents of Φ20 mm steel balls.

As shown in Figure 28, when the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ25 mm is 10% and 90%, the grinding technical efficiency increases approximately linearly with the increase in the filling rate. When the percentage of Φ20 mm steel balls is 30%, the grinding technical efficiency increases first and then decreases as the filling rate increases. When the percentage of Φ20 mm steel balls is 50% and 70%, the grinding technical efficiency increases first and then decreases with the increase in the filling rate.

- (2)

- Grinding test results of steel ball combinations of Φ20 mm and Φ30 mm

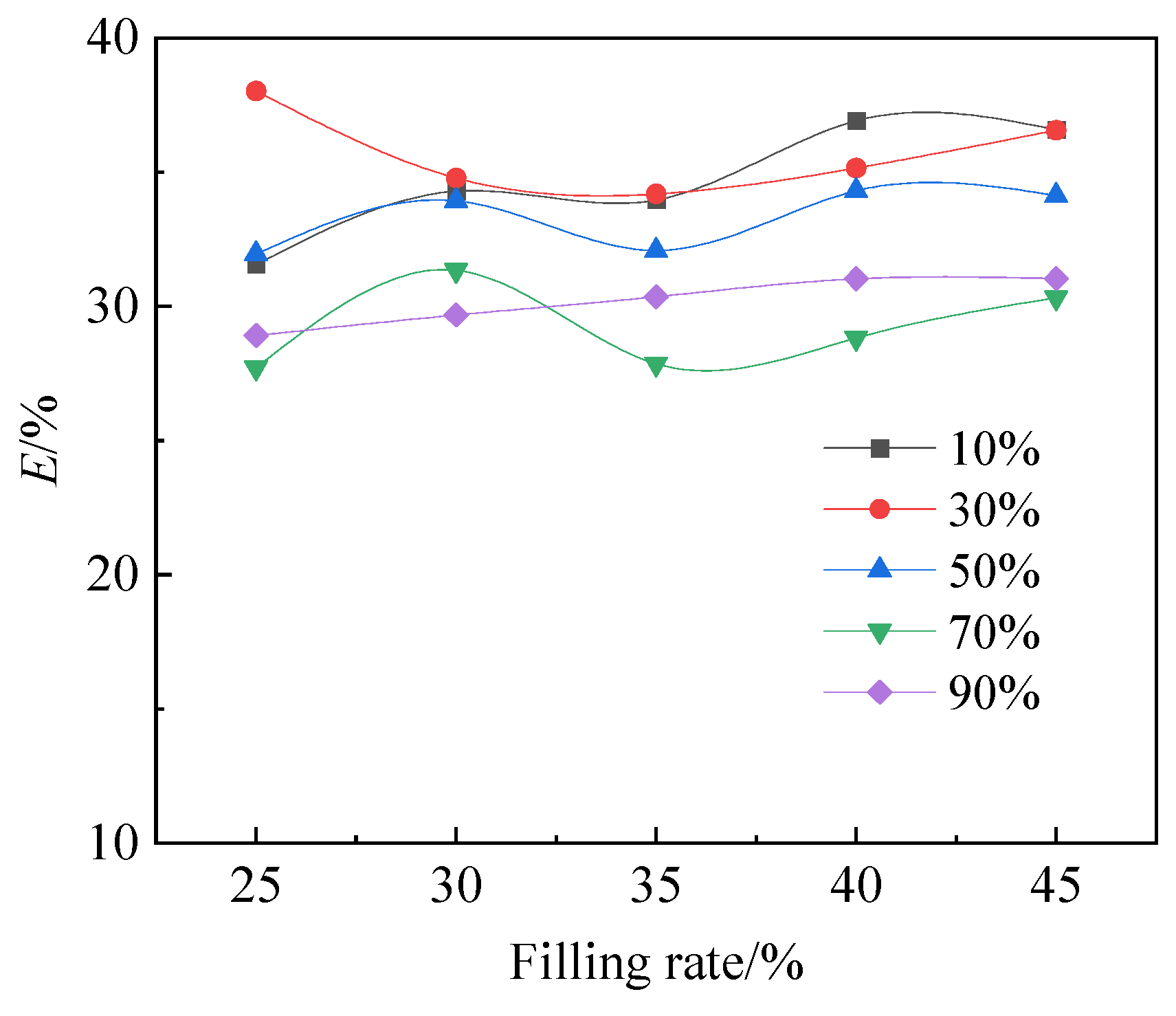

Based on the grinding test data in Section 3.3.2 Effect of mill filling rate on the particle size composition of grinding products, the corresponding grinding technical efficiency can be calculated by using Equation (2), with the results shown in Figure 29.

Figure 29.

The effect of mill filling rate on grinding technical efficiency under different contents of Φ20 mm steel balls.

As can be seen from Figure 29, when the percentage of Φ20 mm steel balls in the combination of Φ20 mm and Φ30 mm is 10% and 90%, the grinding technical efficiency increases with the increase in the filling rate. When the percentage of Φ20 mm steel balls is 50% and 70%, the grinding technical efficiency basically increases with the increase in the filling rate. When the percentage of Φ20 mm steel balls is 30%, the grinding technical efficiency decreases as the filling rate increases. In addition, when the filling rate is constant, the grinding technical efficiency generally decreases as the percentage of 20 mm steel balls increases.

The effect of filling rate on the grinding technical efficiency of grinding products has been studied under the combinations of steel balls of Φ20 mm and Φ25 mm and Φ20 mm and Φ30 mm. It can be concluded that the grinding technical efficiency of the first combination varies significantly with an increase in the filling rate, while the grinding technical efficiency of the second combination varies only slightly with an increase in the filling rate. The grinding technical efficiency of the first combination increases with an increase in the percentage of Φ20 mm steel balls; the grinding technical efficiency of the second combination decreases with an increase in the percentage of Φ20 mm steel balls.

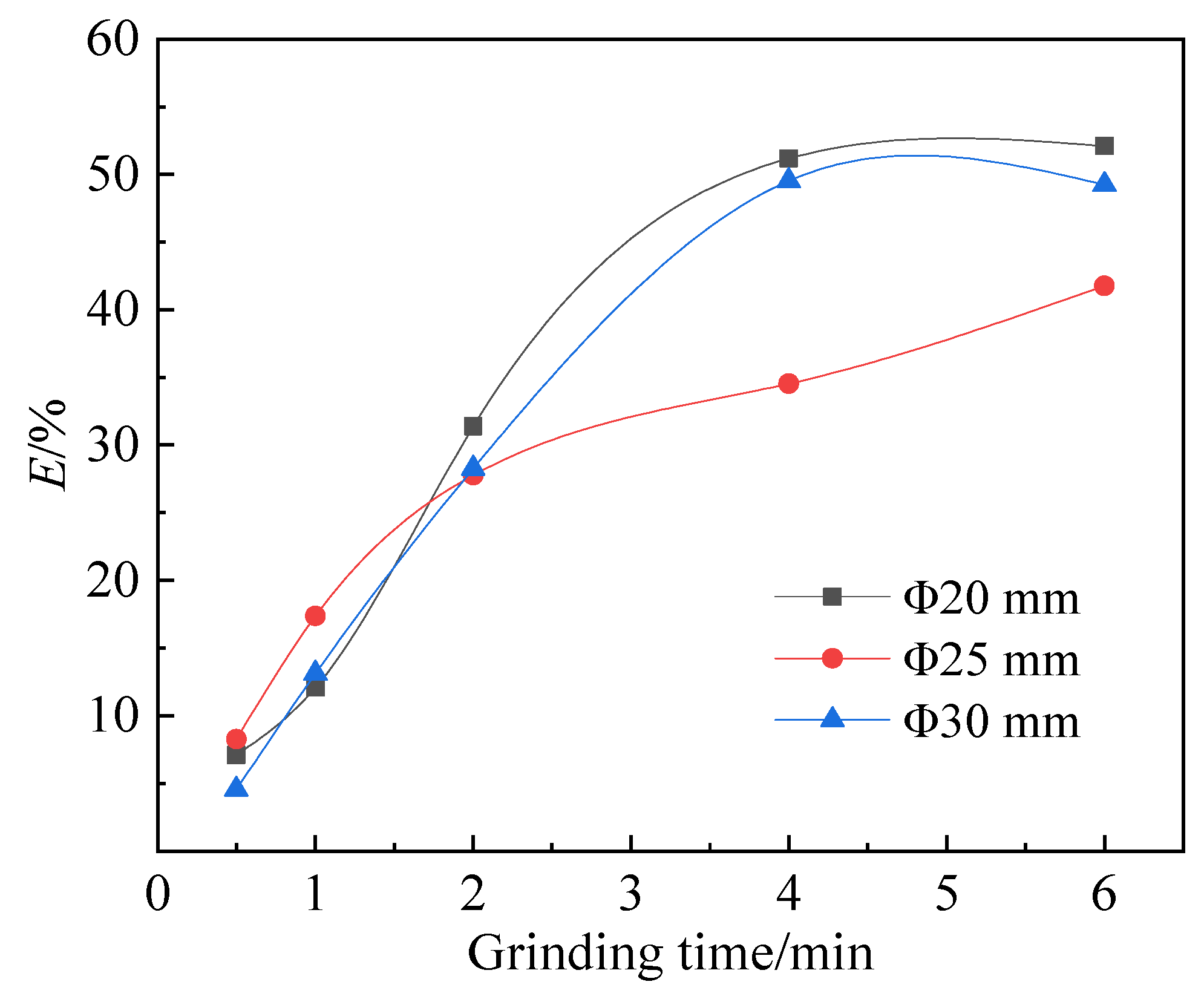

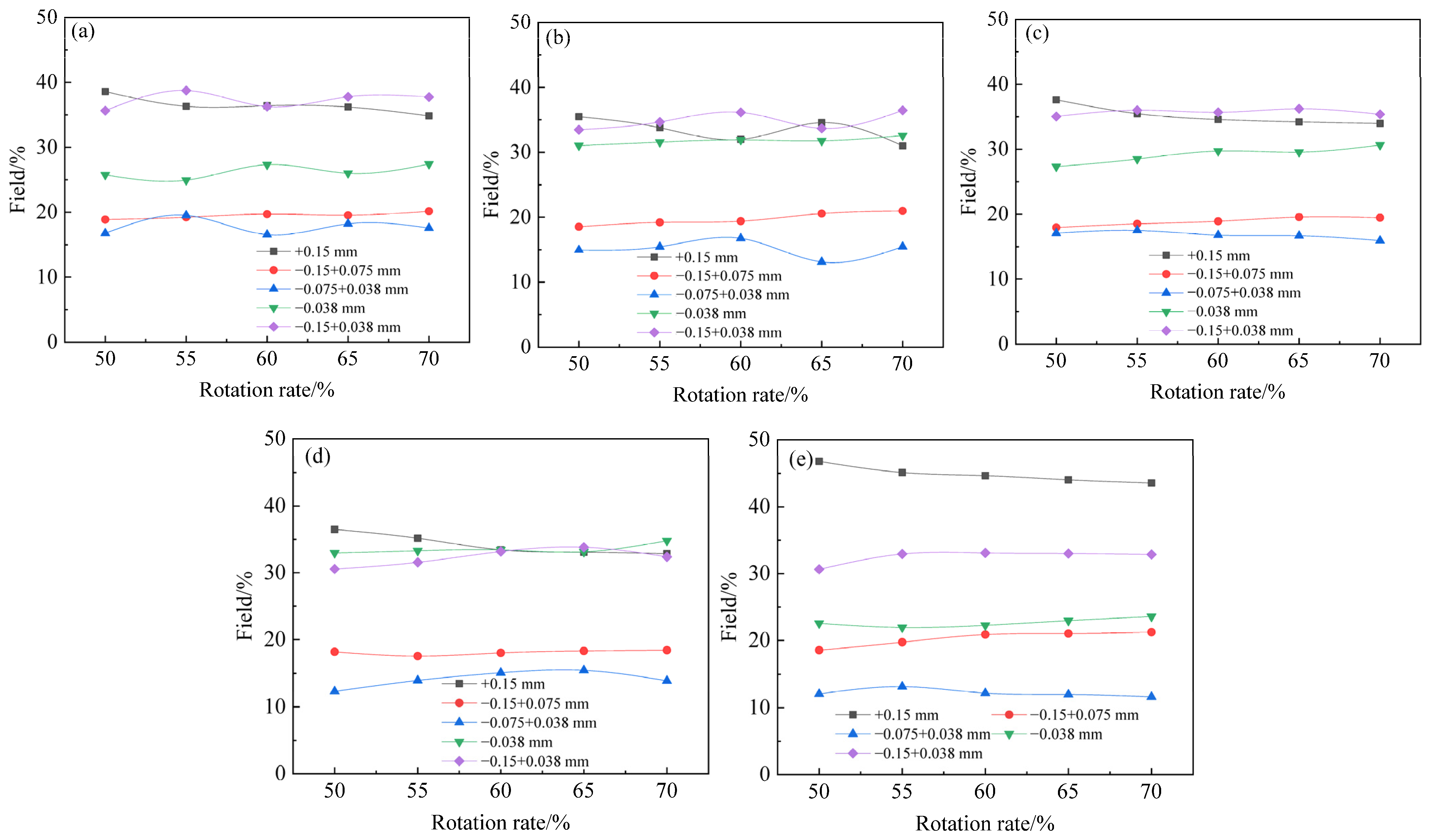

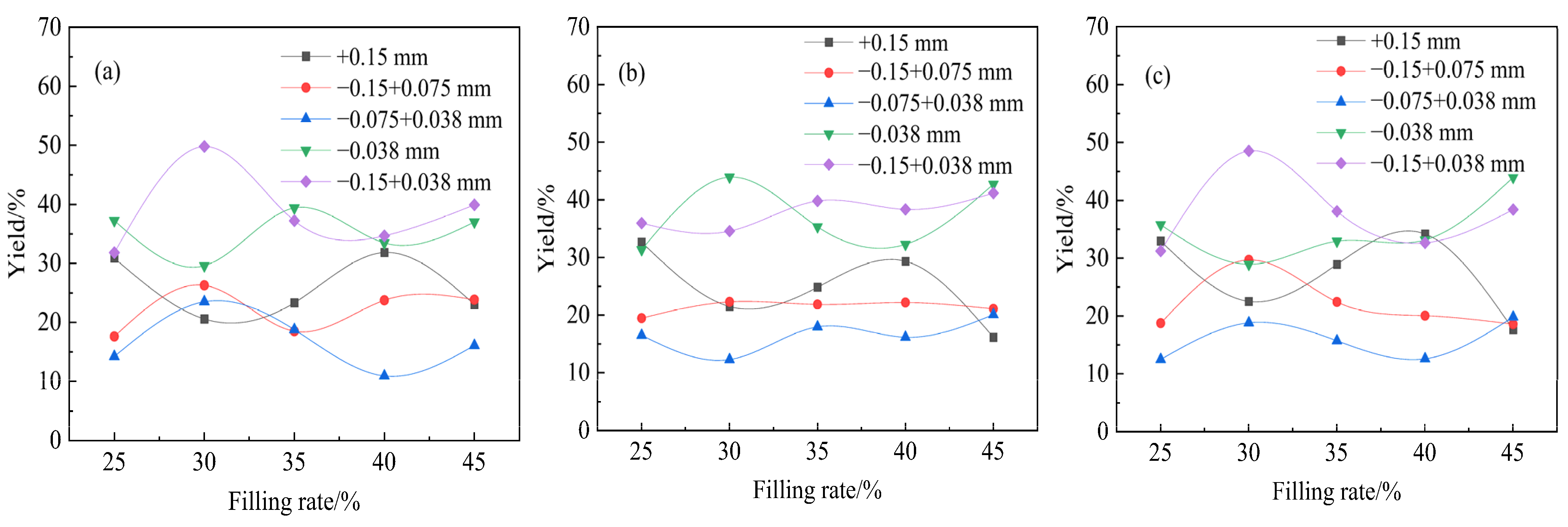

3.4. Comparative Study of Grinding Test Results Under the Single Media and the Different Media Combinations

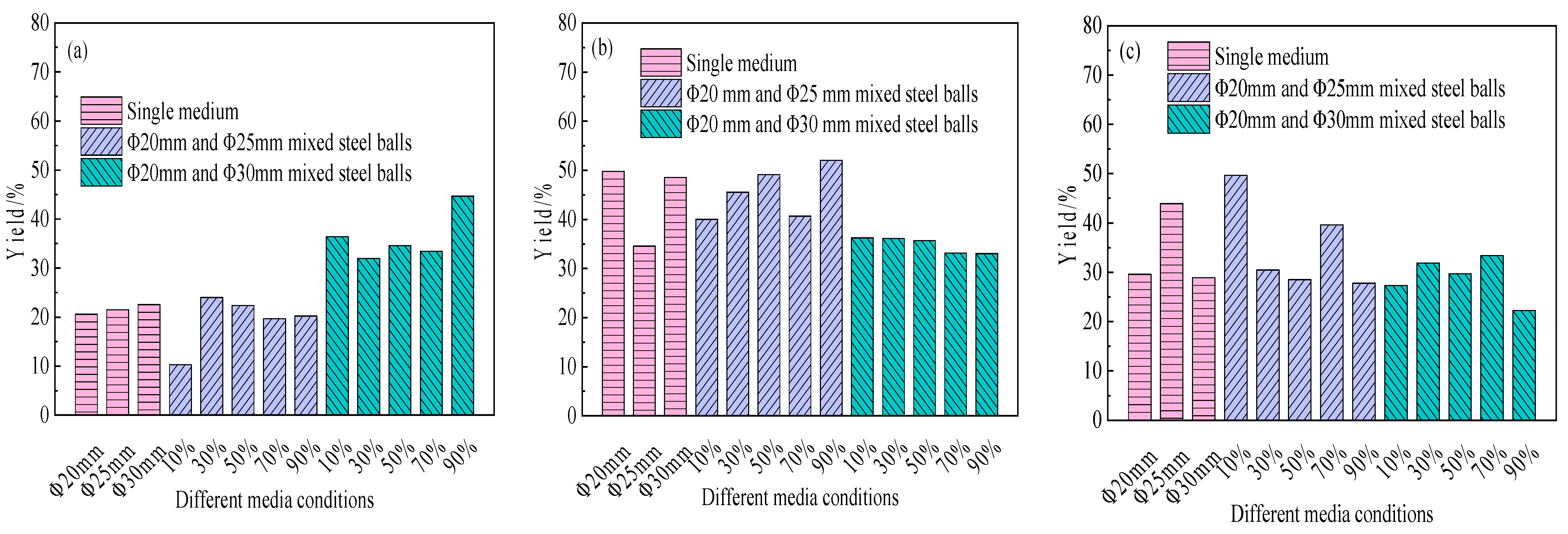

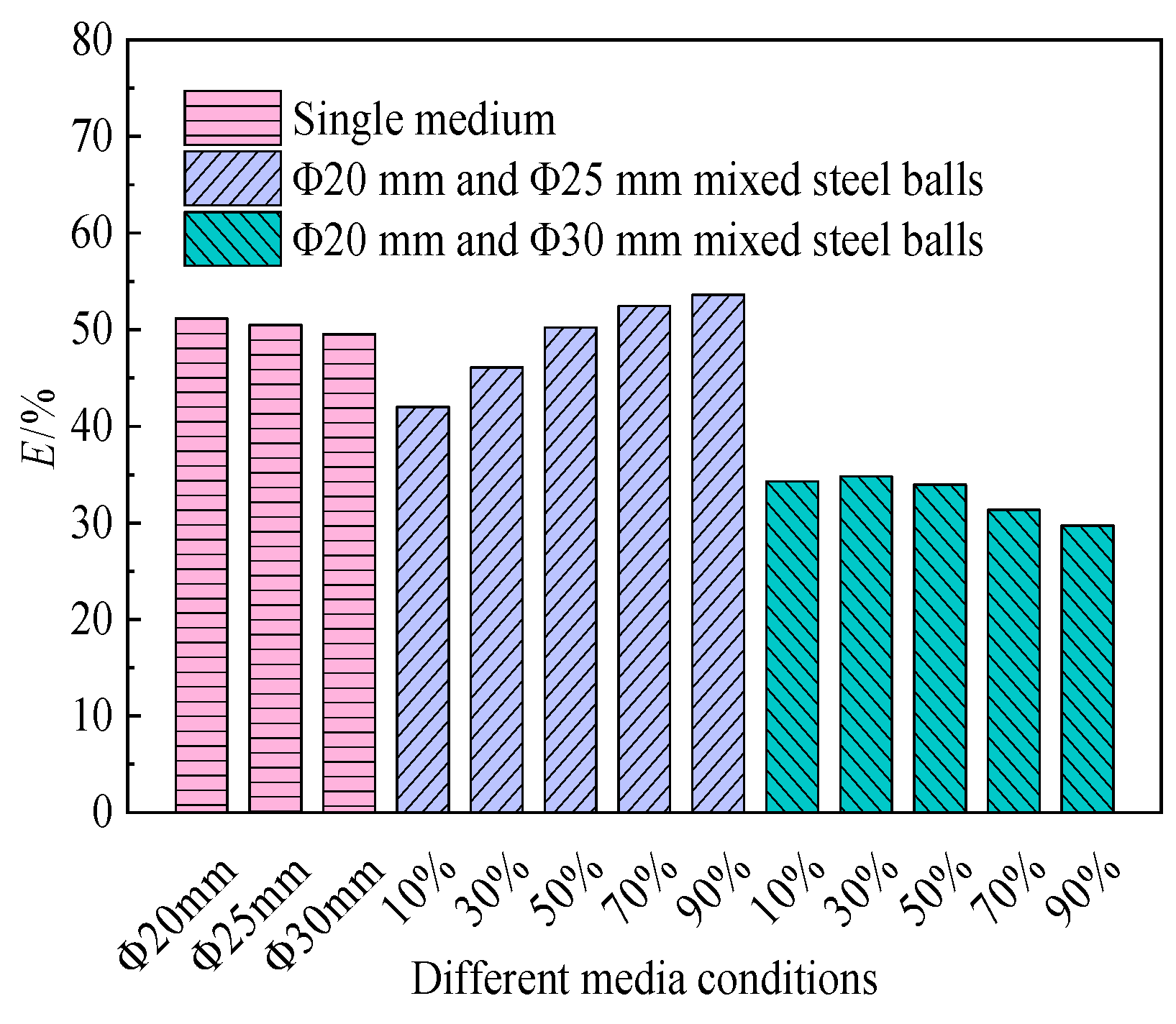

Based on the results of the study in Section 3.1, Section 3.2 and Section 3.3, under the conditions of grinding time of 4 min, rotational rate of 60%, and filling rate of 35%, the media of single and different combinations are selected for the batch grinding tests. The yields of under-grinding particle size (+0.15 mm), qualified particle size (−0.15 + 0.038 mm), over-ground particle size (−0.038 mm), and the grinding technical efficiency are compared and analyzed. The results are shown in Figure 30 and Figure 31.

Figure 30.

Comparison of yield of various particle sizes in the grinding products under different media combination conditions ((a): +0.15 mm; (b): −0.15 + 0.038 mm; (c): −0.038 mm).

Figure 31.

Comparison of grinding technical efficiency under different media conditions.

As can be seen from Figure 30a, when the grinding medium is a single medium, the yield of the +0.15 mm particle size increases with the increase in the diameter of the steel balls. When the grinding media consists of a combination of Φ20 mm and Φ25 mm steel balls, the yield of the +0.15 mm particle size decreases gradually with an increase in the percentage of Φ20 mm. When the grinding media consists of a combination of Φ20 mm and Φ30 mm steel balls, the yield of the +0.15 mm particle size increases gradually with the increase in the percentage of Φ20 mm balls. Additionally, the yield of the +0.15 mm particle size under the combination of Φ20 mm and Φ30 mm steel balls is higher than that under conditions of single medium and the combination of Φ20 mm and Φ25 mm.

As can be seen from Figure 30b, when the grinding medium is a single medium, the yield of the −0.15 + 0.038 mm particle size under the conditions of 20 mm and 30 mm steel balls is greater than that under the conditions of 25 mm steel balls. When the combination of grinding media is composed of Φ20 mm and Φ25 mm steel balls, the yield of the −0.15 + 0.038 mm particle size increases gradually with the increase in the percentage of Φ20 mm steel balls. When the combination of grinding media is composed of Φ20 mm and Φ30 mm steel balls, the yield of the −0.15 + 0.038 mm particle size decreases gradually with an increase in the percentage of Φ20 mm balls. In addition, the media conditions with the highest yield of particle size of −0.15 + 0.038 mm are the single medium of Φ20 mm and Φ30 mm steel balls, and a combination of Φ20 mm and Φ25 mm steel balls with a Φ20 mm steel ball content of 50% and 70%.

As can be seen from Figure 30c, when the grinding medium is a single medium, the yield of the −0.038 mm particle size under the conditions of Φ20 mm and Φ30 mm steel balls is less than the yield of the −0.038 mm particle size under the conditions of Φ25 mm.

When the grinding media consists of the combination of Φ20 mm and Φ25 mm steel balls, the yield of the −0.038 mm particle size gradually decreases with an increase in the percentage of Φ20 mm steel balls. When the grinding media consists of a combination of Φ20 mm and Φ30 mm steel balls, with an increase in the percentage of Φ20 mm balls, the yield of the −0.038 mm particle size increases initially and then decreases. In addition, the conditions of media with the highest yield of particle size of −0.038 mm are a combination of Φ20 mm and Φ25 mm steel balls with a Φ20 mm steel ball percentage of 10% and 70%, and a single medium of Φ25 mm.

As can be seen from the literature [31], the valuable minerals in ore have a certain degree of brittleness and are prone to over-grinding. However, the gangue minerals in the ore are hard oxide minerals. Chemical analysis of the ore also confirms that gangue is mostly composed of oxide minerals in Section 2.1 of the article, and it is difficult to grind. Based on this, a comprehensive analysis of the above studies reveals that, when the single media and the combination of Φ20 mm and Φ25 mm are used for grinding, the yield of under-grinding particle size is small. This indicates that, in the media of single and combinations of Φ20 mm and Φ25 mm, the soft minerals (sulfide minerals, cassiterite) of coarse fraction are highly efficient impacted crushing [32]. Therefore, the yield of coarse fraction ore entering the qualified particle size is relatively high. The yield of under-grinding particle size in the combination of Φ20 mm and Φ30 mm is relatively high. Due to the large difference in diameter between the two steel balls, although the larger media can effectively impact crushing the minerals in coarse fraction, the smaller media have poorer selectivity for the minerals of coarse fraction [33]. Meanwhile, the large balls have a smaller specific surface area, which results in fewer contact points with minerals when the synergistic work of the two types of balls [34]. Therefore, they cannot effectively impact crushing the ore of coarse fraction. The yield of the under-grinding particle size is relatively high, while the yield of the coarse fraction size entering the qualified particle size is relatively low. A reanalysis of the above results shows that, overall, when the yield of qualified particle size of the grinding product is used as an evaluation criterion, The yield of the qualified particle size of the grinding products is used as an evaluation index, the order of the grinding effect of different media conditions was as follows: steel ball combination of Φ20 mm and Φ25 mm > steel balls of three single sizes > steel ball combination of Φ20 mm and Φ30 mm.

As can be seen from Figure 31, when the grinding media are single type, the grinding technical efficiency gradually decreases with the increase in the diameter of the steel balls. When the diameter of medium is 20 mm, its impact crushing energy is just enough to effectively grind the coarse fraction, i.e., the valuable mineral in the cassiterite polymetallic sulfide ore is also effectively crushed under the diameter of media. As the diameter of the ball increases, the specific surface area of the ball decreases when the power output of the ball mill remains constant [35]. Therefore, the grinding technical efficiency will decrease. When the grinding media consists of the combination of Φ20 mm and Φ25 mm steel balls, the grinding technical efficiency increases gradually with an increase in the percentage of Φ20 mm steel balls. The reason for this is that the diameter of medium is 20 mm; the impact crushing energy is just sufficient to effectively grind coarse fraction during grinding with the synergistic action of two balls. Therefore, as the proportion of 20 mm media increases, the grinding technical efficiency gradually increases. When the proportion of 20 mm media is greater than 70%, the overall grinding technical efficiency is higher than that of single media. The reason for this is that when the two balls work together, the larger media have the greater impact crushing energy, which can efficiently grind coarse fractions while the smaller media can further crush coarser particles that were unable to be broken or nipped in the feed [36]. Therefore, the synergistic effect of the two types of balls is relatively superior, and the grinding technical efficiency of the ore is relatively high. When the grinding media consists of the combination of Φ20 mm and Φ30 mm steel balls, the grinding technical efficiency decreases gradually as the percentage of Φ20 mm steel balls increases. The reason is an excessive gap between the diameters of the two balls. Although the large media can effectively break the coarse fraction, the small media cannot effectively break the coarse fraction which is mixed in the feed or coarse particles broken by large media [37]. Therefore, the proportion of coarse fraction entering the qualified particle size for the sample is relatively small, which leads to the problem of low grinding technical efficiency in this type of media ratio. A comprehensive analysis shows that, overall, the combination of Φ20 mm and Φ25 mm > three single-size > the combination of Φ20 mm and Φ30 mm. At the same time, this reasonable media ratio will effectively synergize the best grinding effect of large and small media. The optimal grinding media ratios are recommended combination of Φ20 mm and Φ25 mm (the percentage of the Φ20 mm ball is 90%).

4. Conclusions

- (1)

- Grinding time has a significant effect on the particle size distribution of the grinding products. Regardless of whether the media size of the single or the combination of two different sizes is used. The yield of qualified particle size (−0.15 + 0.038 mm) increases with grinding time, but the yield of over-grinding particle size also increases accordingly. After 4 min of grinding, the yield of over-grinding particle size approaches that of the qualified particle size and even exceeds it. Therefore, in the actual grinding process of cassiterite polymetallic sulfide ore, more attention should be paid to reasonable grinding time, and the products of qualified particle size should be expelled in a timely manner to prevent over-grinding. After comprehensive consideration, 4 min is the most appropriate grinding time.

- (2)

- The rotational rate has little effect on the particle size distribution of the grinding products. Under the conditions of the single media. The yield of qualified particle size (−0.15 + 0.038 mm) increases slightly with increasing rotational rate, reaching a maximum at 60%. Under the combination of two media conditions of Φ20 mm and Φ25 mm and Φ20 mm and Φ30 mm, as the rotational rate increases, the yield of coarse particle size decreases, while the yield of qualified size and fine particle size both increases. At the constant rotational rate, the higher the percentage of Φ20 mm steel balls, the better the grinding effect, and the less pronounced the over-grinding phenomenon. Therefore, the rotational rate of 60% is more appropriate.

- (3)

- The filling rate has a significant impact on the particle size distribution of the grinding products. Under the conditions of the single medium. The yield of particle sizes of −0.15 + 0.038 mm increases first and then decreases with increasing filling rate, reaching a maximum at 30%, and the optimal filling rate is 30%. Under the combination conditions of two different media. When the filling rate is constant, the higher the ball percentage, the better the grinding effect and the less obvious the over-grinding phenomenon. After the comprehensive consideration, the filling rate of 35% is considered appropriate.

- (4)

- Under the optimal parameters of grinding operations, the yield of qualified particle size and grinding technical efficiency are used as evaluation indices. Overall, the order of the grinding effect of different media conditions was as follows: steel ball combination of Φ20 mm and Φ25 mm > steel balls of three single sizes > steel ball combination of Φ20 mm and Φ30 mm. Whether in the single media or the mixed media, 20 mm steel balls play a crucial role in the grinding effect on the cassiterite polymetallic sulfide ore. Among them, the best grinding effect is achieved when the media ratios are Φ20 mm and Φ25 mm (the percentage of the Φ20 mm ball is 90%). Therefore, in the actual grinding of cassiterite polymetallic sulfide ore, the reasonable grinding media ratios and selection of ball diameter are crucial for the effective synergy between large and small media to achieve the best grinding efficiency.

Author Contributions

Conceptualization, J.Y. and P.Z.; Data curation, X.D. and D.W.; Formal analysis, X.D. and H.L.; Funding acquisition, S.M.; Investigation, X.D. and P.Z.; Methodology, J.Y. and S.M.; Project administration, J.Y. and P.Z.; Validation, H.L. and D.W.; Writing—Original draft, J.Y. and D.W.; Writing—Review and editing, J.Y. and D.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. 52274258) and was supported by the Special Fund for Science and Technology Development of Guangxi (No. AD25069078).

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy reasons.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tian, C.; Gao, P.; Tang, Z. Optimization of grinding parameters and efficient separation of iron and rare earths from poor oxide ores in magnetic separation operation. Powder Technol. 2025, 458, 120962. [Google Scholar] [CrossRef]

- Li, Q.; Wu, L.; Yang, Y.; Gu, G.; Wang, Y. The relationship among pyrite fine grinding by stirred ball mill and tumbling ball mill, the properties of the product and the flotation behavior. Miner. Eng. 2025, 229, 109401. [Google Scholar] [CrossRef]

- Pereira, L.; Kupka, N.; Huu Hoang, D. On the impact of grinding conditions in the flotation of semi-soluble salt-type mineral-containing ores driven by surface or particle geometry effects? Int. J. Min. Sci. Technol. 2023, 33, 855–872. [Google Scholar] [CrossRef]

- Yang, B.; He, J. New insights into selective depression mechanism of Tamarindus indica kernel gum in flotation separation of fluorapatite and calcite. Sep. Purif. Technol. 2025, 354, 128787. [Google Scholar] [CrossRef]

- Akkaya, B.; Toroğlu, İ.; Bilen, M. Studying the effect of different operation parameters on the grinding energy efficiency in laboratory stirred mill. Adv. Powder Technol. 2020, 31, 4517–4525. [Google Scholar] [CrossRef]

- Urbaniak, D.; Kolmasiak, C.; Wylecial, T. Using of fluidized-bed jet mill to a super fine comminution of steel composite. Metalurgij 2015, 54, 201–203. [Google Scholar]

- Krishnaraj, L.; Ravichandran, P.T. Investigation on grinding impact of fly ash particles and its characterization analysis in cement mortar composites. Ain Shams Eng. J. 2019, 10, 267–274. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, S.; Deng, S. Effect of grinding aids on the fracture energy of mica. Met. Mine 2010, 402, 80–84. (In Chinese) [Google Scholar] [CrossRef]

- Wu, N.; Li, S. Test on Copper Separation Process of a Pyrrhotite-type Low-grade Copper Ore. Mod. Min. 2023, 39, 169–172. (In Chinese) [Google Scholar]

- Yang, X.; Hu, G.; Wang, S. Research Progress of Magnesium Removal Technology from Medium and Low Grade Phosphate Rocks. Conserv. Util. Miner. Resour. 2022, 42, 67–73. (In Chinese) [Google Scholar]

- Xue, H.Y.; Lv, G.Z.; Wang, L.; Zhang, T.A. Review of rare earth extraction and product preparation technologies and new thinking for clean utilization. Miner. Eng. 2024, 215, 108796. [Google Scholar] [CrossRef]

- Guo, M.C.; Yang, Y.K.; Yu, S.L. Effects of Grinding Parameters on Galena Particle Size Distribution and Flotation Performance. Minerals 2025, 15, 618. [Google Scholar] [CrossRef]

- Fang, X.; Wu, C.B.; Liao, N.N. Investigating the Influence of Medium Size and Ratio on Grinding Characteristics. Minerals 2024, 14, 875. [Google Scholar] [CrossRef]

- Si, L.; Cao, Y.J.; Fan, G.X. The Effect of Grinding Media on Mineral Breakage Properties of Magnetite Ores. Geofluids 2021, 2021, 1–9. [Google Scholar] [CrossRef]

- Muanpaopong, N.; Davé, R.; Bilgili, E. Application of TUSSIM with a variable Tromp curve for predicting optimal operation of multi-compartment mills with various ball size distributions. Adv. Powder Technol. 2023, 34, 104171. [Google Scholar] [CrossRef]

- Genç, Ö. Effect of ball load and size distribution on grinding and classification performance. Zkg Int. 2015, 68, 40–51. [Google Scholar]

- Ma, S.; Deng, J.; Xing, D.; Zhang, Y.; Ren, J.; Hu, M.; Huang, Y.; Wu, B. Effects of controllable shock wave on particle size characteristics of tin polymetallic ore crushing products. J. Mater. Res. Technol. 2023, 26, 3676–3685. [Google Scholar] [CrossRef]

- Liu, Y.-P.; Ni, P.; Pan, J.-Y.; Su, W.-C.; Albanese, S.; Cui, J.-M.; Cai, Y.-F.; Fan, M.-S.; Cheng, Z.-L. Geochemistry of sulfides from massive carbonate replacement type tin ore at Gaofeng, Dachang orefield: Insights into precipitation conditions and enrichment of critical metals. J. Geochem. Explor. 2025, 275, 107787. [Google Scholar] [CrossRef]

- Liu, S.Q.; Tong, X.; Song, B.X.; Wang, W.P. In Case Study on Beneficiation of Cassiterite-Polymetallic Sulphide Ores. In Proceedings of the 2nd International Conference on Automation, Communication, Architectonics and Materials (ACAM 2012), Hefei, China, 23–24 June 2012; pp. 28–31. [Google Scholar]

- Aikawa, K.; Ito, M.; Segawa, T.; Jeon, S.; Park, I.; Tabelin, C.B.; Hiroyoshi, N. Depression of lead-activated sphalerite by pyrite via galvanic interactions: Implications to the selective flotation of complex sulfide ores. Miner. Eng. 2020, 152, 106367. [Google Scholar] [CrossRef]

- Yang, J.; Shuai, Z.; Zhou, W.; Ma, S. Grinding Optimization of Cassiterite-Polymetallic Sulfide Ore. Minerals 2019, 9, 134. [Google Scholar] [CrossRef]

- Chimwani, N.; Mulenga, F.K.; Hildebrandt, D. Ball size distribution for the maximum production of a narrowly-sized mill product. Powder Technol. 2015, 284, 12–18. [Google Scholar] [CrossRef]

- Cho, H.; Kwon, J.; Kim, K.; Mun, M. Optimum choice of the make-up ball sizes for maximum throughput in tumbling ball mills. Powder Technol. 2013, 246, 625–634. [Google Scholar] [CrossRef]