Abstract

High-gradient magnetic separation is a key step in the pre-concentration of ilmenite before flotation, particularly in the gravity separation process. However, as the amount of weakly magnetic gangue minerals increases, the grade of the coarse concentrate from high-gradient magnetic separation decreases. This paper investigates the mineralogical factors affecting the enrichment efficiency of high-gradient magnetic separation. Additionally, a newly developed stirred fluidized bed device, an agitated reflux classifier (ARC), was successfully applied to remove weakly magnetic gangue minerals that are difficult to separate by high-gradient magnetic separation (HGMS). For low-grade ilmenite with a feed grade of 3.97%, a combined process of magnetic separation and gravity separation was employed, achieving a concentrate with a grade of 16.50% and a recovery rate of 54.11%. This concentrate meets the requirements for flotation feed. This study provides a new approach for the beneficiation of low-grade ilmenite.

1. Introduction

Titanium is a strategic metal widely used in aerospace, petrochemical, and automobile industries because of its outstanding physical and chemical properties. China, with vast global titanium reserves, exhibits a distinct geographical concentration of titanium ore resources [1,2,3,4,5].

The Panxi region (Panzhihua City and surrounding areas in Sichuan Province) is the core base of China’s titanium resources, accounting for 93% of the country’s total reserves. This region is of significant importance as a material base for the development of China’s titanium industry. Currently, the raw material for titanium concentrate in the Panzhihua area is derived from tailings generated during iron ore beneficiation. As the requirements for iron ore beneficiation operations increase in terms of mining depth and grinding fineness, the poor, fine, and impure characteristics of the ore become more prominent. The deposits in this region are of magmatic crystallization and differentiation, and consist of vanadium–titanium magnetite deposits. These deposits are associated with a basal-ultrabasic heterogeneous rock body. Titanium exists in two forms: one as analogous or homogeneous solid solution decomposition products in the titanium magnetite lattice, which are lost with the iron concentrate during beneficiation. The other form exists as granular ilmenite in independent mineral phases, accounting for approximately 50% of the total titanium metal in the deposits and constituting the main target minerals for titanium beneficiation [4,6]. Of particular concern is the small difference in specific magnetization coefficients between ilmenite and gangue minerals, ranging from (2.5 to 3.8) × 10−7 Am2/kg, which complicates effective magnetic separation in intense magnetic fields. Gravity separation, flotation, HGMS, and their combinations are commonly used to separate fine ilmenite.

Flotation is a conventional method for purifying titanium from roughing concentrates [7,8,9]. The challenge lies in the similar flotation characteristics of titanium-bearing ores, such as titanium pyroxene and ilmenite, which reduce flotation efficiency. Pre-concentration is therefore crucial for recovering low-grade ilmenite. HGMS is widely used on an industrial scale for pre-concentration low-grade fine ilmenite ores, effectively removing non-magnetic minerals. However, mechanical entrainment reduces the selectivity of the HGMS process for valuable minerals. Therefore, obtaining a high-grade concentrate solely through magnetic separation is challenging, and it is also difficult to maintain a specific enrichment effect while ensuring recovery [10,11,12].

In gravity separation, the process is typically based on the density differences between the target and gangue minerals. Therefore, for gangue minerals with similar magnetic susceptibility, gravity separation can achieve more efficient separation. Utilizing gravity separation equipment to process HGMS concentrates and remove gangue minerals has emerged as a viable option. The reflux classifier (RC) is a novel high-capacity solid–liquid fluidized bed separation device [13,14]. Developed by Australian professor Galvin in 2002, it was first applied to coal separation [15,16,17]. It has also shown notable applications in iron ore. Compared with traditional fluidized bed equipment, the RC incorporates parallel inclined plates in the upper bed zone, enhancing separation efficiency. In previous research, Zhenqiang Liu used an improved laboratory RC to process titanium iron ore (8.77% feed grade), and experimental tests on ultrafine titanomagnetite with a feed grade of 8.77% resulted in a concentrate containing 20.3% titanium dioxide, with a recovery rate of 82.8%. The tailings grade was reduced to 2.44%, with a yield of 62.6% [18]. Although good results can be achieved through desliming and gravity separation tests, the process remains complex. To simplify the process, the ARC (ARC) was employed. The ARC is an advanced countercurrent gravity separation instrument that introduces agitation, allowing stable bed regulation at high concentrations [19,20]. A previous study examined how different parameters of an agitator-driven countercurrent affect the recovery and separation efficiency of 10 µm ilmenite particles [21]. The research demonstrated that an appropriate agitation speed helps to dilute the slurry concentration in the zone, thereby ensuring positive dispersion between particles and enabling better separation of particles based on their size.

This study focuses on identifying factors affecting HGMS efficiency through mineralogical analysis of the concentrates. Additionally, experiments on direct separation of high-gradient magnetic concentrates were conducted, aiming to develop a combined process of magnetic separation and gravity-based pre-concentration to significantly improve flotation feed grade.

2. Materials and Methods

2.1. Materials

The samples used in this study are sourced from the Panxi region, with a TiO2 grade of 8.92%. It was obtained after HGMS. The results of HGMS are shown in Table 1. It is difficult to further improve the TiO2 grade by HGMS.

Table 1.

High gradient magnetic separation test result percentages.

2.2. Equipment

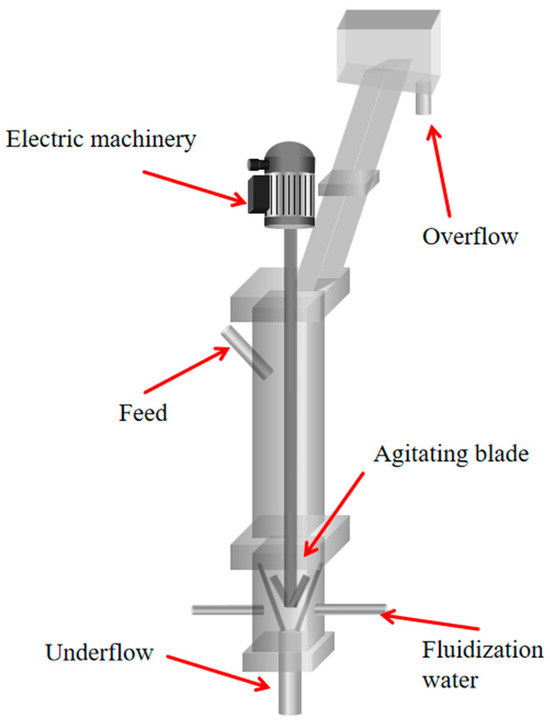

The equipment employed in this study is a laboratory-scale ARC, as illustrated in Figure 1, developed by Central South University [19]. The device is primarily divided into four sections, the inclined channel at the top and the inclined chamber, set at a 70-degree angle relative to the horizontal plane. The inclined chamber is partitioned into 23 evenly spaced channels by 22 stainless steel plates, each with uniform spacing and dimensions. The vertical prismatic column in the center serves as the fluidized bed separation zone. The stirrer blades, selected to be of the folding type, are connected to a motor positioned in the middle of the column. And the bottom section includes water distribution and underflow discharge ports. The underflow is used to remove heavy particles that settle at the bottom of the fluidized bed, with the discharge rate controlled by a peristaltic pump. Water from the storage tank is pressurized and pumped into the distribution chamber; the fluidizing water is evenly distributed into the fluidized bed through the vertical micropores on the distribution plate.

Figure 1.

ARC equipment structure diagram.

2.3. Analysis Methods

Mineral characterization involves examining multiple aspects, including elemental composition, particle size distribution, dispersion, and association–dissociation characteristics. The Mineral Liberation Analyzer and MLA Suite 3.1 software (FEI Company, Hillsboro, OR, USA) are used to analyze the particle morphology and chemical composition of the ore.

3. Results and Discussion

3.1. Process Mineralogical Analysis of Ore Samples

3.1.1. Elemental Composition of Ore Samples

As shown in Table 2, these are the main metal elements targeted for recovery. The raw material is an ilmenite ore with a TiO2 grade of 3.97%, which, after HGMS, yields a concentrate with a TiO2 grade of 8.92%. According to the table, the ore contains 19.80% total iron, while the contents of other metallic elements are extremely low, offering virtually no recovery value. The ore has relatively high contents of silicon dioxide, magnesium oxide, and aluminum oxide, indicating the possible presence of more silicate or alumino-magnesian silicate gangue minerals. The general mineral composition of the ore samples was analyzed by X-ray diffraction (X′Pert3 Powder, Malvern Panalytical, Almelo, The Netherlands).

Table 2.

Multi-element analysis of ilmenite ore chemistry (%).

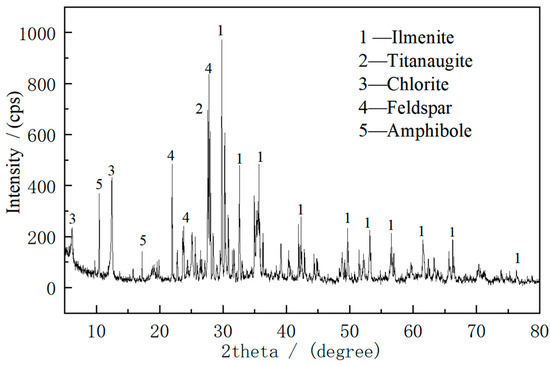

As shown in Table 3 and Figure 2, the mineral composition analysis results indicate that the predominant minerals are ilmenite, olivine, tremolite, and so forth, with hornblende, labradorite, magnetopyrite, and amphibole also present. The focus of this study is the recovery of ilmenite. The gangue minerals with magnetic properties similar to the target mineral, ilmenite, are primarily diopside (content: 19.41%) and olivine (content: 40.54%). As olivine, pyroxene, hornblende, and other minerals, as well as ilmenite, are all weakly magnetic minerals, the difference between ilmenite and gangue minerals in the specific magnetization coefficient between them is negligible. This renders them difficult to remove during the process of high-gradient magnetic separation.

Table 3.

Analysis of the mineral composition of ilmenite (%).

Figure 2.

X-ray diffraction pattern of mineral sample.

The geological information regarding ilmenite mineralization in the western Panxi region highlights several key factors: The region’s complex tectonic structure is part of significant plate tectonics, with ilmenite primarily forming in igneous rocks, particularly basalt and diabase, due to magmatic intrusions. The deposits are mainly sedimentary, formed in volcanic and sedimentary rocks, with magmatic differentiation playing a crucial role in concentrating ilmenite. Ilmenite (FeTiO3) typically contains iron and titanium, along with traces of chromium and nickel, and is often found alongside minerals like magnetite and chlorite. The mineralization process is linked to magmatic intrusions, fluid activity, and high-temperature metamorphism, which contribute to the concentration of ilmenite. Mineralization is also associated with specific lithological units, such as igneous and volcanic sedimentary rocks. These geological factors collectively contribute to the formation of ilmenite deposits in the region [4,6].

3.1.2. Distribution State of Valuable Elements

From the chemical phase analysis of titanium in the sample from high-gradient magnetic separation in Table 4, it can be seen that titanium is predominantly present in the form of ilmenite, accounting for 92.23%, with ilmenite being the main target for recovery. A small amount of titanium is also found in titanomagnetite, accounting for 1.69%, while the remaining titanium is mainly distributed in gangue minerals such as diopside, rutile, olivine, and biotite.

Table 4.

Chemical phase analysis of titanium (%).

Meanwhile, the chemical phase analysis of iron in the high-gradient magnetic separation roughing concentrate, as shown in Table 5, indicates that iron is not only present in ilmenite but is also commonly found in gangue minerals such as olivine, diopside, amphibole, and biotite. Due to the presence of iron, these gangue minerals exhibit weak magnetic properties similar to those of ilmenite, which in turn affects the efficiency of high-gradient magnetic separation in removing them.

Table 5.

Chemical phase analysis of iron (%).

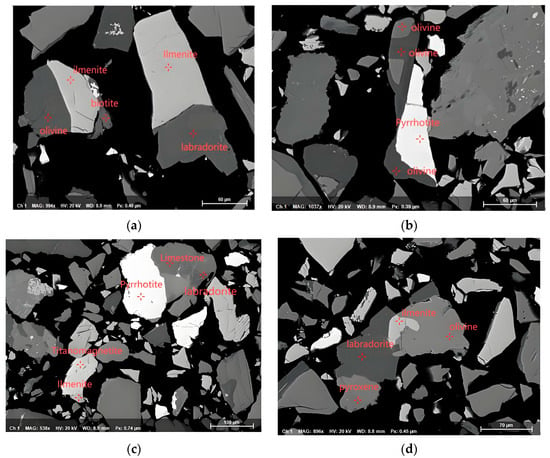

3.1.3. Primary Mineral Distribution Relationships

The intergrowth relationship between ilmenite and other gangue minerals was studied. The particle morphological analysis and overall chemical analysis were carried out using scanning electron microscopy (Helios 5UC, Thermo Fisher Scientific, Waltham, MA, USA) and energy dispersive spectroscopy (Helios 5UC, Thermo Fisher Scientific, Waltham, MA, USA). As shown in Figure 3a, the mineral composition in this region consists of ilmenite, plagioclase, biotite, and olivine, which predominantly occur in a massive form. As shown in Figure 3b, the minerals in this region consist of magnetite and olivine, arranged in a banded embedding pattern. Olivine occupies the majority of the area, with grain sizes reaching up to 100 µm. A small quantity of magnetite particles fills the interior of the olivine. No fine-grained ilmenite or other gangue minerals were observed, indicating that olivine predominates in this region. Figure 3c shows that the minerals in this region consist of magnetite, pyroxene, plagioclase, titanomagnetite, and ilmenite. Ilmenite and titanomagnetite occur in association, while magnetite partially associates with pyroxene and plagioclase. The mineral grains are large, mostly above 50 µm. As shown in Figure 3d, the minerals in this region consist of ilmenite, plagioclase, olivine, and pyroxene. Ilmenite is embedded within olivine and plagioclase, forming aggregates with clearly defined boundaries. The degree of liberation plays a critical role in determining the enrichment efficiency of the ore. When valuable minerals such as ilmenite are fully liberated from the gangue, separation processes like flotation, magnetic separation, or gravity concentration can selectively recover them, resulting in higher-concentrate grades and recoveries. In contrast, if the target mineral remains locked within gangue particles, even highly efficient separation equipment such as the ARC may fail to recover them effectively, leading to lower recovery or dilution of the concentrate. Therefore, insufficient liberation can directly limit the enrichment potential, particularly for fine-grained or complex ores.

Figure 3.

Relationship between the distribution of ilmenite and its associated minerals. (a) ilmenite intergrown with albite, olivine, and biotite; (b) pyrrhotite partially intergrown with pyroxene and albite; (c) well-liberated ilmenite particles; (d) ilmenite aggregate embedded in olivine and albite with clear boundaries.

3.1.4. Analysis of Particle Size Composition and Metal Distribution of Ore Samples

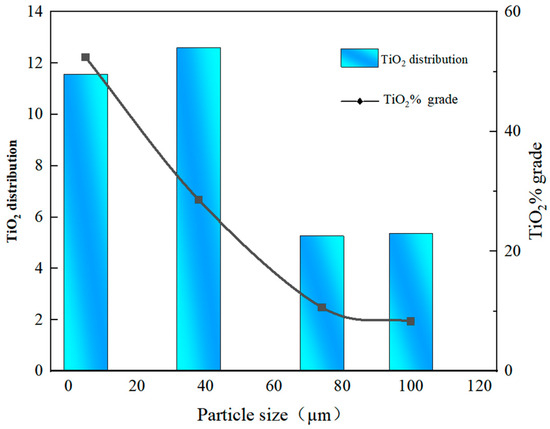

Figure 4 shows the metal distribution of titanium dioxide. About 60% of the TiO2 is distributed in particle sizes smaller than 38 µm.

Figure 4.

The received feed shows the grade of TiO2 as a function of particle size. The change in particle size and the corresponding deposition of TiO2.

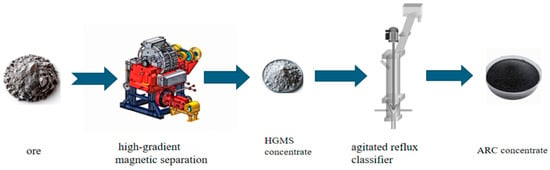

3.1.5. Intergrowth Relationship and Degree of Liberation of Mineral Samples

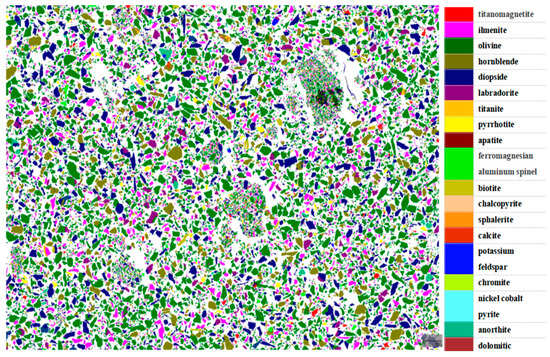

In the detection and analysis of raw ore mines by MLA, the pink coloration corresponds to the target mineral, ilmenite particles, which are noted for their extremely fine size. In contrast, the military green coloration represents the primary gangue mineral, olivine. Not only is olivine abundant in quantity, but it also possesses a relatively rough particle size compared to ilmenite. Additionally, numerous roughing particles of hornblende and diopside were observed, which could adversely affect subsequent reelection and separation processes.

According to the statistical results of the mineral association in Table 6 for the sample of high-gradient magnetic separation, ilmenite has a fine overall particle size and a high degree of liberation. Specifically, 85.38% of the ilmenite particles are well-liberated.

Table 6.

Statistical analysis of the intergrowth relationships of minerals in the HGMS concentrate.

To further illustrate the distribution of ilmenite liberation, the degree of dissociation of ilmenite particles in Figure 5 was analyzed. The degree of dissociation in the rouging concentrate region of high-gradient magnetic separation, as shown in Table 7, reveals that 84.38% of ilmenite particles have a dissociation degree between 90% and 100%, while only 5.72% of the particles fall within a 0% to 50% dissociation range. The high degree of dissociation provides favorable conditions for subsequent ARC tests. Based on the particle scanning images, it can be seen that the insufficiently liberated ilmenite is mainly intergrown with olivine, diopside, and amphibole, which will have a certain impact on the grade of the ARC concentrate.

Figure 5.

MLA analysis results.

Table 7.

Regional dissociation grade of ilmenite in high gradient magnetic separation rough concentrate.

3.2. Exploratory Experiment

In this study, an initial series of tests was conducted using the full particle size of the roughing concentrate from magnetic separation for separation, aiming to preliminarily identify a suitable agitation speed for subsequent multi-factor interaction experiments.

From Table 8, it can be seen that the increase in stirring speed leads to an improvement in particle dispersion, thereby enhancing the concentrate grade and recovery. The optimal indicators are achieved when the stirring speed is 200 r/min, with a TiO2 grade of 19.62% and a recovery of 59.50%. Overall, as the stirring speed increases, both the grade and recovery improve to a certain extent. However, when the speed reaches 200 r/min, further increases in speed cause the indicators to level off. Therefore, a stirring speed of 200 r/min was used for subsequent experiments.

Table 8.

Exploratory experimental conditions.

3.3. Response Surface Interaction Effects Test

An interactive experimental study on the ARC conditions for the roughing concentrate from magnetic separation was conducted. Based on the properties of the ore sample and previous experimental work, tests were carried out on the feed concentration, feed flow rate, fluidization water flow, and underflow rate of the ARC. After determining the optimal condition ranges, a response surface methodology (RSM) experiment was performed to identify the best experimental conditions., as shown in Table 9 and Table 10.

Table 9.

Box–Behnken design of the variables.

Table 10.

Response surface test results of ARC.

Statistical analysis of the BBD separation test results was performed using the statistical software package Design Expert 12.0. Based on these results, the three models representing concentrate TiO2 grade, recovery, and separation efficiency can be expressed as a function of feed concentration (%) feed flow rate (mL/min), fluidization water flow (mL/min), and underflow rate (mL/min). The Grade (TiO2 grade of concentrate), Recovery (TiO2 recovery) and Efficiency (separation efficiency) model functions are expressed as follows:

A high p-value in the analysis of variance (ANOVA) suggests that certain parameters exert a negligible or statistically insignificant influence on the machining outcome. This implies that variations in these parameters do not lead to meaningful changes in the results, thereby diminishing their relevance in evaluating machining performance. Consequently, optimization efforts should prioritize parameters with high p-values. For instance, in the ANOVA results for Grade, the parameter FflowFluidflow exhibited a p-value of 0.9084, indicating a lack of statistical significance and thus was excluded from further analysis.

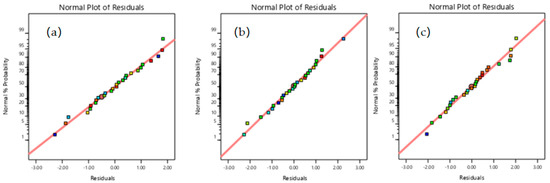

The significance of the three models was estimated by analysis of variance (ANOVA), as shown In Table 11, Table 12 and Table 13, and the f-values calculated from the simulations of the three models (for Grade, Recovery, Efficiency) were 123.45, 62.07, and 4.59, respectively, indicating that the models regressed well. The p-values of the three models are much less than 0.05, and the p-values of the “lack of fit” term are 0.2556 (for Grade), 0.2353 (for Recovery), and 0.14 (for Efficiency) p-values, which are higher than 0.05, indicating that the term is not significant in relation to the pure error. We added an image of the ANOVA results page from the software Design-Expert (version 12, Stat-Ease Inc., Minneapolis, MN, USA) to visually support the statistical analysis. This image is included in the Appendix A as Figure A1.

Table 11.

ANOVA table for Grade.

Table 12.

ANOVA table for Recovery.

Table 13.

ANOVA table for Efficiency.

3.3.1. Effects of Factors on the TiO2 Grade

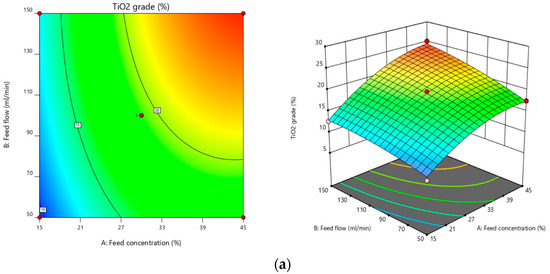

To investigate the effects of individual factors and their interactions on the TiO2 grade of the concentrate, response surface plots were generated, as shown in Figure 6. These plots illustrate the relationships between the independent variables—feed concentration, feed flow rate, fluidization water flow, and underflow rate—and the dependent variable, TiO2 grade.

Figure 6.

Response surface plots of TiO2 concentrate quality. (a) interaction of feed concentration and feed flow rate; (b) interaction of feed concentration and fluidization water flow; (c) interaction of feed concentration and underflow rate; (d) interaction of feed flow rate and underflow rate. Color gradient: green indicates lower response values, transitioning through yellow to red for higher response values.

As depicted in Figure 6a, the TiO2 grade increased sharply as the feed concentration rose from 15% to 45%, highlighting the strong positive effect of feed concentration on concentrate grade. In Figure 6b, both feed concentration and fluidization water flow positively influence the TiO2 grade, but the effect of feed concentration is far more significant, as indicated by the steeper gradient in the response surface and denser contour lines along the X-axis.

Figure 6c examines the interaction between feed concentration and underflow rate. It shows that, when feed flow rate and fluidization water flow are held constant, increasing the feed concentration consistently enhances TiO2 grade, while an increase in underflow rate leads to a noticeable decline. This suggests that a higher underflow rate may disrupt separation stability, causing the premature discharge of partially liberated or fine valuable minerals, thus reducing grade.

Figure 6d further confirms that the influence of fluidization water flow on TiO2 grade is minimal when compared to the dominant effects of feed concentration and feed flow rate. Although underflow rate does exert some impact, its overall contribution is comparatively minor.

In conclusion, feed concentration and feed flow rate are the primary factors affecting concentrate grade, while underflow rate plays a secondary role and fluidization water flow exhibits the least influence within the studied parameter range. This may be attributed to the relatively small variation gradient of the fluidization water flow, making its effect difficult to capture on the response surface.

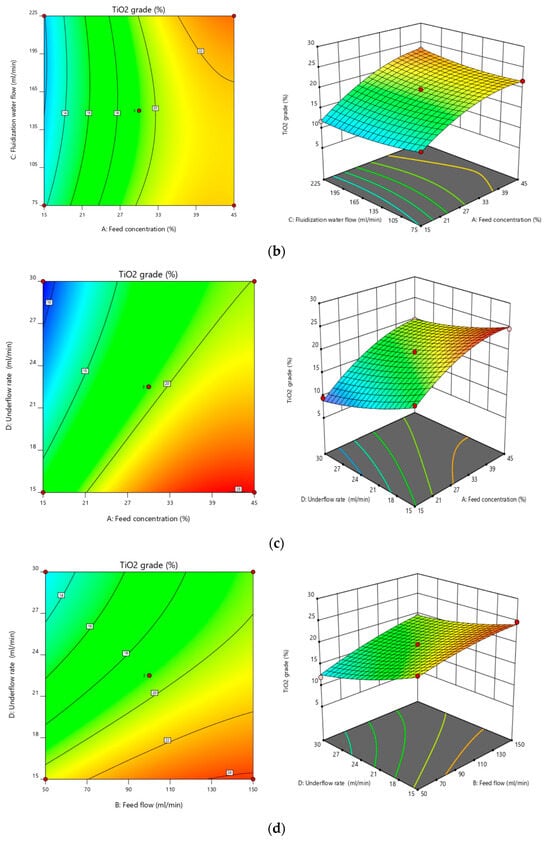

3.3.2. Effects of Factors on the TiO2 Recovery

To illustrate the effects of significant factors and their interactions on recovery, a detailed response surface analysis was conducted based on the ANOVA results. Among all tested variables, the underflow rate (UFflow) exhibited the highest F-value and t-value, underscoring its dominant influence on the separation efficiency of the ARC. Proper regulation of UFflow is essential, as it directly controls the discharge of dense particles, influences particle retention time, and maintains the hydraulic balance within the system. As UFflow increases, recovery initially improves due to enhanced removal of heavier, valuable particles. However, excessive discharge can lead to a premature loss of partially liberated minerals, causing recovery to decline—a behavior captured by the significant quadratic term of UFflow, confirming its nonlinear effect.

In addition, both feed concentration (Fcon) and feed flow rate (Fflow) exhibited strong positive main effects on recovery. Elevated Fcon enhances particle loading, which promotes dense-phase separation, while optimized Fflow improves slurry dynamics and particle stratification, facilitating selective recovery. These trends are evident in the 3D response surface plot shown in Figure 7a, where a rising plane indicates improved recovery with increasing Fcon and Fflow.

Figure 7.

Response surface plots of concentrate TiO2 recovery. (a) Interaction of feed flow rate and fluidization water flow; (b) interaction of fluidization water flow and underflow rate. Color gradient: green indicates lower response values, yellow indicates higher response values.

Conversely, fluidization water flow (Fluidflow) showed a negligible independent effect, as reflected by its low F and t values. However, the interaction between Fflow and Fluidflow was statistically significant. This suggests that while Fluidflow alone may have a limited impact, it modulates the effect of Fflow. Specifically, at moderate fluidization levels, the beneficial impact of Fflow is amplified, whereas excessive Fluidflow may introduce turbulence, undermining separation selectivity.

Overall, the analysis confirms that UFflow, Fcon, and Fflow are the most influential parameters for maximizing recovery. Furthermore, interaction effects and nonlinear responses must be accounted for to ensure optimal process control and efficient operation of the ARC system.

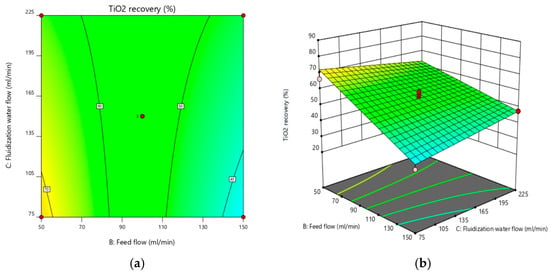

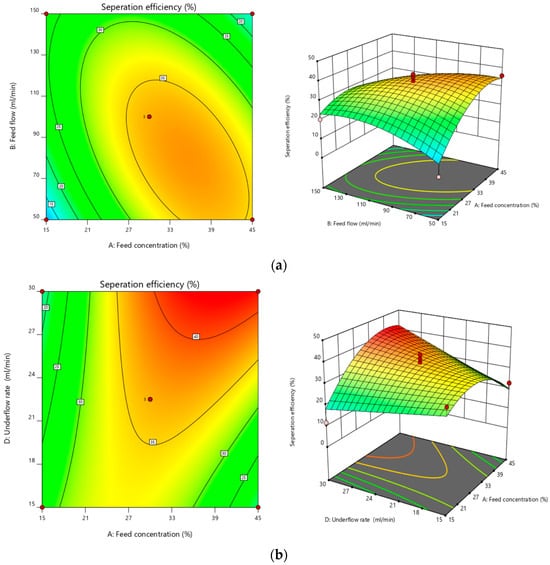

3.3.3. Influence of Factors on Separating Efficiency

To gain deeper insight into the interactions among significant variables and their influence on separation efficiency, three-dimensional response surface plots and corresponding contour plots were generated based on the reduced quadratic model. The interaction between Fcon and Fflow revealed a clear synergistic effect on the response (Figure 8a). As both factors increased within the experimental range, the efficiency improved, indicating that higher feed concentration coupled with optimized feed flow positively influenced system performance. However, beyond certain levels, the response tended to plateau, suggesting a practical optimum.

Figure 8.

Separating efficiency response plot: (a) interaction of feed concentration and feed flow rate; (b) interaction of feed concentration and underflow rate; (c) interaction of feed flow rate and underflow rate. Color gradient: green indicates lower response values, transitioning through yellow to red for higher response values.

Similarly, the interaction plot of Fcon and UFflow (Figure 8b) exhibited a curved response surface. Efficiency increased with higher feed concentrations, particularly when the underflow rate was adjusted within a moderate range. Excessive underflow rates led to a slight decline in efficiency, likely due to increased disturbance or reduced selectivity in the separation process. The interaction between Fflow and UFflow (Figure 8c) showed a moderate interaction effect. Although individually these factors had limited direct influence, their combined adjustment affected efficiency, highlighting the importance of balancing flow parameters to maintain optimal operational conditions. The response surface corresponding to feed concentration (Fcon)2 emphasized the nonlinear relationship between feed concentration and efficiency. The curved nature of the surface confirmed that increasing feed concentration beyond a certain threshold could diminish efficiency, reinforcing the necessity for precise control of this critical parameter.

Multifactor response surface experimental analysis shows that changes in feed concentration and feed flow rate have a particularly large influence on TiO2 grade and recovery of concentrate as well as on the separation efficiency of the ARC. Similarly, reducing the underflow rate will increase concentrate grade and separation efficiency, but at the same time lead to a certain loss of recovery. It is worth noting that changes in fluidized flow have a weak effect on concentrate grade and separation efficiency and a relatively intense effect on recovery. This provides the possibility of maximizing recovery while maintaining concentrate grade. According to the results of response surface optimization, the experimental conditions were determined and are presented in Table 14.

Table 14.

Optimal separation efficiency parameters.

After optimization through response surface methodology (RSM), when the ARC separation efficiency reaches its maximum value of 39.16%, the concentrate grade is 19.61%. At this point, the ARC recovery rate is 58.69%, while tailings with a yield of 74.89% and a TiO2 content of 4.62% are discarded, as show in Table 15. The final optimized experimental results closely match the predicted values, which also demonstrates the reliability of the data modeling.

Table 15.

Response surface optimization test results.

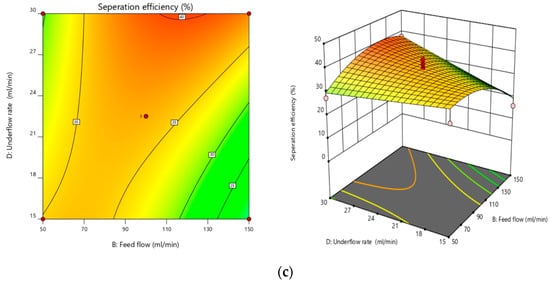

3.4. Results of Experiments

Based on the results of the response surface methodology (RSM), the optimal operating conditions for the ARC were determined as follows: a feed concentration of 40%, a feed flow rate of 105 mL/min, a fluidization water flow of 225 mL/min, and an underflow rate of 30 mL/min. Under these parameters, ARC performance was evaluated following a preliminary separation stage using high-gradient magnetic separation (HGMS). As shown in Table 16, for a raw ore containing 3.97% TiO2, the ARC produced a concentrate with a yield of 13.02%, a TiO2 grade of 16.50%, and a recovery of 54.11%. The corresponding tailings had a yield of 86.98% and a TiO2 grade of 2.10%. The experimental flowsheet is illustrated in Figure 9. These results reflect the effective enrichment mechanism of the ARC. Specifically, the mechanical stirring within the ARC creates a well-controlled fluidization environment that enhances the stratification of particles based on density and settling velocity. The upward flow assists in maintaining a stable fluidized bed, while the underflow discharges the denser. The optimized feed concentration ensures adequate particle loading, while the carefully tuned fluidization rate and underflow rate help minimize entrainment and promote sharp separation. Together, these mechanisms facilitate the selective enrichment of fine-grained minerals, contributing to the high grade and recovery achieved in the concentrate.

Table 16.

Experimental results of combined ARC and HGMS.

Figure 9.

Combination of ARC and HGMS process flow diagram.

Chemical Multi-Element Analysis of Concentrate and Tailings of ARC

The chemical multi-element analyses of the roughing concentrate and tailings obtained from the ARC are presented in Table 17. According to the data, the TiO2 content in the ARC concentrate reaches 16.50%, while the total iron content is 24.30%, and other metal elements remain at low levels. This indicates effective enrichment of the target valuable minerals, primarily ilmenite. In contrast, the TiO2 content in the ARC tailings is only 3.81%, with a total iron content of 16.60%. The concentrations of typical gangue components—SiO2 (35.50%), CaO (4.68%), MgO (21.63%), and Al2O3 (6.22%)—are significantly higher in the tailings than in the concentrate.

Table 17.

Chemical multi-element analysis of ARC concentrate and tailings composition.

These results are consistent with the separation mechanism of the ARC, which relies on density-based stratification enhanced by controlled fluidization and mechanical agitation. In this process, heavier particles such as ilmenite and iron-bearing minerals settle into the lower section and are discharged as concentrate, while lighter gangue minerals are carried upward by the fluidizing water and eventually removed with the overflow or tailings. Mechanical stirring at the base promotes particle dispersion, prevents bed compaction, and enhances the selectivity of separation. Therefore, the distinct difference in elemental composition between concentrate and tailings confirms that ARC effectively enriches high-density, Ti-bearing minerals while rejecting low-density silicate gangue.

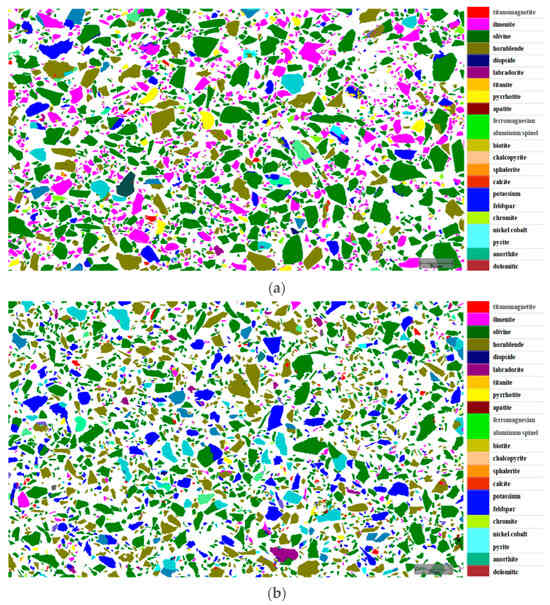

The roughing concentrate and tailings of the ARC were examined and analyzed using MLA (Mineral Liberation Analysis). The microscopic examination results of the roughing concentrate and tailings are shown in Figure 10.

Figure 10.

Microscopic examination results of the ARC concentrate (a) and tailings (b).

Microscopic inspection results of the roughing concentrate from the ARC indicate that not only does the majority of coarse ilmenite enter the concentrate, but a significant amount of fine ilmenite is also present in the roughing concentrate. This demonstrates that the ARC has a higher separation effect on ilmenite of different particle sizes. The main reason affecting ilmenite grade is the presence of a large amount of olivine in the roughing concentrate, followed by diopside and hornblende, mostly in roughing particles. Additionally, pyrrhotite, being a high-density mineral, tends to be enriched in the ARC, which further impacts the separation performance. According to the microscopic inspection results of the roughing concentrate in Figure 10b, it is evident that the majority of the ilmenite lost in the tailings is extremely fine particles (−10 µm). The tailings contain not only a large quantity of fine gangue minerals, but also a significant amount of coarse gangue minerals, indicating the enhanced density-based separation capability of the ARC. The gangue minerals in the tailings include feldspar, diopside, and olivine. Compared to feldspar, olivine is more difficult to separate by the ARC, which can be attributed to its higher density.

4. Conclusions

This study utilizes mineralogical analysis to investigate the reasons for the low separation efficiency of fine-grained ilmenite in high-gradient magnetic separation (HGMS) and explores the use of the agitated reflux classifier (ARC) to enhance separation efficiency. Additionally, response surface methodology is employed to evaluate the effects of various factors on (ARC) separation efficiency, TiO2 recovery, and grade, aiming to optimize the parameters of the ARC.

- (1)

- In the ARC system, after optimizing through response surface methodology, when the feed concentration is 40%, the feed flow rate is 105 mL/min, the fluidization water flow is 225 mL/min, and the underflow rate is 30 mL/min. A feed grade of TiO2 at 8.39% can achieve a TiO2 concentrate grade of 19.61%, with a recovery of 58.69% for the roughing concentrate. For the low-grade ilmenite ore with a TiO2 grade of 3.97%, a combined magnetic-gravity separation process was used, resulting in a concentrate with a TiO2 grade of 16.50% and a recovery of 54.11% to sample. These results highlight the ARC’s potential for significantly upgrading TiO2 grade while maintaining reasonable recovery.

- (2)

- Chemical multi-element analysis confirmed that the concentrate was highly enriched in titanium and iron, whereas the tailings were rich in gangue components such as SiO2, MgO, and Al2O3. This indicates that the ARC effectively separates valuable minerals from unwanted materials based on density differences. The low TiO2 grade in the tailings further demonstrates the ARC’s selective enrichment capability.

- (3)

- Magnetic separation can effectively remove non-magnetic gangue minerals such as quartz and feldspar, but it is challenging to efficiently remove weakly magnetic gangue minerals like ilmenite and chlorite. Because of that, the use of the ARC can achieve cost-effective and efficient removal of weakly magnetic gangue minerals. Specifically, the application of the ARC can effectively enhance the grade of the concentrate obtained from high-gradient magnetic separation.

Author Contributions

Conceptualization, D.L. and Y.L.; methodology, D.L. and Y.L.; validation, Y.L. and Y.Z.; formal analysis, Y.L.; data curation, Y.L.; writing—original draft preparation, Y.L.; writing—review and editing, Y.L., Z.L., D.L., Y.W. and Y.Z.; funding acquisition, D.L. and Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Key Research and Development Program of China (No. 2021YFC2903202), the Research on Fundamental Theories and Utilization Technologies for the Efficient Separation of Low-Grade Vanadium–Titanium Magnetite (FTGZ2024-01), and the National Natural Science Foundation of China (No. 52174270 and No. 51974366).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Figure A1.

Normal probability plot of residuals for the regression equation: (a) concentrate TiO2 grade; (b) concentrate TiO2 recovery rate; (c) separation efficiency.

References

- Wu, F.; Li, X.; Wang, Z.; Wu, L.; Guo, H.J.; Xiong, X.H.; Zhang, X.P.; Wang, X.J. Hydrogen peroxide leaching of hydrolyzed titania residue prepared from mechanically activated Panzhihua ilmenite leached by hydrochloric acid. Int. J. Miner. Process. 2011, 98, 106–112. [Google Scholar] [CrossRef]

- Liu, S.-S.; Guo, Y.-F.; Qiu, G.-Z.; Jiang, T.; Chen, F. Solid-state reduction kinetics and mechanism of pre-oxidized vanadium-titanium magnetite concentrate. Trans. Nonferrous Met. Soc. China 2014, 24, 3372–3377. [Google Scholar] [CrossRef]

- El Khalloufi, M.; Drevelle, O.; Soucy, G. Titanium: An overview of resources and production methods. Minerals 2021, 11, 1425. [Google Scholar] [CrossRef]

- Pang, K.N.; Zhou, M.F.; Lindsley, D.; Zhao, D.; Malpas, J. Origin of Fe–Ti Oxide Ores in Mafic Intrusions: Evidence from the Panzhihua Intrusion, SW China. J. Petrol. 2008, 49, 295–313. [Google Scholar] [CrossRef]

- Yan, W.; Li, W.; Yang, Y.; Zeng, X.; Deng, J.; Li, L. Research on mineral processing technology of ultrafine ilmenite resources in Panzhihua-Xichang area. Multipurp. Util. Miner. Resour. 2023, 8, 55–61. [Google Scholar]

- Cong, Y.; Dong, Q.; Bagas, L.; Xiao, K.; Wang, K. Integrated GIS-based modelling for the quantitative prediction of magmatic Ti-V-Fe deposits: A case study in the Panzhihua-Xichang area of southwest China. Ore Geol. Rev. 2017, 91, 1102–1118. [Google Scholar] [CrossRef]

- Zhai, J.; Chen, P.; Sun, W.; Chen, W.; Wan, S. A review of mineral processing of ilmenite by flotation. Miner. Eng. 2020, 157, 106558. [Google Scholar] [CrossRef]

- Salmani Nuri, O.; Irannajad, M.; Mehdilo, A. Effect of surface dissolution by oxalic acid on flotation behavior of minerals. J. Mater. Res. Technol. 2019, 8, 2336–2349. [Google Scholar] [CrossRef]

- Bulatovic, S.M. Flotation of Titanium Minerals. In Handbook of Flotation Reagents: Chemistry, Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2010; Volume 3, pp. 175–207. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhao, X.; Lu, J.; Lv, H.; Li, L. Innovative pre-concentration technology for recovering ultrafine ilmenite using superconducting high gradient magnetic separator. Int. J. Min. Sci. Technol. 2021, 31, 1043–1052. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, L.; Yang, R.; Tong, X.; Ren, P.; Zheng, Y. Centrifugal high gradient magnetic separation of fine ilmenite. Int. J. Miner. Process. 2017, 168, 48–54. [Google Scholar] [CrossRef]

- Chen, L.; Liao, G.; Qian, Z.; Chen, J. Vibrating high gradient magnetic separation for purification of iron impurities under dry condition. Int. J. Miner. Process. 2012, 102–103, 136–140. [Google Scholar] [CrossRef]

- Nguyentranlam, G.; Galvin, K.P. The development of an innovative classifier. In Proceedings of the 28th Australasian Chemical Engineering Conference, Perth, Australia, 9–12 July 2000; pp. 290–296. [Google Scholar]

- Galvin, K.P.; Doroodchi, E.; Callen, A.M.; Lambert, N.; Pratten, S.J. Pilot plant trial of the reflux classifier. Miner. Eng. 2002, 15, 19–25. [Google Scholar] [CrossRef]

- Galvin, K.P.; Zhou, J.; Dickinson, J.E.; Ramadhani, H. Desliming of dense minerals in fluidized beds. Miner. Eng. 2012, 39, 9–18. [Google Scholar] [CrossRef]

- Galvin, K.P.; Zhou, J.; van Netten, K. Dense medium separation in an inverted fluidised bed system. Miner. Eng. 2018, 126, 101–104. [Google Scholar] [CrossRef]

- Galvin, K.P.; Callen, A.; Zhou, J.; Doroodchi, E. Performance of the reflux classifier for gravity separation at full scale. Miner. Eng. 2005, 18, 19–24. [Google Scholar] [CrossRef]

- Liu, Z.; Su, Z.; Liu, B.; Wang, Y.; Zhang, Y.; Zhong, X.; Chen, K.; Hu, X.; Lu, D. Preconcentrating ultrafine ilmenite tailings using a laboratory-scale reflux classifier. Minerals 2024, 14, 1125. [Google Scholar] [CrossRef]

- Chu, H.; Liu, Z.; Wang, Y.; Lu, D.; Zheng, X.; Zhao, Y. Agitation effect on particle dispersion and separation in an agitated reflux classifier. Miner. Eng. 2022, 187, 107804. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, D.; Wang, Y.; Zhang, Y.; Liu, Y. Processing of fine-grained low-grade antimony oxide tailings using a trapezoidal inclined channel agitated reflux classifier. Min. Metall. Explor. 2025, 42, 421–432. [Google Scholar] [CrossRef]

- Chen, F.; Gao, Y.; Lu, D.; Liu, Z.; Zhao, Y. Study on the application of a reflux classifier in the classification of ultrafine ilmenite. Minerals 2023, 13, 304. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).