Evaluation of Energy Consumption for Mineral Processing of Tungsten Ore in Mongolia: Khovd Aimag and Erdene-Soum as Case Studies

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Calculation of Energy Consumption

2.3. The Power Pinch Analysis (PoPA) Method

3. Results and Discussion

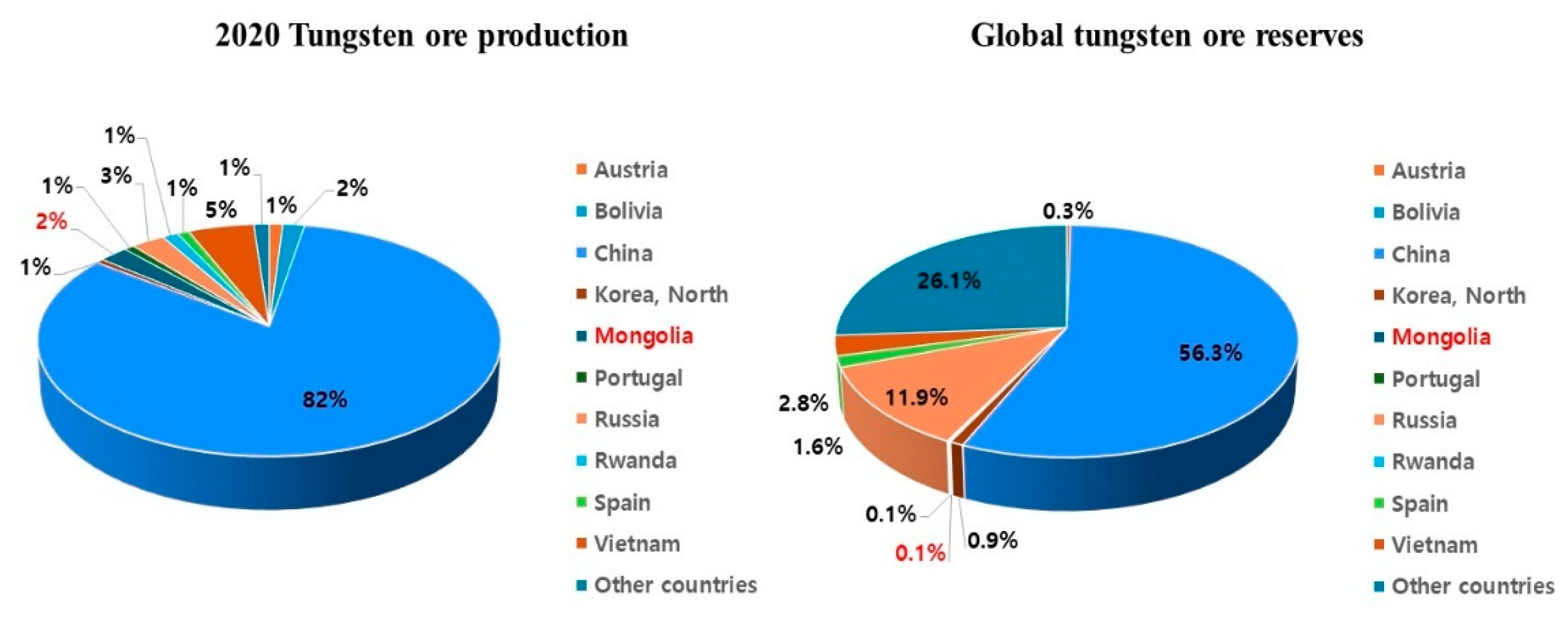

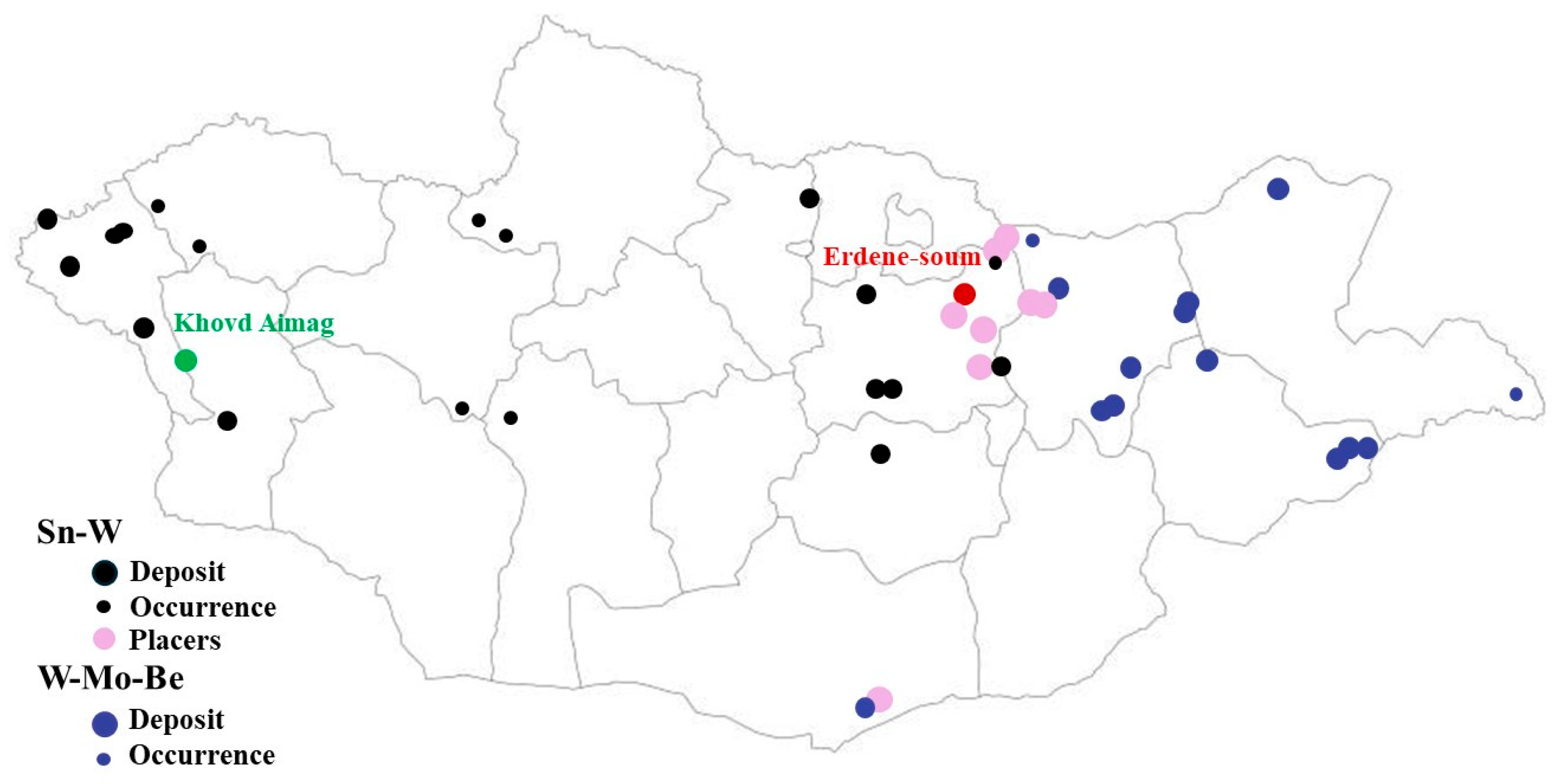

3.1. Tungsten Ore in Mongolia

3.2. Estimation of the Range of Energy Consumption for the Concentration Processing of Tungsten Ore

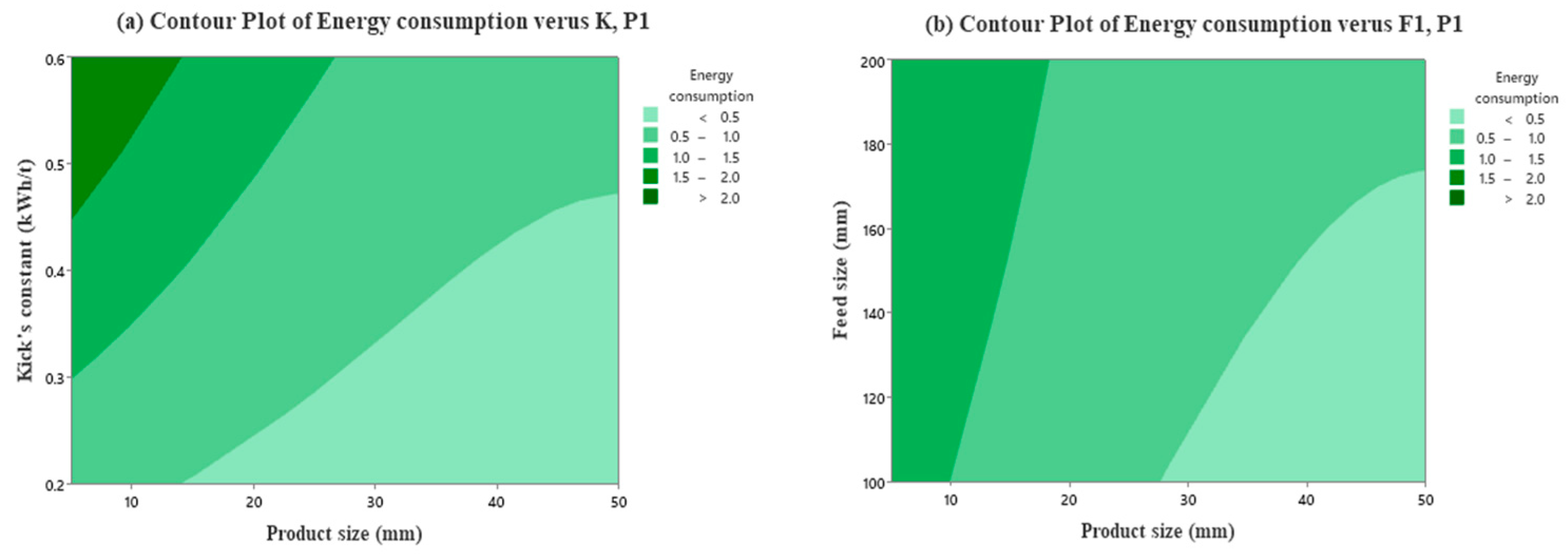

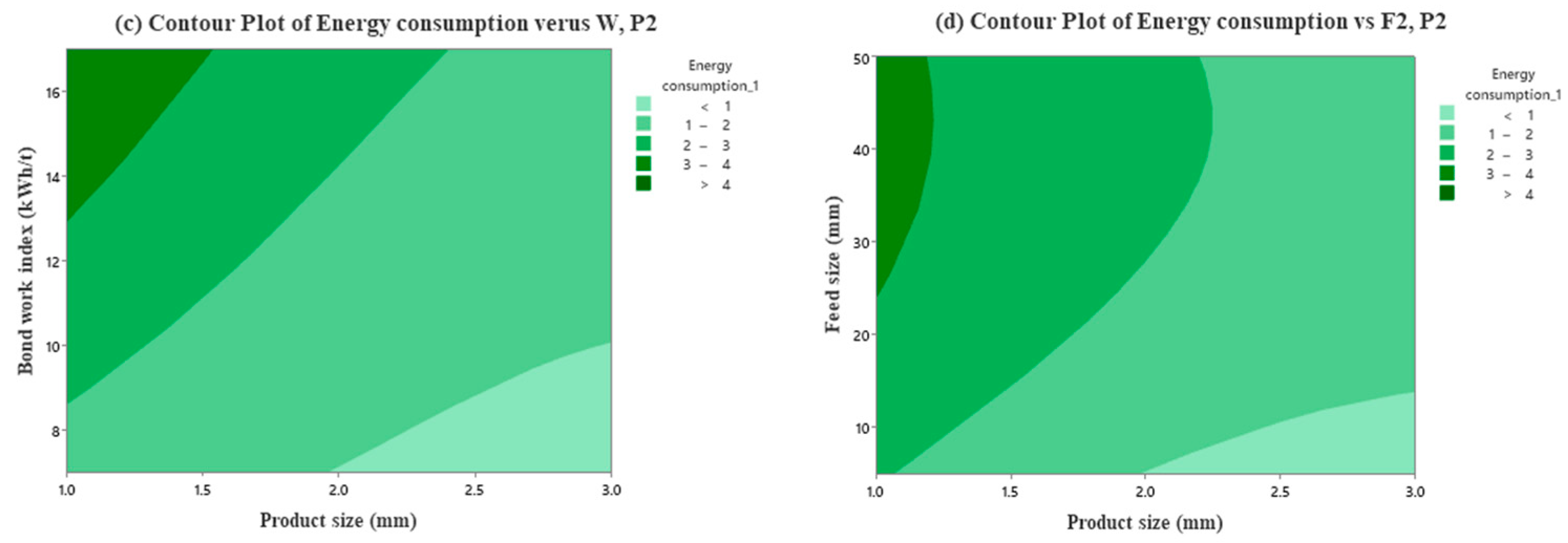

3.2.1. Comminution Stage

3.2.2. Separation Stage

3.2.3. Range of Energy Consumption for the Comminution–Separation Circuit

3.3. Estimation of Energy Consumption for Tungsten Ore Concentration in Mongolia: Erdene-Soum and Khovd Aimag as Case Studies

3.3.1. Estimation of Energy Consumption for the Concentration Process of Erdene-Soum and Khovd Aimag Tungsten Ore

3.3.2. Designing the Energy Supply System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, X. Beneficiation studies of tungsten ores—A review. Miner. Eng. 2018, 125, 111–119. [Google Scholar] [CrossRef]

- Shen, L.; Li, X.; Lindberg, D.; Taskinen, P. Tungsten extractive metallurgy: A review of processes and their challenges for sustainability. Miner. Eng. 2019, 142, 105934. [Google Scholar] [CrossRef]

- Singh Gaur, R.P.; Wolfe, T.A.; Braymill, S.A. Sodium carbonate-roasting-aqueous-leaching method to process flot-grade scheelite-sulfide tungsten ore concentrates. Ind. Eng. Chem. Res. 2025, 64, 8339–8358. [Google Scholar] [CrossRef]

- Han, Z.; Golev, A.; Edraki, M. A review of tungsten resources and potential extraction from mine waste. Minerals 2021, 11, 701. [Google Scholar] [CrossRef]

- Wang, X.; Qin, W.; Jiao, F.; Dong, L.; Guo, J.; Zhang, J.; Yang, C. Review of tungsten resource reserves, tungsten concentrate production and tungsten beneficiation technology in China. Trans. Nonferrous Met. Soc. China 2022, 32, 2318–2338. [Google Scholar] [CrossRef]

- United States Geological Survey. Mineral Commodity Summaries 2021; United States Geological Survey: Reston, VA, USA, 2021.

- Das, S.K.; Nagesh, C.H.R.V.S.; Sreenivas, T.; Kundu, T.; Angadi, S.I. A treatise on occurrence, beneficiation and plant practices of tungsten-bearing ores. Powder Technol. 2023, 429, 118938. [Google Scholar] [CrossRef]

- Lu, Y.; Ding, R.; Li, G.; Song, X.; Cao, Y.; Jia, K. Research Progress with Scheelite Flotation Reagents: A Review. Minerals 2023, 13, 1257. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Jamett, N.; Gálvez, E.D. Approximate recovery values for each stage are sufficient to select the concentration circuit structures. Miner. Eng. 2015, 83, 175–184. [Google Scholar] [CrossRef]

- Gómez, J.S.; Rodriguez, J.; Garcia, C.; Tarisciotti, L.; Flores-Bahamonde, F.; Pereda, J.; Nuñez, F.; Cipriano, A.Z.; Salas, J.C. An overview of microgrids challenges in the mining industry. IEEE Access 2020, 8, 191378–191393. [Google Scholar] [CrossRef]

- Igogo, T.; Awuah-Offei, K.; Newman, A.; Lowder, T.; Engel-Cox, J. Integrating renewable energy into mining operations: Opportunities, challenges, and enabling approaches. Appl. Energy 2021, 300, 117375. [Google Scholar] [CrossRef]

- Atawi, I.E.; Kassem, A.M.; Zaid, S.A. Modeling, management, and control of an autonomous wind/fuel cell micro-grid system. Processes 2019, 7, 85. [Google Scholar] [CrossRef]

- Choi, Y.; Song, J. Review of photovoltaic and wind power systems utilized in the mining industry. Renew. Sustain. Energy Rev. 2017, 75, 1386–1391. [Google Scholar] [CrossRef]

- Son, T.; Trinh, H.B.; Kim, S.; Dugarjav, B.; Lee, J. Estimation of energy consumption for concentrate process of tungsten ore towards the integration of renewable energy sources in Mongolia. Minerals 2023, 13, 1059. [Google Scholar] [CrossRef]

- Jose-Luis, P.; Abadias, A.; Valero, A.; Valero, A.; Reuter, M. The energy needed to concentrate minerals from common rocks: The case of copper ore. Energy 2019, 181, 494–503. [Google Scholar] [CrossRef]

- Palacios, J.-L.; Fernandes, I.; Abadias, A.; Valero, A.; Valero, A.; Reuter, M.A. Avoided energy cost of producing minerals: The case of iron ore. Energy Rep. 2019, 5, 364–374. [Google Scholar] [CrossRef]

- Calvo, G.; Palacios, J.-L.; Valero, A. The influence of ore grade decline on energy consumption and GhG emissions: The case of gold. Environ. Dev. 2022, 41, 100683. [Google Scholar] [CrossRef]

- Kim, S.G.; Jeon, H.S.; Baek, S.H.; Kim, B.B. Mongolia Erden-soum tungsten development. J. Miner. Soc. Korea 2015, 28, 1–13. [Google Scholar]

- Kim, S.; Davaadorj, T.; Jeong, D.; Jeon, H. Research on the separation process for the development of Khovd Aimag tungsten mineral in Mongolia. Resour. Recycl. 2025, 34, 44–51. [Google Scholar] [CrossRef]

- Bond, F.C. Crushing and grinding calculations, Part I. Br. Chem. Eng. 1961, 6, 378–385. [Google Scholar]

- Richardson, J.F.; Harker, J.H.; Backhurst, J.R. Particle Size Reduction and Enlargement. In Chemical Engineering Volume 2 Particle Technology and Separation Processes, 5th ed.; Richardson, J.F., Harker, J.H., Backhurst, J.R., Eds.; Elsevier: Great Britain, UK, 2002; pp. 95–145. [Google Scholar]

- Cheng, G.; Liu, J.; Ma, L.; Cao, Y.; Li, J.; Huang, G. Study on energy consumption in fine coal flotation. Int. J. Coal Prep. Util. 2014, 34, 38–48. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Peck, E.A.; Vining, G.G. Introduction to Linear Regression Analysis, 5th ed.; Balding, D.J., Cressie, N.A.C., Fitzmaurice, G.M., Goldstein, H., Johnstone, I.M., Molenberghs, G., Scott, D.W., Smith, A.F.M., Tsay, R.S., Weisberg, S., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 67–121. [Google Scholar]

- Trinh, H.B.; Kim, S.; Lee, J.; Lee, J.-C. Variation in the determination of platinum group metals using ICP OES induced by the effect of complex matrices and the correction method based on multivariate calibration. J. Anal. At. Spectrom. 2022, 37, 330–337. [Google Scholar] [CrossRef]

- Trinh, H.B.; Kim, S.; Lee, J.; Lee, J.-C. The effect of complexity of a matrix on variation of platinum group metal determination using ICP OES and correction method: A spent catalyst as a case study. ACS Omega 2025, 10, 1234–1245. [Google Scholar] [CrossRef]

- Rozali, N.E.M.; Alwi, S.R.W.; Manan, Z.A.; Klemeš, J.J.; Hassan, M.Y. Optimal sizing of hybrid power systems using power pinch analysis. J. Clean. Prod. 2014, 71, 158–167. [Google Scholar] [CrossRef]

- THEnergy. Database: Solar & Wind Systems in the Mining Industry. Available online: https://www.th-energy.net/english/platform-renewable-energy-and-mining/database-solar-wind-power-plants (accessed on 18 May 2025).

- A Guide to Biomass Power Plants. Available online: https://www.theecoexperts.co.uk/blog/biomass-power-plant (accessed on 18 May 2025).

- Kim, D.; Lee, S. Geology and mineralization characteristics of rare metal (Li, Mo, W, and Nb-Ta) deposits in Mongolia. J. Korean Soc. Miner. Energy Resour. Eng. 2025, 62, 123–135. [Google Scholar] [CrossRef]

- Tungalag, N.; Jargalan, S.; Odbayar, O. Tungsten and tin deposits of Mongolia. Miner. Resour. Mong. Spec. 2016, 66, 127–133. [Google Scholar]

- Gerel, O. Rare metals: Tin, tungsten, molybdenum, lithium, tantalum, and niobium deposits. In Mineral Resources of Mongolia; Gerel, O., Pirajno, F., Batkhishig, B., Dostal, J., Eds.; Springer: Singapore, 2021; pp. 129–184. [Google Scholar]

- Sandvik, A.B. CH440 Cone Crusher. Available online: https://www.rockprocessing.sandvik/en/products/stationary-crushers-and-screens/stationary-cone-crushers/ch440-cone-crusher/ (accessed on 18 May 2025).

- Sandvik, A.B. CJ815 Jaw Crusher. Available online: https://www.rockprocessing.sandvik/en/products/stationary-crushers-and-screens/stationary-jaw-crushers/cj815-jaw-crusher/ (accessed on 18 May 2025).

- Weiss, N.L. SME Mineral Processing Handbook; Society for Mining, Metallurgy, and Exploration: Englewood, CO, USA, 1985. [Google Scholar]

- Li, S.; Lu, D.; Chen, X.; Zheng, X.; Li, X.; Chu, H.; Wang, Y. Industrial application of a modified pilot-scale Jameson cell for the flotation of spodumene ore in high altitude area. Powder Technol. 2017, 320, 358–361. [Google Scholar] [CrossRef]

- Brezáni, I.; Sisol, M.; Marcin, M.; Sykora, M.; Matasovsky, M.; Varga, P. Beneficiation of talc-magnesite ore with Cu-Co mineralization. Inżynieria Miner. 2019, 21, 141–144. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Ribeiro, C.H.T. New mega-sized wet high intensity magnetic separator: A cost-effective solution to reclaim iron ore fines from tailing dams. REM—Int. Eng. J. 2013, 66, 13–19. [Google Scholar] [CrossRef]

| Name | Mineral Type | Major Chemical Composition (%) | Final Tungsten Grade (%) |

|---|---|---|---|

| Erden-soum (Tuv Aimag, central region) | Ferberite (FeWO4) | WO3: 3.96% SiO2: 86.15% Al2O3: 5.52% Fe2O3: 2.59% Sn: 0.7% | WO3 67% |

| Khovd Aimag (western region) | Hubnerite (MnWO4) Scheelite (CaWO4) | WO3: 2.55% SiO2: 64.12% Al2O3: 12.57% Fe2O3: 5.5% CaO: 3.68% MnO: 0.71% | WO3 62% |

| Renewable Source | Operating Time | Time Interval (h) | Capacity (MW) | Energy Generation (MWh) | ||

|---|---|---|---|---|---|---|

| AC | DC | From | To | |||

| Wind | 0 | 12 | 12 | 3 | 18 | |

| Biomass | 0 | 24 | 24 | 4 | 48 | |

| Solar | 8 | 18 | 10 | 3 | 15 | |

| Parameter | Unit | Value |

|---|---|---|

| Kick’s constant | kWh/t | Kk: 0.2, 0.4 and 0.6 |

| Bond work index | kWh/t | Wi: 7, 12 and 17 |

| Feed size | mm | Crushing (F1): 100, 150, 200 Grinding (F2): 5, 25, 50 |

| Product size | mm | Crushing (P1): 5, 25, 50 Grinding (P2): 1, 2, 3 |

| Source | Crushing | Grinding | ||

|---|---|---|---|---|

| AdjSS | p-Value | AdjSS | p-Value | |

| Kk/Wi | 3.049 | 0.000 | 11.18 | 0.000 |

| Feed size | 0.345 | 0.012 | 5.762 | 0.000 |

| Product size | 3.691 | 0.000 | 11.58 | 0.000 |

| Regression | 7.086 | 0.000 | 28.52 | 0.000 |

| Regression equation | W = 0.12 + 2.1Kk + 0.003F1 − 0.02P1 | W = 0.94 + 0.16Wi + 0.03F2 − 0.8P2 | ||

| Model summary | R2 = 87% | R2 = 88% | ||

| Process Stage | Equipment | Kk or Wi * (kwh/t) | Feed Size (mm) | Product Size (mm) | Power (kW) | Capacity (t) | Energy Consumption Per Hour (ECPH, kWh) |

|---|---|---|---|---|---|---|---|

| Comminution | Jaw crusher (C1) | 0.2–0.6 | 200–100 | 50–25 | 200 | 480–1160 | Min: 114 Max: 1845 |

| Cone crusher (C2) | 0.2–0.6 | 50–25 | 10–5 | 220 | 58–336 | Min: 27 Max: 436 | |

| Rod mill (M1) | 7–17 | 25–6 | 3–1 | 1600 | 200–580 | Min: 112 Max: 1800 | |

| Ball mill (M2) | 7–17 | <20 | 3–1 | 800 | 800 | Min: 230 Max: 3692 | |

| Separation | Flotation (F) | - | - | - | 55 | 90 | 435 |

| Shaking table (S) | - | - | - | 1.1 | 80 | 103 | |

| Magnetic (M) | - | - | - | 20 | 880 | 120 |

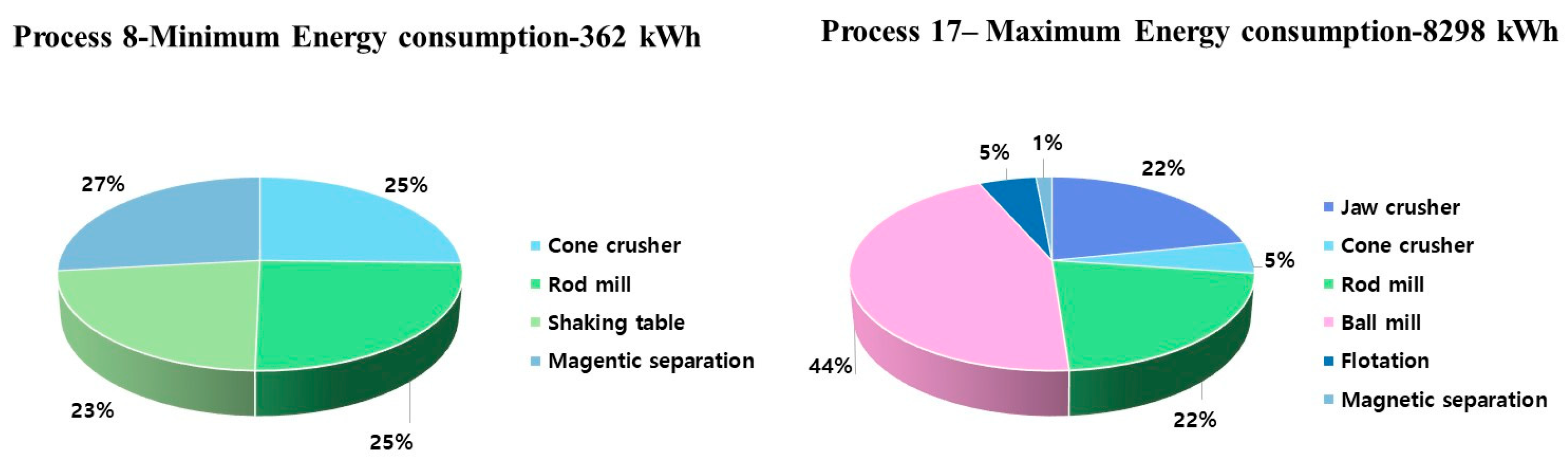

| Process No. | Comminution | Separation | Min ECPH (kWh) | Max ECPH (kWh) | |||||

|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | M1 | M2 | F | S | M | |||

| 1 | O | O | O | O | 781 | 4170 | |||

| 2 | O | O | O | O | 449 | 3838 | |||

| 3 | O | O | O | O | 899 | 6062 | |||

| 4 | O | O | O | O | 567 | 5730 | |||

| 5 | O | O | O | O | O | 1011 | 7862 | ||

| 6 | O | O | O | O | O | 679 | 7530 | ||

| 7 | O | O | O | O | 694 | 2791 | |||

| 8 | O | O | O | O | 362 | 2459 | |||

| 9 | O | O | O | O | 812 | 4683 | |||

| 10 | O | O | O | O | 480 | 4351 | |||

| 11 | O | O | O | O | O | 924 | 6483 | ||

| 12 | O | O | O | O | O | 592 | 6151 | ||

| 13 | O | O | O | O | O | 808 | 4606 | ||

| 14 | O | O | O | O | O | 476 | 4274 | ||

| 15 | O | O | O | O | O | 926 | 6498 | ||

| 16 | O | O | O | O | O | 594 | 6166 | ||

| 17 | O | O | O | O | O | O | 1038 | 8298 | |

| 18 | O | O | O | O | O | O | 706 | 7966 | |

| Tungsten Ore Deposit | Mineral Processing | Energy Consumption per Hour (ECPH, kWh) |

|---|---|---|

| Erden-soum (Tuv Aimag, central region of Mongolia) | 2 Crushing (jaw and cone crusher) 2 Grinding (rod mill) 3 Shaking table 1 Magnetic separation | Min: 794 Max: 6280 |

| Khovd Aimag (western region) | 2 Crushing (jaw and cone crusher) 1 Grinding (ball mill) 4 Shaking table | Min: 826 Max: 6355 |

| Time | Time Interval (h) | Capacity (MW) | Energy Generation (MWh) | Cumulative Storage | Energy Demand (MWh) | |||

|---|---|---|---|---|---|---|---|---|

| AC | DC | AC | DC | AC to DC 1 | DC | DC | ||

| 0 | ||||||||

| 8 | 8 (Period 1) | 7 | 0 | 56 | 0 | 53.2 | 2.0 | 51.2 |

| 12 | 4 (Period 2) | 7 | 3 | 28 | 12 | 38.6 | 13.0 | 25.6 |

| 18 | 6 (Period 3) | 4 | 3 | 24 | 18 | 40.8 | 2.4 | 38.4 |

| 24 | 6 (Period 4) | 4 | 0 | 24 | 0 | 22.8 | 38.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trinh, H.B.; Kim, S.; Son, T.; Song, J.; Lee, J. Evaluation of Energy Consumption for Mineral Processing of Tungsten Ore in Mongolia: Khovd Aimag and Erdene-Soum as Case Studies. Minerals 2025, 15, 660. https://doi.org/10.3390/min15060660

Trinh HB, Kim S, Son T, Song J, Lee J. Evaluation of Energy Consumption for Mineral Processing of Tungsten Ore in Mongolia: Khovd Aimag and Erdene-Soum as Case Studies. Minerals. 2025; 15(6):660. https://doi.org/10.3390/min15060660

Chicago/Turabian StyleTrinh, Ha Bich, Seunghyun Kim, Taehun Son, Junkun Song, and Jaeryeong Lee. 2025. "Evaluation of Energy Consumption for Mineral Processing of Tungsten Ore in Mongolia: Khovd Aimag and Erdene-Soum as Case Studies" Minerals 15, no. 6: 660. https://doi.org/10.3390/min15060660

APA StyleTrinh, H. B., Kim, S., Son, T., Song, J., & Lee, J. (2025). Evaluation of Energy Consumption for Mineral Processing of Tungsten Ore in Mongolia: Khovd Aimag and Erdene-Soum as Case Studies. Minerals, 15(6), 660. https://doi.org/10.3390/min15060660