1. Introduction

Crushing and grinding operations are material preparation processes in the field of mineral processing for downstream separation. However, the comminution equipment is energy-intensive, and it is estimated that typically less than 10% of the overall comminution energy input is used to reduce particle size, with the remaining energy lost as heat, noise, and other forms of waste [

1,

2]. Therefore, as mineral resource development progresses, improving the efficiency of comminution technologies and reducing energy consumption have become pressing issues that need to be addressed.

High-pressure grinding rolls (HPGRs), as high-efficiency crushing equipment, embody the concept of ‘more crushing, less grinding’ through its unique interparticle compression crushing mechanism. It has increasingly become a significant piece of equipment in the ore processing industry, particularly in the tertiary and quaternary crushing stages of metal ore beneficiation [

3]. In comparison to conventional crushing equipment, the HPGR not only boasts a high energy utilization rate but also offers selective crushing (i.e., preferential breakage based on mineral hardness, grain boundaries, or particle size differences) and a higher proportion of fine-grained products, making it a pivotal device for energy conservation and consumption reduction [

4,

5].

With the increasing difficulty of mineral resource extraction, mining companies are facing the challenge of developing low-grade fine-grained mineral resources. To reduce energy consumption in crushing and grinding operations, optimize product particle size distribution, and achieve the goal of “more crushing and less grinding”, as well as to improve the energy efficiency of comminution circuits, the combined process of high-pressure grinding rolls and stirred mills (such as tower mills, TM) is increasingly becoming a research focus. This process has the potential to replace traditional high-energy-consuming ball mill operations for fine and ultrafine milling applications [

6].

In the Xiaoling lead–zinc mine in Heilongjiang Province, China, a comminution flowsheet consisting of a WGM-8040 HPGR (manufactured by Shenyang Shengshi Wuhuan Science and Technology Co., Ltd., Shenyang, China) connected to a WTM-355 tower mill (manufactured by Shenyang Shengshi Wuhuan Science and Technology Co., Ltd., Shenyang, China) was installed, using a flip-flop screen for pre-screening to generate −1 mm feed material for the tower mill. This circuit configuration achieved a reduction in energy consumption by over 20% compared to the pebble crusher + semi-autogenous mill + ball mill (SABC) [

7] circuit and improved mineral liberation effects [

8]. The HPGR’s compressive crushing mechanism effectively promotes the formation of internal micro-cracks in the material, significantly improving the grindability of the material and providing a reliable basis for the direct connection of the tower mill. In the HPGR and tower mill direct connection process, the HPGR’s circulation load in the ultrafine crushing stage has a crucial impact on the overall process energy consumption, product particle size distribution, equipment efficiency, and wear. However, due to significant differences in the crushing characteristics of ore types, determining the appropriate circulation load presents a challenge.

Currently, the most accurate method for determining the circulation load is through HPGR closed-circuit tests at the pilot scale to obtain data. However, pilot-scale tests are time-consuming and require a large amount of material, making them generally difficult to implement [

9,

10,

11]. As an alternative, the industry commonly employs laboratory-scale closed-circuit crushing tests. In cases where the test material is insufficient for closed-circuit testing, open-circuit crushing tests are often used to infer the results of closed-circuit tests [

12]. Nevertheless, there are differences between open-circuit and closed-circuit tests, making it challenging to ensure the accuracy of the circulation load. Additionally, in the absence of ore samples, the question of how to proceed with the preliminary design of the process and the selection of equipment remains a practical issue for mining companies.

In recent years, HPGR modeling research has made notable progress, providing valuable references for industrial applications in multiple aspects. For instance, the industrial-scale model developed by Campos et al. has demonstrated good performance in predicting iron ore concentrate crushing behavior [

13], while the scale-up model proposed by Daniel and Morrell offers useful theoretical support for equipment parameter optimization [

9]. Additionally, the modular dynamic process model developed by Johansson et al. [

14] and the simplified modeling approach based on piston press tests by Pamparana [

15] provide feasible solutions for HPGR performance prediction and experimental method optimization from different perspectives. Altun et al.’s exploration of integrating HPGR and ball mill models [

16] also offers valuable insights for the simulation of grinding circuits. These studies have advanced HPGR modeling technology in diverse dimensions, including crushing behavior prediction, equipment parameter optimization, dynamic system monitoring, and experimental-scale reduction. Despite these diversified achievements, several challenges remain for further investigation. On one hand, the inherent dynamic characteristics and material recirculation effects of closed-circuit systems introduce additional complexities in modeling. On the other hand, some models require extensive pilot-scale data or substantial computational resources, which may limit their applicability in the early stages of mineral exploration. Therefore, under conditions of insufficient preliminary process design data, achieving cost-saving and efficient performance prediction for closed-circuit systems remains a topic requiring further research.

Building upon our research team’s previous findings on the integrated high-pressure grinding roller and tower mill process [

8], this study systematically conducted HPGR closed-circuit crushing tests targeting −1 mm particle size using seven distinct ore types. Through the innovative integration of experimental data, mass balance principles, and first-order crushing kinetics theory, we developed a novel numerical simulation methodology capable of accurately predicting both −1 mm material content and circulating load characteristics in HPGR closed-circuit crushing systems. This method enables the prediction of the circulating load for the −1 mm particle size fraction when the sample mass is extremely limited (such as when the quantity is less than 100 kg), making it insufficient for closed-circuit testing.

3. Results and Discussion

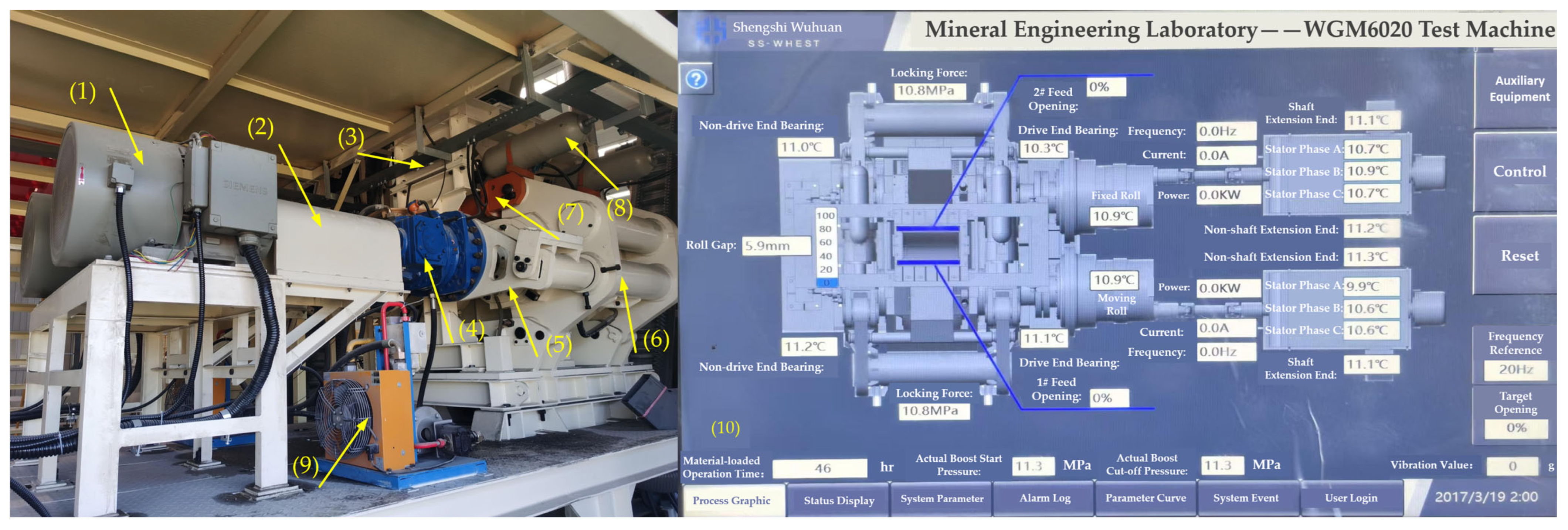

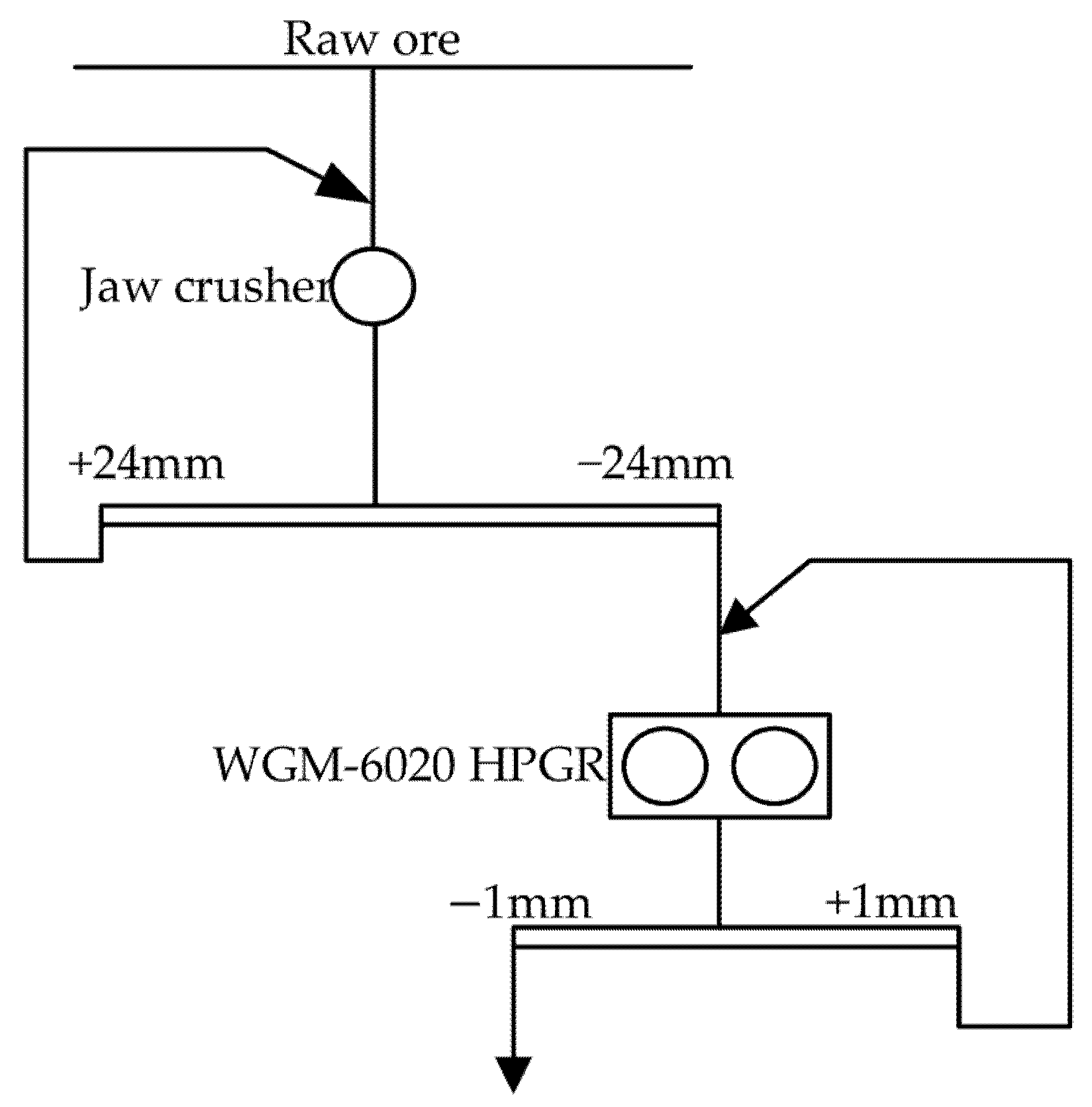

We tested seven samples using the pilot-scale closed-circuit cycle HPGR crushing tests method, described in

Section 2.3, to evaluate its universal applicability to different types of ores. As shown in

Figure 5, this study systematically investigated the particle size distribution (PSD) characteristics of seven ore types. The gold ores (Samples 1 and 4) exhibit finer PSDs, with sub-1 mm particles reaching 14.47% and 16.65%, respectively. Their negative cumulative curves show the steepest slopes in the fine particle range (<5 mm), indicating more concentrated distributions in this range and lower proportions of coarse particles (>10 mm). In contrast, the magnetite (Samples 2 and 3) and hematite ores (Samples 6 and 7) demonstrate more uniform PSDs with higher proportions of both fine and coarse particles, suggesting more balanced breakage behavior. The field-collected Sample 5 displays a distinct PSD with only 2.22% sub-1 mm particles.

The mineral hardness of samples 1 to 7 is shown in

Table 2, with fine particle (−1 mm) contents of 16.65%, 8.87%, 15.05%, 14.47%, 2.22%, 7.47%, and 7.86%, respectively.

3.1. Analysis of Circulating Load and Specific Energy Consumption

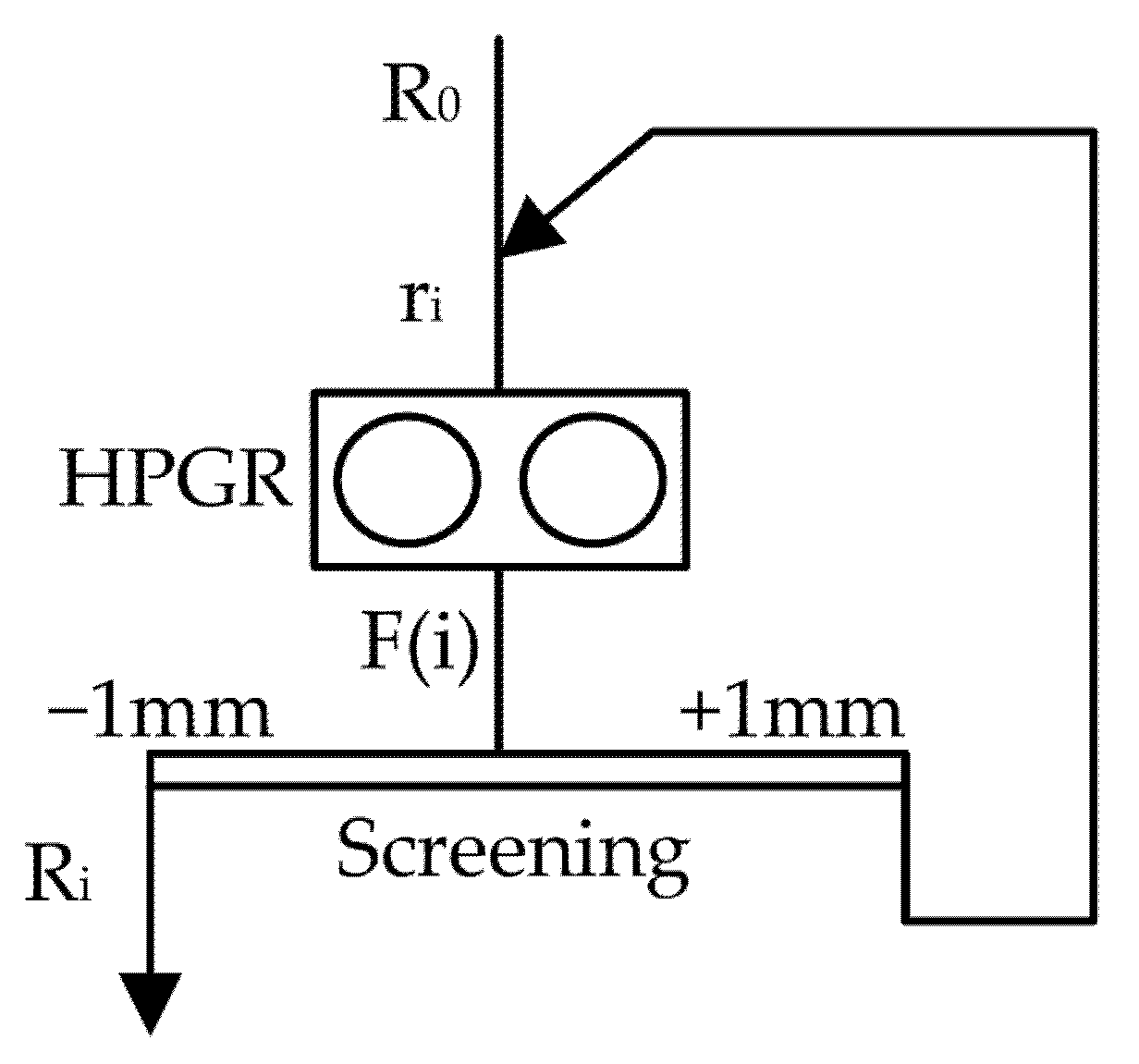

A pilot-scale closed-circuit cycle HPGR crushing test was conducted on 7 samples under different specific pressing forces until the specific energy consumption and cycle load reached a stable state. This was performed to evaluate the impact of specific pressing force and ore properties on the closed-circuit cycle HPGR crushing test. The specific energy consumption and circulating load obtained for each cycle and all tests are shown in

Figure 6 and

Figure 7. The specific energy consumption and circulating loads for the last three cycles reached their respective averages within a ±95% confidence interval [

22]. Once these criteria are achieved, the cycles are considered stable.

Due to the WGM-type HPGR used in this paper, which invented a self-positioning locking function arch frame and a pressure roller end flange baffle structure, the “edge effect” of traditional HPGR was overcome [

22]. Therefore, this paper does not consider the “edge effect”.

Figure 6 and

Figure 7 illustrate that specific energy consumption and circulating load in the closed-circuit crushing process showed decreasing trends with the increase in the number of closed-circuit cycles. For the same type of ore sample, as the specific pressing force increases, the number of cycles required for the specific energy consumption and circulating load to reach a stable state decreases. With the increase in specific pressing force, the influence of ore characteristics on the number of cycles becomes increasingly insignificant. Specifically, at a specific pressing force of 4.5 N/mm

2, nearly all types of ore samples achieve a stable state for both specific energy consumption and circulating load after only four cycles. This indicates that a higher specific pressing force enhances crushing efficiency, allowing particles to reach an equilibrium in particle size distribution in fewer cycles, and a high specific pressing force can overcome the inherent characteristics of the ore, leading to a more consistent crushing process.

The results presented in

Table 1 indicate a significant correlation between circulating load, specific energy consumption, and fine particle content with specific pressing force. For the same type of mineral material in a closed-circuit equilibrium state, the circulating load shows a gradual decrease as the specific pressing force increases. However, the magnitude of this decrease diminishes with the rising specific pressing force. This reflects how increasing the specific pressing force can significantly enhance the crushing efficiency and reduce the circulating load. However, as the specific pressing force rises, the hydrostatic pressure generated within the particle bed may gradually offset this positive effect, hindering further particle breakage and causing the crushing efficiency to approach saturation [

23]. Under these conditions, the particle size reduction benefit per unit energy input correspondingly weakens, ultimately manifesting as a deceleration in the rate of circulating load reduction. Concurrently, specific energy consumption gradually increases with higher specific pressing force. As described by Ozcan et al., an increased specific pressing force results in a higher content of fine particles, which leads to greater energy absorption but lower energy utilization efficiency [

24].

Additionally, for the same type of mineral material under the same specific pressing forces, the specific energy consumption in a closed-circuit equilibrium state is lower than that in an open-circuit condition, and the P

80 value in the closed-circuit equilibrium state is lower than the P

80 value under open-circuit conditions. The content of fine particles below −1 mm also increases significantly. In the closed-circuit crushing process, the new feed for the HPGR consists of mineral ore and the oversized return material from the product. Due to the presence of a significant amount of fine and medium-sized particles in the oversized return material, the new feed to the HPGR becomes finer [

15]. The further reduction of this fine and medium material during the closed-circuit crushing process results in a finer, more uniform particle size distribution, with the overall effect on the HPGR crushing process being higher throughput and potentially lower specific energy consumption [

3,

25].

3.2. Particle Size Distributions

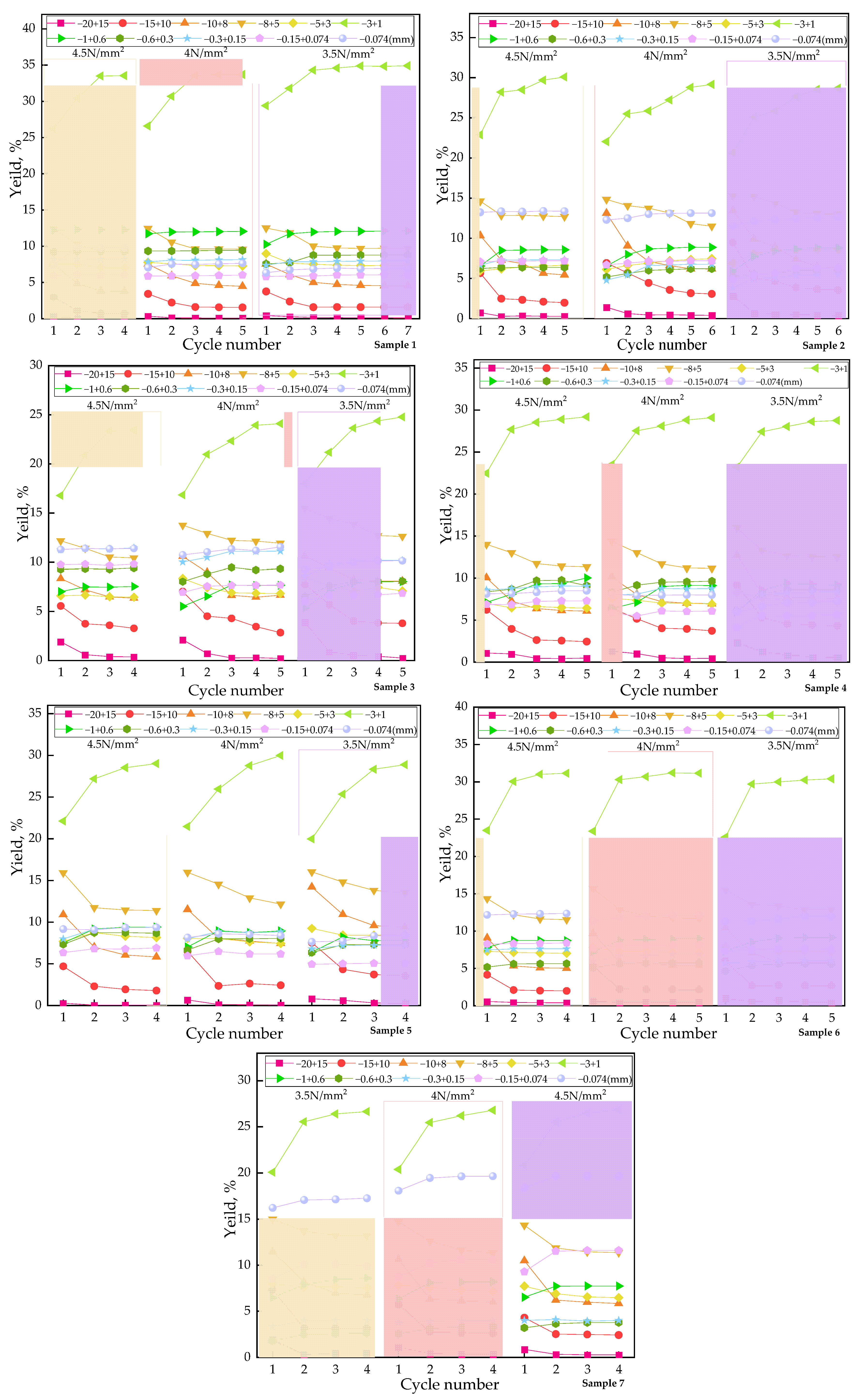

Figure 8 shows the variation trend of the particle size distribution of seven ore products with the number of cycles in the −1 mm closed-circuit cycle HPGR crushing test under different specific pressing forces.

In the closed-circuit crushing process of an HPGR, as depicted in

Figure 8, the dynamic process of particle size reduction is primarily characterized by a gradual decrease in the content of coarse particles larger than 3 mm with increasing numbers of crushing cycles, with the rate of decrease trending towards stability. This phenomenon reflects the progressive refinement of particles by the HPGR in the closed-circuit crushing process. In the initial stage, larger particles are more easily fractured under high pressure, leading to a rapid decline in the content of coarse particles. However, as the number of cycles increases, the hardness of the remaining coarse particles increases and their size decreases, making further crushing more difficult and resulting in a gradual reduction in the rate of decrease.

Concurrently, the content of fine particles smaller than 3 mm exhibits an opposite trend, gradually increasing with the number of crushing cycles, but the rate of increase also slows down until the system reaches an equilibrium state in particle size distribution. At this point, the number of particles that can be further refined decreases, and consequently, the rate of increase in fine particles also diminishes. As detailed in the analysis of the crushing of coarse and fine mixtures within a closed granular bed [

25], fine particles exert control over the fracture of coarse particles. Moreover, the introduction or accumulation of fine particles during the crushing process can impede the breakage kinetics of coarse particles.

3.3. Mathematical Modeling of Closed-Circuit Crushing

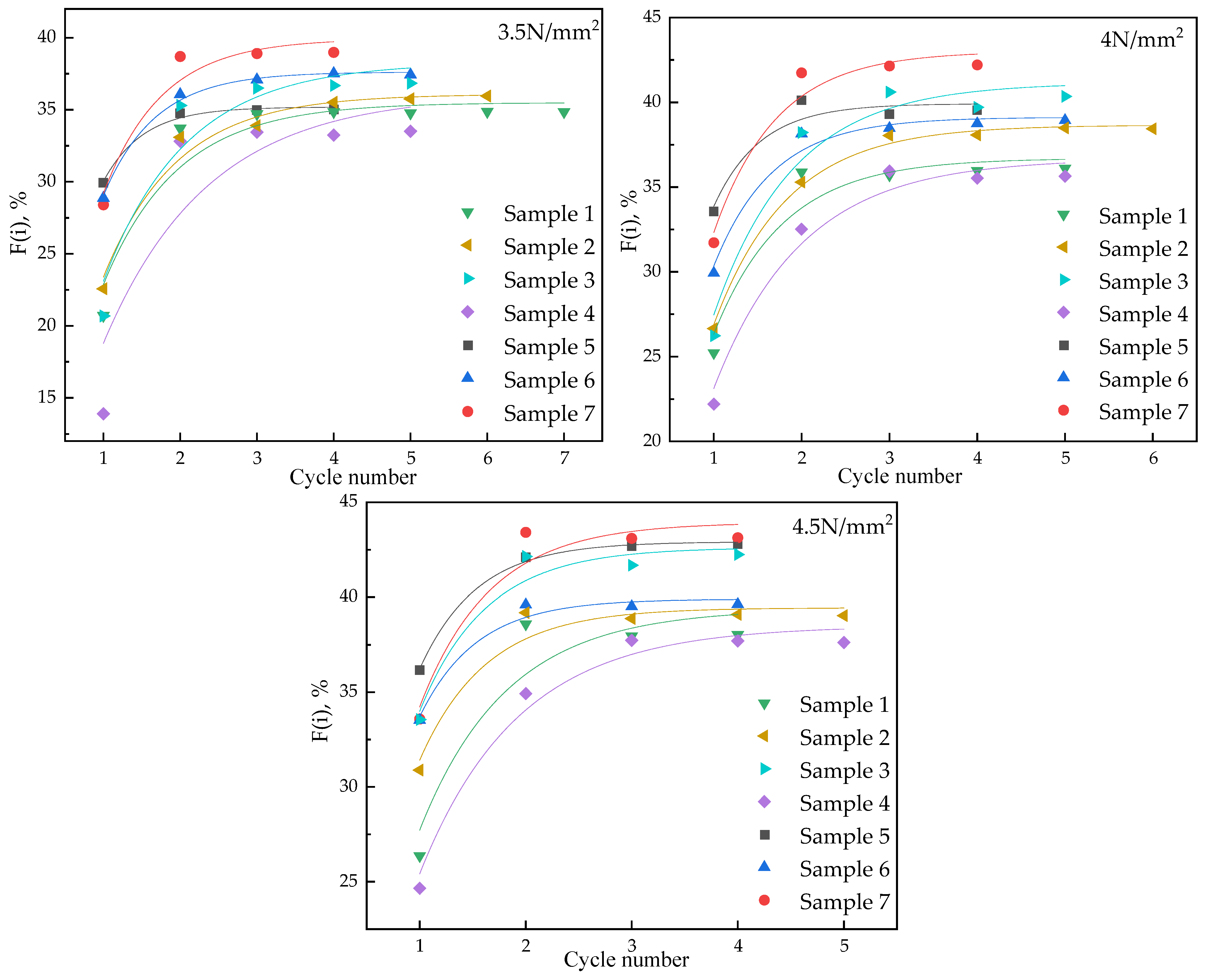

As shown in

Figure 9, this study systematically investigated the evolution of newly generated −1 mm particle content with cycle number (

i) through closed-circuit cycle HPGR crushing tests of seven different minerals under specific pressing forces ranging from 3.5 to 4.5 N/mm

2. The fitting analysis based on the first-order kinetic model (Equation (9)) demonstrates (

Table 3) that the goodness-of-fit R

2 values generally exceed 0.90, confirming the applicability of this kinetic model under the conditions investigated. The results reveal the following: (1) Parameter

a (steady-state limit of fine particle content) exhibits a monotonically increasing trend with a rising specific pressing force, which is primarily attributed to enhanced particle breakage probability under high-pressure conditions, while significant variations in parameter values among different minerals indicate its predominant dependence on ore properties such as mineral hardness and cleavage characteristics. (2) Parameter

b (crushing rate constant) displays distinct response patterns to pressure variations—most samples show a monotonically increasing trend, suggesting improved crushing efficiency under high pressure, while some samples exhibit decreasing trends or peak-and-decline behaviors, potentially related to critical effects in crushing energy efficiency. These findings demonstrate that crushing kinetic parameters are simultaneously influenced by both mineral characteristics and process conditions. Based on these results, this study recommends establishing a multidimensional parameter database for precise model calibration according to specific operational conditions (e.g., pressure selection, feed particle size distribution) to enhance the applicability of Equation (9) in engineering applications.

3.4. Model Validation and Comparative Analysis

To test the predictive ability of the mathematical model for closed-circuit crushing, this study referenced data from a previous experimental study [

26]. The experiment aimed to determine the appropriate transition particle sizes for high-pressure grinding rolls and tower mills. It was conducted using the WGM-3156 HPGR to perform closed-circuit cycle HPGR crushing tests on Nanfen magnetite ore with a maximum feed size of 12 mm (−1 mm content of 14.66%) at a specific pressing force of 4.5 N/mm

2. A feed quantity of 30 kg was used for each test and an artificial dry screening method was employed, where the oversized material was returned as sand, and raw ore material equal to the undersized material mass was weighed and combined to form the new feed for the subsequent cycle. The test data indicated that the closed-circuit crushing process reached a stable equilibrium after approximately six cycles. In particular, the content of −1 mm material in the product was 42.93% after a single closed-circuit cycle (i.e., open-circuit conditions), while at equilibrium, the content was elevated to 45.09% with a cyclic loading of 121.78%. Since the ore properties of the Nanfen magnetite in this study are similar to those of the mineral materials used in the above-mentioned research, the

a,

b values of Nanfen magnetite at 4.5 N/mm

2 were chosen to estimate the results of its −1 mm closed-circuit crushing. The estimation results show that after reaching equilibrium, the content of −1 mm material in the product is expected to be 46.15% with a cyclic loading of 116.71%. Comparing the experimental data, the error rate of the calculation results of −1 mm material content in the equilibrium condition and the test results is 2.34%, and the cyclic loading has a negative deviation of about 4.17%, which may be related to the influence of the ore fineness and equipment parameters. Overall, the calculation results of the model are still more satisfactory. Although there is a certain deviation in the prediction under close-circuit conditions, this deviation is still within acceptable limits considering the influence of ore fineness and equipment parameters. Therefore, the model provides useful theoretical support for the design and optimization of the closed-circuit crushing process. Future research directions can focus on how to reduce the prediction deviation and thus improve the prediction accuracy of the model.

4. Conclusions

This study systematically analyzes the −1 mm closed-circuit crushing process of seven ore samples using a side-flange HPGR under three different pressure conditions. The results show that as the number of crushing cycles increases, the content of coarse particles in the product gradually decreases and stabilizes, while the content of fine particles correspondingly increases. Additionally, both the cycle load and specific energy consumption show a decreasing trend. The study further reveals that when the crushing process reaches a steady state, the cycle load stabilizes between 100% and 200%, and the specific energy consumption remains between 1 and 2.5 kWh/t. Notably, the specific energy consumption in the closed-circuit crushing steady state is significantly lower than that in the open-circuit crushing process.

Based on experimental data and the principle of mass balance, this study innovatively developed a numerical simulation method by integrating first-order crushing kinetics, aiming to predict both the −1 mm material content and circulating load in the HPGR closed-circuit crushing process. The method uses the formula to describe the generation of −1 mm material content at different cycle stages, where the parameters a and b are closely related to ore properties and operating conditions. Through iterative calculations, the method effectively predicts the cycle load. Additional sample validation results show that the predicted −1 mm particle content at the steady state in the closed-circuit crushing process deviates by less than ±5% from the actual HPGR test result. The deviations may be attributed to differences in feed particle size and equipment models used in the HPGR validation tests.

Although the current predictive method is primarily applicable to scenarios akin to experimental settings, it has furnished significant theoretical support and practical guidance for reducing the workload of closed-circuit cycle HPGR crushing tests and optimizing the combined high-pressure grinding roll and tower mill process. Future research will aim to expand the model’s applicability by incorporating a broader spectrum of ore types, particle size distributions, and operational parameters, thereby enhancing the model’s versatility and the potential for optimization in comminution processes.