Using Brazilian Nepheline Syenite Waste as an Alternative Mineral Resource for Various Applications

Abstract

1. Introduction

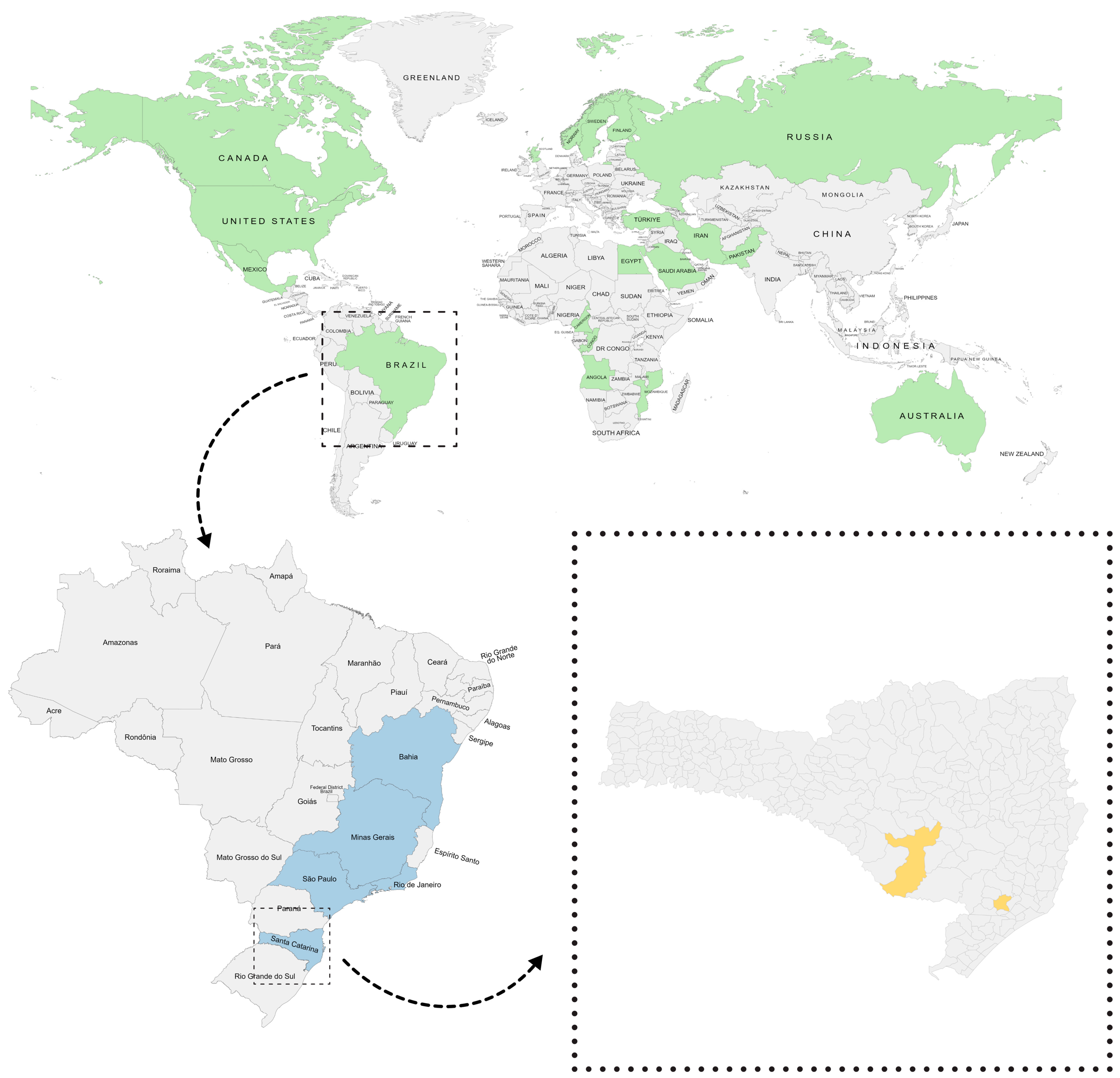

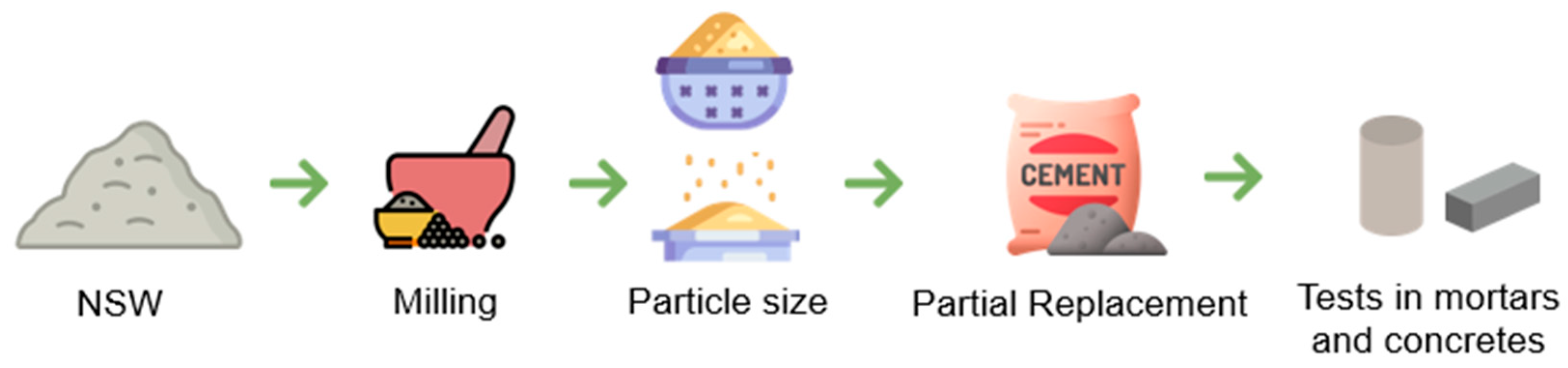

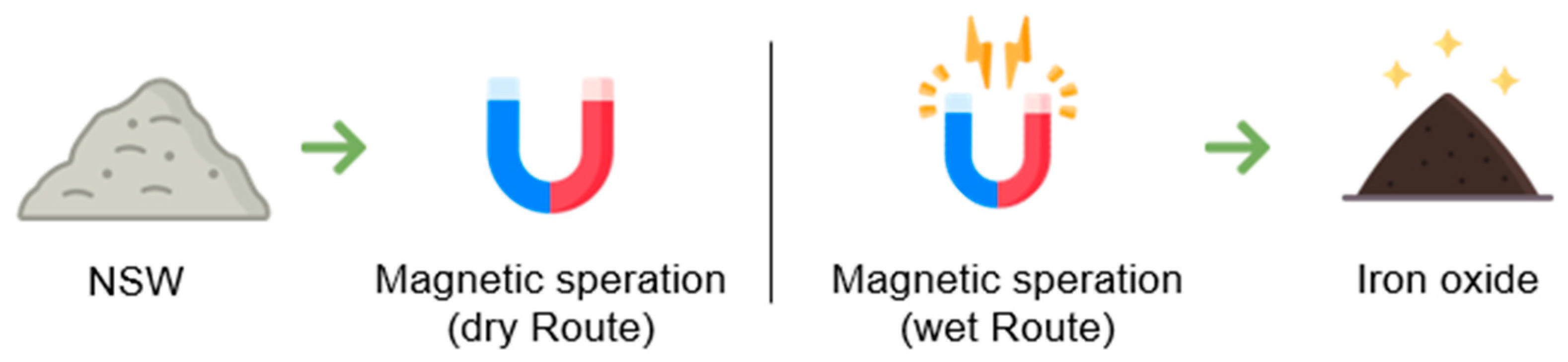

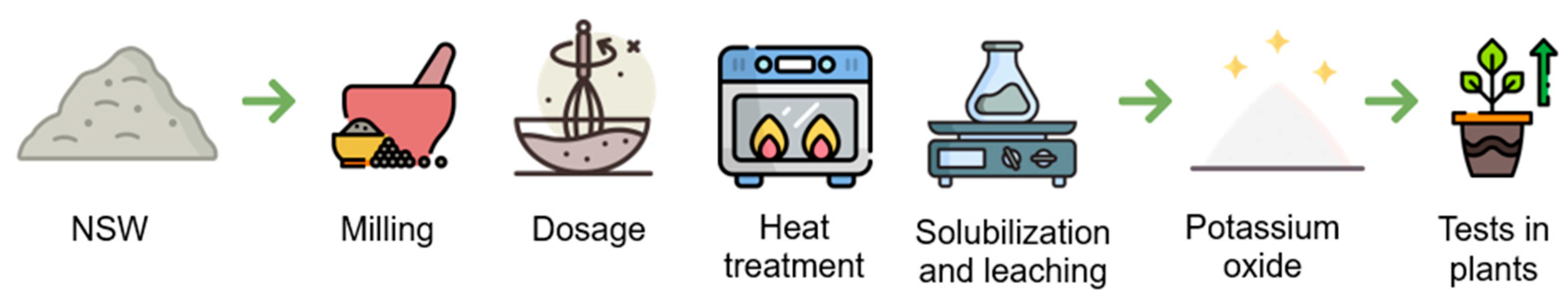

2. Materials and Methods

| Criteria | Standard | Analysis |

|---|---|---|

| C—Classification | NBR 10004 [41] | Environmental classification |

| P—Potentiality | SEM XRD XRF NBR NM 248 [42] NBR NM 46 [43] NBR NM 52 [44] NBR NM 45 [45] NBR NM 30 [46] NBR 15261 [47] NBR 13583 [40] NBR 5751 [48] NBR 5752 [49] | Morphological aspects Mineralogical identification Chemical composition Particle size distribution Powder materials Specific gravity Bulk density Water absorption Dimensional variation in air Dimensional variation in sodium sulfate Pozzolanic test using lime Pozzolanic test using cement Portland |

| Q/v—Quantity/viability | Mining reports and scientific articles | Data on mineral reserves, processing and waste generated |

3. Results and Discussion

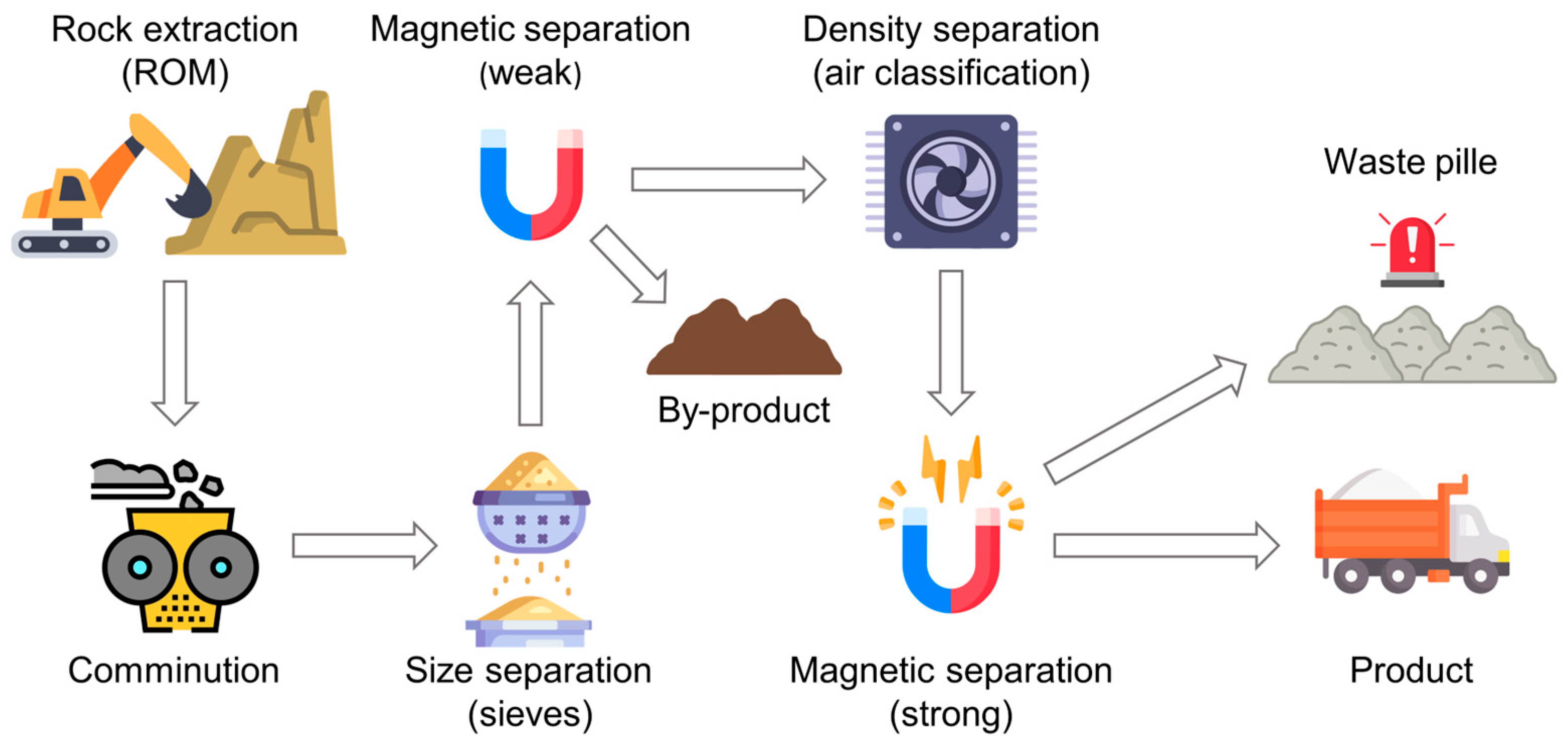

3.1. Classification (C) and Mineral Processing

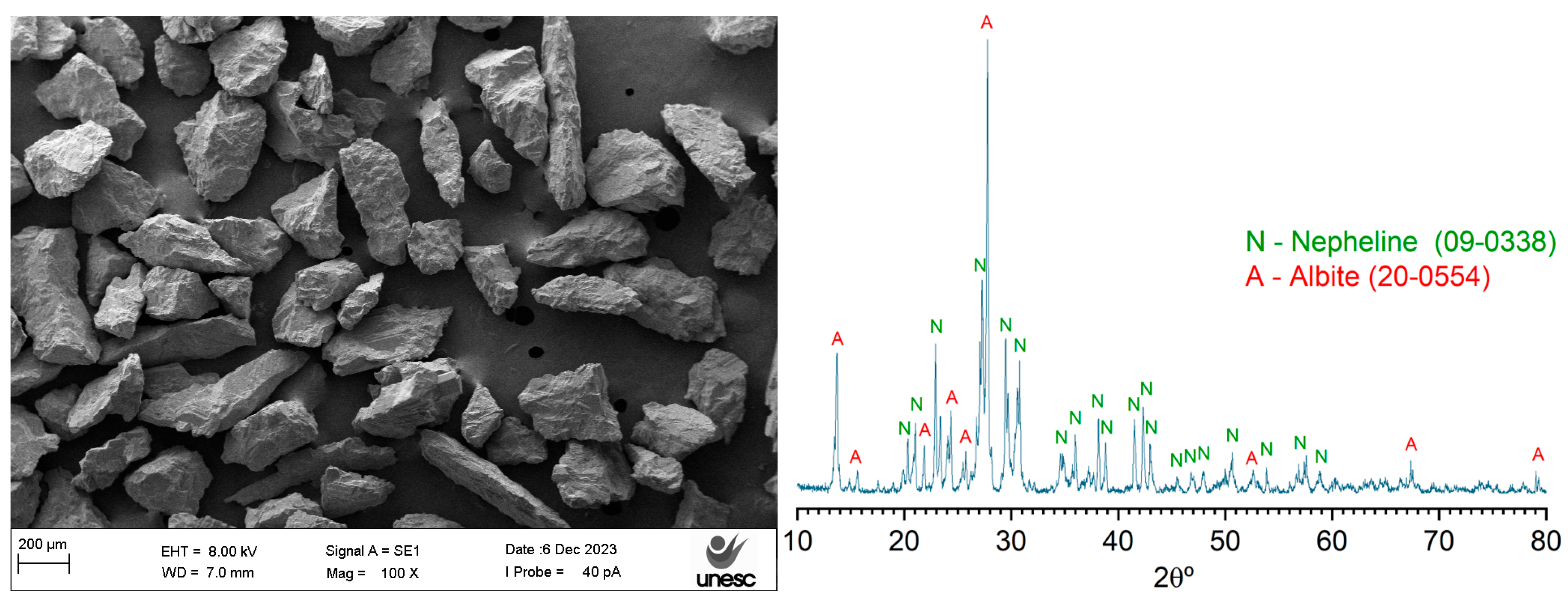

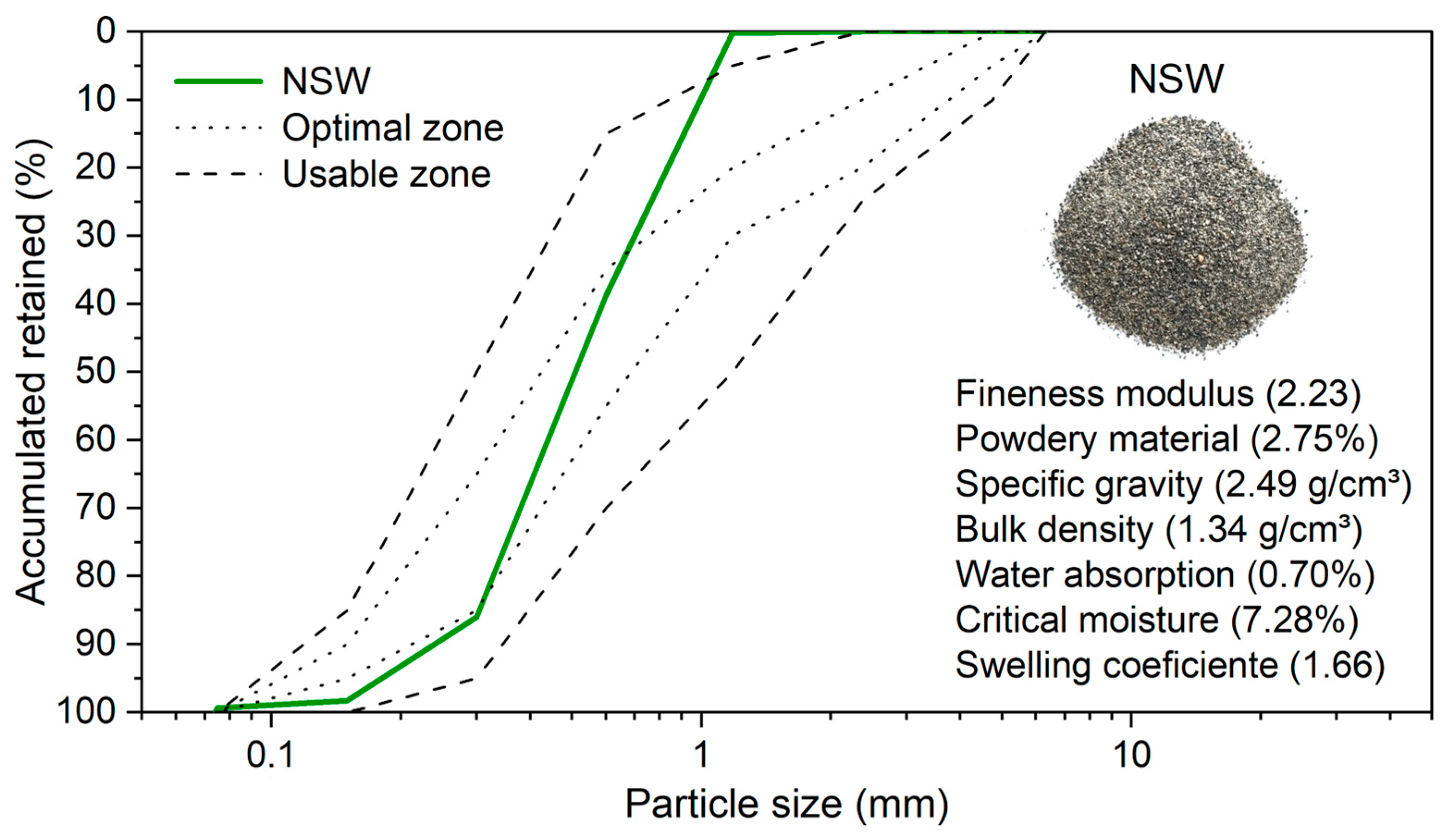

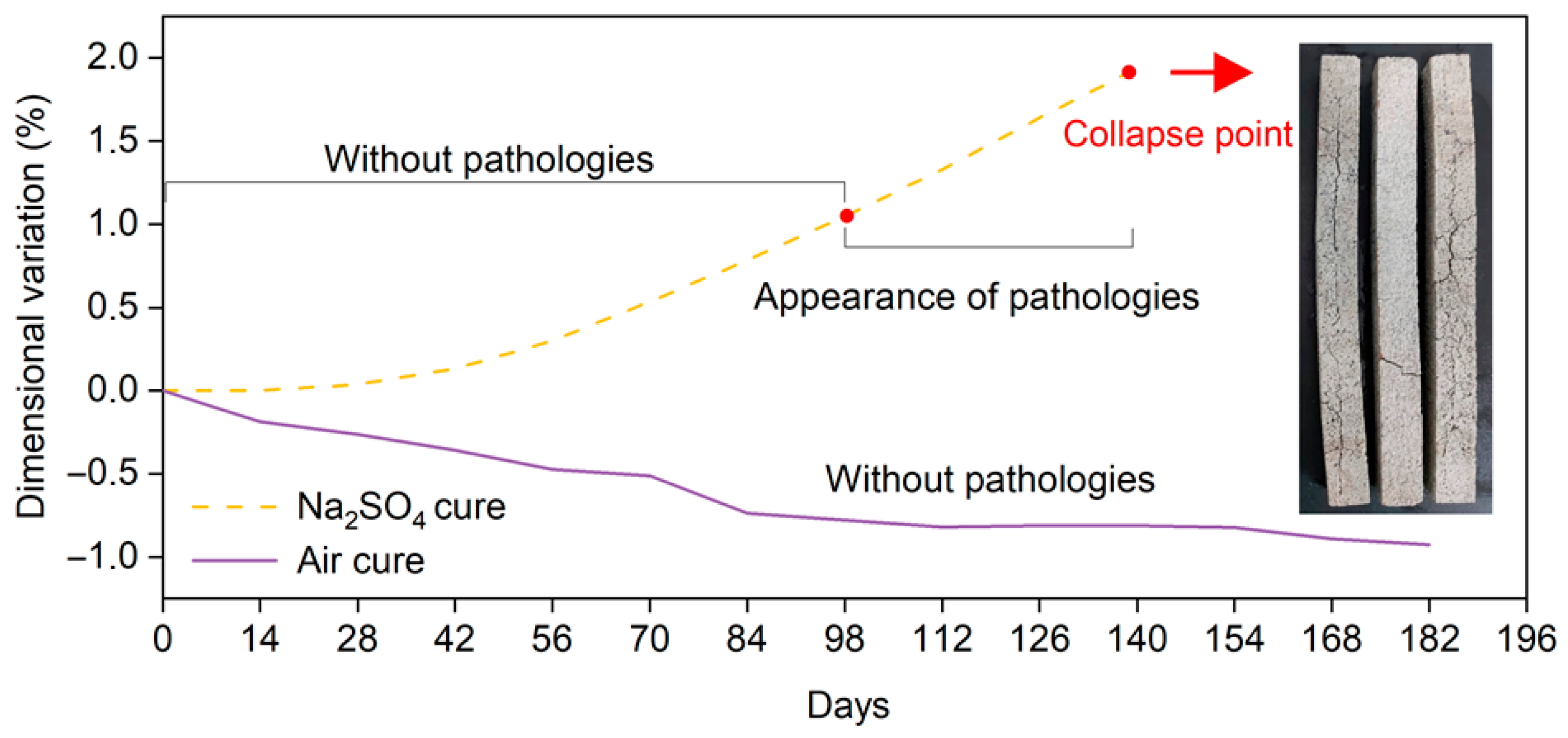

3.2. Potentiality (P)

3.3. Quantity/Viabibility (Qv)

3.4. Application (A)

3.4.1. Use as Small Aggregates

3.4.2. Use as Supplementary Cementitious Material (SCM)

3.4.3. Iron Oxide

3.4.4. Potassium Oxide

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hegab, H.; Shaban, I.; Jamil, M.; Khanna, N. Toward Sustainable Future: Strategies, Indicators, and Challenges for Implementing Sustainable Production Systems. Sustain. Mater. Technol. 2023, 36, e00617. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a Circular Economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Suzanne, E.; Absi, N.; Borodin, V. Towards Circular Economy in Production Planning: Challenges and Opportunities. Eur. J. Oper. Res. 2020, 287, 168–190. [Google Scholar] [CrossRef]

- Abad-Segura, E.; Batlles-delaFuente, A.; González-Zamar, M.-D.; Belmonte-Ureña, L.J. Implications for Sustainability of the Joint Application of Bioeconomy and Circular Economy: A Worldwide Trend Study. Sustainability 2021, 13, 7182. [Google Scholar] [CrossRef]

- Tan, J.; Tan, F.J.; Ramakrishna, S. Transitioning to a Circular Economy: A Systematic Review of Its Drivers and Barriers. Sustainability 2022, 14, 1757. [Google Scholar] [CrossRef]

- Souza, M.T.; Simão, L.; Montedo, O.R.K.; Raupp Pereira, F.; de Oliveira, A.P.N. Aluminum Anodizing Waste and Its Uses: An Overview of Potential Applications and Market Opportunities. Waste Manag. 2019, 84, 286–301. [Google Scholar] [CrossRef] [PubMed]

- Gambalonga, B.; Nicolini, J.L.; Inocente, J.M.; Pich, C.T.; Angioletto, E.; Pereira, F.R.; Montedo, O.R.K.; Arcaro, S. Valorization of Waste Foundry Sand Aggregates in Hot-Mix Asphalt. Process Saf. Environ. Prot. 2023, 173, 277–288. [Google Scholar] [CrossRef]

- Oliveira, K.A.; Simão, L.; Rebouças, L.B.; Hotza, D.; Montedo, O.R.K.; Novaes de Oliveira, A.P.; Raupp-Pereira, F. Ceramic Shell Waste Valorization: A New Approach to Increase the Sustainability of the Precision Casting Industry from a Circular Economy Perspective. Waste Manag. 2023, 157, 269–278. [Google Scholar] [CrossRef]

- Hodge, R.A.; Ericsson, M.; Löf, O.; Löf, A.; Semkowich, P. The Global Mining Industry: Corporate Profile, Complexity, and Change. Miner. Econ. 2022, 35, 587–606. [Google Scholar] [CrossRef]

- Vilaça, A.S.I.; Simão, L.; Montedo, O.R.K.; Novaes de Oliveira, A.P.; Raupp-Pereira, F. Waste Valorization of Iron Ore Tailings in Brazil: Assessment Metrics from a Circular Economy Perspective. Resour. Policy 2022, 75, 102477. [Google Scholar] [CrossRef]

- Worlanyo, A.S.; Jiangfeng, L. Evaluating the Environmental and Economic Impact of Mining for Post-Mined Land Restoration and Land-Use: A Review. J. Environ. Manag. 2021, 279, 111623. [Google Scholar] [CrossRef] [PubMed]

- Capasso, I.; Lirer, S.; Flora, A.; Ferone, C.; Cioffi, R.; Caputo, D.; Liguori, B. Reuse of Mining Waste as Aggregates in Fly Ash-Based Geopolymers. J. Clean. Prod. 2019, 220, 65–73. [Google Scholar] [CrossRef]

- Francklin, I.; Ribeiro, R.P.; Corrêa, F.A. Quartzite Mining Waste: Diagnosis of ASR Alkali-Silica Reaction in Mortars and Portland Cement Concrete. Materials 2021, 14, 7642. [Google Scholar] [CrossRef] [PubMed]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-Thinking Mining Waste through an Integrative Approach Led by Circular Economy Aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef]

- UNEP Global Resources Outlook 2019: Natural Resources for the Future We Want. A Report of the International Resource Panel. Available online: https://www.resourcepanel.org/reports/global-resources-outlook-2019 (accessed on 9 December 2022).

- Boom Cárcamo, E.A.; Peñabaena-Niebles, R. Opportunities and Challenges for the Waste Management in Emerging and Frontier Countries through Industrial Symbiosis. J. Clean. Prod. 2022, 363, 132607. [Google Scholar] [CrossRef]

- EPA Rules and Regulations. Available online: https://www.govinfo.gov/content/pkg/FR-2015-01-13/pdf/FR-2015-01-13.pdf (accessed on 5 December 2022).

- Falagán, C.; Grail, B.M.; Johnson, D.B. New Approaches for Extracting and Recovering Metals from Mine Tailings. Miner. Eng. 2017, 106, 71–78. [Google Scholar] [CrossRef]

- Nalluri, S.; Ragi, M.R. Nepheline Syenite: A Potential Alternative for Feldspar in the Mineral Industry—A Case Study from SE India. J. Indian Geophys. Union 2020, 24, 33–38. [Google Scholar]

- Unluer, A.T.; Budakoglu, M.; Doner, Z.; Abdelnasser, A. The Evolution of the REE-Bearing Özvatan Nepheline Syenite-Carbonatite Complex, Central Turkey: Mineralogical, Geochemical, and Stable Isotopic Approaches. Minerals 2023, 13, 667. [Google Scholar] [CrossRef]

- Dumańska-Słowik, M.; Powolny, T.; Nguyen Khac, G. Mineralogy and Geochemistry of Nepheline Syenite From the Bang Phuc Massif of the Alkaline Cho Don Complex in North-Eastern Vietnam—Implications for Magma Evolution and Fluid–Rock Interactions. J. Petrol. 2023, 64, egad042. [Google Scholar] [CrossRef]

- Bagani, M.; Balomenos, E.; Panias, D. Nepheline Syenite as an Alternative Source for Aluminum Production. Minerals 2021, 11, 734. [Google Scholar] [CrossRef]

- Jena, S.K.; Dhawan, N.; Rao, D.S.; Misra, P.K.; Mishra, B.K.; Das, B. Studies on Extraction of Potassium Values from Nepheline Syenite. Int. J. Miner. Process. 2014, 133, 13–22. [Google Scholar] [CrossRef]

- McLemore, V.T. Nepheline Syenite. In Industrial Minerals & Rocks—Commodities, Markets and Uses; Kogel, J.E., Trivedi, N.C., Barker, J.M., Krukowski, S.T., Eds.; Society for Mining, Metallurgy, and Exploration, Inc. (SME): Littleton, CO, USA, 2009; pp. 653–669. [Google Scholar]

- Cruz, C.M.; Oliveira, D.C.; Faustino, L.M.; Roveri, C.D.; Maestrelli, S.C. The Use of Nepheline as Alternative Source of Alkalis in Porcelain Tiles: Rheological and Physical Evaluation. Cerâmica 2018, 64, 230–235. [Google Scholar] [CrossRef]

- Mena Silva, C.A.; Ellefmo, S.L.; Sandøy, R.; Sørensen, B.E.; Aasly, K. A Neural Network Approach for Spatial Variation Assessment—A Nepheline Syenite Case Study. Miner. Eng. 2020, 149, 106178. [Google Scholar] [CrossRef]

- Wang, H.; Tang, Y.; Xu, Y.-S.; Zhang, H.; Lv, Z.-H.; Qin, S.-X.; Song, Y.-W. Textures and Chemical Compositions of Nb-Bearing Minerals and Nb Mineralization in the Shuangshan Nepheline Syenite Pluton, East Qinling, China. Minerals 2021, 11, 1163. [Google Scholar] [CrossRef]

- Nogueira, T.A.R.; Miranda, B.G.; Jalal, A.; Lessa, L.G.F.; Filho, M.C.M.T.; Marcante, N.C.; Abreu-Junior, C.H.; Jani, A.D.; Capra, G.F.; Moreira, A.; et al. Nepheline Syenite and Phonolite as Alternative Potassium Sources for Maize. Agronomy 2021, 11, 1385. [Google Scholar] [CrossRef]

- Bain, A.; Shenoy, M.; Ashton, W.; Chertow, M. Industrial Symbiosis and Waste Recovery in an Indian Industrial Area. Resour. Conserv. Recycl. 2010, 54, 1278–1287. [Google Scholar] [CrossRef]

- Zurbrügg, C.; Gfrerer, M.; Ashadi, H.; Brenner, W.; Küper, D. Determinants of Sustainability in Solid Waste Management—The Gianyar Waste Recovery Project in Indonesia. Waste Manag. 2012, 32, 2126–2133. [Google Scholar] [CrossRef]

- Sakir, S.; Raman, S.N.; Safiuddin, M.; Kaish, A.B.M.A.; Mutalib, A.A. Utilization of By-Products and Wastes as Supplementary Cementitious Materials in Structural Mortar for Sustainable Construction. Sustainability 2020, 12, 3888. [Google Scholar] [CrossRef]

- Nicoara, A.I.; Stoica, A.E.; Vrabec, M.; Šmuc Rogan, N.; Sturm, S.; Ow-Yang, C.; Gulgun, M.A.; Bundur, Z.B.; Ciuca, I.; Vasile, B.S. End-of-Life Materials Used as Supplementary Cementitious Materials in the Concrete Industry. Materials 2020, 13, 1954. [Google Scholar] [CrossRef]

- Ndahirwa, D.; Zmamou, H.; Lenormand, H.; Leblanc, N. The Role of Supplementary Cementitious Materials in Hydration, Durability and Shrinkage of Cement-Based Materials, Their Environmental and Economic Benefits: A Review. Clean. Mater. 2022, 5, 100123. [Google Scholar] [CrossRef]

- Raupp-Pereira, F. Valorization of Industrial Waste as an Alternative Mineral Source: Ceramic and Cementitious Compositions; Universidade de Aveiro: Aveiro, Portugal, 2006. [Google Scholar]

- Acordi, J.; Simão, L.; Faraco, M.N.S.; Borgert, C.H.; Olivo, E.; Montedo, O.R.K.; Raupp-Pereira, F. Waste Valorization of Coal Mining Waste from a Circular Economy Perspective: A Brazilian Case Study Based on Environmental and Physicochemical Features. Resour. Policy 2023, 80, 103243. [Google Scholar] [CrossRef]

- Machado, D.M.; Gambalonga Júnior, B.; Simão, L.; Ribeiro, M.J.; Montedo, O.R.K.; Raupp-Pereira, F.; Arcaro, S. Valorization of Brazilian Waste Foundry Sand from Circular Economy Perspective. J. Clean. Prod. 2023, 407, 137046. [Google Scholar] [CrossRef]

- Simão, L.; Souza, M.T.; Ribeiro, M.J.; Klegues Montedo, O.R.; Hotza, D.; Novais, R.M.; Raupp-Pereira, F. Assessment of the Recycling Potential of Stone Processing Plant Wastes Based on Physicochemical Features and Market Opportunities. J. Clean. Prod. 2021, 319, 128678. [Google Scholar] [CrossRef]

- Dunstan, E.R. An Enhanced Procedure to Measure Strength and Durability of Pozzolans. ACI Mater. J. 2019, 116, 183–192. [Google Scholar] [CrossRef]

- Ramanujam, I.V.R.; Reddy, K.R.; Ramana, N.V. Evaluation of Pozzolanic Activity and Lime Reactivity of Fly Ash, GGBS, Mica Powder and Pumice as Binders. In Proceedings of the International Conference on Sustainable Goals in Materials, Energy and Environment (ICSMEE’24), Kottayam, India, 2–3 May 2024; Volume 529, p. 01008. [Google Scholar] [CrossRef]

- ABNT NBR 13583; Portland Cement—Determination of Volumetric Change of Portland Cement Mortar Bars Exposed to Sodium Sulphate Solution. ABNT: Rio de Janeiro, Brazil, 2014.

- ABNT NBR 10004; Solid Waste—Classification. ABNT: Rio de Janeiro, Brazil, 2004.

- ABNT NBR NM 248; Aggregates—Sieve Analysis of Fine and Coarse Aggregates. ABNT: Rio de Janeiro, Brazil, 2003.

- ABNT NBR NM 46; Aggregates—Determination of Material Finer than 75 Micrometer Sieve by Washing. ABNT: Rio de Janeiro, Brazil, 2003.

- ABNT NBR NM 52; Fine Aggregate—Determinação of the Bulk Specific Gravity and Apparent Specific Gravity. ABNT: Rio de Janeiro, Brazil, 2009.

- ABNT NBR NM 45; Aggregates—Determination of the Unit Weight and Air-Void Contents. ABNT: Rio de Janeiro, Brazil, 2006.

- ABNT NBR NM 30; Fine Aggregate—Test Method for Water Absorption. ABNT: Rio de Janeiro, Brazil, 2001.

- ABNT NBR 15261; Mortars Applied on Walls and Ceilings—Determination of Dimensional Charges (Shrinkage). ABNT: Rio de Janeiro, Brazil, 2005.

- ABNT NBR 5751; Pozzolanic Materials—Determination of Pozzolanic Activity with Lime at Seven Days. ABNT: Rio de Janeiro, Brazil, 2015.

- ABNT NBR 5752; Pozzolanic Materials—Determination of the Performance Index with Portland Cement at 28 Days. ABNT: Rio de Janeiro, Brazil, 2014.

- OJ L226: 2000/532/EC: Commission Decision of 3 May 2000 Replacing Decision 94/3/EC Establishing a List of Wastes Pursuant to Article 1(a) of Council Directive 75/442/EEC on Waste and Council Decision 94/904/EC Establishing a List of Hazardous Waste Pursuant. Available online: https://eur-lex.europa.eu/eli/dec/2000/532/oj (accessed on 14 February 2023).

- Agrizzi, C.P.; Carvalho, E.A.S.; Borlini Gadioli, M.C.; Barreto, G.N.S.; de Azevedo, A.R.G.; Monteiro, S.N.; Vieira, C.M.F. Comparison between Synthetic and Biodegradable Polymer Matrices on the Development of Quartzite Waste-Based Artificial Stone. Sustainability 2022, 14, 6388. [Google Scholar] [CrossRef]

- Almada, B.S.; Melo, L.d.S.; Dutra, J.B.; Bubani, L.C.; Silva, G.J.B.; dos Santos, W.J.; Aguilar, M.T.P. Influence of the Heterogeneity of Waste from Wet Processing of Ornamental Stones on the Performance of Portland Cement Composites. Constr. Build. Mater. 2020, 262, 120036. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P. Concrete: Microstructure, Properties, and Materials; IBRACON: São Paulo, Brazil, 2014. [Google Scholar]

- Westerholm, M.; Lagerblad, B.; Silfwerbrand, J.; Forssberg, E. Influence of Fine Aggregate Characteristics on the Rheological Properties of Mortars. Cem. Concr. Compos. 2008, 30, 274–282. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 4th ed.; Longman Group: London, UK, 1995. [Google Scholar]

- Jiang, J.; Chen, S.; Jin, C.; Wang, G.; Liu, T.; Xu, T.; Lei, L.; Dang, W.; Yang, X.; Ding, T.; et al. Preparation and Properties of High-Strength Lightweight Aggregate Ceramsite from Nepheline Tailings. Constr. Build. Mater. 2023, 368, 130458. [Google Scholar] [CrossRef]

- ABNT NBR 7211; Aggregates for Concrete—Requirements. ABNT: Rio de Janeiro, Brazil, 2009.

- Raif Boğa, A.; Ferdi Şenol, A. The Effect of Waste Marble and Basalt Aggregates on the Fresh and Hardened Properties of High Strength Self-Compacting Concrete. Constr. Build. Mater. 2023, 363, 129715. [Google Scholar] [CrossRef]

- Tolstoy, A.; Lesovik, V.; Fediuk, R.; Amran, M.; Gunasekaran, M.; Vatin, N.; Vasilev, Y. Production of Greener High-Strength Concrete Using Russian Quartz Sandstone Mine Waste Aggregates. Materials 2020, 13, 5575. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concreto: Microestrutura, Propriedades e Materiais; PINI: São Paulo, Brazil, 2008. [Google Scholar]

- Rana, A.; Kalla, P.; Verma, H.K.; Mohnot, J.K. Recycling of Dimensional Stone Waste in Concrete: A Review. J. Clean. Prod. 2016, 135, 312–331. [Google Scholar] [CrossRef]

- Ghafoori, N.; Batilov, I.; Najimi, M. Resistance to Sulfate Attack of Mortars Containing Colloidal Nanosilica and Silica Fume. J. Mater. Civ. Eng. 2020, 32, 06020019. [Google Scholar] [CrossRef]

- Mao, Y.; Liu, J.; Shi, C. Autogenous Shrinkage and Drying Shrinkage of Recycled Aggregate Concrete: A Review. J. Clean. Prod. 2021, 295, 126435. [Google Scholar] [CrossRef]

- Zhang, W.; Zakaria, M.; Hama, Y. Influence of Aggregate Materials Characteristics on the Drying Shrinkage Properties of Mortar and Concrete. Constr. Build. Mater. 2013, 49, 500–510. [Google Scholar] [CrossRef]

- He, Z.; Yang, Y.; Yuan, Q.; Shi, J.; Liu, B.; Liang, C.; Du, S. Recycling Hazardous Water Treatment Sludge in Cement-Based Construction Materials: Mechanical Properties, Drying Shrinkage, and Nano-Scale Characteristics. J. Clean. Prod. 2021, 290, 125832. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary Cementitious Materials: New Sources, Characterization, and Performance Insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Panesar, D.K.; Zhang, R. Performance Comparison of Cement Replacing Materials in Concrete: Limestone Fillers and Supplementary Cementing Materials—A Review. Constr. Build. Mater. 2020, 251, 118866. [Google Scholar] [CrossRef]

- ANM State Mineral Yearbook—Santa Catarina. Available online: https://www.gov.br/anm/pt-br/centrais-de-conteudo/publicacoes/serie-estatisticas-e-economia-mineral/anuario-mineral (accessed on 6 December 2022).

- Volkmann, A.R. Studies on Beneficiation Routes of Nepheline Syenite for Application as a Flux in Ceramic Body of Porcelain Tile; Federal University of Rio Grande do Sul—UFRGS: Porto Alegre, Brazil, 2004. [Google Scholar]

- Rentier, E.S.; Cammeraat, L.H. The Environmental Impacts of River Sand Mining. Sci. Total Environ. 2022, 838, 155877. [Google Scholar] [CrossRef]

- Rosa, L.P.; Santos, D.H.; Zaccaron, A.; Ribeiro, M.J.; Klegues Montedo, O.R.; Arcaro, S.; Raupp-Pereira, F. Rheological Behavior of Nepheline Syenite Beneficiation Waste-Based Mortars. J. Build. Eng. 2024, 98, 111403. [Google Scholar] [CrossRef]

- Zhang, Y.; Ling, T.-C. Reactivity Activation of Waste Coal Gangue and Its Impact on the Properties of Cement-Based Materials—A Review. Constr. Build. Mater. 2020, 234, 117424. [Google Scholar] [CrossRef]

- Orris, G.J.; Cocker, M.D.; Dunlap, P.; Wynn, J.C.; Spanski, G.T.; Briggs, D.A.; Gass, L.; Bliss, J.D.; Bolm, K.S.; Yang, C.; et al. Potash: A Global Overview of Evaporate-Related Potash Resources, Including Spatial Databases of Deposits, Occurrences, and Permissive Tracts; U.S. Geological Survey: Reston, VA, USA, 2014.

- Samantray, J.; Anand, A.; Dash, B.; Ghosh, M.K.; Behera, A.K. Silicate Minerals—Potential Source of Potash—A Review. Miner. Eng. 2022, 179, 107463. [Google Scholar] [CrossRef]

- Haseli, P.; Majewski, P.; Christo, F.C.; Hammond, B.; Bruno, F. Thermochemical and Experimental Kinetic Analysis of Potassium Extraction from Ultrapotassic Syenite Using Molten Chloride Salts. Ind. Eng. Chem. Res. 2019, 58, 7397–7407. [Google Scholar] [CrossRef]

- BRASIL National Fertilizer Plan 2050—A Strategy for Fertilizers in Brazil. Available online: https://www.gov.br/agricultura/pt-br/assuntos/insumos-agropecuarios/insumos-agricolas/fertilizantes/plano-nacional-de-fertilizantes/o-plano-nacional-de-fertilizantes (accessed on 13 December 2022).

| SiO2 | Al2O3 | K2O | Na2O | Fe2O3 | CaO | TiO2 | MnO | MgO | Others | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|---|

| 56.16 | 20.46 | 4.68 | 10.35 | 5.48 | 1.15 | 0.46 | 0.53 | 0.07 | 0.03 | 0.63 |

| Criteria | Lime (NBR 5751) [48] | Cement Portland (NBR 5752) [49] | |

|---|---|---|---|

| % retained (45 μm sieve) | 17.40 (<20.00) | 17.40 (<20.00) | |

| Average size (μm) | 22.75 (<45.00) | 22.75 (<45.00) | |

| Lime (g) | 208.00 | 0.00 | 0.00 |

| Portland cement (g) | 0.00 | 624.00 | 468.00 |

| PNSW (g) | 530.00 | 0.00 | 156.00 |

| Standardized sand (g) | 1872.00 | 1872.00 | 1872.00 |

| Water (g) | 460.00 | 300.00 | 300.00 |

| Compressive strength (MPa) | 3.10 (>6.00) | 24.49 | 21.64 |

| Performance index (%) | 51.67 (>100) | 88.36 (>90) | |

| Classification | Non-pozzolanic | Non-pozolanic | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, D.H.; Rosa, L.P.; Alves, C.R.; Simão, L.; Zaccaron, A.; Arcaro, S.; Montedo, O.R.K.; Raupp-Pereira, F. Using Brazilian Nepheline Syenite Waste as an Alternative Mineral Resource for Various Applications. Minerals 2025, 15, 554. https://doi.org/10.3390/min15060554

Santos DH, Rosa LP, Alves CR, Simão L, Zaccaron A, Arcaro S, Montedo ORK, Raupp-Pereira F. Using Brazilian Nepheline Syenite Waste as an Alternative Mineral Resource for Various Applications. Minerals. 2025; 15(6):554. https://doi.org/10.3390/min15060554

Chicago/Turabian StyleSantos, Diego Haltiery, Laura Pereira Rosa, Cleidson Rosa Alves, Lisandro Simão, Alexandre Zaccaron, Sabrina Arcaro, Oscar Rubem Klegues Montedo, and Fabiano Raupp-Pereira. 2025. "Using Brazilian Nepheline Syenite Waste as an Alternative Mineral Resource for Various Applications" Minerals 15, no. 6: 554. https://doi.org/10.3390/min15060554

APA StyleSantos, D. H., Rosa, L. P., Alves, C. R., Simão, L., Zaccaron, A., Arcaro, S., Montedo, O. R. K., & Raupp-Pereira, F. (2025). Using Brazilian Nepheline Syenite Waste as an Alternative Mineral Resource for Various Applications. Minerals, 15(6), 554. https://doi.org/10.3390/min15060554