1. Introduction

Phosphogypsum is a byproduct of the phosphate industry. Due to the increased demand for phosphate-based products (e.g., fertilizers, animal feed) over the past decades, large quantities of phosphogypsum have been produced worldwide. Since this material has low economic value and limited usefulness, it is typically disposed of in designated areas, forming large deposits [

1,

2]. The contamination of water resources with phosphogypsum can have significant consequences, as it is classified as a material containing natural radioactivity. In large quantities and when in contact with groundwater, it may lead to serious environmental issues. Beyond the radiation-related health risks, phosphogypsum may also contain trace elements such as arsenic, lead, cadmium, chromium, fluoride, zinc, antimony, and copper. According to the U.S. Environmental Protection Agency (USEPA), the concentrations of these elements can pose a chemical hazard to human health and the environment [

3]. However, with proper management and adherence to the guidelines (e.g., the guidelines set by the Greek Atomic Energy Commission [

4]), phosphogypsum can be safely disposed of and even used in agriculture as a soil conditioner or in the construction industry as a building material. When used in limited quantities or managed appropriately, it is considered safe.

Today, within the framework of the circular economy, international research is being conducted to explore the potential reuse of phosphogypsum in various applications (e.g., [

2,

5]). In the current era of sustainable development and the circular economy, there is growing consensus that both environmental and economic priorities support the extensive recycling and beneficial reuse of materials [

6]. Despite this, the utilization of phosphogypsum (PG) accounts for a very small percentage of the total produced volume, e.g., [

2]. Over the past 20 years, numerous studies have investigated the potential use of PG in various engineering applications. Some of them include thermal energy storage for low temperature applications [

7], soil reclamation [

8,

9], soil stabilization [

10,

11,

12,

13], infrastructure materials [

14,

15], manufacturing [

16,

17,

18,

19], the cement industry [

20,

21,

22], and even coastal applications [

23]. An in-depth overview of the potential uses of phosphogypsum is presented in [

24].

One additional application not systematically explored is its use (mainly in combination with soil materials to create mixtures with suitable properties) for filling quarry excavations as part of land rehabilitation efforts. Quarry reclamation is an essential post-mining practice aimed at restoring the ecological and socio-economic value of degraded landscapes. Modern strategies emphasize the use of external backfill materials, such as inert waste, tailings, or industrial byproducts like phosphogypsum, to reshape quarry voids and re-establish land stability and ecosystem services. Successful reclamation requires a site-specific approach, integrating geotechnical safety, environmental sustainability, and long-term land use planning [

25,

26,

27,

28].

In Greece, significant phosphogypsum deposits have accumulated due to industrial activities. In the vicinity of these deposits, numerous closed or abandoned quarries can be found, some of which could be candidates for reclamation. At the north part of Greece (located at Nea Karvali in Kavala gulf in Northwestern Greece), a phosphate fertilizer industry has been in operation since 1965, producing about 500,000 tons of phosphate fertilizer per year [

29]. The produced phosphogypsum has been deposited continuously near the industry, by the seaside, in an open land disposal area of about 500,000 m

2. The estimated phosphogypsum mass was about 13 million tons in 2019 [

30]. This deposit is in Northwestern Greece, relatively close to various quarries in the Drama and Kozani regions, which are appropriate candidates for backfill reclamation. Additionally, between 1979 and 1989, approximately 10 million tons of phosphogypsum were disposed of in an abandoned limestone quarry in Schistos, near Piraeus [

31]. This site has since been remediated with geomembranes and soil cover to mitigate environmental risks.

In the case of backfill reclamation with phosphogypsum, the key required properties of the backfill material include low permeability to prevent material leakage, maximum dry density, and sufficient strength to ensure stable restoration slopes. Understanding the geotechnical properties of phosphogypsum is crucial for assessing its potential for reuse in such applications. This study presents the results of laboratory investigations evaluating the geotechnical properties of phosphogypsum. Additionally, various mixtures were tested to determine whether they enhance maximum density or reduce permeability. To this end, phosphogypsum was mixed with a typical clayey material with finer particles to modify grain size distribution and potentially improve density, permeability, and cstrength. Phosphogypsum remained the primary material in all mixtures. Furthermore, an additional mixture was included, incorporating marble dust—a byproduct of marble quarries—since its grain size distribution and properties could be beneficial. In this third mixture, phosphogypsum was again the main component. The geotechnical characterization of phosphogypsum and all tested mixtures was conducted using grain size distribution analysis, Atterberg limits, classification indices, and measurements of natural moisture content and specific gravity. Additional tests were performed to examine key parameters, including modified Proctor compaction tests, permeability tests, one-dimensional compression tests, and direct shear tests under drained and undrained conditions.

This study aims to evaluate the suitability of phosphogypsum, both in its initial form and in combination with natural, generally available materials, for use in quarry reclamation, focusing specifically on its compaction behavior, permeability, compressibility, and shear strength. The novelty of this research lies in its systematic geotechnical assessment of Greek-sourced phosphogypsum and even more its mixtures with other largely available materials, a study area mainly unexplored in the literature. Furthermore, the incorporation of marble dust, another industrial byproduct, offers a novel approach to enhancing material performance while promoting circular economy practices. By targeting quarry backfilling applications, this study addresses a practical and environmentally relevant challenge, contributing original insights into the reuse potential of phosphogypsum in the context of land restoration.

2. Materials, Mixture Design, and Experimental Procedures

An experimental program was organized and carried out to quantify the fundamental properties of phosphogypsum and to assess the impact of mixing it with other materials. In total, three materials were used:

Phosphogypsum (PG) industrial byproduct from a fertilizer company in Greece.

Clay (A)—“typical” clay sourced from a borrow pit in the region of Thebes.

Marble dust (MD)—commercially available material originating from a Boeotian quarry.

This phosphogypsum has been analyzed for its environmental properties [

32,

33] and is characterized primarily by high concentrations of calcium and sulfates, which are typical of this industrial byproduct. Specifically, the phosphogypsum analyzed in previous works contained 24.9% calcium and 51.1% sulfates, present in the form of gypsum (CaSO

4·2H

2O). In addition, it included smaller amounts of iron (0.215%), silicon (0.57%), and phosphates (0.759%). The mineralogical analysis confirmed the presence of gypsum as the dominant crystalline phase, along with quartz (SiO

2). These findings highlight the basic composition of PG, which is influenced by the raw phosphate rock used and the specific industrial processing conditions.

The chemical compositions of clay and marble dust materials are typical. The clay material was sourced from a borrow pit in Thebes (Greece). Based on the geological context of the area and typical characteristics of similar clay deposits in Central Greece, the material is expected to consist primarily of silicate minerals such as kaolinite, illite, and possibly smectite, along with varying amounts of quartz, calcium carbonate, and iron oxides. The commercial marble dust originated from a quarry in the Boeotia region. Based on the geological characteristics of marbles of the area, the material is expected to consist predominantly of calcium carbonate (CaCO3), with possible minor amounts of dolomite (CaMg(CO3)2), quartz (SiO2), and possibly traces of other oxides.

The experimental program included the preparation and testing of phosphogypsum (PG) in its pure form as well as in three mixtures. The mix designs were developed using phosphogypsum as the primary material, combined with sourced clay and marble dust. The specific compositions of the three mixtures were as follows (percentages are given by dry weight):

M1: 95% phosphogypsum + 5% clay

M2: 90% phosphogypsum + 10% clay

M3: 90% phosphogypsum + 5% clay + 5% marble dust

The materials used (phosphogypsum, clay, and marble dust) were first dried and then prepared in dry form. The materials were sieved to ensure consistent particle size and mixed in predetermined proportions by dry weight. Moisture was added to each mixture in stages to reach the desired water content for compaction, based on preliminary Proctor testing. Standard geotechnical lab procedures were followed to achieve homogeneity before sample compaction and testing. For each geotechnical test described in the following, the mixtures were initially compacted in a cylindrical mold using the modified Proctor method following E 105-86 §10,11 [

34]. This preparation and testing methodology ensured consistency across all samples and allowed for direct comparison of the geotechnical behavior of each material. For consistency, two specimens were tested for each material and mixture. The only exception was the marble dust, which is a standardized commercial product.

Firstly, physical parameters were measured (grain size distribution, Atterberg limits, specific gravity, natural moisture content) followed by material classification. Furthermore, five types of tests were conducted to evaluate the geotechnical properties of materials, with emphasis on behavior relevant to quarry backfilling applications: Proctor compaction, permeability (oedometer and constant head), one-dimensional compression, and direct shear tests under both unconsolidated-undrained (UU) and consolidated-drained (CD) conditions.

2.1. Grain Size Distribution and Material Characterization

For the three materials—phosphogypsum (PG), clay (A), and marble dust (MD)—as well as the three mixtures, grain size distribution was determined using standard sieving methods (EN 17892-4 [

34]) and hydrometer analysis (when appropriate). This process provides essential information on the proportions of sand, silt, and clay in the sample, which is vital for soil classification and assessing filtration or drainage behavior. To assess the fines content, the percentage of particles passing the No. 200 sieve (0.075 mm) was measured (E 105-86 §8 [

35]). This is a key indicator of the soil’s cohesiveness and its potential to retain water. For the fine-grained materials, the Atterberg limits were also determined (EN 17892-12 [

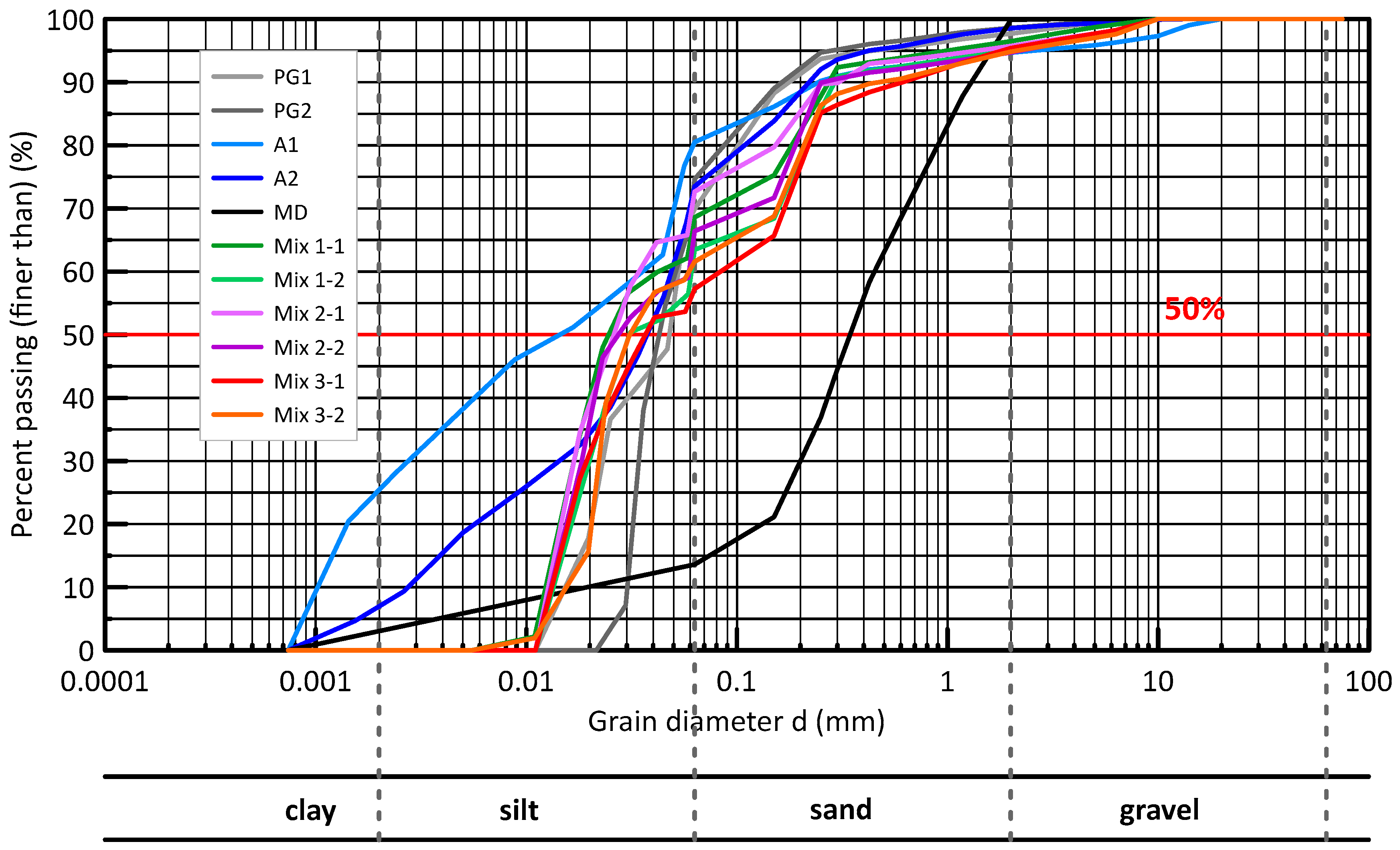

34]), and classification was conducted according to the Unified Soil Classification System (USCS). These limits reflect the soil’s plasticity and its consistency behavior across varying moisture contents, providing insight into shrink-swell potential and workability. The grain size distributions of the materials are shown in

Figure 1, while the Atterberg limits are summarized in

Table 1.

Based on the grain size analysis, all samples except for marble dust contain more than 50% fine-grained particles. Additionally, the phosphogypsum samples, as well as the mixtures (that primarily consist of phosphogypsum), exhibit silt-like particle distributions. The phosphogypsum itself, along with the mixtures containing clay, is poorly graded. However, the addition of marble dust (due to its specific characteristics) results in a well-graded mixture (M3). The plasticity limit for phosphogypsum and its mixtures is not included in

Table 1, as they exhibited non-plastic behavior, making it impossible to form samples for measurement.

The preparation of disturbed soil samples in their dry state involved drying, disaggregation, and homogenization of the material to ensure consistent conditions (E 105-86 §1 [

35]). Bulk density, both dry and wet, was measured. This is essential for converting test results to field conditions and for calculating void ratios and degree of saturation (EN 17892-2 [

34]). The specific gravity of the soil solids was determined (EN 17892-3 [

34]), which is necessary for interpreting other test results, including void ratio and relative compaction.

2.2. Modified Proctor Tests

Modified Proctor compaction tests were carried out to determine the optimum moisture content and maximum dry density of the soils and mixtures (E 105-86 §10,11 [

34]). These tests involve compacting the materials in the laboratory at varying moisture levels and measuring the resulting dry densities, which helps identify the conditions under which each material achieves its maximum strength and minimum compressibility. This information is essential for establishing compaction specifications in the field and is especially important for the construction of embankments and engineered fills. In quarry backfilling, a material that compacts effectively with minimal water is preferred, and the modified Proctor test provides a clear assessment of that behavior.

In this study, dry density–moisture content curves were developed for each material and mixture using at least three different moisture levels per test. A high-order polynomial curve was fitted to represent the results, allowing for accurate interpretation of compaction trends. To ensure reliability, three samples of phosphogypsum were tested due to its critical role in the study, while two samples were used for each of the other mixtures.

2.3. Permeability Tests

Permeability testing was conducted using two methods to evaluate the hydraulic behavior of phosphogypsum and its mixtures; permeability is an essential property given its direct implications for groundwater safety and environmental protection. The oedometer permeability test was employed to measure vertical hydraulic conductivity (EN 17892-11 [

34]) while the soil was subjected to consolidation loading, simulating stress conditions representative of in situ fine-grained soils. This method is particularly valuable for assessing the long-term drainage behavior of materials like clays, silts, and phosphogypsum under realistic loading. To complement this, the constant head permeability test was also applied (E 105-86 §17 [

34]). This widely used and straightforward method involves maintaining a constant water head and recording the resulting flow rate through the soil sample, providing reliable estimates of hydraulic conductivity under steady-state flow conditions.

In this study, the permeability of phosphogypsum and its mixtures was of particular interest due to its significance in controlling leachate migration and minimizing environmental risks. While phosphogypsum disposal is typically coupled with sealing measures to prevent contamination, enhancing its performance—specifically by lowering its permeability—can significantly improve its viability as a safe and effective backfilling material. For each material tested, the oedometer permeability test was performed, and results were validated using a second sample in the constant head apparatus, allowing for cross-validation and a more comprehensive understanding of flow behavior under both loaded and unloaded conditions.

2.4. 1D Compression Tests (Oedometer Tests)

The oedometer test was employed to assess the compressibility and consolidation behavior of the soil (EN 17892-5 [

34]). By applying incremental vertical loading to a confined soil specimen, the test simulates the stress conditions experienced in the field and provides essential parameters such as the compression index, recompression index, and preconsolidation pressure. These parameters are vital for predicting the magnitude and rate of settlement in fine-grained soils, which is critical for foundation design and the long-term performance of infrastructure.

2.5. Direct Shear Tests

To evaluate the shear strength of the materials and their suitability for potential slope design during excavation backfilling, direct shear tests were conducted under both unconsolidated-undrained (UU) and consolidated-drained (CD) conditions (EN 17892-10 [

34]). These tests simulate different field conditions and provide valuable data for stability assessments. In the UU direct shear test, specimens were sheared without allowing for drainage or prior consolidation, representing short-term loading conditions typical of rapid construction or sudden stress applications in cohesive soils, where pore water pressures cannot dissipate. In contrast, the CD direct shear test involved both consolidation of the specimen and drainage throughout the shearing process, reflecting long-term stability conditions once pore pressures have equilibrated. These tests are fundamental for assessing a material’s resistance to shearing along a defined failure plane and are commonly used in the design of slopes, earth-retaining structures, and engineered fills. The combination of both test types provides a comprehensive understanding of the material behavior under different stress and drainage regimes.

3. Results and Discussion of Geotechnical Properties

3.1. Modified Proctor Tests

Figure 2 presents the results of all modified Proctor tests, with individual data points corresponding to measured values and the continuous curves showing the fitted relationships. The maximum dry density of phosphogypsum ranged from 1.44 to 1.50 g/cm

3, with an optimum moisture content between 23% and 28%. Two of the three samples lie within a narrower range of 27%–28%. In contrast, clay showed a significantly higher maximum dry density of 1.87–1.90 g/cm

3 and a much lower optimum moisture content of 12%–13%. Marble dust exhibited distinctly different behavior due to its nature, with a very low optimum moisture content of 2%–4% and a high maximum dry density of about 1.96 g/cm

3.

For phosphogypsum mixtures, increasing clay content resulted in a gradual rise in optimum moisture content, from 27%–28% (pure PG) to 28%–29% (5% clay) and 29%–30% (10% clay). Concurrently, maximum dry density decreased slightly from 1.44–1.52 g/cm

3 to 1.42–1.44 g/cm

3 (5% clay) and 1.40–1.44 g/cm

3 (10% clay). The addition of marble dust significantly altered the compaction behavior. The mixture became well-graded (

Figure 1), the optimum moisture content dropped sharply to 16%–17%, and the maximum dry density increased to 1.60–1.64 g/cm

3, substantially higher than the values for phosphogypsum-clay blends.

Overall, marble dust exhibited the lowest moisture content and the highest maximum dry density, whereas clay was relatively similar to phosphogypsum, as it is a natural soil. The phosphogypsum samples and their mixtures with clay had closely related characteristics. Finally, the phosphogypsum-clay-marble dust mixture had the lowest moisture requirement and the highest maximum dry density compared to phosphogypsum and the other mixtures.

The increase in optimum moisture content and corresponding decrease in dry density with the addition of clay suggests reduced compaction efficiency due to the higher water retention capacity and possibly lower grain interlock of fine particles. In contrast, the addition of marble dust improves grain size distribution and facilitates denser packing of grains, which is probably the reason leading to higher dry densities at significantly lower moisture contents. These results indicate that mixtures incorporating marble dust are likely to require less water and compaction energy in the field while achieving more stable fills. This is particularly beneficial in quarry environments where water management and compaction control can be challenging.

3.2. Permeability Tests

The outcomes of permeability tests in the oedometer apparatus are illustrated in

Figure 3, and a comparison with constant head measurements is summarized in

Table 2. As expected, permeability decreases as the applied stress increases. Between 20 kPa and 200 kPa, the permeability of phosphogypsum and its mixtures decreases by up to an order of magnitude. Phosphogypsum itself exhibits moderate permeability (10

−4–10

−5 cm/s), which aligns with its previously described silty grain size distribution. The mixtures containing only clay maintain permeability values of the same order, though slightly higher. This happens because clay aggregates with phosphogypsum. Thus, instead of reducing permeability by introducing finer particles, it creates larger clusters that may increase it.

On the other hand, the mixture containing marble dust significantly reduces overall permeability and makes it more stable under increasing stress levels. Once again, the M3 mixture (phosphogypsum-clay-marble dust) proves to be the best option, though the improvement in permeability remains moderate.

A comparison between the falling head and constant head methods (

Table 2) does not reveal any discrepancies in the overall observations. The constant head method generally confirms the initial findings, with slightly higher permeability values for phosphogypsum and clay and slightly lower values for the mixtures. However, the order of magnitude remains unchanged, and the practical impact of permeability in real-world applications remains the same.

The permeability values of pure phosphogypsum and its clay mixtures, although moderate, highlight a potential risk for leaching if used in bulk. Permeability decreases with increasing stress consistently with expected consolidation behavior, as pore spaces are reduced. However, the fact that the addition of clay did not significantly lower permeability—likely due to aggregation or flocculation effects—is notable. In contrast, the mixture with marble dust showed improved sealing characteristics, suggesting that it could function effectively as a surface layer in reclamation schemes aimed at isolating potentially reactive materials from infiltrating water.

3.3. 1D Compression Tests (Oedometer Tests)

Figure 4 presents the results of one-dimensional compression tests for phosphogypsum, clay, and their mixtures, while

Table 3 summarizes the corresponding recompression indices. A pre-consolidation trend is observed, affecting the slope of the compression curves, which corresponds to stress levels of approximately 100–300 kPa.

The compression index (C

c)—which is based on the logarithm of stress and void ratio and is defined during the primary compression stage—was found to be 0.054 and 0.067 for the two phosphogypsum samples (

Table 3). These values are low compared to natural soils; for example, normally consolidated clays (of moderate sensitivity) typically have C

c values ranging from 0.5 to 2 [

36]. Thus, the compression index of phosphogypsum is at the lower bound of clays.

An unloading process was applied after reaching a vertical stress of 800 kPa. The swelling upon unloading for phosphogypsum was minimal, leading to an almost negligible recompression index. The phosphogypsum-clay mixtures exhibited a compression index closer to that of clay, despite their high phosphogypsum content. This suggests that even a small fraction of clay significantly influences the compression behavior. On the other hand, the addition of marble dust reduces the compression index compared to the clay mixtures, yielding values of 0.071–0.096, which are slightly higher than those of pure phosphogypsum.

The low compression index values observed for phosphogypsum indicate relatively limited long-term settlement potential under typical loading conditions. However, the increased compressibility seen in mixtures with clay, despite their low clay content, suggests that the presence of plastic fines can significantly influence the deformation characteristics of the backfill. This effect should be considered to avoid unexpected differential settlement, particularly in thicker fills. The inclusion of marble dust in the mixtures appears to offset this effect, producing compressibility behavior slightly higher than that of pure phosphogypsum, making it suitable for upper-layer filling.

Given the fine-grained material type and silt-like behavior of phosphogypsum, its use as a backfill material throughout the entire depth of a quarry may lead to long-term settlement, despite moderate compressibility. Therefore, its most suitable application may be in the upper layers of the backfill, or as a filtration or sealing layer, particularly when mixed with marble dust to enhance stability. In this context, filling quarry workings with phosphogypsum, in principle, should be interpreted with caution and probably indicate partial or surface-layer backfilling.

3.4. Direct Shear Tests

The results of direct shear tests, including the shear strength parameters friction angle (φ) and cohesion (c), are presented in

Table 4. From the UU tests on phosphogypsum, it was found that the friction angle ranged between 32° and 33°, while cohesion was measured at 38–41 kPa. In comparison, the clay samples had a lower friction angle of 25°–26° and cohesion between 27 and 32 kPa. Although clay generally has lower strength, mixing it with phosphogypsum alters the overall structure, meaning that the resulting material does not necessarily exhibit reduced shear strength. The friction angle of the mixture varies slightly compared to pure phosphogypsum when clay is added. Specifically, with a 5% clay addition, the friction angle slightly increases to 33°–36°, whereas with 10% clay, it slightly decreases to 28°–30°.

Cohesion also changes with the addition of clay, reaching 74–80 kPa for 5% clay (a significant increase) and 44–53 kPa for 10% clay (a moderate increase). This increase is believed to be due to structural changes associated with the clay content and the altered grain composition of the mixture. When marble dust is added in combination with clay and phosphogypsum, the mixture’s cohesion becomes closer to that of pure phosphogypsum, but the friction angle increases. This increase in friction angle is attributed to the improved particle size distribution of the mixture due to the presence of marble dust.

In the CD shear tests, the effective cohesion and friction angle of phosphogypsum were measured between 26 and 50 kPa and 31° and 33°, respectively. There was significant variability in cohesion; however, in general, it remained lower than the values obtained from the UU tests. For clay, the effective cohesion was 11–12 kPa, while the friction angle was 23°, which falls within the typical range for a normally consolidated clay.

When 5% clay was added to phosphogypsum, the friction angle increased to 33°–37°, but with 10% clay, it decreased to 26°–30°. Additionally, for 5% clay content, the effective cohesion varied significantly, ranging from 23 to 61 kPa, whereas for 10% clay, the cohesion values were between 18 and 35 kPa. Overall, the cohesion does not change drastically compared to phosphogypsum samples, but it remains highly variable. It is likely that small amounts of clay enhance the friction angle due to structural modifications, but further additions lead to its reduction. Cohesion, which is already highly variable, remains within similar limits across different compositions. For the M3 mixture, which includes marble dust along with clay and phosphogypsum, the friction angle was found to be 31°, practically the same as that of pure phosphogypsum. However, due to the addition of marble dust, cohesion decreased to 15–16 kPa, compared to 25–50 kPa for phosphogypsum alone.

These test results indicate that phosphogypsum possesses relatively high shear strength in its undrained condition, with moderate cohesion and friction angle. The addition of 5% clay surprisingly improves shear strength, especially cohesion, possibly due to structural reorganization. However, further increasing clay content leads to a slight decline in strength. The mixture containing marble dust exhibits a balanced strength profile with high friction and moderate cohesion, indicating improved grain structure. This suggests that such a mixture would perform well in sloped backfills or upper layers.

4. Conclusions

This study presents the results of a laboratory program focusing on the geotechnical behavior of Greek phosphogypsum. Phosphogypsum and its mixtures were examined to assess their suitability for quarry backfilling and land restoration.

Phosphogypsum is a poorly graded fine-grained material, primarily composed of silt-sized particles (~70%), with a liquid limit of 25%–27% and non-plastic behavior. Adding 5% or 10% clay, or a combination of 5% clay and 5% marble dust, does not alter its classification, which remains low-plasticity silt. However, clay addition significantly increases the liquid limit (44%–48%) without notably differentiating the gradation. Only with the addition of marble dust does the mixture become well-graded. The maximum dry density ranges from 1.44 to 1.50 g/cm3, while the optimum moisture content varies between 23% and 28%. Increasing clay content raises the optimum moisture content while slightly reducing maximum dry density. Marble dust has a more favorable impact, reducing the optimum moisture content to 16%–17% and increasing the maximum dry density to 1.60–1.64 g/cm3, indicating improved compaction efficiency.

Phosphogypsum exhibits a permeability of 1–5 × 10−5 cm/s, with similar values observed in clay mixtures. The addition of marble dust reduces permeability further (though not below 5 × 10−6 cm/s), making it more suitable in applications where limited seepage is desired. The compression index (Cc) for phosphogypsum is 0.054–0.067, relatively low for natural soils, with a minimal elastic rebound. Clay addition increases compressibility, whereas marble dust lowers it compared to clay-containing mixtures, remaining slightly higher than pure phosphogypsum.

Shear strength parameters from UU tests indicate friction angles of 32°–33° and cohesion of 38–41 kPa for phosphogypsum. While clay addition slightly affects friction angle, it significantly increases cohesion. CD shear tests show an effective cohesion of 26–50 kPa and a friction angle of 31°–33°. Cohesion remains relatively stable in mixtures, and friction angle does not follow a clear trend. With marble dust, cohesion decreases significantly, while friction angle remains unchanged.

In conclusion, adding up to 10% clay does not improve phosphogypsum’s key properties for quarry backfilling. However, incorporating marble dust creates a well-graded material with lower permeability, making it a potential alternative with slightly enhanced properties compared to pure phosphogypsum. Based on the experimental results, the most suitable application of this phosphogypsum may be in the upper layers of the backfill, or as a filtration or sealing layer, particularly when mixed with marble dust to enhance stability.