Optimizing Infill Drill Hole Decisions While Capturing the Spatial Continuity of Geochemical and Geometallurgical Properties: Application to Gol Gohar Iron Ore Mine, Iran

Abstract

1. Introduction

1.1. Context and Problem Statement

1.2. State of the Art

1.3. Our Contributions

1.4. Optimization Strategy: Global or Sequential?

2. Methodology

2.1. Mineral Resource Classification

- Allocate a panel volume at the center of the SMU for classification;

- Assess the ore grades of the blocks within the panel through simulation;

- Compute the mean panel grade and subsequently establish lower and upper thresholds for each classification, aligning them with the desired level of accuracy;

- Count the number of blocks falling within the thresholds for each classification;

- Determine the classification based on the requisite confidence interval for each class.

2.2. Particle Swarm Optimization

2.3. Genetic Algorithms

2.4. Random Search

- Solution optimality. Unlike the GA and PSO, which rely heavily on population dynamics and historical solutions, the RS samples solutions randomly throughout the search space, and is able to explore diverse regions without bias, enhancing its capability of escaping local optima—a common challenge faced by the GA and PSO due to their reliance on previously selected solutions [52,53]. In mineral deposits with a complex geology and spatial distribution of key technical variables, this advantage may significantly increase the likelihood of identifying optimal drilling locations [54].

- Robustness to noise. Geological and mining data often present a considerable amount of noise arising from geological variability and measurement errors. Previous studies have shown the robustness of the RS in such noisy environments, since it does not depend on gradient information or population interactions prone to erratic behavior. In scenarios characterized by uncertainty—where mineral deposits may shift unexpectedly based on real-time data—the RS proves to be effective due to its stochastic nature allowing for steadier performance amidst variability [55].

- Efficacy in high dimensional problems. The efficacy of optimization algorithms typically decreases when increasing the problem dimensionality—a phenomenon known as the “curse of dimensionality”. Research indicates that, while the GA and PSO may struggle with maintaining diversity among candidate solutions as dimensions rise, the RS maintains efficiency through its independent sampling strategy. In high-dimensional search spaces representative of complex mining datasets that incorporate multiple geological features, this scalability allows the RS not only quick evaluations, but greater adaptability during optimizations [56].

- Ease of implementation. The RS offers substantial advantages with respect to implementation simplicity, compared with more sophisticated algorithms like the GA or PSO, which require extensive parameter tuning, including crossover rates or swarm sizes, to achieve desired results. The straightforward nature of the RS makes it particularly appealing for dynamic applications where conditions change frequently, allowing practitioners immediate adaptability without undergoing lengthy pre-processing stages required by other techniques [57].

2.5. Proposed Objective Function

- N is the number of blocks (selective mining units) discretizing the resource model;

- Gi is the expected ore grade of block i (average of the realizations);

- Pi is the extraction priority of block i (0 ≤ Pi ≤ 1);

- Ci is the resource classification ranking of block i (0 for measured and 1 for indicated);

- Vi is the unit block volume (1 for a block, a fraction between 0 and 1 for a sub-block);

- w1,i, w2,i, w3,i, and w4,i are the weights associated with each parameter, reflecting their relative importance in the objective function (0 ≤ w ≤ 1).

2.6. Proposed Optimization Algorithm

2.7. Proposed Methodology

- Data preparation in a suitable format.

- Divide the block model into smaller, more defined zones for a comprehensive and precise analysis of potential drill hole placements.

- Place an infill drill hole randomly within each restricted zone, ensuring compliance with the defined maximum distance to the initial drill holes or to the other drill holes undergoing optimization. Care must be taken to maintain reasonable distances both in relation to the existing drill holes and among the new set of drill holes themselves.

- Randomly select one infill drill hole (Equation (2)) and shift its position within its restricted zone subject to the above distance restrictions.

- Evaluate the objective function to accept or reject the shift proposed in Step 4.

- Go back to Step 3 and loop until the objective function does not increase any more, or a maximum number of iterations (3000) is reached. The resulting configuration of infill drill holes (one per restricted zone) is the optimal one, or close to the optimal one.

- Evaluate the cumulated contribution to the objective function of each infill drill hole and select the best three drill holes.

- Update the database by adding the three new drill holes to the existing ones, and update the realizations of the block model, by re-rerunning the simulation of the ore grade and recovered metal conditioned to the information of the updated database.

- Continue the placement process using the updated database, repeating Steps 3 to 7 until the desired number of optimal infill drill holes is achieved.

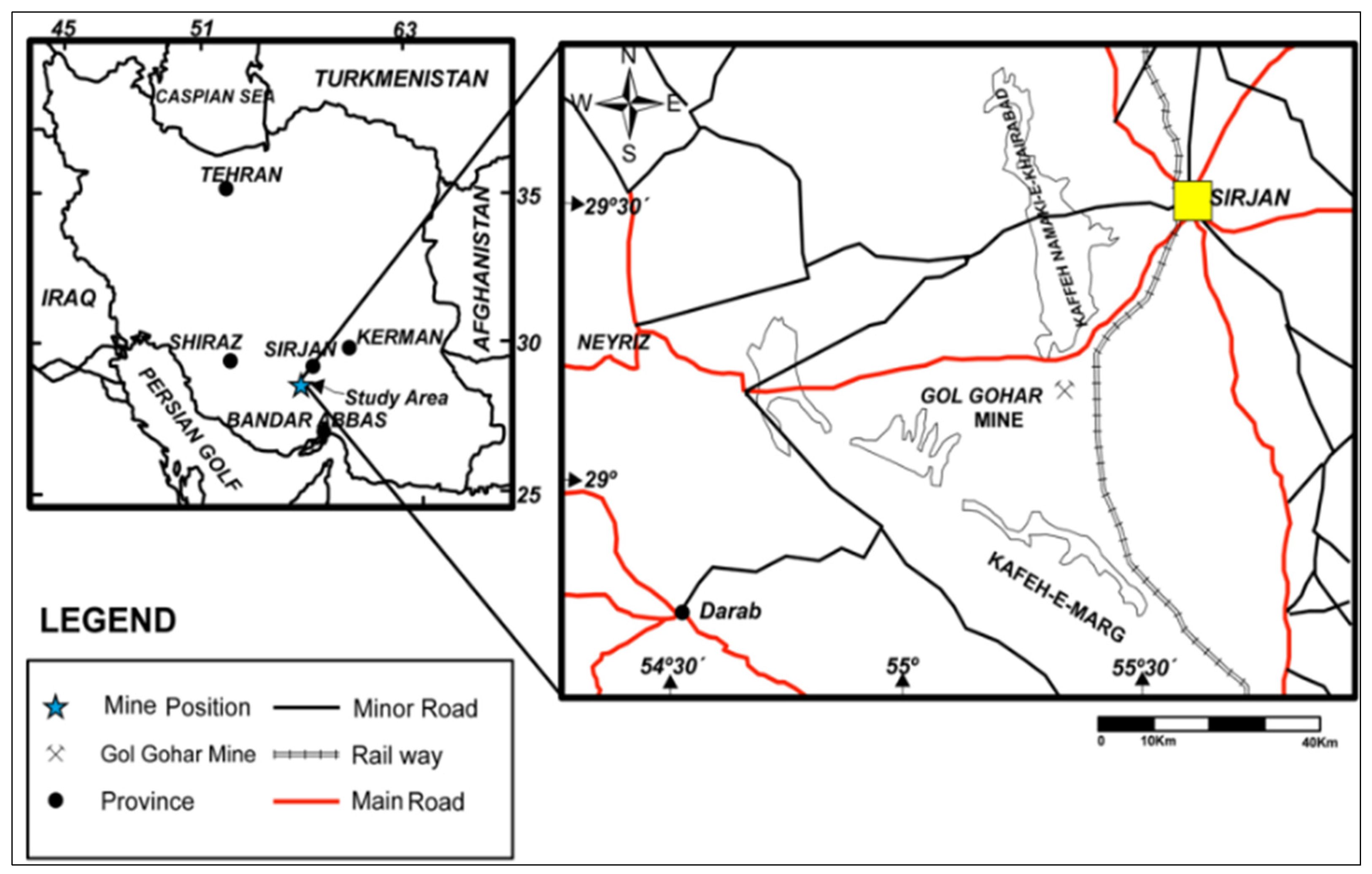

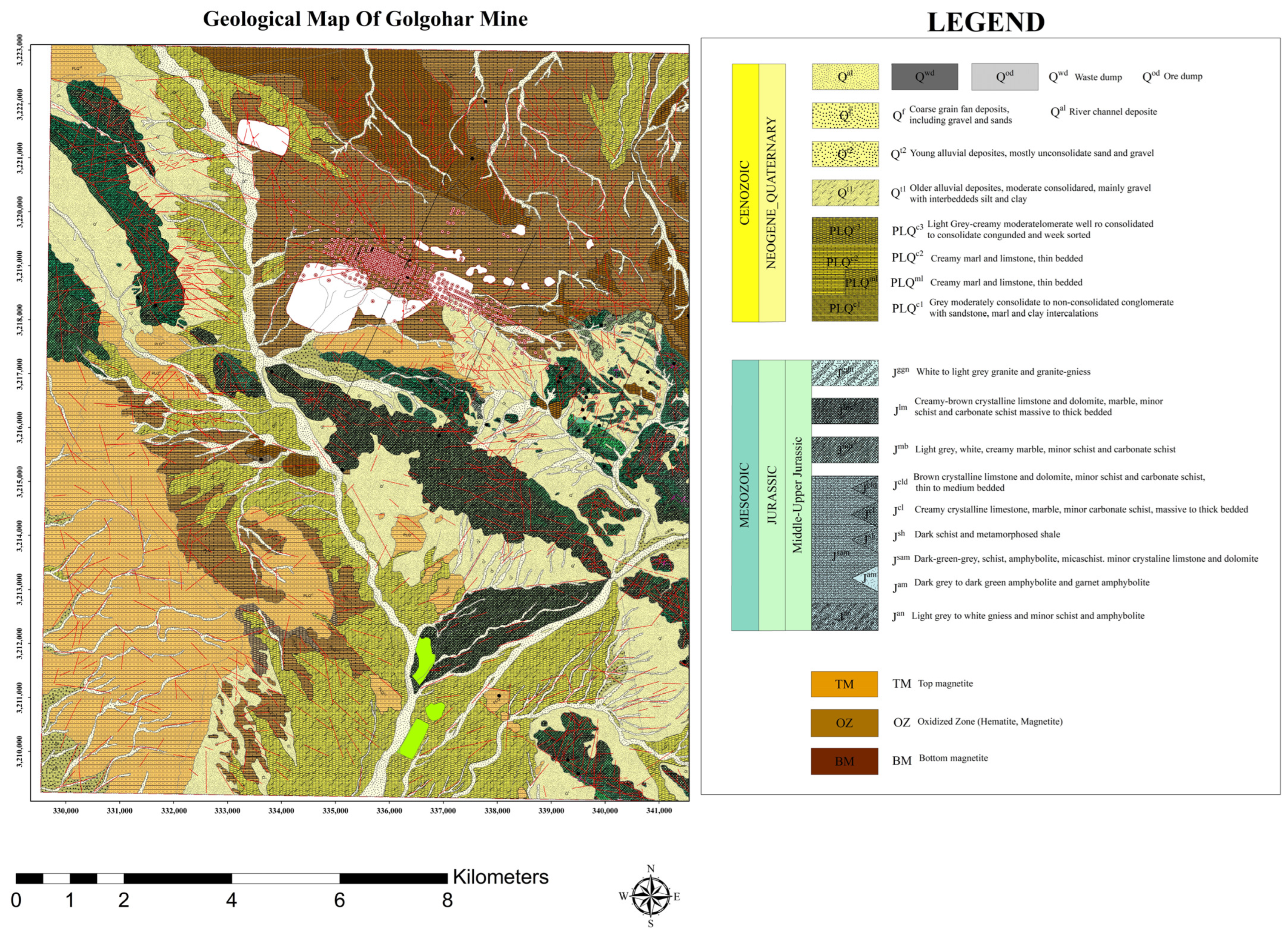

3. Case Study

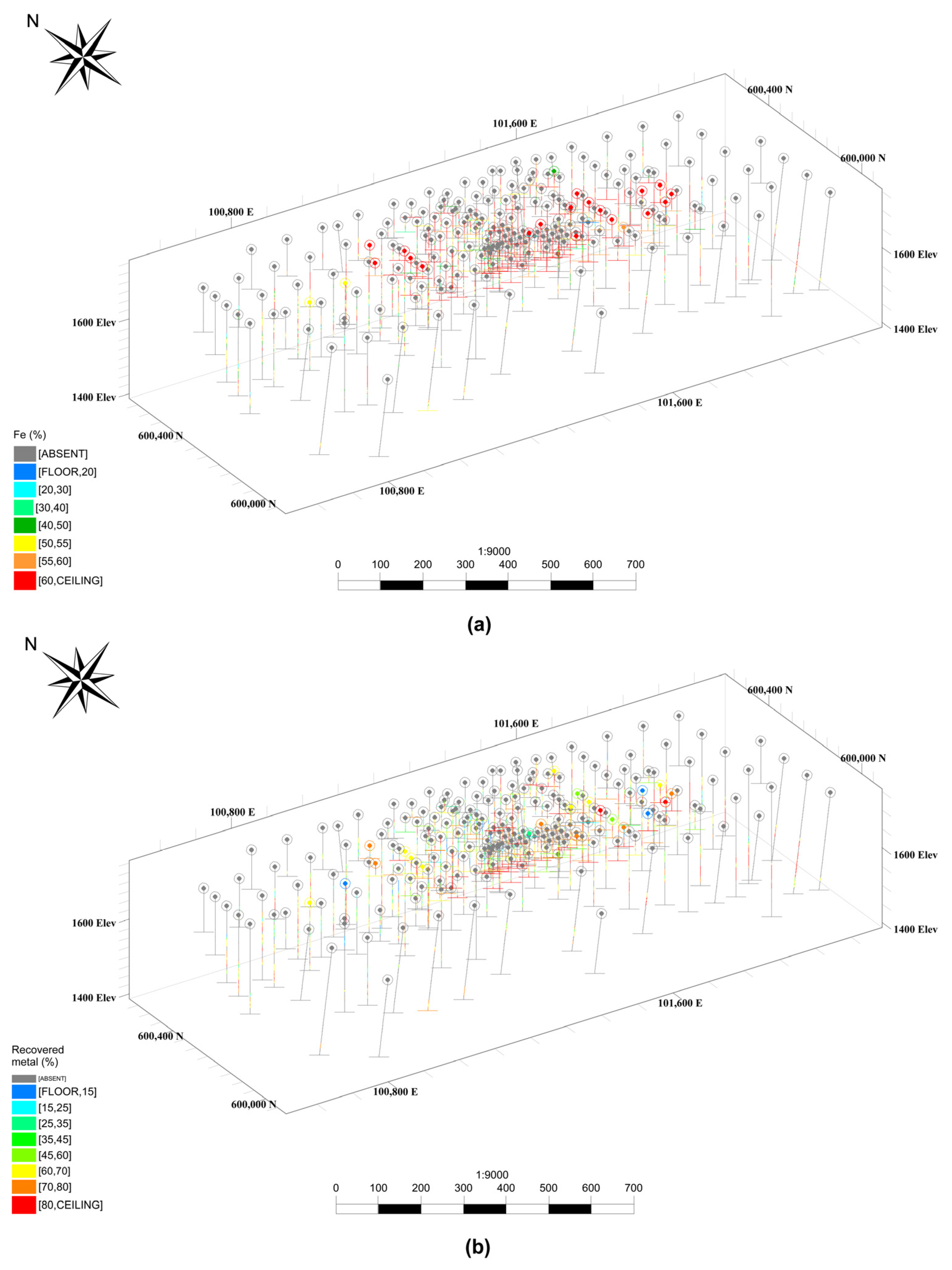

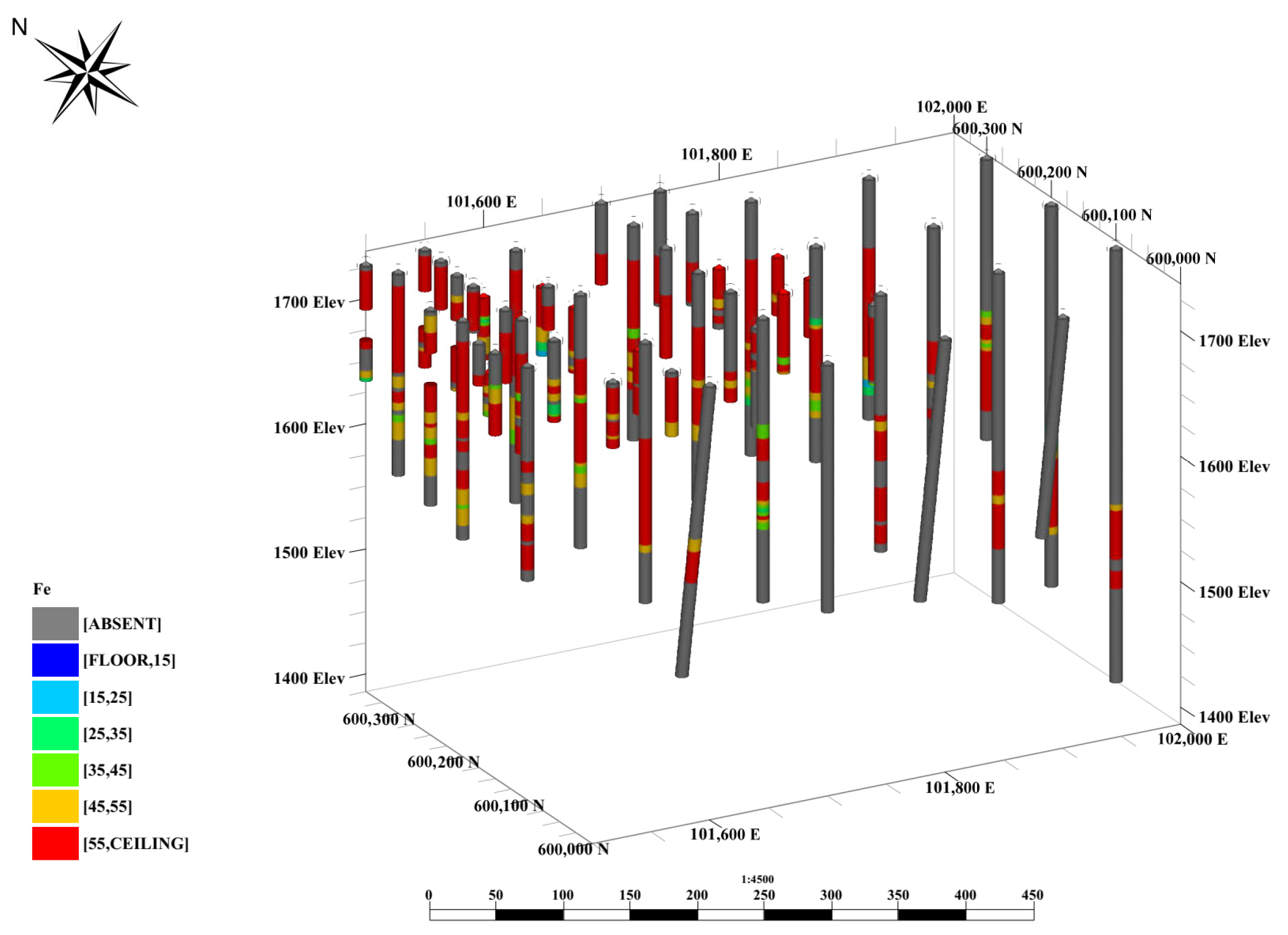

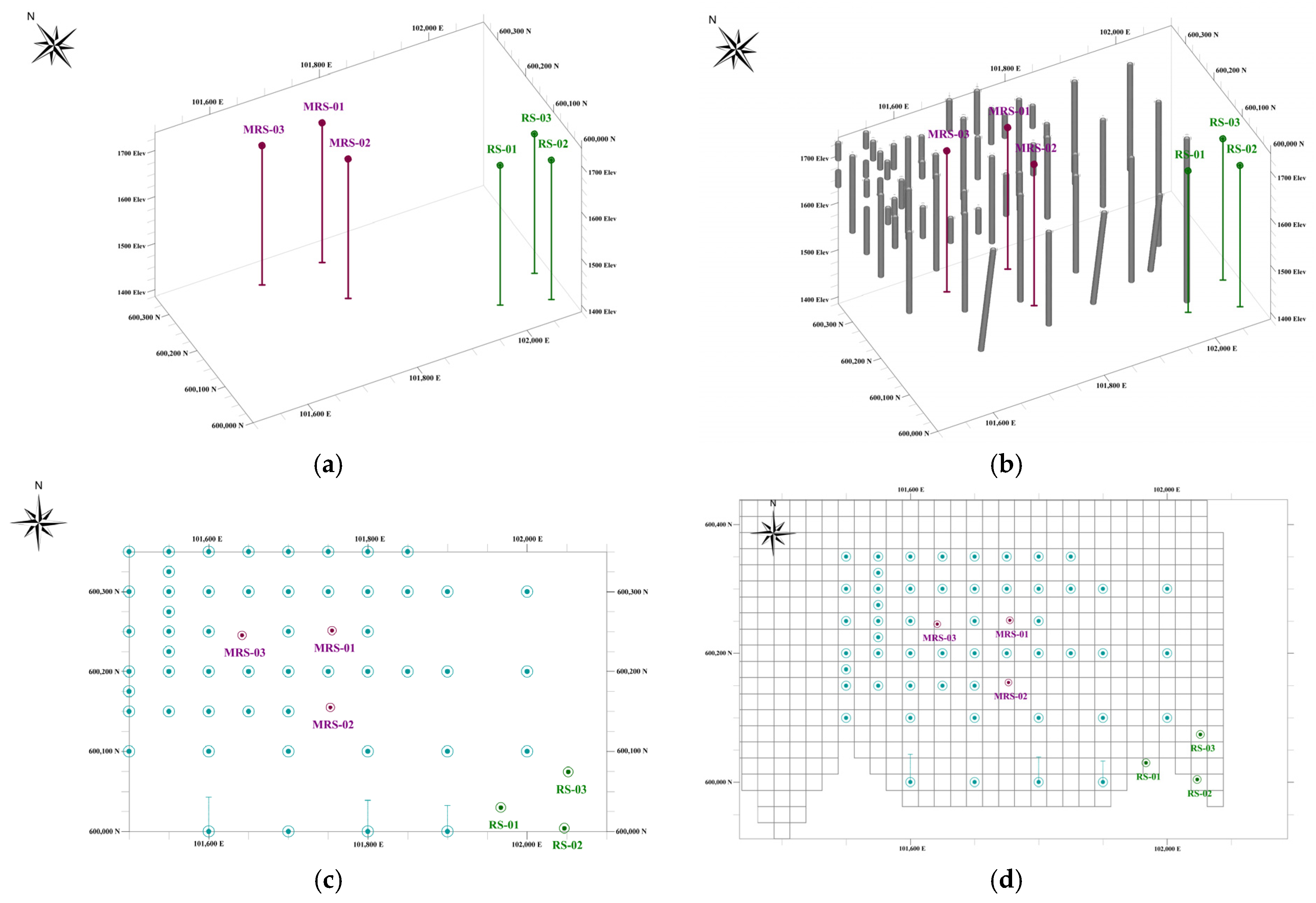

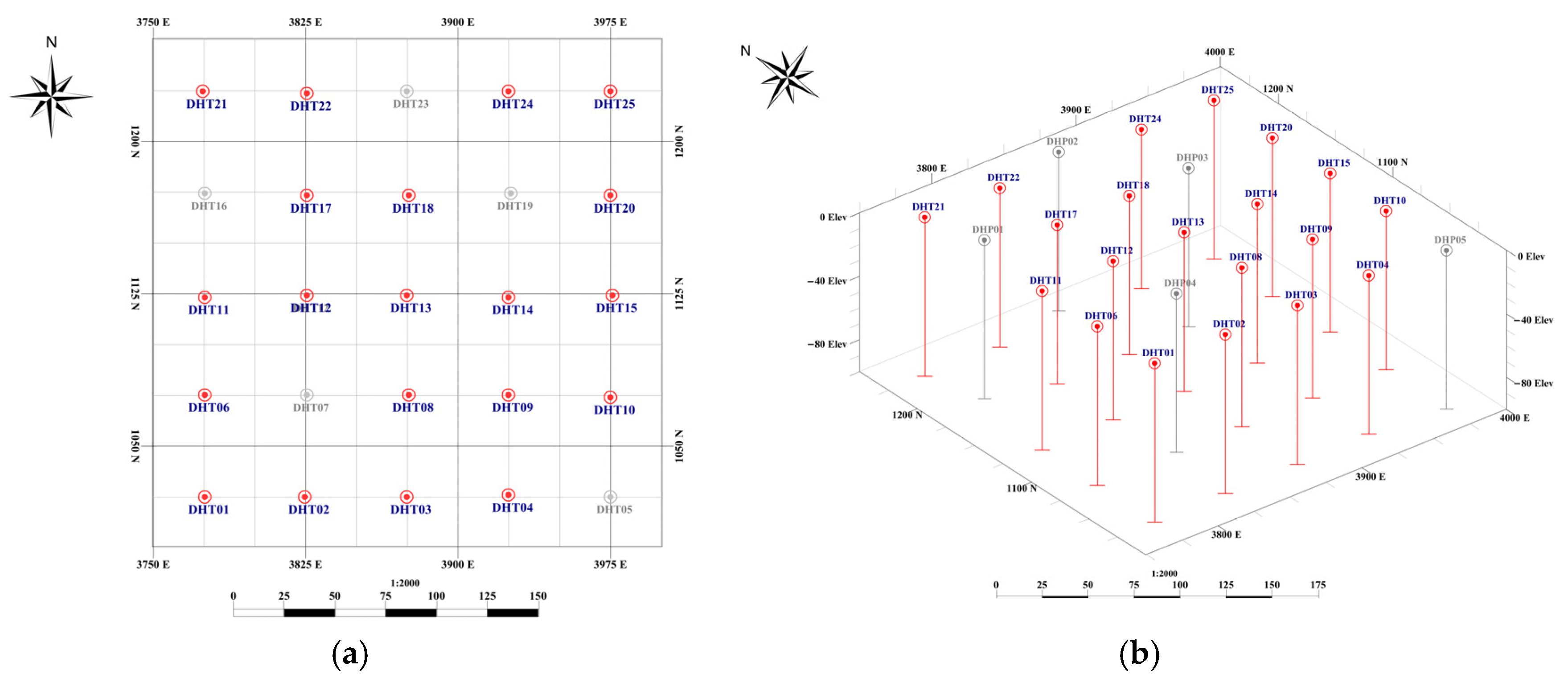

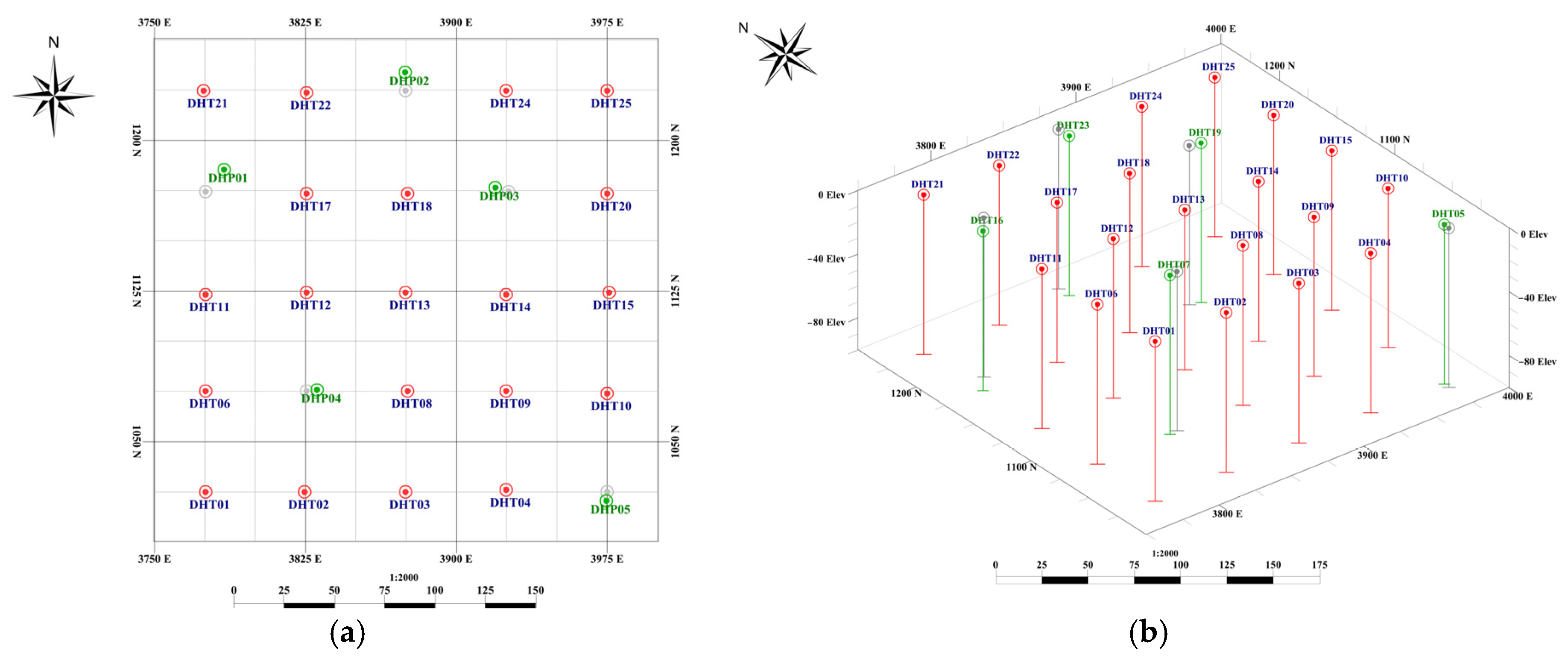

3.1. Deposit and Data

3.2. Application of the Proposed Methodology

4. Results and Discussions

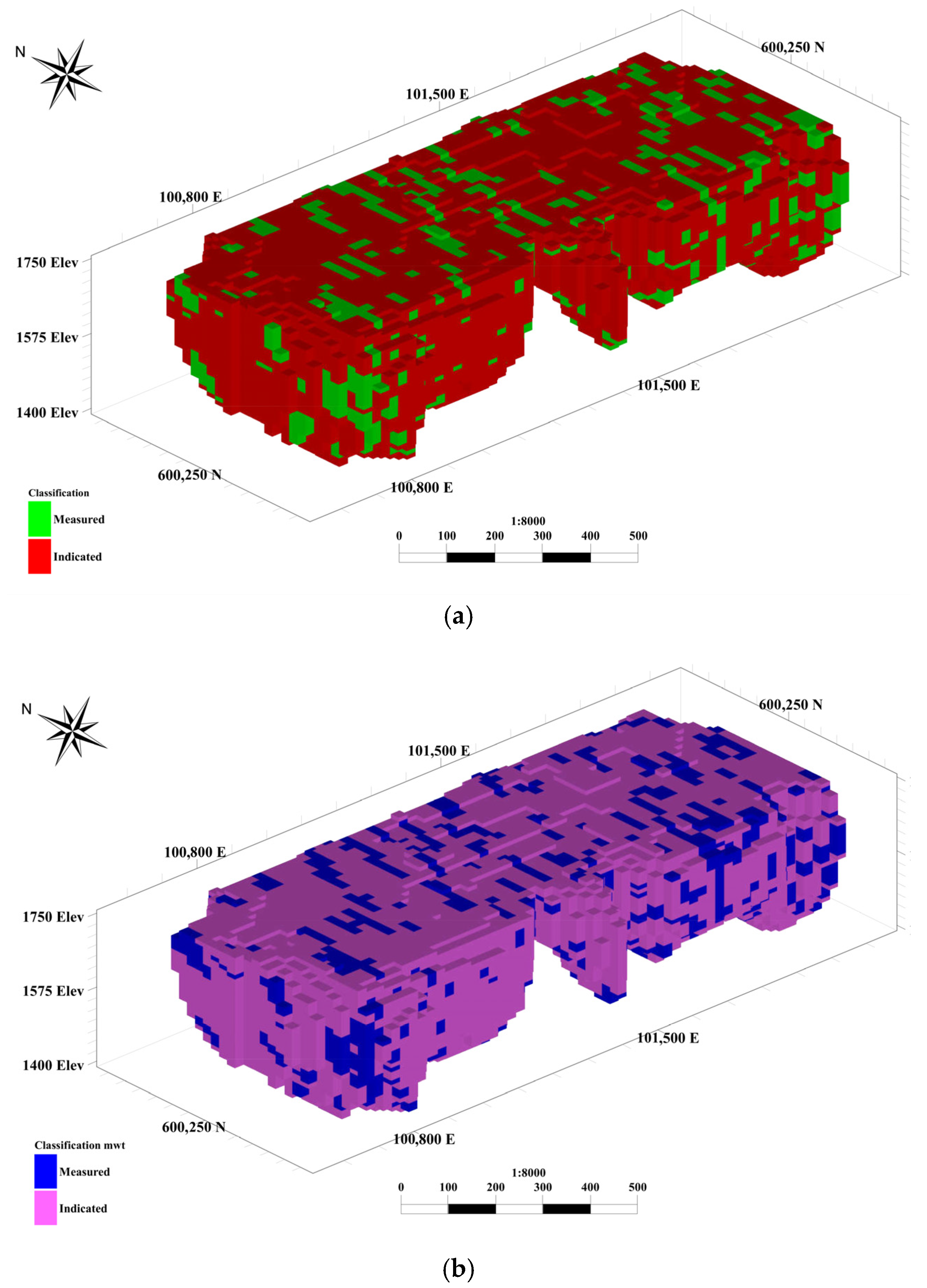

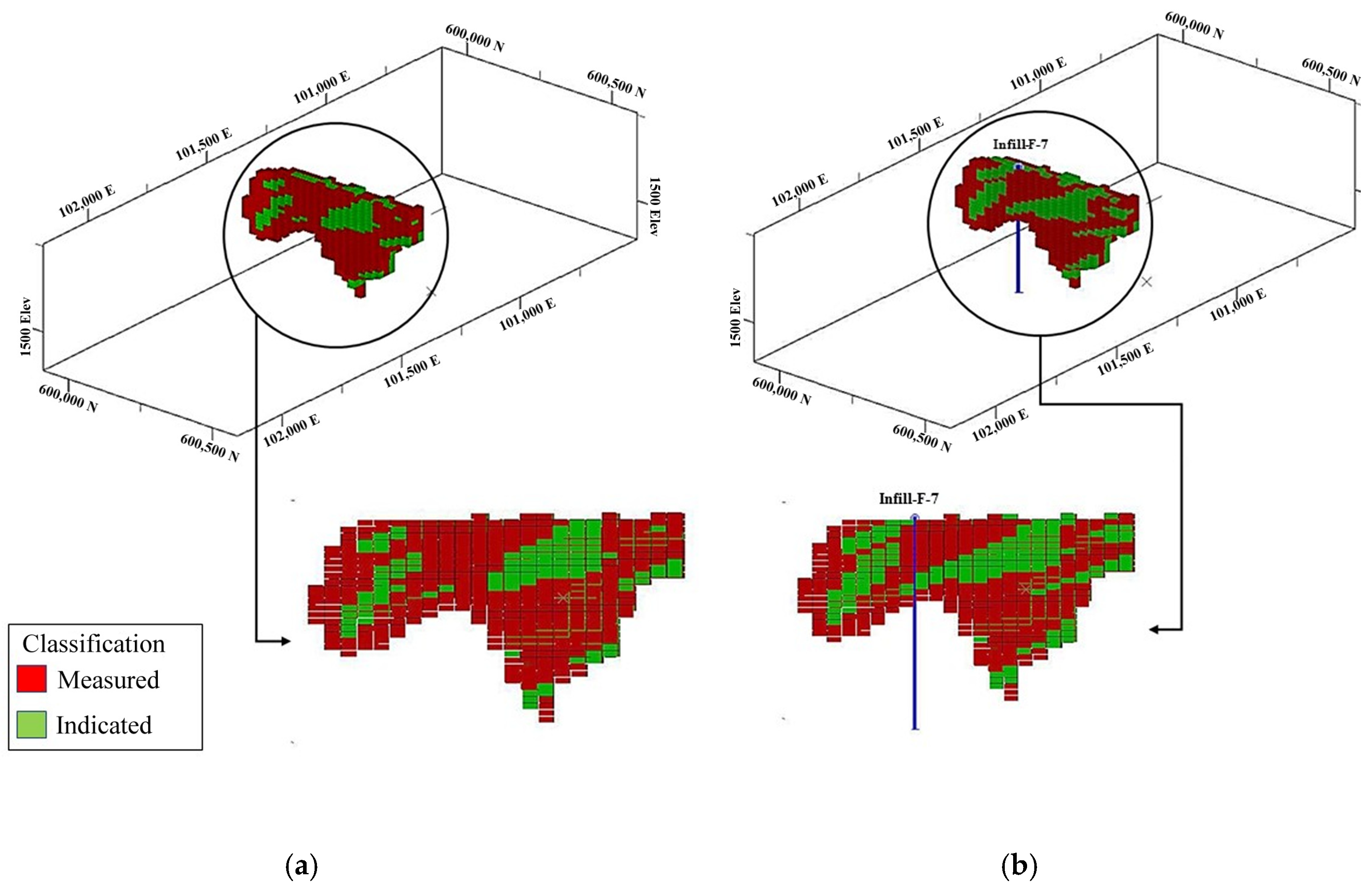

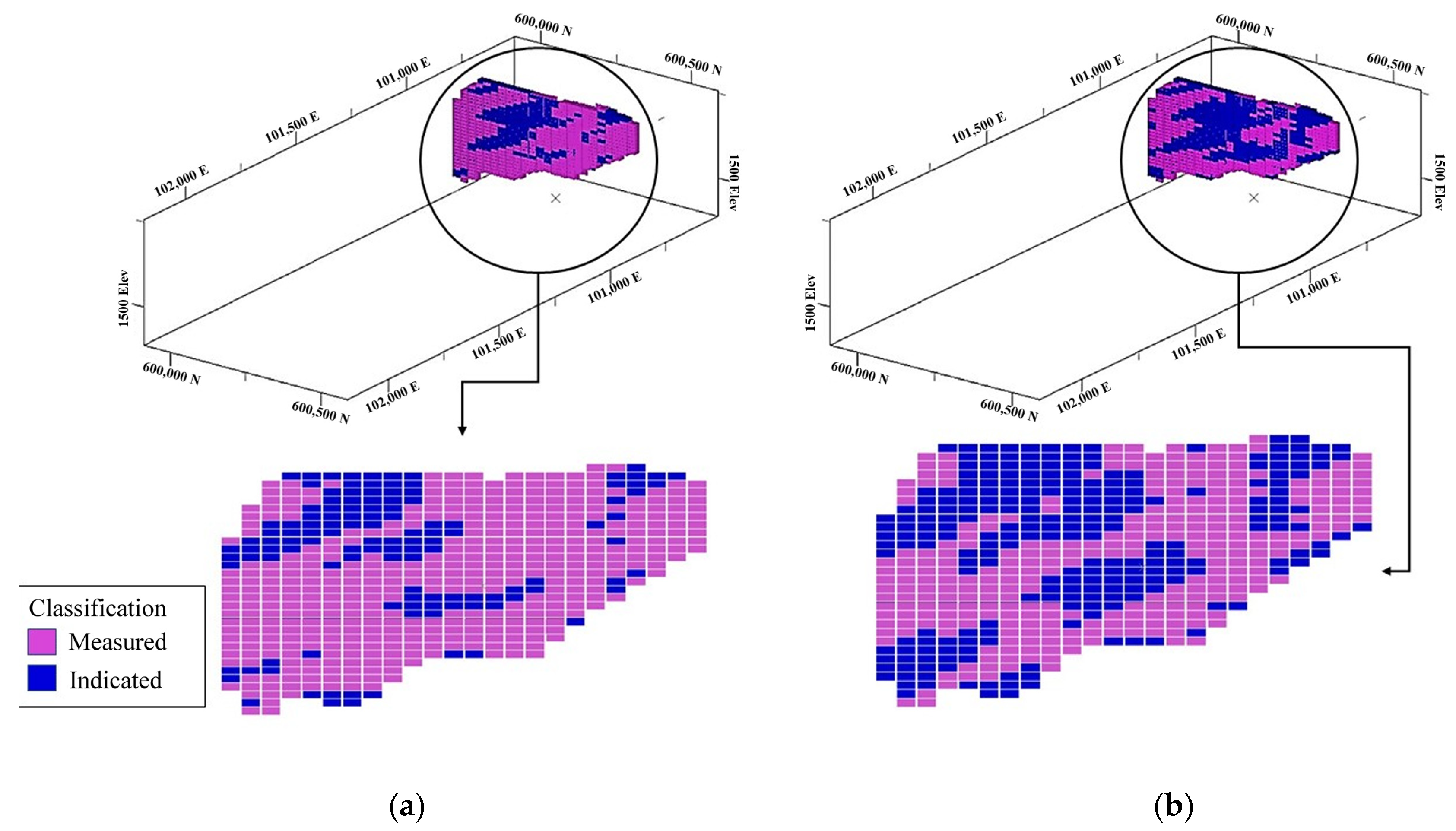

4.1. Simulation and Resource Classification

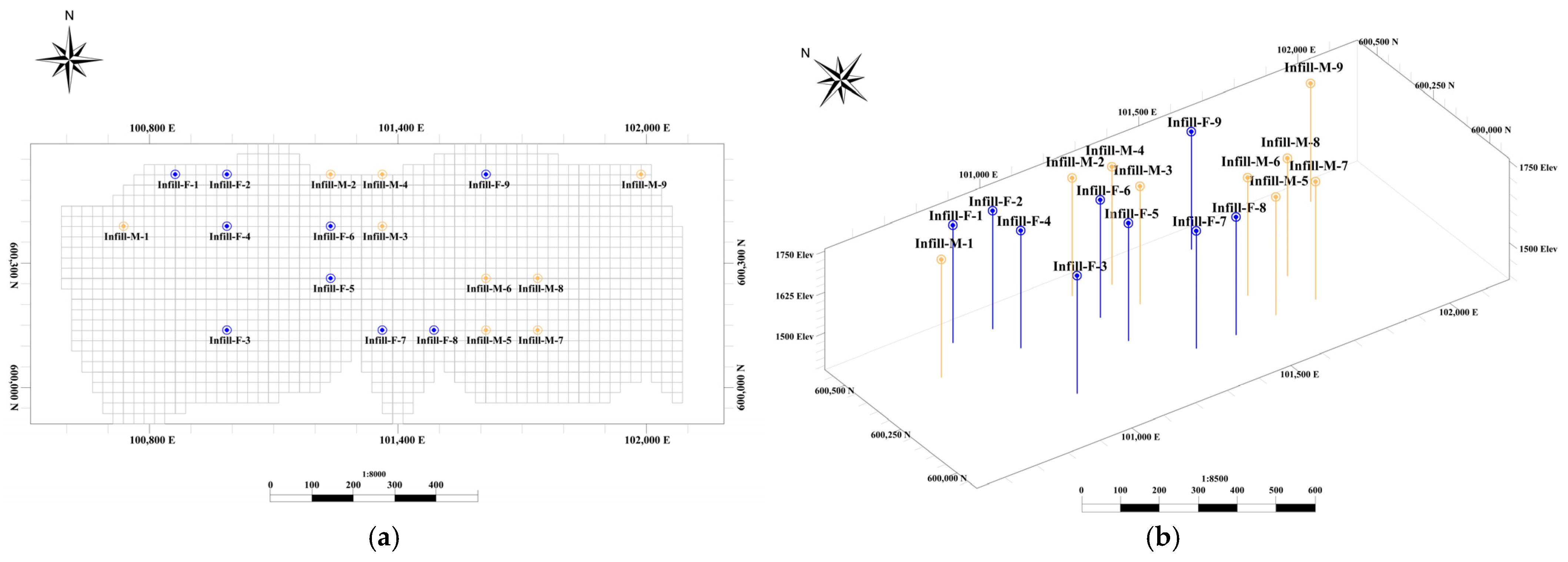

4.2. Infill Sampling Based on Iron Grade Data

4.3. Infill Sampling Based on Recovered Metal Data

4.4. Comparison of Results

4.5. Comparison of Optimization Algorithms

4.6. Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chilès, J.P.; Delfiner, P. Geostatistics: Modeling Spatial Uncertainty, 2nd ed.; Wiley: New York, NY, USA, 2012. [Google Scholar]

- Rossi, M.E.; Deutsch, C.V. Mineral Resource Estimation; Springer: New York, NY, USA, 2014. [Google Scholar]

- Abzalov, M. Applied Mining Geology; Springer: New York, NY, USA, 2016. [Google Scholar]

- Rossi, M.E. Uncertainty and risk models for decision-making processes. In Proceedings of the 28th Symposium on Application of Computers and Operations Research to the Minerals Industry, Perth, WA, Australia, 2–4 December 2019; Dagdelen, K., Ed.; Colorado School of Mines: Golden, CO, USA, 1999; pp. 185–195. [Google Scholar]

- White, M.E.; Harrington, I. Feasibility studies–Scope and accuracy. In Mineral Resource and Ore Reserve Estimation: The AusIMM Guide to Good Practice; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 507–518. [Google Scholar]

- Minnitt, R.C.A. Sampling: The impact on costs and decision making. J. S. Afr.Inst. Min. Metall. 2007, 107, 451–462. [Google Scholar]

- Dailami, K.; Nasriani, H.R.; Sajjadi, S.A.; Rafiee, M.R.; Whitty, J.; Francis, J. Optimizing the ultimate recovery by infill drilling using streamline simulation. Acta Sci.–Technol. 2020, 42, 1–9. [Google Scholar] [CrossRef]

- Soltani-Mohammadi, S.; Safa, M.; Sohrabian, B.J. Reducing uncertainty in mineralization boundary by optimally locating additional drill holes through particle swarm optimization. Nat. Resour. Res. 2021, 30, 2067–2083. [Google Scholar] [CrossRef]

- Fatehi, M.; Asadi, H.H.; Hossein Morshedy, A. 3D Design of optimum complementary boreholes by integrated analysis of various exploratory data using a sequential-MADM approach. Nat. Resour. Res. 2020, 29, 1041–1061. [Google Scholar] [CrossRef]

- Soltani-Mohammadi, S.; Hezarkhani, A. Optimum locating of additional drillholes to optimize the statistical value of information. J. Min. Metall. 2013, 49A, 21–29. [Google Scholar]

- Dirkx, R.; Dimitrakopoulos, R. Optimizing infill drilling decisions using multi-armed bandits: Application in a long-term, multi-element stockpile. Math. Geosci. 2018, 50, 35–52. [Google Scholar] [CrossRef]

- Caers, J.; Scheidt, C.; Yin, Z.; Wang, L.; Mukerji, T.; House, K. Efficacy of information in mineral exploration drilling. Nat. Resour. Res. 2022, 31, 1157–1173. [Google Scholar] [CrossRef]

- Hossein-Morshedy, A.; Khorram, F.; Emery, X. A multi-objective approach for optimizing the layout of additional boreholes in mineral exploration. Minerals 2023, 13, 1252. [Google Scholar] [CrossRef]

- Silva, D.S.F. Mineral Resource Classification and Drill Hole Optimization Using Novel Geostatistical Algorithms with A Comparison to Traditional Techniques. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2015. [Google Scholar]

- Cuba, M.A.; Boisvert, J.B.; Deutsch, C.V. Evaluation of infill drilling in the SLM framework. In CCG Annual Report 14; University of Alberta: Edmonton, AB, Canada, 2012. [Google Scholar]

- Soltani, S.; Safa, M. Optimally locating additional drill holes to increase the accuracy of ore/waste classification. Trans. Inst. Min. Metall. Sect. A: Min. Technol. 2015, 124, 213–221. [Google Scholar] [CrossRef]

- Sabourin, R.L. Application of a geostatistical method to quantitatively define various categories of resources. In Geostatistics for Natural Resources Characterization; Verly, G., David, M., Journel, A.G., Maréchal, A., Eds.; Springer: Dordrecht, The Netherlands, 1984; pp. 201–215. [Google Scholar]

- Dutaut, R.; Marcotte, D. A new semi-greedy approach to enhance drillhole planning. Nat. Resour. Res. 2020, 29, 3599–3612. [Google Scholar] [CrossRef]

- Diehl, P.; David, M. Classification of ore reserves/resources based on geostatistical methods. C. Bull. 1982, 75, 838. [Google Scholar]

- Scheck, D.E.; Chou, D.R. Optimum locations for exploratory drill holes. Int. J. Min. Eng. 1983, 29, 343–355. [Google Scholar] [CrossRef]

- Gershon, M.; Allen, L.E.; Manley, G. Application of a new approach for drillholes location optimization. Int. J. Surf. Min. Reclam. Environ. 1988, 2, 27–31. [Google Scholar] [CrossRef]

- Barnes, R.J. Sample design for geologic site characterization. In Geostatistics; Armstrong, M., Ed.; Springer: Dordrecht, The Netherlands, 1989; pp. 809–822. [Google Scholar]

- Hossein Morshedy, A.; Memarian, H. A novel algorithm for designing the layout of additional boreholes. Ore Geol. Rev. 2015, 67, 34–42. [Google Scholar] [CrossRef]

- Delmelle, E.M.; Goovaerts, P. Second-phase sampling designs for non-stationary spatial variables. Geoderma 2009, 153, 205–216. [Google Scholar] [CrossRef]

- Goria, S.; Armstrong, M.; Galli, A. Quantifying the impact of additional drilling on an open-pit gold project. In Proceedings of the Annual Conference of the International Association for Mathematical Geology, IAMG2001, Cancun, Mexico, 6–12 September 2001. [Google Scholar]

- Dimitrakopoulos, R.; Jewbali, A. Joint stochastic optimisation of short and long term mine production planning: Method and application in a large operating gold mine. Min. Technol. 2013, 122, 110–123. [Google Scholar] [CrossRef]

- Kumral, M.; Ozer, U. Planning additional drilling campaign using two-space genetic algorithm: A game theoretical approach. Comput. Geosci. 2013, 52, 117–125. [Google Scholar] [CrossRef]

- Soltani-Mohammadi, S.; Safa, M.; Mokhtari, H. Comparison of particle swarm optimization and simulated annealing for locating additional boreholes considering combined variance minimization. Comput. Geosci. 2016, 95, 146–155. [Google Scholar] [CrossRef]

- Fatehi, M.; Asadi Haroni, H.; Hossein Morshedy, A. Designing infill directional drilling in mineral exploration by using particle swarm optimization algorithm. Arab. J. Geosci. 2017, 10, 487. [Google Scholar] [CrossRef]

- Jafrasteh, B.; Fathianpour, N. Optimal location of additional exploratory drillholes using a fuzzy-artificial bee colony algorithm. Arab. J. Geosci. 2017, 10, 213. [Google Scholar] [CrossRef]

- Aspie, D.; Barnes, R.J. Infill-sampling design and the cost of classification errors. Math. Geol. 1990, 22, 915–932. [Google Scholar] [CrossRef]

- Pilger, G.G.; Costa, J.F.C.L.; Koppe, J.C. Additional samples: Where they should be located. Nat. Resour. Res. 2001, 10, 197–207. [Google Scholar] [CrossRef]

- Hossein Morshedy, A.; Torabi, S.A.; Memarian, H. A new method for 3D designing of complementary exploration drilling layout based on ore value and objective functions. Arab. J. Geosci. 2015, 8, 8175–8195. [Google Scholar] [CrossRef]

- Boucher, A.; Dimitrakopoulos, R.; Vargas-Guzmán, J. Joint simulations, optimal drillhole spacing and the role of the stockpile. In Geostatistics Banff 2004; Leuangthong, O., Deutsch, C.V., Eds.; Springer: Dordrecht, The Netherlands, 2005; pp. 35–44. [Google Scholar]

- Verly, G.; Parker, H.M. Conditional simulation for mineral resource classification and mining dilution assessment from the early 1990s to now. Math. Geosci. 2021, 53, 279–300. [Google Scholar] [CrossRef]

- Levinson, Z.; Dimitrakopoulos, R. A reinforcement learning approach for selecting infill drilling locations considering long-term production planning in mining complexes with supply uncertainty. Min. Technol. 2024, 133, 176–187. [Google Scholar] [CrossRef]

- Williams, S.R.; Richardson, J.M. Geometallurgical mapping: A new approach that reduces technical risk geometallurgical mapping. In Proceedings of the 34th Annual Canadian Mineral Processors Meeting; Canadian Institute of Mining, Metallurgy and Petroleum: Ottawa, ON, Canada, 2004; pp. 1–13. [Google Scholar]

- Keeney, L. The Development of a Novel Method for Integrating Geometallurgical Mapping and Orebody Modelling. Ph.D. Thesis, The University of Queensland, Brisbane, Australia, 2010. [Google Scholar]

- Ramos, G.Z. Hybrid Objective Function Applied to Optimize Infill Sampling Location. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 2022. [Google Scholar]

- Su, S.; Schulze-Riegert, R.; Mustapha, H.; Lang, P.; Kada Kloucha, C. Artificial intelligence for infill well placement and design optimization in multi-layered/stacked reservoirs under subsurface uncertainty. In Abu Dhabi International Petroleum Exhibition and Conference; Society of Petroleum Engineers: Houston, TX, USA, 2021; p. D021S027R003. [Google Scholar]

- Tang, E.; Zhang, J.; Xia, A.; Jin, Y.; Li, L.; Chen, J.; Sun, X. Infill well placement optimization for polymer flooding in offshore oil reservoirs via an improved Archimedes optimization algorithm with a Halton sequence. Energies 2024, 17, 5552. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithm in Search, Optimization and Machine Learning; Addison-Wesley: Reading, MA, USA, 1989. [Google Scholar]

- Kirkpatrick, S.; Gelatt, C.D., Jr.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Morosov, A.L.; Bratvold, R.B. Drilling-campaign optimization using sequential information and policy analytics. SPE J. 2021, 26, 3609–3625. [Google Scholar] [CrossRef]

- Hall, T.; Scheidt, C.; Wang, L.; Yin, Z.; Mukerji, T.; Caers, J. Sequential value of information for subsurface exploration drilling. Nat. Resour. Res. 2022, 31, 2413–2434. [Google Scholar] [CrossRef]

- Caers, J. Modeling Uncertainty in the Earth Sciences; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Meinert, L.D.; Robinson, G.R., Jr.; Nassar, N.T. Mineral resources: Reserves, peak production and the future. Resources 2016, 5, 14. [Google Scholar] [CrossRef]

- Silva, D.S.F.; Boisvert, J.B. Mineral resource classification: A comparison of new and existing techniques. J. S. Afr. Inst. Min. Metall. 2014, 114, 265–273. [Google Scholar]

- Owusu, S.K.A.; Dagdelen, K. Critical review of mineral resource classification techniques in the gold mining industry. In Mining Goes Digital; Mueller, C., Assibey-Bonsu, W., Baafi, E., Dauber, C., Doran, C., Jaszczuk, M.J., Nagovitsyn, O., Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 201–209. [Google Scholar]

- Stephenson, P.R.; Allman, A.; Carville, D.P.; Stoker, P.T.; Mokos, P.; Tyrrell, J.; Burrows, T. Mineral resource classification—It’s time to shoot the spotted dog! In Proceedings of the Sixth International Mining Geology Conference; The Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2006; pp. 91–96. [Google Scholar]

- Mery, N.; Maleki, M.; País, G.; Molina, A.; Cáceres, A.; Emery, X. Fuzzy classification of mineral resources: Moving towards overlapping categories to account for geological, economic, metallurgical, environmental, and operational criteria. Nat. Resour. Res. 2025, 34, 1271–1299. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; IEEE: New York, NY, USA, 1995; pp. 1942–1948. [Google Scholar]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Schaffer, J.D. Multiple objective optimization with vector evaluated genetic algorithms. In Proceedings of the First International Conference on Genetic Algorithms; Grefenstette, J.J., Ed.; Taylor & Francis: Boca Raton, FL, USA, 1985; pp. 93–100. [Google Scholar]

- Storn, R.; Price, K. Differential evolution–a simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- De Jong, K.A. An Analysis of the Behavior of a Class of Genetic Adaptive Systems. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 1975. [Google Scholar]

- Hutter, F.; Hoos, H.H.; Stützle, T. Automatic algorithm configuration based on local search. In Association for the Advancement of Artificial Intelligence; AAAI: Washington, DC, USA, 2007; pp. 1152–1157. [Google Scholar]

- Spall, J.C. Stochastic optimization. In Handbook of Computational Statistics: Concepts and Methods; Gentle, J., Härdle, W., Mori, Y., Eds.; Springer: Heidelberg, Germany, 2012; pp. 173–201. [Google Scholar]

- Masri, S.F.; Bekey, G.A.; Safford, F.B. A global optimization algorithm using adaptive random search. Appl. Math. Comput. 1980, 7, 353–375. [Google Scholar] [CrossRef]

- Zagré, G.E.; Marcotte, D.; Gamache, M.; Guibault, F. New tabu algorithm for positioning mining drillholes with blocks uncertainty. Nat. Resour. Res. 2019, 28, 609–629. [Google Scholar] [CrossRef]

- Nayak, S. Fundamentals of Optimization Techniques with Algorithms; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Blackwell, G.H.; Anderson, M.; Ronson, K. Simulated grades and open pit mine planning–Resolving opposed positions. In Proceedings of the 28th Symposium on Application of Computers and Operations Research to the Minerals Industry, Perth, WA, Australia, 2–4 December 2019; Dagdelen, K., Ed.; Colorado School of Mines: Golden, CO, USA, 1999; pp. 205–215. [Google Scholar]

| Fe Grade (%) | Recovered Metal (%) | |

|---|---|---|

| Total records | 9340 | 9340 |

| Minimum | 8.7 | 0 |

| Maximum | 68 | 93 |

| Mean | 56.35 | 62.05 |

| Variance | 95.97 | 475.04 |

| Standard deviation | 9.8 | 21.8 |

| Coefficient of variation | 0.174 | 0.351 |

| Skewness | −1.78 | −1.138 |

| Kurtosis | 3.57 | 0.531 |

| 5th Percentile | 35.8 | 13.68 |

| 25th Percentile | 52.7 | 51.7 |

| 50th Percentile | 59.6 | 68.7 |

| 75th Percentile | 63.1 | 78.23 |

| 95th Percentile | 65.8 | 86 |

| Before Infill Drill Holes | After Infill Drill Holes | Improvement | |

|---|---|---|---|

| Number of measured blocks | 13,407 | 19,775 | 11% of 58,946 indicated blocks (6368 blocks) upgraded to measured |

| Number of indicated blocks | 58,946 | 52,578 | |

| Total | 72,353 | 72,353 |

| Before Infill Drill Holes | After Infill Drill Holes | Improvement | |

|---|---|---|---|

| Number of measured blocks | 15,660 | 27,456 | 21% of 56,693 indicated blocks (11,796 blocks) upgraded to measured |

| Number of indicated blocks | 56,693 | 44,897 | |

| Total | 72,353 | 72,353 |

| Number of Measured Blocks | Improvement | ||

|---|---|---|---|

| Without Infill Drill Holes | With Infill Drill Holes | ||

| Fe | 13,407 | 19,775 | 11% |

| Recovered metal | 15,660 | 27,456 | 21% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aghlan, M.H.; Asghari, O.; Emery, X. Optimizing Infill Drill Hole Decisions While Capturing the Spatial Continuity of Geochemical and Geometallurgical Properties: Application to Gol Gohar Iron Ore Mine, Iran. Minerals 2025, 15, 478. https://doi.org/10.3390/min15050478

Aghlan MH, Asghari O, Emery X. Optimizing Infill Drill Hole Decisions While Capturing the Spatial Continuity of Geochemical and Geometallurgical Properties: Application to Gol Gohar Iron Ore Mine, Iran. Minerals. 2025; 15(5):478. https://doi.org/10.3390/min15050478

Chicago/Turabian StyleAghlan, Mohammad Hossein, Omid Asghari, and Xavier Emery. 2025. "Optimizing Infill Drill Hole Decisions While Capturing the Spatial Continuity of Geochemical and Geometallurgical Properties: Application to Gol Gohar Iron Ore Mine, Iran" Minerals 15, no. 5: 478. https://doi.org/10.3390/min15050478

APA StyleAghlan, M. H., Asghari, O., & Emery, X. (2025). Optimizing Infill Drill Hole Decisions While Capturing the Spatial Continuity of Geochemical and Geometallurgical Properties: Application to Gol Gohar Iron Ore Mine, Iran. Minerals, 15(5), 478. https://doi.org/10.3390/min15050478