Abstract

Romania has some huge ferrous slag stockpiles that are secondary resources of minerals. Although a sizable portion of ferrous slags is recycled for use in building roads and other infrastructure, a sizable portion is still dumped. By November 2026, Member States must submit information on the quantity of critical raw materials (CRMs) in their secondary resources, as well as the quantification techniques employed, in accordance with Regulation (EU) 2024/1252. Therefore, the XRFS reliable measurements carried on ferrous slags were addressed to prevent dissipative loss of CRMs in cases where an improper slag recycling route is operated. The main novelty of this paper is the method of ensuring the reliability of the XRFS results based on weighted arithmetic mean and on the maximum likelihood approach. Secondly, the XRFS measurements carried on ferrous slags demonstrate that they contain CRMs like Ba, Sr, Y, etc.; however, below the minimum cut-off grade for CRMs, recovery XRFS cannot detect light CRMs. Our preliminary LIBS measurements on ferrous slags disclosed the presence of Li and Be. The drawbacks of the XRFS technique impose further research to develop an integrated XRFS, LIBS, and XRD procedure for comprehensive and trustworthy CRMs screening in extractive waste piles.

1. Introduction

Steel is, and will remain for a long time, the main metal vector that drives the top branches of the modern economy (automotive industry, metallic construction, food industry, aircraft and defense industries, etc.) [1,2]. Also, cast iron plays an important role in different industrial sectors like machine construction and sewerage construction, but mainly as the precursor of steel alloys [2,3,4]. Unfortunately, the production of a ton of steel in an integrated steel plant implies the generation of approximately 2 tons of waste [5,6,7]. Among the unavoidable wastes and by-products generated in an integrated steel plant are iron and steel slags that play technologically beneficial roles during iron oxide reduction in blast furnaces or during smelting and refining the composition of a steel grade [3,7]. During the last century and in the first decades of the third millennium, huge amounts of ferrous slag have accumulated in Romania as landfilled piles in Galati, Hunedoara, Călan, Târgoviște, etc. Although the production of iron and steel in Romania has diminished in the last decade, ferrous slag still accumulates in dumps [8]. These dumps have created environmental detriments through flying dust pollution, surface and underground water pollution through rainwater leaching, and visual discomfort [9]. In addition, some industrial waste deposits enter under the incidence of Cause 301/17 of the European Court of Justice. Cause 301/17 states that Romania has not fulfilled its obligations under Article 14 letter (b) of Directive 1999/31 concerning the obligation to take all necessary measures to close, as quickly as possible, 68 landfills, which, in accordance with Article 8 of the said directive, have not received authorization to allow them to continue to function [10]. The metallurgical waste dump Călan is included in the list of deposits of non-hazardous industrial waste subject to Cause 301/17 as being operated by S.C. FOREVER—S.R.L., Călan [11]. This deposit ceased waste storage before July 2009 [11]. The Călan dump stores mainly blast furnace slag (BFS) and associated waste resulting from pig iron production and from foundry shops that were integrated in the Călan steel plant [11,12]. The steel slag deposit in Târgovişte has a similar status, which has accumulated significant amounts of steel slag and associated wastes.

Ferrous slags have been subjected to debate regarding their status, i.e., waste or not waste [13,14]. Thus, ferrous slags were classified as waste according to the following European Waste Catalog entries [11]: 10 02 01 waste from the processing of slag; 10 02 02 unprocessed slags. The European Waste Catalog was adopted in Romania, and the above entries are mentioned in a recent governmental document, i.e., in OUG 92/2021, approved by Law 17/2023, art. 8 para. (3) Appendix no. 1 [12]. The revised position paper of EUROFER in 2023 clearly states that “slag is a by-product of the steelmaking process” [14]. The ferrous slag status of by-product is particularly important, as a waste that ceases to be waste also ceases to be waste for the purpose of the recovery and recycling targets set out in Directives 94/62/EC and other relevant CE legislation [15,16].

Recently, Regulation (EU) 2024/1252, further on referred to as Regulation, has turned the paradigm of the historical and ongoing slag dumps from the source of environmental detriment into a potential secondary resource that can mitigate the access risk of the EU to raw materials that are essential for its economy and for critical raw materials (Article 8) [17]. Moreover, Regulation stipulates the following: “By 24 November 2027, Member States shall adopt and implement measures to promote the recovery of critical raw materials from extractive waste, in particular from closed extractive waste facilities.” Also, Regulation (Art. 27) laid down the obligation of the operators of the extractive waste facilities from each EU Member State “to provide to the competent authority a preliminary economic assessment study regarding the potential recovery of critical raw materials, from waste stored in their facilities by 24 November 2026. The study shall at least include an estimation of the quantities and concentrations of critical raw materials contained in the extractive waste and in the extracted volume and an assessment of their technical and economic recoverability. Operators shall specify the methods used to estimate those quantities and concentrations.” Ferrous slags enter into the incidence of Regulation as they are the results of the processing of the iron ores that are among the main targets of the extractive industry [18,19,20]. Consequently, the upcycling route of the ferrous slag as a cement precursor loses its prevalence. Thus, before the issuing of this regulation, the use of the ferrous slags as precursors in the cement industry was considered an upcycling approach, while, in the new context, the new upcycling route for ferrous slags has turned into a precursor of the critical raw materials [21,22,23,24]. To fulfill this new trend, it is mandatory to screen for CRMs in the targeted waste deposit to identify which of the CRMs has significant abundance [25]. The presence of CRMs in ferrous slags has been addressed in the literature [25,26]. It was reported that the concentrations of REEs in blast furnace slags are several times higher than in those other metallurgical slags [25,26,27].

In the frame of the new paradigm of slag upcycling, this paper addresses a preliminary screening for CRMs in the iron slag from the Călan dump and in the steel slag from the Târgoviște dump. The screening for CRMs in a stockpile implies a complex serial process consisting of the following: a preliminary investigation of the site, the construction of the site conceptual model based on available information, site inspection, planning the sampling campaign, sample collection, on-site sample preparation, sample transport to laboratories, laboratory measurements, data analysis, and, finally, the construction of the source model regarding targeted analytes [28,29,30]. Such a complex process needs considerable financial and human efforts. In our case, there is no available information on the CRM contents in the Călan and Târgoviște dumps, nor on the main composition of the substances deposited in these piles. All of the knowledge we have about the Călan dump is that it was used for the deposition of the blast furnace slag (BFS) coming out of the Călan iron plant during 1886–2007 [2]. Most probably, wastes associated with pig iron production and casting, like blast furnace dust, used sand, waste linings, etc., were co-deposited into the Călan dump. Also, limited data are available on the Electric Arc Furnace (EAF) slag deposited nearby Târgoviște, Colanu village [31]. Being aware of the lack of information about CRM abundance in these dumps, a preliminary study was conducted to ground a more pertinent study in case the results of this study are positive. Also, this study aims to establish the performance characteristics of the XRFS technique, which is the cheapest and most accessible technique for measuring the composition of solid wastes [32,33]. XRFS reported compositions of the blast furnace slags that encompassed both oxides and elemental mass concentrations [21,30,32]. The characteristics of the analytical performances of the XRFS technique can be assessed through the limit of quantifications, the accuracy, and the relative expanded uncertainty for each constituent [33,34].

With the aforementioned factors in mind, we addressed two synergic objectives in this study, i.e., establishing the analytical performances of our XRFS laboratory procedure dedicated to ferrous slag investigation and screening for CRMs in dumped ferrous slags. Both objectives are critical for complying with the requirements of the Regulation, because the lack of accuracy of the measurement will compromise the screening for CRMs, while non-screening for CRMs contravenes to the requirements of the Regulation. This study was conducted on a certified reference material made from steel slag, aiming to assess the characteristics of the analytical performance of the XRFS procedure. Subsequently, XRFS measurements were conducted on four ferrous slags aliquots (two of EAF slag and two of air-cooled BFS, also known as ACBFS). The main novelty of this paper is the method of ensuring the reliability of the XRFS results. Another important novelty of this paper is the way in which the performance characteristics of the XRFS procedure were established based on weighted arithmetic mean and on the maximum likelihood approach. The XRFS measurements carried on ferrous slags demonstrate that they contain CRMs like Ba, Bi, Sr, Ti, W, Y, etc., but below the minimum cut-off grade for CRM recovery [35]. Thus, the usage of these slags in cement industry, road construction, etc., will not provoke a significant dissipative loss of CRMs, at least at the actual level of CRM recovery technologies. Our preliminary LIBS measurements on these slags disclosed the presence of light CRMs like Li and Be, which cannot be detected by XRFS. Further research is envisaged to develop an integrated XRFS, LIBS, and XRD procedure for comprehensive and reliable CRM screening in ferrous slag dumps.

2. Materials and Methods

The first XRFS measurements were carried out on the certified reference material, Certificate No. 050616-101-Slag, provided by Brammer Standard Company, Inc. The material is a fine powder that was dried for one hour at 105 °C and mixed well before use. The steel slag samples were obtained from the Târgovişte (Colanu) slag dump. The aliquots were prepared from slag fraction 8–63 mm (Figure 1a).

Figure 1.

Images of dumped steel and BFS slags: (a) steel slag pile; (b) ACBFS pile.

The collected gross sample of EAF slag weighed approximately 4 kg. The gross sample was crushed, grinded, and milled until achieving a powdered state. The fraction that had been sieved using a 1 mm mesh was coned, then quartered, and a subsample weighing about 0.2 kg underwent advanced milling using a ball mill (Retsch PM100) (Retsch GmbH, Haan, Germany). The milling process lasted until the residue on the sieve (65 μm mesh) was less than 10%. The powder that passed through a 65 μm mesh sieve underwent subsampling through coning and quartering, and circa 50 g of the powder was selected for XRFS measurements. The XRFS measurements were carried out with an Xepos ED(P)-XRF spectrometer (SPECTRO Analytical GmbH, Kleve, Germany), which uses three secondary scattering targets to diminish the background intensity of the X-ray fluorescence spectra, which helps to increase the sensitivity of the instrument in detecting the light elements from Na to Ti. The aliquots for the XRFS measurements were prepared as a pressed pellet. The pellet contained 6.25 g of powdered slag and 1.75 g of lithium tetraborate. The XRF spectra were processed with the Turboquant Pellets analytical program, which can deliver elemental composition or a combination of oxide and elemental composition, also known as bond composition. The same aliquot preparation and XRFS measurement processes were applied to the ACBFS samples (Figure 1b).

The accuracy of the XRFS measurement procedure for an analyte was estimated as the absolute relative difference between the certified value of the reference sample and the weighted mean obtained through repeated measurements on the aliquots prepared from the reference material. The weighted arithmetic mean was calculated as follows [35]:

where is the weighted arithmetic mean of a suite of measurements; is the measured concentration in the ith round; and is the weight of the Ci variable.

A frequent practice in mathematical statistics is to consider the measurand as a random variable, written in capitals, while its value is written in small letters. The term in Equation (1) can be considered as the occurrence probability of the ci value, also known as the weight of the Ci variable.

The variance of the weighted mean, V(, is calculated as follows:

where is the variance of the measurand and is considered an independent random variable for every i = 1…n.

The maximum likelihood approach [36] imposes the minimization of the value, which, in turn, implies the following derivatives:

The solution of the system made of n equations of the form Equation (3), with the unknowns wi, i = 1…n, is as follows:

In the frame of the maximum likelihood approach (https://en.wikipedia.org/wiki/Maximum_likelihood_estimator accessed on 25 February 2025), the weight of Ci is as follows:

Substituting given by Equation (5) in Equation (2), one obtains the following:

The performance characteristics of the XRFS procedure considered in this paper are relative accuracy and uncertainty ratio, defined as follows:

- ➢

- Relative accuracy (RA) is the ratio between accuracy and the certified value, as follows:

- ➢

- Uncertainty ratio (RU) is the ratio between measurement uncertainty and certified uncertainty, where they are of the same type, i.e., compound uncertainty or expanded uncertainty. The RU is expressed as a rational number.

The characteristics are qualitatively assessed according to Table 1.

Table 1.

The criteria matrix for qualifying the XRFS measurement characteristics of performances.

Once we have evidence that our XRFS procedure provides reliable outcomes, we proceed with slag characterization as a potential source of positive minerals and possibly as CRMs secondary resources. Also, the chemical character of a slag was estimated according to conventional practice using the basicity index, denoted BI, which is the ratio between the content of basic oxides and acidic oxides [20], as follows:

where the concentrations of the oxides are given in %wt.

The strongest basic oxides ranked in descending order are as follows: Na2O, K2O, CaO, MgO, BaO, FeO, MnO, Cu2O, NiO, ZnO, Fe2O3, Cr2O3, and PbO [20]. Al2O3 is considered as amphoteric oxide [20]. The strongest acid oxides are SiO2, V2O5, Cr2O3, MoO3, WO3, and Mn2O7.

The basic ferrous slags are many times sub-divided based on the CaO ÷ SiO2 concentration ratio, as follows [20]: (a) weak basic slag for CaO ÷ SiO2 < 1.5; (b) average basic slags for CaO ÷ SiO2 = 1.6 ÷ 2.5; and (c) strongly basic slag for CaO ÷ SiO2 > 2.5.

The presence of very important light CRMs like Li, Be, and B cannot be investigated using the XRFS technique. To overcome this drawback, preliminary LIBS measurements were carried out on some ACBFS lumps at SciAps Laboratory (Krefeld, Germany) using the SciAps Z903 LIBS Analyzer instrument. The instrument uses an NdYAG laser with a wavelength of 1064 nm. The laser pulses are emitted with a frequency of 50 Hz and have an energy output of approx. 6 mJ. All measurements on the samples were taken using the instrument’s built-in argon flush system, which greatly increases the intensities of the spectra. A gating period of approximately 650 ns between plasma ignition and the acquisition of spectral data was used to improve the signal-to-noise ratio. Each location chosen for analysis was measured with 16 singular spots in a 4 × 4 grid, amounting to a size of approx. 2.25 mm2. The spectra from all 16 individual spots were averaged into a singular spectrum, which is consequently used for semi-quantitative and qualitative analyses using SciAps Profilebuilder software.

3. Results and Discussion

The results of four repeated measurements carried out on aliquots prepared from powdered BS 101-3 reference material are shown in Table 2.

Table 2.

Measurement results obtained in 4 repeated trials carried out on the MRC BS 101-3 aliquots.

In Table 2 are shown only the components that can be compared with the certified composition values given in Certificate No. 050616-101-SLAGS (Table 3). The synthetic analysis of the XRFS measurement performances is shown in Table 3, including the weighted arithmetic means of the four repeated measurements (), the expanded measurement uncertainty with 95% degree of confidence, denoted U (95%), calculated for the coverage factor k = 2, RA, RU, and QMPC parameters.

Table 3.

Performance characteristics of the measured constituents.

As can be seen in Table 3, the measurement uncertainties calculated in the frame of the maximum likelihood are less than the certified uncertainties, i.e., RU < 1. Also, the RA exceeds 5% in only two cases whose characteristics of performance were considered to be of superior quality. In all other cases, the performance characteristics of the measurements are very good and excellent.

The BI of the certified steel slag calculated with certified values is 3.98, while the BI calculated with the measured values is 3.81. The BI values are close to each other and differ by circa 4.4%. The ratio of /, calculated based on the certified values, is 2.86, while that calculated based on measured values is 2.90, i.e., the ratios differ by circa 1.4%. Both ratios let one qualify the slag as a strongly basic slag. The values of the BI and of the ratio / obtained on certified slag also show that the XRFS procedure we use is robust and reliable. Thus, we are confident that the measurement values we obtained on four slag aliquots are reliable and could serve as a preliminary survey for CRMs in the above-mentioned slag piles. The XRFS measurement results obtained on aliquots prepared from ACBFS and EAF slags are shown in Table 4.

Table 4.

The compositions of the ACBFS and EAF slags measured by XRFS and their assigned SDs.

The data presented in Table 4 are as they were delivered by the Turboquant software, therefore, the common law of the same number of digits cannot be respected in Table 4. This is also due to the large differences between the values of the measured concentrations. However, the concentrations of major constituents (values measured in %wt.) are comparable with the literature data and can be considered as reliable [25,32].

The BI of the investigated slags and their CaO÷SiO2 ratios are given in Table 5.

Table 5.

The BI and CaO/SiO2 values for the investigated slags.

The BI index values of 1.2 and 1.5 show that the ACBFS slag in the Călan dump is of common type, i.e., the Călan plant produced common cast iron. The BI index values of the EAF slags of 2.4 and 2.7 and their CaO÷SiO2 ratios are common for EAF slags. The BI index and CaO÷SiO2 ratio values of the EAF slags indicate the possibility to use them as amendments for acid soils.

The screening for CRMs implies data analysis at the ppm level; therefore, a selection of the CRMs measured by XRFS and their concentrations in ppm (wt.) is given in Table 6. The maximum value of a CRM’s concentration (Cmax) is shown in the 10th column of the table, while in the 11th is its abundance in Earth’s crust [35]. The 12th column contains the one-digit rounded ratio between the measured concentration and its known concentration in Earth’s crust (CEC). The reader should be aware that the concentration of a CRM in Table 6 refers to its oxide, while the reference value of CEC is for the element. Thus, the ratio in 12th column is informative. For a comparison element to element, the composition in Table 6 must be recalculated. This is not an impossible task, but for the present case, it is beyond the scope of this study.

Table 6.

Excerpt from Table 4 regarding the concentrations (in ppm wt.) of the CRMs found in slag samples and their assigned SDs (in ppm wt.).

The CRM concentrations in Table 6 are close to their concentration in Earth’s crust.

Even though the concentrations of Ta, W, and Bi in the Colanu EAF dump are bigger than those of their CECs, their values do not afford their recovery at reasonable costs. The concentrations of some CRMs found in the ACBFS Călan dump (Table 6), such as V, As, Ba, and Hf, are greater than those of their CECs, but their values are lower compared to the actual cutting edge for their recovery [37].

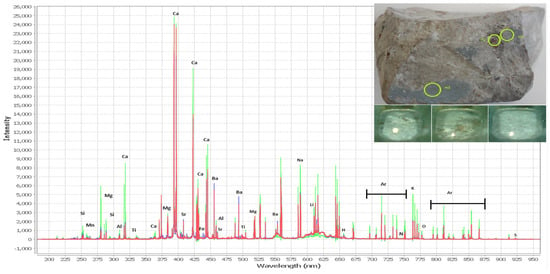

Three superimposed LIBS spectra are shown in Figure 2, where the images of the sample and of three laser spots are shown as insets.

Figure 2.

LIBS spectra obtained on an ACBFS lump and inset images of the spotted areas.

Figure 2 clearly shows the presence of the characteristic lines of light elements, such as H, Li, O, Mg, etc. A semi-quantitative estimation of the elemental composition of the sample based on the spectra shown in Figure 2 is given in Table 7.

Table 7.

Semi-quantitative estimation of the elemental composition of the ACBFS lump.

The data in Table 7 attest the potential of the LIBS technique to measure elemental concentration in a broad range, i.e., from ppm to % wt., but LIBS needs proper calibration on ferrous slags to provide reliable quantitative results. In this direction, we consider that LIBS in combination with XRFS and XRD measurements on the same aliquots can provide a more thorough analysis of the CRMs into ferrous slags. Accordingly, further research is required to obtain an integrated XRFS, LIBS, and XRD procedure for trustworthy CRM screening, as Regulation requires.

4. Conclusions

The aim of this study was to develop a reliable measurement approach for the major, minor, and trace elements in old ACBFS and EAF stockpiles using the ED-XRFS technique and proper statistical data analysis. The performance characteristics of the XRFS procedure we used to measure the chemical composition of the ferrous slags (ACBFS, EAF) are fitted to the preliminary screening purpose for investigating the recycling possibilities of these slags.

Special attention was drawn to the CRM analysis so as to come in line with Regulation (EU) 2024/1252, which recommends to the Member States, among others, “to promote the recovery of critical raw materials from extractive waste, in particular from closed extractive waste facilities.” A challenge of CRM recovery from closed extractive waste facilities is the lack of information on the CRM harvesting potential. Avoiding dissipative loss of CRMs contained in landfilled ferrous slags, which can be significant [26,38], is another challenge. Accordingly, it is mandatory to assess CRM contents in slag dumps before any conventional slag recycling route. Therefore, a cheaper, rapid, and reliable measurement procedure, as we show in the paper, plays an important role in implementing the requirements of Regulation (EU) 2024/1252.

Our measurements show that ferrous slags in the Călan and Colanu dumps contain CRMs, but these slag stockpiles cannot be considered as secondary sources of any CRM from the evidence of the Cmax/CEC ratios (Table 6) and the actual cutting edges for CRM recovery [37].

Therefore, there is no risk on dissipative loss of CRMs where those slags will be recycled in cement industry, road construction, etc. The use of ACBFS as admixtures in a clinker precursor is considered an upcycling route with the following two major benefits: (1) saving genuine clinker precursors and (2) diminishing the carbon foot print through energy saving during the clinkerisation process [39].

The preliminary LIBS measurements demonstrate that Li, which is a light CRM, is contained in ferrous slags. It is noteworthy that the XRFS, and even XRD, cannot detect light CRMS; therefore, they cannot ensure a trustworthy screening for a complete list of CRMs. Therefore, the paper emphasizes the need for an integrated XRFS, LIBS, and XRD procedure for reliable screening of the CRMs in secondary resources, as Regulation requires.

The authors are aware of the importance of the sampling plan and statistical data processing as critical factors for the decision on harvesting CRMs from these secondary resources. Therefore, further research is expected on this topic.

Author Contributions

Conceptualization, A.-L.T., I.P., Z.K. and R.-N.T.; methodology, A.-L.T., I.P., Z.K., A.P. and G.I.; validation, I.P., C.U. and D.-F.M.; formal analysis, A.P. and F.N.; investigation, A.-L.T., I.P., P.G., C.U., F.N. and R.-N.T.; resources, A.-L.T., Z.K., G.I. and D.-F.M.; data curation, A.P., C.U. and D.-F.M.; writing—original draft preparation, I.P., P.G., R.-N.T. and G.I.; writing—review and editing, I.P., P.G., R.-N.T. and G.I.; visualization, I.P., C.U. and R.-N.T.; supervision, A.-L.T. and I.P.; project administration, A.-L.T. and I.P.; funding acquisition, A.-L.T., Z.K. and D.-F.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data are available at request.

Acknowledgments

The authors would like to thank Kristof Endre, KIMET Ltd., Targu Secuiesc, Romania, for his advice on using LIBS in our research and for facilitating LIBS measurements at SciAps Laboratory, Germany.

Conflicts of Interest

Zbynek Karas is a member of staff of the Destro Kladno s.r.o., Zbecno, Czech Republic. The paper reflects the views of the scientist and not the company. Philipp Gründken is an employee of SciAps, Inc., Krefeld, Germany. The paper reflects the views of the scientist and not the company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Nicolae, M.; Sohaciu, M.G.; Dumitrescu, R.; Ciuca, S.; Nicolae, A. Vectors of Sustainable Development and Global Knowledge in the Metallic Materials Industry in Romania. Sustainability 2022, 14, 9911. [Google Scholar] [CrossRef]

- Riposan, I.; Stan, S. History of Metallurgy. In Mechanics, Processing Techniques and Constructions; Publishing House of the Romanian Academy: Bucharest, Romania, 2019; Volume 24, pp. 61–106. ISBN 978-973-27-3054-6. (In Romanian) [Google Scholar]

- Riposan, I.; Chira, I.; Chisamera, M.; Sofroni, L.; Stan, S. Cast Iron. In Treatise on the Science and Engineering of Metallic Materials; AGIR: Bucharest, Romania, 2009; Volume 3, pp. 463–580. (In Romanian) [Google Scholar]

- Popescu, N.; Saban, R.; Bunea, D.; Pencea, I. Material Science for Mechanical Engineering, 1st ed.; Fair Partner Publishers: Bucharest, Romania, 2000; pp. 213–226. [Google Scholar]

- Mihaiescu, D.C.; Predeanu, G.; Panaitescu, C. Characterization of some Blast Furnace Waste Dusts. Univ. Politeh. Buchar. Sci. Bull. Ser. B-Chem. Mater. Sci. 2014, 76, 227–234. [Google Scholar]

- Ciocan, A. Assessment of Blast Furnace Slag Transformation into Value Added By-Products on Basis on Knowledge of Slag Characteristics. Ann. “Low. Danub.” Univ. Galati. Fascicle IX. Metall. Mater. Sci. 2012, 35, 78–87. [Google Scholar]

- Piatak, N.M.; Ettler, V. Introduction: Metallurgical Slags–Environmental Liability or Valuable Resource ? Chapter 1. In Metallurgical Slags: Environmental Geochemistry and Resource Potential; The Royal Society of Chemistry, Ed.; Royal Society of Chemistry: London, UK, 2021; Electronic; pp. 1–13. ISSN 2516-2632. [Google Scholar]

- Baicoianu, V.; Parvu, M. Activity of the Metallurgical Sector; National Institute of Statistics: Bucharest, Romania, 2023; pp. 1–4. [Google Scholar]

- Adevarul.ro. Available online: https://adevarul.ro/stiri-locale/galati/un-munte-de-deseuri-de-22-de-ori-mai-mare-decat-1686240.html (accessed on 19 June 2024). (In Romanian).

- Cause C-301/17. ECLI Identifier: ECLI:EU:C:2018:846. Available online: https://eur-lex.europa.eu/legal-content/RO/ALL/?uri=CELEX:62017CJ0301 (accessed on 20 June 2024).

- Emergency Ordinance no. 96 of 2 November 2023, Regarding Some Measures to Improve the Efficiency of Waste Management, as Well as for the Modification and Completion of Some Normative Acts. Official Gazette no. 1003 of 3 November 2023. Available online: https://www.eea.europa.eu/help/glossary/eea-glossary/european-waste-catalogue-1 (accessed on 13 May 2024).

- Emergency Ordinance no. 92 of 19 August 2021 Regarding the Waste Regime Issuer: The Government of Romania, 2021, Published in the Official Gazette no. 820 of 26 August 2021. Available online: https://legislatie.just.ro/Public/DetaliiDocument/245846 (accessed on 20 June 2024).

- EUROSLAG. Position Paper on the Status of Ferrous Slag Complying with the Waste Framework Directive (Articles 5/6) and the REACH Regulation. Available online: https://www.euroslag.com/wp-content/uploads/2019/01/Position_Paper_April_2012.pdf (accessed on 8 July 2024).

- EUROFER. EUROFER Position Paper on the Registration Duties for Downstream Users of Multi-Constituent Substances (MCS) in the Steel Industry Revised August 2023. Available online: https://www.eurofer.eu/assets/publications/position-papers/reach-position-papers/Position-paper-on-MCS.V2.pdf (accessed on 8 July 2024).

- EUR-LEX. Directive 2008/98/EC of the European Parliament and of the Council of November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance) Official Journal of the European Union 22.11.2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098 (accessed on 8 May 2024).

- EUR-LEX. European Parliament and Council Directive 94/62/EC of 20 December 1994 on Packaging and Packaging Waste. Available online: http://data.europa.eu/eli/dir/1994/62/oj (accessed on 9 May 2024).

- EUR-LEX. REGULATION (EU) 2024/1252 of the European Parliament and of the Council of 11 April 2024 Establishing a FRAMEWORK for Ensuring a Secure and Sustainable Supply of Critical Raw Materials and Amending Regulations (EU) No 168/2013, (EU) 2018/858, (EU) 2018/1724 and (EU) 2019/1020. Available online: https://eur-lex.europa.eu/eli/reg/2024/1252/oj (accessed on 8 July 2024).

- Hidalgo, I.; Kamiński, J. The iron and steel industry: A global market perspective. Gospod. Surowcami Min. 2011, 27, 5–28. [Google Scholar]

- ProSUM Project. Prospecting Secondary Raw Materials in the Urban Mine and Mining Wastes. Available online: https://www.prosumproject.eu/ (accessed on 19 July 2024).

- Carcea, I.; Roman, C.; Chelariu, R. Metallurgical Process Engineering; Performantica: Iaşi, Romania, 2006; pp. 262–276. ISBN 978-973-730-326-4. (In Romanian) [Google Scholar]

- Timiș, A.L.; Pencea, I.; Karas, Z.; Turcu, R.N.; Niculescu, F.; Sztacho, P.; Ghiţă, M.; Macovei, A.C. DESTRO approach for up-cycling the air-cooled blast furnace slag old dumps. Case Study Călan. UPB Sci. Bull. Ser. B 2024, 86, 201–213. [Google Scholar]

- Blengini, G.A.; Mathieux, F.; Mancini, L.; Nyberg, M.; Viegas, H.M.; Salminen, J.; Garbarino, E.; Orveillon, G.; Saveyn, H.; Mateos Aquilino, V.; et al. Recovery of Critical and Other Raw Materials from Mining Waste and Landfills: State of Play on Existing Practices; EUR 29744 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-08568-3. [Google Scholar]

- European Commission. Critical Raw Materials: Ensuring Secure and Sustainable Supply Chains for EU’s Green and Digital Future. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_1661 (accessed on 8 June 2024).

- European Commission. Critical Raw Materials. Available online: https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials_en (accessed on 23 July 2024).

- Zimmermann, T.; Gößling-Reisemann, S. Critical materials and dissipative losses: A screening study. Sci. Total. Environ. 2013, 461–462, 774–780. [Google Scholar] [CrossRef] [PubMed]

- Kasina, M.; Michalik, M. Iron Metallurgy Slags as a Potential Source of Critical Elements-Nb, Ta and REE. Mineralogia 2016, 47, 15–28. [Google Scholar] [CrossRef]

- Särkkä, H.; Kaartinen, T.; Hannus, E. Assessing the opportunities of landfill mining as a source of critical raw materials in Europe. In Proceedings of the 16th International Waste Management and Landfill Symposium, Sardinia, Italy, 2–6 October 2017; Available online: https://dspace.lib.cranfield.ac.uk/server/api/core/bitstreams/d73cb7e8-08df-4443-b8b4-0dc4bb7ddda3/content (accessed on 20 August 2024).

- Methodology of July 16, 2020 for the Investigation of Potentially Contaminated and Contaminated Sites. Ministry of Envi-ronment, Waters and Forests of Romania. Published in Official Gazette no. 823 bis of September 8, 2020. Available online: http://www.monitoruljuridic.ro/monitorul-oficial/823-bis/2020-09-08/ (accessed on 25 February 2025). (In Romanian).

- Baldassarre, G.; Fiorucci, A.; Marini, P. Recovery of Critical Raw Materials from Abandoned Mine Wastes: Some Potential Case Studies in Northwest Italy. Mater. Proc. 2023, 15, 77. [Google Scholar] [CrossRef]

- Pencea, I.; Turcu, R.N.; Popescu-Argeș, A.C.; Timiș, A.L.; Priceputu, A.; Ungureanu, C.; Matei, E.; Nedelcu, L.; Petrescu, M.I.; Niculescu, F. An improved balanced replicated sampling design for preliminary screening of the tailings ponds aiming at zero-waste valorization. A Romanian case study. J. Environ. Manag. 2023, 331, 117260. [Google Scholar] [CrossRef] [PubMed]

- SC SILNEF SRL. Available online: https://haldatgv.weebly.com/acasa.html (accessed on 15 June 2024).

- Jonczy, I.; Bartłomiej, G.; Wieczorek, A.N.; Gerle, A.; Nuckowski, P.; Staszuk, M. Characteristics of the phase and chemical composition of blast furnace slag in terms of the possibility of its economic use. Gospod. Surowcami Miner.–Miner. Resour. Manag. 2022, 38, 153–172. [Google Scholar]

- Pencea, I. Instrumental Methods and Techniques for Elemental Analysis of Materials, Chapter 8. In Treatise on Materials Science and Engineering; Entitled: Final Processing Technologies of Metallic Materials; Agir Publishing House: Bucharest, Romania, 2011; Volume 5, pp. 1057–1239. ISBN 978-973-720-391-5. (In Romanian) [Google Scholar]

- Rousseau, R.M. Detection limit and estimate of uncertainty of analytical XRF results. Rigaku J. 2001, 18, 33–47. [Google Scholar]

- Dushyantha, N.; Batapola, N.; Iilankoon, M.S.K.; Rohitha, S.; Premasiri, R.; Abeysinghe, B.; Ratnayake, N.; Dissanayake, K. The story of rare earth elements (REEs): Occurrences, global distribution, genesis, geology, mineralogy and global production. Ore. Geol. Rev. 2020, 122, 103521. [Google Scholar] [CrossRef]

- Ibe, C.O. Moments of Random Variables Chapter 3. In Fundamentals of Applied Probability and Random Processes, 2nd ed.; Academic Press: San Diego, CA, USA, 2014; pp. 81–102. ISBN 9780128008522. [Google Scholar] [CrossRef]

- Available online: https://pub.norden.org/temanord2025-505/4-instruments-and-measures-for-better-crm-recycling-in-the-nordics-.html (accessed on 25 February 2025).

- Abhilash, M.P.; Sarkar, S.; Venugopalan, T. Exploring blast furnace slag as a secondary resource for extraction of rare earth elements. Min. Metall. Explor. 2017, 34, 178–182. [Google Scholar] [CrossRef]

- Timiș, A.L.; Pencea, I.; Karas, Z.; Priceputu, A.; Ungureanu, C.; Niculescu, F.; Turcu, R.N.; Marcu, D.F.; Ciucă, S.; Iacob, G. Research concerning the upcycling of aircooled blast furnace slag from old Călan dump as admixture in clinker precursor. UPB Sci. Bull. Ser. B 2024, 86, 231–244. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).