Towards Circularity in Serbian Mining: Unlocking the Potential of Flotation Tailings and Fly Ash

Abstract

1. Introduction

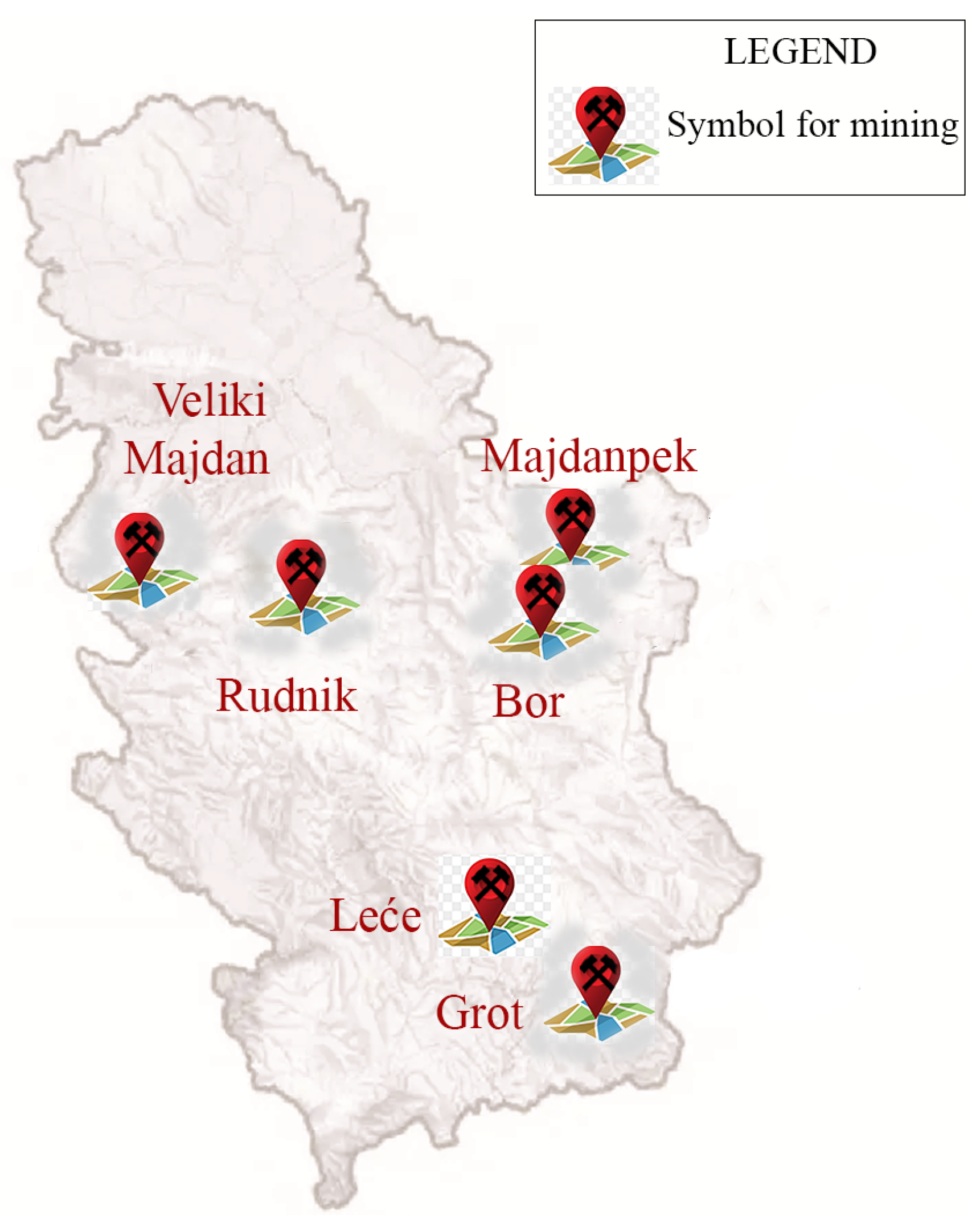

2. The Principles and Possibilities of Circular Economy Within Mining Sector

3. Circular Economy Within Mining Sector in Serbia

- The primary step (primary extraction) involves

- (a)

- The usage of coal through combustion with residual fly ash obtained. Note: The fly ash, adequate for use in cement and/or concrete production, can only be produced at high combustion temperatures or the combustion of coal results in fluidized ash with an irregular particle structure and unstable properties (often inadequate for mentioned applications) [83].

- (b)

- The processing of ore to obtain concentrate and flotation tailings.

- The secondary step focuses on revaluing metals from (a) fly ash and (b) flotation tailings, providing critical raw materials (CRMs) but with residual waste. Serbia’s ore deposits are recognized as a significant source for obtaining mineral raw materials, including CRM [72].

- Tertiary step: In the context of a circular economy, this step refers to the potential for reducing, reusing, and/or recycling the remaining waste to obtain material for further use. This may include, for example, stabilization processes like desulphurization and the utilization of leftover material within the construction sector.

3.1. Reuse Potential of Mining Waste and Fly Ash in Serbia

3.2. Legislation in Serbia

3.3. European Practice and Serbian Perspective for Mining Waste Management

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dale, G. Extraction of Raw Materials Could Rise 60% by 2060—And Making Mining ‘Greener’ Won’t Stop the Damage. The Conversation 2024. Available online: https://theconversation.com/extraction-of-raw-materials-could-rise-60-by-2060-and-making-mining-greener-wont-stop-the-damage-222818 (accessed on 16 February 2024).

- Lèbre, É.; Corder, G.D.; Golev, A. Sustainable Practices in the Management of Mining Waste: A Focus on the Mineral Resource. Miner. Eng. 2017, 107, 34–42. [Google Scholar] [CrossRef]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How Circular is the Global Economy? An Assessment of Material Flows, Waste Production, and Recycling in the European Union and the World in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Wang, C.; Harbottle, D.; Liu, Q.; Xu, Z. Current State of Fine Mineral Tailings Treatment: A Critical Review on Theory and Practice. Miner. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Dimitrijević, M.D.; Milić, S.M. Sulfidni Rudarski Otpad: Karakteristike, Uticaj na Životnu Sredinu i Tretman; Univerzitet u Beogradu, Tehnički Fakultet: Bor, Serbia, 2017; ISBN 978-86-6305-063-1. [Google Scholar]

- Abaka-Wood, G.B.; Addai-Mensah, J.; Skinner, W. The Concentration of Rare Earth Elements from Coal Fly Ash. J. S. Afr. Inst. Min. Metall. 2022, 122, 7–15. [Google Scholar] [CrossRef]

- Karanac, M. The Utilization of Fly Ash Modified by Calcium Hydroxide and Ferric Oxide for the Removal of Heavy Metal Ions from Water. Ph.D. Dissertation, University of Belgrade, Faculty of Technology and Metallurgy, Belgrade, Serbia, 2018. [Google Scholar]

- Hakkou, R.; Benzaazou, M.; Bussiere, B. Valorization of Phosphate Waste Rocks and Sludge from the Moroccan Phosphate Mines: Challenges and Perspectives. Procedia Eng. 2016, 138, 110–118. [Google Scholar] [CrossRef]

- Marković, R.; Marjanović, V.M.; Stevanović, Z.; Gardić, V.; Petrović, J.; Kovačević, R.; Štirbanović, Z.; Friedrich, B. Importance of Changes in the Copper Production Process through Mining and Metallurgical Activities on the Surface Water Quality in the Bor Area, Serbia. Metals 2024, 14, 649. [Google Scholar] [CrossRef]

- Pierwoła, J.; Ciesielczuk, J.; Misz-Kennan, M.; Fabiańska, M.J.; Bielińska, A.; Kruszewski, Ł. Structure and thermal history of the Wełnowiec dump, Poland: A municipal dump rehabilitated with coal waste. Int. J. Coal Geol. 2018, 197, 1–19. [Google Scholar] [CrossRef]

- Trifunović, V.; Avramović, L.; Božić, D.; Jonović, M.; Šabaz, D.; Bugarin, D. Flotation Tailings from Cu-Au Mining (Bor, Serbia) as a Potential Secondary Raw Material for Valuable Metals Recovery. Minerals 2024, 14, 905. [Google Scholar] [CrossRef]

- Ke, X.; Zhou, X.; Wang, X.; Wang, T.; Hou, H.; Zhou, M. Effect of Tailings Fineness on the Pore Structure Development of Cemented Paste Backfill. Constr. Build. Mater. 2016, 126, 345–350. [Google Scholar] [CrossRef]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-Thinking Mining Waste through an Integrative Approach Led by Circular Economy Aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef]

- Trace.org.au. Exploring the Potential of Fly Ash. Available online: https://trace.org.au/exploring-the-potential-of-fly-ash/ (accessed on 23 January 2025).

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste: A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- IMARC Group. Fly Ash Market Size, Share, Trends and Forecast to 2033. Available online: https://www.imarcgroup.com/fly-ash-market (accessed on 23 January 2025).

- RoyChowdhury, A.; Sarkar, D.; Datta, R. Remediation of Acid Mine Drainage-Impacted Water. Curr. Pollut. Rep. 2015, 1, 131–141. [Google Scholar] [CrossRef]

- Dimitrijević, M.D.; Alagić, S.Č. Passive Treatment of Acid Mine Drainage. Bakar 2012, 37, 57–68. [Google Scholar]

- Petronijević, N.S. Analysis of the Mechanism of Acid Mine Drainage Neutralization Using Flotation Tailings and Fly Ash. Ph.D. Dissertation, University of Belgrade, Faculty of Technology and Metallurgy, Belgrade, Serbia, 2022. [Google Scholar]

- Manchisi, J.; Ndlovu, S. Prediction of Acid Mine Drainage Formation. In Acid Mine Drainage; CRC Press: Boca Raton, FL, USA, 2021; pp. 31–56. [Google Scholar] [CrossRef]

- Saleem, S.; Hu, G.; Li, J.; Hewage, K.; Sadiq, R. Evaluation of Offshore Oil Spill Response Waste Management Strategies: A Lifecycle Assessment-Based Framework. J. Hazard. Mater. 2022, 432, 128659. [Google Scholar] [CrossRef]

- Alivojvodic, V.; Kokalj, F. Drivers and Barriers for the Adoption of Circular Economy Principles towards Efficient Resource Utilisation. Sustainability 2024, 16, 1317. [Google Scholar] [CrossRef]

- Alivojvodic, V.; Kokalj, F. Redefining Waste: R-Strategies and Metrics as a Framework for Driving Progress of Circular Economy Performance. In New Trends in Engineering Research 2024; in Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2024; Volume 1216. [Google Scholar] [CrossRef]

- Petronijević, N.; Alivojvodić, V.; Sokić, M.; Marković, B.; Stanković, S.; Radovanović, D. Sustainable Mining Towards Accomplishing Circular Economy Principles. J. Appl. Eng. Sci. 2020, 18, 493–499. [Google Scholar] [CrossRef]

- Van Wynsberghe, A. Sustainable AI: AI for sustainability and the sustainability of AI. AI Ethics 2021, 1, 213–218. [Google Scholar] [CrossRef]

- Falagan, C.; Grail, B.M.; Johnson, D.B. Bioleaching of Metals from Mine Tailings. Miner. Eng. 2017, 106, 71–78. [Google Scholar] [CrossRef]

- Shengo, L.M. Potentially Exploitable Reprocessing Routes for Recovering Copper and Cobalt Retained in Flotation Tailings. J. Sustain. Met. 2021, 7, 60–77. [Google Scholar] [CrossRef]

- Lei, B.; Li, X.; Guo, Y.; Qu, F.; Zhao, C.; Tam, V.W.Y.; Wu, V.; Li, W. Recycling of Copper Tailing as Filler Material in Asphalt Paving Mastic: A Sustainable Solution for Mining Waste Recovery. Case Stud. Constr. 2024, 20, e03237. [Google Scholar] [CrossRef]

- Ndlovu, S.; Simate, G.S.; Matinde, E. Waste Production and Utilization in the Metal Extraction Industry; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Connors, E. Coal-ash management by U.S. electric utilities: Overview and recent developments. Util. Policy 2015, 34, 30–33. [Google Scholar] [CrossRef]

- Argane, R.; Benzaazoua, M.; Hakkou, R.; Bouamrane, A. A Comparative Study on the Practical Use of Low Sulfide Base-Metal Tailings as Aggregates for Rendering and Masonry Mortars. J. Clean. Prod. 2015, 87, 914–925. [Google Scholar] [CrossRef]

- Abbadi, A.; Mucsi, G. A Review on Complex Utilization of Mine Tailings: Recovery of Rare Earth Elements and Residue Valorization. J. Environ. Chem. Eng. 2024, 12, 113118. [Google Scholar] [CrossRef]

- Alcalde, J.; Kelm, U.; Vergara, D. Historical Assessment of Metal Recovery Potential from Old Mine Tailings: A Study Case for Porphyry Copper Tailings, Chile. Miner. Eng. 2018, 127, 334–338. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Chen, T.; Zhao, Y.; Bao, S. Preparation of Eco-Friendly Construction Bricks from Hematite Tailings. Constr. Build. Mater. 2011, 25, 2107–2111. [Google Scholar] [CrossRef]

- Dardona, M.; Mohanty, S.K.; Allen, M.J.; Dittrich, T.M. From ash to oxides: Recovery of rare-earth elements as a step towards valorization of coal fly ash waste. Sep. Purif. Technol. 2023, 314, 123532. [Google Scholar] [CrossRef]

- Thomas, B.S.; Bhattacharya, S. Quantification and recovery prospects of critical metals and rare earth elements in Victorian brown coal fly ash: A promising secondary source for critical metal extraction. Hydrometallurgy 2025, 211, 106428. [Google Scholar] [CrossRef]

- Kokalj, F.; Alivojvodić, V.; Lešnik, L.; Petronijević, N.; Radovanović, D.; Samec, N. Enhancing Utilization of Municipal Solid Waste Bottom Ash by the Stabilization of Heavy Metals. Sustainability 2025, 17, 1078. [Google Scholar] [CrossRef]

- Borbor, A.K.K.G.; Nwaila, G.; Manzi, M.; Ghorbani, Y.; Ndlovu, S.; Petersen, J. The Valorisation of Platinum Group Metals from Flotation Tailings: A Review of Challenges and Opportunities. Miner. Eng. 2023, 201, 108216. [Google Scholar] [CrossRef]

- Adrianto, L.R.; Pfister, S. Prospective Environmental Assessment of Reprocessing and Valorization Alternatives for Sulfidic Copper Tailings. Resour. Conserv. Recycl. 2022, 186, 106567. [Google Scholar] [CrossRef]

- Opara, C.B.; Blannin, R.; Ebert, D.; Frenzel, M.; Pollmann, K.; Kutschke, S. Bioleaching of Metal(loid)s from Sulfidic Mine Tailings and Waste Rock from the Neves Corvo Mine, Portugal, by an Acidophilic Consortium. Miner. Eng. 2022, 188, 107831. [Google Scholar] [CrossRef]

- Gitari, M.W.; Akinyemi, S.A.; Thobakgale, R.; Ngoejana, P.C.; Ramugondo, L.; Matidza, M.; Mhlongo, S.E.; Dacosta, F.A.; Nemapate, N. Physicochemical and Mineralogical Characterization of Musina Mine Copper and New Union Gold Mine Tailings: Implications for Fabrication of Beneficial Geopolymeric Construction Materials. J. Afr. Earth Sci. 2018, 137, 218–228. [Google Scholar] [CrossRef]

- Li, Z.; Guo, L.; Zhao, Y.; Peng, X.; Kyegyenbai, K. A Particle Size Distribution Model for Tailings in Mine Backfill. Metals 2022, 12, 594. [Google Scholar] [CrossRef]

- Huynh, T.P.; Nguyen, T.M.; Lam, T.K. Utilization of High Volumes of Copper Mine Tailings in the Production of Fine-Grained Concrete. Mater. Today 2022, 65, 543–548. [Google Scholar] [CrossRef]

- Özdemir, E.; Lang, A.; Saari, J.; Liipo, J. Recovery of Sulfur, Copper, and Gold by Reprocessing Old Flotation Tailings at Bor, Serbia. Asp. Min. Miner. Sci. 2024, 12, 000783. [Google Scholar]

- Ejtemaei, M.; Nguyen, A. Characterisation of Sphalerite and Pyrite Surfaces Activated by Copper Sulphate. Miner. Eng. 2017, 100, 223–232. [Google Scholar] [CrossRef]

- Lottermoser, B.G. Recycling, reuse and rehabilitation of mine wastes. Elements 2011, 7, 405–410. [Google Scholar] [CrossRef]

- Ouyang, D.; Zhuo, Y.; Hu, L.; Zeng, Q.; Hu, Y.; He, Z. Research on the Adsorption Behavior of Heavy Metal Ions by Porous Material Prepared with Silicate Tailings. Minerals 2019, 9, 291. [Google Scholar] [CrossRef]

- Pizarro Barraza, F.; Thiyagarajan, D.; Ramadoss, A.; Manikandan, V.S.; Dhanabalan, S.S.; Venegas Abarzúa, C.; Sotomayor Soloaga, P.; Campos Nazer, J.; Morel, M.J.; Thirumurugan, A. Unlocking the potential: Mining tailings as a source of sustainable nanomaterials. Renew. Sustain. Energy Rev. 2024, 202, 114665. [Google Scholar] [CrossRef]

- Feng, W.; Yu, Z.; Bao, R.; Xiong, J.; Yan, K.; Liu, R.; Zhang, R.; Lu, X. From waste to resource: Advanced activation techniques for tailings in sustainable cement production. J. Build Eng. 2024, 97, 110780. [Google Scholar] [CrossRef]

- Ikramova, Z.; Mukhamedzhanova, M.T.; Tukhtaeva, G.G. Tungsten–molybdenum ore flotation tailings for ceramic tile production. Glass Ceram. 2009, 66, 102–103. [Google Scholar] [CrossRef]

- Araujo, F.S.M.; Taborda-Llano, I.; Nunes, E.B.; Santos, R.M. Recycling and Reuse of Mine Tailings: A Review of Advancements and Their Implications. Geosciences 2022, 12, 319. [Google Scholar] [CrossRef]

- Flores-Badillo, J.; Salinas-Rodríguez, E.; Hernández-Ávila, J.; Vargas-Ramírez, M.; Flores-Hernández, J.A.; Rodríguez-Lugo, V.; Cerecedo-Sáenz, E. Design and Production of a New Construction Material (Bricks), Using Mining Tailings. Int. J. Eng. Sci. Res. Technol. 2016, 6, 225. [Google Scholar] [CrossRef]

- Stolboushkin, A.Y.; Ivanov, A.I.; Fomina, O.A. Use of Coal-Mining and Processing Wastes in Production of Bricks and Fuel for Their Burning. Procedia Eng. 2016, 150, 1496–1502. [Google Scholar] [CrossRef][Green Version]

- Taha, Y.; Benzaazoua, M.; Hakkou, R.; Mansori, M. Coal Mine Wastes Recycling for Coal Recovery and Eco-Friendly Bricks Production. Miner. Eng. 2017, 107, 123–138. [Google Scholar] [CrossRef]

- Nikvar-Hassani, A.; Hodges, R.; Zhang, L. Production of Green Bricks from Low-Reactive Copper Mine Tailings: Durability and Environmental Aspects. Constr. Build. Mater. 2022, 337, 127571. [Google Scholar] [CrossRef]

- Lam, E.J.; Zetola, V.; Ramírez, Y.; Montofré, Í.L.; Pereira, F. Making Paving Stones from Copper Mine Tailings as Aggregates. Int. J. Environ. Res. Public Health 2020, 17, 2448. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.; Li, T.; Liu, B.; Li, B.; Zhou, Y. Mechanical Properties and Pore Structure of Recycled Aggregate Concrete Made with Iron Ore Tailings and Polypropylene Fibers. J. Build. Eng. 2021, 33, 101572. [Google Scholar] [CrossRef]

- Stevanović, D.; Karanac, M.; Ilić, M.; Miletić, S. Fly Ash from Coal Power Plants and its Application—A Step Towards Green Building. Met. Mater. Data 2024, 1, 117–123. [Google Scholar] [CrossRef]

- Sathiparan, N.; Jaasim, J.H.M.; Banujan, B. Sustainable Production of Cement Masonry Blocks with the Combined Use of Fly Ash and Quarry Waste. Materialia 2022, 26, 101621. [Google Scholar] [CrossRef]

- Siddique, R. Performance Characteristics of High-Volume Class F Fly Ash Concrete. Cement Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Kumar, V. (Eds.) Circular Economy and Fly Ash Management: 2020 Overview; Springer: Kolkata, India, 2020. [Google Scholar] [CrossRef]

- European Commission; Eurostat. Waste Generation. [Data Set]. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wasgen/default/table?lang=en (accessed on 20 February 2025).

- Ministry of Environmental Protection of the Republic of Serbia. Waste Management Program in the Republic of Serbia for the Period 2022–2031; Ministry of Environmental Protection: Belgrade, Serbia, 2022. (In Serbian) [Google Scholar]

- Statistical Office of the Republic of Serbia. Waste and Hazardous Chemicals; Statistical Office of the Republic of Serbia: Belgrade, Serbia, 2023. Available online: https://www.stat.gov.rs/en-us/oblasti/zivotna-sredina/otpad-i-opasne-hemikalije/ (accessed on 20 January 2025).

- Biznis i Finansije. Kružna Ekonomija: Nije Svako Đubre za Bacanje; Biznis i Finansije: 2020; Volume 178. BIF Press, Belgrade, Serbia; Available online: https://bif.rs/2020/10/biznis-finansije-178-kruzna-ekonomija-nije-svako-dubre-za-bacanje/ (accessed on 30 January 2025).

- Jelena, D.; Marinkovic, S.; Ignjatovic, I.; Tosic, N. Concrete Based on Alkali Activated Fly Ash from One Power Plant in Serbia. Int. J. Res. Eng. Technol. 2014, 3, 1–9. [Google Scholar]

- Alivojvodic, V.; Petronijevic, N. Position of copper within urban mining—Recovering potential from mine tailings. In Proceedings of the XV International Mineral Processing and Recycling Conference, Belgrade, Serbia, 17–19 May 2023; pp. 309–315. [Google Scholar]

- Adewuyi, S.O.; Anani, A.; Luxbacher, K. Advancing Sustainable and Circular Mining Through Solid-Liquid Recovery of Mine Tailings. Process Saf. Environ. Prot. 2024, 189, 31–46. [Google Scholar] [CrossRef]

- Urošević, S.; Vuković, M.; Pejčić, B.; Štrbac, N. Mining-Metallurgical Sources of Pollution in Eastern Serbia and Environmental Consciousness. Int. J. Environ. Pollut. 2018, 34, 103–115. [Google Scholar] [CrossRef]

- Maksimović, M.; Bugarin, M.; Stevanović, Z.; Marinković, V. Technogenic Deposit in the Area of the Old Flotation Tailing Dump in Bor (Field 1 and Field 2); Mining and Metallurgy Institute Bor: Bor, Serbia, 2014; Volume 16. [Google Scholar]

- Pantović, R. Potencijal Tehnogenih Ležišta Bakra i Zlata (Flotaciona Jalovina) u Rudnom Kompleksu Bor-Srbija, 2021. Available online: https://mibor.rs/wp-content/uploads/2021/12/Analiza-rudnickog-otpda-u-Boru-RP.pdf (accessed on 19 January 2025).

- Vukas, R.B. Mineralne Sirovine Srbije na Listi EU CRM-2020 Tokom Pandemije Covid-19 u Harmonizaciji sa Kodovima UNFC-2009 i Pojmovima PERC Standarda. Tehnika 2023, 73, 295–309. [Google Scholar] [CrossRef]

- Sokolović, J.M.; Stanojlović, R.; Andrić, L.; Štirbanović, Z. Flotation Studies of Copper Ore Majdanpek to Enhance Copper Recovery and Concentrate Grade with Different Collectors. J. Min. Metall. Sect. A Min. 2019, 55, 53–65. [Google Scholar] [CrossRef]

- Markovic, M. €2 Million EU-Funded Database of Serbian Mining Waste Incomplete. Analysis, Balkan Insight, 2024. Available online: https://balkaninsight.com/2024/10/22/e2-million-eu-funded-database-of-serbian-mining-waste-incomplete/ (accessed on 29 January 2025).

- Lilić, N. Studija o Proceni Uticaja na Životnu Sredinu Projekta Eksploatacije Rude Olova i Cinka “Vučkovog Ležišta“ i Ležišta “Kula“ u Sklopu Rudnika “Grot” A.D.—Kriva Feja; Rudarsko-geološki fakultet, Univerzitet u Beogradu: Beograd, Serbia, 2019. [Google Scholar]

- Antonijević, M.M.; Dimitrijević, M.D.; Stevanović, Z.O.; Šerbula, S.M.; Bogdanović, G.D. Investigation of the Possibility of Copper Recovery from the Flotation Tailings by Acid Leaching. J. Hazard. Mater. 2008, 158, 23–34. [Google Scholar] [CrossRef]

- Stevanović, Z.; Antonijević, M.; Bogdanović, G.; Bugarin, M. The Effect of Oxidants Through a Tailing Dump Depth and the Leaching of Copper. Carpathian J. Earth Environ. Sci. 2013, 8, 29–38. [Google Scholar]

- Stanković, S.; Morić, I.; Pavić, A.; Vojnović, S.; Vasiljević, B.; Cvetković, V. Bioleaching of Copper from Samples of Old Flotatio Tailings (Copper Mine Bor, Serbia). J. Serb. Chem. Soc. 2015, 80, 391–405. [Google Scholar] [CrossRef]

- Sokić, M.D.; Milošević, V.D.; Stanković, V.D.; Matković, V.L.; Marković, B.R. Acid Leaching of Oxide-Sulfide Copper Ore Prior the Flotation: A Way for an Increased Metal Recovery. Chem. Ind. 2015, 69, 453–458. [Google Scholar] [CrossRef]

- Stevanović, Z.; Antonijević, M.; Jonović, R.; Avramović, L.; Marković, R.; Bugarin, M.; Trujić, V. Leach-SX-EW Copper Revalorization from Overburden of Abandoned Copper Mine Cerovo, Eastern Serbia. J. Min. Metall. Sect. B Metall. 2009, 45, 45–57. [Google Scholar] [CrossRef]

- Stanković, V.; Milošević, V.; Milićević, D.; Gorgievski, M.; Bogdanović, G. Reprocessing of the Old Flotation Tailings Deposited on the Bor Tailings Pond—A Case Study. Chem. Ind. Chem. Eng. Q. 2018, 24, 334–344. [Google Scholar] [CrossRef]

- European Commission: Directorate-General for Internal Market, Industry; Entrepreneurship and SMEs; Grohol, M.; Veeh, C. Study on the Critical Raw Materials for the EU 2023—Final Report; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- European Commission, Joint Research Centre (JRC). Best Available Techniques (BAT) Reference Document for Large Combustion Plants (LCP BREF); Publications Office of the European Union: Luxembourg, 2017; Available online: https://eippcb.jrc.ec.europa.eu/sites/default/files/2019-11/JRC_107769_LCPBref_2017.pdf (accessed on 16 February 2025).

- Energija Balkana. Upotrebom Pepela, Šljake i Gipsa Štedi se Novac. Available online: https://energijabalkana.net/upotrebom-pepela-sljake-i-gipsa-stedi-se-novac/ (accessed on 20 January 2025).

- Vukicevic, M.; Popović, Z.; Despotovic, J.; Lazarević, L. Fly Ash and Slag Utilization for the Serbian Railway Substructure. Transport 2016, 33, 1–10. [Google Scholar] [CrossRef]

- Ministry of Environmental Protection; Environmental Protection Agency. Report on the State of the Environment in the Republic of Serbia for 2023; Ministry of Environmental Protection: Belgrade, Serbia, 2024; (In Serbian). Available online: https://sepa.gov.rs/wp-content/uploads/2024/12/ZivotnaSredina2023.pdf (accessed on 20 February 2025).

- Radovanović, D.Đ.; Kamberović, Ž.J.; Korać, M.S.; Rogan, J.R. Solidified structure and leaching properties of metallurgical wastewater treatment sludge after solidification/stabilization process. J. Environ. Sci. Health Part A 2016, 51, 34–43. [Google Scholar] [CrossRef]

- Štulović, M.; Radovanović, D.; Dikić, J.; Gajić, N.; Djokić, J.; Kamberović, Ž.; Jevtić, S. Utilization of Copper Flotation Tailings in Geopolymer Materials Based on Zeolite and Fly Ash. Materials 2024, 17, 6115. [Google Scholar] [CrossRef]

- Ðolić, M.; Karanac, M.; Radovanović, D.; Umicević, A.; Kapidzić, A.; Velicković, Z.; Marinković, A.; Kamberović, Z. Closing the loop: As(V) adsorption onto goethite impregnated coalcombustion fly ash as integral building materials. J. Clean. Prod. 2021, 303, 126924. [Google Scholar] [CrossRef]

- Petronijević, N.; Radovanović, D.; Štulović, M.; Sokić, M.; Jovanović, G.; Kamberović, Ž.; Stanković, S.; Stopić, S.; Onjia, A. Analysis of the Mechanism of Acid Mine Drainage Neutralization Using Fly Ash as an Alternative Material: A Case Study of the Extremely Acidic Lake Robule in Eastern Serbia. Water 2022, 14, 3244. [Google Scholar] [CrossRef]

- Petronijević, N.; Stanković, S.; Radovanović, D.; Sokić, M.; Marković, B.; Stopić, S.R.; Kamberović, Ž. Application of the Flotation Tailings as an Alternative Material for an Acid Mine Drainage Remediation: A Case Study of the Extremely Acidic Lake Robule (Serbia). Metals 2020, 10, 16. [Google Scholar] [CrossRef]

- Law on Environmental Protection. Official Gazette of the Republic of Serbia, No. 135/2004-29, 36/2009-144, 36/2009-115, 72/2009-164, 43/2011-88, 14/2016-3, 76/2018-3, 95/2018-267, 94/2024-391. (In Serbian). Available online: https://www.paragraf.rs/propisi/zakon_o_zastiti_zivotne_sredine.html (accessed on 10 January 2025).

- Law on Waste Management. Official Gazette of the Republic of Serbia, No. 36/2009, 88/2010, 14/2016, 95/2018, 35/2023. (In Serbian). Available online: https://www.paragraf.rs/propisi/zakon_o_upravljanju_otpadom.html (accessed on 10 January 2025).

- Law on Water. Official Gazette of the Republic of Serbia, No. 30/2010, 93/2012, 101/2016, 95/2018. (In Serbian). Available online: https://www.paragraf.rs/propisi/zakon_o_vodama.html (accessed on 10 January 2025).

- Air Protection Law. Official Gazette of the RS, no. 36/2009, 10/2013, 26/2021. (In Serbian). Available online: https://www.paragraf.rs/propisi/zakon_o_zastiti_vazduha.html (accessed on 10 January 2025).

- Law on Mining and Geological Research. Official Gazette of the RS, no. 101/2015, 95/2018, 40/2021. (In Serbian). Available online: https://gras.org.rs/wp-content/uploads/2017/10/law-on-mining-and-geological-explorations-of-serbia-2015.pdf (accessed on 10 January 2025).

- Rule Book on Categories, Testing and Classification of Waste. Official Gazette of the RS, no. 56/2010, 93/2019, 39/2021, 65/2024. (In Serbian). Available online: https://www.paragraf.rs/propisi/pravilnik-o-kategorijama-ispitivanju-i-klasifikaciji-otpada.html (accessed on 10 January 2025).

- Rule Book of Environmental Protection of the Republic of Serbia. Rulebook on Types of Waste for Which a Request Can Be Submitted, Permitted Procedures and Treatment Technologies for Types of Waste and Other Special Elements for Determining the Termination of Waste Status; “Official Gazette of RS”, No. 19/2024, 47/2024. (In Serbian). Available online: https://www.ekologija.gov.rs/propisi/pravilnici (accessed on 10 January 2025).

- Rulebook on Technical Requirements and Other Special Criteria for Certain Types of Waste That Cease to Be Waste. Official Gazette of the RS, no. 78/2019. (In Serbian). Available online: https://www.pravno-informacioni-sistem.rs/SlGlasnikPortal/eli/rep/sgrs/ministarstva/pravilnik/2019/78/1 (accessed on 10 January 2025).

- Directive 1999/31—Landfill of Waste. Available online: https://eur-lex.europa.eu/eli/dir/1999/31/oj/eng (accessed on 20 December 2024).

- Directive 2006/21/EC. Directive on the Management of Waste from Extractive Industries. Official Journal of the European Union 2006. Available online: https://eur-lex.europa.eu/eli/dir/2006/21/oj/eng (accessed on 16 December 2024).

- Directive 2008/98/EC. Waste Framework Directive. Official Journal of the European Union 2008. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 16 December 2024).

- European Commission. Communication from the Commission to the Council and the European Parliament—The Raw Materials Initiative: Meeting Our Critical Needs for Growth and Jobs in Europe. EUR-Lex 2008, Document 52008DC0699. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52008DC0699 (accessed on 16 December 2024).

- Directive 2010/75/EU. Directive on Industrial Emissions (Integrated Pollution Prevention and Control). Official Journal of the European Union 2010. Available online: https://eur-lex.europa.eu/eli/dir/2010/75/oj/eng (accessed on 16 December 2024).

- Directive 2000/60/EC. Water Framework Directive. Official Journal of the European Union 2000. Available online: https://eur-lex.europa.eu/eli/dir/2000/60/oj/eng (accessed on 16 December 2024).

- Directive 2014/95/EU. Non-Financial Reporting Directive (NFRD). Official Journal of the European Union 2014. Available online: https://eur-lex.europa.eu (accessed on 16 December 2024).

- EN 12620:2002+A1:2008; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, 2008.

- European Commission. The European Green Deal; COM(2019) 640 final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; COM(2020) 98 final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Regulation (EU) 2024/3110 of the European Parliament and of the Council of 27 November 2024 Laying Down Harmonised Rules for the Marketing of Construction Products and Repealing Regulation (EU) No 305/2011 (Text with EEA Relevance). Off. J. Eur. Union 2024, L 3110, 18.12.2024. Available online: https://eur-lex.europa.eu/eli/reg/2024/3110/oj/eng (accessed on 16 January 2025).

- Best Available Techniques (BAT) Reference Document for the Management of Waste from Extractive Industries, in Accordance with Directive 2006/21/EC; EUR 28963 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-77178-1. Available online: https://ec.europa.eu/environment/pdf/waste/mining/MWEI%20BREF.pdf (accessed on 16 January 2025).

- ASTM C618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- Statista. Cement Decarbonization Costs Worldwide 2023 by Approach. Available online: https://www.statista.com/statistics/1557813/cement-decarbonization-costs-worldwide-by-approach/ (accessed on 21 February 2025).

- EPS. Sales of Dry Fly Ash and Landfill Ash (Waste Slag) for 2023. (In Serbian). Available online: https://www.eps.rs/cir/tent/oglasi/Pages/Prodaja-suvog-lete%C4%8Deg-pepela-i-pepela-sa-deponije-(otpadne-%C5%A1ljake)-za-2023.godinu.aspx (accessed on 20 February 2025).

- ES2536464B1. Process for the Inertization of Ash from the Combustion of Municipal Solid Waste. Available online: https://patents.google.com/patent/ES2536464B1/en (accessed on 16 February 2025).

- Velásquez, J.R.; Schwartz, M.; Phipps, L.M.; Restrepo-Baena, O.J.; Lucena, J.; Smits, K.M. A review of the environmental and health implications of recycling mine tailings for construction purposes in artisanal and small-scale mining communities. Extr. Ind. Soc. 2022, 9, 101019. [Google Scholar] [CrossRef]

- ISO. The Circular Economy: Building Trust through Conformity Assessment. Available online: https://www.iso.org/sectors/environment/circular-economy (accessed on 20 February 2025).

| Category | Description | Characteristics and Impacts |

|---|---|---|

| Overburden | Material removed to access mineral deposits. |

|

| Waste rock | Material with low concentrations of minerals is not economically viable for extraction. |

|

| Tailings | Finely ground material is generated during the processing of mineral resources. |

|

| Mine water | Water generated during mining activities. |

|

| Sludge | Sludge produced from mine water treatment in active facilities. |

|

| Gaseous waste | Gaseous emissions from mining processes. |

|

| Fly ash * | Ash is produced during coal combustion in thermal power plants. |

|

| Material | Application |

|---|---|

| Mine tailings (various types) | Recycling and reuse in construction materials [51,52] |

| Hematite tailings | Production of eco-friendly construction bricks [34] |

| Coal mining and processing wastes | Brick production and fuel for burning [53,54] |

| Copper mine tailings | Brick production [55] |

| Production of fine-grained concrete [43,56] | |

| Production of paving stones as aggregates [56] | |

| Iron ore tailings | Recycled aggregate concrete with polypropylene fibers [56,57] |

| Low-sulfide base-metal tailings | Rendering and masonry mortars [56] |

| Applications/Category | Descriptions | Advantages |

|---|---|---|

| Construction industry |

| |

| Soil reclamation and stabilization |

|

|

| Industrial application |

|

|

| Environmental and energy applications |

|

|

| Metal | [g/t *] | [t **] |

|---|---|---|

| Au | 0.53 | 118 |

| Ag | 2.83 | 63.1 |

| Cu | 2300 | 51,290 |

| Law/Regulation | |

|---|---|

| SERBIA | Description |

| Environmental Protection Act [92] | Establishes an integrated system for environmental protection, sets obligations for entities, and outlines the environmental permitting process. |

| Waste Management Act [93] | Regulates waste management, including mining waste, focusing on reducing environmental impacts. |

| Water Act [94] | Governs the protection and use of water resources, including regulations on wastewater discharge from mining operations. |

| Air Protection Act [95] | Sets air quality standards and measures to reduce industrial pollution, including emissions from mining activities. |

| Mining and Geological Research Act [96] | Regulates mining and geological activities, emphasizing environmental protection during operations. |

| Various regulations and decrees (e.g., Decree on Waste Categories and Recycling Standards) [97] | Includes specific regulations, such as the Decree on Waste Categories, detailing recycling standards for mining waste. |

| The End-of-Waste Status [98,99] | Rulebook on the types of waste for which an application may be submitted, permitted procedures and treatment technologies for types of waste, and other special elements for determining the end-of-waste status (“Official Gazette of the Republic of Serbia”, No. 19/2024 and 47/2024) [98]: This regulation prescribes in detail the types of waste for which an application for end-of-waste status may be submitted, the permitted procedures and treatment technologies, as well as other special elements relevant for the determination of end-of-waste status. Regulation on technical requirements and other special criteria for certain types of waste that cease to be waste (“Official Gazette of the Republic of Serbia”, No. 78/2019) [99]: This regulation prescribes technical requirements and specific criteria for certain types of waste (such as glass, paper, textile, aggregate, and metal), which, after meeting certain conditions, cease to be classified as waste. |

| European Union | Description |

| Landfill Directive [100] | It aims to prevent or reduce as much as possible any negative impact of landfills on surface water, groundwater, soil, air, or human health by introducing stringent technical requirements. |

| Directive 2006/21/EC on the Management of Waste from Extractive Industries [101] | Provides a framework for the sustainable management of mining waste, including preventive measures to minimize environmental impacts. |

| Directive 2008/98/EC on Waste [102] | Defines general principles for waste management, focusing on prevention, reuse, and recycling within a circular economy. |

| Raw Materials Initiative (COM(2008)699) [103] | This study is an important step towards understanding the recycling potential of mining waste in the EU. Its results provide the basis for a more sustainable approach to the use of raw materials and enable the development of effective policies that support the circular economy and sustainable development |

| Directive 2010/75/EU on Industrial Emissions [104] | Covers industrial emissions, requiring the best available techniques (BATs) for environmental protection. |

| Water Framework Directive (2000/60/EC) [105] | Establishes a framework for water protection and sustainable use, including monitoring and management of water pollution. |

| Directive 2014/95/EU on Non-Financial Reporting [106] | Requires companies to disclose environmental and social information, promoting transparency and sustainability. |

| EN 12620:2002+A1:2008; Aggregates for Concrete [107] | The standard specifies the requirements for aggregates in concrete, including natural, recycled, and manufactured types, to ensure quality and performance. |

| European Green Deal [108] | The European Green Deal is an EU initiative to achieve climate neutrality by 2050 through sustainable resource use, biodiversity protection, pollution reduction, and a just transition across all sectors. |

| Circular Economy Action Plan [109] | Outlines EU’s strategic approach to circular economy, focusing on reducing waste, increasing recycling, and fostering sustainable industries. |

| New Construction Products Regulation (CPR) [110] | Establishes harmonized rules for marketing construction products in the EU (replacing regulation (EU) No. 305/20111) in order to improve legal clarity, reduce administrative burdens, and support the EU’s climate and circular economy goals while ensuring safety. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vujović, N.; Alivojvodić, V.; Radovanović, D.; Štulović, M.; Sokić, M.; Kokalj, F. Towards Circularity in Serbian Mining: Unlocking the Potential of Flotation Tailings and Fly Ash. Minerals 2025, 15, 254. https://doi.org/10.3390/min15030254

Vujović N, Alivojvodić V, Radovanović D, Štulović M, Sokić M, Kokalj F. Towards Circularity in Serbian Mining: Unlocking the Potential of Flotation Tailings and Fly Ash. Minerals. 2025; 15(3):254. https://doi.org/10.3390/min15030254

Chicago/Turabian StyleVujović, Nela, Vesna Alivojvodić, Dragana Radovanović, Marija Štulović, Miroslav Sokić, and Filip Kokalj. 2025. "Towards Circularity in Serbian Mining: Unlocking the Potential of Flotation Tailings and Fly Ash" Minerals 15, no. 3: 254. https://doi.org/10.3390/min15030254

APA StyleVujović, N., Alivojvodić, V., Radovanović, D., Štulović, M., Sokić, M., & Kokalj, F. (2025). Towards Circularity in Serbian Mining: Unlocking the Potential of Flotation Tailings and Fly Ash. Minerals, 15(3), 254. https://doi.org/10.3390/min15030254