Preparation Process and Performance of Mineral Admixtures Derived from High-Sulfur Lead-Zinc Tailings

Abstract

1. Introduction

2. Experiment

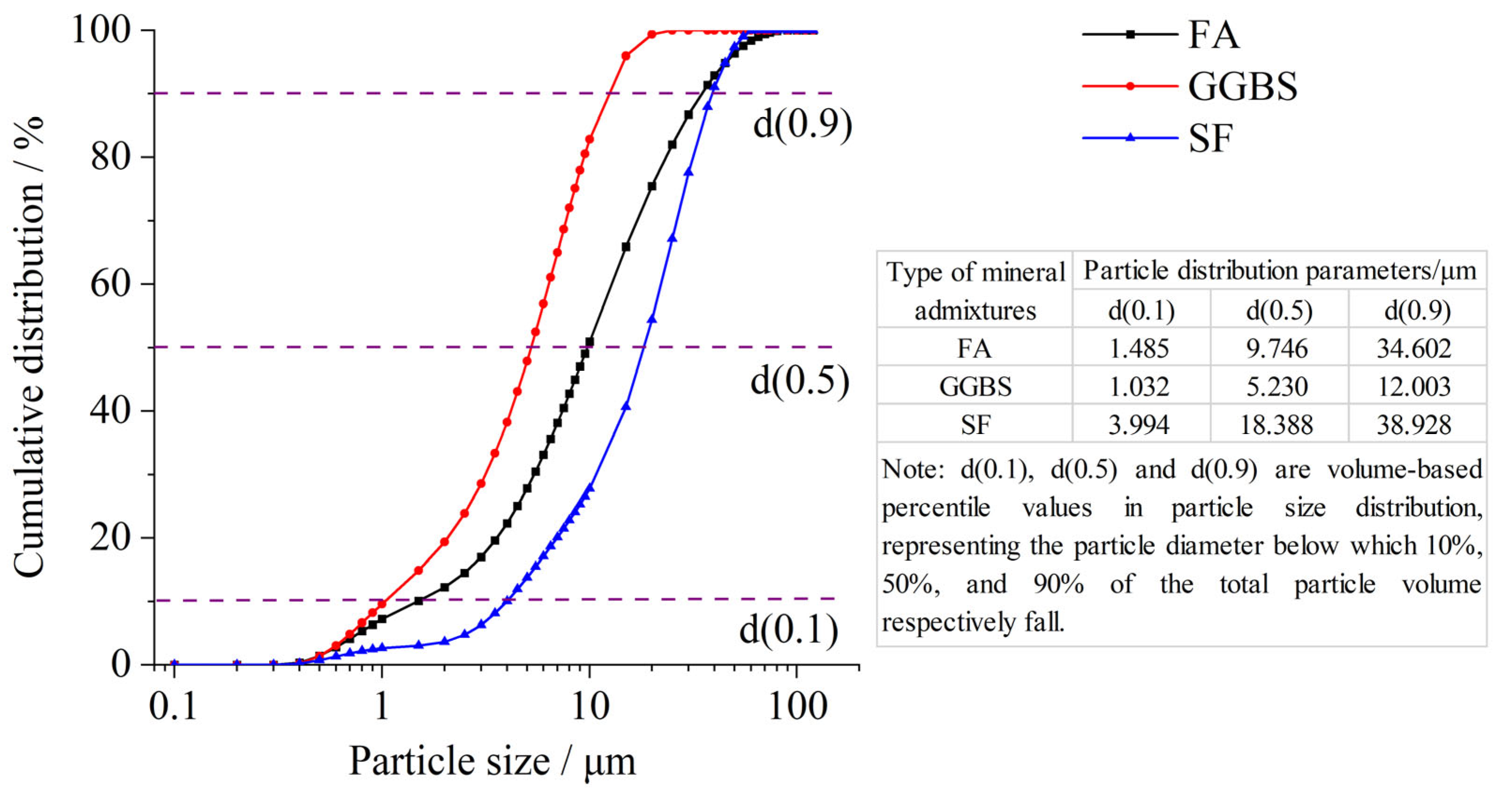

2.1. Raw Material

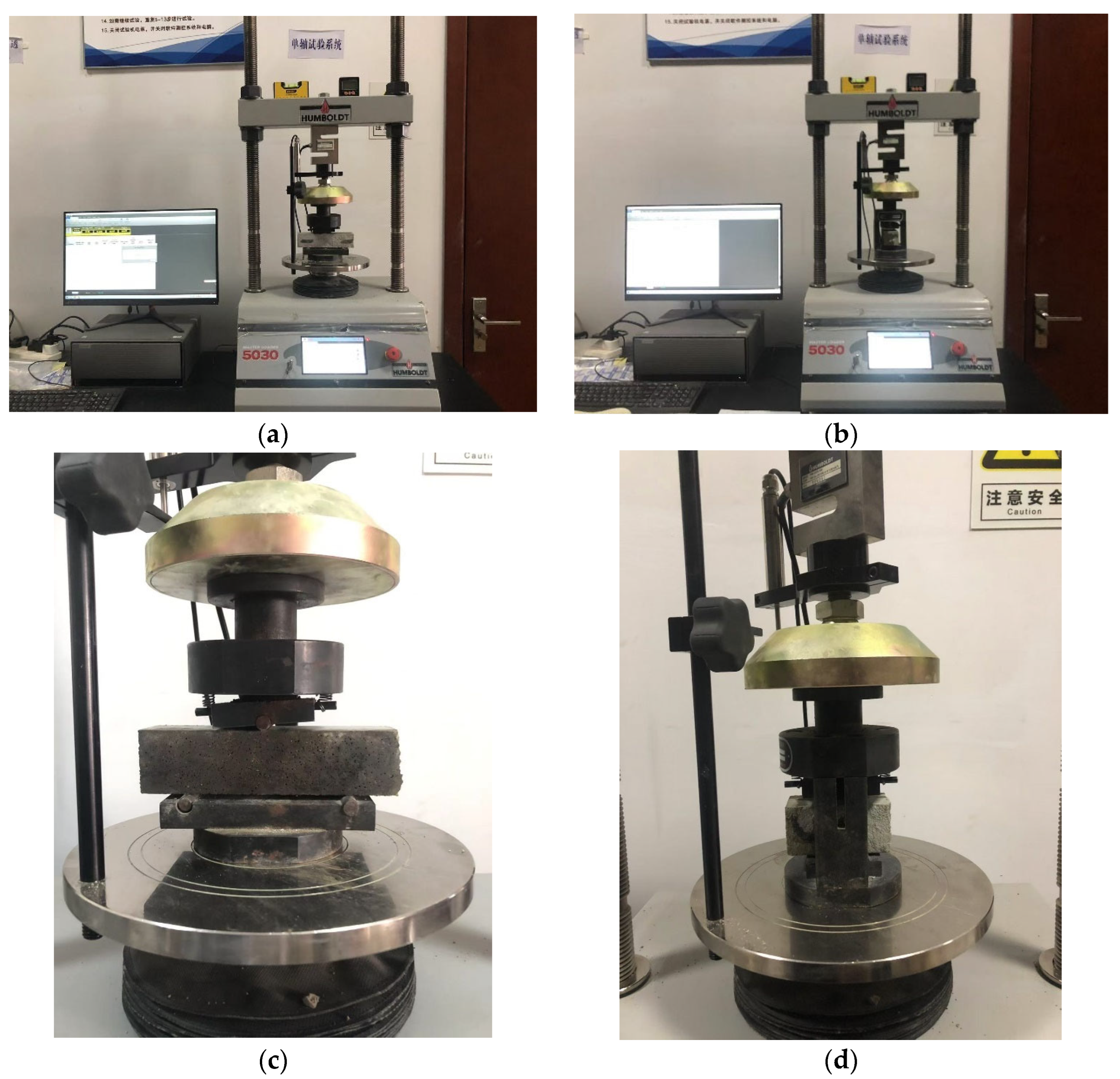

2.2. Test Methods

2.2.1. Mechanical Grinding Test

2.2.2. Wet Magnetic Separation Test

2.2.3. Mortar Specimen Preparation and Activity Evaluation

3. Results and Discussion

3.1. Mechanical Grinding Characteristics of Tailings

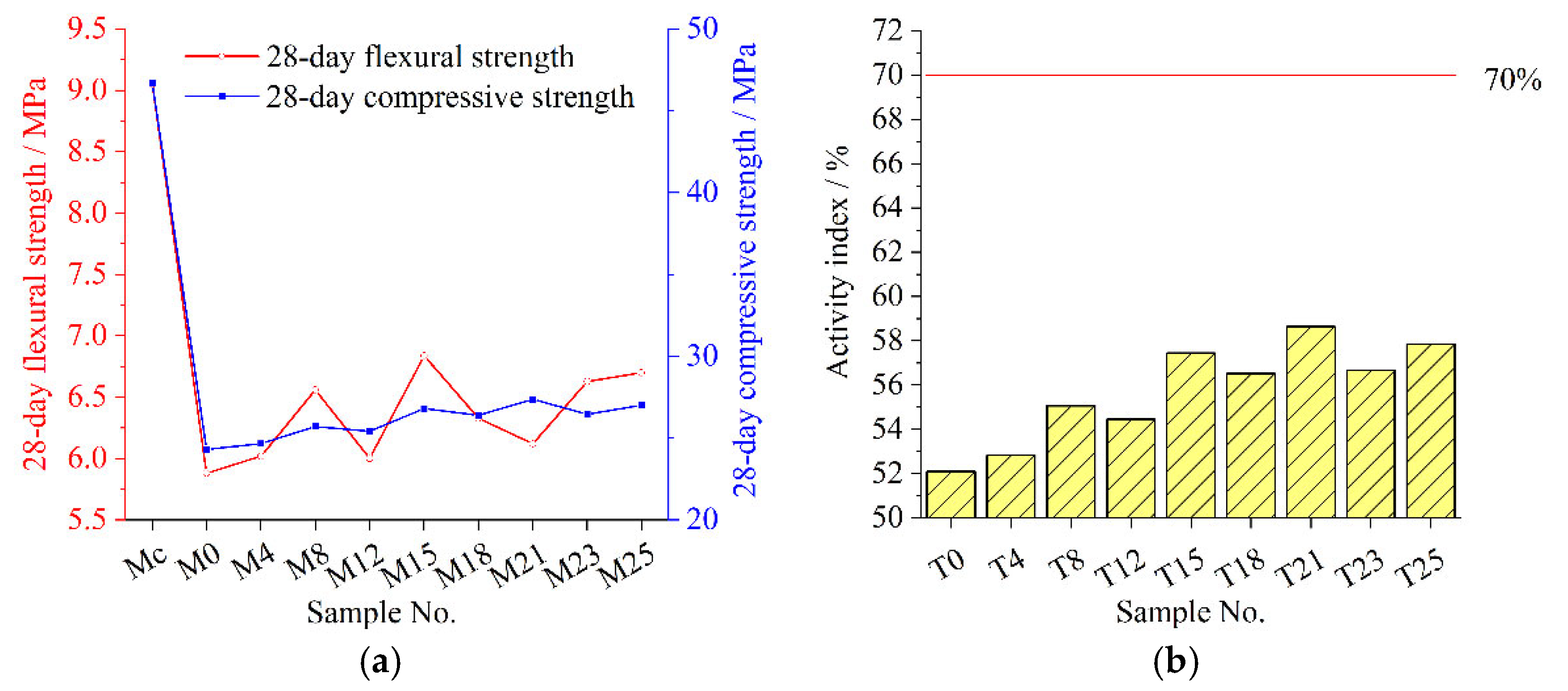

3.1.1. Tailings Mechanical Grinding

3.1.2. Activation Effect of Mechanical Grinding

3.2. Desulfurization Effect of Wet Magnetic Separation

3.3. Effect of Combined Activation via Wet Magnetic Separation and Mechanical Grinding

3.3.1. Large-Scale Magnetic Separation Test of Tailings

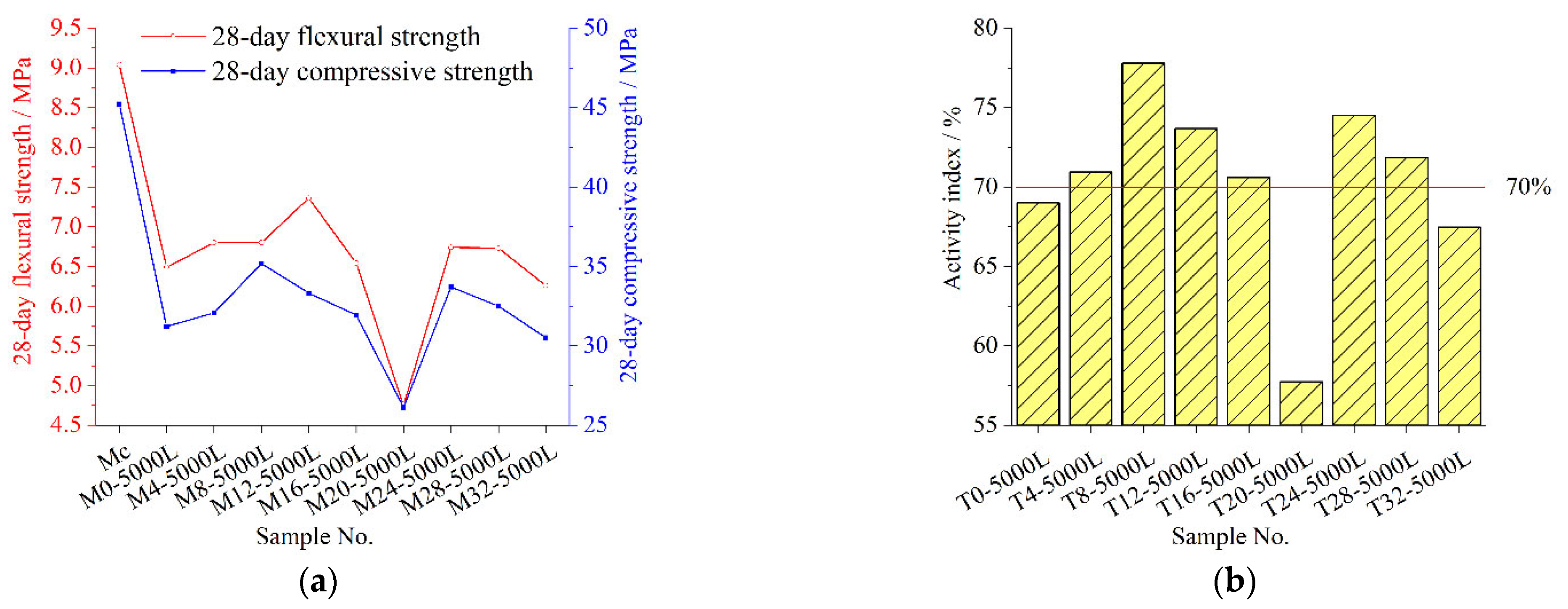

3.3.2. Mechanical Grinding Test of the Low-Sulfur Fraction from Wet Magnetic Separation of Tailings

3.3.3. Investigation of Tailings Activation Performance Based on Mortar Tests

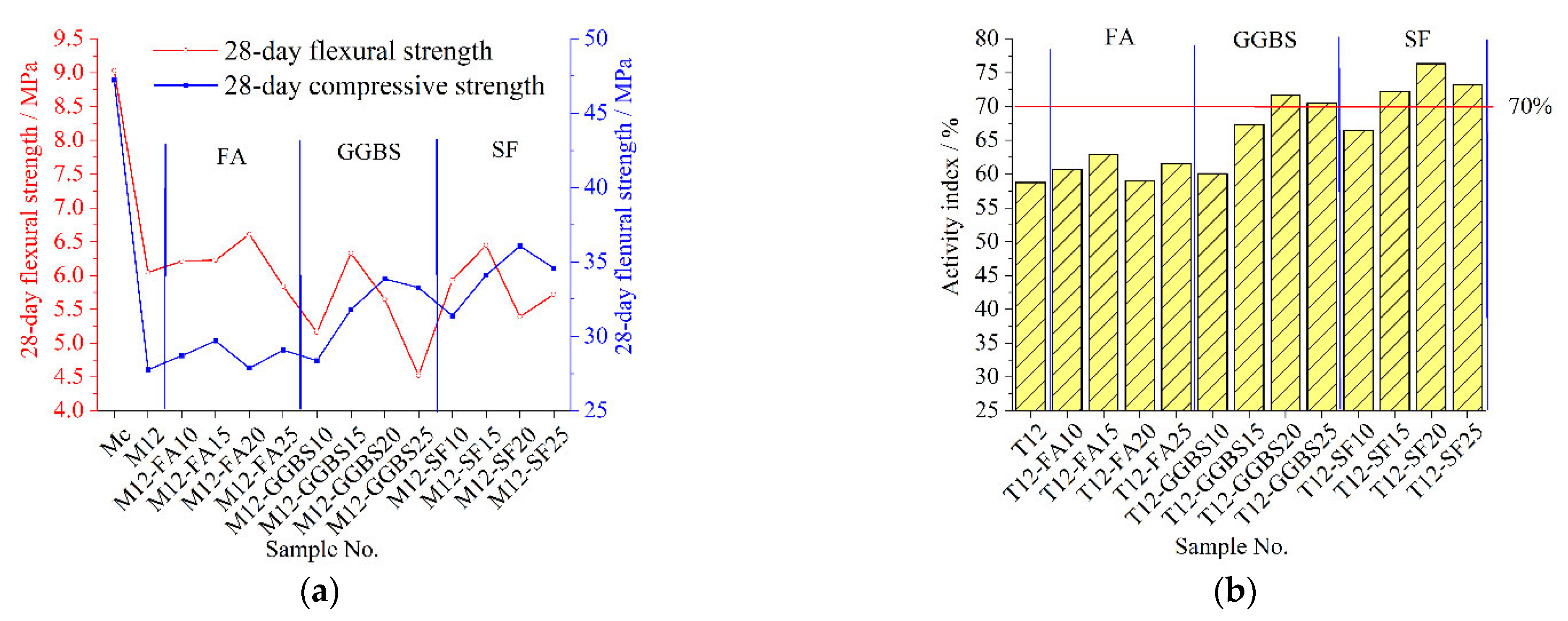

3.4. Effect of Synergistic Modification by Mechanical Grinding and Highly Active Mineral Admixtures

3.4.1. Minimum Dosage of Highly Active Mineral Admixture

3.4.2. Synergistic Modification of Tailings by Mechanical Grinding and Highly Active Mineral Admixtures

4. Production Process of Mineral Admixtures

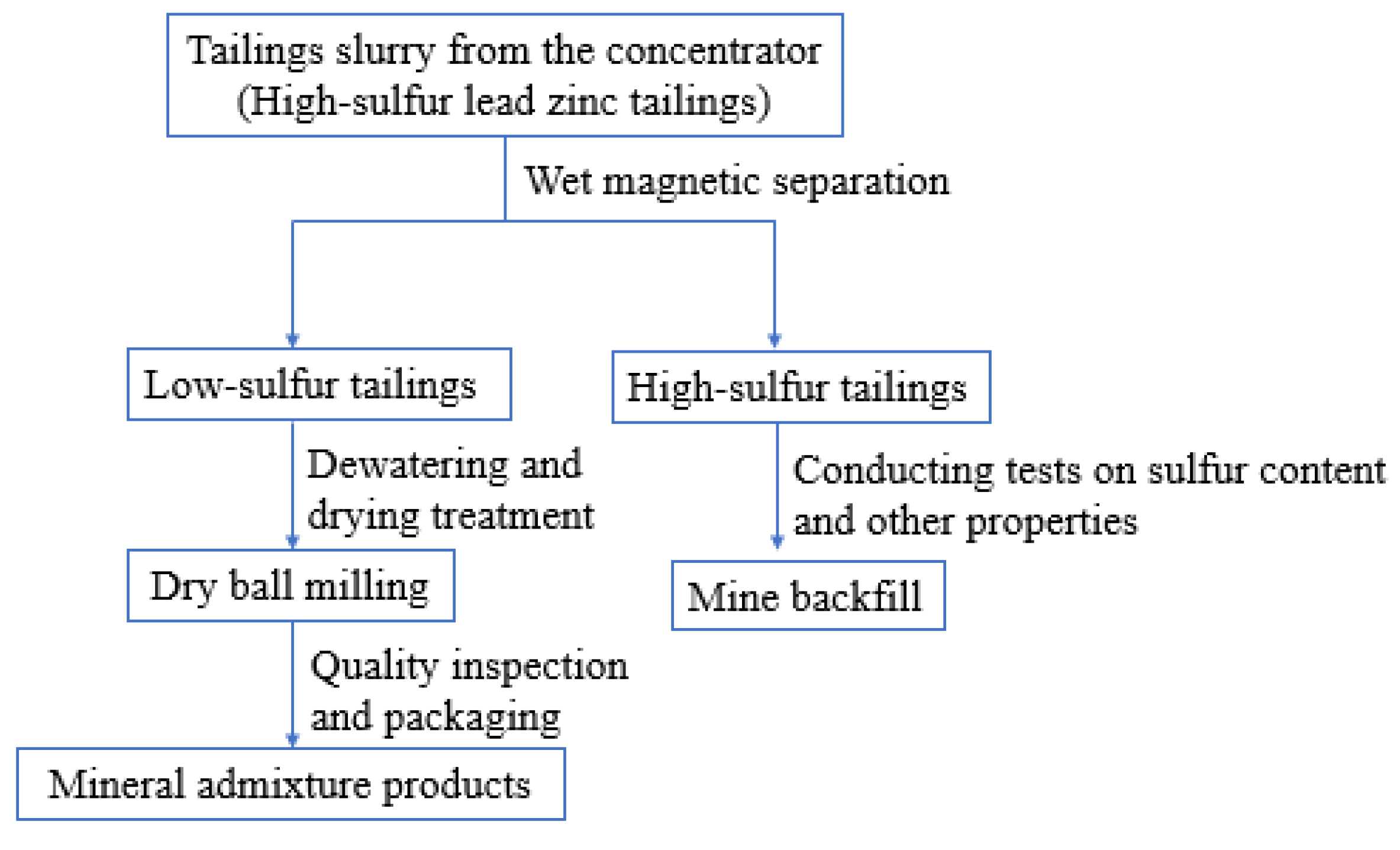

4.1. Production Process of Mineral Admixtures via Combined Wet Magnetic Separation and Mechanical Grinding Activation Using High-Sulfur Lead–Zinc Tailings

- (1)

- Wet magnetic separation: High-sulfur lead–zinc tailings are subjected to wet magnetic separation using a wet magnetic separator. The sulfur content in the separated low-sulfur and high-sulfur fractions is measured. The SO3 content of the low-sulfur fraction should be below 3.5% to allow further use in mineral admixture production, while the elemental sulfur content of the high-sulfur fraction should be below 8% to meet underground backfilling requirements.

- (2)

- Dewatering and drying: The low-sulfur tailings fraction meeting the SO3 requirement is dewatered and dried using a tailings filter press and tailings dryer to remove water content.

- (3)

- Mechanical grinding: The dewatered and dried low-sulfur tailings are mechanically ground in a ball mill to the desired fineness. After quality inspection and packaging, the mineral admixture product is obtained.

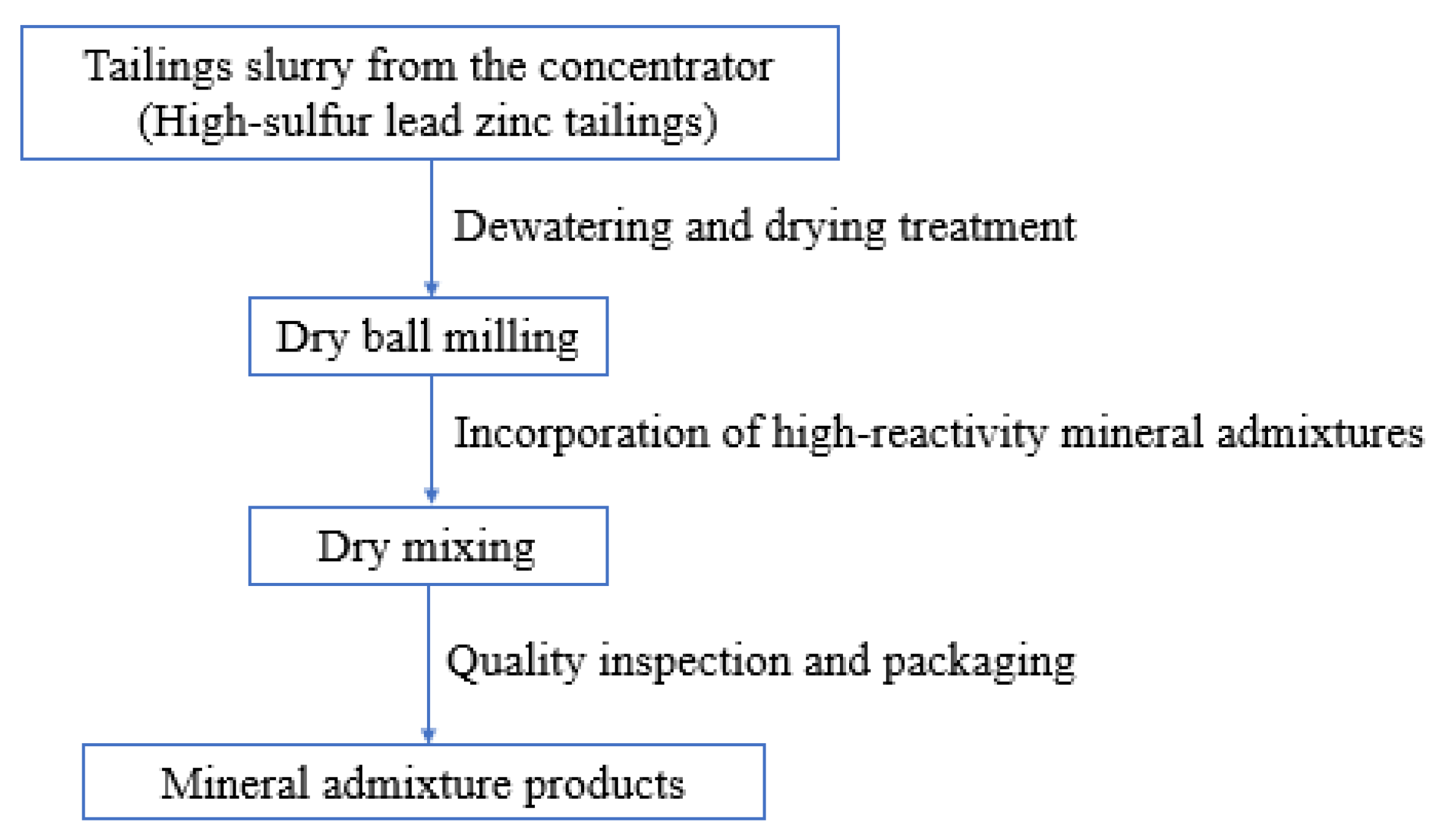

4.2. Production Process of Mineral Admixtures via Mechanical Grinding–Highly Active Mineral Admixture Synergistic Modification Using High-Sulfur Lead–Zinc Tailings

- (1)

- Dewatering and drying: Tailings slurry is dewatered and dried using a tailings filter press and tailings dryer to remove water.

- (2)

- Mechanical grinding: The dewatered and dried tailings are mechanically ground in a ball mill to the required fineness.

- (3)

- Synergistic modification with highly active mineral admixtures: An appropriate amount of highly active mineral admixture (GGBS or SF) is added to the mechanically ground tailings and thoroughly mixed in a dry-mixing machine. After quality inspection and packaging, the tailings-based mineral admixture is obtained.

4.3. Analysis of Optimal Production Process

5. Conclusions

- (1)

- Mechanical grinding can effectively refine tailings particles, optimize particle size distribution and specific surface area, thereby enhancing their potential pozzolanic activity. When the grinding time reaches at least 12 min, the 45 μm sieve residue of the tailings is below 30%, and the 28-day strength activity index can reach up to 58.64%. While mechanical grinding alone provides good activation, it is insufficient to achieve high-grade reactivity.

- (2)

- Wet magnetic separation of high-sulfur lead–zinc tailings can efficiently remove high-sulfur fractions, reducing the SO3 content from 3.67% to 2.10%, thereby meeting the Grade II mineral admixture limit in GB/T 1596–2017 [16] and laying a foundation for subsequent activation.

- (3)

- The “wet magnetic separation–mechanical grinding” combined activation process enables synergistic optimization of desulfurization and activation. The low-sulfur tailings obtained after magnetic separation and subsequent grinding exhibit superior fineness and reactivity compared with solely ground samples, with a 28-day strength activity index reaching 74.51%, meeting Grade II mineral admixture standards. This process significantly enhances reactivity while maintaining SO3 control.

- (4)

- Incorporating highly active mineral admixtures can further improve the reactivity and chemical stability of tailings. Silica fume shows the most pronounced activation effect; at a dosage of 14.81%, the 28-day strength activity index reaches 76.35%. The mechanism involves the secondary reaction between amorphous SiO2 and Ca(OH)2, generating additional C–S–H gel and improving the compactness of the cementitious structure.

- (5)

- The study identifies the mechanical grinding–highly active mineral admixture synergistic modification process as the optimal production method. The resulting mineral admixture products exhibit low SO3 content, appropriate fineness, and high reactivity, with no adverse impact on underground backfilling. Tailings utilization can reach 100%, achieving reduction, detoxification, and value-added reuse of tailings. This process has significant engineering implications for promoting green mining and the circular utilization of mineral waste.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Chen, L.; Li, B.; Chen, B. Modification of magnesium phosphate cement by lead-zinc tailings: Dual benefits in mechanical strength enhancement and leaching toxicity reduction. Constr. Build. Mater. 2025, 497, 143906. [Google Scholar] [CrossRef]

- Biglari, H.; Mousavi, S.M.; Yaghmaeian, K.; Dehghani, M.H.; Nodehi, R.N.; Nazmara, S.; Alimohammadi, M. Comprehensive health and environmental risk assessment of zanjan lead-zinc hydrometallurgy tailings. Results Eng. 2025, 26, 105160. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Z.; Li, Z.; Xie, R.; Jiang, X.; Cheng, J.; Chen, T.; Yang, X. Heavy metals release in lead-zinc tailings: Effects of weathering and acid rain. J. Hazard. Mater. 2025, 483, 136645. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, S.; You, F.; Saha, N.; Chan, T.-S.; Huang, L. Attenuation of pollution risks in sulfidic lead-zinc tailings through accelerating weathering of sulfides by indigenous acidithiobacillus consortia. Chem. Geol. 2025, 683, 122765. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, A.; Wang, S.; Zhao, Y. From performance to mechanism: Analysis of controlling strength attenuation of high-sulfur lead-zinc tailings cemented paste backfill. Miner. Eng. 2025, 225, 109233. [Google Scholar] [CrossRef]

- Tian, B.; Wang, N.; Ye, R.; Li, X.; Zhang, B. The utilization of wet grinding copper tailing for preparing ultra-high performance concrete. Next Mater. 2025, 9, 101085. [Google Scholar] [CrossRef]

- Hou, S.; Guo, Y.; Sun, J.; Jiang, J.; Gao, H.; Liu, J. Prospect of gold tailings as a new mineral admixture: Effect on hydration, pore structure and mechanical properties of concrete, Mater. Today Sustain. 2025, 29, 101078. [Google Scholar] [CrossRef]

- Yalley, P.P.; Kankam, C.K. Compressive, flexural and corrosion permeability resistance properties of concrete with bauxite tailing as supplementary mineral admixtures. Sci. Afr. 2022, 18, e01409. [Google Scholar] [CrossRef]

- Jindal, B.B. Investigations on the properties of geopolymer mortar and concrete with mineral admixtures: A review. Constr. Build. Mater. 2019, 227, 116644. [Google Scholar] [CrossRef]

- Zheng, Z.; Tan, H.; He, X.; Su, Y.; Wang, Y.; Yang, J.; Li, Y. Physical-chemical characterization and application research of copper tailings with wet-grinding activation for use as supplementary cementitious material. Constr. Build. Mater. 2025, 489, 142077. [Google Scholar] [CrossRef]

- Zhao, Z.; Ji, C.; Wang, J.; Zhu, L.; Wang, D.; Tošić, N. Investigation of gold mine tailings as supplementary cementitious material: Performance and carbon footprint. J. Cleaner Prod. 2025, 518, 145933. [Google Scholar] [CrossRef]

- Zhang, B.; Muhammad, F.; Yu, T.; Fahimizadeh, M.; Hassan, M.A.S.; Liang, J.; Ning, X.; Yuan, P. Harnessing iron tailings as supplementary cementitious materials in limestone calcined clay cement (LC3): An innovative approach towards sustainable construction. Constr. Build. Mater. 2024, 453, 139111. [Google Scholar] [CrossRef]

- Yao, Z.; Kashani, A.; Rawal, A.; Song, H.; Kim, T. Heat-induced phase transitions in mining tailings to create alternative supplementary cementitious materials. Resour. Conserv. Recycl. 2024, 210, 107818. [Google Scholar] [CrossRef]

- He, Q.; Cao, S.; Yilmaz, E. Characterizing mechanical and multiscale porosity features of cementitious high sulfur tailings backfill using CT technology. Process Saf. Environ. Prot. 2025, 194, 858–872. [Google Scholar] [CrossRef]

- Huang, S.; Pi, Z.; Cai, C.; Li, H. Utilization of high-sulfur iron ore tailings in cement mortar by considering the influence of curing temperature and tailing content. J. Build. Eng. 2023, 74, 106826. [Google Scholar] [CrossRef]

- GB/T 1596–2017; Fly Ash Used for Cement and Concrete. National Standard of the People’s Republic of China: Beijing, China, 2017.

- Gu, X.; Liu, B.; Li, Z.; Wang, H.; Liu, J.; Nehdi, M.L.; Zhang, Y. Mechanical grinding kinetics and particle packing novel characterization of iron ore tailings as inert filler for cement mortar. J. Build. Eng. 2023, 78, 107558. [Google Scholar] [CrossRef]

- Yao, G.; Liu, Q.; Wang, J.; Wu, P.; Lyu, X. Effect of mechanical grinding on pozzolanic activity and hydration properties of siliceous gold ore tailings. J. Cleaner Prod. 2019, 217, 12–21. [Google Scholar] [CrossRef]

- Zhang, H.; Zeng, J.; Ji, Y.; Chen, L. Separation characteristics and magnetic agglomeration behavior in wet low-intensity magnetic separation process: Based on CFD-DEM-FEM. Powder Technol. 2026, 469 Pt 2, 121794. [Google Scholar] [CrossRef]

- Bazin, C.; Sista, R.; Légaré, B.; Caron, J.; Lavoie, F. Investigation of the effect of mineral composition and size on particle separation in wet low and high intensities magnetic separators: An industrial case. Miner. Eng. 2024, 218, 109003. [Google Scholar] [CrossRef]

- Duarte, M.S.; Almada, B.S.; Santos, W.J.D.; Bessa, S.A.L.; da Silva Bezerra, A.C.; Aguilar, M.T.P. Influence of mechanical treatment and magnetic separation on the performance of iron ore tailings as supplementary cementitious material. J. Build. Eng. 2022, 59, 105099. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, T.; Guo, X.-Y.; Tian, Q.-H.; Zhong, S.-P.; Dong, L.; Qin, H.; Liu, Z.-W.; Makuza, B. Sustainable processing of gold cyanide tailings: Reduction roasting, mechanical activation, non-cyanide leaching, and magnetic separation. Hydrometallurgy 2023, 217, 106028. [Google Scholar] [CrossRef]

- Li, Y.; Dang, F.; Zhou, M.; Zhang, Y. Activity characteristics and activation mechanism of molybdenum tailings under mechanical, mechano-thermal, mechano-chemical, and mechano-thermal-chemical activation. Constr. Build. Mater. 2025, 463, 140109. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Z.; Cheng, Z.; Zhang, H. Effects of wet grinding combined with chemical activation on the activity of iron tailings powder. Case Stud. Constr. Mat. 2022, 17, e01385. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). National Standard of the People’s Republic of China: Beijing, China, 2021.

- GB/T 51450-2022; Technology Standard for Backfill Engineering in Metallic and Non-Metallic Mines. National Standard of the People’s Republic of China: Beijing, China, 2022.

- Yoon, J.; Jafari, K.; Tokpatayeva, R.; Peethamparan, S.; Olek, J.; Rajabipour, F. Characterization and quantification of the pozzolanic reactivity of natural and non-conventional pozzolans. Cem. Concr. Compos. 2022, 133, 104708. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.Y.; Wang, W.; Ouyang, D.; Wang, P.; Xing, F. Pozzolanic reactivity of silica fume and ground rice husk ash as reactive silica in a cementitious system: A comparative study. Materials 2016, 9, 146. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Zhou, C.; Ahmad, W.; Usanova, K.I.; Karelina, M.; Mohamed, A.M.; Khallaf, R. Fly ash application as supplementary cementitious material: A review. Materials 2022, 15, 2664. [Google Scholar] [CrossRef]

| Composition | Content | Composition | Content | Composition | Content |

|---|---|---|---|---|---|

| Si | 34.38 | Ti | 0.12 | Bi | <0.005 |

| Fe | 9.36 | Zn | 0.096 | Cd | <0.005 |

| Ca | 6.41 | Pb | 0.089 | Co | <0.005 |

| Al | 6.21 | As | 0.074 | Li | <0.005 |

| K | 3.04 | Ba | 0.070 | Ni | <0.005 |

| S | 1.47 | Sr | 0.042 | Sb | <0.005 |

| Mg | 0.76 | P | 0.028 | Sn | <0.005 |

| C | 0.68 | Cu | 0.014 | V | <0.005 |

| Mn | 0.51 | Cr | 0.0078 | LOI | 4.23 |

| Na | 0.38 | Be | <0.005 |

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2Oeq |

|---|---|---|---|---|---|---|---|

| FA | 55.60 | 28.00 | 5.19 | 4.07 | 1.13 | 0.67 | 3.28 |

| GGBS | 14.76 | 15.99 | 0.34 | 38.77 | 8.31 | 1.37 | 1.43 |

| SF | 92.99 | 0.02 | 0.24 | 0.60 | 0.70 | 0.42 | 1.04 |

| Grade of Cementitious Active Blended Materials | Fineness (Residue on 45 μm Square-Mesh Sieve)/% |

|---|---|

| Grade I | ≤12.0 |

| Grade II | ≤30.0 |

| Grade III | ≤45.0 |

| Sample No. | Tailings Type | Raw Material Mass | |||

|---|---|---|---|---|---|

| Tailings | Reference Cement | Standard Sand | Water | ||

| Mc | None | 0 | 450 | 1350 | 225 |

| M0 | T0 | 135 | 315 | 1350 | 225 |

| M4 | T4 | 135 | 315 | 1350 | 225 |

| M8 | T8 | 135 | 315 | 1350 | 225 |

| M12 | T12 | 135 | 315 | 1350 | 225 |

| M15 | T15 | 135 | 315 | 1350 | 225 |

| M18 | T18 | 135 | 315 | 1350 | 225 |

| M21 | T21 | 135 | 315 | 1350 | 225 |

| M23 | T23 | 135 | 315 | 1350 | 225 |

| M25 | T25 | 135 | 315 | 1350 | 225 |

| Sample No. | Mass Fraction of SO3 | Mass of Sample after Magnetic Separation | Mass Yield |

|---|---|---|---|

| T0-5000H | 3.87% | 348.76 | 70.48% |

| T0-5000L | 2.10% | 146.05 | 29.52% |

| T0-8000H | 4.67% | 273.18 | 55.65% |

| T0-8000L | 1.70% | 217.70 | 44.35% |

| T0-10000H | 4.94% | 321.00 | 54.80% |

| T0-10000L | 1.42% | 264.80 | 45.20% |

| T0-15000H | 5.84% | 264.60 | 45.84% |

| T0-15000L | 1.50% | 312.60 | 54.16% |

| Sample No. | Mass Fraction of SO3 | Mass of Sample after Magnetic Separation | Mass Yield |

|---|---|---|---|

| T0-5000H | 3.90% | 12.4525 kg | 68.78% |

| T0-5000L | 2.10% | 5.6515 kg | 31.22% |

| Sample No. | Tailings Grinding Duration | m1/g | m2/g | Sr/% |

|---|---|---|---|---|

| T0-5000L | 0 min | 30.00 | 24.50 | 81.67% |

| T4-5000L | 4 min | 30.00 | 16.90 | 56.33% |

| T8-5000L | 8 min | 30.00 | 14.30 | 47.67% |

| T12-5000L | 12 min | 30.00 | 10.10 | 33.67% |

| T16-5000L | 16 min | 30.00 | 8.30 | 27.67% |

| T20-5000L | 20 min | 30.00 | 7.80 | 26.00% |

| T24-5000L | 24 min | 30.00 | 6.20 | 20.67% |

| T28-5000L | 28 min | 30.00 | 4.90 | 16.33% |

| T32-5000L | 32 min | 30.00 | 2.70 | 9.00% |

| Sample No. | Tailings Type | Raw Material Mass | |||

|---|---|---|---|---|---|

| Tailings | Reference Cement | Standard Sand | Water | ||

| Mc | / | 0 | 450 | 1350 | 225 |

| M0-5000L | T0-5000L | 135 | 315 | 1350 | 225 |

| M4-5000L | T4-5000L | 135 | 315 | 1350 | 225 |

| M8-5000L | T8-5000L | 135 | 315 | 1350 | 225 |

| M12-5000L | T12-5000L | 135 | 315 | 1350 | 225 |

| M16-5000L | T16-5000L | 135 | 315 | 1350 | 225 |

| M20-5000L | T20-5000L | 135 | 315 | 1350 | 225 |

| M24-5000L | T24-5000L | 135 | 315 | 1350 | 225 |

| M28-5000L | T28-5000L | 135 | 315 | 1350 | 225 |

| M32-5000L | T32-5000L | 135 | 315 | 1350 | 225 |

| Types of Mineral Admixtures | The Minimum Proportion of High-Reactivity Mineral Admixtures |

|---|---|

| FA | 5.67% |

| GGBS | 7.39% |

| SF | 5.23% |

| Sample No. | Highly Active Mineral Admixture | Mass of Other Raw Materials | |||||

|---|---|---|---|---|---|---|---|

| Type | Mass | Proportion | Tailings T12 | Reference Cement | Standard Sand | Water | |

| Mc | / | 0 | / | 0 | 450 | 1350 | 225 |

| M12 | / | 0 | 0% | 135 | 315 | 1350 | 225 |

| M12-FA10 | FA | 10 | 7.41% | 125 | 315 | 1350 | 225 |

| M12-FA15 | FA | 15 | 11.11% | 120 | 315 | 1350 | 225 |

| M12-FA20 | FA | 20 | 14.81% | 115 | 315 | 1350 | 225 |

| M12-FA25 | FA | 25 | 18.52% | 110 | 315 | 1350 | 225 |

| M12-GGBS10 | GGBS | 10 | 7.41% | 125 | 315 | 1350 | 225 |

| M12-GGBS15 | GGBS | 15 | 11.11% | 120 | 315 | 1350 | 225 |

| M12-GGBS20 | GGBS | 20 | 14.81% | 115 | 315 | 1350 | 225 |

| M12-GGBS25 | GGBS | 25 | 18.52% | 110 | 315 | 1350 | 225 |

| M12-SF10 | SF | 10 | 7.41% | 125 | 315 | 1350 | 225 |

| M12-SF15 | SF | 15 | 11.11% | 120 | 315 | 1350 | 225 |

| M12-SF20 | SF | 20 | 14.81% | 115 | 315 | 1350 | 225 |

| M12-SF25 | SF | 25 | 18.52% | 110 | 315 | 1350 | 225 |

| Production process | Wet magnetic separation–mechanical grinding | Mechanical grinding–synergistic modification with highly active mineral admixtures |

| Maximum activity index of the product | The mineral admixture T24–5000L exhibits the highest activity, reaching 74.51%. | The mineral admixture M12–SF20 exhibits the highest activity, reaching 76.35%. |

| Main process equipment | Wet magnetic separator Tailings dewatering filter press Tailings dryer Ball mill | Tailings dewatering filter press Tailings dryer Ball mill Dry-mixing mixer |

| Highly active mineral admixture | None | GGBS or SF |

| Impact on other production processes | High-sulfur tailings produced by wet magnetic separation have higher sulfur content and yield, which can easily affect the quality of mine backfill. | No impact. |

| Tailings utilization rate | Taking mineral admixture T24–5000L as an example, after wet magnetic separation, the yield of low-sulfur tailings available for mineral admixture preparation is only 31.22% (see Table 6). | All tailings can be used 100% for the production of mineral admixtures. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Gong, M.; Li, H.; Guo, L.; Li, Z.; Guo, X.; Yin, Y.; Ren, T. Preparation Process and Performance of Mineral Admixtures Derived from High-Sulfur Lead-Zinc Tailings. Minerals 2025, 15, 1256. https://doi.org/10.3390/min15121256

Li M, Gong M, Li H, Guo L, Li Z, Guo X, Yin Y, Ren T. Preparation Process and Performance of Mineral Admixtures Derived from High-Sulfur Lead-Zinc Tailings. Minerals. 2025; 15(12):1256. https://doi.org/10.3390/min15121256

Chicago/Turabian StyleLi, Mengyuan, Mingshan Gong, Hangkong Li, Lijie Guo, Zhong Li, Xin Guo, Yanying Yin, and Tingting Ren. 2025. "Preparation Process and Performance of Mineral Admixtures Derived from High-Sulfur Lead-Zinc Tailings" Minerals 15, no. 12: 1256. https://doi.org/10.3390/min15121256

APA StyleLi, M., Gong, M., Li, H., Guo, L., Li, Z., Guo, X., Yin, Y., & Ren, T. (2025). Preparation Process and Performance of Mineral Admixtures Derived from High-Sulfur Lead-Zinc Tailings. Minerals, 15(12), 1256. https://doi.org/10.3390/min15121256