Experimental Study on the True Triaxial Unloading Mechanical Properties of Cement Tailings Backfill Under Different Intermediate Principal Stresses

Abstract

1. Introduction

2. Materials and Methods

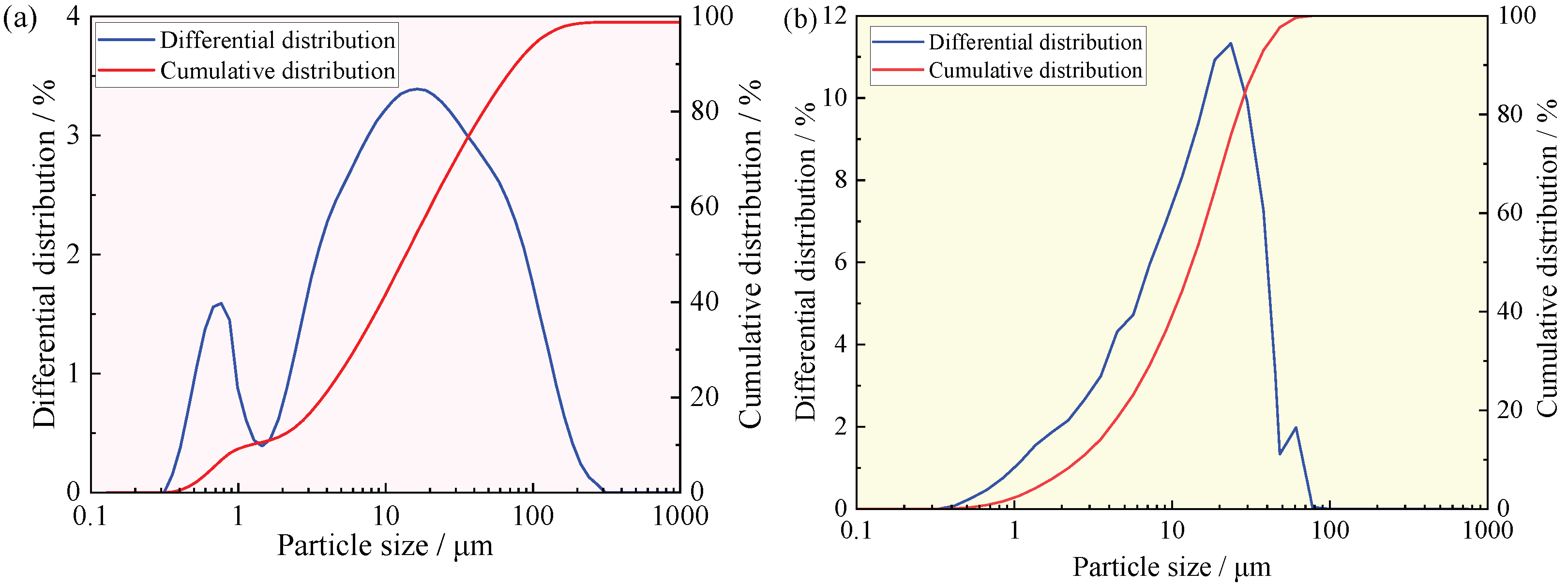

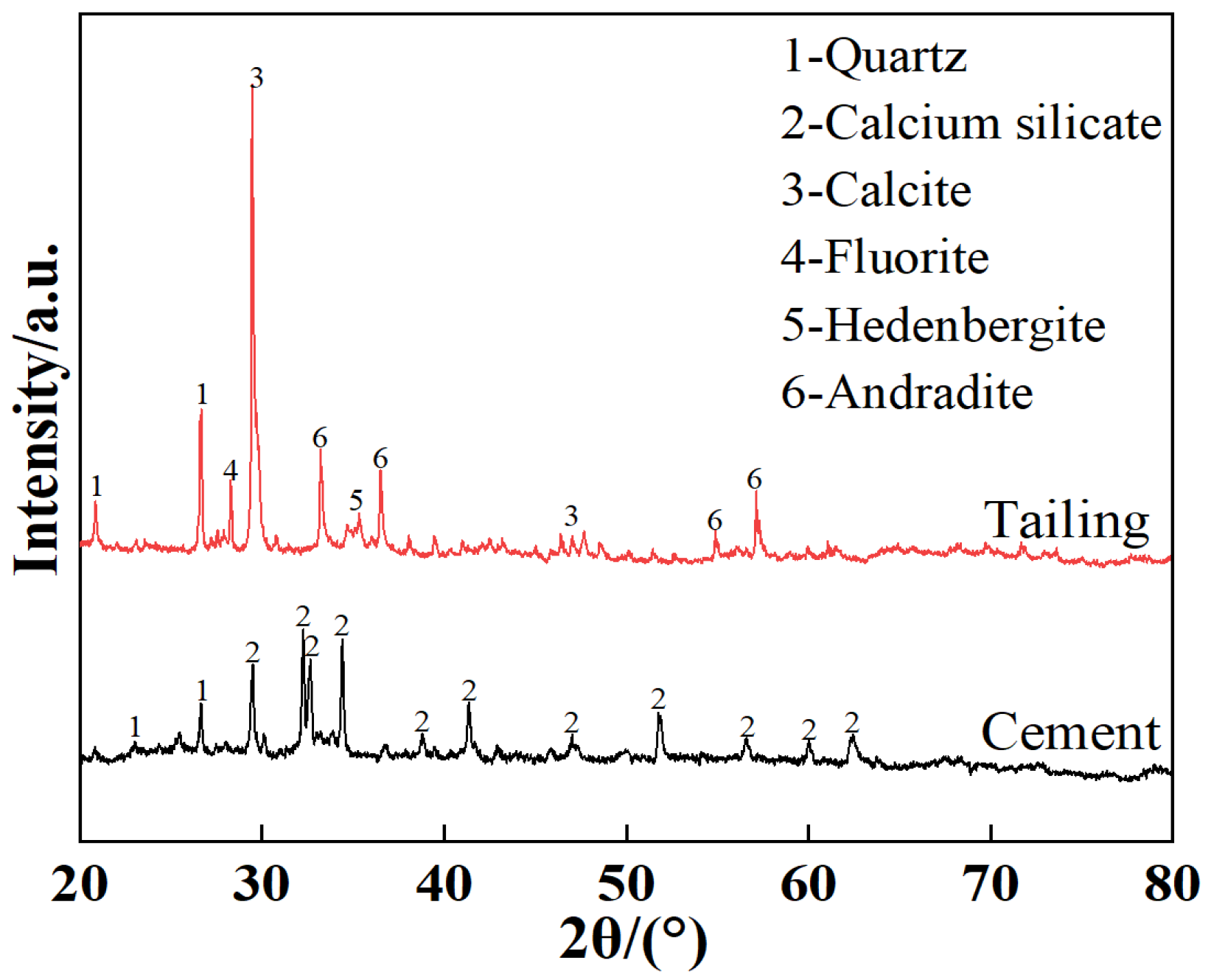

2.1. Materials

2.2. Specimens Preparation

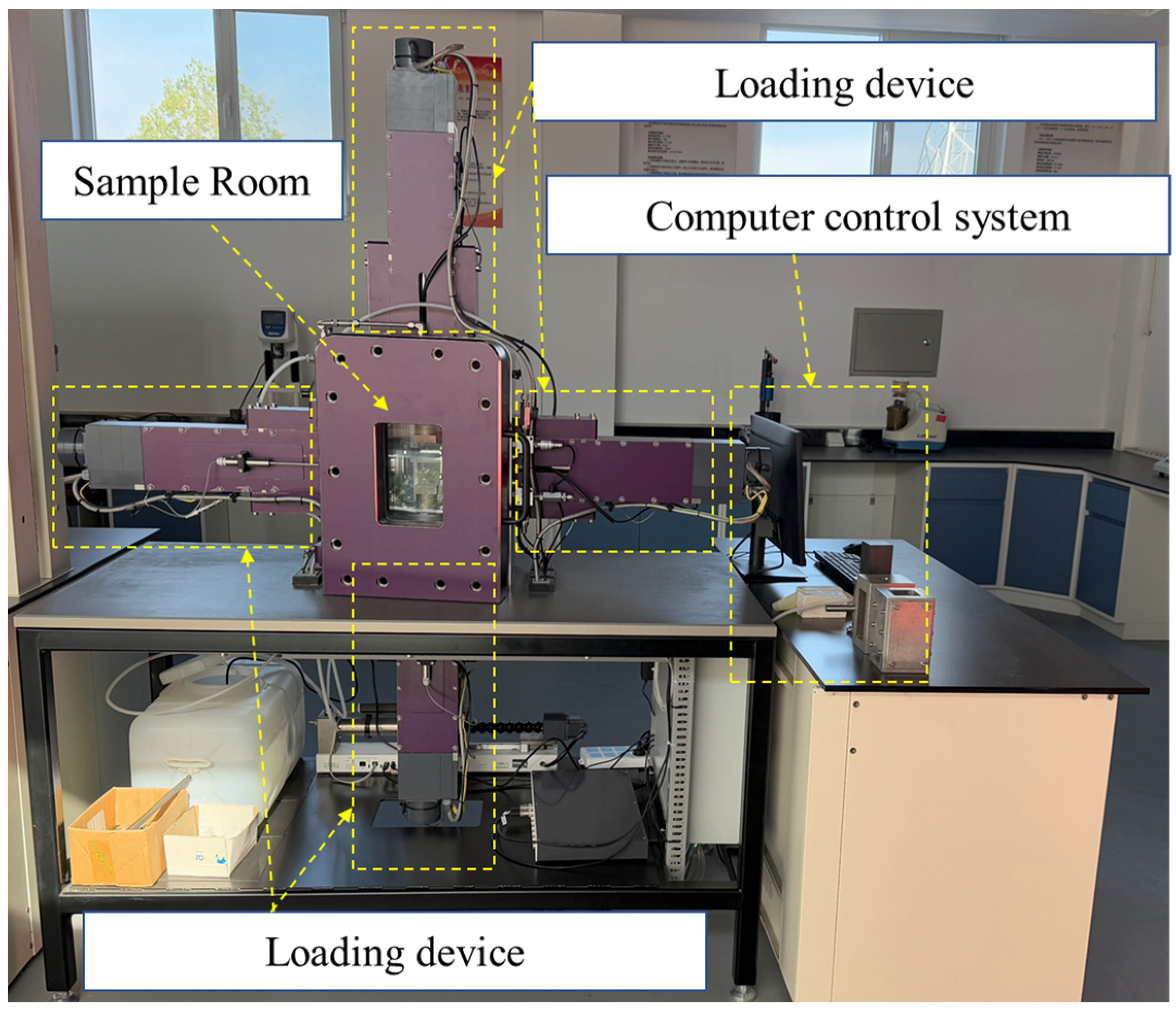

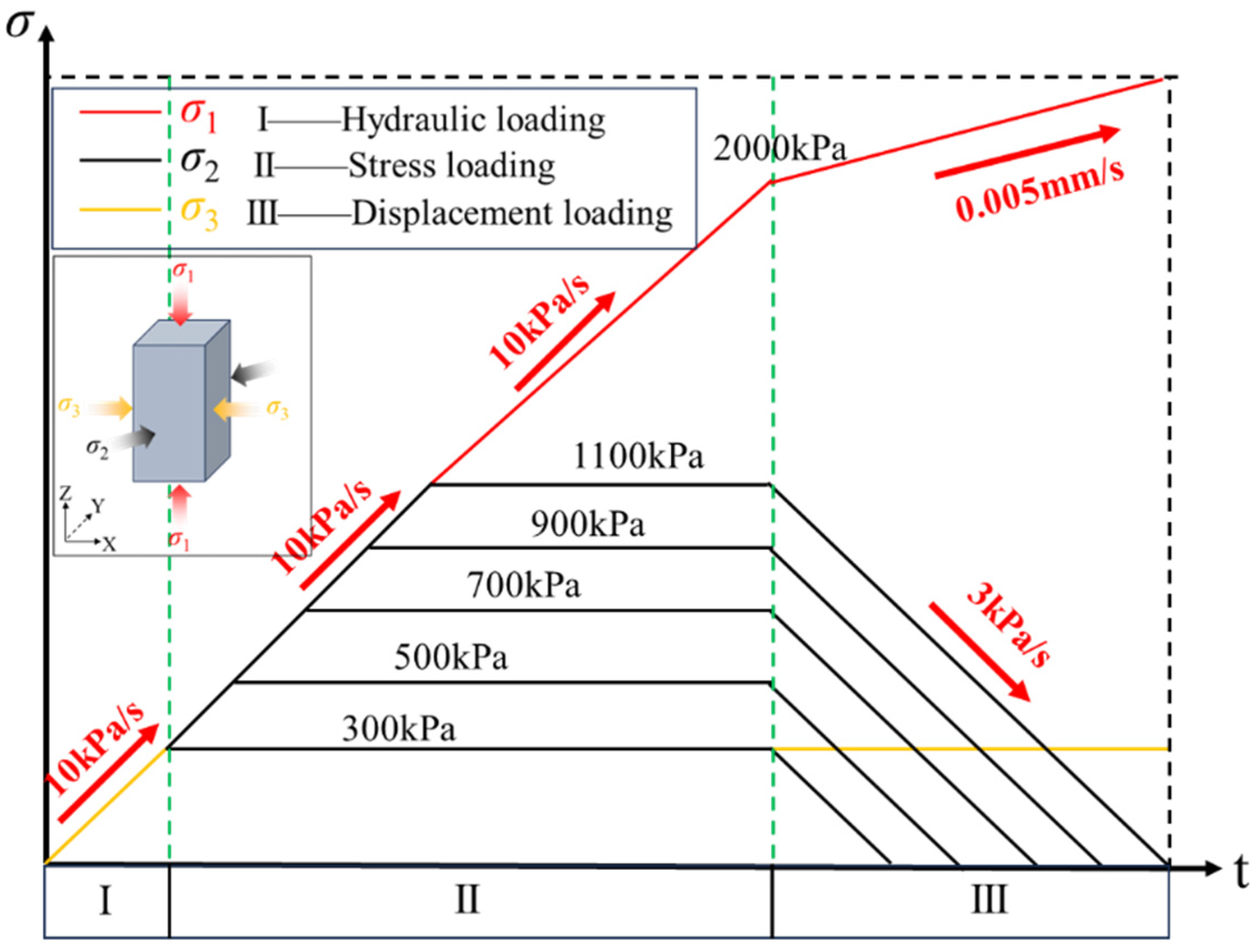

2.3. Testing Equipment

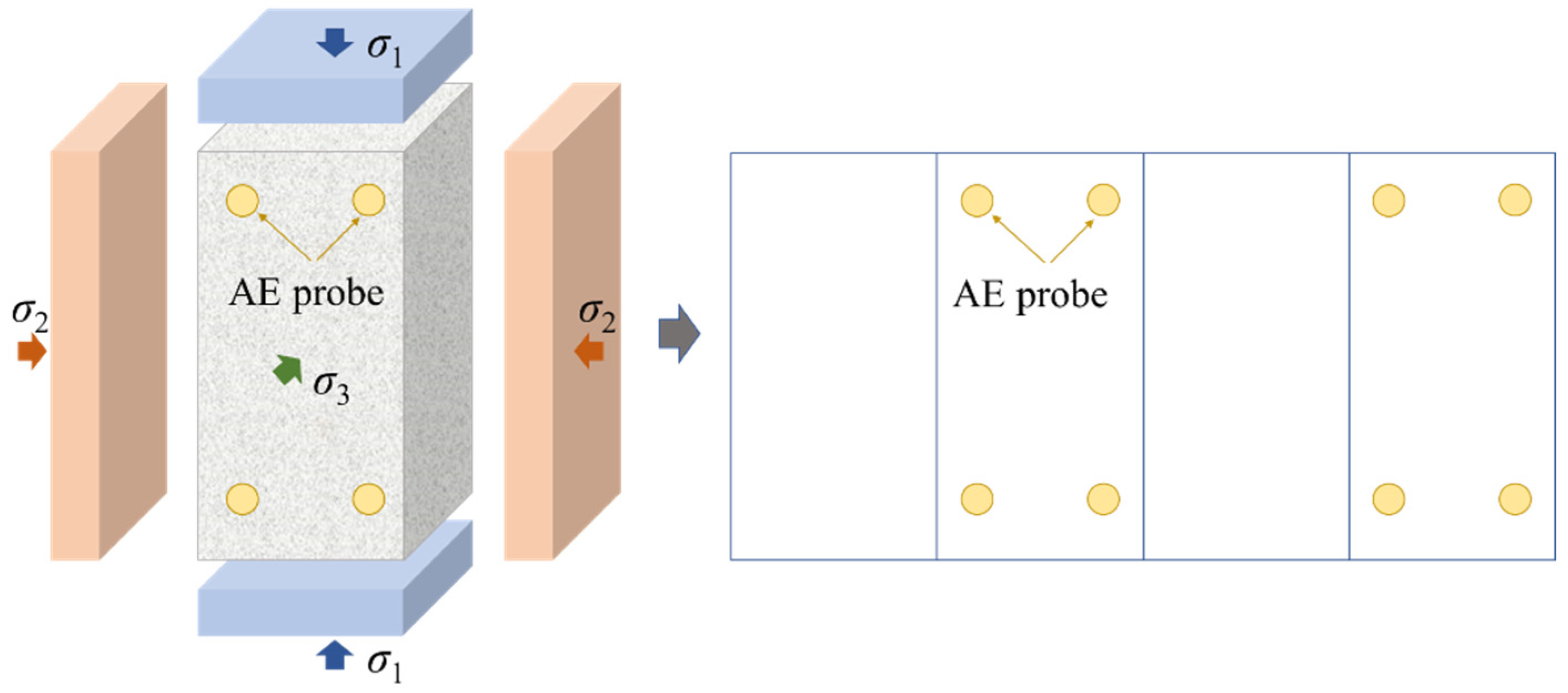

2.4. Acoustic Emission Monitoring

3. Results and Discussion

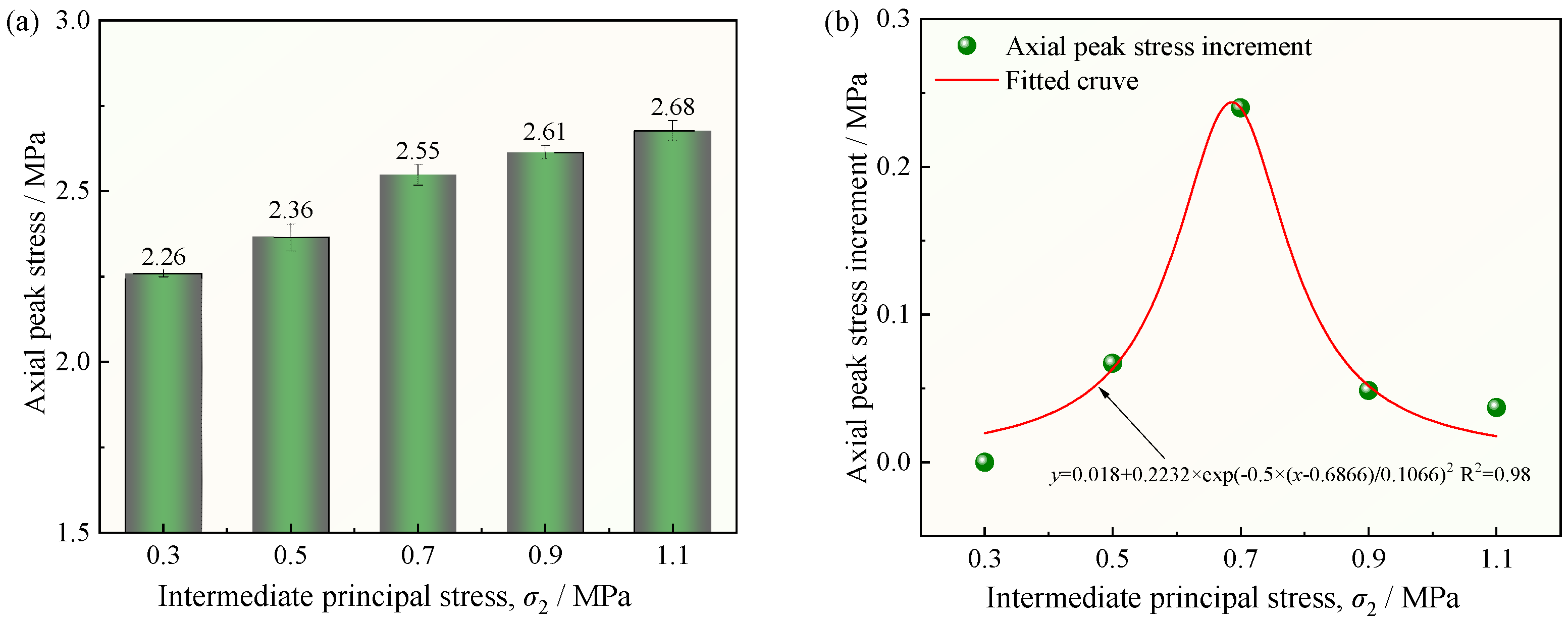

3.1. True Triaxial Unloading Strength Characteristics

3.2. Deformation Characteristics Under True Triaxial Unloading Conditions

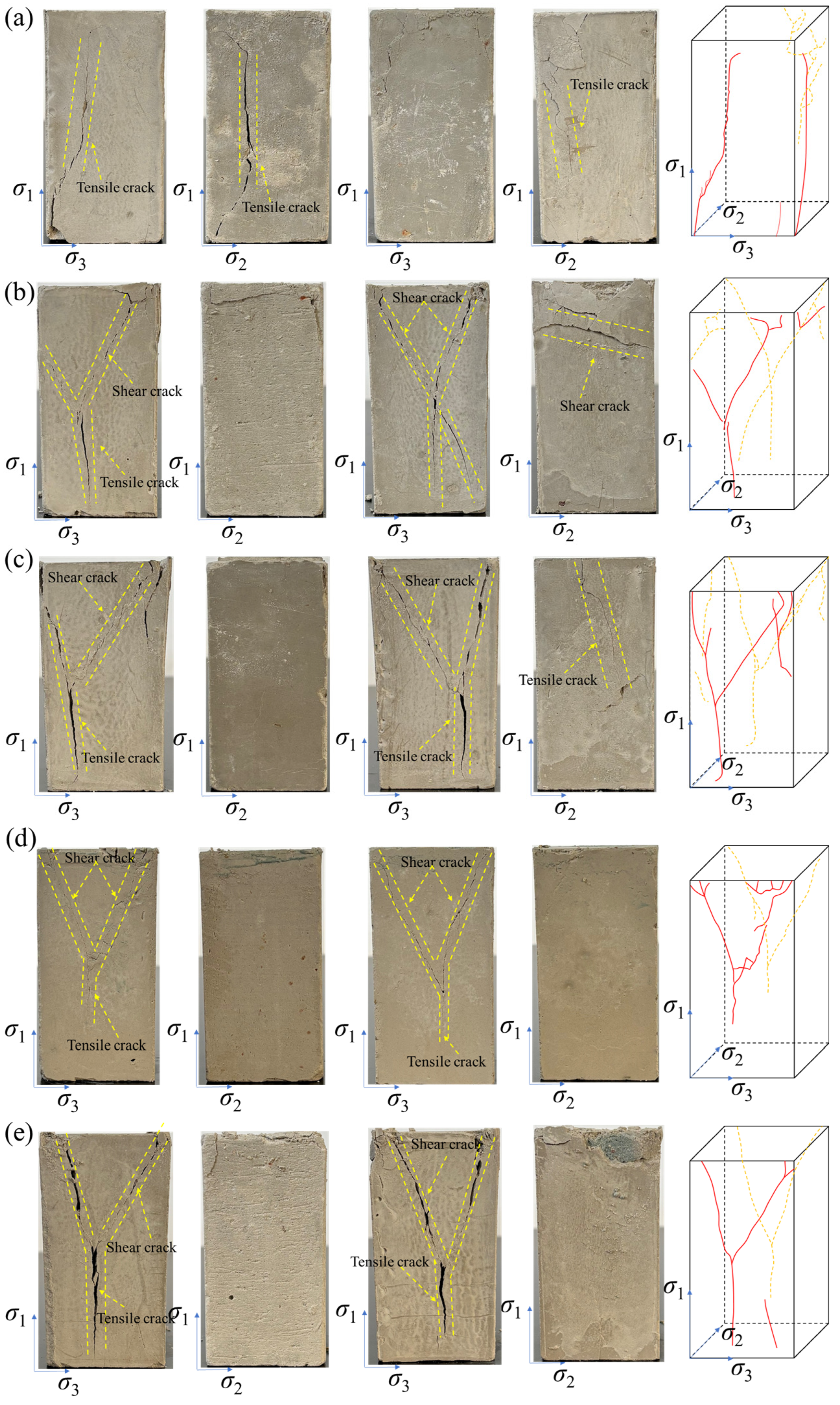

3.3. Failure Mode Analysis

3.4. Acoustic Emission Results Analysis

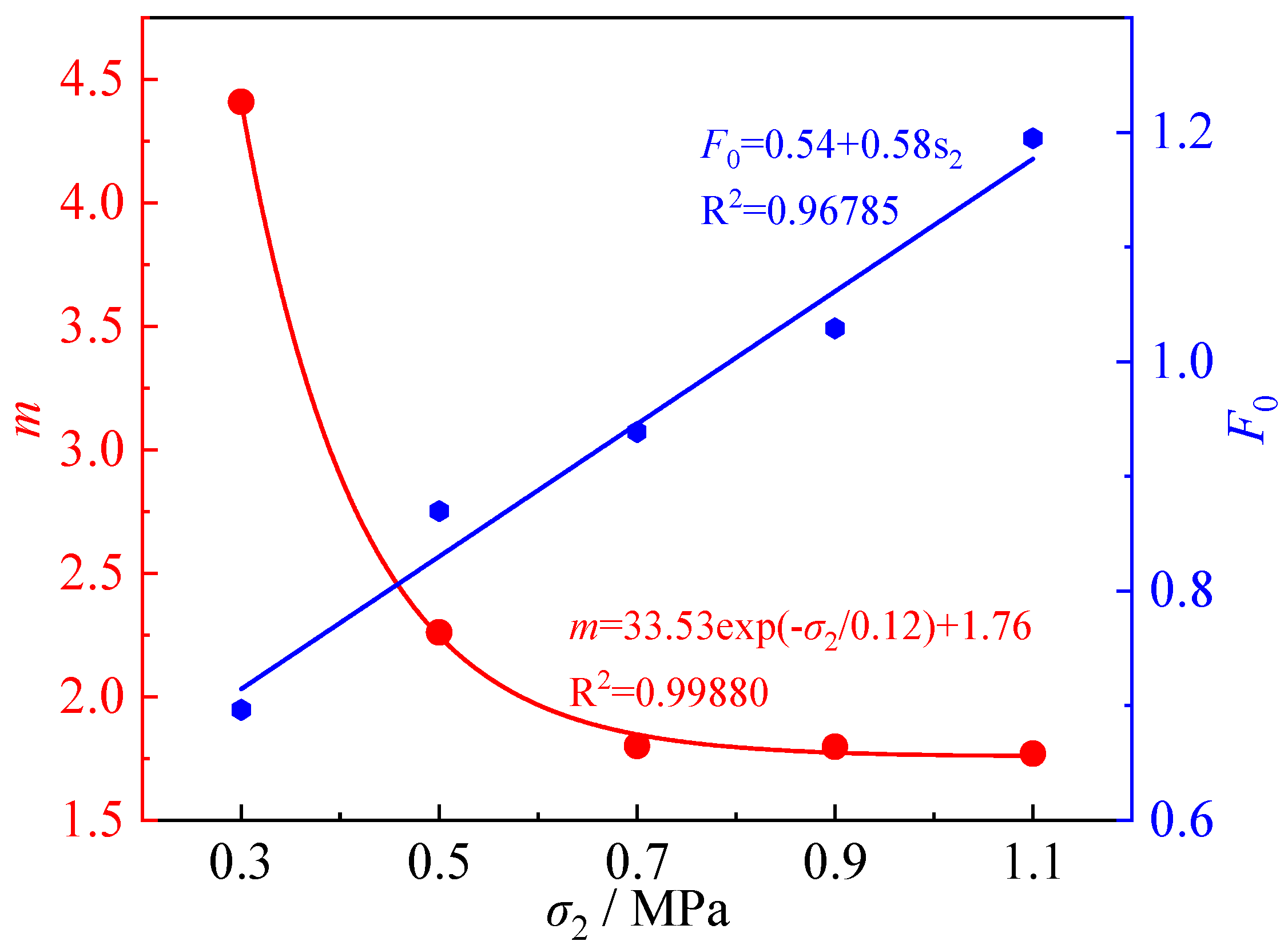

3.5. Constitutive Equation

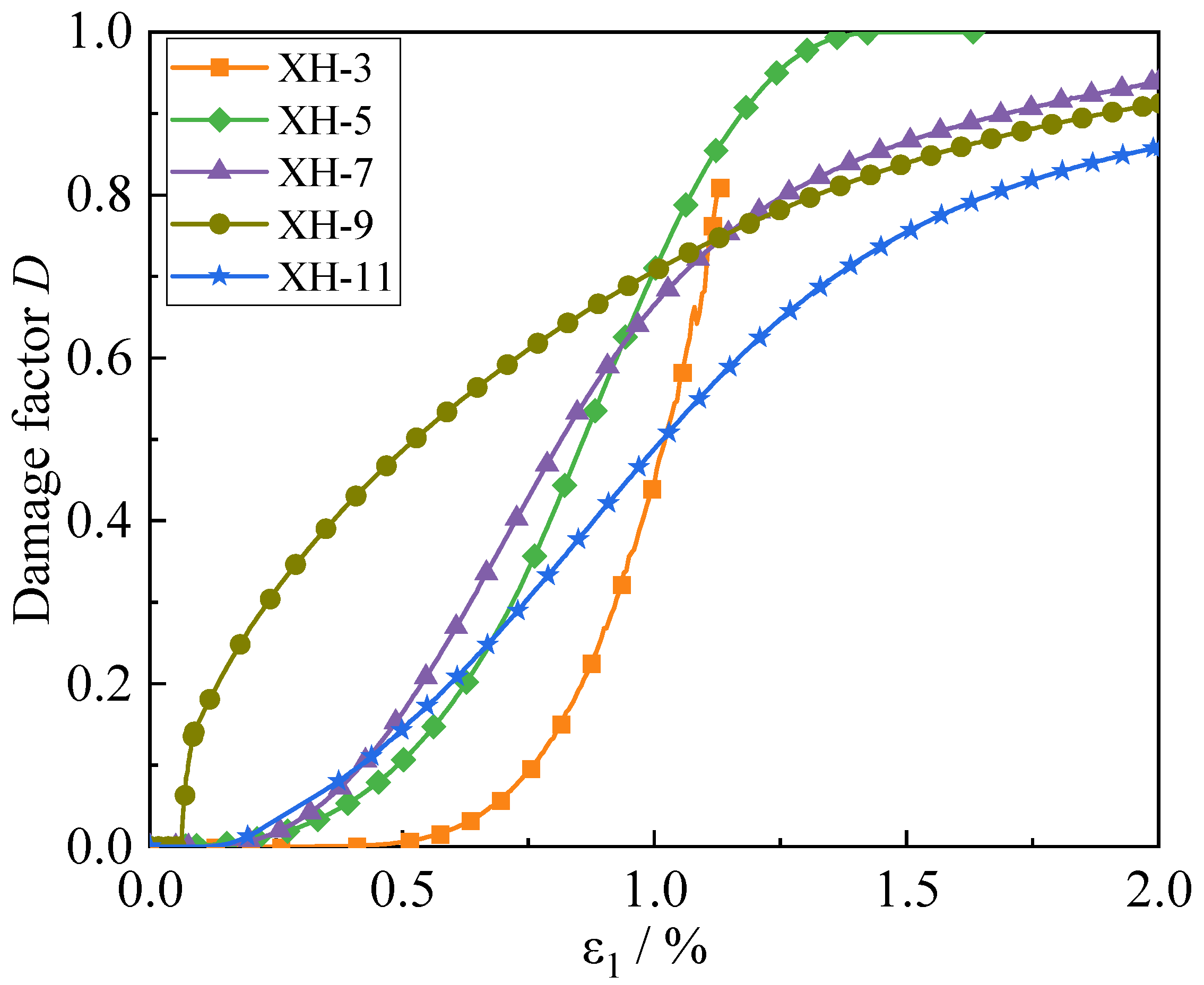

3.5.1. Damage Theory and Model Parameters

3.5.2. Damage Models and Validation

3.5.3. Model Calibration, Uncertainty, and Parametric Behavior

3.6. Limitations and Scope for Generalization

4. Conclusions

- (1)

- Under unloading conditions, σ2 is the key factor enhancing the CTB’s load-bearing capacity and deformability. The peak strain and peak stress increase nonlinearly with σ2, resulting from the combined effects of the strengthening and damage mechanisms. The increment in unloading strength first rises and then decreases with σ2, with 700 kPa identified as the critical intermediate principal stress.

- (2)

- The intermediate principal stress σ2 is the key factor governing the pre-peak deformation capacity and post-peak failure behavior of CTB. As σ2 increases, the peak strain exhibits nonlinear growth, the post-peak stress drop slows, and the material transitions from brittle to ductile behavior. The instantaneous reduction in axial stress at the unloading point strongly depends on the initial stress state. Under conventional triaxial isotropic conditions (σ2 = σ3), unloading induces severe stress redistribution, causing an abrupt drop in axial stress. In contrast, under true triaxial anisotropic conditions (σ2 > σ3), the stress adjustment occurs more gradually, and the axial stress drop is significantly reduced.

- (3)

- The CTB failure mode is closely related to the magnitude of σ2 and the unloading path. When σ2 = σ3, tensile cracks dominate, while at σ2 > σ3, failure is characterized by a combination of tensile and shear cracks. Regarding crack distribution, cracks primarily occur in the σ1-σ3 plane. As σ2 increases, cracks in the σ1-σ2 plane diminish, resulting in more localized and directional failure.

- (4)

- AE ringing count of CTB under different σ2 unloading paths exhibits three distinct stages: quiescent, rising, and active. The cumulative ring count shows a stepwise growth pattern. As the σ2 level increases, AE events occur earlier and at higher frequencies, and the cumulative ringing count transitions from a regular stepwise platform to an inclined stepwise pattern. This reflects that greater σ2 accelerates crack initiation and development, advancing the transition from brittle to ductile failure.

- (5)

- By introducing the damage factor D, a damage constitutive model for CTB under a true triaxial unloading path with different σ2 levels was established. Model validation against laboratory data shows excellent agreement with theoretical curves, confirming the model’s reliability and applicability.

- (6)

- This study distinguishes itself from existing granular micromechanics approaches (e.g., Poorsolhjouy et al. [30], which focused on thermo-mechanical simulation and micro-scale force evolution under loading paths) by providing direct experimental evidence and a macroscopic damage constitutive model for the failure behavior of CTB under true triaxial unloading conditions. Theoretically, the established model, which incorporates the intermediate principal stress effect through a damage variable, offers a practical and validated tool for predicting the nonlinear strength and damage evolution of backfill, bridging a gap between micromechanical theories and engineering-scale material behavior. Practically, the findings and the model provide a crucial basis for assessing the stability of backfill structures in deep mining, where excavation-induced unloading is a dominant stress path, thereby guiding safer and more efficient backfill design.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kaiser, P.K.; Yazici, S.; Maloney, S. Mining-induced stress change and consequences of stress path on excavation stability—A case study. Int. J. Rock Mech. Min. Sci. 2001, 38, 167–180. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Chen, Y.; Jia, M.; Zhang, M.; Li, R. Synergetic mining of geothermal energy in deep mines: An innovative method for heat hazard control. Appl. Therm. Eng. 2022, 210, 118398. [Google Scholar] [CrossRef]

- Jiang, M.; Cao, S.; Yilmaz, E. Exploring microstructure and mechanical features of coupled cementitious tail-sand concrete by partial replacement of tungsten tailings. Process Saf. Environ. Prot. 2024, 190, 863–875. [Google Scholar] [CrossRef]

- Deng, H.; Xiao, Y. Experimentation of Heat-Insulating Materials for Surrounding Rocks in Deep Mines and Simulation Study of Temperature Reduction. Minerals 2024, 14, 938. [Google Scholar] [CrossRef]

- Cai, M.; Brown, E.T. Challenges in the Mining and Utilization of Deep Mineral Resources. Engineering 2017, 3, 432–433. [Google Scholar] [CrossRef]

- Hou, Z.; Xiao, F.; Liu, G.; Bashkov, O.V.; Lyu, L. Mechanical Properties and Acoustic Emission Characteristics of Unloading Instability of Sandstone under High Stress. Minerals 2022, 12, 722. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W.; Zhang, Y.; Wang, Y. Mechanical behavior, acoustic emission properties and damage evolution of cemented paste backfill considering structural feature. Constr. Build. Mater. 2020, 261, 119958. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Lu, G.; Fall, M.; Cui, L. A multiphysics-viscoplastic cap model for simulating blast response of cemented tailings backfill. J. Rock Mech. Geotech. Eng. 2017, 9, 551–564. [Google Scholar] [CrossRef]

- Qi, W.; Zhang, J.; Zhou, N.; Wu, Z.; Zhang, J. Mechanism by which backfill body reduces amount of energy released in deep coal mining. Shock. Vib. 2019, 2019, 8253269. [Google Scholar] [CrossRef]

- Tan, Y.; Yang, J.; Deng, Y.; Kou, Y.; Li, Y.; Song, W. Research on the Long-Term Mechanical Behavior and Constitutive Model of Cemented Tailings Backfill Under Dynamic Triaxial Loading. Minerals 2025, 15, 276. [Google Scholar] [CrossRef]

- Haimson, B.; Chang, C. A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite. Int. J. Rock Mech. Min. Sci. 2000, 37, 285–296. [Google Scholar] [CrossRef]

- Li, X.; Feng, F.; Li, D.; Du, K.; Ranjith, P.G.; Rostami, J. Failure Characteristics of Granite Influenced by Sample Height-to-Width Ratios and Intermediate Principal Stress Under True-Triaxial Unloading Conditions. Rock Mech. Rock Eng. 2018, 51, 1321–1345. [Google Scholar] [CrossRef]

- Singh, M.; Raj, A.; Singh, B. Modified Mohr–Coulomb criterion for non-linear triaxial and polyaxial strength of intact rocks. Int. J. Rock Mech. Min. Sci. 2011, 48, 546–555. [Google Scholar] [CrossRef]

- Feng, X.-T.; Zhang, X.; Kong, R.; Wang, G. A Novel Mogi Type True Triaxial Testing Apparatus and Its Use to Obtain Complete Stress–Strain Curves of Hard Rocks. Rock Mech. Rock Eng. 2016, 49, 1649–1662. [Google Scholar] [CrossRef]

- Li, K.; Du, G.; Han, D.; Yin, Z.; Li, J.; Lin, H. Mechanical and acoustic emission characteristics of anisotropic rock subjected to tiered cyclic intermediate principal stress. Eng. Geol. 2025, 358, 108403. [Google Scholar] [CrossRef]

- Alam, M.F.; Balaji, V.; Tucci, F.; Krishnaswamy, H.; Chakkingal, U. A critical evaluation of shear specimen geometry for accurate stress triaxiality control. Eng. Fract. Mech. 2025, 328, 111562. [Google Scholar] [CrossRef]

- Zhang, H.; Ma, Q.; Yang, Z.J.; Huang, K.; Ma, D.; Yao, Z.; Wang, Z.; Liu, F. Stress-Strain Behavior and Strength Criterion of Frozen Silty Clay under Varying Intermediate Principal Stresses. Cold Reg. Sci. Technol. 2025, 240, 104653. [Google Scholar] [CrossRef]

- Lee, H.; Haimson, B.C. True triaxial strength, deformability, and brittle failure of granodiorite from the San Andreas Fault Observatory at Depth. Int. J. Rock Mech. Min. Sci. 2011, 48, 1199–1207. [Google Scholar] [CrossRef]

- Feng, X.-T.; Gao, Y.; Zhang, X.; Wang, Z.; Zhang, Y.; Han, Q. Evolution of the mechanical and strength parameters of hard rocks in the true triaxial cyclic loading and unloading tests. Int. J. Rock Mech. Min. Sci. 2020, 131, 104349. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, J.; Deng, Z.; Yang, H.; Mei, J.; Huang, J. Experimental and modelling investigation of stress-strain behavior of basalt fiber-reinforced coral aggregate concrete under uniaxial and triaxial compression. Constr. Build. Mater. 2025, 496, 143856. [Google Scholar] [CrossRef]

- Wang, B.; He, B.-G.; Shang, J.; Zhu, Z.; Yu, H.; Lei, X. Failure mechanism of deep TBM tunnels subjected to dynamic disturbance under true triaxial unloading stress path. Int. J. Rock Mech. Min. Sci. 2025, 191, 106128. [Google Scholar] [CrossRef]

- Gao, L.; Zhao, H.; Liu, C. Study on the influence of true triaxial principal stress loading and unloading on gas permeability characteristics of coal seams containing gangue. Results Eng. 2025, 27, 105667. [Google Scholar] [CrossRef]

- Cheng, G.; Liu, X.; Chen, J.; Zhang, N.; Li, Y. True triaxial test study on triggering mechanisms of structure-type rockbursts using low-strength and high-brittleness materials under unloading and dynamic disturbance. Eng. Fail. Anal. 2025, 182, 110062. [Google Scholar] [CrossRef]

- Que, X.; Zhu, S.; Zhu, Z.; Zhang, J.; Niu, Z. Numerical modeling of columnar jointed basalt with a dual irregular joint network and its unloading response under true triaxial conditions. Comput. Geotech. 2025, 189, 107660. [Google Scholar] [CrossRef]

- Mogi, K. Effect of the intermediate principal stress on rock failure. J. Geophys. Res. 1967, 72, 5117–5131. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.; Wang, Y.; Huang, W.; Han, Z. Cracking mechanism and strength criteria evaluation of granite affected by intermediate principal stresses subjected to unloading stress state. Int. J. Rock Mech. Min. Sci. 2021, 143, 104783. [Google Scholar] [CrossRef]

- Feng, F.; Xie, Z.; Chen, S.; Li, D.; Peng, S.; Zhang, T. True triaxial unloading test on the mechanical behaviors of sandstone: Effects of the intermediate principal stress and structural plane. J. Rock Mech. Geotech. Eng. 2025, 17, 2208–2226. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, G.; Xu, W.; Meng, X.; Liu, Z.; Cheng, X.; Lin, G. Experimental study on failure characteristics of single-sided unloading rock under different intermediate principal stress conditions. Int. J. Min. Sci. Technol. 2023, 33, 275–287. [Google Scholar] [CrossRef]

- Poorsolhjouy, P.; Misra, A. Effect of intermediate principal stress and loading-path on failure of cementitious materials using granular micromechanics. Int. J. Solids Struct. 2017, 108, 139–152. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.; Han, Z.; Golsanami, N.; Liang, P.; Xie, Z. Influence of moisture content and intermediate principal stress on cracking behavior of sandstone subjected to true triaxial unloading conditions. Eng. Fract. Mech. 2023, 284, 109265. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J.M. Advances in understanding hydration of Portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Li, X.F.; Li, J.J.; Kou, Y.P.; Song, W.D. Analysis of true triaxial mechanical behavior and energy dissipation of backfill under different unloading rates. Chin. J. Eng. 2025, 47, 1387–1397. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, G.; Wang, Z.; Liu, D. Fracture Evolution Analysis of Rock Bridges in Hard Rock with Nonparallel Joints in True Triaxial Stress States. Rock Mech. Rock Eng. 2023, 56, 997–1023. [Google Scholar] [CrossRef]

- You, M. True-triaxial strength criteria for rock. Int. J. Rock Mech. Min. Sci. 2009, 46, 115–127. [Google Scholar] [CrossRef]

- Mehranpour, M.H.; Kulatilake, P.H.S.W. Comparison of six major intact rock failure criteria using a particle flow approach under true-triaxial stress condition. Geomechancie Geophys. Geo-Energy Geo-Resour. 2016, 2, 203–229. [Google Scholar] [CrossRef]

- Yu, X.; Kemeny, J.; Tan, Y.; Song, W.; Huang, K. Mechanical properties and fracturing of rock-backfill composite specimens under triaxial compression. Constr. Build. Mater. 2021, 304, 124577. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, D.; Tian, Y.; Liu, X. Numerical simulation of stress-strain behaviour of cemented paste backfill in triaxial compression. Eng. Geol. 2017, 231, 165–175. [Google Scholar] [CrossRef]

- Shi, Y.; Xu, F.; Song, X.; Wang, G.; Zuo, Y.; Li, X.; Ji, J. Rock damage evolution in the production process of the enhanced geothermal systems considering thermal-hydrological-mechanical and damage (THM-D). Energy 2023, 285, 129421. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Song, W.; Fu, J. Pore structure, mechanical behavior and damage evolution of cemented paste backfill. J. Mater. Res. Technol. 2022, 17, 2864–2874. [Google Scholar] [CrossRef]

- Zhao, L. Numerical investigation on the mechanical behaviour of combined backfill-rock structure with KCC model. Constr. Build. Mater. 2021, 283, 122782. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | CaO | Fe2O3 | K2O | SO3 | Others | |

|---|---|---|---|---|---|---|---|

| Tailings | 61.75 | 12.69 | 9.18 | 5.95 | 4.44 | 0.25 | 5.74 |

| Cement | 24.13 | 8.96 | 52.65 | 4.36 | 1.84 | 2.64 | 5.42 |

| ID | Initial σ1/MPa | σ2/kPa | σ3/kPa | Unloading Rate/kPa·s−1 |

|---|---|---|---|---|

| XH-3 | 2.0 | 300 → 0 | 300 | 3 |

| XH-5 | 2.0 | 500 → 0 | 300 | 3 |

| XH-7 | 2.0 | 700 → 0 | 300 | 3 |

| XH-9 | 2.0 | 900 → 0 | 300 | 3 |

| XH-11 | 2.0 | 1100 → 0 | 300 | 3 |

| ID | E (MPa) | σ1,f (MPa) | ε1,f (%) | m | F0 |

|---|---|---|---|---|---|

| XH-3 | 268.57 | 2.26 | 0.85 | 4.41 ± 0.15 | 0.697 ± 0.022 |

| XH-5 | 358.35 | 2.33 | 0.70 | 2.26 ± 0.09 | 0.870 ± 0.018 |

| XH-7 | 452.34 | 2.57 | 0.64 | 1.80 ± 0.07 | 0.939 ± 0.015 |

| XH-9 | 691.85 | 2.62 | 0.89 | 1.80 ± 0.08 | 1.029 ± 0.020 |

| XH-11 | 334.60 | 2.66 | 0.83 | 1.77 ± 0.06 | 1.195 ± 0.025 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Li, J.; Kou, Y.; Song, W. Experimental Study on the True Triaxial Unloading Mechanical Properties of Cement Tailings Backfill Under Different Intermediate Principal Stresses. Minerals 2025, 15, 1227. https://doi.org/10.3390/min15111227

Li Q, Li J, Kou Y, Song W. Experimental Study on the True Triaxial Unloading Mechanical Properties of Cement Tailings Backfill Under Different Intermediate Principal Stresses. Minerals. 2025; 15(11):1227. https://doi.org/10.3390/min15111227

Chicago/Turabian StyleLi, Qiang, Jiajian Li, Yunpeng Kou, and Weidong Song. 2025. "Experimental Study on the True Triaxial Unloading Mechanical Properties of Cement Tailings Backfill Under Different Intermediate Principal Stresses" Minerals 15, no. 11: 1227. https://doi.org/10.3390/min15111227

APA StyleLi, Q., Li, J., Kou, Y., & Song, W. (2025). Experimental Study on the True Triaxial Unloading Mechanical Properties of Cement Tailings Backfill Under Different Intermediate Principal Stresses. Minerals, 15(11), 1227. https://doi.org/10.3390/min15111227