Forensic Investigation of the Seepage-Induced Flow Failure at La Luciana Tailings Storage Facility (1960 Spain)

Abstract

1. Introduction

Objectives and Motivation

- Scientific motivation—to demonstrate how an evidence-based forensic approach, rather than a traditional back-analysis, can reconstruct historical TSF failures under uncertainty, identifying the relative contribution of stratigraphic heterogeneity, saturation, and construction method to the onset of instability.

- Practical motivation—to extract technical lessons relevant for present-day tailings management, particularly regarding pond position control, drainage performance, and early-warning interpretation in legacy or partially documented facilities.

- To compile and interpret available historical, field and laboratory data to characterize the materials and depositional zones of the La Luciana TSF.

- To define a simplified but representative zonation model integrating the dam, discharge, transition, and pond areas.

- To perform a steady-state stability and seepage analysis under reconstructed boundary conditions, identifying the combination of factors leading to critical stability.

- To propose a forensic reconstruction of the failure mechanism consistent with field evidence, describing the sequence as a cascading (domino-effect) failure event.

- To highlight operational and methodological implications for the evaluation and management of similar upstream-raised TSFs.

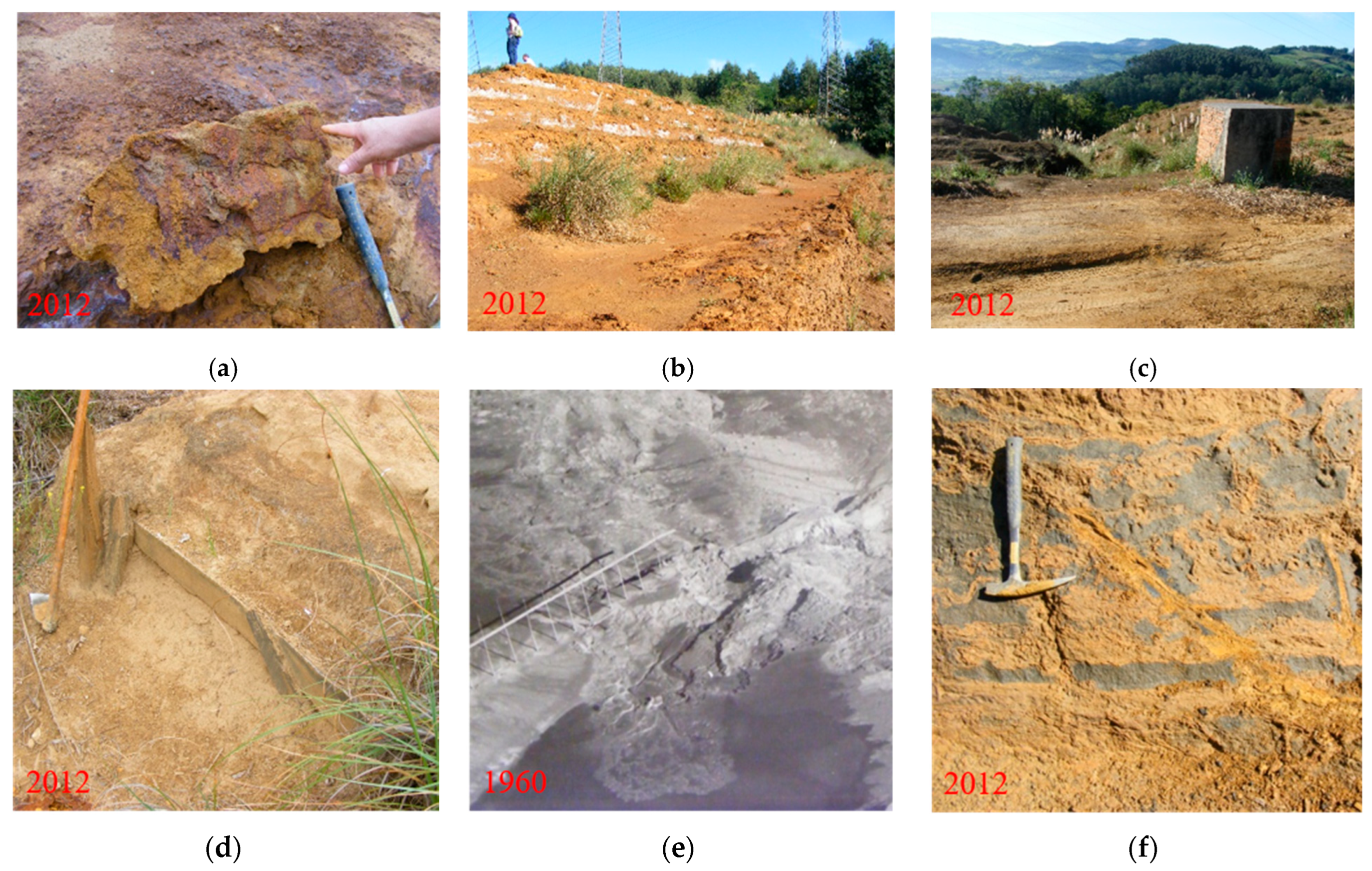

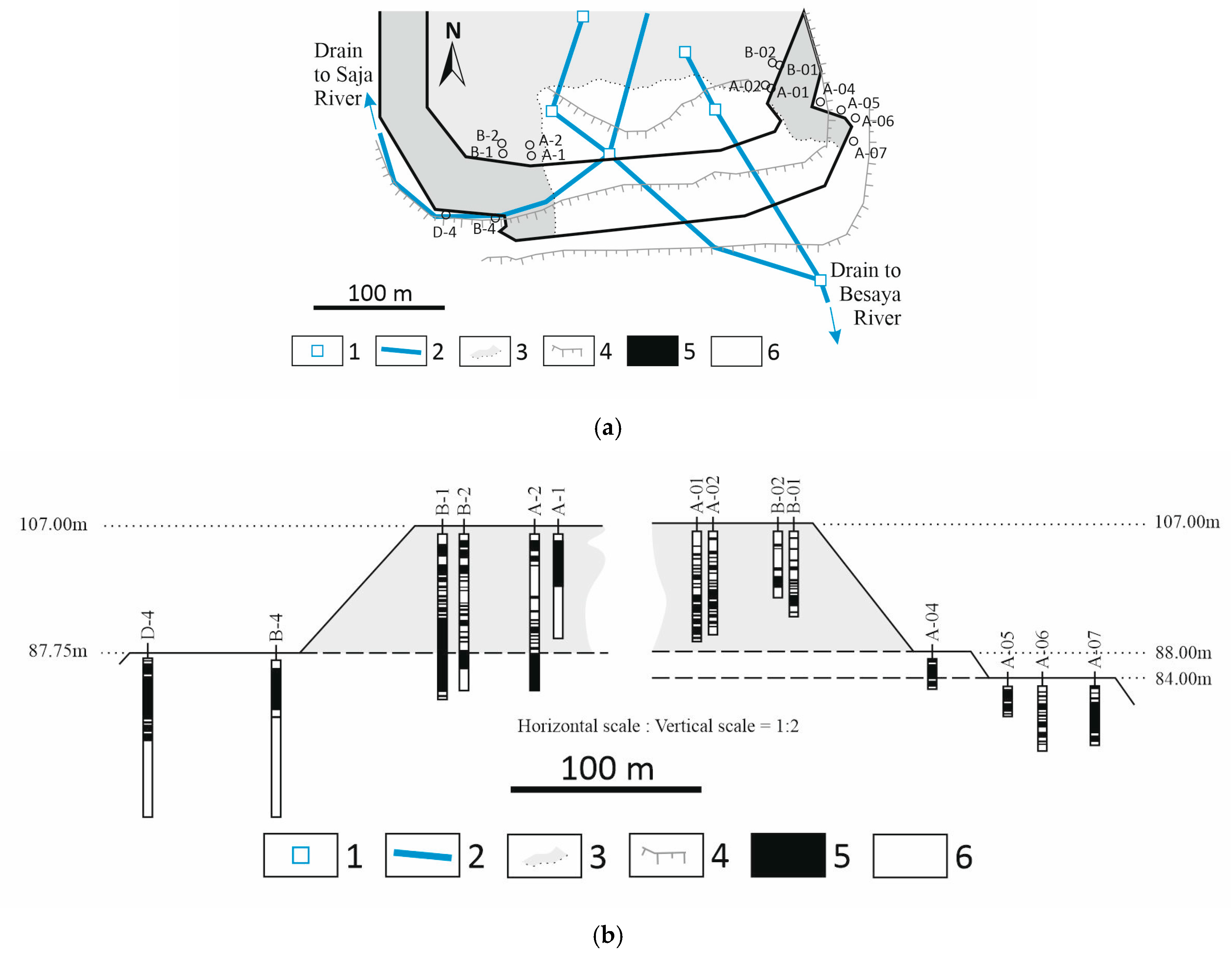

2. Main Characteristics of the La Luciana TSF

2.1. Case of Study: La Luciana TSF Failure

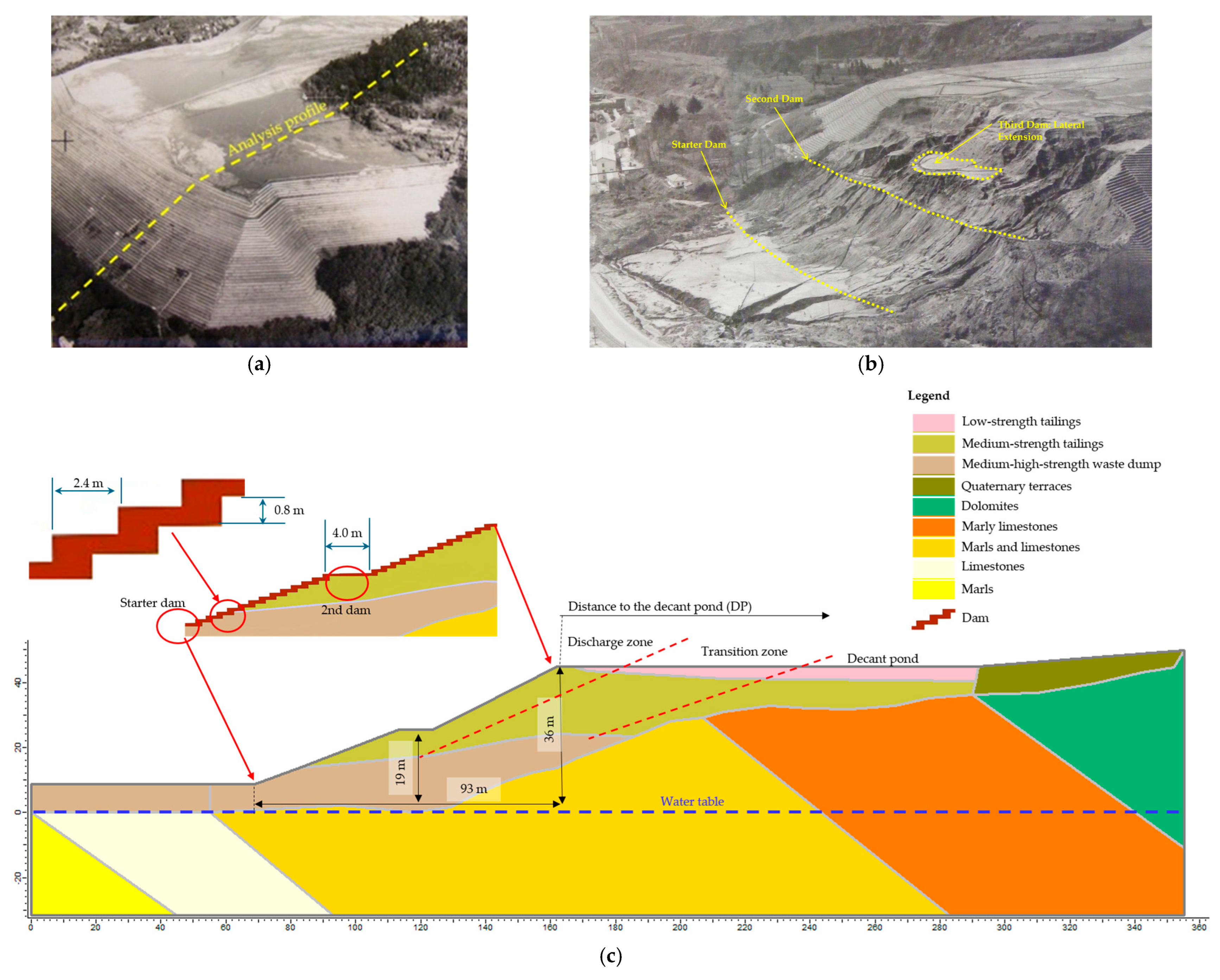

2.2. Construction Method

2.3. The Drainage System

2.4. The Decant System

2.5. The Geological Background

2.6. Hypothesis of the Cause of the Flow Failure of the La Luciana TSF

3. Materials and Methods

3.1. Geotechnical Characterization of Tailings

3.2. Measurement of Internal Friction Angle and Cohesion

3.3. Hydraulic Characterization of Tailings

4. Results

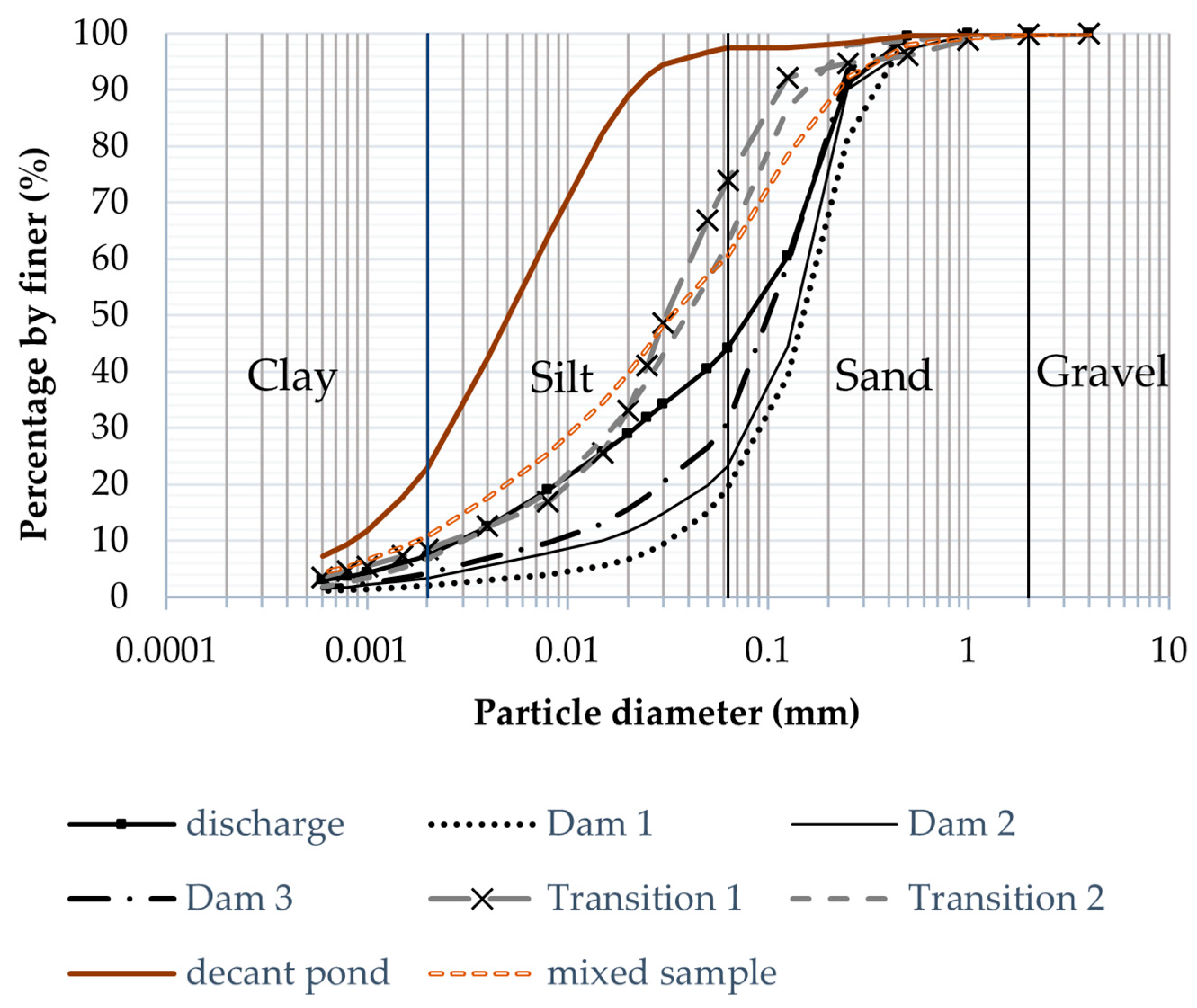

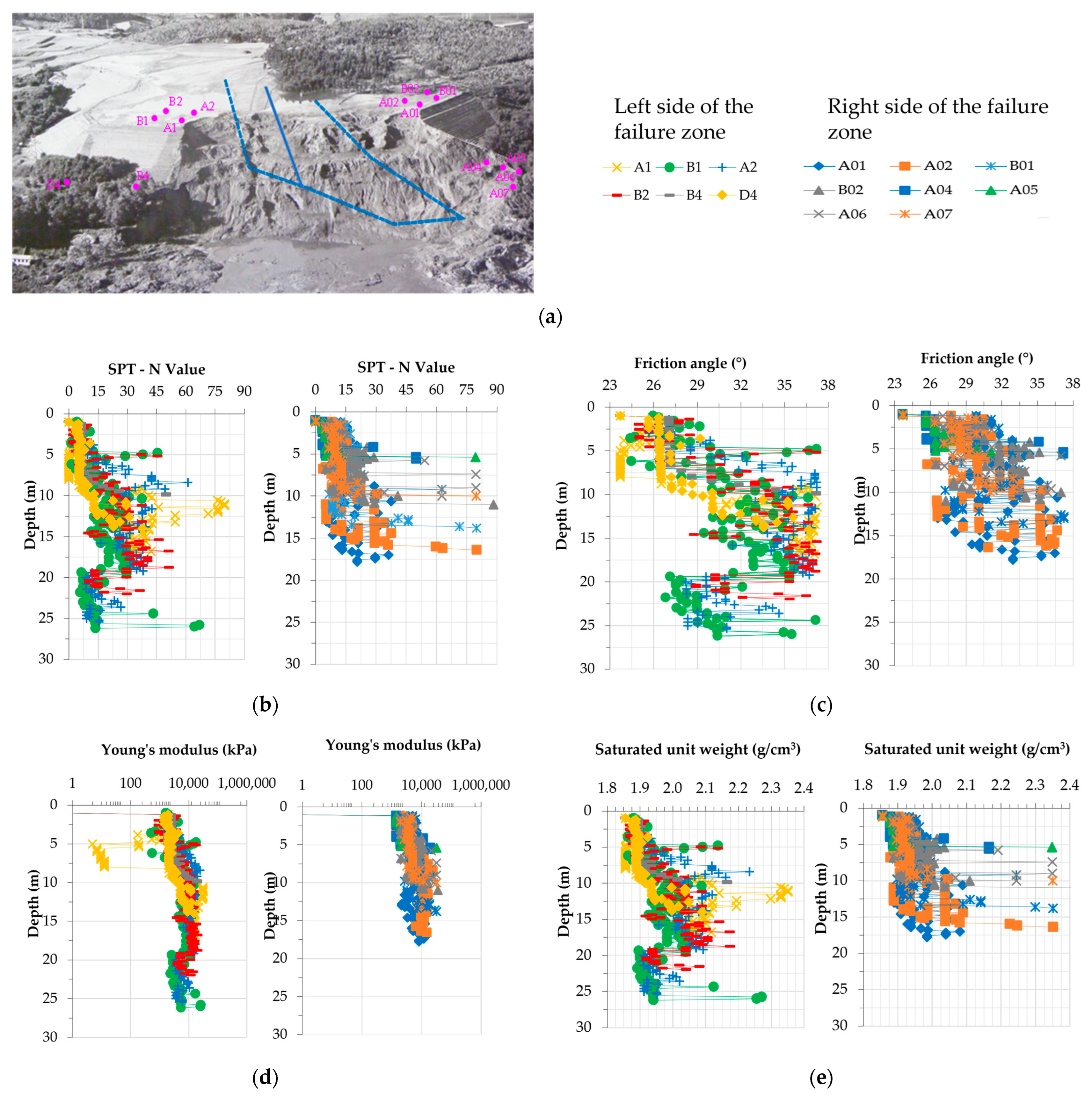

4.1. Geotechnical Characterization of Tailings

4.2. Hydraulic Characterization of Tailings

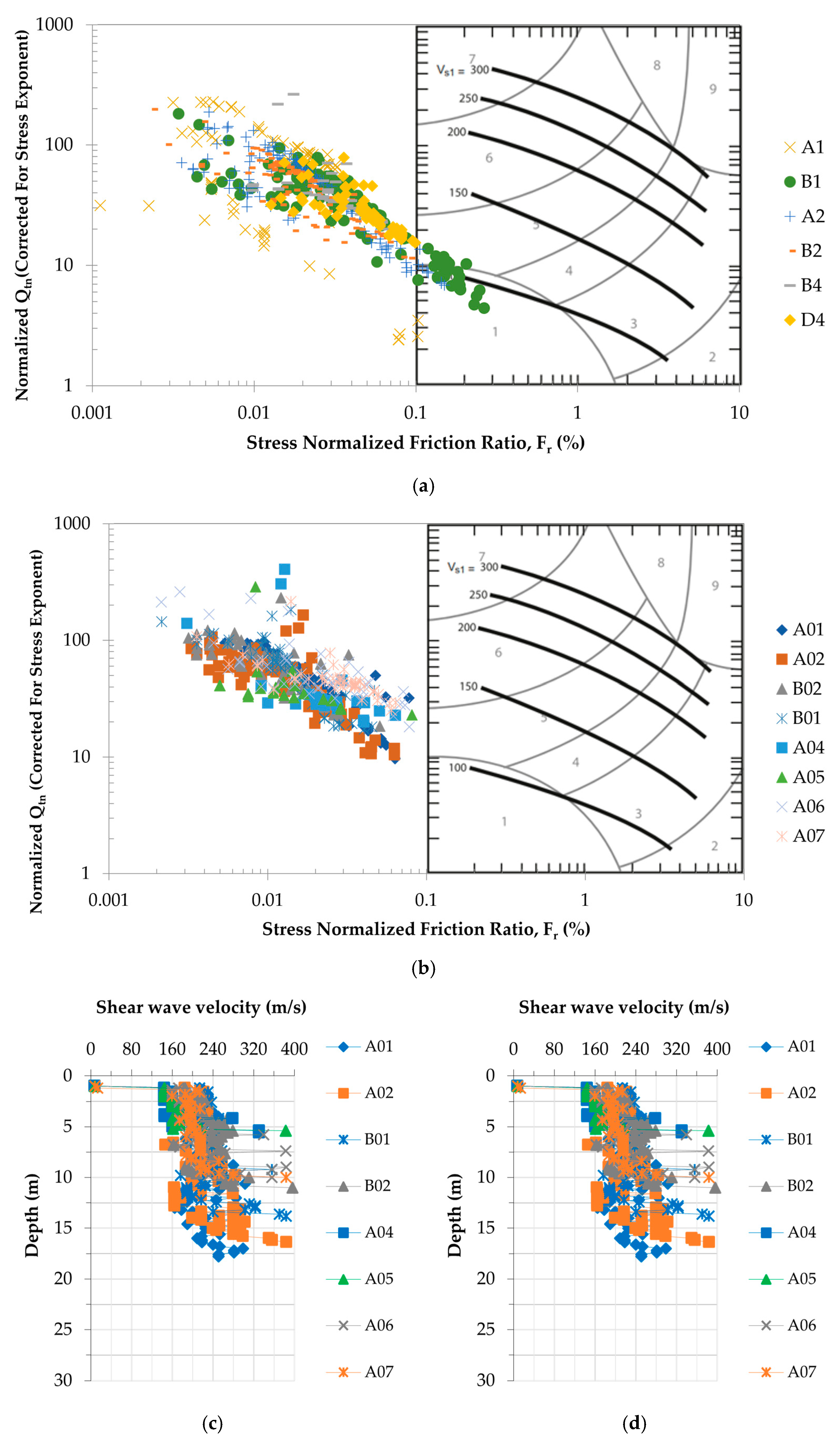

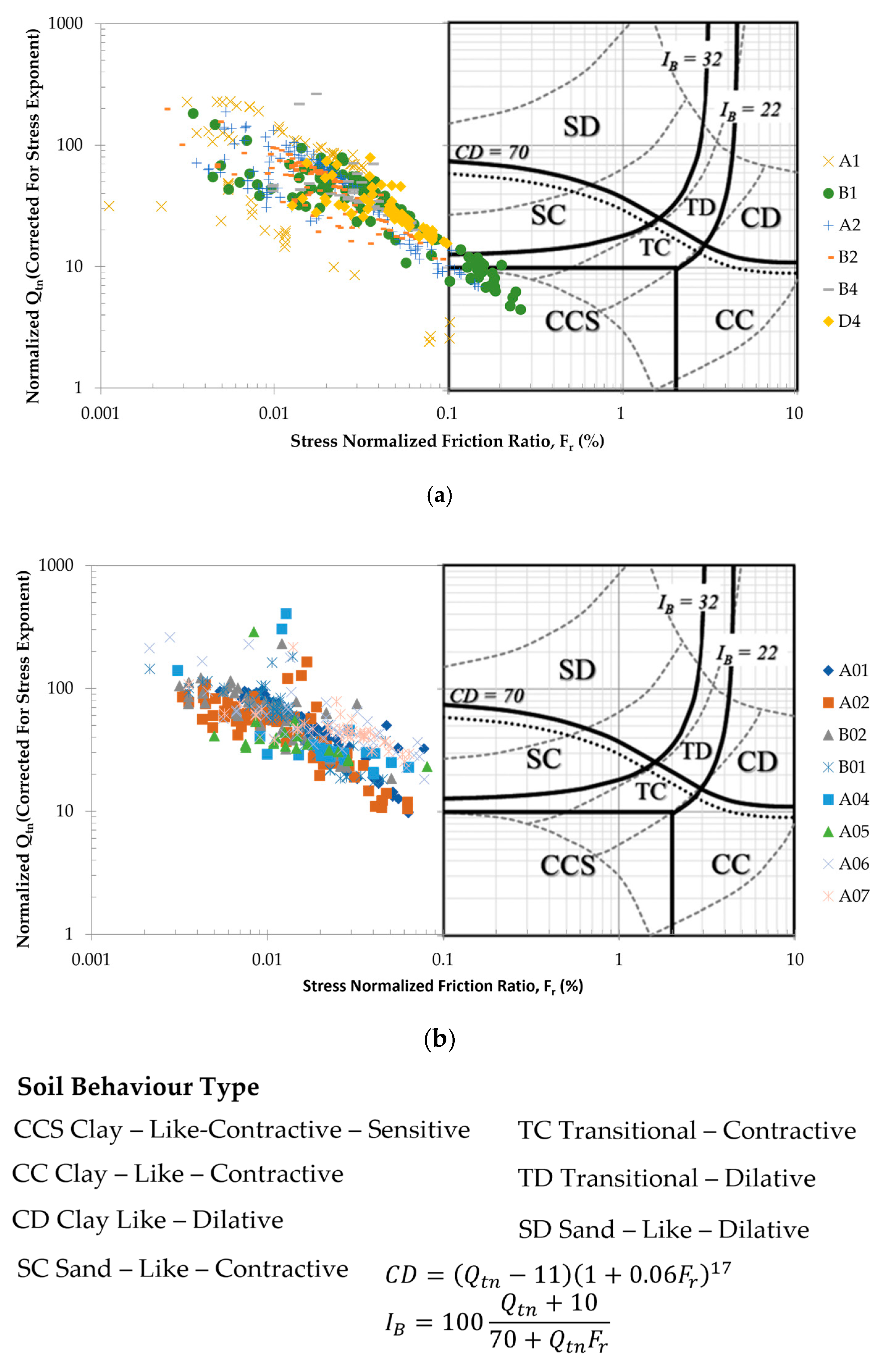

4.3. Evaluation of CPT-Based Soil Classification Methods

4.3.1. Soil Type Classification

4.3.2. Contractive-Dilative Tailings Behaviour

4.4. Shear Wave Velocity (Vs)

4.5. Mineralogical Composition of Tailings

4.6. Definition of Geometry and Materials Properties

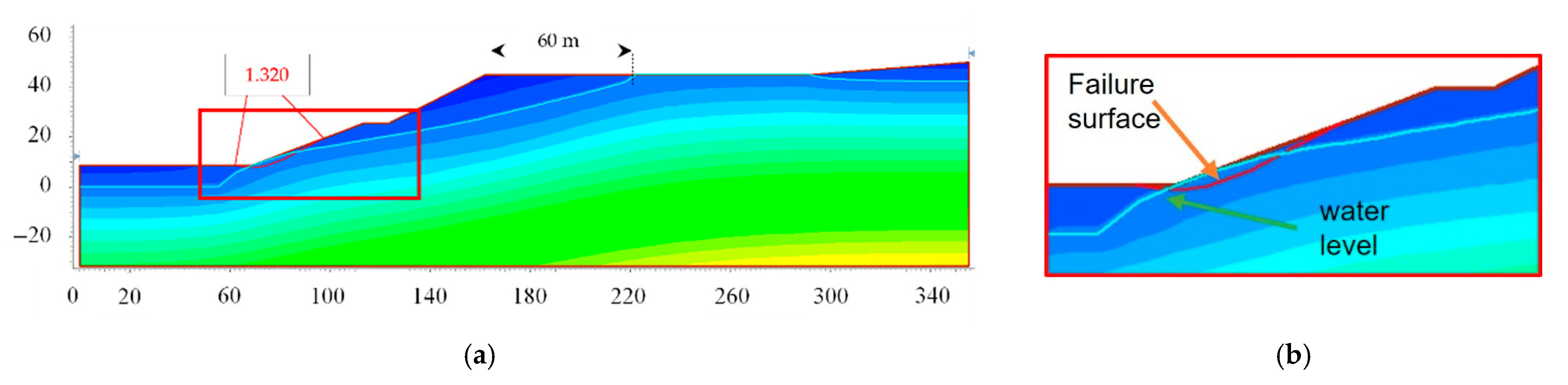

4.7. Numerical Simulations

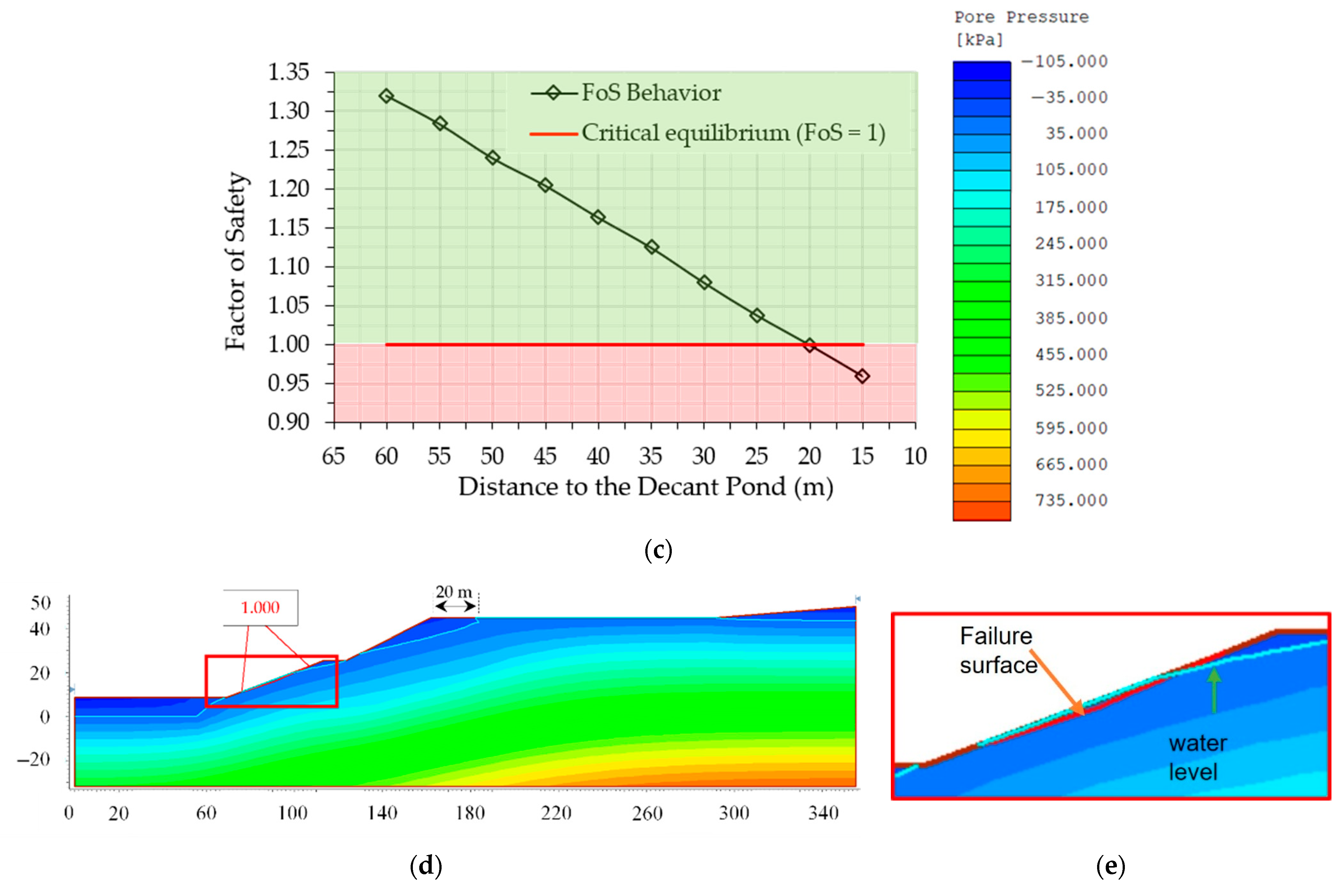

- (i)

- Seepage analysis: computation of steady-state solutions for different distances between the decant pond (distal zone) and the dam;

- (ii)

- Stability analysis: determination of safety factors and potential breach surfaces corresponding to the steady-state solutions;

- (iii)

- Stress–strain analysis: computation of displacements for the steady-state solutions.

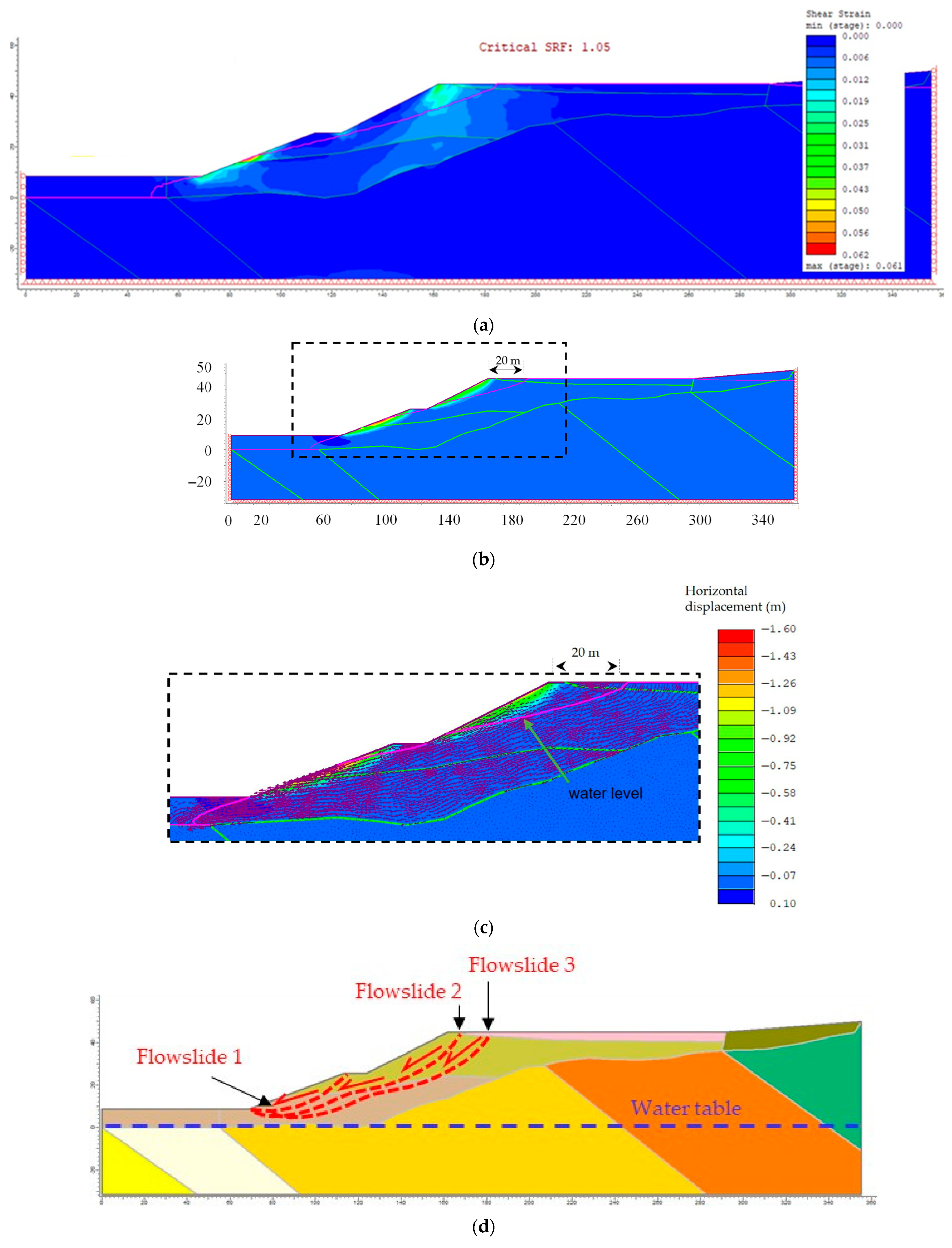

5. Discussion

5.1. La Luciana TSF Failure Mechanism

5.2. Limitations and Uncertainty

5.3. Lessons Learned for TSFs Management

5.4. Implications for Future Research and Monitoring in TSFs

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rana, N.M.; Ghahramani, N.; Azam, S.; Wilson, G.W.; van Zyl, D.; Caldwell, J.; Morgenstern, N. Global magnitude–frequency statistics of the failures and impacts of large water-retention dams and mine tailings impoundments. Earth-Sci. Rev. 2022, 232, 104144. [Google Scholar] [CrossRef]

- Piciullo, L.; Storrøsten, E.B.; Syvertsen, G.E.; Cepeda, J.M. A new look at the statistics of tailings dam failures. Eng. Geol. 2022, 303, 106657. [Google Scholar] [CrossRef]

- Global Industry Standard on Tailings Management (GISTM). Available online: https://globaltailingsreview.org/wp-content/uploads/2020/08/global-industry-standard-on-tailings-management.pdf (accessed on 17 October 2024).

- Directive 2006/21/EC. Available online: https://eur-lex.europa.eu/homepage.html?locale=en (accessed on 15 October 2024).

- Jeyapalan, J.K.; Duncan, J.M.; Seed, H.B. Investigation of flow failures of tailings dams. J. Geotech. Eng. 1983, 109, 172–189. [Google Scholar] [CrossRef]

- Rana, N.M.; Ghahramani, N.; Evans, S.G.; McDougall, S.; Small, A.; Take, W.A. Catastrophic mass flows resulting from tailings impoundment failures. Eng. Geol. 2021, 292, 106262. [Google Scholar] [CrossRef]

- Rico, M.; Benito, G.; Díez-Herrero, A. Floods from tailings dam failures. J. Hazard. Mater. 2008, 154, 79–87. [Google Scholar] [CrossRef]

- García, C. Impacto y Riesgo Ambiental de Los Residuos Minero-Metalúrgicos de La Sierra de Cartagena-La Unión (Murcia, Spain). Ph.D. Thesis, Universidad Politécnica de Cartagena, Cartagena, Spain, 2004. [Google Scholar]

- Simeoni, L. The Stava Catastrophic Failure of July 19, 1985 (Italy); University of Trento Technical Report; University of Trento: Trento, Italy, 2017. [Google Scholar]

- Pirulli, M. The failure of the Stava Valley tailings dams (Northern Italy): Numerical analysis of the flow dynamics and rheology. Geoenviron. Disasters 2017, 4, 3. [Google Scholar] [CrossRef]

- Fourie, A.B.; Blight, G.E.; Papageorgiou, G. Static liquefaction as a possible explanation for the Merriespruit tailings dam failure. Can. Geotech. J. 2001, 38, 707–719. [Google Scholar] [CrossRef]

- Eptisa. Investigation of the Failure of the Aznalcóllar Tailings Dam: Summary Report; Junta de Andalucía: Seville, Spain, 1998. [Google Scholar]

- Independent Expert Engineering Investigation and Review Panel. Report on Mount Polley Tailings Storage Facility Breach; Government of British Columbia: Victoria, BC, Canada, 2015. [Google Scholar]

- Fundão Tailings Dam Review Panel. Report on the Immediate Causes of the Failure of the Fundão Dam; Samarco: Belo Horizonte, Brazil, 2016; Available online: https://www.resolutionmineeis.us/documents/fundao-2016 (accessed on 9 September 2025).

- Robertson, P.K.; de Melo, L.; Williams, D.J.; Wilson, G.W. Report of the Expert Panel on the Technical Causes of the Failure of Feijão Dam I; Expert Panel: London, UK, 2019; Available online: http://www.b1technicalinvestigation.com/#:~:text=This%20website%20was%20created%20to%20share%20the%20Report,Ph.D.%3B%20and%20G.%20Ward%20Wilson%2C%20Ph.D.%20%28the%20%E2%80%9CPanel%E2%80%9D%29 (accessed on 8 September 2025).

- Berzal, J.L. Presas de residuos mineros. Rev. Obras Publicas 1976, 123, 301–333. (In Spanish) [Google Scholar]

- Fernandez-Naranjo, F.J.; Rodriguez, V.; Rodríguez, R.; Alberruche, M.E.; Arranz, J.C.; Vadillo, L. Liquefaction susceptibility assessment and study of “la luciana” tailings dam fault (Spain, 1960) based on historical documents. Dyna 2015, 82, 189–198. Available online: https://api.semanticscholar.org/CorpusID:110437056 (accessed on 23 November 2024). (In Spanish) [CrossRef]

- Biblioteca de la Universidad de Cantabria. 2024. Available online: https://web.unican.es/buc/biblioteca/colecciones/fondos-originales-y-colecciones-especiales/fondo-mina-reocin (accessed on 5 December 2024).

- ASTM D3080/D3080M-11; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D5084-21; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM International: West Conshohocken, PA, USA, 2021.

- Cancela, M.D. Comportamiento Geotécnico de Presas de Residuos Bajo Acciones Estáticas y Dinámicas. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 1987. (In Spanish). [Google Scholar]

- Henry, S.V. Geotechnical Stability Analysis of the Tailings Dam “La Luciana” (Torrelavega, Spain). Master’s Thesis, Universidad Complutense, Madrid, Spain, 2019. [Google Scholar]

- Fernandez-Naranjo, F.J.; Rodriguez, V.; Rodriguez, R.; Alberruche, M.E.; Arranz, J.C.; Vadillo, L. Analysis of tailing dam failure based on historical documents: The case study of ’la luciana’, Spain. In Proceedings of the First JTC1 Workshop on Advances in Landslide Understanding, Barcelona, Spain, 24–26 May 2017; pp. 1–4. [Google Scholar]

- Schmertmann, J.H. Guidelines for Cone Penetration Test: Performance and Design; Technical Report; United States of America, Federal Highway Administration, Office of Research and Development: McLean, VA, USA, 1978. Available online: https://rosap.ntl.bts.gov/view/dot/958 (accessed on 12 November 2024).

- Meyerhof, G.G. Penetration tests and bearing capacity of cohesionless soils. J. Soil Mech. Found. Div. 1956, 82, 1–19. [Google Scholar] [CrossRef]

- Meyerhof, G.G. Shallow foundations. J. Soil Mech. Found. Div. 1965, 91, 21–31. [Google Scholar] [CrossRef]

- Peck, R.B.; Hanson, W.E.; Thornburn, T.H. Foundation Engineering, 2nd ed.; John Willey & Sons: Hoboken, NJ, USA, 1974. [Google Scholar]

- Wolff, T. Pile Capacity Prediction Using Parameter Functions; ASCE Geotechnical Special Publication: Reston, VA, USA, 1989; Volume 23, pp. 21–31. Available online: https://api.semanticscholar.org/CorpusID:114072210 (accessed on 27 September 2024).

- AASHTO. Standard Specifications for Highway Bridges, 6th ed.; Technical Report; American Association of State Highway and Transportation Officials, Inc.: Washington, DC, USA, 1996; Available online: https://store.transportation.org/Common/DownloadContentFiles?id=632 (accessed on 10 December 2024).

- Imai, T.; Tonouchi, K. Correlation of N-value with S-wave velocity and shear modulus. In Proceedings of the 2nd European Symposium on Penetration Testing, Amsterdam, The Netherlands, 24–27 May 1982. [Google Scholar]

- Robertson, P.K.; Campanella, R.G. Interpretation of Cone Penetration Tests: Sands and Clays. Can. Geotech. J. 1983, 20, 734–745. [Google Scholar] [CrossRef]

- Robertson, P.K.; Campanella, R.G.; Gillespie, D.; Greig, J. Use of Piezometer Cone Data. In American Society of Civil Engineers, Proceedings of the In-Situ 86 Specialty Conference, Blacksburg, VA, USA, 23–25 June 1986; ASCE: Reston, VA, USA, 1986; pp. 1263–1280. [Google Scholar]

- Robertson, P.K. Soil classification using the cone penetration test. Can. Geotech. J. 1990, 27, 151–158. [Google Scholar] [CrossRef]

- Robertson, P.K. Interpretation of cone penetration tests—A unified approach. Can. Geotech. J. 2009, 46, 1337–1355. [Google Scholar] [CrossRef]

- Robertson, P.K. Cone penetration test (CPT)-based soil behaviour type (SBT) classification system—An update. Can. Geotech. J. 2016, 53, 1910–1927. [Google Scholar] [CrossRef]

- Jefferies, M.G.; Davies, M.P. Use of CPTu to estimate equivalent SPT N60. Geotech. Test. J. 1993, 16, 458–468. [Google Scholar] [CrossRef]

- Olson, S.M.; Stark, T.D. Yield strength ratio and liquefaction analysis of Slopes and embankments. J. Geotech. Geoenviron. Eng. 2003, 129, 727–737. [Google Scholar] [CrossRef]

- NCSR-02. Real Decreto 997/2002, de 27 de Septiembre, Por el Que se Aprueba la Norma de Construcción Sismorresistente: Parte General y Edificación. 2002. Available online: https://www.transportes.gob.es/recursos_mfom/0820200.pdf (accessed on 16 October 2024).

- Rodríguez-Pacheco, R.; Butlanska, J.; Oliva-González, A.O. Geotechnical and Hydrogeological Zonation of Tailings Storage Facilities: Importance for Design, Construction, Operation and Closure. Minerals 2025, 15, 105. [Google Scholar] [CrossRef]

- Vick, S.G. Planning, Design, and Analysis of Tailings Dams; BiTech Publishers Ltd.: Richmond, BC, Canada, 1990. [Google Scholar]

- WISE Uranium Project. Available online: https://www.wise-uranium.org/index.html (accessed on 10 September 2025).

- International Commission on Large Dams (ICOLD). Bulletin 194: Tailings Dam Safty. Available online: https://www.icold-cigb.org/article/GB/publications/bulletins (accessed on 16 October 2024).

- Conte, E.; Silvestri, F.; Troncone, A. Stability analysis of slopes in soils with strain-softening behaviour. Comput. Geotech. 2010, 37, 710–722. [Google Scholar] [CrossRef]

- Mohsan, M.; Vardon, P.J.; Vossepoel, F.C. On the use of different constitutive models in data assimilation for slope stability. Comput. Geotech. 2021, 138, 104332. [Google Scholar] [CrossRef]

- Rocscience. Slide 2 Groundwater. In Verification Manual; Rocscience: Toronto, ON, Canada, 2024. [Google Scholar]

- Rocscience. RS2, 2D finite element program for stress analysis and support design around excavations in soil and rock. In Ground Water Verification Manual; Rocscience: Toronto, ON, Canada, 2022. [Google Scholar]

- Bishop, A.; Morgenstern, N. Stability coefficients for earth slopes. Géotechnique 1960, 10, 129–153. [Google Scholar] [CrossRef]

- Morgenstern, N.R.; Price, V.E. The analysis of the stability of general slip surfaces. Géotechnique 1965, 15, 79–93. [Google Scholar] [CrossRef]

- Morgenstern, N.R.; Price, V.E. A numerical method for solving the equations of stability of general slip surfaces. Comput. J. 1967, 9, 388–393. Available online: https://api.semanticscholar.org/CorpusID:123514044 (accessed on 27 June 2024). [CrossRef]

- Zandarin, M.T.; Oldecop, L.A.; Rodríguez, R.; Zabala, F. The role of capillary water in the stability of tailings dams. Eng. Geol. 2009, 10, 108–118. [Google Scholar] [CrossRef]

- Rodriguez, R.; Muñoz-Moreno, A.; Caparros, A.V.; García-García, C.; Brime-Barrios, A.; Arranz-González, J.C.; Rodriguez-Gómez, V.; Fernandez-Naranjo, F.J.; Alcolea, A.F. How to prevent flow failures in tailings dams. Mine Water Environ. 2021, 40, 83–112. [Google Scholar] [CrossRef]

- Royal Decree 975/2009. Available online: https://www.boe.es/buscar/act.php?id=BOE-A-2009-984 (accessed on 15 October 2024).

- Royal Decree 777/2012. Available online: https://www.boe.es/diario_boe/txt.php?id=BOE-A-2012-6500 (accessed on 15 October 2024).

- EU Water Framework Directive 2000/60/EC. Available online: https://eur-lex.europa.eu/eli/dir/2000/60/oj/eng (accessed on 15 October 2024).

- Directive 2004/35/EC. Available online: https://eur-lex.europa.eu/eli/dir/2004/35/oj/eng (accessed on 16 October 2024).

| Sample | Fine Content (d < 75 μm) | D10 | D30 | D50 | D60 | D90 | Cu | Cc | k* = C·(D10)2 | hc ** |

|---|---|---|---|---|---|---|---|---|---|---|

| (%) | (mm) | (mm) | (mm) | (mm) | (mm) | (-) | (-) | (m/s) | (m) | |

| Dam 1 | 20 | 0.015 | 0.077 | 0.135 | 0.170 | 0.245 | 11.5 | 2.4 | 2.2 × 10−6 | 1.33/0.79 |

| Dam 2 | 17 | 0.031 | 0.090 | 0.145 | 0.180 | 0.340 | 5.8 | 1.4 | 9.7 × 10−6 | 0.63/0.37 |

| Dam 3 | 30.9 | 0.008 | 0.062 | 0.100 | 0.125 | 0.200 | 15.1 | 3.4 | 6.4 × 10−7 | 2.46/1.46 |

| Discharge | 40 | 0.003 | 0.022 | 0.078 | 0.120 | 0.242 | 42.1 | 1.4 | 9 × 10−8 | 6.91/4.1 |

| Transition 1 | 70 | 0.003 | 0.018 | 0.031 | 0.040 | 0.113 | 13.9 | 2.9 | 9 × 10−8 | 6.91/4.1 |

| Transition 2 | 60 | 0.003 | 0.017 | 0.039 | 0.060 | 0.148 | 21.1 | 1.8 | 9 × 10−8 | 6.91/4.1 |

| Decant pond | 97 | 0.0009 | 0.003 | 0.005 | 0.007 | 0.021 | 7.6 | 1.1 | 8.1 × 10−9 | 21.84/12.93 |

| Mixed sample | 60.5 | 0.002 | 0.010 | 0.032 | 0.060 | 0.216 | 30 | 0.8 | 4.0 × 10−8 | 9.83/5.82 |

| Reference | φ (°) | c (kPa) |

|---|---|---|

| [16]—Dam (measured) | 36 | 0 |

| [21]—fines (measured) | 21 | 0 |

| [22]—(calculated)– | NA | |

| Dam | 30.5 | |

| Tailings | 37.3–40.5 | |

| CPT analysis (this study) | 23–37 | NA |

| Laboratory—direct shear test with remoulded samples (in this study) | ||

| Dam | 44.8 | 0 |

| Descarge zone | 33.8 | 18.2 |

| Transition zone | 32.1 | 28.3 |

| Decant pond | 28.3 | 86.6 |

| Parameter | Soil Type | Equation | Reference |

|---|---|---|---|

| SPT—N value | Sands, sandy silts and clay-silt-sand mixtures | qc/NSPT = 2~5 | [24] |

| Saturated density, γsat [g/cm3] | Granular | γsat = 1.8559 + 0.0062 (NSPT) | [24] |

| Effective friction angle, Φ′ [°] | Sands and silts with more than 5% fines | Φ′ = 23.7 + 0.57 N60 − 0.006 (N60)2 | [25,26] |

| Granular | Φ′ = 27 + 0.3 N60 | [27] | |

| Φ′ = 27.1 + 0.3 N60 − 0.00054 (N60)2 | [28] | ||

| Young’s modulus, E [kPa] | Sands and silts | E/qc = 1.5~2 | [24] |

| Equivalent elastic modulus, Ee [kPa] | Silts, silty sands, slightly cohesive mixtures | 400 N60 | [29] |

| Medium fine clean sand and mixture of silt and sand | 700 N60 | ||

| Quartz sand and sand with small gravels | 1000 N60 | ||

| Gravel, sand | 1200 N60 | ||

| Shear wave velocity, vs. (m/s) | Granular | Vs = 97(NSPT)0.314 | [30] |

| Zone | Fines Content (%) | D10 (mm) | Cu | ks (m/s) |

|---|---|---|---|---|

| Dam | 20 | 0.015 | 11.5 | 2.2 × 10−6 |

| Discharge area | 40 | 0.003 | 42.1 | 9.5 × 10−8 |

| Transition zone | 60 | 0.003 | 21.1 | 1.2 × 108 |

| Decant pond | 97 | 0.0009 | 7.6 | 8.0 × 10−9 |

| Ground Type | Vs (ms) | Soil Description |

|---|---|---|

| I | >750 | Compact rock, cemented soil or very dense granular soil |

| II | 750 ≥ Vs > 400 | Highly fractured rock, dense granular soils or hard cohesive soils |

| III | 400 ≥ Vs > 200 | Medium-compact granular soil, or firm to very firm cohesive soil. |

| IV | ≤200 | Loose granular soil or soft cohesive soil |

| Category | Typical Material (Origin) | φ (°) | c (kPa) | E (MPa) | γsat (kN/m3) | ks (m/s) | Key Features |

|---|---|---|---|---|---|---|---|

| Low strength | Fine-grained pond tailings | 23–27 | 0–10 | <8 | ~18.5 | 1 × 10−9–1 × 10−8 | Highly contractive, very low permeability, high saturation |

| Medium strength | Transitional silty–sandy tailings | 28–33 | 5–15 | 10–20 | 20–22 | 1 × 10−8–1 × 10−7 | Mixed textures, moderate stiffness, partially drained behaviour |

| Medium–high strength | Coarse sand Dam | 34–37+ | 10–20 | >20 | 22–23.5 | 1 × 10−6–1 × 10−5 | Dilative response, permeable layers, preferential drainage |

| High strength | Foundation units (dolomites, limestones, dense gravels) | 38–42 | 15–30 | 50–100+ | 23–25 | 1 × 10−5–1 × 10−4 | Very dense, high stiffness, durable; act as competent foundation with high shear resistance |

| Material Name | Unit Weight (kN/m3) | Cohesion (kPa) | φ (°) | E (kPa) | ν | ksh (m/s) | ksv (m/s) |

|---|---|---|---|---|---|---|---|

| Low-strength tailings | 18.60 | 0 | 27.10 | 2000 | 0.35 | ||

| Medium-strength tailings | 18.90 | 0 | 28.00 | 6711.76 | 0.35 | ||

| Medium–high-strength waste dump | 19.40 | 0 | 29.23 | 12,503.68 | 0.35 | ||

| Foundation units: Quaternary terraces | 20 | 50 | 25 | 50,000 | 0.30 | ||

| Dolomites | 20 | 1000 | 50 | 50,000 | 0.30 | ||

| Marly limestone | 20 | 1000 | 50 | 50,000 | 0.30 | ||

| Marl and limestone | 20 | 50 | 25 | 50,000 | 0.30 | ||

| Limestones | 22 | 1000 | 50 | 50,000 | 0.30 | ||

| Marls | 20 | 50 | 25 | 50,000 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliva-González, A.O.; Butlanska, J.; Fernández-Merodo, J.A.; Rodríguez-Pacheco, R.L. Forensic Investigation of the Seepage-Induced Flow Failure at La Luciana Tailings Storage Facility (1960 Spain). Minerals 2025, 15, 1131. https://doi.org/10.3390/min15111131

Oliva-González AO, Butlanska J, Fernández-Merodo JA, Rodríguez-Pacheco RL. Forensic Investigation of the Seepage-Induced Flow Failure at La Luciana Tailings Storage Facility (1960 Spain). Minerals. 2025; 15(11):1131. https://doi.org/10.3390/min15111131

Chicago/Turabian StyleOliva-González, Aldo Onel, Joanna Butlanska, José Antonio Fernández-Merodo, and Roberto Lorenzo Rodríguez-Pacheco. 2025. "Forensic Investigation of the Seepage-Induced Flow Failure at La Luciana Tailings Storage Facility (1960 Spain)" Minerals 15, no. 11: 1131. https://doi.org/10.3390/min15111131

APA StyleOliva-González, A. O., Butlanska, J., Fernández-Merodo, J. A., & Rodríguez-Pacheco, R. L. (2025). Forensic Investigation of the Seepage-Induced Flow Failure at La Luciana Tailings Storage Facility (1960 Spain). Minerals, 15(11), 1131. https://doi.org/10.3390/min15111131