Research on the Mechanical and Microstructure Characteristics of Cemented Paste Backfill in Deep In Situ Environments

Abstract

1. Introduction

2. Materials and Method

2.1. Materials

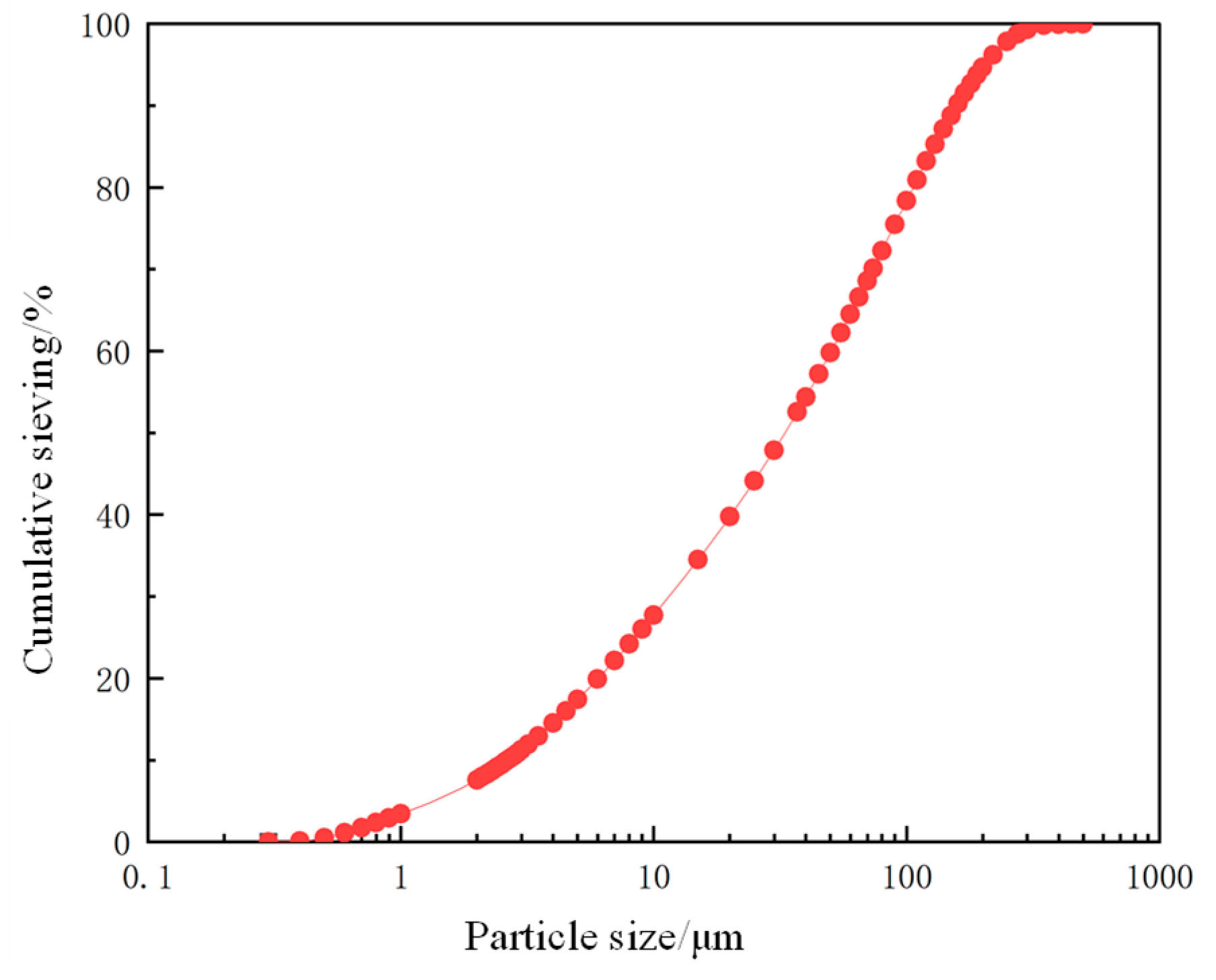

2.1.1. Tailings

2.1.2. Binder and Water

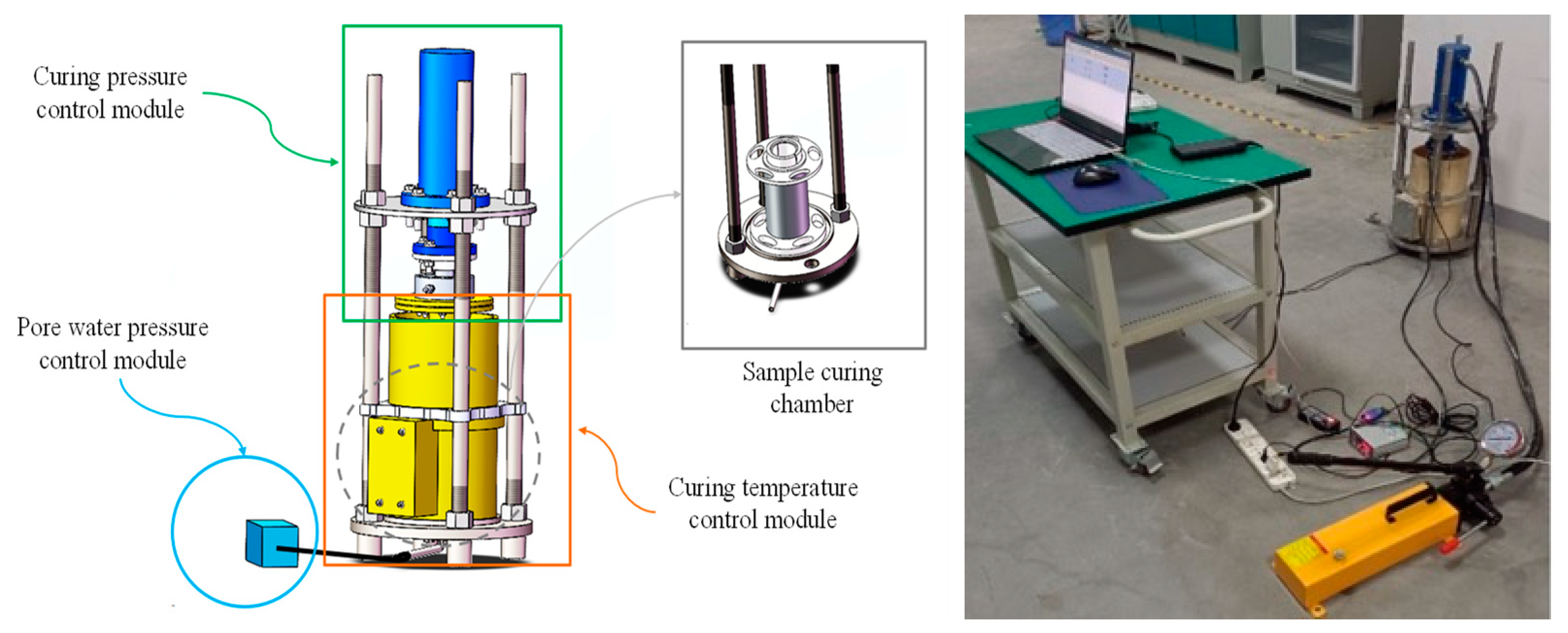

2.2. Design of In Situ Environmental Simulation Maintenance Device

2.3. Sample Preparation

2.4. Testing Procedures

2.4.1. UCS Tests

2.4.2. Mercury Intrusion Porosimetry (MIP)

3. MIP Test Results and Analysis

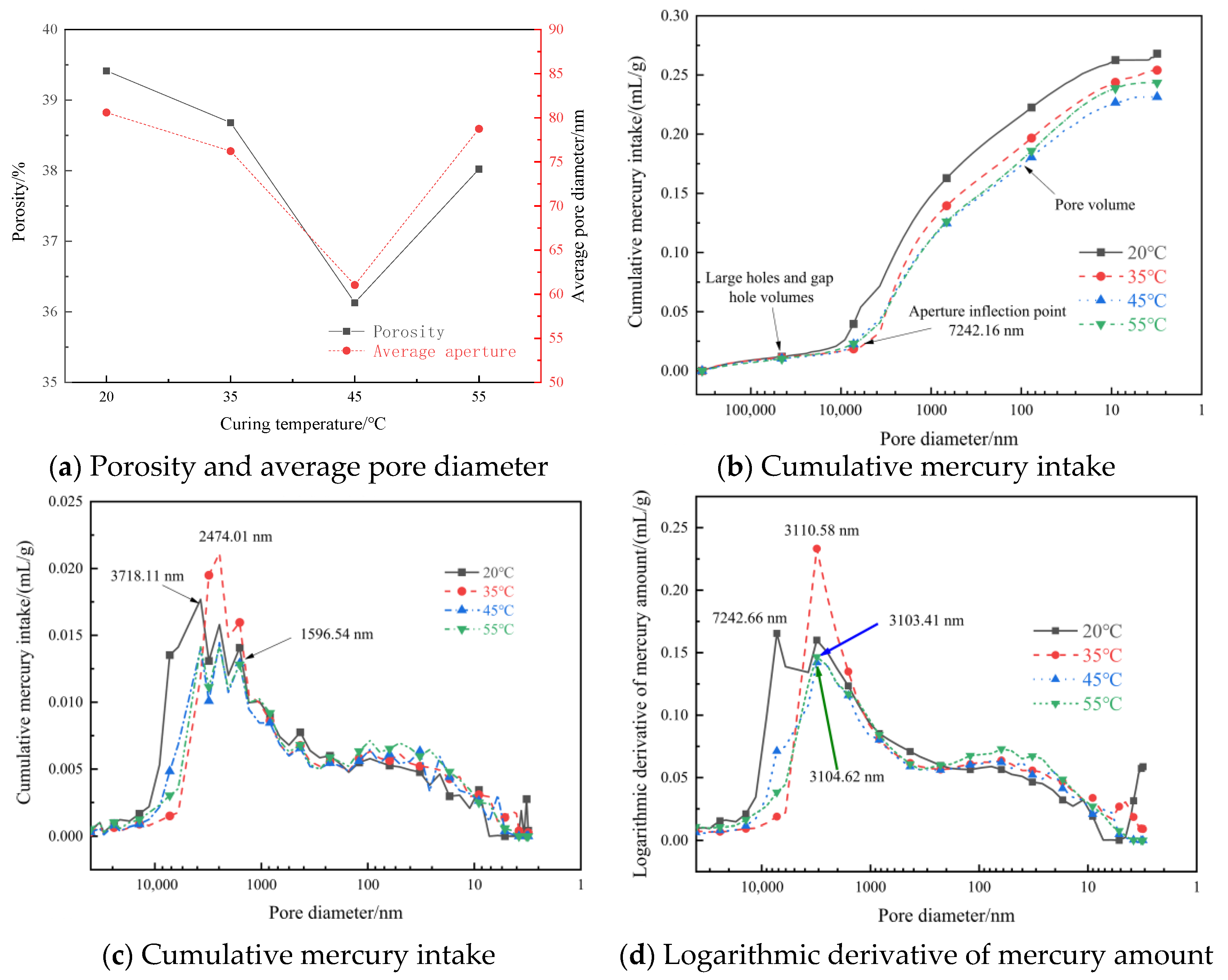

3.1. Effect of Curing Temperature on Pore Structure

3.2. Effect of Curing Pressure on Pore Structure

3.3. Effect of Pore Water Pressure on Pore Structure

4. Strength Test Results and Analysis

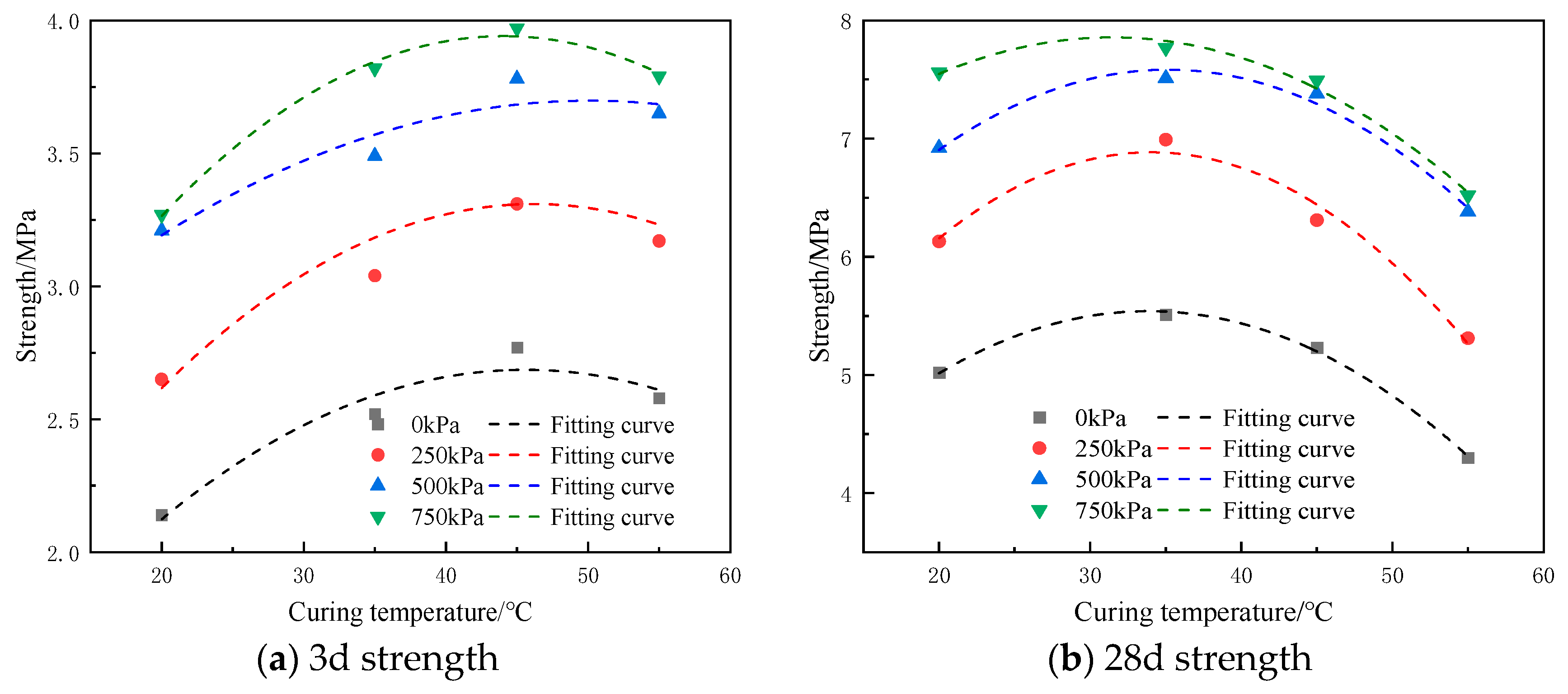

4.1. Effect of Curing Temperature on Strength

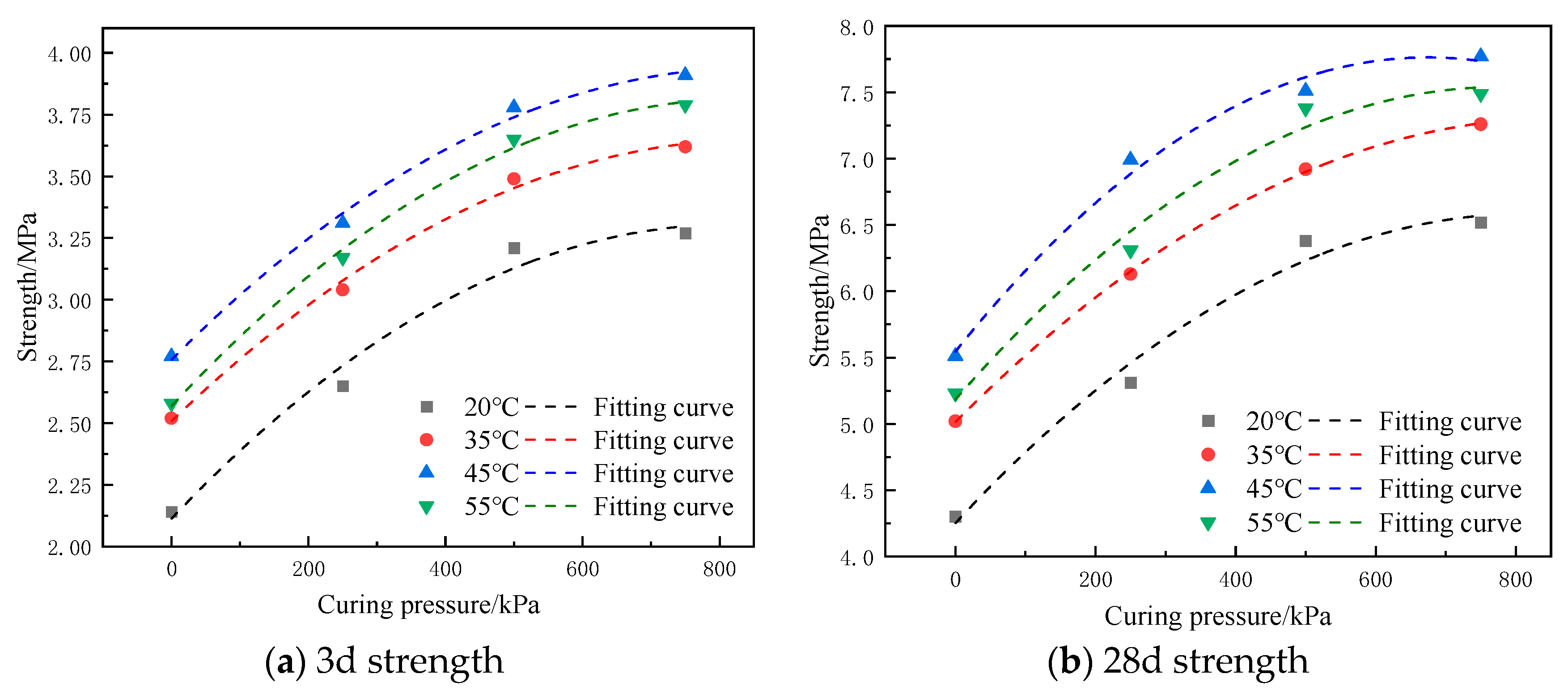

4.2. Effect of Curing Pressure on Strength

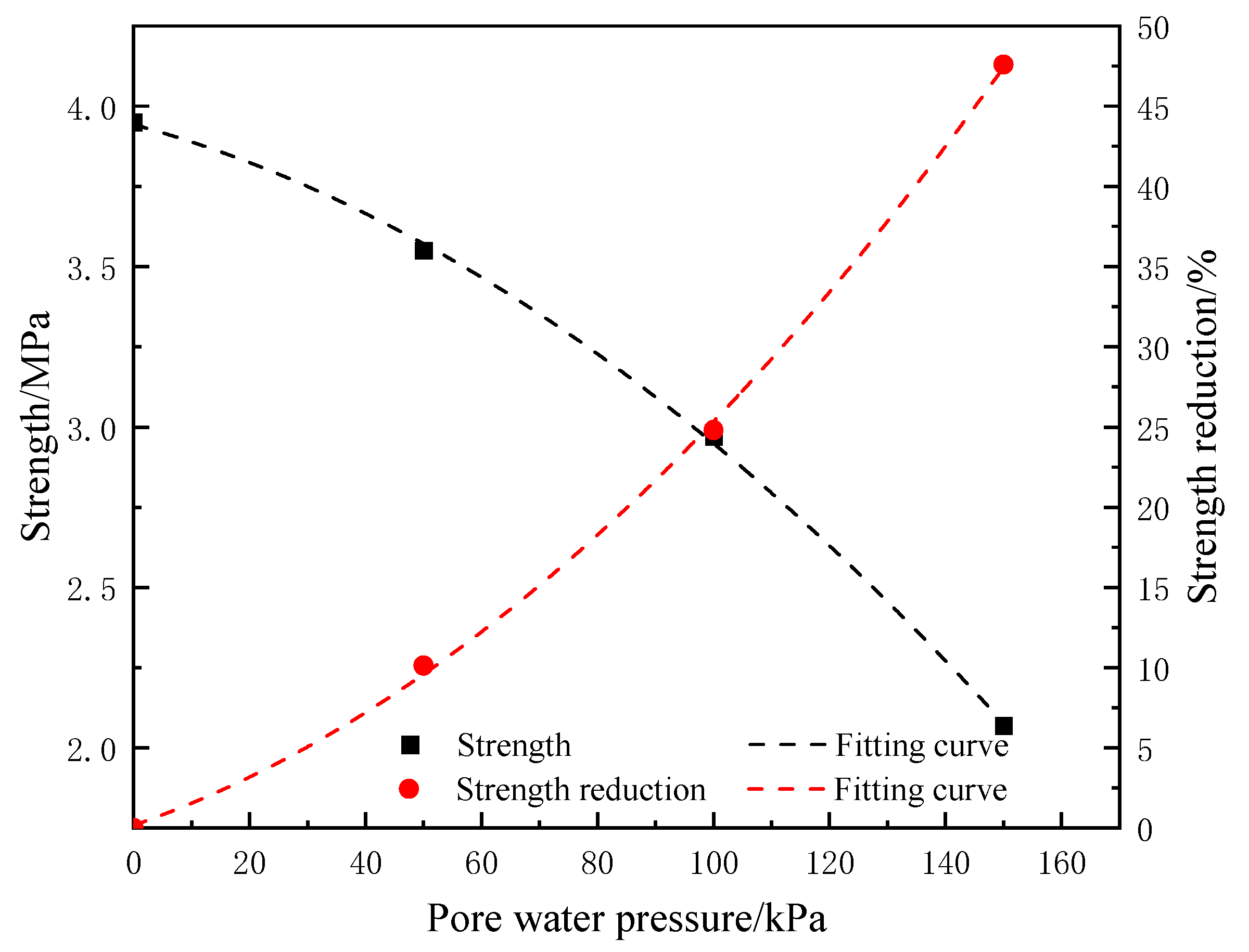

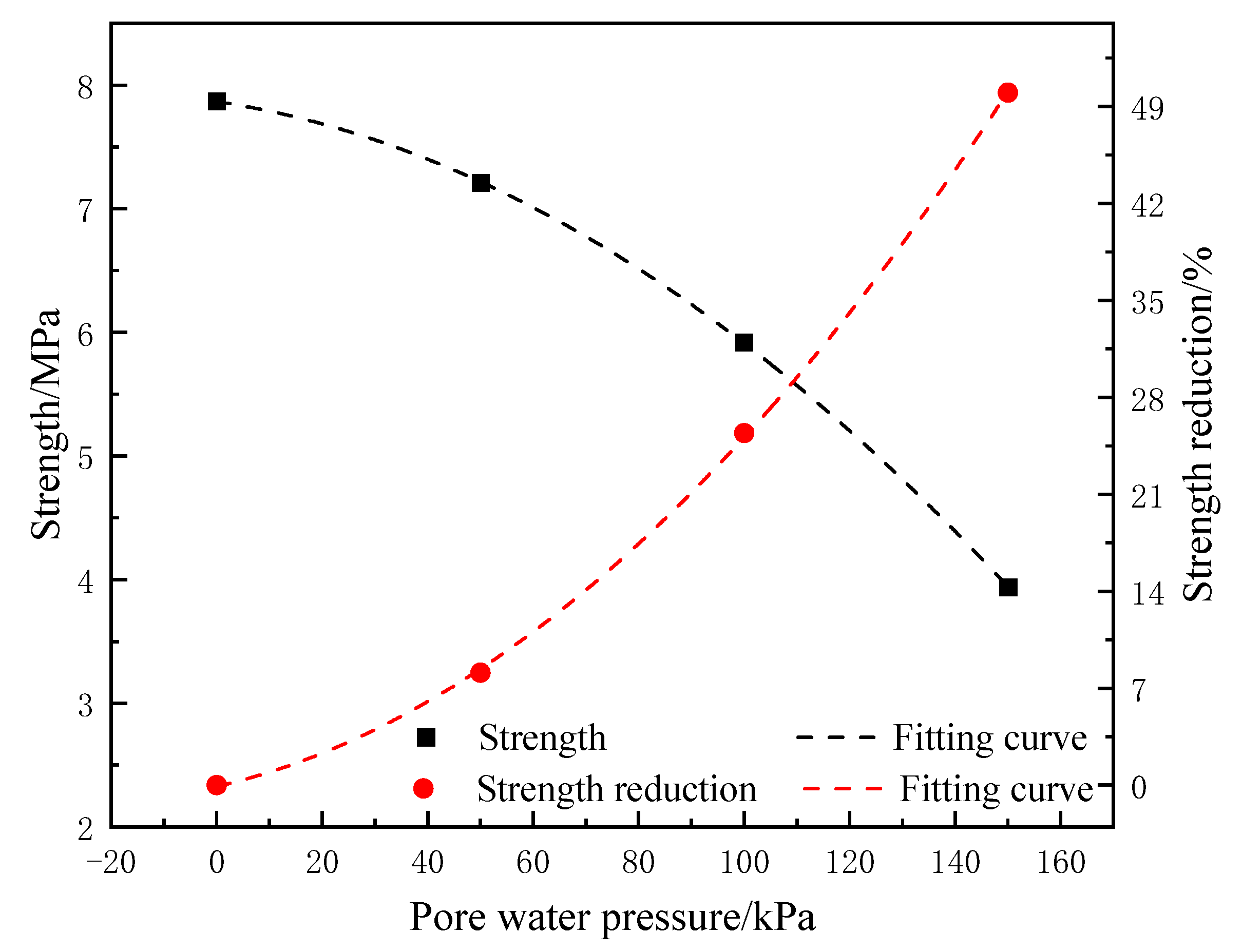

4.3. Effect of Pore Water Pressure on Strength

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dong, Q.; Cao, L. The hole-filling method and the multiscale computation for the wave equations in perforated domains. Comput. Math. Appl. 2015, 70, 1743–1756. [Google Scholar] [CrossRef]

- Hollinderbaeumer, E.W.; Kraemer, U. Waste disposal and backfilling technology in the German hard coal mining industry. Bulk Solids Handl. 1994, 14, 795–798. [Google Scholar]

- Guo, L.; Liu, G.; Ma, Q.; Chen, X. Research progress on mining with backfill technology of underground metalliferous mine. J. China Coal Soc. 2022, 47, 4182–4200. [Google Scholar] [CrossRef]

- Xie, H.; Gao, F.; Ju, Y.; Gao, M.; Zhang, R.; Gao, Y.; Liu, J.; Xie, L. Quantitative definition and investigation of deep mining. J. China Coal Soc. 2015, 40, 1–10. [Google Scholar] [CrossRef]

- Ayhan, K.; Erol, Y.; Bayram, E. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Lin, F.; Meyer, C. Hydration kinetics modeling of Portland cement considering the effects of curing temperature and applied pressure. Cem. Concr. Res. 2009, 39, 255–265. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Y.; Liu, Y. Mechanical performance and ultrasonic properties of cemented gangue backfill with admixture of fly ash. Ultrasonics 2016, 64, 89–96. [Google Scholar] [CrossRef]

- Helinski, M.; Fahey, M.; Fourie, A. Behavior of Cemented Paste Backfill in Two Mine Stopes: Measurements and Modeling. J. Geotech. Geoenviron. Eng. 2010, 137, 171–182. [Google Scholar] [CrossRef]

- Qiao, P.; Cheng, W.; Zhang, L.; Yao, W.; Wang, X.; Wang, H. Modern Mining Concepts and Filling Technique. Nonferrous Met. Sci. Eng. 2011, 2, 7–14. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and Application of Underground Mine Paste Backfill Technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Le Roux, K.; Bawden, W.F.; Grabinsky, M.F. Field properties of cemented paste backfill at the Golden Giant mine. Min. Technol. 2013, 114, 65–80. [Google Scholar] [CrossRef]

- Yilmaz, E. One-Dimensional Consolidation Parameters Of Cemented Paste Backfills/Parametry Jednowymiarowej Konsolidacji Podsadzki W Postaci Cementowej Pasty. Gospod. Surowcami Miner. Miner. Resour. Manag. 2012, 28, 29–45. [Google Scholar] [CrossRef]

- Tang, G.; Guo, L.; Liu, G.; Yang, X. Experimental study on tensile strength of cemented tailings backfill and influencing factors. China Min. Mag. 2022, 31, 124–131. [Google Scholar]

- Zhou, K.; Liu, W.; Zhou, Y.; LIn, Y.; Xue, K. Mechanical properties and damage-softening constitutive model of backfill with different osmotic pressures. Rock Soil Mech. 2019, 40, 3724–3732. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled thermo-hydro-mechanical-chemical behaviour of cemented paste backfill in column experiments. Part I: Physical, hydraulic and thermal processes and characteristics. Eng. Geol. 2013, 164, 195–207. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, S.; Zhang, X.; Li, J. A Novel Prediction Model of Strength of Paste Backfill Prepared from Waste-Unclassified Tailings. Adv. Mater. Sci. Eng. 2019, 2019, 3574190. [Google Scholar] [CrossRef]

- Xu, W.; Wan, C.; Tian, X. Coupling effect of temperature and fracture on the strength and crack propagation mode of backfill mass. J. Min. Saf. Eng. 2018, 35, 612–619. [Google Scholar] [CrossRef]

- Pouramini, Z.; Pokharel, M.; Fall, M.; Aldhafeeri, Z. Temperature dependence of the reactivity of cemented paste backfill. Appl. Geochem. J. Int. Assoc. Geochem. Cosmochem. 2016, 72, 10–19. [Google Scholar]

- Fahey, M.; Helinski, M.; Fourie, A. Development of Specimen Curing Procedures that Account for the Influence of Effective Stress During Curing on the Strength of Cemented Mine Backfill. Geotech. Geol. Eng. 2011, 29, 709–723. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled thermo-hydro-mechanical–chemical behaviour of cemented paste backfill in column experiments: Part II: Mechanical, chemical and microstructural processes and characteristics. Eng. Geol. 2014, 170, 11–23. [Google Scholar] [CrossRef]

- Cui, L.; Fall, M. Mechanical and thermal properties of cemented tailings materials at early ages: Influence of initial temperature, curing stress and drainage conditions. Constr. Build. Mater. 2016, 125, 553–563. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q.; Zhang, Q. A strength prediction model using artificial intelligence for recycling waste tailings as cemented paste backfill. J. Clean. Prod. 2018, 183, 566–578. [Google Scholar] [CrossRef]

- Chen, S.; Yilmaz, E.; Xiang, Z.-G.; Wang, Y. Curing conditions effect on pore structure, compressive strength and elastic modulus of cementitious tailings backfills. Powder Technol. 2023, 422, 118458. [Google Scholar] [CrossRef]

- Chen, S. Research on the Mechanical Characteristics and its Responsemechanism of Cemented Paste Backfill Under the Effect of Stress and Temperature. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2020. [Google Scholar]

- He, X.; Wei, L.; Yang, K.; Wen, Z.; Zhang, L.; Hou, Y. Effects of curing temperature and age on the mechanical properties and damage law of coal-based solid waste cemented backfill. Case Stud. Constr. Mater. 2025, 23, e04937. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, W.; Chen, Z. Effects of curing temperature on mechanical properties and damage evolution of rod-milled sand cemented paste backfill. Results Eng. 2025, 28, 107268. [Google Scholar] [CrossRef]

- Yilmaz, E.; Benzaazoua, M.; Belem, T.; Bussière, B. Effect of curing under pressure on compressive strength development of cemented paste backfill. Miner. Eng. 2012, 22, 772–785. [Google Scholar] [CrossRef]

- Ke, Y.; Zeng, J.; Hu, K.; Shen, Y.; Yu, S.; Ma, Y. Triaxial mechanical properties and evolution mechanism of fully cemented unclassified tailings backfill under seepage pressure. Nonferrous Met. Sci. Eng. 2024, 15, 422–431. [Google Scholar] [CrossRef]

- Shen, Y. Study on the Mechanical Properties and Macro and Microdamage Laws of Paste Backfill Under Seepage. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2024. [Google Scholar]

| Aggregate | Chemical Composition (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | MgO | Al2O3 | Fe2O3 | SO3 | K2O | Other | |

| Tailings | 76.22 | 2.20 | 1.50 | 0.93 | 12.09 | 1.5 | 3.37 | 1.34 |

| Cement | 28.36 | 48.28 | 2.50 | 11.87 | 2.88 | 4.15 | 1.07 | 0.88 |

| Curing Temperature/°C | Pore Water Pressure/kPa | Curing Pressure/kPa |

|---|---|---|

| 20 | 50 | 0, 250, 500, 750 |

| 35 | 50 | 0, 250, 500, 750 |

| 45 | 50 | 0, 250, 500, 750 |

| 55 | 50 | 0, 250, 500, 750 |

| 45 | 0, 50, 100, 150 | 750 |

| Curing Pressure/kPa | Fitting Type | Fitting Result | Correlation Coefficient/R2 | |

|---|---|---|---|---|

| 3 d | 0 | Quadratic | 0.991 | |

| 250 | Quadratic | 0.914 | ||

| 500 | Quadratic | 0.925 | ||

| 750 | Quadratic | 0.947 | ||

| 28 d | 0 | Quadratic | 0.997 | |

| 250 | Quadratic | 0.986 | ||

| 500 | Quadratic | 0.992 | ||

| 750 | Quadratic | 0.991 |

| Curing Age | Curing Temperature/°C | Fitting Type | Fitting Result | Correlation Coefficient/R2 |

|---|---|---|---|---|

| 3 d | 20 | Quadratic | 0.985 | |

| 35 | Quadratic | 0.997 | ||

| 45 | Quadratic | 0.994 | ||

| 55 | Quadratic | 0.997 | ||

| 28 d | 20 | Quadratic | 0.984 | |

| 35 | Quadratic | 0.999 | ||

| 45 | Quadratic | 0.992 | ||

| 55 | Quadratic | 0.988 |

| Fitting Object | Fitting Type | Fitting Result | Correlation Coefficient/R2 |

|---|---|---|---|

| Strength | Quadratic | 0.9896 | |

| Strength reduction | Quadratic | 0.9928 |

| Fitting Object | Fitting Type | Fitting Result | Correlation Coefficient/R2 |

|---|---|---|---|

| Strength | Quadratic | 0.9892 | |

| Strength reduction | Quadratic | 0.9981 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Yan, Z.; Wang, G.; Guo, L.; Zhang, Y.; Zhao, Y.; Jia, C. Research on the Mechanical and Microstructure Characteristics of Cemented Paste Backfill in Deep In Situ Environments. Minerals 2025, 15, 1087. https://doi.org/10.3390/min15101087

Chen Y, Yan Z, Wang G, Guo L, Zhang Y, Zhao Y, Jia C. Research on the Mechanical and Microstructure Characteristics of Cemented Paste Backfill in Deep In Situ Environments. Minerals. 2025; 15(10):1087. https://doi.org/10.3390/min15101087

Chicago/Turabian StyleChen, Yin, Zepeng Yan, Guoqiang Wang, Lijie Guo, Yunwei Zhang, Yue Zhao, and Chong Jia. 2025. "Research on the Mechanical and Microstructure Characteristics of Cemented Paste Backfill in Deep In Situ Environments" Minerals 15, no. 10: 1087. https://doi.org/10.3390/min15101087

APA StyleChen, Y., Yan, Z., Wang, G., Guo, L., Zhang, Y., Zhao, Y., & Jia, C. (2025). Research on the Mechanical and Microstructure Characteristics of Cemented Paste Backfill in Deep In Situ Environments. Minerals, 15(10), 1087. https://doi.org/10.3390/min15101087