Optimization of High-Pressure Grinding Roll (HPGR) Performance in an Industrial-Scale HPGR/Tower Mill Comminution Circuit

Abstract

1. Introduction

2. Materials and Methods

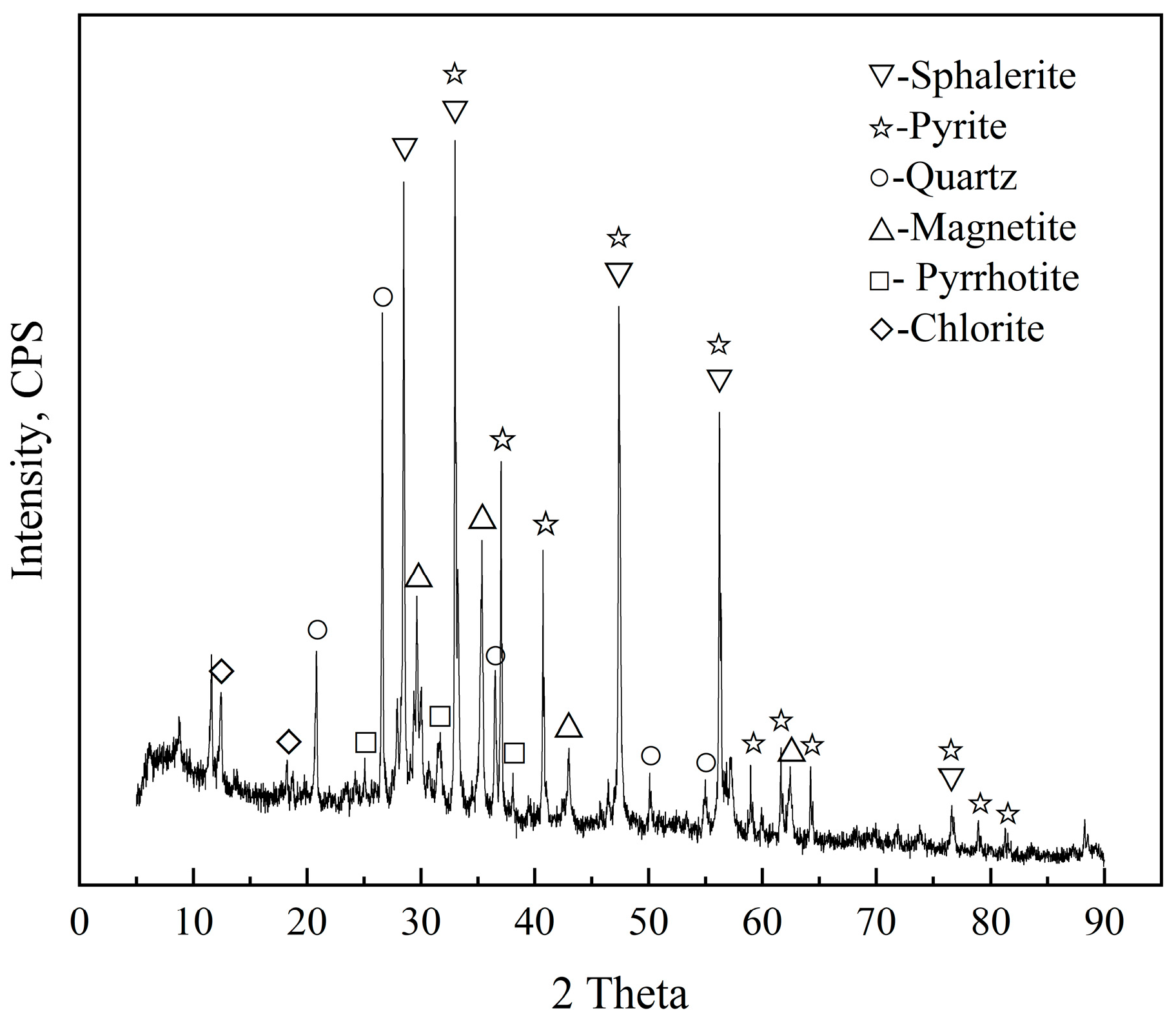

2.1. Sample and Characterization

2.2. Bond Work Index

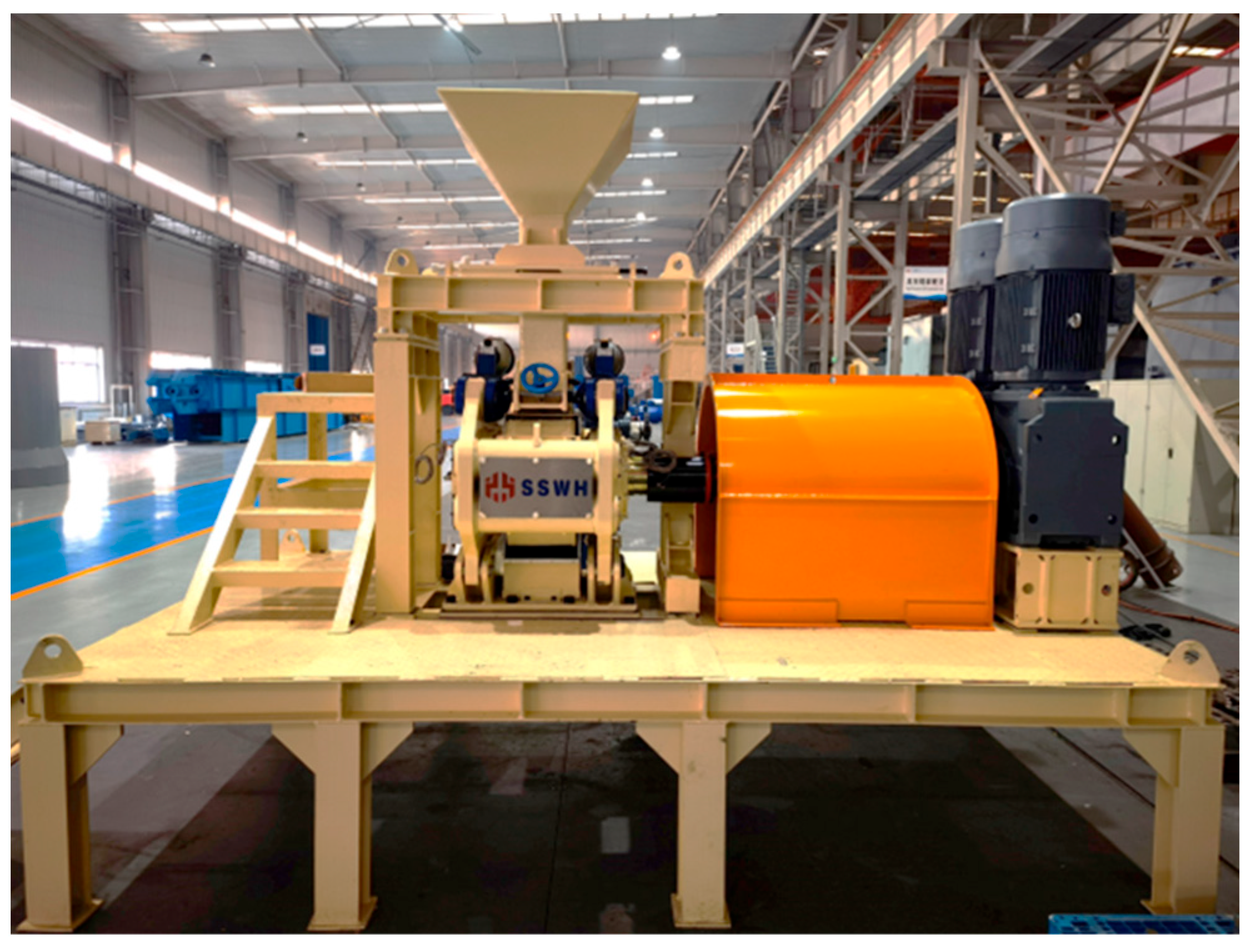

2.3. Laboratory-Scale Tests

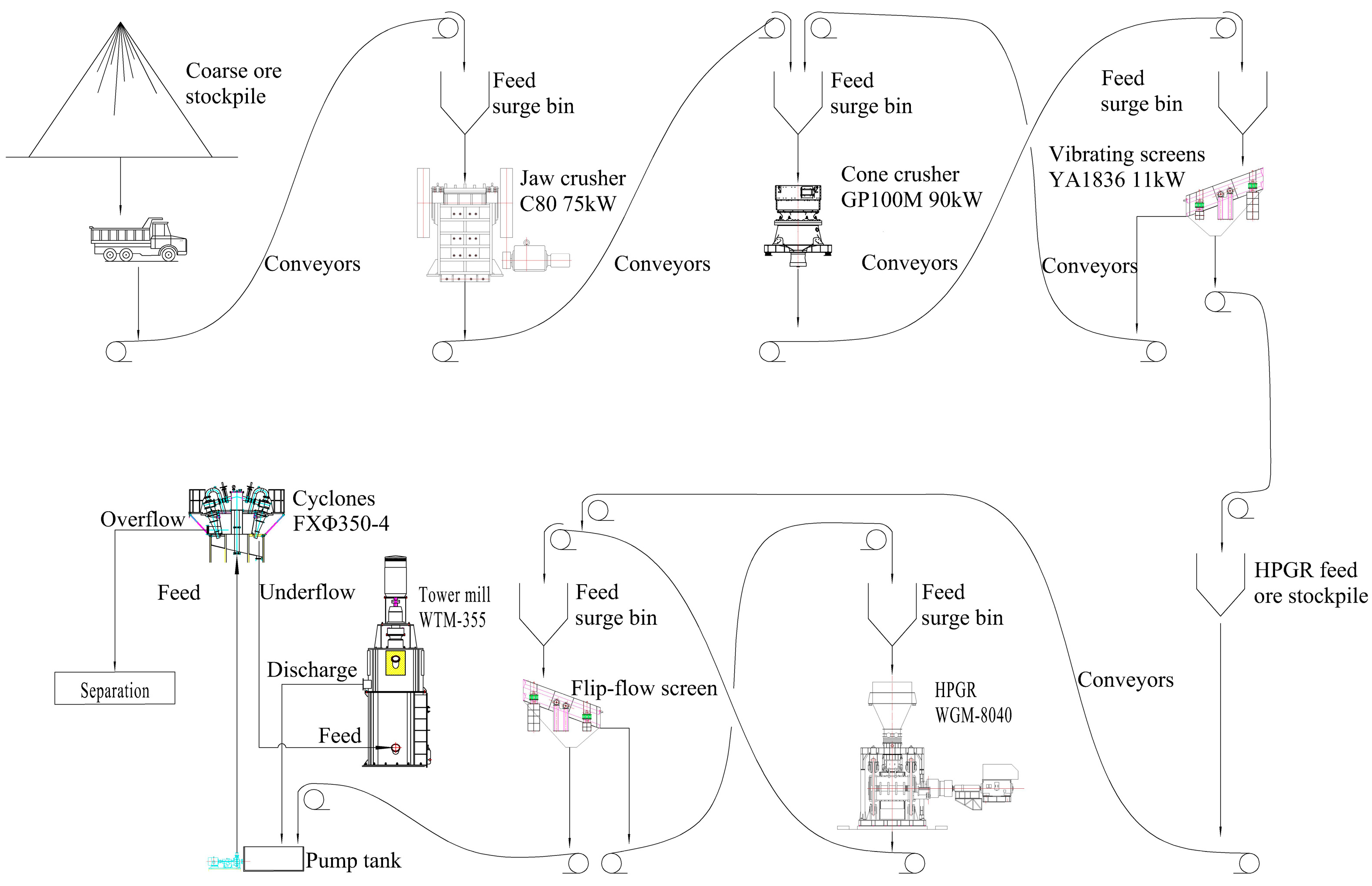

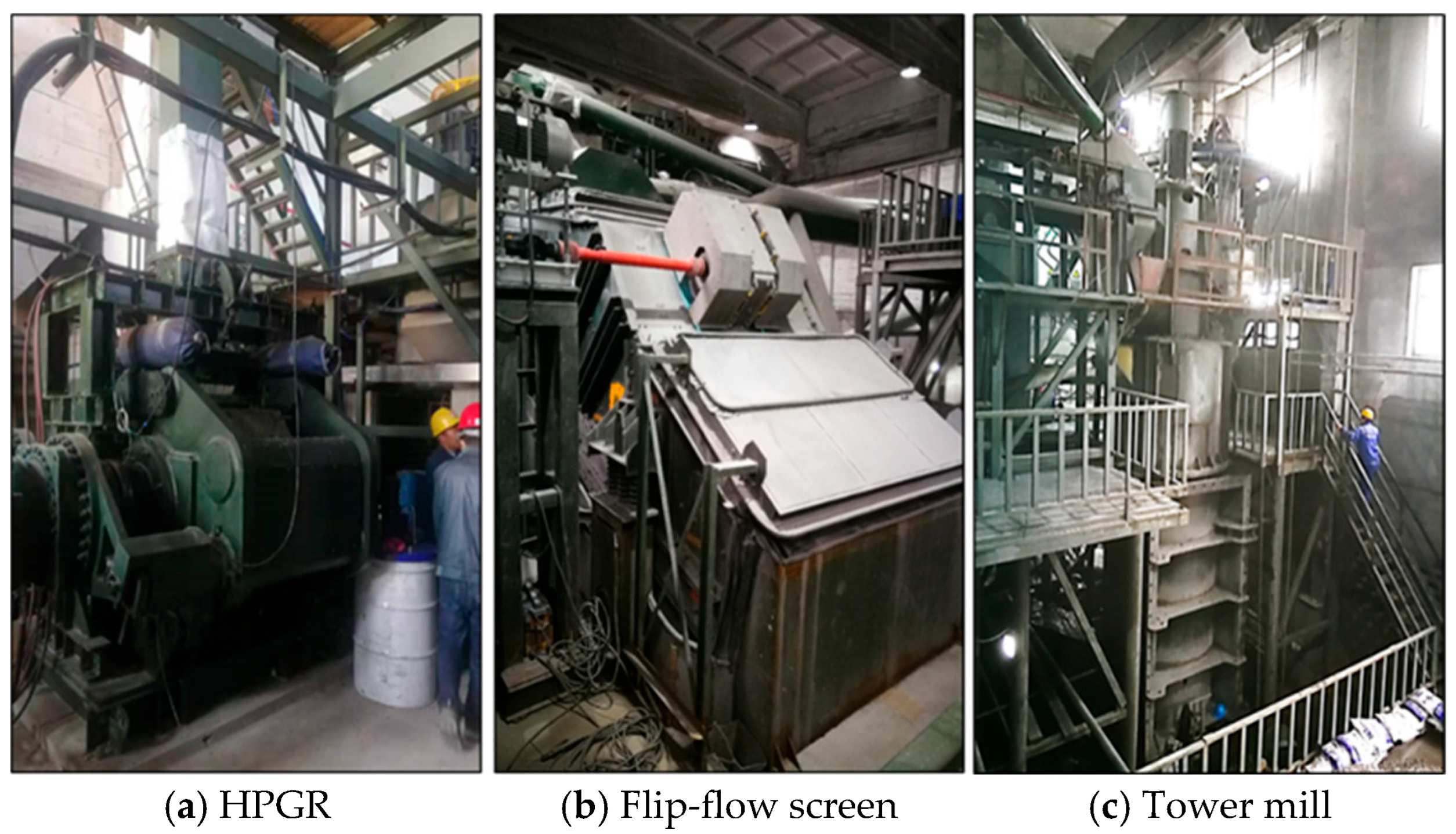

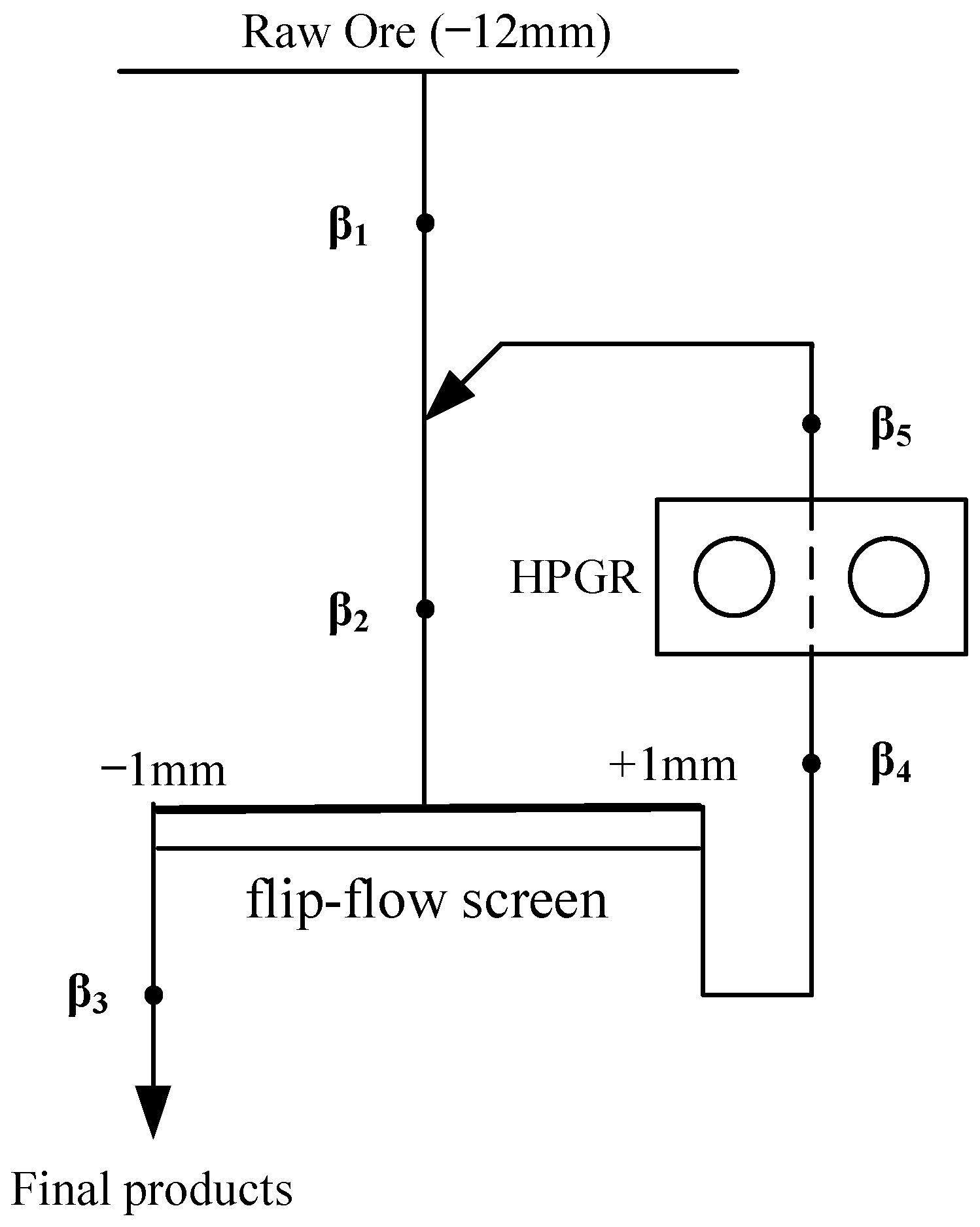

2.4. Industrial-Scale HPGR Tests

3. Results and Discussion

3.1. Laboratory-Scale Tests

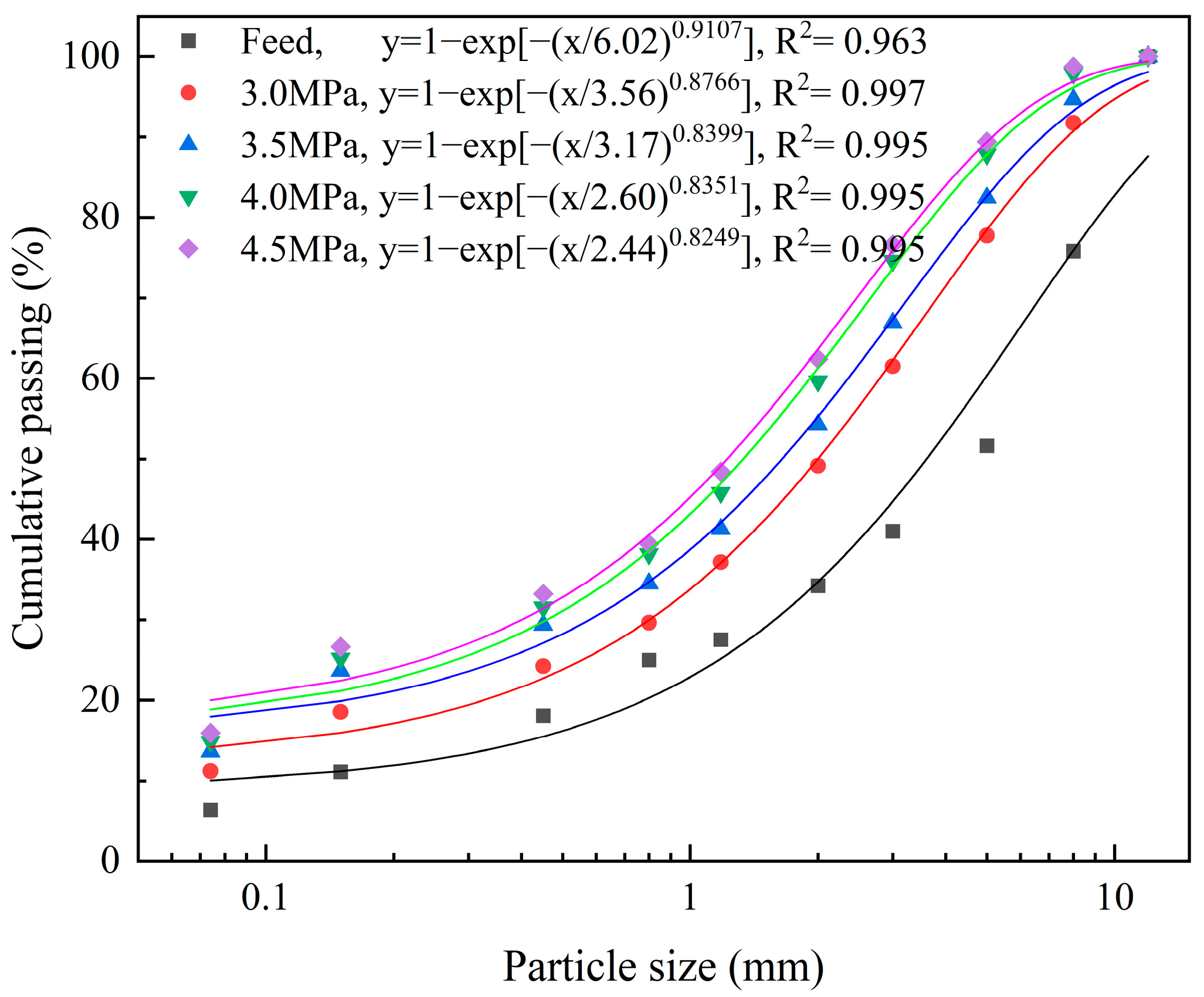

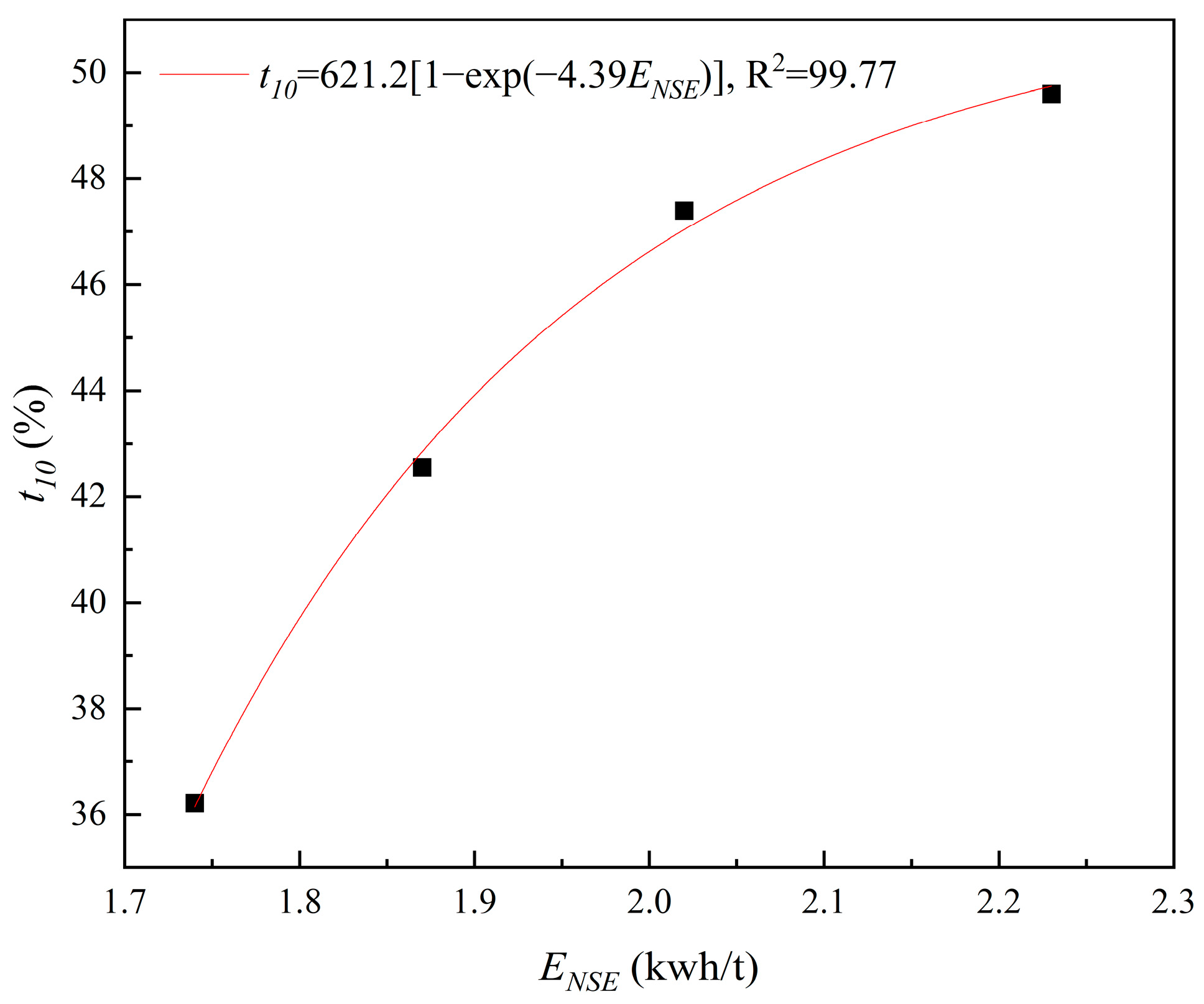

3.1.1. Open HPGR Circuit

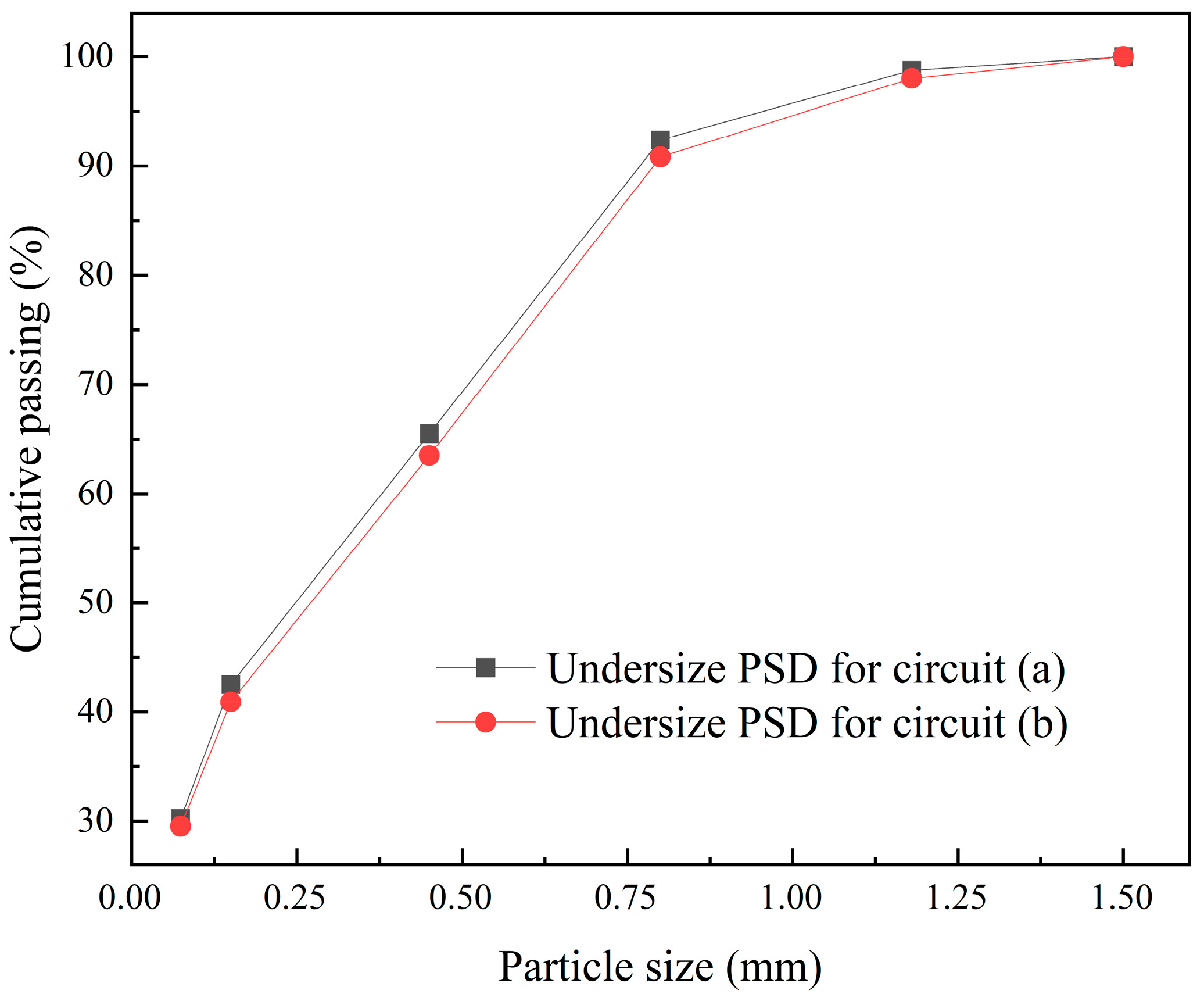

3.1.2. Closed HPGR Circuit

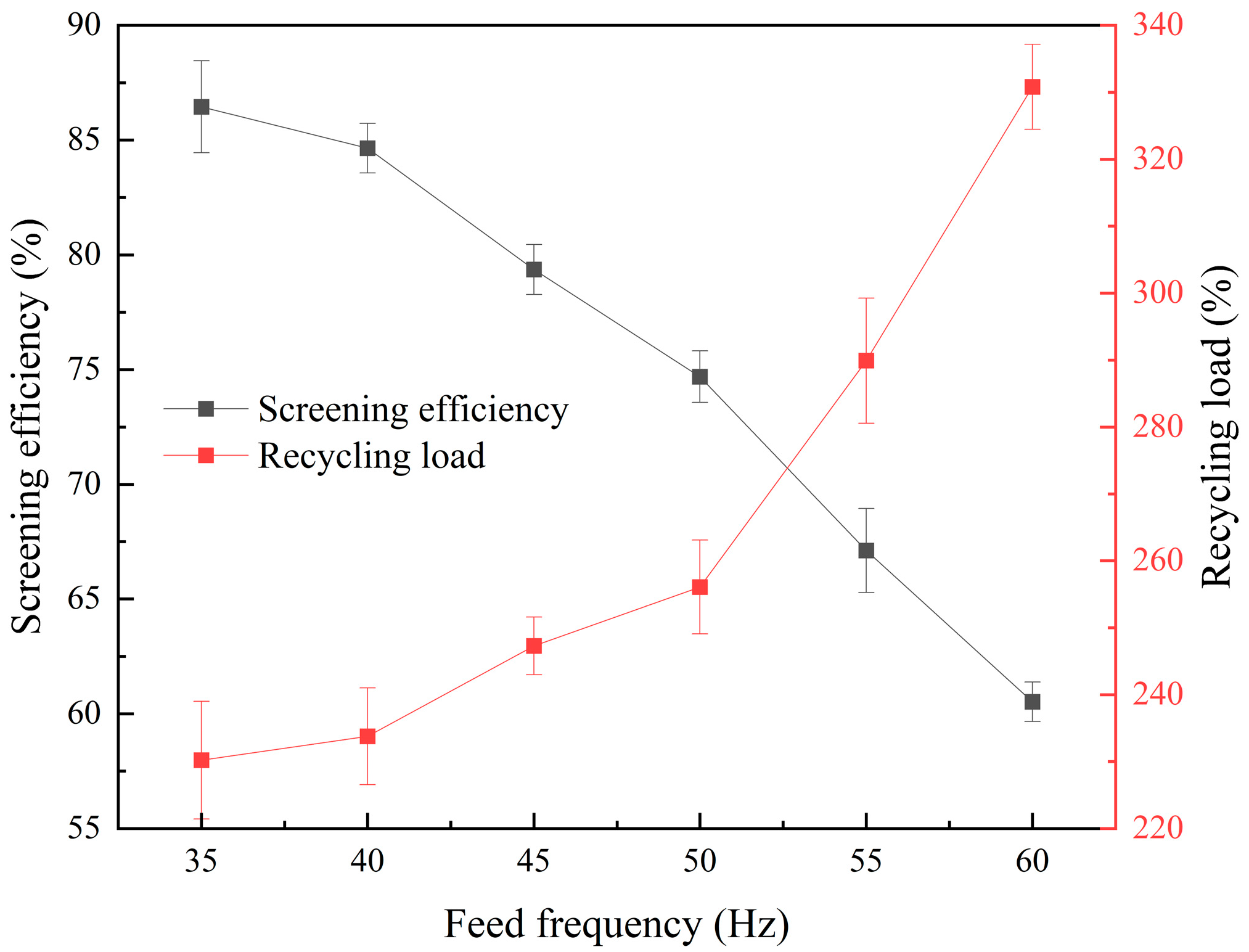

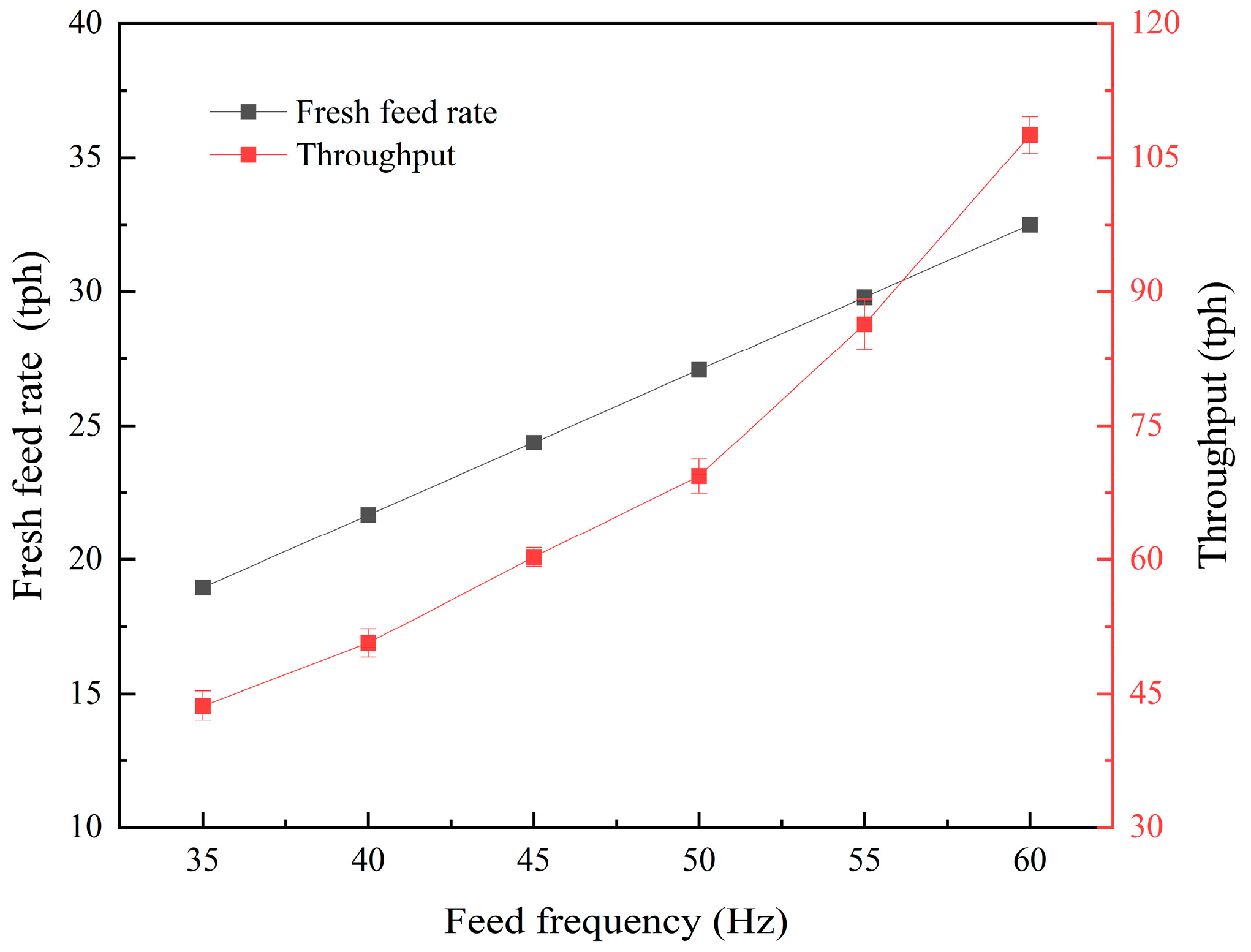

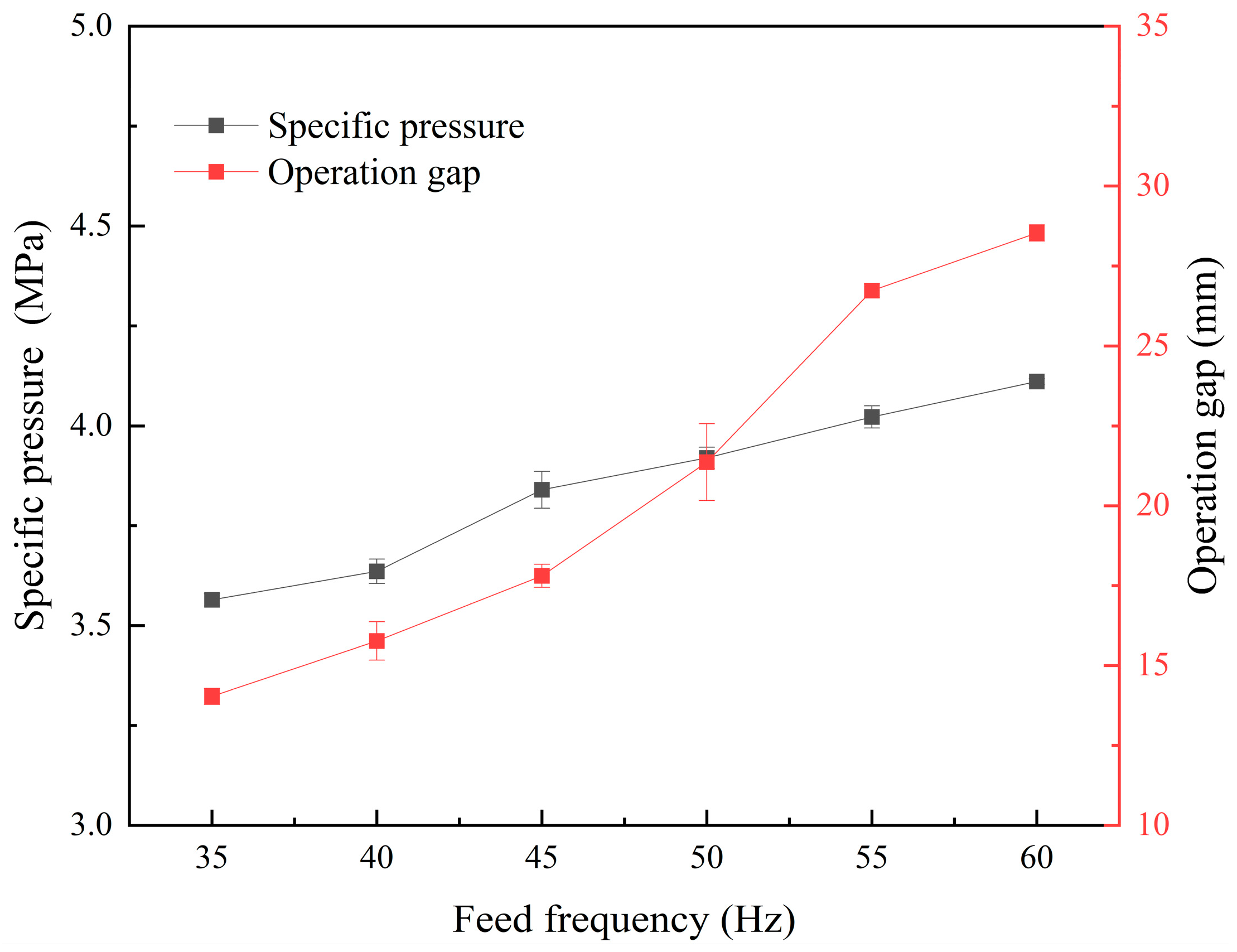

3.2. Industrial Test Results

4. Conclusions and Outlook

- (1)

- Higher specific pressures resulted in finer products and increased energy consumption. A specific pressure of 4.0 MPa was identified as the optimal balance, achieving reasonable product fineness and moderate energy consumption.

- (2)

- Compared to forward classification, a reverse classification circuit with a scalped feed to the laboratory-scale HPGR reduced the recycling load by 30.84%, and the throughput was reduced by 58.41%.

- (3)

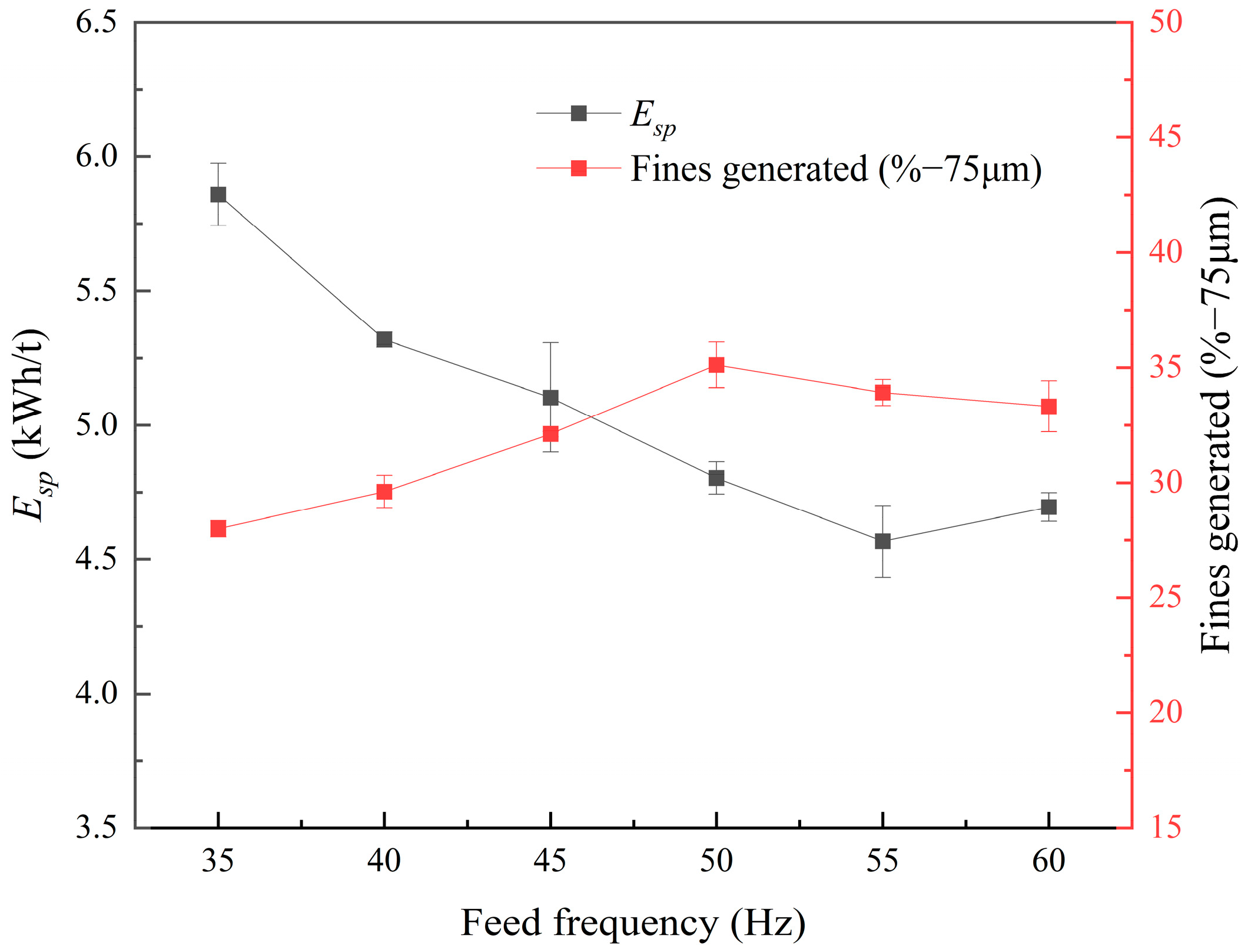

- An appropriate increase in feed rate reduced screening efficiency but enhanced HPGR performance, particularly in terms of energy efficiency. Increasing the fresh-feed rate from 18.98 tph to 32.50 tph initially reduced specific energy consumption from 5.86 kWh/t to 4.57 kWh/t at 29.79 tph, after which it slightly increased to 4.70 kWh/t.

- (4)

- With a throughput of 27.08 t/h, the circuit has operated for more than 10,000 h, confirming that an HPGR operating with a closed-circuit flip-flow screen aperture of approximately 1 mm can efficiently provide the feed to a downstream stirred mill in an HPGR/tower mill comminution circuit.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Napier-Munn, T. Is progress in energy-efficient comminution doomed? Miner. Eng. 2015, 73, 1–6. [Google Scholar] [CrossRef]

- Kumar, A.; Wang, C.; Gong, D.; Saud, C.; Pamparana, G.; Klein, B. Development of Locked-cycle piston press test procedure to simulate closed circuit HPGR comminution. Miner. Eng. 2023, 201, 108160. [Google Scholar] [CrossRef]

- Tohry, A.; Yazdani, S.; Hadavandi, E.; Mahmudzadeh, E.; Chelgani, S.C. Advanced modeling of HPGR power consumption based on operational parameters by BNN: A “Conscious-Lab” development. Powder Technol. 2021, 381, 280–284. [Google Scholar] [CrossRef]

- Liu, L.; Tan, Q.; Liu, L.; Li, W.; Lv, L. Comparison of grinding characteristics in high-pressure grinding roller (HPGR) and cone crusher (CC). Physicochem. Probl. Miner. Process. 2017, 53, 1009–1022. [Google Scholar]

- van der Meer, F.P.; Gruendken, A. Flowsheet considerations for optimal use of high pressure grinding rolls. Miner. Eng. 2010, 23, 663–669. [Google Scholar] [CrossRef]

- Saramak, D.; Foszcz, D.; Gawenda, T.; Konieczny, A.; Pawlos, W. Influence of type of lining in high-pressure grinding rolls on effectiveness of copper ore comminution. Physicochem. Probl. Miner. Process. 2016, 52, 182–192. [Google Scholar]

- Liu, Z.; Wu, J.; Cui, S.; Guo, X.; Dai, S. Development of Piston Press Test to Simulate the Energy Consumption of HPGR Comminution. JOM 2024, 76, 6709–6717. [Google Scholar] [CrossRef]

- Guo, X.; Dai, S.; Wang, Q. Influence of different comminution flowsheets on the separation of vanadium titano-magnetite. Miner. Eng. 2020, 149, 108268. [Google Scholar] [CrossRef]

- Cao, J.; Liu, L.; Han, Y.; Feng, A. Comminution behavior and mineral liberation characteristics of low-grade hematite ore in high pressure grinding roll. Physicochem. Probl. Miner. Process. 2019, 55, 575–585. [Google Scholar]

- Santosh, T.; Eswaraiah, C.; Soni, R.K.; Kumar, S. Size reduction performance evaluation of HPGR/ball mill and HPGR/stirred mill for PGE bearing chromite ore. Adv. Powder Technol. 2023, 34, 103907. [Google Scholar] [CrossRef]

- Rodríguez-Torres, I.; Tuzcu, E.T.; Reyes, I.A.; Rosales, G. A quantitative study between HPGR and cone crusher aided ball mill grinding: Mathematical modeling by evaluating the possible microfracture effect produced by HPGR technology and cone crusher. Physicochem. Probl. Miner. Process. 2024, 60, 177620. [Google Scholar] [CrossRef]

- Barani, K.; Balochi, H. A comparative study on the effect of using conventional and high pressure grinding rolls crushing on the ball mill grinding kinetics of an iron ore. Physicochem. Probl. Miner. Process. 2016, 52, 920–931. [Google Scholar]

- Liu, L.; Tan, Q.; Yue, T.; Guo, Z.; Lv, L. Pre-Concentration of Ultrafine Crushed Hematite Ores. Sep. Sci. Technol. 2014, 49, 1442–1448. [Google Scholar] [CrossRef]

- Liu, L. The hematite ore liberation and separation properties in different comminution way. Sep. Sci. Technol. 2022, 57, 131–140. [Google Scholar] [CrossRef]

- Thivierge, A.; Bouchard, J.; Desbiens, A. Modelling the product mass flow rate of high-pressure grinding rolls. IFAC-PapersOnLine 2021, 54, 127–132. [Google Scholar] [CrossRef]

- Wang, Z.; Hou, Y.; Sobhy, A. Prediction and optimization of tower mill grinding power consumption based on GA-BP neural network. Physicochem. Probl. Miner. Process. 2023, 59, 172096. [Google Scholar] [CrossRef]

- Mazzinghy, D.B.; Schneider, C.L.; Alves, V.K.; Galéry, R. Vertical Agitated Media Mill scale-up and simulation. Miner. Eng. 2015, 73, 69–76. [Google Scholar] [CrossRef]

- Curry, J.A.; Ismay, M.J.L.; Jameson, G.J. Mine operating costs and the potential impacts of energy and grinding. Miner. Eng. 2014, 56, 70–80. [Google Scholar] [CrossRef]

- Jameson, G.J. New directions in flotation machine design. Miner. Eng. 2010, 23, 835–841. [Google Scholar] [CrossRef]

- Awatey, B.; Thanasekaran, H.; Kohmuench, J.N.; Skinner, W.; Zanin, M. Optimization of operating parameters for coarse sphalerite flotation in the HydroFloat fluidised-bed separator. Miner. Eng. 2013, 50, 99–105. [Google Scholar] [CrossRef]

- Santosh, T.; Soni, R.K.; Eswaraiah, C.; Kumar, S.; Rao, D.S.; Venugopal, R. Modeling and application of stirred mill for the coarse grinding of PGE bearing chromite ore. Sep. Sci. Technol. 2023, 58, 149–163. [Google Scholar] [CrossRef]

- Walter Valery, A.J. The future of comminution. In Proceedings of the 34th IOC on Mining and Metallurgy, Bor Lake, Serbia, 30 September–3 October 2002. [Google Scholar]

- Wang, B.C.; Nadolski, S.; Mejia, O.; Drozdiak, J.; Klein, B. Energy and cost comparisons of HPGR based circuits with the SABC circuit installed at the Huckleberry mine. In Proceedings of the 45th Annual Meeting of the Canadian Mineral Processors, Ottawa, ON, Canada, 22 January 2013. [Google Scholar]

- Li, L.; Wei, B.; Zhang, Q.; Zhang, J.; Zhang, X.; Wang, C.; Li, N.; Liu, Z. Evaluating the performance of an industrial-scale high pressure grinding rolls (HPGR)-tower mill comminution circuit. Miner. Eng. 2023, 191, 107973. [Google Scholar] [CrossRef]

- Rodríguez-Torres, I.; Tuzcu, E.T.; Andrade-Martínez, J.; Rosales-Marín, G. Estimation methodology for Bond ball mill work index experiment output via mathematical modeling. Miner. Eng. 2023, 201, 108186. [Google Scholar] [CrossRef]

- Gong, S.; Zhang, F.; Xu, N.; Zhao, G.; Liu, B.; Guo, J.; Guo, Y. Equal-thickness screening mechanism of multi-mass vibrating flip-flow screens. Physicochem. Probl. Miner. Process. 2025, 61, 206993. [Google Scholar] [CrossRef]

- Wu, T.; Gong, S.; Zhao, G.; Xu, N.; Liu, B.; Zhang, F. Separation mechanism and kinematic characteristics of particles on screen panel with different vibration modes. Physicochem. Probl. Miner. Process. 2025, 61, 205443. [Google Scholar] [CrossRef]

- Kumar, R.; Gopireddy, S.R.; Jana, A.K.; Patel, C.M. Study of the discharge behavior of Rosin-Rammler particle-size distributions from hopper by discrete element method: A systematic analysis of mass flow rate, segregation and velocity profiles. Powder Technol. 2020, 360, 818–834. [Google Scholar] [CrossRef]

- Zhang, G.; Fan, Y.; Yang, R.; Li, S. Application of the Rosin-Rammler function to describe quartz sandstone particle size distribution produced by high-pressure gas rapid unloading at different infiltration pressure. Powder Technol. 2022, 412, 117982. [Google Scholar] [CrossRef]

- Zuo, W.; Shi, F. A t 10 -based method for evaluation of ore pre-weakening and energy reduction. Miner. Eng. 2015, 79, 212–219. [Google Scholar] [CrossRef]

- Baawuah, E.; Kelsey, C.; Addai-Mensah, J.; Skinner, W. Comparison of the performance of different comminution technologies in terms of energy efficiency and mineral liberation. Miner. Eng. 2020, 156, 106454. [Google Scholar] [CrossRef]

- Uttarwar, K.; Sonawwanay, P.D.; Bhosale, S. Finite element analysis of high-pressure grinding rolls for crack prediction to determine safe working conditions. Mater. Today Proc. 2022, 56, 2952–2959. [Google Scholar] [CrossRef]

- Zhou, W.-T.; Han, Y.-X.; Sun, Y.-S.; Yang, J.-L.; Ma, S.-J. Multi-scale impact crushing characteristics of polymetallic sulphide ores. Trans. Nonferrous Met. Soc. China 2019, 29, 1929–1938. [Google Scholar] [CrossRef]

- Shi, F.; Kojovic, T. Validation of a model for impact breakage incorporating particle size effect. Int. J. Miner. Process. 2007, 82, 156–163. [Google Scholar] [CrossRef]

- Schönert, K. A first survey of grinding with high-compression roller mills. Int. J. Miner. Process. 1988, 22, 401–412. [Google Scholar] [CrossRef]

- Aminalroaya, A.; Pourghahramani, P. The Effect of Feed Characteristics on Particles Breakage and Weakening Behavior in High Pressure Grinding Rolls (HPGR). Miner. Process. Extr. Metall. Rev. 2021, 43, 610–621. [Google Scholar] [CrossRef]

- Liu, L.X.; Powell, M. New approach on confined particle bed breakage as applied to multicomponent ore. Miner. Eng. 2016, 85, 80–91. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J.A. Chapter 7—Grinding Mills. In Wills’ Mineral Processing Technology, 8th ed.; Wills, B.A., Finch, J.A., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2016; pp. 147–179. [Google Scholar]

- Abouzeid, A.-Z.M.; Fuerstenau, D.W. Grinding of mineral mixtures in high-pressure grinding rolls. Int. J. Miner. Process. 2009, 93, 59–65. [Google Scholar] [CrossRef]

- Wang, W.; Pan, M.; Duan, C.; Jiang, H.; Zhao, Y.; Lu, H. Dry deep screening of spodumene and its mineral processing technology. Miner. Eng. 2022, 179, 59–65. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J.A. Chapter 8—Industrial Screening. In Wills’ Mineral Processing Technology, 8th ed.; Wills, B.A., Finch, J.A., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2016; pp. 181–197. [Google Scholar]

- Lim, W.I.L.; Weller, K.R. Some benefits of using studded surfaces in high pressure grinding rolls. Miner. Eng. 1999, 12, 187–203. [Google Scholar] [CrossRef]

- Pamparana, G.; Klein, B. A methodology to predict the HPGR operational gap by using piston press tests. Miner. Eng. 2021, 166, 106875. [Google Scholar] [CrossRef]

- Barrios, G.K.P.; Tavares, L.M. A preliminary model of high pressure roll grinding using the discrete element method and multi-body dynamics coupling. Int. J. Miner. Process. 2016, 156, 32–42. [Google Scholar] [CrossRef]

- Johansson, M.; Evertsson, M. A time dynamic model of a high pressure grinding rolls crusher. Miner. Eng. 2019, 132, 27–38. [Google Scholar] [CrossRef]

- Benzer, H.; Aydogan, N.A.; Dündar, H. Investigation of the breakage of hard and soft components under high compression: HPGR application. Miner. Eng. 2011, 24, 303–307. [Google Scholar] [CrossRef]

- Campos, T.M.; Andersson, C.; Evertsson, M.; Powell, M.; Tavares, L.M. Energy-based modelling of single-particle breakage by slow compression. Miner. Eng. 2024, 208, 106875. [Google Scholar] [CrossRef]

- Saramak, D.; Leśniak, K. Impact of HPGR operational pressing force and material moisture on energy consumption and crushing product fineness in high-pressure grinding processes. Energy 2024, 302, 131908. [Google Scholar] [CrossRef]

- Ballantyne, G.R.; Peukert, W.; Powell, M.S. Size specific energy (SSE)—Energy required to generate minus 75 micron material. Int. J. Miner. Process. 2015, 136, 2–6. [Google Scholar] [CrossRef]

- Tavares, L.M. Particle weakening in high-pressure roll grinding. Miner. Eng. 2005, 18, 651–657. [Google Scholar] [CrossRef]

- Morrell, S. Helping to reduce mining industry carbon emissions: A step-by-step guide to sizing and selection of energy efficient high pressure grinding rolls circuits. Miner. Eng. 2022, 179, 131908. [Google Scholar] [CrossRef]

- Sadangi, J.K.; Das, S.P. Potential of High-Pressure Grinding Roll (HPGR) for Size Reduction of Hard Banded Iron Ore. Trans. Indian Inst. Met. 2022, 75, 1797–1811. [Google Scholar] [CrossRef]

| Elements | Fe2O3 | S | SiO2 | Zn | Cu | Pb |

|---|---|---|---|---|---|---|

| Content | 21.31 | 12.55 | 28.35 | 3.52 | 0.40 | 0.83 |

| Bulk Density | F80 | P80 | Closing Screen Size | BBWI |

|---|---|---|---|---|

| 2.07 t/m3 | 1820 μm | 51.18 μm | 74 μm | 16.06 kwh/t |

| Item | Description |

|---|---|

| HPGR model | WGM-3516 |

| Roll diameter | 350 mm |

| Roll width | 160 mm |

| Initial gap (gap zero) | 6 mm |

| Maximum gap | 15 mm |

| Wear surface | Studded |

| Motor power | 2 × 18.5 kW |

| Maximum specific pressure | 6 N/mm2 |

| Variable speed drive | 0~0.4 m/s |

| Equipment Type | Quantity | Specification | Power (kW) |

|---|---|---|---|

| Primary jaw crusher | 1 | C80 | 75 |

| Secondary cone crusher | 1 | GP100M | 90 |

| Circular vibrating screen | 1 | YA1836 | 11 |

| HPGR | 1 | WGM8040 | 2 × 110 |

| Vibrating flip-flow screen | 1 | SSMS2461 | 33 |

| Tower mill | 1 | WTM-355 | 355 |

| Cyclones | 1 | FXΦ350-4 | - |

| Cyclone feed pump | 1 | 150JZ | 55 |

| Item | Description |

|---|---|

| HPGR model | WGM-8040 |

| Roll diameter | 800 mm |

| Roll width | 400 mm |

| Initial gap (gap zero) | 8 mm |

| Maximum gap | 20 mm |

| Wear surface | Studded |

| Motor power | 2 × 110 kW |

| Maximum specific pressure | 8.5 N/mm2 |

| Variable speed drive | Up to 40 rpm (1.55 m/s) |

| Item | Description |

|---|---|

| Screen model | SSMS2461 (single layer) |

| Screen area | 14.64 m2 |

| Screen size | 1 mm × 10 mm |

| Power | 30 kW |

| Speed | 800 rpm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, B.; Yuan, Z.; Feng, Q.; Zhang, Q.; Xu, X.; Meng, Q.; Klein, B.; Li, L. Optimization of High-Pressure Grinding Roll (HPGR) Performance in an Industrial-Scale HPGR/Tower Mill Comminution Circuit. Minerals 2025, 15, 1065. https://doi.org/10.3390/min15101065

Wei B, Yuan Z, Feng Q, Zhang Q, Xu X, Meng Q, Klein B, Li L. Optimization of High-Pressure Grinding Roll (HPGR) Performance in an Industrial-Scale HPGR/Tower Mill Comminution Circuit. Minerals. 2025; 15(10):1065. https://doi.org/10.3390/min15101065

Chicago/Turabian StyleWei, Bo, Zhitao Yuan, Quan Feng, Qiang Zhang, Xinyang Xu, Qingyou Meng, Bern Klein, and Lixia Li. 2025. "Optimization of High-Pressure Grinding Roll (HPGR) Performance in an Industrial-Scale HPGR/Tower Mill Comminution Circuit" Minerals 15, no. 10: 1065. https://doi.org/10.3390/min15101065

APA StyleWei, B., Yuan, Z., Feng, Q., Zhang, Q., Xu, X., Meng, Q., Klein, B., & Li, L. (2025). Optimization of High-Pressure Grinding Roll (HPGR) Performance in an Industrial-Scale HPGR/Tower Mill Comminution Circuit. Minerals, 15(10), 1065. https://doi.org/10.3390/min15101065