Mineralogy and Geochemistry of High-Sulfur Coals from the M8 Coal Seam, Shihao Mine, Songzao Coalfield, Chongqing, Southwestern China

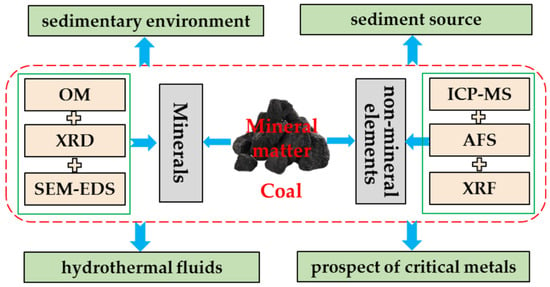

Abstract

1. Introduction

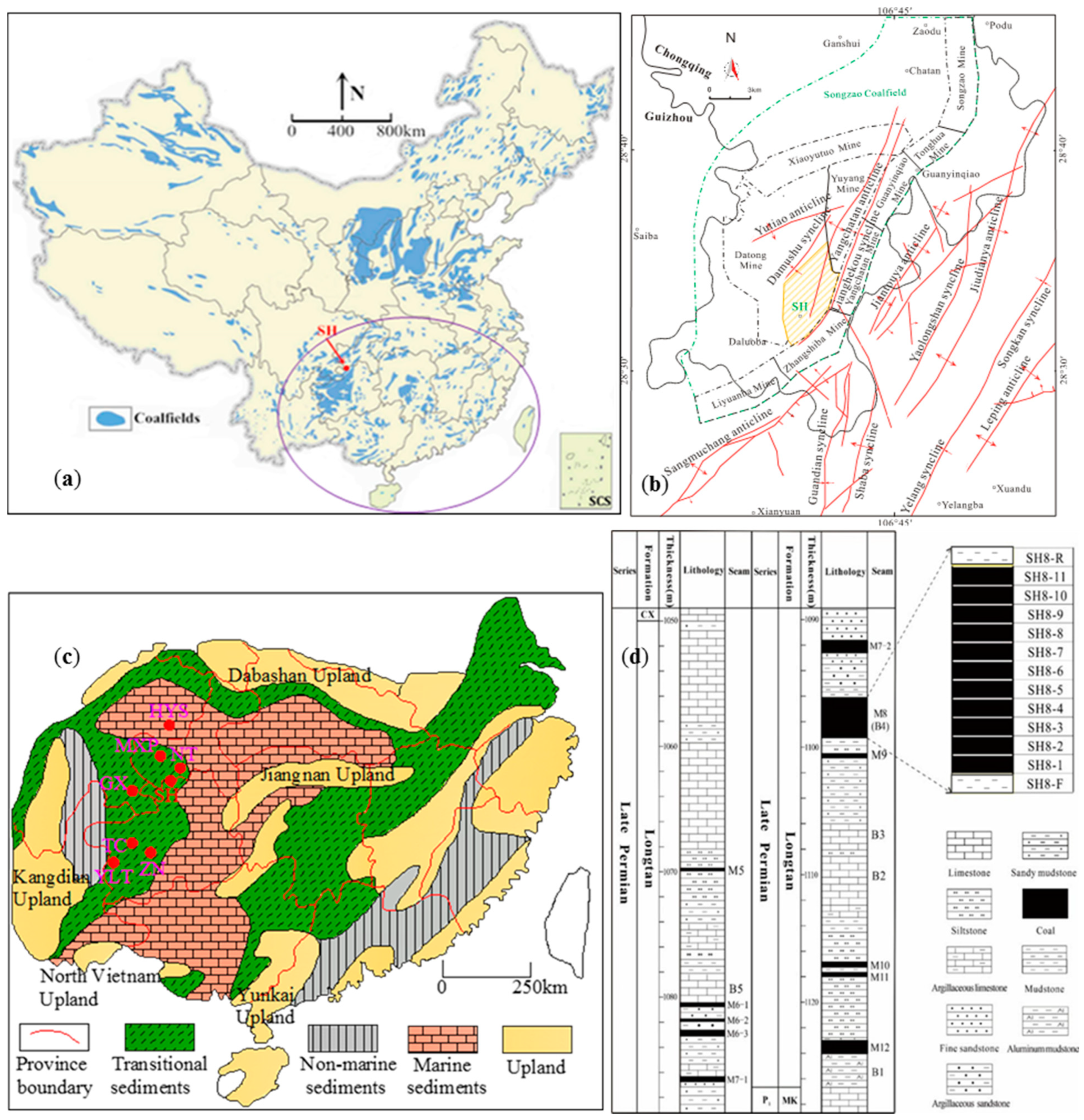

2. Geological Setting

3. Sample Collection and Analytical Methods

3.1. Sample Collection and Preparation

3.2. Experimental Analytical Methods

4. Results

4.1. Coal Chemistry

4.2. Mineralogy

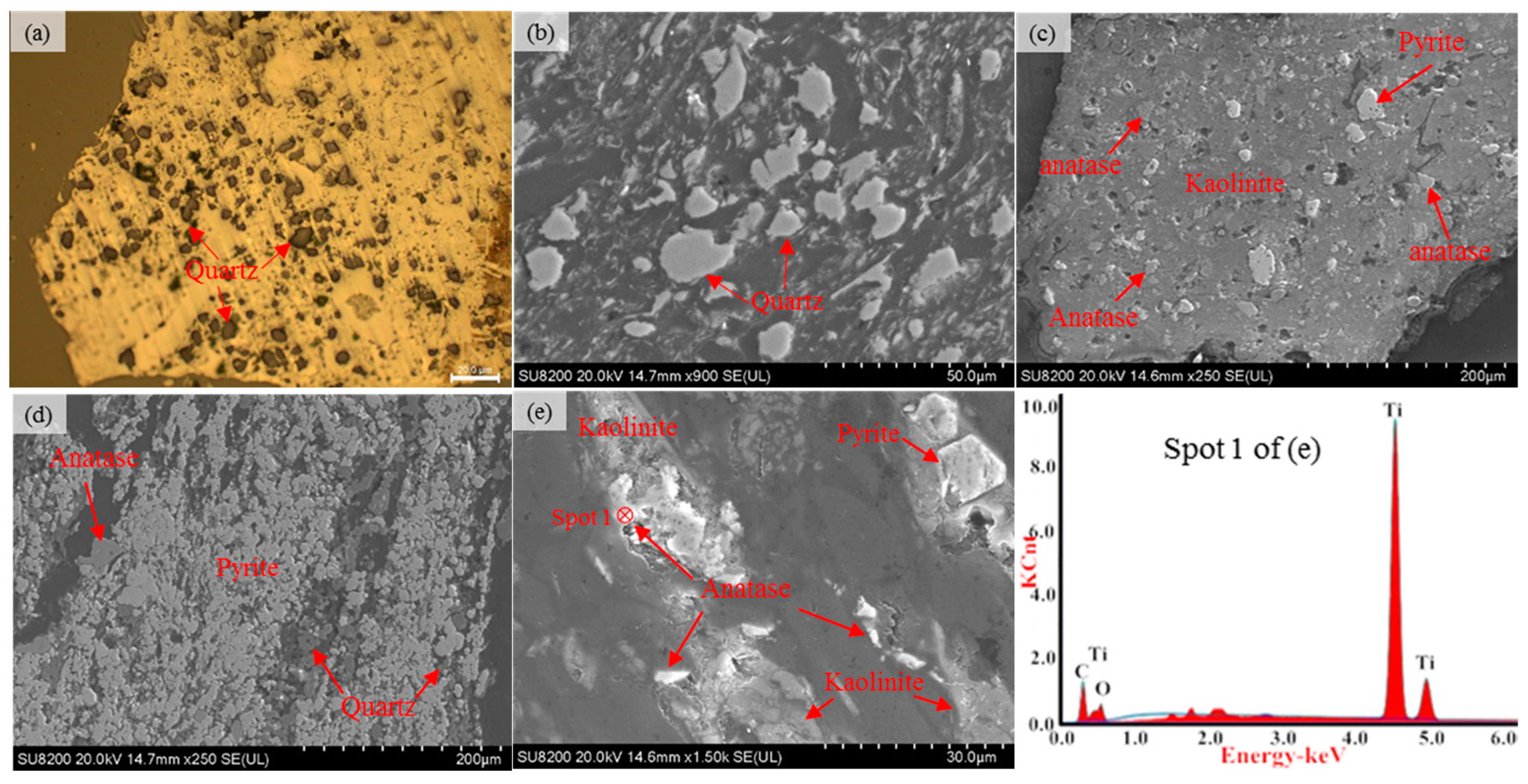

4.2.1. Clay Minerals

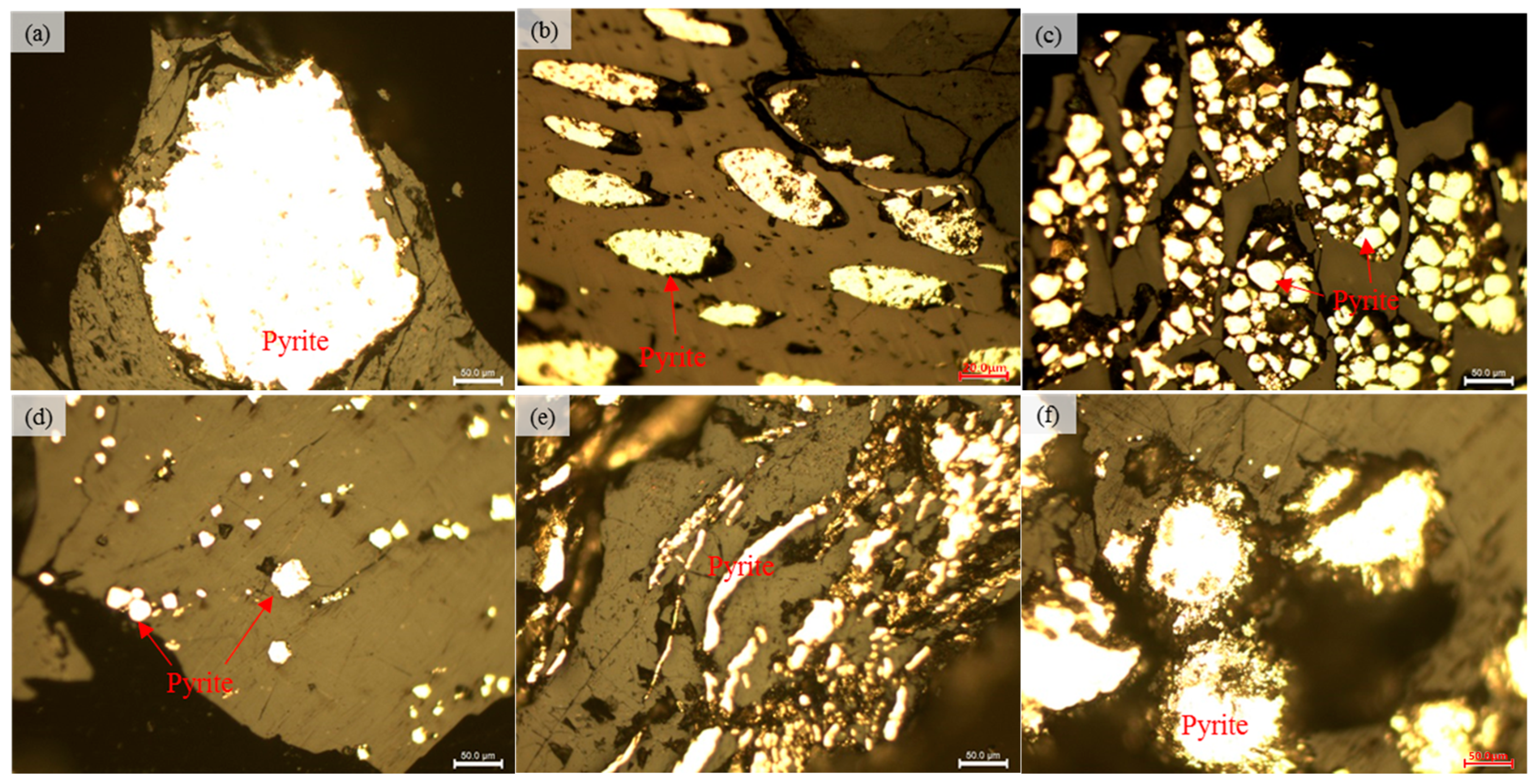

4.2.2. Sulfide Minerals

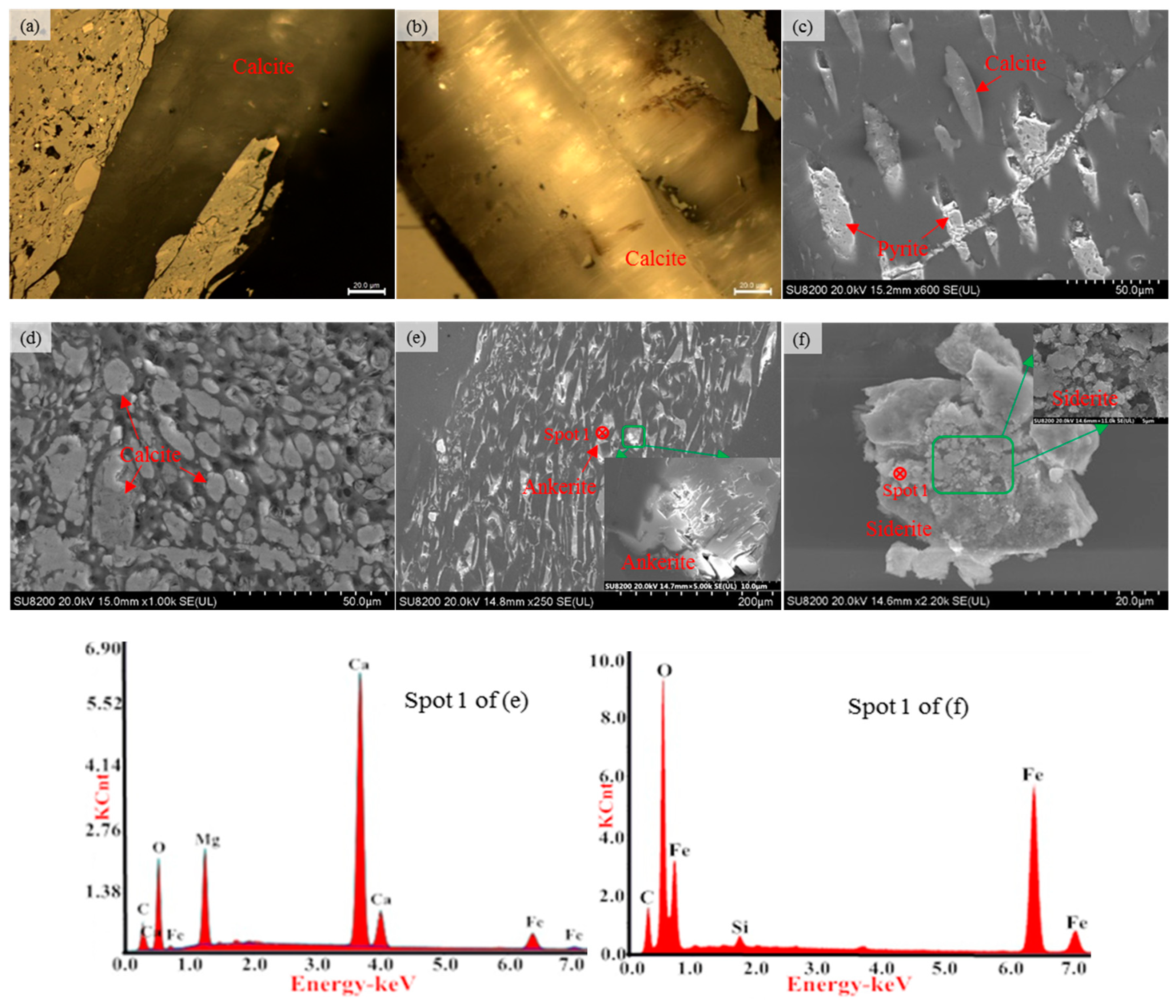

4.2.3. Carbonate Minerals

4.2.4. Oxide Minerals

4.3. Geochemistry

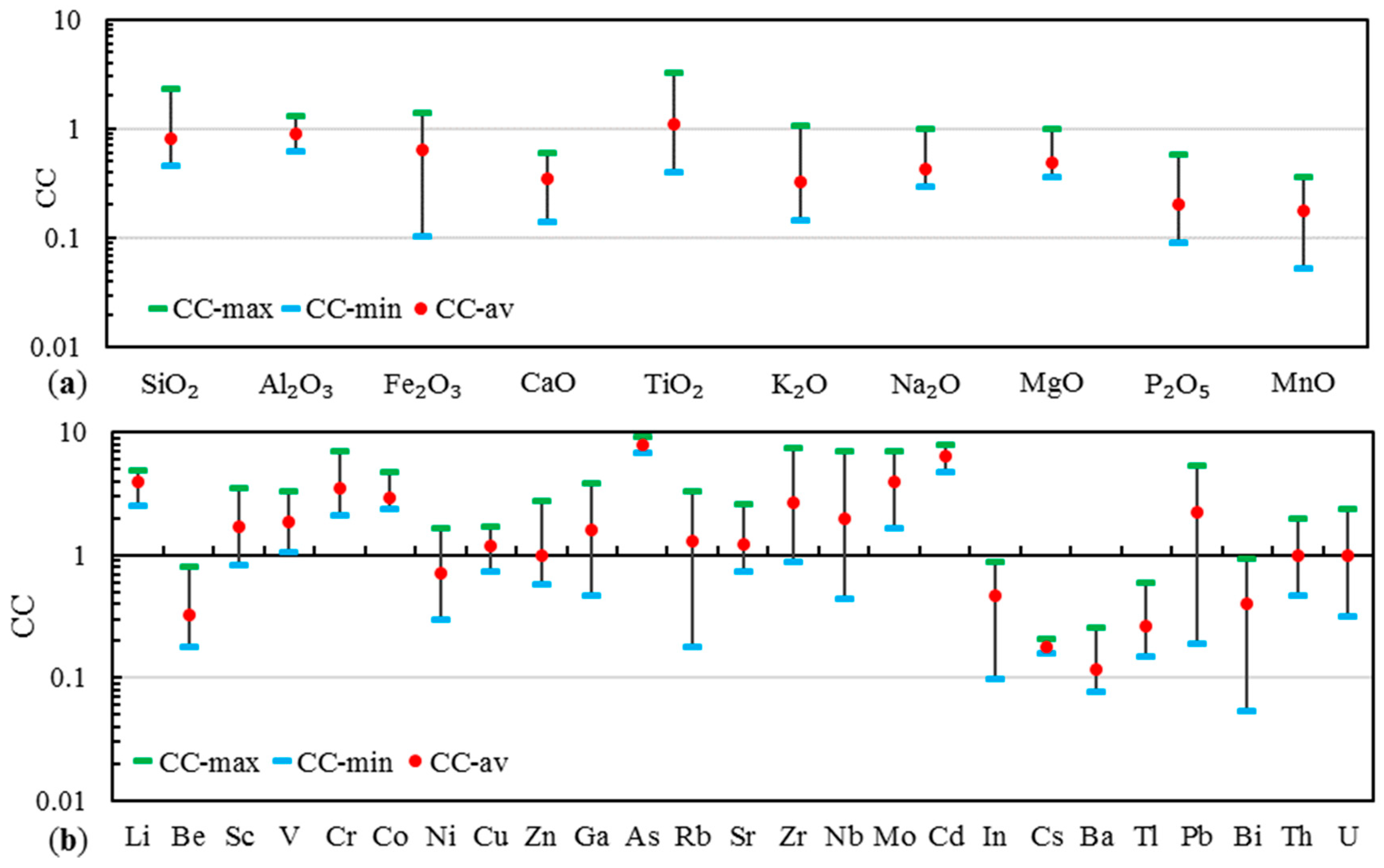

4.3.1. Major-Element Oxides and Trace Elements in Coal

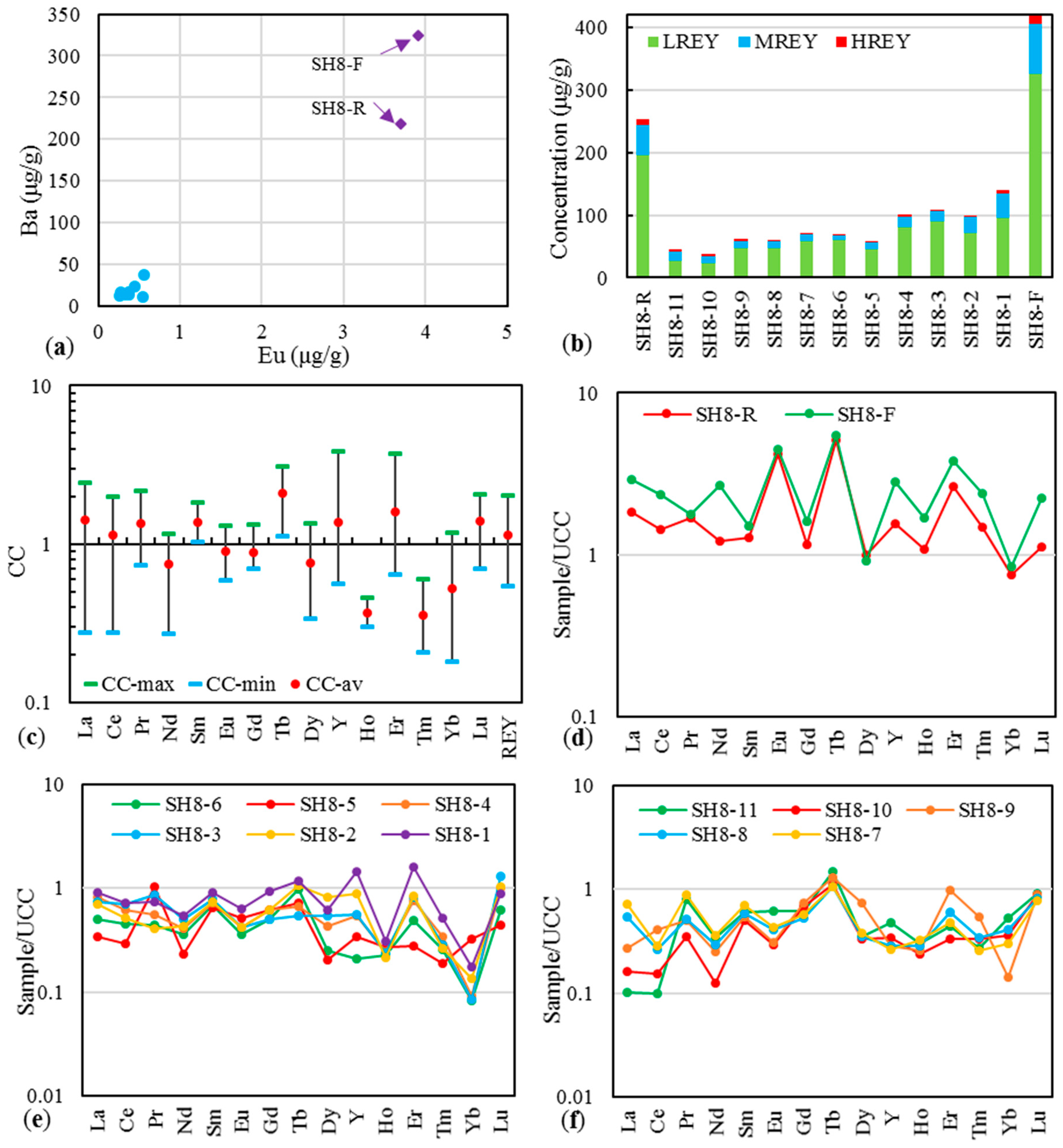

4.3.2. Rare Earth Elements and Yttrium

5. Discussion

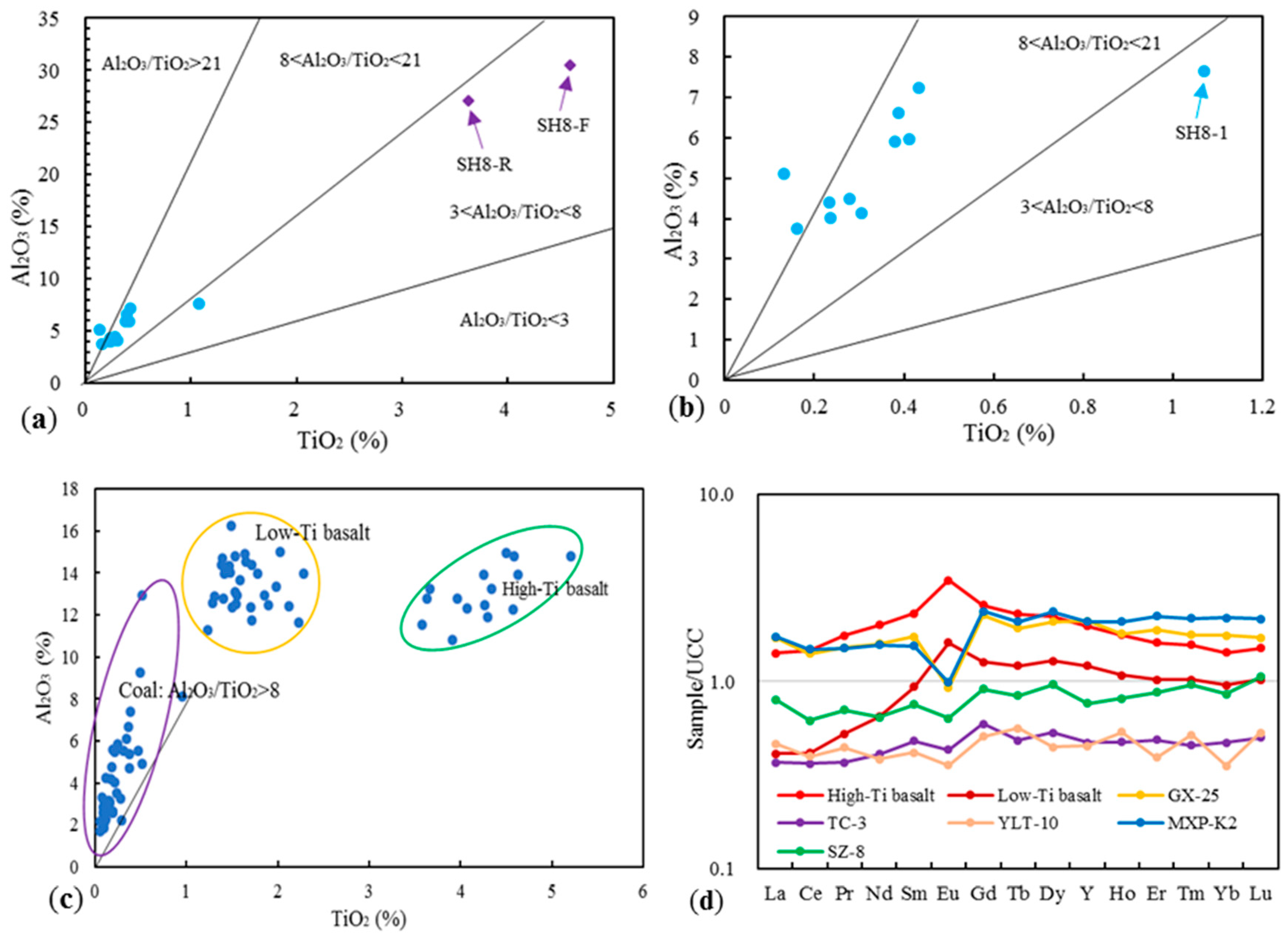

5.1. Sediment Sources

5.2. Depositional Environment

5.3. Hydrothermal Fluid Injections

5.4. Evaluation of Critical Metals

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- BP P.L.C. Bp Statistical Review of World Energy, 71st ed.; BP P.L.C.: London, UK, 2022. [Google Scholar]

- Dai, S.F.; Zhao, L.; Wei, Q.; Song, X.L.; Wang, W.F.; Liu, J.J.; Duan, P.P. Resources of critical metals in coal-bearing sequences in China: Enrichment types and distribution. Chin. Sci. Bull. 2020, 65, 3715–3729, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Dai, S.F.; Hower, J.C.; Finkelman, R.B.; Graham, I.T.; French, D.; Ward, C.R.; Eskenazy, G.; Wei, Q.; Zhao, L. Organic associations of non-mineral elements in coal: A review. Int. J. Coal Geol. 2020, 218, 103347. [Google Scholar] [CrossRef]

- Jia, R.K.; Liu, J.J.; Han, Q.C.; Zhao, S.M.; Shang, N.D.; Tang, P.Q. Mineral matter transition in lignite during ashing process: A case study of Early Cretaceous lignite from the Hailar Basin, Inner Mongolia, China. Fuel 2022, 328, 125252. [Google Scholar] [CrossRef]

- Hou, Y.J.; Dai, S.F.; Nechaev, V.P.; Finkelman, R.B.; Wang, H.D.; Zhang, S.W.; Di, S.B. Mineral matter in the Pennsylvanian coal from the Yangquan Mining District, northeastern Qinshui Basin, China: Enrichment of critical elements and a Se-Mo-Pb-Hg assemblage. Int. J. Coal Geol. 2023, 266, 104178. [Google Scholar] [CrossRef]

- Ward, C.R. Analysis, origin and significance of mineral matter in coal: An updated review. Int. J. Coal Geol. 2016, 165, 1–27. [Google Scholar] [CrossRef]

- Xu, F.; Qin, S.J.; Li, S.Y.; Wang, J.X.; Qi, D.E.; Lu, Q.F.; Xing, J.K. Distribution, occurrence mode, and extraction potential of critical elements in coal ashes of the Chongqing Power Plant. J. Clean. Prod. 2022, 342, 130910. [Google Scholar] [CrossRef]

- Li, C.; Zhou, C.C.; Li, W.W.; Zhu, W.R.; Shi, J.Q.; Liu, G.J. Enrichment of critical elements from coal fly ash by the combination of physical separations. Fuel 2023, 336, 127156. [Google Scholar] [CrossRef]

- Xiong, Y.; Ning, Z.P.; Liu, Y.Z.; Gomez, M.; Xiao, T.F. Emission and transformation behaviors of trace elements during combustion of Cd-rich coals from coal combustion related endemic fluorosis areas of Southwest, China. Ecotoxicol. Environ. Saf. 2022, 246, 114145. [Google Scholar] [CrossRef] [PubMed]

- Duan, P.P.; Wang, W.F.; Liu, X.H.; Qian, F.C.; Sang, S.X.; Xu, S.C. Distribution of As, Hg and other trace elements in different size and density fractions of the Reshuihe high-sulfur coal, Yunnan Province, China. Int. J. Coal Geol. 2017, 173, 129–141. [Google Scholar] [CrossRef]

- Dai, S.F.; Finkelman, R.B. Coal as a promising source of critical elements: Progress and future prospects. Int. J. Coal Geol. 2018, 186, 155–164. [Google Scholar] [CrossRef]

- Dai, S.F.; Liu, C.Y.; Zhao, L.; Liu, J.J.; Wang, X.B.; Ren, D.Y. Strategic metal resources in coal-bearing strata: Significance and challenges. J. China Coal Soc. 2022, 47, 1743–1749, (In Chinese with English Abstract). [Google Scholar]

- Dai, S.F.; Finkelman, R.B.; French, D.; Hower, J.C.; Graham, I.T.; Zhao, F.H. Modes of occurrence of elements in coal: A critical evaluation. Earth-Sci. Rev. 2021, 222, 103815. [Google Scholar] [CrossRef]

- Qin, S.J.; Xu, F.; Cui, L.; Wang, J.X.; Li, S.Y.; Zhao, Z.S.; Xiao, L.; Guo, Y.X.; Zhao, C.L. Geochemistry characteristics and resource utilization of strategically critical trace elements from coal-related resources. Coal Sci. Technol. 2022, 50, 1–38, (In Chinese with English Abstract). [Google Scholar]

- Chen, J.; Li, Y.; Jiang, P.J.; Zeng, J.; Chen, P.; Liu, W.Z.; Wang, X.M. Geochemistry of Neogene Mengtuo lignite in the Lincang from western Yunnan, southwestern China: Implications for its sediment material provenance and model of element enrichment. Ore Geol. Rev. 2021, 139, 104536. [Google Scholar] [CrossRef]

- Qin, S.; Gao, K.; Sun, Y.; Wang, J.; Zhao, C.; Li, S.; Lu, Q. Geochemical Characteristics of Rare-Metal, Rare-Scattered, and Rare-Earth Elements and Minerals in the Late Permian Coals from the Moxinpo Mine, Chongqing, China. Energy Fuels 2018, 32, 3138–3151. [Google Scholar] [CrossRef]

- Lu, Q.F.; Qin, S.J.; Wang, W.F.; Wang, Q.; Kang, S. Geochemistry of Late Permian coals from the Yueliangtian coal deposit, Guizhou: Evidence of sediment source and evaluation on critical elements. Sci. Total Environ. 2023, 856, 159123. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Sheng, W.Q.; Li, L.Y.; Zheng, L.G.; Miao, C.H.; Sun, R.Y. Alteration behavior of mineral structure and hazardous elements during combustion of coal from a power plant at Huainan, Anhui, China. Environ. Pollut. 2018, 239, 768–776. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.J.; Dai, S.F.; Song, H.J.; Nechaev, V.P.; French, D.; Spiro, B.F.; Graham, I.T.; Hower, J.C.; Shao, L.Y.; Zhao, J.T. Geological factors controlling variations in the mineralogical and elemental compositions of Late Permian coals from the Zhijin-Nayong Coalfield, western Guizhou, China. Int. J. Coal Geol. 2021, 247, 103855. [Google Scholar] [CrossRef]

- Lu, Q.F.; Qin, S.J.; Xu, F.; Chang, X.C.; Wang, W.F. Maceral and Organic Geochemical Characteristics of the Late Permian Coals from Yueliangtian Mine, Guizhou, Southwestern China. ACS OMEGA 2021, 6, 3149–3163. [Google Scholar] [CrossRef]

- Li, B.Q.; Zhuang, X.G.; Li, J.; Querol, X.; Font, O.; Moreno, N. Geological controls on mineralogy and geochemistry of the Late Permian coals in the Liulong Mine of the Liuzhi Coalfield, Guizhou Province, Southwest China. Int. J. Coal Geol. 2016, 154–155, 1–15. [Google Scholar] [CrossRef]

- Li, B.Q.; Zhuang, X.G.; Li, J.; Querol, X.; Font, O.; Moreno, N. Enrichment and distribution of elements in the Late Permian coals from the Zhina Coalfield, Guizhou Province, Southwest China. Int. J. Coal Geol. 2017, 171, 111–129. [Google Scholar] [CrossRef]

- Zhuang, X.G.; Su, S.C.; Xiao, M.G.; Li, J.; Alstuey, A.; Querol, X. Mineralogy and geochemistry of the Late Permian coals in the Huayingshan coal-bearing area, Sichuan Province, China. Int. J. Coal Geol. 2012, 94, 271–282. [Google Scholar] [CrossRef]

- Chen, J.; Chen, P.; Yao, D.X.; Liu, Z.; Wu, Y.S.; Liu, W.Z.; Hu, Y.B. Mineralogy and geochemistry of Late Permian coals from the Donglin Coal Mine in the Nantong coalfield in Chongqing, southwestern China. Int. J. Coal Geol. 2015, 149, 24–40. [Google Scholar] [CrossRef]

- Dai, S.F.; Seredin, V.V.; Ward, C.R.; Hower, J.C.; Xing, Y.W.; Zhang, W.G.; Song, W.J.; Wang, P.P. Enrichment of U-Se-Mo-Re-V in coals preserved within marine carbonate successions: Geochemical and mineralogical data from the Late Permian Guiding Coalfield, Guizhou, China. Miner. Depos. 2015, 50, 159–186. [Google Scholar] [CrossRef]

- Qin, S.J.; Gao, K.; Wang, J.X.; Li, Y.H.; Lu, Q.F. Geochemistry of the associated elements in the Late Permian coal from the Huoshaopu and Jinjia Mines, Southwestern Guizhou. J. China Coal Soc. 2016, 41, 1507–1516, (In Chinese with English Abstract). [Google Scholar]

- Qin, S.; Lu, Q.; Gao, K.; Bo, P.; Wu, S. Geochemistry of elements associated with Late Permian coal in the Zhongliangshan mine, Chongqing, Southwest China. Energy Explor. Exploit. 2018, 36, 1655–1673. [Google Scholar] [CrossRef]

- Li, B.Q.; Zhuang, X.G.; Querol, X.; Moreno, N.; Cordoba, P.; Shangguan, Y.; Yang, L.J.; Li, J.; Zhang, F. Geological controls on the distribution of REY-Zr (Hf)-Nb (Ta) enrichment horizons in late Permian coals from the Qiandongbei Coalfield, Guizhou Province, SW China. Int. J. Coal Geol. 2020, 231, 103604. [Google Scholar] [CrossRef]

- Liu, J.J.; Nechaev, V.P.; Dai, S.F.; Song, H.J.; Nechaeva, E.V.; Jiang, Y.F.; Graham, I.T.; French, D.; Yang, P.; Hower, J.C. Evidence for multiple sources for inorganic components in the Tucheng coal deposit, western Guizhou, China and the lack of critical-elements. Int. J. Coal Geol. 2020, 223, 103468. [Google Scholar] [CrossRef]

- Dai, S.F.; Wang, X.B.; Chen, W.M.; Li, D.H.; Chou, C.-L.; Zhou, Y.P.; Zhu, C.S.; Li, H.; Zhu, X.W.; Xing, Y.W.; et al. A high-pyrite semianthracite of Late Permian age in the Songzao Coalfield, southwestern China: Mineralogical and geochemical relations with underlying mafic tuffs. Int. J. Coal Geol. 2010, 83, 430–445. [Google Scholar] [CrossRef]

- Zhao, L.; Ward, C.R.; French, D.; Graham, I.T. Mineralogical composition of Late Permian coal seams in the Songzao Coalfield, southwestern China. Int. J. Coal Geol. 2013, 116–117, 208–226. [Google Scholar] [CrossRef]

- Zhao, L.; Ward, C.R.; French, D.; Graham, I.T. Major and Trace Element Geochemistry of Coals and Intra-Seam Claystones from the Songzao Coalfield, SW China. Minerals 2015, 5, 870–893. [Google Scholar] [CrossRef]

- GB/T 482-2008; Sampling of Coal Seams. Chinese Management Committee of Standard Specifications: Beijing, China, 2008; p. 9.

- ASTM Standard D3173-11; Standard Test Method for Moisture in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM Standard D3174-11; Standard Test Method for Ash in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM Standard D3175-11; Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM Standard D5865-13; Standard Test Method for Gross Calorific Value of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM Standard D3177-02; Standard Test Methods for Total Sulfur in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM Standard D2492-02; Standard Test Method for Forms of Sulfur in Coal. ASTM International: West Conshohocken, PA, USA, 2002.

- GB/T 16773-2008; Method of Preparing Coal Samples for the Coal Petrographic Analysis. Chinese Management Committee of Standard Specifications: Beijing, China, 2008; p. 20.

- Finkelman, R.B.; Dai, S.F.; French, D. The importance of minerals in coal as the hosts of chemical elements: A review. Int. J. Coal Geol. 2019, 212, 103251. [Google Scholar] [CrossRef]

- Li, Y.; Huang, W.H.; Jiu, B.; Sun, Q.L.; Che, Q.S. Modes of Occurrence and Origin of Minerals in Permian Coals from the Huainan Coalfield, Anhui, China. Minerals 2020, 10, 399. [Google Scholar] [CrossRef]

- Yan, X.Y. Enrichment and Differentiation Mechanism of Minerals and Trace Elements in the Paleogene Coals from Baise area of Guangxi Province, China; China University of Mining and Technology: Beijing, China, 2020; pp. 1–150. [Google Scholar]

- Liu, J.J. Occurrence Characteristics of Mineral Matters in Low-Rank Coals and Their Implications for Geological Process; China University of Mining and Technology: Beijing, China, 2019; pp. 1–253. [Google Scholar]

- Dai, S.F.; Zhou, Y.P.; Ren, D.Y.; Wang, X.B.; Li, D.; Zhao, L. Geochemistry and mineralogy of the Late Permian coals from the Songzao coalfield, Chongqing, southwestern China. Sci. China Ser. D Earth Sci. 2007, 50, 678–688. [Google Scholar] [CrossRef]

- Knight, J.A.; Burger, K.; Bieg, G. The pyroclastic tonsteins of the Sabero Coalfield, north-western Spain, and their relationship to thestratigraphy and structural geology. Int. J. Coal Geol. 2000, 44, 187–226. [Google Scholar] [CrossRef]

- Duan, P.P.; Wang, W.F.; Liu, X.H.; Sang, S.X.; Ma, M.Y.; Zhang, W. Differentiation of rare earth elements and yttrium in different size and density fractions of the Reshuihe coal, Yunnan Province, China. Int. J. Coal Geol. 2019, 207, 1–11. [Google Scholar] [CrossRef]

- Chen, P.; Jiang, D.D. Characteristics and geological genesis of minerals in coals of Huainan. J. Anhui Univ. Sci. Technol. Nat. Sci. 2012, 32, 1–6, (In Chinese with English Abstract). [Google Scholar]

- Dai, S.F.; Ren, D.Y.; Chou, C.L.; Finkelman, R.B.; Seredin, V.V.; Zhou, Y.P. Geochemistry of trace elements in Chinese coals: A review of abundances, genetic types, impacts on human health, and industrial utilization. Int. J. Coal Geol. 2012, 94, 3–21. [Google Scholar] [CrossRef]

- Yan, X.Y.; Dai, S.F.; Graham, I.T.; He, X.; Shan, K.H.; Liu, X. Determination of Eu concentrations in coal, fly ash and sedimentary rocks using a cation exchange resin and inductively coupled plasma mass spectrometry (ICP-MS). Int. J. Coal Geol. 2018, 191, 152–156. [Google Scholar] [CrossRef]

- Ketris, M.P.; Yudovich, Y.E. Estimations of Clarkes for carbonaceous biolithes: World average for trace element contents in black shales and coals. Int. J. Coal Geol. 2009, 78, 135–148. [Google Scholar] [CrossRef]

- Taylor, S.R.; McLennan, S.H. The Continental Crust: Its Composition and Evolution; Blackwell: Oxford, UK, 1985; p. 312. [Google Scholar]

- Dai, S.F.; Xie, P.P.; Jia, S.H.; Ward, C.R.; Hower, J.C.; Yan, X.Y.; French, D. Enrichment of U-Re-V-Cr-Se and rare earth elements in the late Permian coals of the Moxinpo Coalfield, Chongqing, China: Genetic implications from geochemical and mineralogical data. Ore Geol. Rev. 2017, 80, 1–17. [Google Scholar] [CrossRef]

- Lu, Q.F.; Qin, S.J.; Bai, H.Y.; Wang, W.F.; Qi, D.E.; He, X.; Zhang, B.F. Geochemistry of rare earth elements and yttrium in Late Permian coals from the Zhongliangshan coalfield, Southwestern China. Front. Earth Sci. 2023, 17, 230–250. [Google Scholar] [CrossRef]

- Dai, S.F.; Graham, I.T.; Ward, C.R. A review of anomalous rare earth elements and yttrium in coal. Int. J. Coal Geol. 2016, 159, 82–95. [Google Scholar] [CrossRef]

- Shao, H.; Xu, Y.; He, B.; Huang, X.; Luo, Z. Petrology and geochemistry of the late stage acidic volcanic rocks of the Emeishan large igneous province. Bull. Mineral. Petrol. Geochem. 2007, 26, 350–358, (In Chinese with English Abstract). [Google Scholar]

- Liu, J.J.; Han, Q.C.; Zhao, S.M.; Jia, R.K. The sources of abnormally enriched critical metals in the Late Permiancoals of Western Guizhou Province. J. China Coal Soc. 2022, 47, 1782–1794. [Google Scholar]

- Chen, Z.S.; Wu, Y.D. Late Permian Emeishan Basalt and Coal-bearing Formation in Southern Sichuan Area. Coal Geol. China 2010, 22, 14–18. [Google Scholar]

- Xiao, L.; Xu, Y.G.; Mei, H.J.; Zheng, Y.F.; He, B.; Pirajno, F. Distinct mantle sourcesof low-Ti and high-Ti basalts from the western Emeishan large igneous province, SW China: Implications for plume–lithosphere interaction. Earth and Planetary Science. Letters 2004, 228, 525–546. [Google Scholar] [CrossRef]

- Chou, C.-L. Sulfur in coals: A review of geochemistry and origins. Int. J. Coal Geol. 2012, 100, 1–13. [Google Scholar] [CrossRef]

- Zhao, S.Q. Practical Coal Petrology; Geological Publishing House: Beijing, China, 1991; p. 205. [Google Scholar]

- Ye, D.M.; Luo, J.W.; Xiao, W.Z. Maceral Properties and Its Application of Petrography in Southwest China; Geological Publishing House: Beijing, China, 1997; p. 125. [Google Scholar]

- Dai, S.; Bechtel, A.; Eble, C.F.; Flores, R.M.; French, D.; Graham, I.T.; Hood, M.M.; Hower, J.C.; Korasidis, V.A.; Moore, T.A.; et al. Recognition of peat depositional environments in coal. A review. Int. J. Coal Geol. 2020, 219, 103383. [Google Scholar] [CrossRef]

- Xie, P.P.; Song, H.J.; Wei, J.P.; Li, Q.Q. Mineralogical Characteristics of Late Permian Coals from the Yueliangtian Coal Mine, Guizhou, Southwestern China. Minerals 2016, 6, 29. [Google Scholar] [CrossRef]

- Wang, P.P. Enrichment and Differentiation Mechanism of Minerals and Trace Elements in the Late Permian Coals from Eastern Yunnan and Western Guizhou Province; China University of Mining and Technology: Beijing, China, 2017; pp. 1–179. [Google Scholar]

- Han, D.X. Coal Petrology of China; China University of Mining and Technology Press: Xuzhou, China, 1996. (In Chinese) [Google Scholar]

- Zhao, L.X. Enrichment Mechanism of Rare Metals in Coal-Hosted Niobium Predominated Polymetallic Ore Deposit from the Late Permian Strata, Northeastern Yunnan Province, Southwest China; China University of Mining and Technology: Beijing, China, 2016. [Google Scholar]

- Ward, C.R. Analysis and significance of mineral matter in coal seams. Int. J. Coal Geol. 2002, 50, 135–168. [Google Scholar] [CrossRef]

- Seredin, V.V.; Dai, S.F. Coal deposits as potential alternative sources for lanthanides and yttrium. Int. J. Coal Geol. 2012, 94, 67–93. [Google Scholar] [CrossRef]

| Samples | Ro,ran | Mad | Aad | Vad | Ad | Vdaf | FCd | St,d | Sp,d | Ss,d | So,d | Qgr,d |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SH8-11 | 2.19 | 2.25 | 15.5 | 13.8 | 15.9 | 16.7 | 70.0 | 7.12 | 5.29 | 1.18 | 0.65 | 30.1 |

| SH8-10 | 2.02 | 1.51 | 12.4 | 12.7 | 12.6 | 14.8 | 74.5 | 4.69 | 3.38 | 0.42 | 0.89 | 32.2 |

| SH8-9 | 2.08 | 1.25 | 15.6 | 11.1 | 15.8 | 13.4 | 73.0 | 2.73 | 2.40 | 0.12 | 0.21 | 31.2 |

| SH8-8 | 1.95 | 1.16 | 10.8 | 10.9 | 10.9 | 12.3 | 78.2 | 2.21 | 1.79 | 0.03 | 0.39 | 33.2 |

| SH8-7 | 2.10 | 1.24 | 11.6 | 10.9 | 11.7 | 12.5 | 77.3 | 2.27 | 2.06 | 0.10 | 0.11 | 33.0 |

| SH8-6 | 1.95 | 1.17 | 10.5 | 10.8 | 10.6 | 12.2 | 78.4 | 1.73 | 1.13 | 0.02 | 0.58 | 33.2 |

| SH8-5 | 1.86 | 2.35 | 16.5 | 14.6 | 16.9 | 18.1 | 68.1 | 5.92 | 4.56 | 0.87 | 0.48 | 29.2 |

| SH8-4 | 1.90 | 1.59 | 18.2 | 13.2 | 18.5 | 16.4 | 68.2 | 5.81 | 3.43 | 0.69 | 1.70 | 29.5 |

| SH8-3 | 2.00 | 1.84 | 19.5 | 13.3 | 19.8 | 16.8 | 66.7 | 4.10 | 3.31 | 0.61 | 0.18 | 29.5 |

| SH8-2 | 2.09 | 1.81 | 16.9 | 11.7 | 17.3 | 14.4 | 70.9 | 2.33 | 2.07 | 0.10 | 0.15 | 29.9 |

| SH8-1 | 2.20 | 2.70 | 36.8 | 13.1 | 37.8 | 21.6 | 48.7 | 7.45 | 5.58 | 1.53 | 0.34 | 18.1 |

| Average | 2.03 | 1.71 | 16.8 | 12.4 | 17.1 | 15.4 | 70.4 | 4.21 | 3.18 | 0.52 | 0.52 | 29.9 |

| Kao | Pyr | Cal | Qua | I/S | Alb | Ana | Rut | Sid | Bas | Chl | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SH8-R | 60.4 | 6.5 | 3.1 | 12.9 | 7.7 | 2.3 | 3.6 | 0.7 | 1.8 | 1 | |

| SH8-11 | 50.4 | 37.8 | 2.7 | 2.2 | 2.3 | 2 | 1.1 | 1.5 | |||

| SH8-10 | 57.9 | 25.6 | 9.6 | 0.9 | 3 | 1.3 | 0.7 | 1 | |||

| SH8-9 | 68.8 | 14.6 | 7.9 | 1.2 | 1.8 | 1 | 4.2 | 0.5 | |||

| SH8-7 | 51.4 | 21.3 | 22.4 | 0.7 | 2 | 1.2 | 1 | ||||

| SH8-5 | 25.6 | 22.6 | 4.7 | 0.4 | 38.4 | 3.1 | 0.2 | 1.3 | 1.7 | 2 | |

| SH8-3 | 66.2 | 17.4 | 5.7 | 3.1 | 5.1 | 2 | 0.5 | ||||

| SH8-1 | 33.8 | 20.7 | 2.5 | 35.1 | 3.1 | 1.3 | 2.7 | 0.3 | 0.5 | ||

| SH8-F | 47.8 | 7.7 | 4.5 | 9.6 | 10.5 | 3.5 | 8.1 | 1.2 | 7.1 |

| Samples | SiO2 | Al2O3 | Fe2O3 | CaO | TiO2 | K2O | Na2O | MgO | P2O5 | MnO |

|---|---|---|---|---|---|---|---|---|---|---|

| SH8-R | 39.9 | 27.0 | 6.52 | 0.63 | 3.63 | 1.95 | 1.80 | 0.741 | 0.252 | 0.031 |

| SH8-11 | 4.49 | 4.01 | 6.20 | 0.27 | 0.23 | 0.036 | 0.084 | 0.065 | 0.011 | 0.003 |

| SH8-10 | 3.87 | 3.76 | 3.63 | 0.47 | 0.16 | 0.032 | 0.084 | 0.058 | 0.010 | 0.003 |

| SH8-9 | 6.53 | 5.97 | 1.74 | 0.45 | 0.41 | 0.073 | 0.080 | 0.084 | 0.012 | 0.003 |

| SH8-8 | 4.39 | 4.13 | 1.29 | 0.28 | 0.30 | 0.048 | 0.061 | 0.058 | 0.036 | 0.002 |

| SH8-7 | 4.66 | 4.49 | 1.37 | 0.36 | 0.28 | 0.040 | 0.061 | 0.060 | 0.053 | 0.002 |

| SH8-6 | 4.93 | 4.40 | 0.51 | 0.17 | 0.23 | 0.058 | 0.056 | 0.060 | 0.008 | 0.001 |

| SH8-5 | 5.10 | 5.09 | 4.79 | 0.74 | 0.13 | 0.063 | 0.063 | 0.087 | 0.013 | 0.005 |

| SH8-4 | 6.88 | 6.61 | 3.04 | 0.66 | 0.39 | 0.059 | 0.073 | 0.082 | 0.015 | 0.004 |

| SH8-3 | 7.87 | 7.22 | 2.81 | 0.53 | 0.43 | 0.075 | 0.073 | 0.084 | 0.014 | 0.002 |

| SH8-2 | 7.95 | 5.91 | 1.94 | 0.33 | 0.38 | 0.057 | 0.064 | 0.068 | 0.011 | 0.002 |

| SH8-1 | 19.6 | 7.65 | 6.84 | 0.49 | 1.07 | 0.235 | 0.186 | 0.160 | 0.022 | 0.004 |

| SH8-F | 43.2 | 30.4 | 2.37 | 0.33 | 4.59 | 3.667 | 1.820 | 0.835 | 0.085 | 0.006 |

| SH-av. | 6.94 | 5.39 | 3.10 | 0.43 | 0.37 | 0.071 | 0.081 | 0.079 | 0.019 | 0.003 |

| Chinese | 8.47 | 5.98 | 4.85 | 1.23 | 0.33 | 0.22 | 0.19 | 0.16 | 0.092 | 0.015 |

| Samples | Li | Be | Sc | V | Cr | Co | Ni | Cu | Zn | Ga | As | Rb | Sr | Zr | Nb | Mo | Cd | In | Cs | Ba |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SH8-R | 101 | 1.84 | 18.8 | 328 | 230 | 98.5 | 65.5 | 159 | 480 | 13.4 | 77.5 | 72.5 | 274 | 490 | 44.2 | 156 | 1.20 | 0.02 | 1.55 | 218 |

| SH8-11 | 34.7 | 0.36 | 5.54 | 47.7 | 87.5 | 19.4 | 26.5 | 21.1 | 27.7 | 22.7 | 64.9 | 59.5 | 112 | 53.2 | 2.22 | 9.50 | 1.15 | 0.03 | 0.21 | 11.5 |

| SH8-10 | 50.4 | 0.47 | 5.30 | 56.1 | 51.1 | 15.7 | 9.54 | 17.3 | 77.1 | 8.88 | 82.6 | 26.3 | 127 | 37.6 | 1.76 | 10.2 | 1.59 | 0.01 | 0.23 | 12.5 |

| SH8-9 | 57.8 | 0.75 | 4.17 | 93.1 | 52.1 | 18.5 | 11.63 | 26.9 | 19.2 | 3.84 | 69.3 | 29.5 | 80.3 | 56.8 | 3.97 | 5.67 | 1.30 | 0.02 | 0.19 | 17.4 |

| SH8-8 | 47.9 | 0.49 | 7.28 | 53.9 | 42.1 | 16.5 | 8.28 | 16.5 | 17.7 | 5.44 | 71.0 | 15.3 | 167 | 43.8 | 3.27 | 3.48 | 1.18 | 0.02 | 0.17 | 13.3 |

| SH8-7 | 50.1 | 0.39 | 7.11 | 40.1 | 42.3 | 14.8 | 6.96 | 17.6 | 17.5 | 5.59 | 81.7 | 16.5 | 256 | 44.5 | 3.52 | 3.90 | 1.39 | 0.02 | 0.19 | 16.5 |

| SH8-6 | 66.1 | 0.60 | 3.41 | 38.6 | 36.2 | 14.1 | 6.29 | 22.2 | 16.1 | 2.82 | 75.5 | 25.8 | 110 | 31.3 | 2.01 | 3.50 | 1.25 | 0.02 | 0.19 | 13.7 |

| SH8-5 | 53.1 | 0.61 | 3.07 | 29.0 | 69.3 | 14.7 | 11.7 | 17.4 | 31.9 | 15.8 | 75.2 | 32.4 | 129 | 44.5 | 2.72 | 12.8 | 1.41 | 0.04 | 0.19 | 23.2 |

| SH8-4 | 67.2 | 0.53 | 6.13 | 56.0 | 54.5 | 15.9 | 8.62 | 20.4 | 22.9 | 6.81 | 67.9 | 18.0 | 108 | 98.9 | 6.07 | 14.6 | 1.07 | 0.03 | 0.18 | 14.3 |

| SH8-3 | 67.4 | 0.74 | 9.68 | 48.5 | 58.3 | 17.1 | 8.34 | 18.2 | 23.1 | 8.34 | 61.5 | 20.7 | 74.0 | 126 | 11.8 | 5.95 | 1.36 | bdl | 0.21 | 16.6 |

| SH8-2 | 69.0 | 0.67 | 13.10 | 40.3 | 41.1 | 15.6 | 5.09 | 11.8 | 18.5 | 4.60 | 66.2 | 3.22 | 80.5 | 250 | 27.9 | 10.5 | 0.93 | 0.02 | 0.21 | 14.6 |

| SH8-1 | 47.2 | 1.59 | 5.16 | 78.3 | 118 | 28.2 | 28.1 | 20.9 | 33.7 | 22.0 | 71.9 | 10.0 | 120 | 267 | 22.5 | 10.2 | 1.32 | 0.01 | 0.22 | 38.1 |

| SH8-F | 127 | 0.24 | 45.26 | 408 | 197 | 87.7 | 45.5 | 176 | 170 | 5.91 | 79.8 | 11.1 | 504 | 1324 | 152 | 67.6 | 1.66 | 0.01 | 1.55 | 323 |

| SH-av. | 55.5 | 0.65 | 6.36 | 52.9 | 59.3 | 17.3 | 11.9 | 19.1 | 27.71 | 9.71 | 71.6 | 23.4 | 124 | 95.8 | 7.97 | 8.21 | 1.27 | 0.02 | 0.20 | 17.4 |

| World | 14 | 2 | 3.7 | 28 | 17 | 6 | 17 | 16 | 28 | 6 | 9 | 18 | 100 | 36 | 4 | 2.1 | 0.2 | 0.04 | 1.1 | 150 |

| Samples | Tl | Pb | Bi | Th | U | La | Ce | Pr | Nd | Sm | Eu | Gd | Tb | Dy | Y | Ho | Er | Tm | Yb | Lu |

| SH8-R | 0.49 | 41.2 | 0.24 | 5.75 | 2.78 | 55.3 | 91.3 | 12.0 | 31.6 | 5.76 | 3.70 | 4.36 | 3.26 | 3.49 | 34.2 | 0.86 | 6.03 | 0.49 | 1.66 | 0.35 |

| SH8-11 | 0.10 | 22.9 | 0.35 | 6.41 | 4.44 | 3.02 | 6.36 | 5.73 | 8.80 | 2.68 | 0.54 | 2.34 | 0.95 | 1.23 | 10.5 | 0.24 | 1.02 | 0.09 | 1.17 | 0.29 |

| SH8-10 | bdl | 1.70 | 0.99 | 2.83 | 1.68 | 4.92 | 9.84 | 2.51 | 3.26 | 2.28 | 0.26 | 2.61 | 0.72 | 1.15 | 7.44 | 0.19 | 0.76 | 0.11 | 0.79 | 0.29 |

| SH8-9 | 0.12 | 20.6 | 0.11 | 1.92 | 0.90 | 8.20 | 25.9 | 3.56 | 6.46 | 2.42 | 0.27 | 2.81 | 0.84 | 2.59 | 6.30 | 0.20 | 2.25 | 0.18 | 0.31 | 0.29 |

| SH8-8 | 0.12 | 9.27 | 0.47 | 1.87 | 0.87 | 16.2 | 17.0 | 3.64 | 7.61 | 2.64 | 0.36 | 2.02 | 0.68 | 1.21 | 6.31 | 0.23 | 1.40 | 0.11 | 0.91 | 0.26 |

| SH8-7 | 0.12 | 2.62 | 0.88 | 1.93 | 0.86 | 21.5 | 18.5 | 6.27 | 9.26 | 3.17 | 0.38 | 2.15 | 0.69 | 1.33 | 5.86 | 0.26 | 1.10 | 0.08 | 0.67 | 0.25 |

| SH8-6 | bdl | 14.6 | 0.24 | 1.50 | 0.59 | 15.1 | 29.2 | 3.10 | 9.36 | 3.08 | 0.31 | 1.92 | 0.63 | 0.86 | 4.57 | 0.18 | 1.13 | 0.08 | 0.18 | 0.20 |

| SH8-5 | bdl | 23.8 | 1.03 | 4.81 | 3.08 | 10.2 | 18.8 | 7.37 | 6.04 | 2.91 | 0.45 | 2.31 | 0.46 | 0.72 | 7.44 | 0.22 | 0.64 | 0.06 | 0.71 | 0.14 |

| SH8-4 | 0.17 | 15.2 | 0.33 | 2.54 | 1.38 | 24.4 | 39.2 | 3.98 | 10.5 | 3.25 | 0.37 | 2.36 | 0.43 | 1.48 | 12.0 | 0.19 | 1.72 | 0.11 | 0.20 | 0.32 |

| SH8-3 | 0.27 | 32.3 | 0.06 | 2.97 | 1.74 | 22.0 | 45.2 | 6.14 | 13.1 | 3.50 | 0.37 | 1.88 | 0.35 | 1.90 | 12.3 | 0.19 | 1.90 | 0.09 | 0.19 | 0.41 |

| SH8-2 | 0.34 | 26.1 | 0.16 | 1.83 | 0.93 | 21.1 | 33.1 | 2.87 | 11.2 | 3.32 | 0.36 | 2.36 | 0.68 | 2.83 | 19.5 | 0.17 | 1.94 | 0.09 | 0.30 | 0.33 |

| SH8-1 | 0.17 | 48.6 | 0.22 | 6.26 | 4.34 | 26.9 | 45.8 | 5.19 | 14.0 | 4.03 | 0.56 | 3.57 | 0.75 | 2.15 | 31.8 | 0.24 | 3.71 | 0.17 | 0.38 | 0.29 |

| SH8-F | 0.11 | 67.0 | 0.25 | 1.09 | 0.94 | 88.1 | 150 | 12.6 | 69.7 | 6.82 | 3.92 | 6.09 | 3.50 | 3.22 | 62.4 | 1.35 | 8.69 | 0.79 | 1.87 | 0.72 |

| SH-av. | 0.15 | 19.8 | 0.44 | 3.17 | 1.89 | 15.8 | 26.3 | 4.58 | 9.06 | 3.03 | 0.38 | 2.39 | 0.65 | 1.59 | 11.3 | 0.21 | 1.60 | 0.11 | 0.53 | 0.28 |

| World | 0.58 | 9 | 1.1 | 3.2 | 1.9 | 11 | 23 | 3.4 | 12 | 2.2 | 0.43 | 2.7 | 0.31 | 2.1 | 8.2 | 0.57 | 1 | 0.3 | 1 | 0.2 |

| Sample | L/M | L/H | M/H | (La/Lu)N | (La/Sm)N | (Gd/Lu)N | Type | δEu | δCe |

|---|---|---|---|---|---|---|---|---|---|

| SH8-R | 3.99 | 20.9 | 5.22 | 1.66 | 1.44 | 1.04 | L | 1.66 | 0.81 |

| SH8-11 | 1.71 | 9.45 | 5.53 | 0.11 | 0.17 | 0.67 | H | 0.69 | 0.22 |

| SH8-10 | 1.87 | 10.7 | 5.72 | 0.18 | 0.32 | 0.77 | H | 0.41 | 0.59 |

| SH8-9 | 3.63 | 14.4 | 3.95 | 0.31 | 0.51 | 0.83 | H | 0.39 | 1.04 |

| SH8-8 | 4.45 | 16.2 | 3.63 | 0.66 | 0.92 | 0.65 | H | 0.55 | 0.51 |

| SH8-7 | 5.64 | 24.8 | 4.40 | 0.92 | 1.02 | 0.73 | H | 0.52 | 0.36 |

| SH8-6 | 7.21 | 33.7 | 4.67 | 0.82 | 0.74 | 0.83 | H | 0.46 | 0.97 |

| SH8-5 | 3.98 | 25.6 | 6.44 | 0.77 | 0.52 | 1.38 | H | 0.77 | 0.43 |

| SH8-4 | 4.88 | 32.0 | 6.54 | 0.82 | 1.13 | 0.62 | H | 0.60 | 0.89 |

| SH8-3 | 5.35 | 32.3 | 6.04 | 0.57 | 0.94 | 0.39 | H | 0.60 | 0.88 |

| SH8-2 | 2.78 | 25.3 | 9.09 | 0.68 | 0.95 | 0.60 | H | 0.49 | 0.94 |

| SH8-1 | 2.47 | 20.0 | 8.10 | 1.01 | 0.99 | 1.05 | L-M | 0.64 | 0.88 |

| SH8-F | 4.13 | 24.4 | 5.90 | 1.31 | 1.94 | 0.72 | L | 1.58 | 0.99 |

| Average | 4.00 | 22.2 | 5.83 | 0.62 | 0.75 | 0.77 | 0.56 | 0.70 |

| Elements | World’s Hard | Chinese Coal | Cut-off Grade | Shihao | ||||

|---|---|---|---|---|---|---|---|---|

| Coal | Coal Ash | Coal Basis | Ash Basis | Coal | Coal Ash | CC-Coal Ash | ||

| Li | 14.0 | 82.0 | 31.8/28.9 | 120 | - | 55.5 | 371 | 4.52 |

| Sc | 3.70 | 24.0 | 4.38 | - | 100 | 6.40 | 41.8 | 1.74 |

| V | 28.0 | 170 | 35.0 | - | 1000 | 52.9 | 341 | 2.01 |

| Ga | 6.00 | 36.0 | 6.55 | 30 | 100 | 9.70 | 57.4 | 1.59 |

| Nb | 4.00 | 22.0 | 9.44 | - | 300 | 7.97 | 42.7 | 1.94 |

| Zr | 36.0 | 230 | 89.5 | - | 2000 | 95.8 | 524 | 2.28 |

| REY | 68.4 | 445 | 136 | 300 | 1000 | 77.7 | 566 | 1.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Q.; Qin, S.; Wang, W.; Wu, S.; Shao, F. Mineralogy and Geochemistry of High-Sulfur Coals from the M8 Coal Seam, Shihao Mine, Songzao Coalfield, Chongqing, Southwestern China. Minerals 2024, 14, 95. https://doi.org/10.3390/min14010095

Lu Q, Qin S, Wang W, Wu S, Shao F. Mineralogy and Geochemistry of High-Sulfur Coals from the M8 Coal Seam, Shihao Mine, Songzao Coalfield, Chongqing, Southwestern China. Minerals. 2024; 14(1):95. https://doi.org/10.3390/min14010095

Chicago/Turabian StyleLu, Qingfeng, Shenjun Qin, Wenfeng Wang, Shihao Wu, and Fengjun Shao. 2024. "Mineralogy and Geochemistry of High-Sulfur Coals from the M8 Coal Seam, Shihao Mine, Songzao Coalfield, Chongqing, Southwestern China" Minerals 14, no. 1: 95. https://doi.org/10.3390/min14010095

APA StyleLu, Q., Qin, S., Wang, W., Wu, S., & Shao, F. (2024). Mineralogy and Geochemistry of High-Sulfur Coals from the M8 Coal Seam, Shihao Mine, Songzao Coalfield, Chongqing, Southwestern China. Minerals, 14(1), 95. https://doi.org/10.3390/min14010095