Abstract

Communities and authorities have been dismayed by globally recorded tailings storage facility (TSF) failures in recent years, which have negatively affected the safety of people and the integrity of the environment. In this context, obtaining the social and environmental license to operate TSFs has become a challenging process for mining companies. This has promoted the trend of using mine tailings dewatering technologies in the mining industry, with dry stacking of filtered mine tailings being recognized worldwide as one of the most acceptable, safe, and environmentally friendly solutions. This article presents a new paradigm in managing mine tailings, with disruptive and futuristic characteristics, considering the dry stacking of filtered mine tailings for large-scale industrial production rates over 100,000 metric tons per day (mtpd). Aspects of filtered tailings management are discussed, such as (i) dewatering process plant with thickening/filtering equipment, (ii) conveyance using fixed and movable conveyor belts, (iii) construction of dry stacking of filtered mine tailings facility, and (iv) implementation of Industry 4.0 technologies for automation of the mining processes. Finally, the article discusses how the large-scale filtered mine tailings solution is applied, considering the advances in the equipment’s performance and implementation of Industry 4.0 technologies as well as the experience gained worldwide in several mining operations. The future global trend is that mining operations with high daily production of mine tailings will apply dry stacking technology without dams to guarantee sustainability, promote continuity of the mining business, ensure the safety of communities, and conserve the environment.

1. Introduction

1.1. Mine Tailings Management under a Complex Social and Environmental Pressure Scenario

Clean technologies and green infrastructure solutions such as electric vehicles and renewable energy power plants for the low-carbon planet future carry intense mineral demands [1]. Considering this scenario, mining will still play a key role after 2050 since the demand for mining commodities will increase as the developing countries move toward per capita usage of metals comparable to the developed countries [2].

A fundamental component of sustainable development, like a climate change mitigation strategy, involves shifting from fossil fuel-dominated energy production to renewable and less environmentally detrimental energy sources, such as solar, wind, and geothermal [3]. On the other hand, all these alternative energy sources have significant demands for mineral resources, in some cases, more extensive than fossil fuel-derived energy [1]. These needs include historically important commodities such as iron (e.g., for the steel necessary to build up wind turbines), copper (e.g., for conveying electricity from renewable energy power plants to the cities), as well as less conventional, critical raw materials (e.g., lithium, cobalt, rare earth elements, gallium, germanium, rhenium, required for the fabrication of batteries and aerospace elements), most of which are geochemically scarce in the planet [4]. One can conclude that this sustainable development and climate change mitigation strategy would result in increased mining, with its accompanying historical record of severe environmental impacts and associated social opposition [5].

In this context, mineral production and mine tailings will increase [6]. Also, considering the mineral grades of the mining deposits are increasingly low and the need for the profitability of the mining business, in many cases, there will be mining operations with mine tailings production of over 100,000 mtpd, which will require new sites to store millions of tons of mine tailings in the territory [7]. In this sense, communities, Non-Governmental Organizations (NGOs), and local authorities are concerned, mainly due to inadequate mining waste practices in the past. They fear that negative environmental impacts will be generated by the contamination of soils, water, and air and the affectation of ecosystems and biodiversity [8,9,10]. In addition, susceptible areas to high seismic activity, there is a rejection by the communities of the construction of huge conventional mine tailings (CTD). These containment infrastructures contain large amounts of water and occupy vast areas of the territory—moreover, containment infrastructures materialized by dams are sometimes over 200 m high [11]. The fears of the communities are mainly due to the cases of failure of mine tailings storage facilities registered in recent years worldwide that have negatively impacted the environment and have also recorded the death of human beings (e.g., Spain, Hungary, Brazil, Canada, South Africa, and Tanzania, among others) [12,13,14].

It is important to mention that the local authorities in charge of reviewing, evaluating, and approving the social and environmental license to operate a new mine tailings storage facility are very strict in their evaluation processes [15]. In addition, mining companies are being asked to implement the highest management standards of mine tailings that need to be stored in the territory for guaranteed sustainability [16].

This is how new forms of mine tailings storage are required, in such a way that they provide safety to the communities and sustainability to the territory in the long term. Mine tailings solid–liquid separation technologies such as thickened mine tailings (TTD), paste mine tailings (PTD), and filtered mine tailings (FTD) allow the storage of these materials with low water contents [6,17]. Thus allowing the mine tailings deposited at the storage site to have a greater capacity for support and reduce the risks of instability failures due to static or dynamic liquefaction induced by earthquakes [18]. In addition, with these mine tailings dewatering technologies, depositing a high-density material can reduce the land-use footprint concerning the occupied area [19]. Thus, it is also possible to recover water from the tailings and reuse it in mining-metallurgical processes [20]. These technologies also make it possible to reduce the height of mine tailings containment dams considerably. In the case of filtered tailings, only smaller structures are required to contain potential spills in contingency events [21]. Finally, mine tailings dewatering solutions that allow savings in freshwater consumption, mitigation of physical instability risks of containment dams, reduction of the footprint for mine tailings disposal in the use of land in the territory, and implementation of progressive mine closure activities; these characteristics being attractive in a context of the development of the green mining paradigm [4].

1.2. The Positioning of Mine Tailings Dewatering Technologies as Green Mining Solutions

Mining, like humanity, evolves, and this is how new paradigms are positioned in the sustainable development that the industry seeks [22]. The concept of green mining is relatively new and disruptive, and, little by little, it is positioning itself as an alternative solution to build relationships of trust with communities and allow for a relationship of harmony with the environment [4]. This is how green mining seeks to minimize negative socio-environmental impacts in the territory, putting into practice the best available technologies (BATs), the best applicable practices (BAPs), the best environmental practices (BEPs), and the highest management standards [15]. Along with this, the principle of the 3Rs (Reduce, Recycle, and Reuse) is also considered, which are implemented in mining-metallurgical processes, seeking the potential for alternative uses for mining waste and industrial effluents as resources and reintroducing them to the process in a virtuous cycle [23,24].

The concept of the 3Rs applied to mining means added value to achieve a responsible and sustainable activity with the environment and communities [25,26,27].

Finally, corporate social responsibility and environmental, social, and governance (ESG) guidelines are considered throughout the life cycle of mining projects, from its conception to the post-closure stage, making the communities neighboring the mine a key stakeholder [16,28,29].

This is how high-density mine tailings and dewatering technologies such as filtered tailings are positioning themselves as green mining solutions [30]. There are numerous practical cases worldwide where this technology has been implemented, achieving important social, environmental, and economic benefits linked to the mining business [19]. Some countries where these filtered mine tailings technology has been implemented in copper, gold, silver, iron, and bauxite mining are, for example, (i) Chile, (ii) Peru, (iii) Mexico, (iv) Australia, (v) United States, (vi) Canada, (vii) China and (viii) Brazil, among others [21,30,31].

An increasingly popular green mining alternative for storing mine tailings is filling underground mines with mine tailings, which has been applied in different countries around the world [32,33,34]. A particular case to highlight is the experience acquired in Peru, the second largest producer of copper in the world, where the use of mine tailings inside underground mines is being used to avoid the generation of acid rock drainage (ARD), eliminate the emission of particulate matter and thus avoid socio-environmental impacts in hydrographic basins [35].

Today, society demands that mining implement solutions with the latest technology in terms of mine tailings storage management, understanding that the high capital costs (CAPEX) considered in the implementation of filtered mine tailings are recovered in the medium and long term, considering (i) safety issues in physical stability, (ii) comprehensive environmental care and (iii) protection of the lives of families living in neighboring communities [36]. Today, these mining wastes are no longer allowed to be considered the backyard of the mining operation. Still, on the contrary, they are an important part of the mining process and the value chain of the mining business, promoting responsible management actions and safe decision-making at all times regarding aspects of controlled management of mine tailings [37].

1.3. Towards a New Paradigm for the Management of Filtered Mine Tailings Considering Unprecedented High Production Rates

Considering that mining deposits have increasingly low ore grades, the use of current mineral flotation technologies, and a high demand for copper for the coming decades due to electromobility and renewable energy, it is expected that a higher rate of treatment of minerals in metallurgical plants and an associated high generation of mine tailings [38]. This is how many mining operations will generate more than 100,000 mtpd, 24 h a day and almost 365 days a year, requiring the storage of their mine tailings for years or even decades or centuries [5]. Considerations regarding land use restrictions in the territory for mine tailings storage, compared to other activities such as urban areas, agricultural areas, livestock areas, cultural heritage areas, and natural conservation areas, make it challenging for the mining industry to manage mine tailings [39]. In addition, an issue that affects the physical stability of the TSF corresponds to the uncertainty of magnitude, duration, and intensity of hydrometeorological events that exist in the face of the threat of climate change [40,41]. This is a factor more considered for the controlled and responsible management of mine tailings in the territory [42,43].

Faced with this scenario, it is necessary to implement mine tailings management solutions that provide society confidence and guarantee the mining business’s long-term sustainability. This has promoted the mining industry’s use of mine tailings dewatering technologies [44]. Dry stacking of filtered mine tailings is recognized worldwide as one of the most acceptable solutions by communities, providing safety from the point of view of physical stability and being environmentally friendly.

Filtered mine tailings are mechanically dewatered to a point where they no longer behave as a slurry and are more characteristic of partially saturated soil [45]. Mechanical dewatering is typically achieved using pressure filters or vacuum filters. Filtered mine tailings typically have a solids content (Cw) of 80%–85% by weight or greater for copper mine tailings [17]. The filtered mine tailings are typically transported by conveyor or hauled by truck to the mine tailings storage facility, where they are placed and compacted as a homogenous, non-segregated, and partially saturated mass [30].

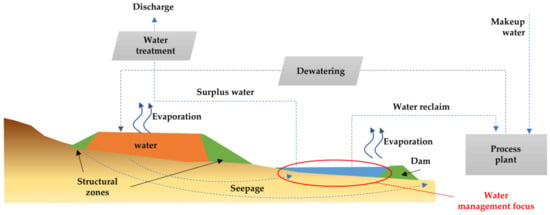

Filtered mine tailings storage facilities are typically constructed, operated, and closed like mine waste rock storage facilities or heap leach pads. The consequences of a hypothetical failure of a filtered mine tailings storage facility may be significantly less than for a conventional mine tailings storage facility (slurry tailings pond) due to the absence of a supernatant process water pond and the lower mobility of the stored mine tailings [46]. The main stages of considering in filtered mine tailings management are (i) Dewatering of mine tailings to obtain a cake, (ii) Material handling and transport of dewatered mine tailings considering filter cake, (iii) Placement and deposition of filtered mine tailings, and (iv) Monitoring and remediation of filtered mine tailings (See Figure 1).

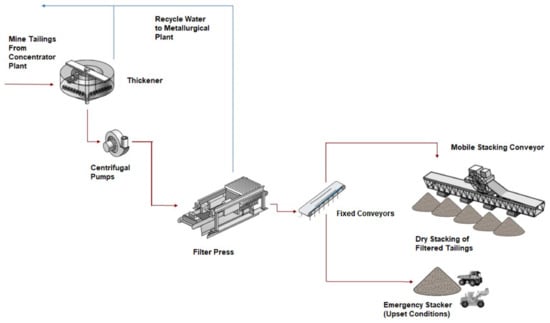

Figure 1.

Schematical process diagram of filtered mine tailings management.

According to Figure 1, mine tailings slurry will be dewatered and thickened in mine tailings thickeners. Thickener underflow will be pumped by centrifugal pumps to the mine tailings filter press. Then, the filtered mine tailings cake will be transferred to mine tailings belt feeders and then to fixed mine tailings conveyors in series before being discharged to the mine tailings placement system.

The mine tailings placement system consists of movable and shiftable conveyors and a stacking conveyor system that will be used to deposit the filtered mine tailings behind large pre-formed containment buttresses constructed from mine waste rock in the mine tailings storage facility area.

Variability in ore and the resulting mine tailings production rate may generate upset operating conditions in the filter plant. A temporary mine tailings storage facility with one to three days capacity be included to store off-specification filtered mine tailings and/or unfiltered mine tailings to provide operational flexibility [30]. Allowances must be included to re-slurry the off- specification tailings for reprocessing in the filter plant. Additional process water tanks or ponds are required at the filter plant to manage the recovered process water [17].

Some advantages of the dry stacking of filtered mine tailings method over conventional (slurry) tailings disposal are: (i) it eliminates the need for an engineered dam and seepage containment system; (ii) it maximizes water conservation and minimizes water makeup requirements; (iii) it results in a very compact site that limits disturbance to single drainage; and, (iv) it allows opportunities for progressive reclamation in the mine closure plan and dust control.

1.4. Aim of the Article

This article presents a new paradigm in the management of mine tailings, with disruptive and futuristic characteristics, considering the implementation of dry stacking of filtered mine tailings for large-scale industrial productions over 100,000 metric tons per day (mtpd). Aspects of the filtered mine tailings management are discussed, such as (i) dewatering process plant with thickening/filtering equipment, (ii) conveyance using fixed and movable conveyor belts, (iii) construction of dry stacking of filtered mine tailings facility and (iv) implementation of Industry 4.0 technologies for automation of the mining processes.

This article looks at the overall mine tailings dewatering and stacking plant design. Issues covered include filter feed slurry characteristics and their effects on filter performance and maintenance, positioning of filters and ancillary equipment in the filter building, options for conveying the filter cake to the stacking area, and selection of the cake stacking equipment.

The novelty of the article is to discuss, based on technological advances and real practical experience, that it is feasible to develop filtered tailings technology through dry stacking considering industrial-scale mine tailings production over 100,000 mtpd.

Finally, the article is presented with the following chapter structure: (i) Introduction, (ii) Dewatering process plant: thickening and filtering of mine tailings, (iii) Filtered mine tailings conveyance system, (iv) Dry stacking of filtered mine tailings: geometric configuration and placement scheme, (v) Safety and sustainability of a dry stacking of filtered mine tailings: Physical stability, water management, progressive mine closure, and particulate matter control, (vi) Smart mining technologies for the management of filtered mine tailings for high production rates considering Industry 4.0 paradigm, (vii) Outlook and Future Directions and (viii) Conclusions.

2. Dewatering Process Plant: Thickening and Filtering of Mine Tailings

2.1. Influence of Filtered Mine Tailings Particle Size Distribution in the Dewatering Process

Disposal of compacted filtered tailings requires that the mine tailings contain optimum compaction moisture [45]. In Proctor Standard (ASTM D698) geotechnical tests performed in certified laboratories, this moisture varies between 10% and 15% for copper mine tailings with a specific gravity of around 2.7 [30]. Industrial-scale filtration equipment must be used to obtain the required moisture in the mine tailings. Currently, there are various types of equipment with different principles of operation. Between them, we have [21]:

- Vacuum ceramic disc filters.

- Vacuum band filters.

- Pressure filters (filter presses).

The moisture content values reached by each filter for the same filtration rate depend on the principle of operation and the characteristics of the mine tailings material to be filtered [47]. Comparing the filters that operate under vacuum with pressure filters for the same material of mine tailings and the same filtration rate, the moisture content resulting from the filtered cake is higher for the vacuum filters [48].

The mine tailings material characteristics, particle size distribution, and specific gravity greatly influence the moisture content of the filter cake characteristics. Therefore, to achieve the moisture required for compaction, and considering that copper mine tailings in many cases contain 5-micron particles that represent more than 20% by weight, it is recommended to use a press-type filter [30]. Even for this type of filter, the filtration rates to reach the moisture content required for maximum compaction increase considerably when the amount of particles smaller than 5 microns increases [17]. That is, the filtering equipment is very sensitive to the high clay content present in mine tailings (See Figure 2).

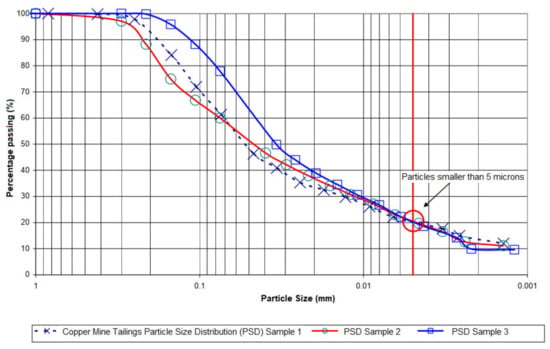

Figure 2.

Example of particle size distribution curve of different mine tailings.

Following Figure 2, to design and size the mine tailings filtration equipment, the grinding conditions according to the SAG mills and ball mills installed in the metallurgical plant must be considered, as well as the amount of clay or ultrafine particles that the mine tailings may have. This could influence the performance, maintenance, and operational availability of the mine tailings filtration equipment, as well as the moisture content conditions of mine-filtered tailings stored in the dry stacking site.

2.2. Thickening and Filtering of Mine Tailings Process Plant

A typical mine tailings dewatering area is shown in Figure 3 and Figure 4, where Figure 3 shows a 3D model of a thickening and filtering process, and Figure 4 shows a layout of the filtering plant. The design consists of two identical thickeners, two agitated filter feed tanks (tailings holding tanks), one train of eight filter presses, three filtrate tanks (process water recovered), filter plate ready racks, a control room, and utilities such as compressed air and water. Thickened underflow is pumped from the mine tailings thickeners to two lines of agitated filter feed tanks. The recommendation for the filter feed tank design is that it has a residence time of 5–7 h.

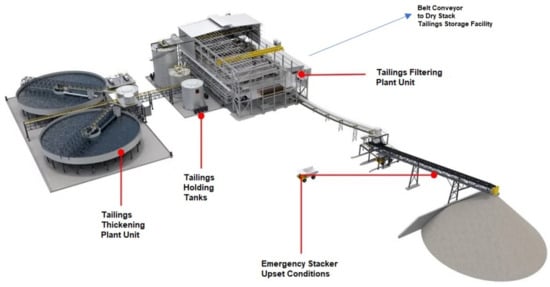

Figure 3.

3D model of a mine tailings thickening and filtering plant for a production rate of 100,000 mtpd.

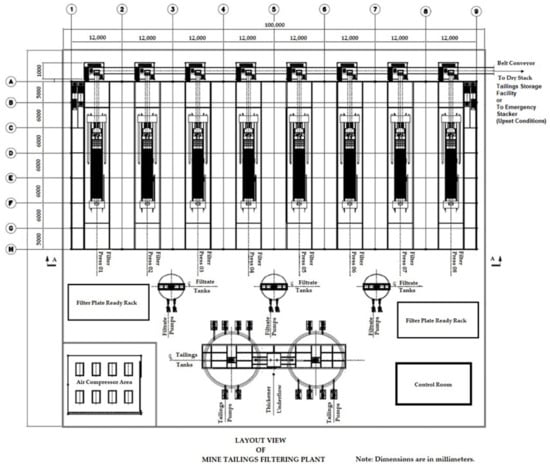

Figure 4.

Layout view of a mine tailings filtering plant for a production rate of 100,000 mtpd.

The design allows for a total of 8 filter presses to be installed to process mine tailings requirements of 100,000 mtpd over the life of the mine. Nevertheless, as a risk mitigation strategy, additional space must be allowed to install two additional filter presses if required. The mine tailings dewatering operation will produce tailings cake with an approximate moisture content of a range of 10%–15%.

Mine tailings filter cake from the filter presses discharges to a single belt feeder. The belt feeder operates continuously but at a low rate to deliver filter cake to the downstream conveyor continuously over the full cycle time of the filter press. The belt feeder of each filter press conducts the mine tailings filter cake to a single transfer conveyor, where filtered mine tailings can be conveyed to a dry stacking TSF or, under upset conditions, to an emergency stacker.

According to Figure 4, the control room for the mine tailings filtering area is mounted on the upper deck of the mine tailings filtering building. Two filter plate ready racks are available for maintenance tasks of the filter press. The dewatering plant includes a drop-down zone for filter components conveying to a stockpile to loading onto a truck under upset conditions by the mine tailings filtering plant (See Figure 3).

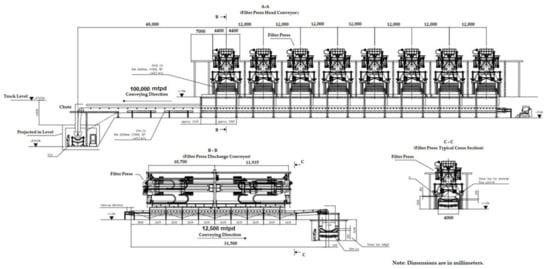

The new generation of filter presses dewaters over 12,000 mtpd of tailings, recovers 500 m3 of process water per hour, and requires significantly less space than old dewatering equipment (See Figure 4). They also increase the amount of process water returned to the metallurgical plant for reuse.

The force from this builds a cake inside the filter press chamber. Most filter presses on mine tailings applications operate with up to a 15 bar driving force; however, the new generation of filter presses can reach the required pressure using just the feed pumps to the filter. High-pressure air, around 10 bar, can be blown through the cake to reduce its moisture content further after the cake is formed to produce a non-saturated cake if required [49].

The new generation of filter presses can treat a range of 150–175 metric tons (mt) of feed in one cycle of approximately 20 min; thus, it can process up to a range of 10,500–12,500 mtpd of mine tailings. The new evolution of filter press nowadays is 1.5 times the size of a volleyball court and weighs 450 metric tons (mt). Another key characteristic is that plates of the new evolution of filter press are 5 m × 5 m.

The automated plate opening system in the new filter presser evolution opens around 140 plates in one min, which is a fast process. The 140 plates of the new generation of filter press give a maximum achieved volume of more than 75 m3. Considering filtration performance, the total filtration area is around 2850 m2.

Feeding and discharge holes in the new evolution of filter presses are sized to minimize abrasion and downtime for maintenance. A maintenance platform on top gives easy access to all of the filtration facilities. For example, operators can perform fast multiple-cloth replacements from the top. It is possible to change the media for multiple chambers simultaneously from both sides quickly and safely [49].

Using automated devices, the low-pressure cloth washing system cleans the whole cloth face simultaneously. The high-pressure cloth washing system, which starts after 20 or 30 cycles, refreshes the filterability of the cloth.

The trend in the last decade (2013–2023) has been that the filter press manufacturers have tried to reduce the number of lines of filter presses required for filtering mine tailings with high-level production, for example, above 100,000 mtpd, by increasing and developing larger size filter presses and optimizing the space in the filtering plant area (See Figure 5 and Figure 6).

Figure 5.

Typical details of a train of filter presses for a production rate of 100,000 mtpd of filtered mine tailings.

Figure 6.

Example of mine tailings filtering plant with use of filter presses.

A dry cake is formed by the pumping of feed slurry tailings under pressure in the chambers of the filter press. Mine tailings filter cake from the filter presses discharges to a single belt feeder via a set of ‘bomb-bay’ doors (See Figure 7).

Figure 7.

Mine tailings filter cake from the filter presses discharges to a single belt feeder via a set of ‘bomb-bay’ doors.

3. Filtered Mine Tailings Conveyance System

The typical design that defines the characteristics of the deposit of filtered tailings (dry stacking) is given by a conveyor belt that takes the filtered mine tailings from the filter press and deposits them in an intermediate fixed belt (transfer conveyor belt). Then, the cake is moved to a fixed distribution belt and finally to a mobile belt with a tripper car, which is in charge of the linear distribution of filtered mine tailings in the dry stacking zone (TSF) [50]. As a complementary activity, using a bulldozer is considered to distribute filtered mine tailings in the dry stacking zone (TSF).

As mechanical equipment is considered for the management of filtered mine tailings, it is recommended:

- Intermediate fixed conveyor belt (transfer conveyor belt).

- Discharge chute (including lining).

- Distribution fixed conveyor belt.

- Discharge chute (including lining).

- Mobile conveyor belt with tripper car.

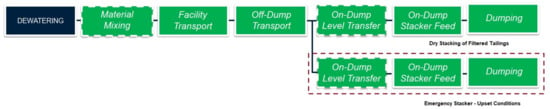

Filtered mine tailings from the transfer conveyor are discharged to a single overland tailings conveyor (distribution fixed conveyor) [30]. This conveyor delivers tailings via a bifurcated chute to either the primary or secondary stacking system, which comprises the material handling system for the dry stacking zone (TSF) and emergency stacker (upset conditions), respectively (See Figure 8).

Figure 8.

Process diagram of filtered tailings management and options for primary or secondary stacking system.

The philosophy for the dry stacking equipment considers the following drivers [51]:

- Minimize stacker downtime for changeovers between lifts and sweeps.

- Maintain stacker progression rates within practical limitations.

- Maximize evaporative drying of the stacked filtered mine tailings.

- Minimize stacker and conveyor costs.

- Equipment should be mechanically robust to minimize unplanned downtime.

- Stack material in a way that addresses geotechnical considerations, including equipment setback distances.

- Permit constraints.

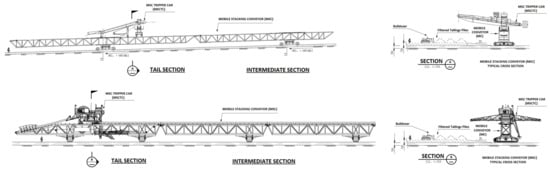

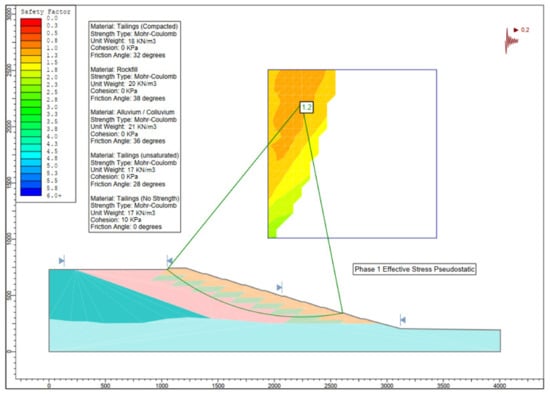

Filtered mine tailings stacking mobile conveyors operate in series and transport filtered mine tailings from the mobile tripper to the extendable mobile filtered mine tailings stacker. During operation, the number of these conveyors required is dependent on the final filtered mine tailings deposition location relative to the position of the shiftable conveyor and mobile tripper. Figure 9 shows different equipment for the transport of filtered mine tailings for disposal of the mine waste at the dry stacking zone.

Figure 9.

Different equipment for the transport of filtered mine tailings for disposal at the dry stacking zone.

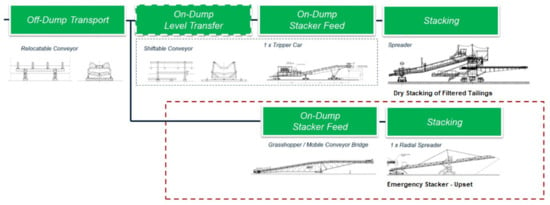

The dry stack TSF in a flat terrain is restricted by the surrounding mine facilities. This type of dry stack TSF construction is relatively easy, either on flat terrain or terrain contouring on gentle alluvial fans. The filtered mine tailings are stacked in relatively thin lifts (0.3 m typically). The successive placement of compacted lifts forms the TSF terraces or pads. The TSF terraces are constructed from the bottom to the top area, decreasing the filtered tailings placement surface when the dry stack filtered TSF is raised. Figure 10 shows a layout view of a dry stack pad configuration and a dry stack fan configuration.

Figure 10.

Layout view of dry stacking disposal scheme of filtered mine tailings with the use of mobile stacking conveyor [30].

Mobile stacking conveyor system uses advance stacking rather than retreat stacking, which has the advantage of compressing the stacks as it layers. All the sections of the mobile conveyor are modular. They are moveable and detachable, which allows the operator to elongate the system as required. This is useful for times when mine tailings production rates change, such as concentrator plant shutdowns. Figure 11 shows an example of two different models of mobile stacking conveyors with tripper cars for the disposal of filtered mine tailings.

Figure 11.

Example of 2 different models of mobile stacking conveyor with tripper car for disposal of filtered mine tailings [30].

Mobile stacking conveyor technology can ensure a smooth operation, eliminating operator errors and reducing dozer work. It calculates precise stacking to a reference height with a GPS data accuracy of 2 cm. The GPS identifies the discharge point and velocity of the pile build-up, then sends a speed output to the stacker based on the difference of reference height and actual pile height, also considering the velocity of the current pile build-up. The automatic stacking conveyor will customize the stacked area profile with GPS-ensured stacking height, compensating for incoming volume. Adding automation and GPS technology to the system can keep maintenance and servicing issues to a minimum.

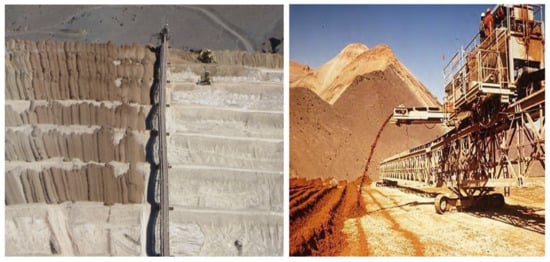

Figure 12 shows a practical experience using a mobile stacking conveyor with a tripper car for the disposal of filtered mine tailings in La Coipa Mine, Chile.

Figure 12.

Practical experience using mobile stacking conveyor with tripper car for disposal of filtered mine tailings in La Coipa Mine, Chile [30].

4. Dry Stacking of Filtered Mine Tailings: Geometric Configuration and Placement Scheme

4.1. Geometric Configuration of Dry Stacking of Filtered Mine Tailings

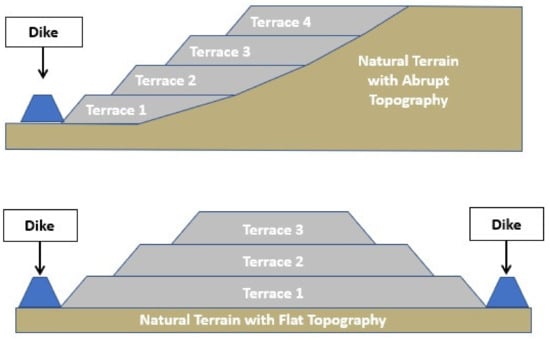

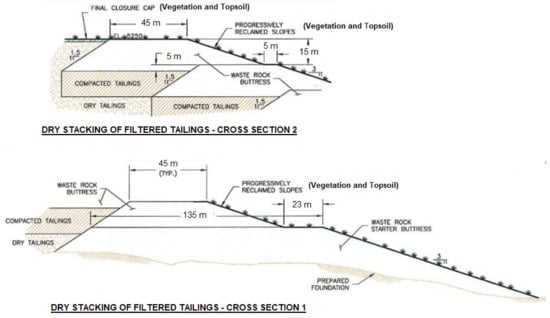

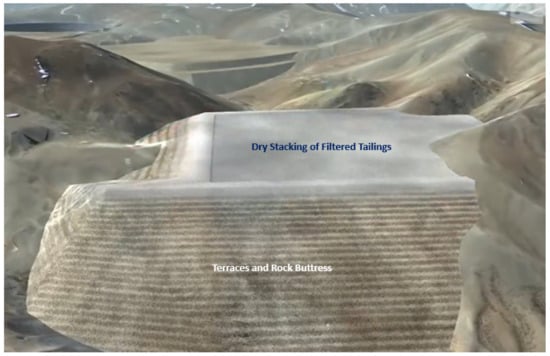

The geometric configuration of the dry stacking of filtered mine tailings will depend on the topographic conditions of the mine tailings storage site [52]. This means that the geometry of dry stacking will be different considering flat terrain and mountainous terrain. The basic principle of stacking filtered mine tailings is the formation of compacted layers that are successively placed one on top of the other, thus achieving the formation of terraces or platforms (lifts) [53].

Thus, in the case of abrupt topographies with the presence of mountain slopes, the terraces or platforms of the dry stacking of filtered mine tailings will be built in a direction from the bottom up in contact with the slopes [21]. On the other hand, in the case of flat topographies without the presence of mountain slopes, the terraces or platforms of the dry stacking of filtered mine tailings will be built from the bottom up, mounting one terrace on another successively [54].

In Figure 13, it is possible to see the 2 cases presented above, considering abrupt topography and flat topography.

Figure 13.

Example of the typical geometric configuration of dry stacking of filtered mine tailings.

The height of the terraces or platforms is conditioned considering the slopes of dry stacking, both parameters being defined by the analysis of the physical stability of dry stacking. Conservative typical values for these parameters, for the height of terraces or platforms, are in the range of 5–10 m, and local slopes are equivalent to H:V = 3.0:1.0 [30].

Likewise, another important aspect in the geometry of dry stacking is the placement of berms on each terrace or platform, which fulfill the function of being a transit area and installing geotechnical monitoring instrumentation using piezometers or inclinometers. The typical range of berm widths in the dry stacking of filtered mine tailings is between 2–5 m. In addition, it is recommended to install small dikes in the lower part of the dry stacking of filtered mine tailings to contain any eventual spillage of mine tailings or rainwater that has come into contact with the tailings storage facility. Finally, the number of terraces to consider will be influenced by the total amount in cubic meters of filtered mine tailings to be stored during the useful life of the mine (See Figure 14).

Figure 14.

Example of filtered mine tailings disposal considering abrupt topography in La Coipa Mine, Chile [30].

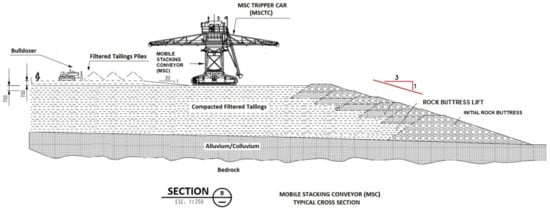

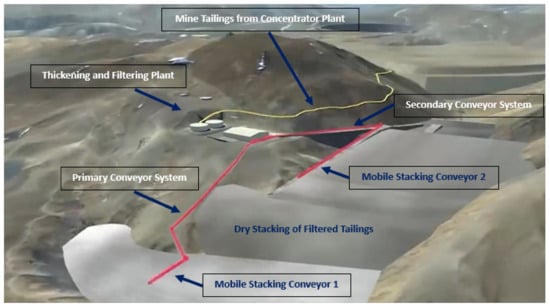

The dry stacking of filtered mine tailings facility will receive dry tailings from the concentrator plant at a nominal rate of 100,000 mtpd. Filtered mine tailings will be stacked behind large containment berms constructed from mine waste rock. The general design concept for the dry stacking of filtered mine tailings facility is to build uniform lifts of filtered mine tailings that are buttressed by starter buttresses. The buttresses will advance ahead of the filtered mine tailings surface to provide containment [30].

An initial buttress will be constructed with mine waste rock to accommodate the initial years of filtered mine tailings storage. A dozer will be used to spread the filtered mine tailings near the containment buttresses and, as needed, to provide sufficient compaction for the movable stacking conveyors and stackers (See Figure 15).

Figure 15.

Typical cross-section of the dry stacking of filtered mine tailings with mobile stacking conveyor working [30].

Concurrent filtered mine tailings and waste rock placement will occur throughout the lifetime of the dry stacking of the filtered mine tailings facility. Mine waste rock will be advanced ahead of the filtered mine tailings level in successive lifts. The waste rock buttresses will have top widths to accommodate two-way haul traffic and outer slopes of H:V = 3.0:1.0 [30].

4.2. Placement Scheme of Dry Stacking of Filtered Mine Tailings

For the placement scheme of dry stacking of filtered mine tailings, a radial stacker is recommended to allow the placement of filtered mine tailings against the starter buttress. A dozer will be used to spread the filtered mine tailings and provide sufficient compaction for the conveyor and stacker as necessary. The dry stacking of filtered mine tailings facility consists of two separate areas: the normal operation stack and the upset conditions stack.

When the primary movable conveyor is active, the filtered mine tailings will be conveyed with the movable conveyor to the normal operation area. When the primary movable conveyor is inactive due to relocation or maintenance, a second movable conveyor, constructed along the tailings storage area, will allow temporary disposal of mine tailings into the dry stacking of filtered mine tailings upset conditions area for placement with dozers (See Figure 16).

Figure 16.

Example of dry stacking of filtered mine tailings facility considering a production rate of 100,000 mtpd.

Filtered mine tailings dewatering by desiccation becomes feasible if low or no rainfall is registered in the mine zone. Additionally, the use of dozers may help the drying process of filtered mine tailings by airing. The filtered mine tailings production rate and time for desiccation are key parameters to consider in evaluating the size and availability of desiccation areas.

For example, for the Cerro Lindo filtered tailings mining project in Peru, considering a production of 7000 mtpd, a dry compaction density equivalent to 2.10 t/m3, 30 cm thick layers for the filtered tailings and 3 days desiccation, an area for depositing filtered tailings equivalent to 3.3 Ha (33,333 m2) is required.

Considering another case, for the La Coipa filtered tailings mining project in Chile, considering the production of 20,000 mtpd, a dry compaction density equivalent to 1.90 t/m3, 30 cm thick layers for the filtered tailings, and 3 days of drying, an area for depositing filtered tailings equivalent to 10.5 Ha (105,265 m2) is required (See Figure 17).

Figure 17.

Evaluating the size and availability of desiccation areas at the dry stacking of filtered mine tailings.

Finally, for a filtered tailings mining project considering the production of 100,000 mtpd, a dry compaction density equivalent to 2.00 t/m3, 30 cm thick layers for the filtered tailings, and 3 days of drying, an area for depositing filtered tailings equivalent to approximately 50.0 Ha (500,000 m2) is required.

Large production rates of filtered mine tailings and longer periods for desiccation may result in extensive desiccation areas, which may be challenging for mining operators.

The dry stacking of filtered mine tailings placement scheme design has unique elements, including the inter-dependence of the stacking configuration, the conveyor, and the stacker system design. This design has many advantages, as follows [21]:

- The initial and overall footprint is minimal.

- Stacker downtime from changeovers is reduced dramatically.

- The system sequence improves the aeration of the material by profiling the stack as its layers.

- This maximizes evaporative drying and improves the density of the stacked filtered mine tailings, lowering stacker and conveyor costs.

- The stack can reach the design high, built in several layers.

- The comparatively tiny footprint is clearly a major advantage over the slurry conventional tailings storage facilities.

- The mobile stacking conveyor machine also compresses and compacts the material as it travels across the dry stacking.

- Progressive reclamation and rehabilitation to manage dust and emission of particulate matter is also made easier with this technology (consolidated tailings).

5. Safety and Sustainability of a Dry Stacking of Filtered Mine Tailings: Physical Stability, Water Management, Progressive Mine Closure and Particulate Matter Control

5.1. Physical Stability of Dry Stacking of Filtered Mine Tailings

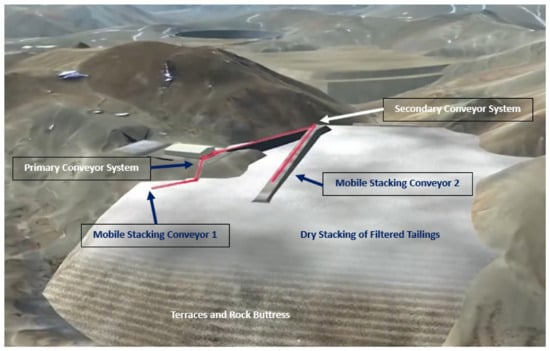

The partially saturated dry stacking of filtered mine tailings must often be stabilized by including outer structural zones to enhance overall perimeter stability. Perimeter berms can be constructed of mine waste rock or borrow materials to achieve stable dry stacking. The filtered mine tailings must be well drained and compacted to minimize the potential for liquefaction due to static and/or seismic loading conditions to maintain structural stability [55].

There is the potential for the filtered mine tailings to liquefy under static and/or seismic loading conditions if high saturation conditions are presented [18]. The dry stacking of filtered mine tailings may require isolated zones within the interior of the dry stacking to store contractive filtered mine tailings with high saturation [31]. The isolated storage zones may also be required to store filtered mine tailings during winter conditions if the filtered mine tailings cannot be placed and compacted before rainfall events. The filtered tailings layers will densify under successive controlled conveyor layer placement and will result in an increase in the lower lift fill strength over time [45].

The dry stacking of filtered mine tailings stability analyses must consider the maximum ultimate height at the maximum section through the tailings storage facility for physical stability.

The filtered mine tailings must be placed in a dewatered state for acceptable handleability during conveyance and trafficability of the filtered mine tailing surface, which will limit susceptibility to liquefaction under dynamic loading (See Figure 18).

Figure 18.

Conveyance and trafficability issues are considered in dry stacking of filtered mine tailings stability analysis.

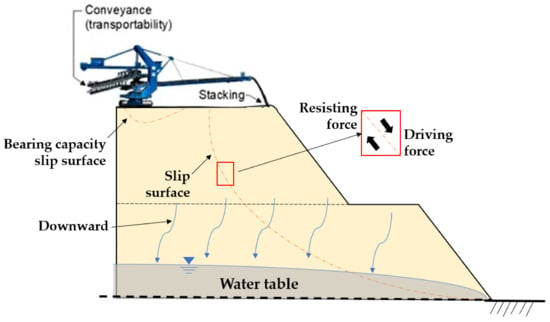

However, limited higher moisture zones within the filtered mine tailings mass created by meteoric water may occur [55]. This condition must be considered in the stability modeling of the dry stacking of filtered mine tailings by applying reduced shear strength to thin layers within the filtered mine tailings mass at various levels to simulate these higher moisture zones and evaluate the facility’s seismic resistance. Thus, adequate safety factors for static and pseudo-static must be obtained from the stability analyses based on the geotechnical parameters from laboratory tests (See Figure 19).

Figure 19.

A typical cross-section of dry stacking of filtered mine tailings considered in a pseudo-static stability analysis.

The use of dry stacking of filtered mine tailings instead of conventional tailings storage facilities reduces the risks of dam failure typically seen with slurry tailings ponds [13].

5.2. Water Management at the Dry Stacking of Filtered Mine Tailings

Although it is known that filtered tailings have low water contents, as a conservative engineering criterion, it is necessary to design infrastructures to manage seepage water and rainwater. Some of the necessary infrastructures are (i) basal drainage systems, (ii) seepage collection ponds, (iii) the use of geomembranes, and (iv) perimeter channels, among others [56]. These infrastructures are of key importance, even more so today, where a scenario of uncertainty is being experienced regarding the threat of climate change [42].

Water management ponds are required downstream of the dry stacking of filtered mine tailings facility to collect and manage seepage and runoff contact water. The size of the ponds will depend on the site characteristics, TSF design details, and climate, among others [11].

Managing storm events may be challenging as the dry stacking of filtered mine tailings needs to have significant capacity to temporarily store runoff from storm events. The surface of a filtered mine tailings facility must be adequately graded to convey precipitation runoff and minimize erosion of the placed filtered mine tailings. Ditches and sedimentation ponds are required to manage contact water from the TSF [7].

All water that comes into contact with filtered mine tailings must be collected and prevented from contacting the environment [15]. For this reason, all these contact waters are recovered and transported to the metallurgical process plant for reuse. If there is a need to discharge contact water into the environment, it must be subjected to a physical-chemical treatment to comply with local environmental regulations (See Figure 20) [22].

Figure 20.

Schematical diagram of water management at the dry stacking of filtered mine tailings facility [5].

5.3. Progressive Mine Closure and Dust Control at the Dry Stacking of Filtered Mine Tailings

Dry stacking of filtered mine tailings may be concurrently reclaimed during the construction phase and is typically more straightforward and less expensive to reclaim at the mine closure phase due to enhanced trafficability [57]. The deposition of filtered mine tailings and mine waste rock will be initiated with a series of perimeter buttresses and berms. The staging of these buttresses will also allow the reclamation part of the progressive mine closure plan to begin early in the operation. Topsoil can be recovered from other places of the mine for use as a vegetation growth medium (like a phytoremediation strategy) (See Figure 21) [58].

Figure 21.

Example of progressive mine closure of dry stacking of filtered mine tailings.

Advantages of the dry stacking of filtered mine tailings method over conventional (slurry) tailings disposal are: (i) it eliminates the need for an engineered dam and seepage containment system; (ii) it maximizes water conservation and minimizes water makeup requirements; (iii) it results in a very compact site that limits disturbance to single drainage; and, (iv) it allows opportunities for progressive reclamation in the mine closure plan and dust control (See Figure 22) [17].

Figure 22.

Example of topsoil—vegetation and borrow material cover at mine closure of dry stacking of filtered mine tailings.

Controlling the emission of particulate matter is a key aspect to be controlled during the operation of the dry stacking of mine filtered tailings. The literature shows that by not adequately controlling the emission of particulate matter in mining tailings storage facilities, a negative environmental impact is produced that can be significant for neighboring communities and the biodiversity of the area [59,60].

Operational and engineering particulate matter emission controls at the dry stacking of filtered mine tailings facility will consist of [30]:

- Buttresses constructed of mine waste rock material will break up the airflow and reduce exposure of large areas of filtered mine tailings to windy conditions. In this manner, dust is less likely to become airborne.

- Moisture content in the filtered mine tailings delivered to the dry stacking area will be between 10% and 15%. This is sufficient moisture to ensure that dust is not generated on the belts or in the filtered mine tailings placement in the stacking operation.

- Filtered mine tailings will be stacked using a tripper arrangement on mobile conveyors. This stacking method creates an irregular shape to the placed filtered mine tailings, again breaking up airflow patterns so dust does not become entrained. Also, dozers, trippers, and mobile conveyors will reduce the need for wheeled vehicles to drive across the filtered mine tailings, minimizing dust.

Contingency controls for the dry stacking of filtered mine tailings facility include:

- Application of a binder material. This material binds particles on the surface of the filtered tailings so that the particles do not become airborne.

- Application of an agglomeration chemical to lines along the conveyor system. This process would bind smaller particles together to make a larger grain size in the placed filtered mine tailings.

- Application of water to suppress dust. Because water conservation is a very high priority, this is the least favorable physical control available.

6. Smart Mining Technologies for the Management of Filtered Mine Tailings for High Production Rates Considering Industry 4.0 Paradigm

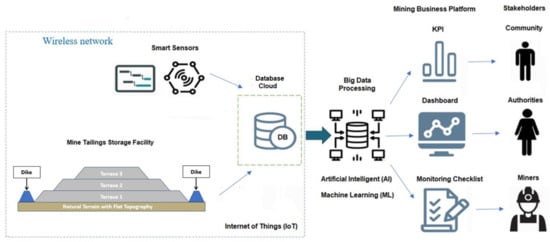

The mining of the future will be a digital mine that will work under the Industry 4.0 paradigm, where 100% of the operation will be monitored by different types of smart sensors that will allow data to be captured in real-time, using different types of connectivity such as Wifi, Bluetooth, Zigbee, LoRa, LTE, XBee, among others [61]. In this way, machines, equipment, and different artifacts of the mining operation will communicate with each other through the Internet of Things (IoT), allowing the collection and storage of information on different operational parameters in a virtual cloud [62]. In the same way, the information collected will be able to feed advanced data analytics algorithms through data analytics, machine learning (ML), and artificial intelligence (AI) that will make it possible to interpret the phenomenology of mining processes and predict the operation of productive systems made up of machinery, and equipment [63]. In addition, the collection and interpretation of the information collected by the sensors will be the basis of the virtual simulation of processes through digital twins, which will generate different operating scenarios and allow prospective decisions to be made in real-time to improve the productivity, reliability, and safety of operations [61].

Engineering projects of the future considering filtered mine tailings stored in dry stacking that consider the Industry 4.0 paradigm will be carried out in a fully digitized and virtualized environment called integrated engineering, where all the information of the engineering project from its conception considering all engineering disciplines will be stored in a cloud or virtual platform [64]. This will allow you always to have access to different data and documentation such as for example, design criteria, process diagrams, P&IDs, electromechanical equipment data sheets, calculation notebooks, plans, virtual models, operation manuals, and technical specifications, among others [65]. This strategy will make it possible to adequately manage knowledge and link with the core of the automation system and, based on this, simulate and analyze whether what is being obtained was what was expected following the original planning of the project [66].

This is how the management of mine tailings, considering filtered tailings stored in dry stacking, will be an activity operated digitally through remote systems and with high automation of electromechanical equipment [64]. The sensors will be able to monitor the operation of critical parameters of the mine tailings filtration equipment, to have a high performance 24 h a day (day and night) and almost 365 days a year, even under different weather conditions characteristic of the winter and summer seasons [61]. In addition, the application of sensors to monitor the operation of feeders, discharge chutes, and fixed and mobile conveyor belts will allow a high efficiency of the filtered tailings transportation process from the dewatering process plant to the dry stacking storage facility. In this way, predictive maintenance can be carried out that will increase the availability of processes, reduce production stoppage events, and real-time monitoring of KPIs will be carried out (e.g., cake moisture, mine tailings production rate, water recovery, power consumption, flowrates, and uptime, among others) (Figure 23). These technologies make it possible to diagnose a problematic situation and thus proceed, for example, with a repair of the electromechanical equipment [67].

Figure 23.

A new filtered mine tailings management paradigm considering Industry 4.0 technologies.

Likewise, smart sensor technologies, data analytics, the Internet of Things (IoT), machine learning (ML), and artificial intelligence (AI) will improve the energy efficiency of all electromechanical equipment for transporting and depositing filtered mine tailings. Advanced statistical and probabilistic data analytics algorithms will be able to process huge volumes of information and thus predict the operation, responses, and performance of electromechanical equipment, which will allow through digital twins to simulate different trends and different production scenarios considering the variation of input parameters (such as mineralogy changes, granulometry changes, changes in the amount of fines, changes in the feed flow, changes in climatic conditions, etc.) [62]. The virtual scenarios generated by the digital twins within the meta-verse, both favorable and unfavorable, will help mine operators to make decisions in real-time with a prospective and holistic approach, improving the planning and management of filtered mine tailings in all production chains in the real world [67].

Information and communication technologies (ICTs) from Industry 4.0 are easily accessed from a computer, smartphone, or tablet. It connects with various platforms, including numerous apps [63]. It offers analytics for decision-making, improved control, tracking and monitoring of types of equipment, help for predictive maintenance, and data that can be used to improve performance. The new evolution of suppliers will monitor the performance of equipment (filter presses and fixed and movable conveyors) to collect data and history about the unit’s performance. For mining operators, this is a collaboration to give help and support for the optimization of the units as well as analyze the implementation of predictive and preventative maintenance [61].

As a post-process component of the mine tailings thickening/filtering process plant, dry stacking is required to accommodate a high solid bulk production rate. Ensuring a robust design with high availability is key, as dry stacking downtime inevitably translates to process plant downtime and lost revenue to the mining business [66]. Redundancy is required in the filtered tailings thickening/filtration plant, but with high cost of capital (CAPEX) components such as filters, therefore ensuring optimal design is critical. In this sense, developing a digital twin, consisting of a virtual simulation model of scenarios (base case and sensitivity cases) that can account for all the main processes, dependencies, and failure modes, is recommended. In this manner, it is possible to correctly evaluate the trade-off between capital equipment and process plant availability. In addition, a digital twin based on a virtual simulation model can identify where bottlenecks will form, test alternative debottlenecking solutions, have high sensitivity to clay content, and eliminate design risk [67].

On the other hand, monitoring technologies with in-situ sensors (such as inclinometers, intelligent geosynthetics, accelerometers, vibrating wire piezometers, load cells, closed-circuit TV cameras, etc.) and remote sensors (satellite images, Insar technology, use of GPS, use of the dispatch system, and use of drones (UAVs), among others) that allow obtaining topographic, geometric, and filling information with filtered tailings from dry stacking, will be compiled through an integrated control center [61]. This will allow for safer and more controlled tailings governance, always planning and management.

Without a doubt, the automation of the different tasks involved in the responsible management of mine tailings will be one of the great contributions of Industry 4.0 since this will allow the mining production process to continue in a safe and controlled manner and will also reduce the possibility of accidents by having less human intervention in the field, and finally applying an environmentally friendly technology with the ecosystem.

Finally, having a digital and automated process for managing filtered mine tailings will improve the operational philosophy of mine tailings management and develop intelligent mining, resilient in the face of climate change uncertainty and optimizing processes, using resources, and delivering continuity to the mining business [65].

7. Outlook and Future Directions

The technology of dry stacking of filtered mine tailings is part of a holistic tailings management solution, which has the following advantages: (i) mitigates the negative environmental impacts on the territory, (ii) decreases the risk of TSF instability, (iii) reduces the water footprint, (iv) is accepted by local communities and local authorities and (v) minimizing the total cost in the lifetime of TSF project [68,69].

The elimination of slurry mine tailings dams and the reuse of process water on the site minimizes environmental risks to the community and helps mining companies obtain a socio-environmental license to operate [15,70].

Many mining projects operated by mining companies are in countries where water is a scarce natural resource, where stakeholders like miners, farmers, tourists, indigenous communities, and urban people, among others, that living in the watersheds need the water use under a climate change scenario [43,71]. Reusing and recycling process water in the mines leads to relevant savings by minimizing the amount of freshwater needed for the mining operation. This allows the equitative use of water considering all stakeholders in the watersheds [44]. In this context, the dry stacking of filtered mine tailings solution, processing over 100,000 mtpd of mine tailings, allows the mine to operate with a water makeup ratio of 0.2 m3/t, compared to conventional slurry tailings dams that have a ratio of 0.7 m3/t [44].

Table 1 shows a comparative analysis of water recovery quantities obtained with different dewatering tailings technologies, assuming a tailings production of 100,000 mtpd.

Table 1.

Water Recovery Comparison between Different Mine Tailings Management Technologies.

Table 1 shows that filtered tailings technology is competitive to recover water from mine tailings, outperforming conventional tailings and thickened tailings technologies and ranking first, with an efficiency of 93%. This indicates that the filtered tailings technology is an attractive option to be implemented to carry out an environmentally controlled management of mine tailings and maximize the water recovery.

Regarding developments with conveyor systems, a new generation of “pipe” or “tubular” conveyor belts is a viable alternative to use with filtered tailings, allowing a confined transport that does not allow the liberation of dust emissions in very windy areas [72,73].

Design criteria for the dry stacking of filtered mine tailings storage facility for large-scale industrial productions include [30]:

- Provision of secure, long-term storage of filtered mine tailings, which is sufficient for the ore to be mined and processed during approximately the project lifetime at a projected production rate over 100,000 mtpd.

- Minimizing water seepage from mine tailings into groundwater in compliance with all applicable regulations, including local water quality standards.

- Creating a site-specific design that accounts for local factors, including climate, geology, hydrogeology, and seismicity.

- Establishment of an effective and efficient mine closure program, with a focus on progressive reclamation.

As a downstream component of the mine tailings dewatering processing plant, dry stacking is required to accommodate a high level of material production. Ensuring a robust design with high availability is key, as dry stacking downtime inevitably translates into concentrator plant downtime and lost revenue. Redundancy is required in the mine tailings filtration plant, but with a high cost of capital components such as filters, it is essential to ensure an optimal design. In this sense, considering the advances in Industry 4.0 technologies, the development of a digital twin is recommended that consists of a virtual scenario simulation model (base case and sensitivity cases) that can account for all the main processes, leaked mine tailings management system dependencies, risks and failure modes [65,66]. In this way, correctly assess the trade-off between the filtration equipment and the availability of the filtration plant. In addition, a digital twin based on a virtual simulation model can identify where bottlenecks will form, test alternative debottlenecking solutions, and eliminate inherent design failure risks [62,63].

Mine tailings storage facilities are generally managed without in-house mine tailings engineer expertise in many mining operations—relying instead on specialized consulting engineers who may change in name and service throughout the mine operation. Although the concept of the engineer of record (EoR) has been around in some countries since the early 20th century, it is not widely used globally and is applied inconsistently in the mining industry. The concept of EoR and associated terminology in the mining industry gained prominence after several tailings dam failures, such as the tailings dam breach at the Ajka alumina plant in western Hungary in 2010 [74,75], the Mount Polley tailings dam failure in Canada in 2014, the Samarco tailings dam failure in Brazil in 2015, and the Brumandinho tailings dam failure in Brazil in 2019 [76,77,78]. Following other recent tailings dam failures, forensic investigations have identified the importance of the EoR in risk reduction and failure prevention, and the publication of the Global Industry Standard on Tailings Management (GISTM) reinforces the importance of the EoR. These forensic investigations, coupled with initiatives by engineering professionals and the mining community, have led to an industry consensus that owners benefit most when continuity in the EoR role is maintained throughout the design, construction, operation phases, and mine closure phases. In this context, it is relevant that the implementation of dry stacking of filtered mine tailings is managed by an EoR that has extensive experience and is highly qualified, being a professional or a consultancy company not only with experience in the geotechnical area but also comprehensively and holistically, with experience in the areas of dewatering processes, electromechanical equipment, environment, geochemistry, and hydraulics, among others. Finally, the EoR must put into practice the highest safety standards, the best available practices (BAPs), and the best environmental practices (BEPs).

8. Conclusions

The dry stacking of filtered mine tailings has the potential for breakthrough or step-change improvements in performance or cost-effectiveness over current conventional (slurry) tailings management solutions. The responsible management of TSFs is critical to maintaining social acceptance and obtaining the environmental license to operate.

The success of the worldwide massive implementation of dry stacking of filtered mine tailings technology will depend on the motivation of the mining companies to bet in innovation, make a change of business approach, trust in the benefits of this solution, and have a clear commitment to contributing to a more sustainable mining industry. These strategic decisions will permit us to move towards a higher level of mine tailings management performance with greater control of processes, reducing uncertainties and leaving obsolete conventional (slurry) tailings management technologies in the past.

Copper mine tailings, particularly in Chile and Peru, are produced in quantities unrivaled in any other mining sector. Dry stacking of filtered mine tailings has become the preferred mine tailings storage method, and pressure filtration is the only practical technology available at this time that reaches the low moisture content demanded by the technical specifications and safety standards of the design of the dry stacking storage facilities.

For a given throughput, for example, over 100,000 mtpd, using a new design of a filtering plant, the number of presses filter trains can be reduced by around two-thirds, and that results in a significantly smaller filter building footprint.

Considering the background presented in this article, it is possible to mention:

- TSF footprint can be reduced by approximately 1/3, compared to a conventional mine tailings storage facility area.

- 90% of the process water can be recovered for reuse in metallurgical plants.

- The operational costs (OPEX) of the dry stacking of filtered mine tailings technology, even on a large industrial scale, is less than 2.0 USD / dry t.

- Mine tailings production rates over 100,000 mtpd can be high-pressure dewatered.

Finally, the article concludes that implementing large-scale filtered mine tailings solutions is no longer just a promise but rather a reality, considering manufacturers’ advances in the equipment’s performance, implementation of Industry 4.0 technologies as well as experience in several mining operations. The technological solution for the dry stacking of filtered mine tailings is scalable; therefore, filtering mine tailings at production rates over 100,000 mtpd is possible. The future global trend is that mining operations with high daily production rates of mine tailings will apply dry stacking of filtered mine tailings technology without dams to guarantee sustainability, promote continuity of the mining business, guarantee the safety of communities, and conserve the environment.

Author Contributions

Conceptualization, C.C. and E.A.; formal analysis, C.C.; investigation, C.C.; resources, E.A.; writing—original draft preparation, C.C.; writing—review and editing, C.C. and E.A.; visualization, C.C.; supervision, E.A. All authors have read and agreed to the published version of the manuscript.

Funding

The research is funded (APC) by the Pontificia Universidad Católica de Valparaíso, Chile.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| TSF | Tailings Storage Facility |

| BATs | Best Available Technologies |

| BAPs | Best Applicable Practices |

| BEPs | Best Environmental Practices |

| ARD | Acid Rock Drainage |

| GISTM | Global Industry Standard on Tailings Management |

| NGOs | Non-Governmental Organizations |

| CTD | Conventional Tailings Disposal |

| TTD | Thickened Tailings Disposal |

| PTD | Paste Tailings Disposal |

| FTD | Filtered Tailings Disposal |

| GPS | Global Positioning System |

| IoT | Internet of Things |

| AI | Artificial Intelligence |

| ML | Machine Learning |

| UAVs | Unmanned Aerial Vehicles |

| KPIs | Key Performance Indicators |

| P&IDs | Piping and Instrumentation Diagrams |

| ESG | Environmental, Social, and Governance |

| EoR | Engineer of Record |

| ICTs | Information and Communication Technologies |

| CAPEX | Capital Costs |

| OPEX | Operational Costs |

| USD | United States Dollar |

| Cw | Slurry tailings solids content by weight |

| mtpd | Metric tons per day |

| masl | Meters above sea level |

References

- Agusdinata, D.B.; Liu, W. Global sustainability of electric vehicles minerals: A critical review of news media. Extr. Ind. Soc. 2023, 13, 101231. [Google Scholar] [CrossRef]

- Liu, W.; Agusdinata, D.B.; Eakin, H.; Romero, H. Sustainable minerals extraction for electric vehicles: A pilot study of consumers’ perceptions of impacts. Resour. Policy 2022, 75, 102523. [Google Scholar] [CrossRef]

- Mavrommatis, E.; Damigos, D.; Mirasgedis, S. Towards a comprehensive framework for climate change multi-risk assessment in the mining industry. Infrastructures 2019, 4, 38. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Atencio, E. In-Pit Disposal of Mine Tailings for a Sustainable Mine Closure: A Responsible Alternative to Develop Long-Term Green Mining Solutions. Sustainability 2023, 15, 6481. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Atencio, E. Past, Present, and Future of Copper Mine Tailings Governance in Chile (1905–2022): A Review in One of the Leading Mining Countries in the World. Int. J. Environ. Res. Public Health 2022, 19, 13060. [Google Scholar] [CrossRef] [PubMed]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- East, D.; Fernandez, R. Managing Water to Minimize Risk in Tailings Storage Facility Design, Construction, and Operation. Mine Water Environ. 2021, 40, 36–41. [Google Scholar] [CrossRef]

- Owen, J.R.; Kemp, D.; Lèbre Svobodova, K.; Pérez Murillo, G. Catastrophic tailings dam failures and disaster risk disclosure. Int. J. Disaster Risk Reduct. 2020, 42, 101361. [Google Scholar] [CrossRef]

- Islam, K.; Murakami, S. Global-scale impact analysis of mine tailings dam failures: 1915–2020. Glob. Environ. Chang. 2021, 70, 102361. [Google Scholar] [CrossRef]

- Kemp, D.; Owen, J.R.; Lèbre, É. Tailings facility failures in the global mining industry: Will a ‘transparency turn’ drive change? Bus. Strategy Env. 2021, 30, 122–134. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Pastor, A.; Valderrama, P.; Atencio, E. Process Water Management and Seepage Control in Tailings Storage Facilities: Engineered Environmental Solutions Applied in Chile and Peru. Water 2023, 15, 196. [Google Scholar] [CrossRef]

- Piciullo, L.; Storrøsten, E.B.; Liu, Z.; Nadim, F.; Lacasse, S. A new look at the statistics of tailings dam failures. Eng. Geol. 2022, 303, 106657. [Google Scholar] [CrossRef]

- Rana, N.M.; Ghahramani, N.; Evans, S.G.; Small, A.; Skermer, N.; McDougall, S.; Take, W.A. Global magnitude-frequency statistics of the failures and impacts of large water-retention dams and mine tailings impoundments. Earth-Science Rev. 2022, 232, 104144. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Cano, D. Spatial and Temporal Study of Supernatant Process Water Pond in Tailings Storage Facilities: Use of Remote Sensing Techniques for Preventing Mine Tailings Dam Failures. Sustainability 2023, 15, 4984. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Cano, D.; Custodio, M. Socio-Environmental Risks Linked with Mine Tailings Chemical Composition: Promoting Responsible and Safe Mine Tailings Management Considering Copper and Gold Mining Experiences from Chile and Peru. Toxics 2023, 11, 462. [Google Scholar] [CrossRef] [PubMed]

- Innis, S.; Kunz, N.C. The role of institutional mining investors in driving responsible tailings management. Extr. Ind. Soc. 2020, 7, 1377–1384. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Atencio, E. An Alternative Technology to Obtain Dewatered Mine Tailings: Safe and Control Environmental Management of Filtered and Thickened Copper Mine Tailings in Chile. Minerals 2022, 12, 1334. [Google Scholar] [CrossRef]

- Ledesma, O.; Sfriso, A.; Manzanal, D. Procedure for assessing the liquefaction vulnerability of tailings dams. Comput. Geotech. 2022, 144, 104632. [Google Scholar] [CrossRef]

- Cacciuttolo Vargas, C.; Marinovic Pulido, A. Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance. Sustainability 2022, 14, 10901. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef]

- Furnell, E.; Bilaniuk, K.; Goldbaum, M.; Shoaib, M.; Wani, O.; Tian, X.; Chen, Z.; Boucher, D.; Bobicki, E.R. Dewatered and Stacked Mine Tailings: A Review. ACS ES&T Eng. 2022, 2, 728–745. [Google Scholar]

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Kinnunen, P.; Karhu, M.; Yli-Rantala, E.; Kivikytö-Reponen, P.; Mäkinen, J. A review of circular economy strategies for mine tailings. Clean. Eng. Technol. 2022, 8, 100499. [Google Scholar] [CrossRef]

- Araujo, F.S.M.; Taborda-Llano, I.; Nunes, E.B.; Santos, R.M. Recycling and Reuse of Mine Tailings: A Review of Advancements and Their Implications. Geosciences 2022, 12, 319. [Google Scholar] [CrossRef]

- Dong, L.; Deng, S.; Wang, F. Some developments and new insights for environmental sustainability and disaster control of tailings dam. J. Clean. Prod. 2020, 269, 122270. [Google Scholar] [CrossRef]

- Franks, D.M.; Boger, D.V.; Côte, C.M.; Mulligan, D.R. Sustainable development principles for the disposal of mining and mineral processing wastes. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-thinking mining waste through an integrative approach led by circular economy aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef]

- Bascompta, M.; Sanmiquel, L.; Vintró, C.; Yousefian, M. Corporate Social Responsibility Index for Mine Sites. Sustainability 2022, 14, 13570. [Google Scholar] [CrossRef]

- Beylot, A.; Bodénan, F.; Guezennec, A.G.; Muller, S. LCA as a support to more sustainable tailings management: Critical review, lessons learnt and potential way forward. Resour. Conserv. Recycl. 2022, 183, 106347. [Google Scholar] [CrossRef]

- Cacciuttolo Vargas, C.; Pérez Campomanes, G. Practical Experience of Filtered Tailings Technology in Chile and Peru: An Environmentally Friendly Solution. Minerals 2022, 12, 889. [Google Scholar] [CrossRef]

- Li, S.; Chen, Q.; Wang, X. Superiority of Filtered Tailings Storage Facility to Conventional Tailings Impoundment in Southern Rainy Regions of China. Sustainability 2016, 8, 1130. [Google Scholar] [CrossRef]

- Yang, L.; Jia, H.; Jiao, H.; Dong, M.; Yang, T. The Mechanism of Viscosity-Enhancing Admixture in Backfill Slurry and the Evolution of Its Rheological Properties. Minerals 2023, 13, 1045. [Google Scholar] [CrossRef]

- Min, C.; Li, X.; He, S.; Zhou, S.; Zhou, Y.; Yang, S.; Shi, Y. Effect of mixing time on the properties of phosphogypsum-based cemented backfill. Constr. Build. Mater. 2019, 210, 564–573. [Google Scholar] [CrossRef]

- Yang, K.; Zhao, X.; Wei, Z.; Zhang, J. Development overview of paste backfill technology in China’s coal mines: A review. Environ. Sci. Pollut. Res. 2021, 28, 67957–67969. [Google Scholar] [CrossRef] [PubMed]

- Cacciuttolo, C.; Marinovic, A. Experiences of Underground Mine Backfilling Using Mine Tailings Developed in the Andean Region of Peru: A Green Mining Solution to Reduce Socio-Environmental Impacts. Sustainability 2023, 15, 12912. [Google Scholar] [CrossRef]

- Araya, N.; Mamani Quiñonez, O.; Cisternas, L.A.; Kraslawski, A. Sustainable Development Goals in Mine Tailings Management: Targets and Indicators. Mater. Proc. 2021, 5, 82. [Google Scholar]

- Dold, B. Sustainability in metal mining: From exploration, over processing to mine waste management. Rev. Environ. Sci. Bio/Technol. 2008, 7, 275–285. [Google Scholar] [CrossRef]

- Lagos, G.; Peters, D.; Lima, M.; Jara, J.J. Potential copper production through 2035 in Chile. Miner. Econ. 2020, 33, 43–56. [Google Scholar] [CrossRef]

- Lim, B.; Alorro, R.D. Technospheric Mining of Mine Wastes: A Review of Applications and Challenges. Sustain. Chem. 2021, 2, 686–706. [Google Scholar] [CrossRef]

- Liu, Y.; Song, W. Influences of extreme precipitation on China’s mining industry. Sustainability 2019, 11, 6719. [Google Scholar] [CrossRef]

- Solé, J. Climate and Energy Crises from the Perspective of the Intergovernmental Panel on Climate Change: Trade-Offs between Systemic Transition and Societal Collapse? Sustainability 2023, 15, 2231. [Google Scholar] [CrossRef]

- Labonté-Raymond, P.L.; Pabst, T.; Bussière, B.; Bresson, É. Impact of climate change on extreme rainfall events and surface water management at mine waste storage facilities. J. Hydrol. 2020, 590, 125383. [Google Scholar] [CrossRef]

- Del Rio, J.I.; Fernandez, P.; Castillo, E.; Orellana, L.F. Assesing Climate Change Risk in the Mining Industry: A Case Study in the Copper Industry in the Antofagasta Region, Chile. Commodities 2023, 2, 246–260. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Valenzuela, F. Efficient Use of Water in Tailings Management: New Technologies and Environmental Strategies for the Future of Mining. Water 2022, 14, 1741. [Google Scholar] [CrossRef]

- Sepúlveda, R.G.; Robert, E.S.; Camacho-Tauta, J. Assessment of the Self-Compaction Effect in Filtered Tailings Disposal under Unsaturated Condition. Minerals 2022, 12, 422. [Google Scholar] [CrossRef]

- Kossoff, D.; Dubbin, W.E.; Alfredsson, M.; Edwards, S.J.; Macklin, M.G.; Hudson-Edwards, K.A. Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Appl. Geochem. 2014, 51, 229–245. [Google Scholar] [CrossRef]

- Liu, D.; Edraki, M.; Malekizadeh, A.; Schenk, P.M.; Berry, L. Introducing the hydrate gel membrane technology for filtration of mine tailings. Min. Eng. 2019, 135, 1–8. [Google Scholar] [CrossRef]

- Dimitriadis, D.; Zachareas, E.; Gazea, V. Upgrading of a Tailings Management Facility for the Disposal of Dry Stack Tailings. Mater. Proc. 2022, 5, 132. [Google Scholar]

- Fränkle, B.; Morsch, P.; Sok, T.; Gleiß, M.; Nirschl, H. Tailings Filtration Using Recessed Plate Filter Presses: Improving Filter Media Selection by Replicating the Abrasive Wear of Filter Media Caused by Falling Filter Cake after Cake Detachment. Mining 2022, 2, 425–437. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, K.; Cao, Y.; Li, M.; Wang, Q.; Li, D.; Zhang, Y. A new paradigm for intelligent status detection of belt conveyors based on deep learning. Measurement 2023, 213, 112735. [Google Scholar] [CrossRef]

- Tessier, J.; Duchesne, C.; Bartolacci, G. A machine vision approach to on-line estimation of run-of-mine ore composition on conveyor belts. Min. Eng. 2007, 20, 1129–1144. [Google Scholar] [CrossRef]

- Burden, R.; Wilson, G.W. Commingling of Waste Rock and Tailings to Improve “Dry Stack” Performance: Design and Evaluation of Mixtures. Minerals 2023, 13, 295. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Z.; Zhu, L.; Yang, X.; Chen, M.; Yang, C. Comparative Life Cycle Assessment of Conventional and Dry Stack Tailings Disposal Schemes: A Case Study in Northern China. Minerals 2022, 12, 1603. [Google Scholar] [CrossRef]

- Gomes, R.B.; De Tomi, G.; Assis, P.S. Iron ore tailings dry stacking in Pau Branco mine, Brazil. J. Mater. Res. Technol. 2016, 5, 339–344. [Google Scholar] [CrossRef]

- Li, Q.; Wu, B.Z.; Li, X.; Jia, S.; Zhen, F.H.; Gao, S. The Relatively Stable Seepage Field: A New Concept to Determine Seepage Field in the Design of a Dry-Stack Tailings Pond. Appl. Sci. 2022, 12, 12123. [Google Scholar] [CrossRef]

- Tuomela, A.; Ronkanen, A.K.; Rossi, P.M.; Rauhala, A.; Haapasalo, H.; Kujala, K. Using geomembrane liners to reduce seepage through the base of tailings ponds—A review and a framework for design guidelines. Geosciences 2021, 11, 93. [Google Scholar] [CrossRef]

- Hancock, G.R. A method for assessing the long-term integrity of tailings dams. Sci. Total Environ. 2021, 779, 146083. [Google Scholar] [CrossRef]

- Burritt, R.L.; Christ, K.L. Full cost accounting: A missing consideration in global tailings dam management. J. Clean. Prod. 2021, 321, 129016. [Google Scholar] [CrossRef]

- Zanetta-Colombo, N.C.; Fleming, Z.L.; Gayo, E.M.; Manzano, C.A.; Panagi, M.; Valdés, J.; Siegmund, A. Impact of mining on the metal content of dust in indigenous villages of northern Chile. Environ. Int. 2022, 169, 107490. [Google Scholar] [CrossRef]

- Mian, M.H.; Yanful, E.K. Tailings erosion and resuspension in two mine tailings ponds due to wind waves. Adv. Environ. Res. 2003, 7, 745–765. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Guzmán, V.; Catriñir, P.; Atencio, E.; Komarizadehasl, S.; Lozano-Galant, J.A. Low-Cost Sensors Technologies for Monitoring Sustainability and Safety Issues in Mining Activities: Advances, Gaps, and Future Directions in the Digitalization for Smart Mining. Sensors 2023, 23, 6846. [Google Scholar] [CrossRef]