Geological and Geomechanical Characterization of Phosphate Mine Waste Rock in View of Their Potential Civil Applications: A Case Study of the Benguerir Mine Site, Morocco

Abstract

:1. Introduction

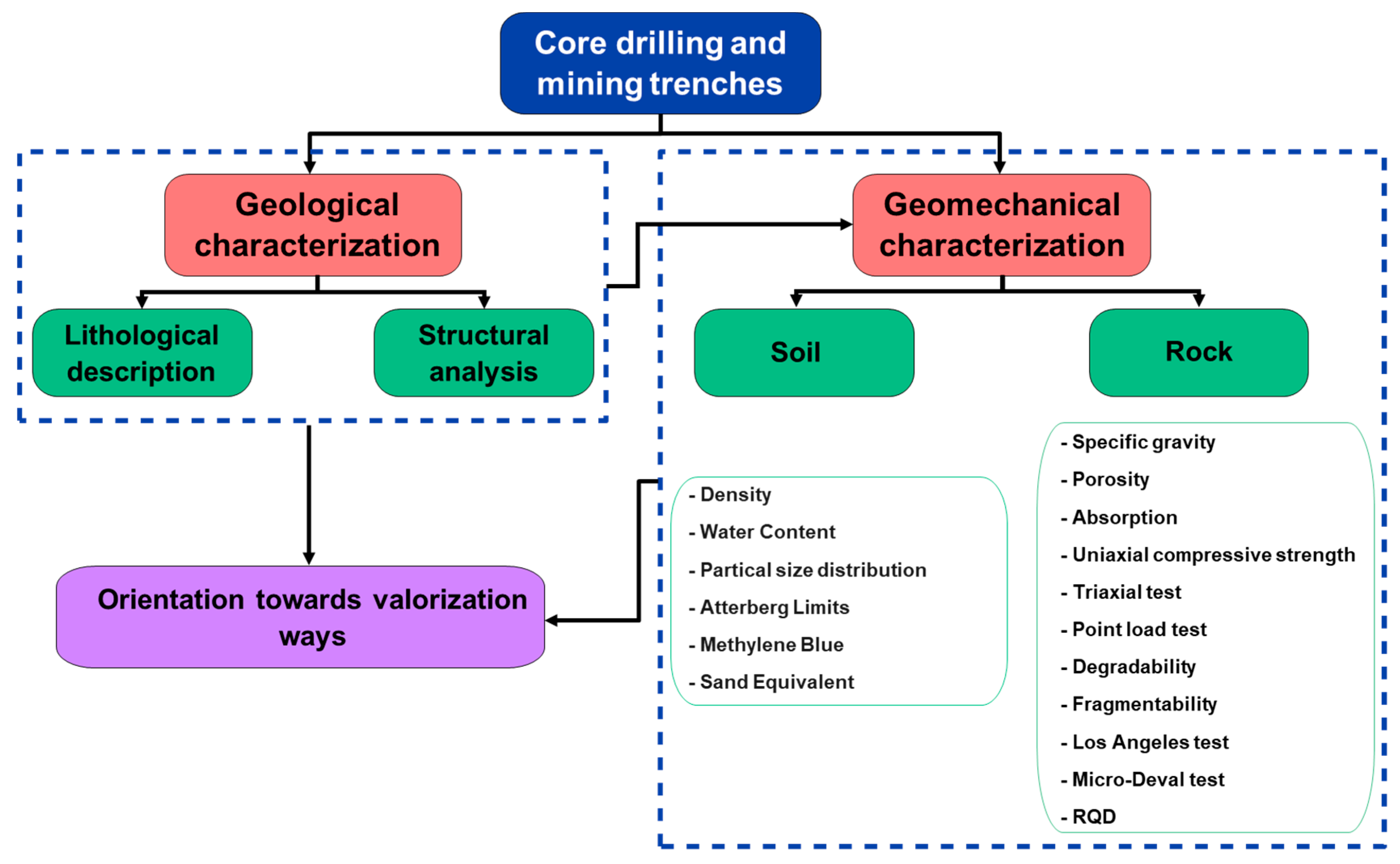

2. Materials and Methods

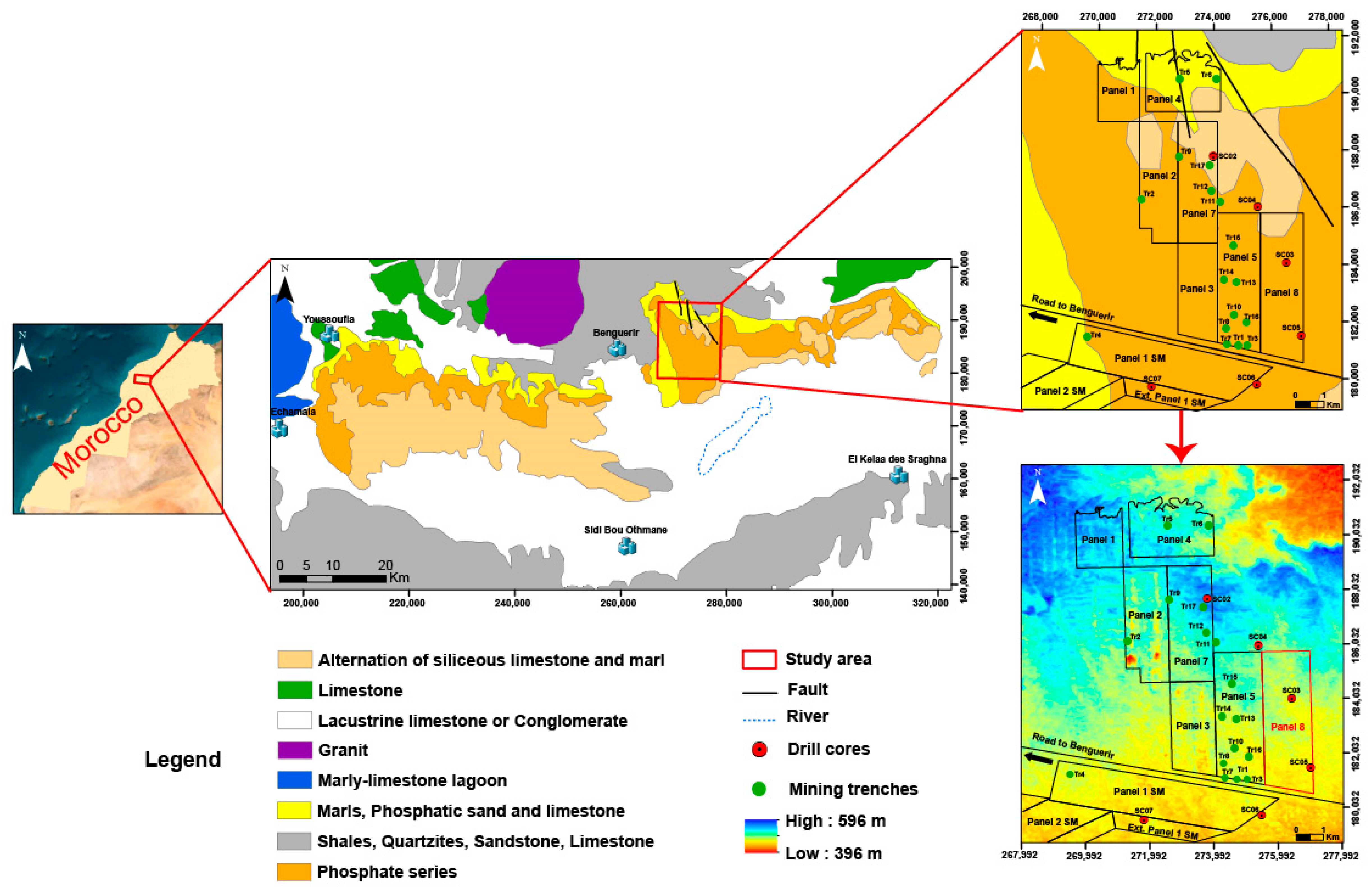

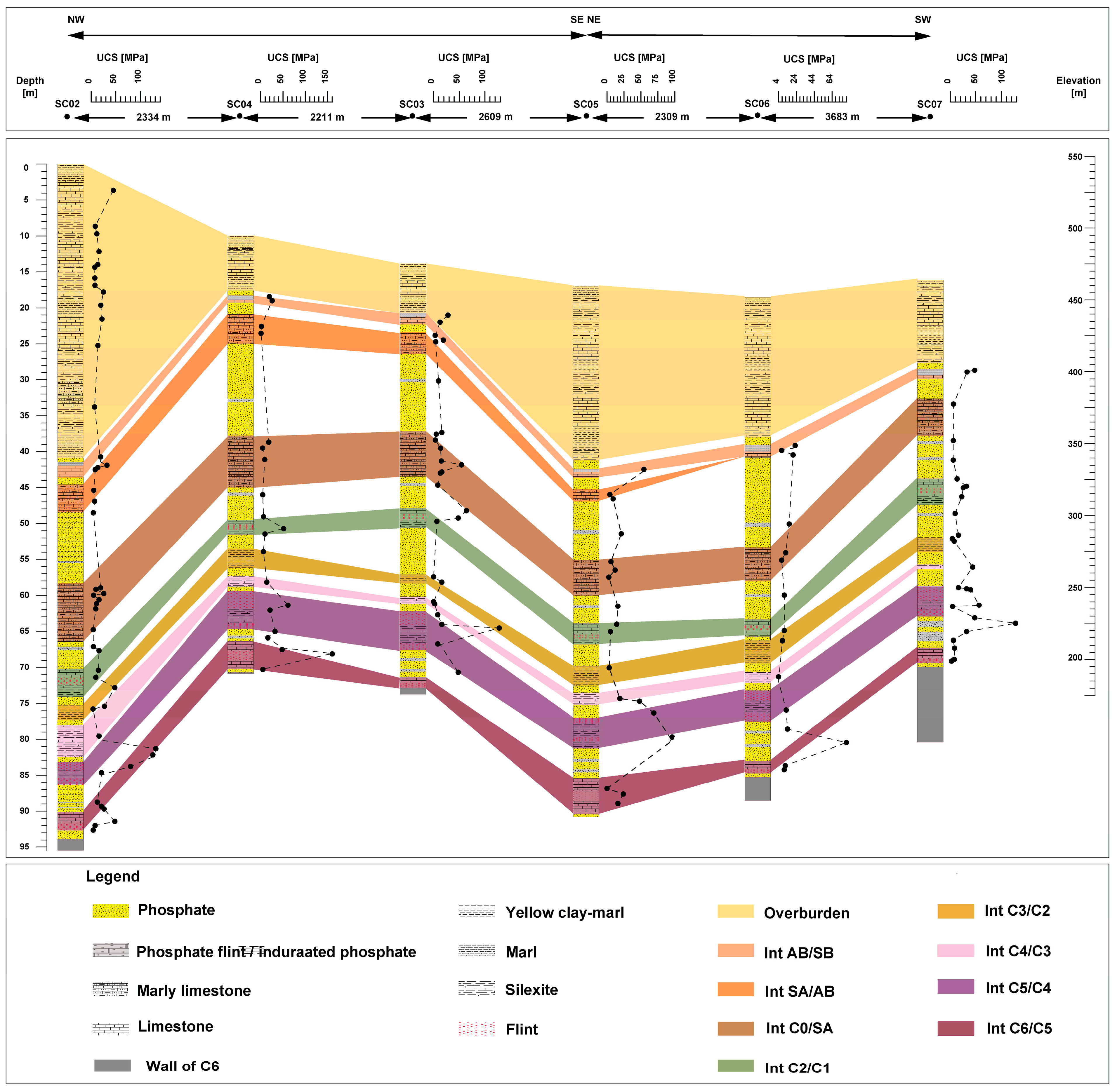

2.1. Mine Site and Drill Core Locations

2.2. Sampling Strategy and Methodology

2.3. Structural Characterization

- Wetting the core to reveal the contrasts;

- Using hydrochloric acid (HCl) to test the presence or absence of carbonate;

- Identifying the hardness of the samples using basic techniques (glass, finger, or steel scraping);

- Petrographic descriptions.

2.4. Geomechanical Characterization

3. Results and Discussion

3.1. Geological Characterization

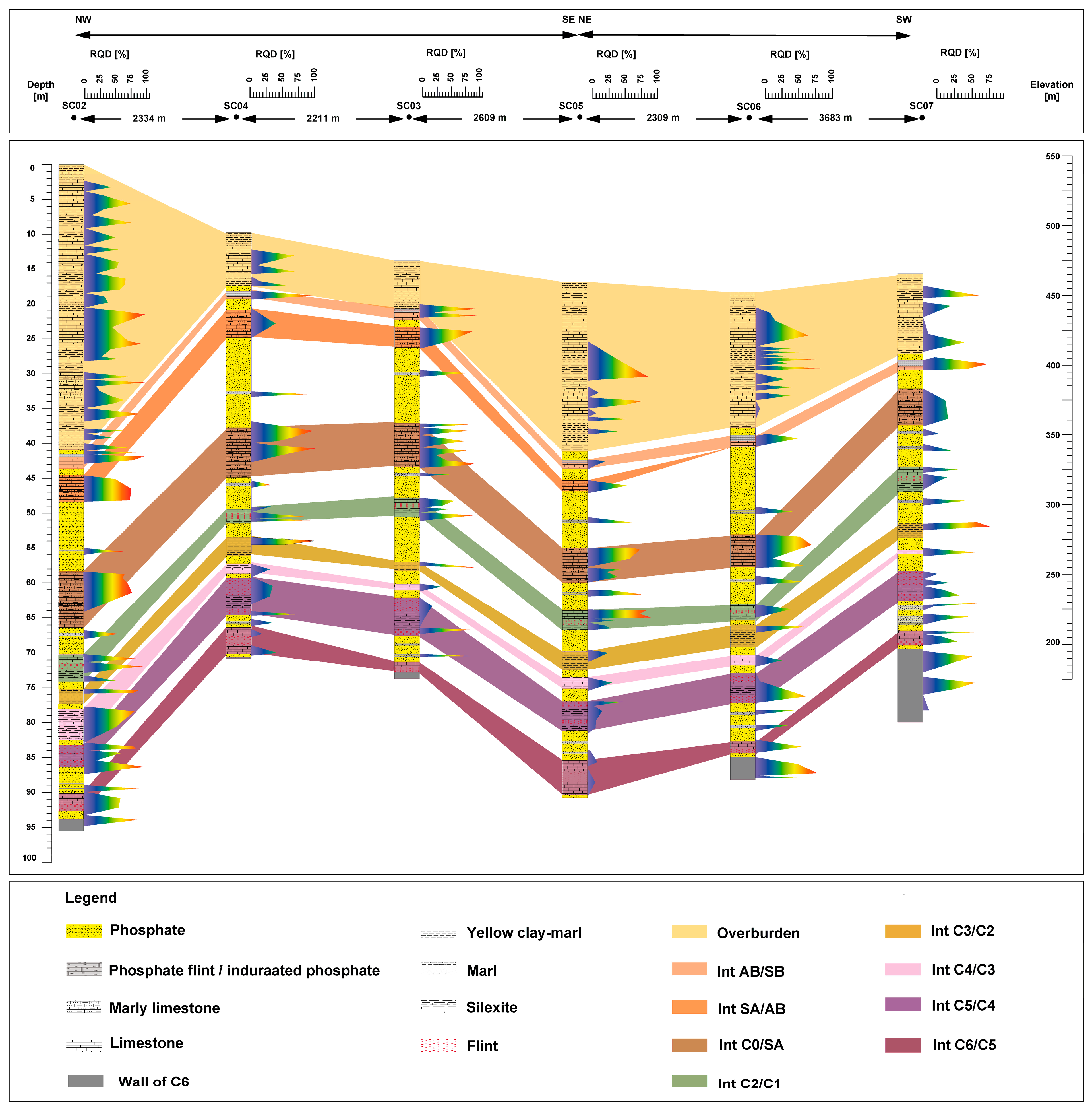

Lithological Description and Rock Quality by RQD

- Int AB/SB: composed of massive and competent limestones, topped by a phosphate limestone/ phosphate flint with coprolites. Indurated marl at the base.

- Int SA/AB: composed of marly limestone with a sandy fraction. It is large and consistent.

- Int C0/SA: this interburden has a thickness that exceeds 8 m and is composed of limestone and whitish siliceous marl mottled with iron and manganese oxides. Phosphate sand at the base.

- Int C2/C1: composed of an alternation in grayish limestone, whitish siliceous marl, and compact beige marl with flint bands at the base.

- Int C3/C2: composed of yellow clay marl. At the top, there is calcified sandy marl.

- Int C4/C3: composed of siliceous marl and brown flint nodules.

- Int C5/C4: composed of an alternation in whitish siliceous marl with brown flint. Passage of phosphate marly sand in the middle.

- Int C6/C5: composed of an alternation in limestone and brown flint.

3.2. Geomechanical Characterization

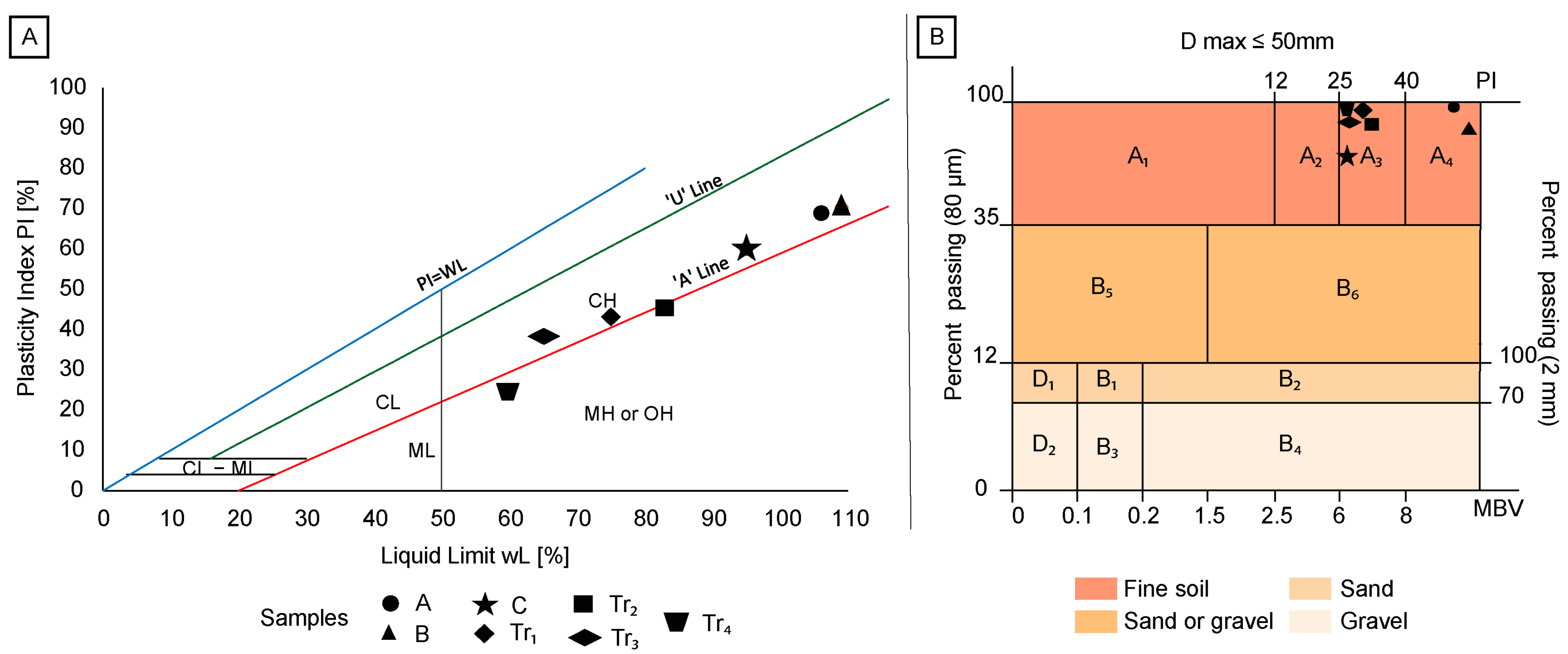

3.2.1. Soil-Like Samples

3.2.2. Hard Rock Samples

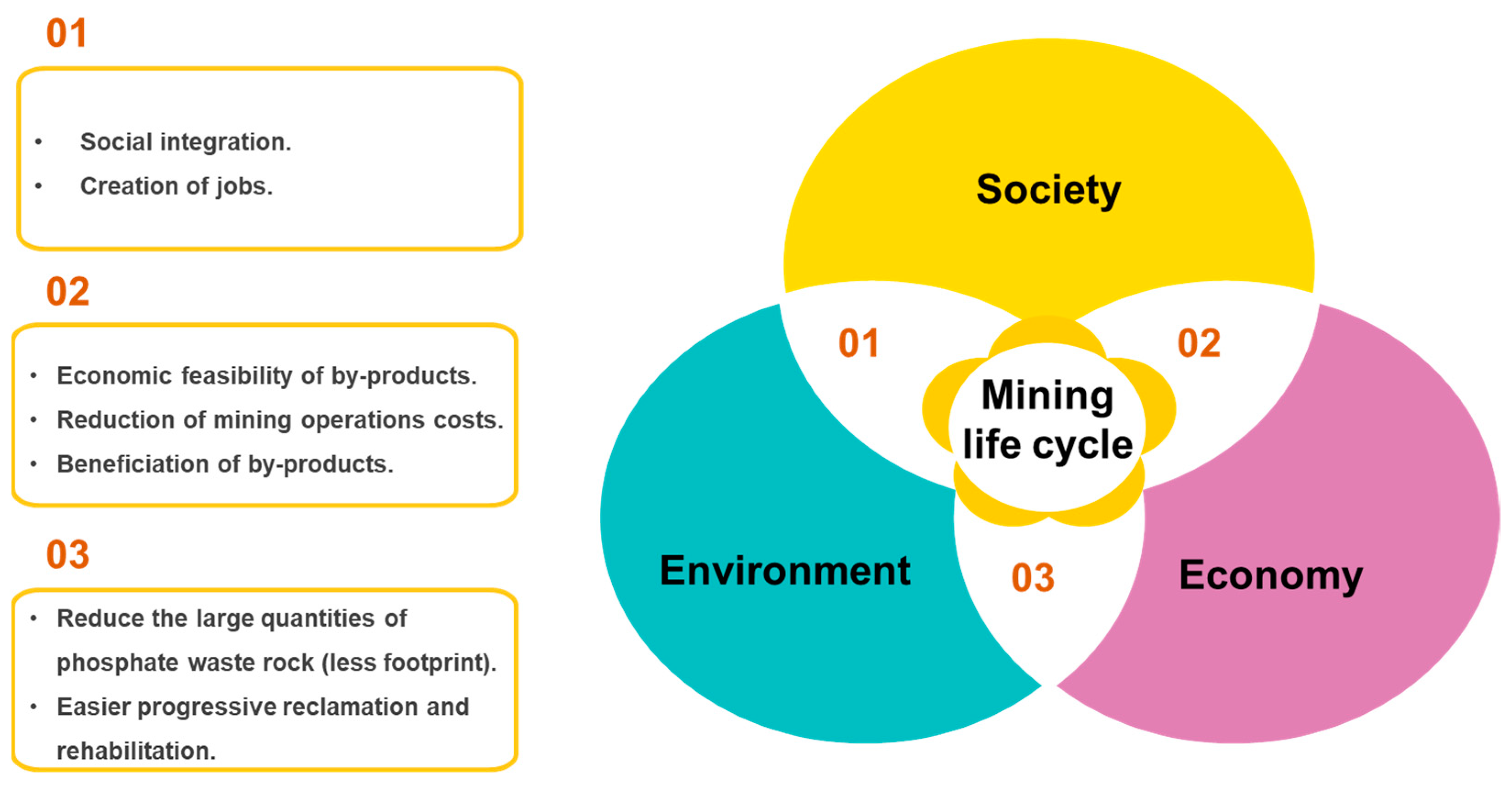

3.3. Implication Results/Discussion

4. Conclusions

- The Benguerir phosphate series was composed, in addition to overburden, of nine phosphate and eight waste layers (interburdens). The existence of other levels called “phosphate slabs” with carbonate or siliceous matrix was present.

- Four types of waste rock were identified: carbonate (limestone and marly limestone), siliceous (flint), marl clay, and phosphate (phosphate flint and indurated phosphate).

- The unit sequences of the Benguerir deposit appeared to be relatively stable in space but with variable thicknesses and sometimes interrupted units.

- The soil-like samples were classified in the category A3–A4 (fine soil), plastic to very plastic, and the category of clayey marl. They could be used as raw materials, especially for brick manufacturing, cement, and field ceramics.

- The hard rock samples presented promising geomechanical properties and could be considered an excellent alternative secondary raw material for civil engineering, the cement industry, and phosphate recovery.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amos, R.T.; Blowes, D.W.; Bailey, B.L.; Sego, D.C.; Smith, L.; Ritchie, A.I.M. Waste-rock hydrogeology and geochemistry. Appl. Geochem. 2015, 57, 140–156. [Google Scholar] [CrossRef]

- Krishna, R.S.; Mishra, J.; Meher, S.; Das, S.K.; Mustakim, S.M.; Singh, S.K. Industrial solid waste management through sustainable green technology: Case study insights from steel and mining industry in Keonjhar, India. Mater. Today Proc. 2020, 33, 5243–5249. [Google Scholar] [CrossRef]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-Thinking Mining Waste through an Integrative Approach Led by Circular Economy Aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef]

- Lèbre, É.; Corder, G. Integrating Industrial Ecology Thinking into the Management of Mining Waste. Resources 2015, 4, 765–786. [Google Scholar] [CrossRef]

- Hakkou, R.; Benzaazoua, M.; Bussière, B. Valorization of Phosphate Waste Rocks and Sludge from the Moroccan Phosphate Mines: Challenges and Perspectives. Procedia Eng. 2016, 138, 110–118. [Google Scholar] [CrossRef]

- Elghali, A.; Benzaazoua, M.; Bouzahzah, H.; Bussière, B.; Villarraga-Gómez, H. Determination of the available acid-generating potential of waste rock, part I: Mineralogical approach. Appl. Geochem. 2018, 99, 31–41. [Google Scholar] [CrossRef]

- Lahmira, B.; Lefebvre, R.; Aubertin, M.; Bussière, B. Effect of heterogeneity and anisotropy related to the construction method on transfer processes in waste rock piles. J. Contam. Hydrol. 2016, 184, 35–49. [Google Scholar] [CrossRef]

- Aubertin, M.; Bussière, B.; Bernier, L.; Chapuis, R.; Julien, M.; Belem, T.; Simon, R.; Mbonimpa, M.; Benzaazoua, M.; Li, L. La Gestion des Rejets Miniers Dans un Contexte de Développement Durable et de Protection de L’environnement. In Proceedings of the Congrès Annuel de la Société Canadienne de Génie Civil, Montréal, QC, Canada, 5–8 June 2002. [Google Scholar]

- Aubertin, M. Waste rock disposal to improve the geotechnical and geochemical stability of piles. In Proceedings of the World Mining Congress, Montreal, QC, Canada, 11–15 August 2013; p. 8. [Google Scholar]

- Maknoon, M.; Aubertin, M. On the Use of Bench Construction to Improve the Stability of Unsaturated Waste Rock Piles. Geotech. Geol. Eng. 2021, 39, 1425–1449. [Google Scholar] [CrossRef]

- Bossé, B.; Bussière, B.; Hakkou, R.; Maqsoud, A.; Benzaazoua, M. Assessment of Phosphate Limestone Wastes as a Component of a Store-and-Release Cover in a Semiarid Climate. Mine Water Environ. 2013, 32, 152–167. [Google Scholar] [CrossRef]

- Nwaila, G.T.; Ghorbani, Y.; Zhang, S.E.; Frimmel, H.E.; Tolmay, L.C.K.; Rose, D.H.; Nwaila, P.C.; Bourdeau, J.E. Valorisation of mine waste—Part I: Characteristics of, and sampling methodology for, consolidated mineralised tailings by using Witwatersrand gold mines (South Africa) as an example. J. Environ. Manag. 2021, 295, 113013. [Google Scholar] [CrossRef] [PubMed]

- Hakkou, R.; Benzaazoua, M.; Bussière, B. Laboratory Evaluation of the Use of Alkaline Phosphate Wastes for the Control of Acidic Mine Drainage. Mine Water Environ. 2009, 28, 206–218. [Google Scholar] [CrossRef]

- Liu, G.; Li, L.; Yao, M.; Landry, D.; Malek, F.; Yang, X.; Guo, L. An Investigation of the Uniaxial Compressive Strength of a Cemented Hydraulic Backfill Made of Alluvial Sand. Minerals 2017, 7, 4. [Google Scholar] [CrossRef]

- Pagé, P.; Li, L.; Yang, P.; Simon, R. Numerical investigation of the stability of a base-exposed sill mat made of cemented backfill. Int. J. Rock Mech. Min. Sci. 2019, 114, 195–207. [Google Scholar] [CrossRef]

- Lee, C.; Gu, F. Co-disposal of waste rock with backfill. In Proceedings of the UMT 2017: Proceedings of the First International Conference on Underground Mining Technology, Sudbury, ON, Canada, 11–13 October 2017; pp. 353–362. [Google Scholar]

- Amrani, M.; Taha, Y.; Kchikach, A.; Benzaazoua, M.; Hakkou, R. Valorization of Phosphate Mine Waste Rocks as Materials for Road Construction. Minerals 2019, 9, 237. [Google Scholar] [CrossRef]

- Loutou, M.; Hajjaji, M.; Mansori, M.; Favotto, C.; Hakkou, R. Phosphate sludge: Thermal transformation and use as lightweight aggregate material. J. Environ. Manag. 2013, 130, 354–360. [Google Scholar] [CrossRef]

- El Machi, A.; Mabroum, S.; Taha, Y.; Tagnit-Hamou, A.; Benzaazoua, M.; Hakkou, R. Use of flint from phosphate mine waste rocks as an alternative aggregates for concrete. Constr. Build. Mater. 2021, 271, 121886. [Google Scholar] [CrossRef]

- Loutou, M.; Taha, Y.; Benzaazoua, M.; Daafi, Y.; Hakkou, R. Valorization of clay by-product from moroccan phosphate mines for the production of fired bricks. J. Clean. Prod. 2019, 229, 169–179. [Google Scholar] [CrossRef]

- Taha, Y.; Benzaazoua, M.; Hakkou, R.; Mansori, M. Coal mine wastes recycling for coal recovery and eco-friendly bricks production. Miner. Eng. 2017, 107, 123–138. [Google Scholar] [CrossRef]

- Zhang, L. Production of bricks from waste materials—A review. Constr. Build. Mater. 2013, 47, 643–655. [Google Scholar] [CrossRef]

- Taha, Y.; Benzaazoua, M.; Mansori, M.; Yvon, J.; Kanari, N.; Hakkou, R. Manufacturing of ceramic products using calamine hydrometallurgical processing wastes. J. Clean. Prod. 2016, 127, 500–510. [Google Scholar] [CrossRef]

- Ahmari, S.A.L.; Zhang, L. Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Abbas, S.; Saleem, M.A.; Kazmi, S.M.S.; Munir, M.J. Production of sustainable clay bricks using waste fly ash: Mechanical and durability properties. J. Build. Eng. 2017, 14, 7–14. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Azevedo-Da Cunha, R.; Corpas-Iglesias, F.A. Effect of sludge from oil refining industry or sludge from pomace oil extraction industry addition to clay ceramics. Appl. Clay Sci. 2015, 114, 202–211. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Y.; Huang, H.; Meng, K.; Hu, K.; Hu, P.; Wang, X.; Zhang, Z.; Meng, X. Novel glass ceramic foams materials based on red mud. Ceram. Int. 2014, 40, 6677–6683. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, Q.; Xia, J.; He, Y.; Liao, G.; Ke, Y. Preparation and crystallization of glass–ceramics derived from iron-rich copper slag. J. Alloys Compd. 2013, 574, 354–360. [Google Scholar] [CrossRef]

- Peyronnard, O.; Benzaazoua, M. Estimation of the cementitious properties of various industrial by-products for applications requiring low mechanical strength. Resour. Conserv. Recycl. 2011, 56, 22–33. [Google Scholar] [CrossRef]

- Mouflih, M. Les Phosphates du Maroc Central et du Moyen Atlas (Maastrichtien-Lutetien, Maroc): Sedimentologie, Stratigraphie Sequentielle, Contexte Genetique et Valorisation; Universite Cadi Ayyad: Marrakesh, Morocco, 2015. [Google Scholar]

- El Bamiki, R.; Raji, O.; Ouabid, M.; Elghali, A.; Khadiri Yazami, O.; Bodinier, J.-L. Phosphate Rocks: A Review of Sedimentary and Igneous Occurrences in Morocco. Minerals 2021, 11, 1137. [Google Scholar] [CrossRef]

- Boujo, A. Contribution à L’étude Géologique du Gisement de Phosphate Crétacé-Éocène des Ganntour (Maroc occidental), in Sciences Géologiques; Mémoire, 43; Université Louis-Pasteur: Institut de Géologie: Strasbourg, France, 1976; pp. 1–227. [Google Scholar]

- XPP94-202; Soil: Investigation and Testing. Soil Sampling. Methodology and Procedures. Association Française de Normalisation: Paris, France, 1995.

- Deere, D. Technical Description of Rock Cores for Engineering Purposes. Rock Mech. Eng. Geol. 1964, 1, 17–22. [Google Scholar]

- Farid, A.T.M. Modified Value of Rock Quality Designation Index RQD in Rock Formation. In Proceedings of the International Conference on Case Histories in Geotechnical Engineering, Chicago, IL, USA, 1–4 May 2013. [Google Scholar]

- NM13.1.152; Soils: Investigation and Testing—Determination of the Water Content by Weight of Materials—Oven Drying Method. IMANOR: Rabat, Morocco, 2011.

- NM13.1.119; Soils—Recognition and Testing—Laboratory Density Determination of Fine Soils—Cutting Kit, Mold and Water Immersion Methods. IMANOR: Rabat, Morocco, 2009.

- NM00.8.083; Soils: Recognition and Test of Granulometric Analysis of Soils Sedimentation Method. IMANOR: Rabat, Morocco, 2015.

- NM13.1.008; Granulometric Analysis. Dry Sieving Method after Washing. Ministry of Industry, Commerce and Crafts: Rabat, Morocco, 1998.

- NF-P94-052-1; Soil: Investigation and Testing. Atterberg Limit Determination. Part 1: Liquid Limit. Cone Penetrometer Method—Sols: Reconnaissance et Essais. Association Française de Normalisation: Paris, France, 1995.

- NF-P94-051; Soil: Investigation and Testing. Determination of Atterberg’s Limits. Liquid Limit Test Using Cassagrande Apparatus. Plastic Limit Test on Rolled Thread—Sols: Reconnaissance et Essais. Association Française de Normalisation: Paris, France, 1993.

- NM00.8.095; Soils: Investigation and Testing. Measuring of the Methylene Blue Adsorption Capacity of à Rocky Soil. Determination of the Methylene Blue of à Soil by Means of the Stain Test. IMANOR: Rabat, Morocco, 2015.

- NF EN 933-8+A1; Tests for Geometrical Properties of Aggregates—Part 8: Assessment of Fines—Sand Equivalent Test. Association Française de Normalisation: Paris, France, 2015.

- NF P94-410-1; Rock—Test for Physical Properties of Rock—Part 1: Determination of Water Content of Rock—Oven-Drying Method. Association Française de Normalisation: Paris, France, 2001.

- NF P94-410-2; Rock—Tests for Physical Properties of Rock—Part 2: Determination of Density—Cutting Curb—Water Immersion Methods. Association Française de Normalisation: Paris, France, 2001.

- NF P94-410-3; Rock—Tests for Physical Properties of Rock—Part 3: Determination of Porosity. Association Française de Normalisation: Paris, France, 2001.

- NF P94-420; Rock—Determination of the Uniaxial Compressive Strength. Association Française de Normalisation: Paris, France, 2000.

- NF P94-074; Sols: Reconnaissance et Essais—Essais à l’appareil Triaxial de Révolution—Appareillage—Préparation des Éprouvettes—Essai (UU) non Consolidé non Drainé—Essai (Cu+U) Consolidé non Drainé Avec Mesure de Pression Interstitielle—Essai (CD) Consolidé Drainé. Association Française de Normalisation: Paris, France, 1994.

- XP P 94-429; Rock—Point Load Strength Test—Franklin Test. Association Française de Normalisation: Paris, France, 2002.

- NF EN 1097-1; Tests for Mechanical and Physical Properties of Aggregates—Part 1: Determination of the Resistance to Wear (Micro-Deval). Association Française de Normalisation: Paris, France, 2011.

- NM.10.1.138; Aggregates: Los Angeles Test. Ministry of Industry, Commerce and Crafts: Rabat, Morocco, 1995.

- NF P94-066; Soils: Investigation and Tests. Fragmentability Coefficient of Rocky Material—Sols: Reconnaissance et Essais. Association Française de Normalisation: Paris, France, 1992.

- NF P94-067; Soils: Investigation and Tests. Degradability Coefficient of ROCKY Material—Sols: Reconnaissance et Essais. Association Française de Normalisation: Paris, France, 1992.

- NF-P11-300; Exécution des Terrassements—Classification des Matériaux Utilisables dans la Construction des Remblais et des Couches de Forme D’infrastructures Routières. Association Française de Normalisation: Paris, France, 1992.

- NF EN 12620; Aggregates for Concrete. Association Française de Normalisation: Paris, France, 2008.

- Dixon, D.E.; Prestrera, J.R.; Burg, G.R.U.; Chairman, S.A.; Abdun-Nur, E.A.; Barton, S.G.; Lee, S.H. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete (ACI 211.1-91); ACI: Farmington Hills, MI, USA, 1991. [Google Scholar]

- Safhi, A.E.M.; Amar, H.; El Berdai, Y.; El Ghorfi, M.; Taha, Y.; Hakkou, R.; Al-Dahhan, M.; Benzaazoua, M. Characterizations and potential recovery pathways of phosphate mines waste rocks. J. Clean. Prod. 2022, 374, 134034. [Google Scholar] [CrossRef]

- Aliyu, M.M.; Shang, J.; Murphy, W.; Lawrence, J.A.; Collier, R.; Kong, F.; Zhao, Z. Assessing the uniaxial compressive strength of extremely hard cryptocrystalline flint. Int. J. Rock Mech. Min. Sci. 2019, 113, 310–321. [Google Scholar] [CrossRef]

- Sidibé, M. Etude de L’utilisation des Granulats de Type Silexlte en Géotechnique Routière (Notamment en Couches de Base et Revêtement des Couches de Chaussées); Ecole Polytechnique de Thiès: Thiès, Senegal, 1995. [Google Scholar]

- Amar, H.; Benzaazoua, M.; Elghali, A.; Hakkou, R.; Taha, Y. Waste rock reprocessing to enhance the sustainability of phosphate reserves: A critical review. J. Clean. Prod. 2022, 381, 135151. [Google Scholar] [CrossRef]

- El Machi, A.; Mabroum, S.; Taha, Y.; Tagnit-Hamou, A.; Benzaazoua, M.; Hakkou, R. Valorization of phosphate mine waste rocks as aggregates for concrete. Mater. Today Proc. 2021, 37, 3840–3846. [Google Scholar] [CrossRef]

- Bahhou, A.; Taha, Y.; El Khessaimi, Y.; Idrissi, H.; Hakkou, R.; Amalik, J.; Benzaazoua, M. Use of phosphate mine by-products as supplementary cementitious materials. Mater. Today Proc. 2021, 37, 3781–3788. [Google Scholar] [CrossRef]

- Knidiri, J.; Bussière, B.; Hakkou, R.; Benzaazoua, M.; Parent, E.; Maqsoud, A. Design, construction and preliminary results for an inclined store-and-release cover experimental cell built on an abandoned mine site in Morocco. In Proceedings of the 10th ICARD, International Conference on Acid Rock Drainage, and IMWA, International Mine Water Association, Santiago, Chile, 21–24 April 2015; pp. 21–24. [Google Scholar]

- Hanein, T.; Thienel, K.-C.; Zunino, F.; Marsh, A.T.M.; Maier, M.; Wang, B.; Canut, M.; Juenger, M.C.G.; Ben Haha, M.; Avet, F.; et al. Clay calcination technology: State-of-the-art review by the RILEM TC 282-CCL. Mater. Struct. 2021, 55, 3. [Google Scholar] [CrossRef]

- Safhi, A.E.M.E. Valorization of Dredged Sediments as Sustainable Construction Resources, 1st ed.; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar] [CrossRef]

- Bayoussef, A.; Oubani, M.; Loutou, M.; Taha, Y.; Benzaazoua, M.; Manoun, B.; Hakkou, R. Manufacturing of high-performance ceramics using clays by-product from phosphate mines. Mater. Today Proc. 2021, 37, 3994–4000. [Google Scholar] [CrossRef]

- Redclift, M. Sustainable development (1987–2005): An oxymoron comes of age. Sustain. Dev. 2005, 13, 212–227. [Google Scholar] [CrossRef]

| Samples C3/C2 | Deviation | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Variables | Units | A | B | C | Tr1 | Tr2 | Tr3 | Tr4 | |

| w | [%] | - | - | - | 4.5 | 7.5 | 5.1 | 6.5 | 1 |

| ρ | [kg/m3] | - | - | - | 1892 | 1917 | 1824 | 1912 | 31 |

| P max | mm | 0.1 | 10 | 25 | 0.3 | 1 | 0.3 | 0.1 | 7 |

| P 80 μm | [%] | 100 | 91 | 64 | 98 | 97 | 98 | 100 | 8.6 |

| P 2 μm | [%] | 74 | 70 | 52 | 38 | 41 | 38 | 45 | 12 |

| MBV | - | 9.2 | 10 | 6 | 6.13 | 6.22 | 6.07 | 6.32 | 1.4 |

| SE | [%] | - | - | - | FS | FS | FS | FS | - |

| LL | [%] | 106 | 109 | 95 | 75 | 83 | 65 | 60 | 16 |

| PL | [%] | 37 | 39 | 35 | 32 | 38 | 27 | 35 | 3 |

| PI | [%] | 69 | 70 | 60 | 43 | 45 | 38 | 25 | 14 |

| Tests | Los Angeles [%] | Micro-Deval [%] | Fragmentability | Degradability |

|---|---|---|---|---|

| Flint | 22–39 | 9–48 | 1–2 | 1 |

| (6) | (12) | (0.5) | (0) | |

| Phosphate flint | 29–33 | 28–40 | 2 | 1 |

| (2) | (6) | (0) | (0) | |

| Silexite | 35–75 | 39–88 | 2–6 | 1–1.4 |

| (13) | (15) | (1.5) | (0.2) | |

| Limestone | 24–77 | 37–98 | 1–6 | 1–12 |

| (15) | (18) | (1.1) | (4.3) | |

| Indurated phosphate | 76–93 | 94–100 | 6–11 | 1–5 |

| (4.5) | (2) | (2.3) | (2) | |

| Marly limestone | 86–99 | 96–100 | 6–9 | 1–5 |

| (2) | (6) | (0) | (0) |

| Lithology | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Units | Flint | Phosphate Flint | Silexite | Limestone | Indurated Phosphate | Marly Limestone | Clayey Marl | ||

| Geomechanical proprieties | UCS | [MPa] | 104 | 35 | 32 | 26 | 11 | 8 | |

| LA | [%] | 33 | 31 | 50 | 62 | 88 | 95 | ||

| MD | [%] | 33 | 34 | 65 | 81 | 98 | 98 | ||

| Fragmentability | - | 2 | 2 | 3 | 4 | 9 | 7 | ||

| Degradability | - | 1 | 1 | 1 | 4 | 2 | 3 | ||

| Specific gravity | - | 2.5 | 2.2 | 1.6 | 1.9 | 1.9 | 1.7 | ||

| porosity | [%] | 3 | 19 | 12 | 25 | 28 | 33 | ||

| Absorption | [%] | 1 | 9 | 6 | 14 | 15 | 20 | ||

| w | [%] | 6 | |||||||

| ρ | [kg/m3] | 1886 | |||||||

| D max | mm | 5 | |||||||

| <80 μm | [%] | 93 | |||||||

| <2 μm | [%] | 51 | |||||||

| MBV | - | 7 | |||||||

| SE | [%] | Fine sand | |||||||

| LL | [%] | 85 | |||||||

| PL | [%] | 35 | |||||||

| Valorization methods | Aggregate | X | X | X | X | ||||

| Lightweight aggregate | X | ||||||||

| Concrete | X | X | X | ||||||

| Asphalt | X | X | |||||||

| Road construction | X | X | X | ||||||

| Embankment | X | X | |||||||

| Brick manufacturing | X | ||||||||

| Cement | X | X | X | X | |||||

| Field ceramics | X | ||||||||

| Neutralization | X | X | |||||||

| Recovery of phosphate | X | X | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chlahbi, S.; Belem, T.; Elghali, A.; Rochdane, S.; Zerouali, E.; Inabi, O.; Benzaazoua, M. Geological and Geomechanical Characterization of Phosphate Mine Waste Rock in View of Their Potential Civil Applications: A Case Study of the Benguerir Mine Site, Morocco. Minerals 2023, 13, 1291. https://doi.org/10.3390/min13101291

Chlahbi S, Belem T, Elghali A, Rochdane S, Zerouali E, Inabi O, Benzaazoua M. Geological and Geomechanical Characterization of Phosphate Mine Waste Rock in View of Their Potential Civil Applications: A Case Study of the Benguerir Mine Site, Morocco. Minerals. 2023; 13(10):1291. https://doi.org/10.3390/min13101291

Chicago/Turabian StyleChlahbi, Safa, Tikou Belem, Abdellatif Elghali, Samia Rochdane, Essaid Zerouali, Omar Inabi, and Mostafa Benzaazoua. 2023. "Geological and Geomechanical Characterization of Phosphate Mine Waste Rock in View of Their Potential Civil Applications: A Case Study of the Benguerir Mine Site, Morocco" Minerals 13, no. 10: 1291. https://doi.org/10.3390/min13101291

APA StyleChlahbi, S., Belem, T., Elghali, A., Rochdane, S., Zerouali, E., Inabi, O., & Benzaazoua, M. (2023). Geological and Geomechanical Characterization of Phosphate Mine Waste Rock in View of Their Potential Civil Applications: A Case Study of the Benguerir Mine Site, Morocco. Minerals, 13(10), 1291. https://doi.org/10.3390/min13101291