Sodium Lauroyl Glutamate as a Collector in Cassiterite Flotation

Abstract

1. Introduction

2. Materials and Methods

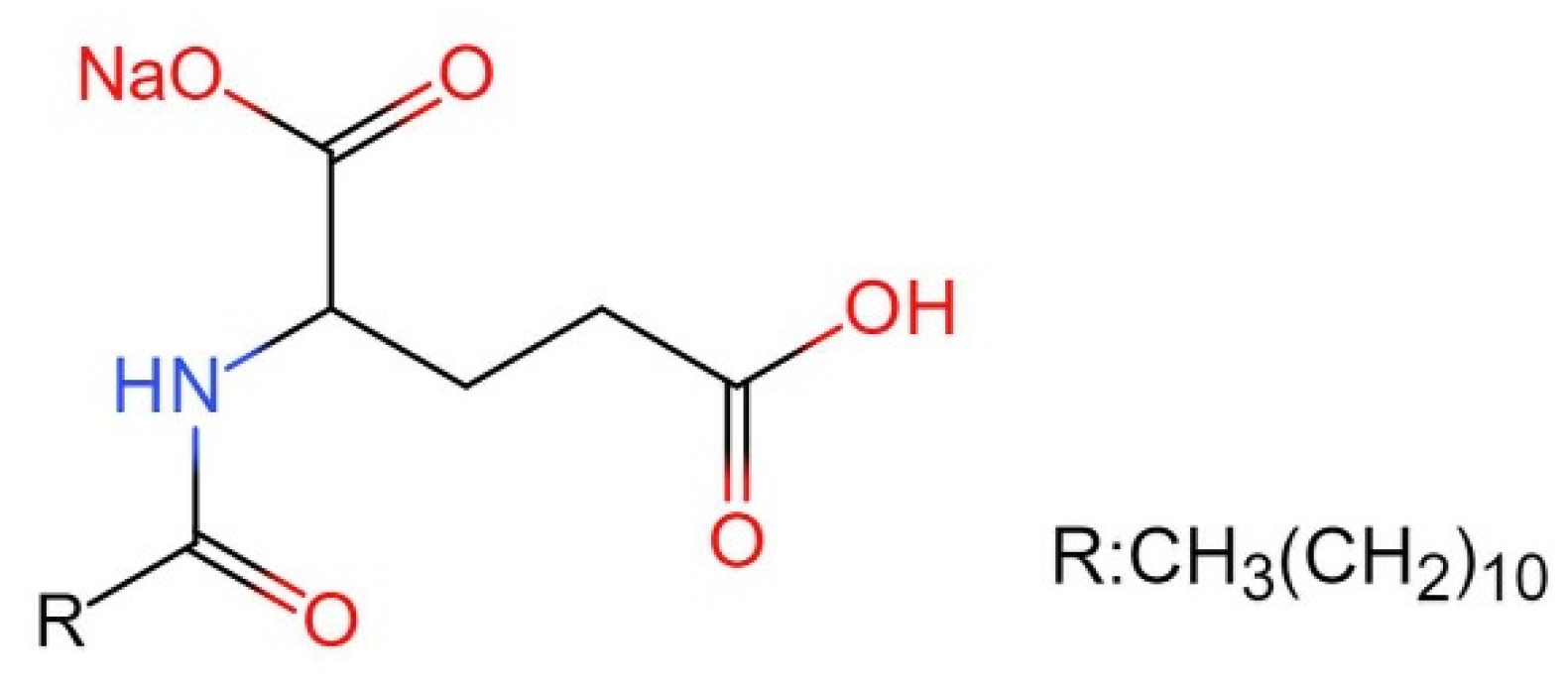

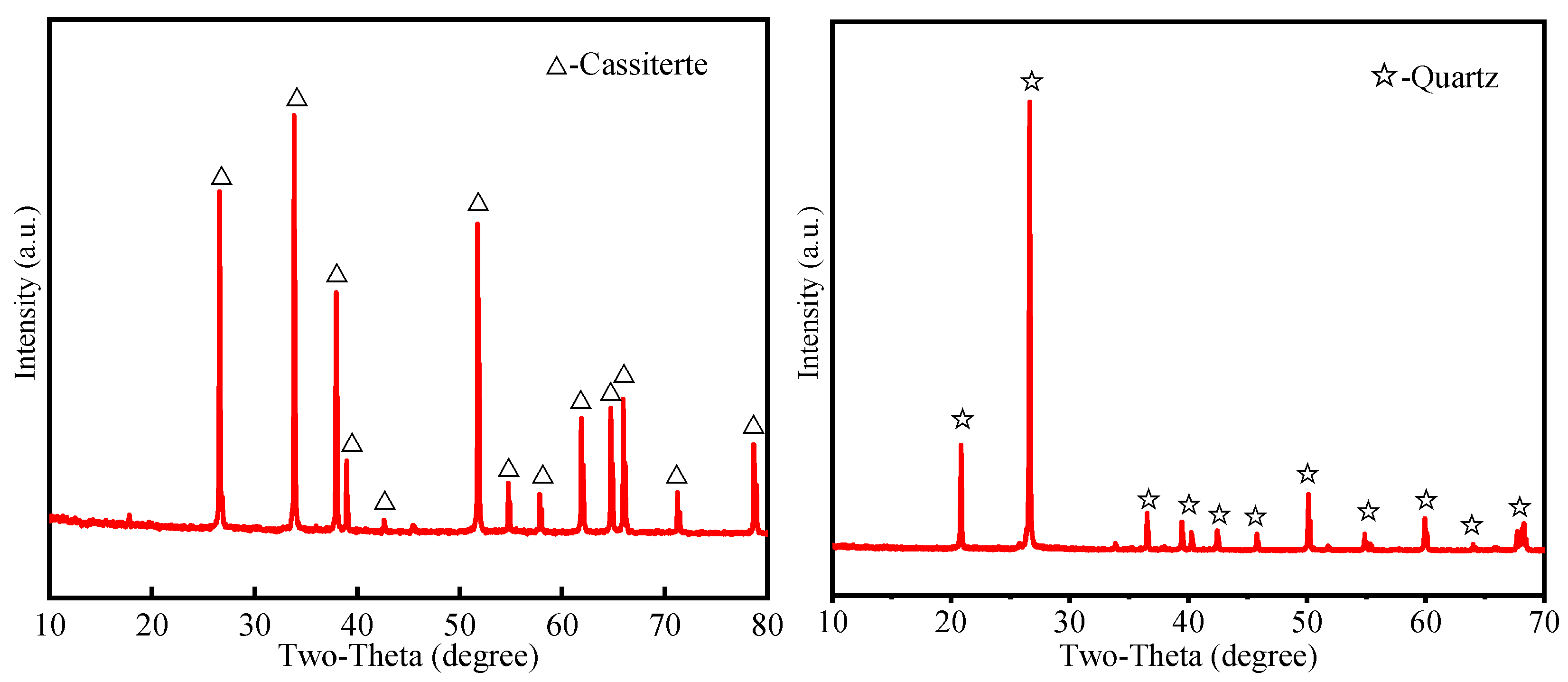

2.1. Materials and Reagents

2.2. Micro-Flotation Tests

2.3. Adsorption Experiments

2.4. Zeta Potential Measurements

2.5. XPS Analysis

2.6. FTIR Analysis

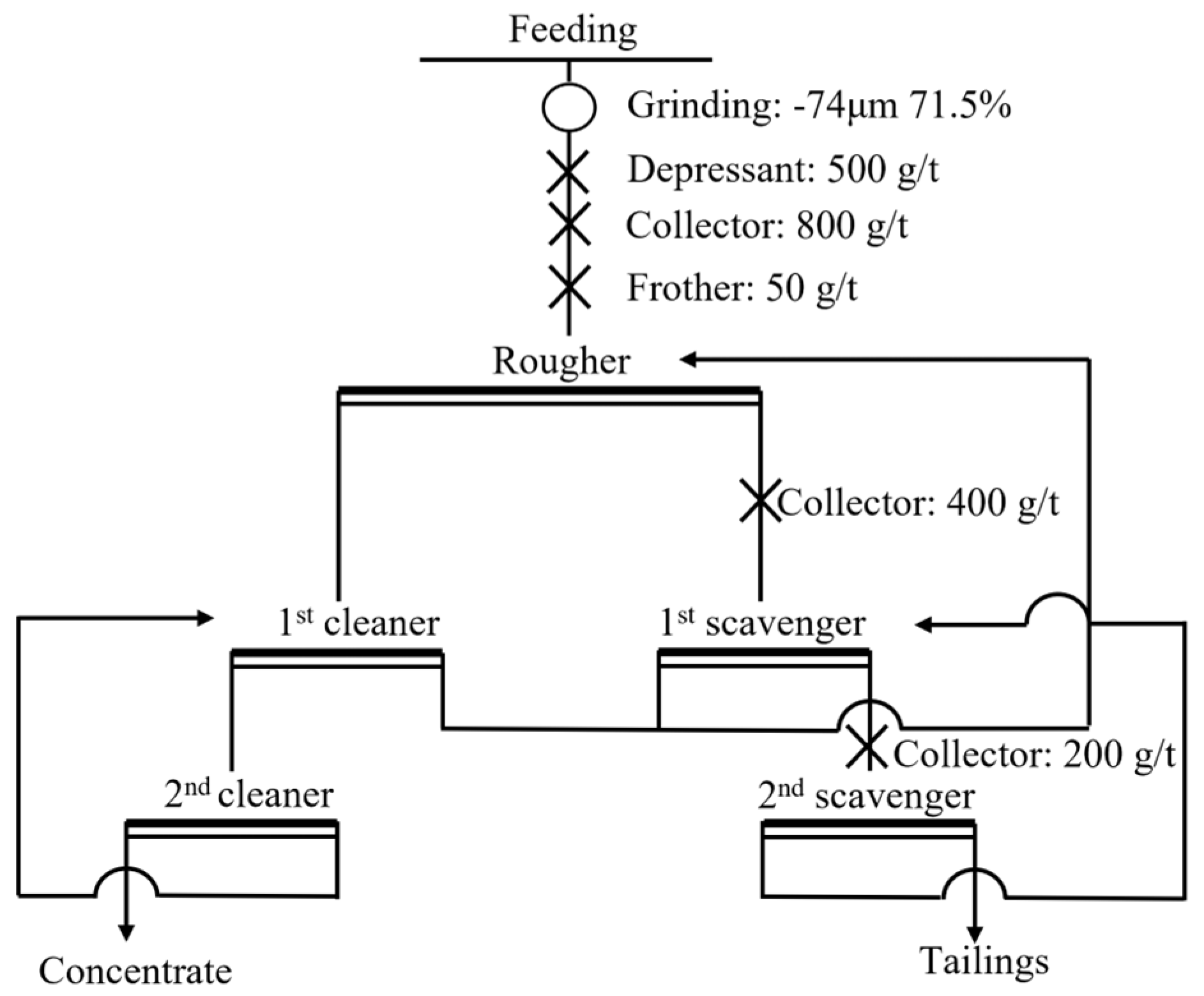

2.7. Bench-Scale Flotation Tests

3. Results

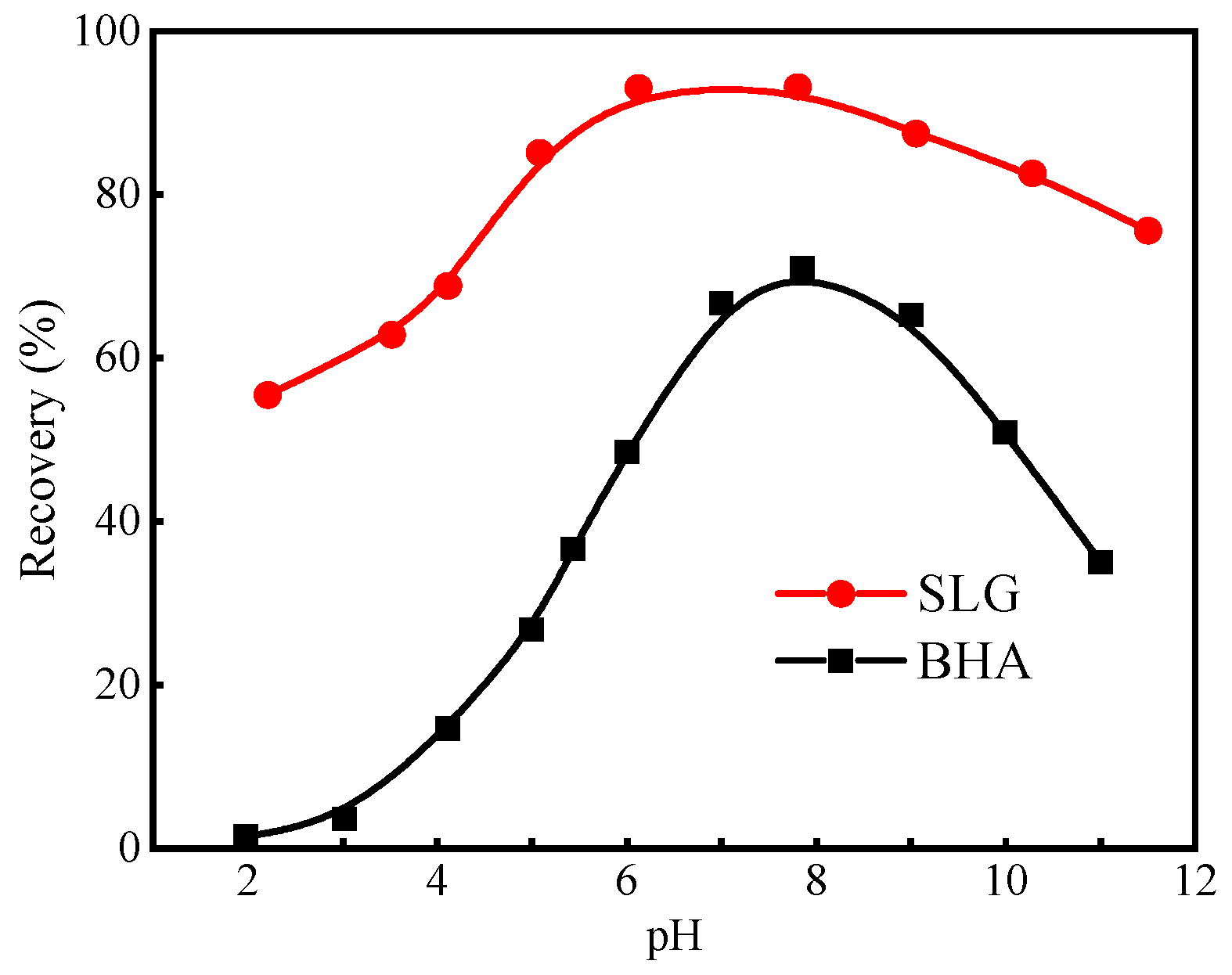

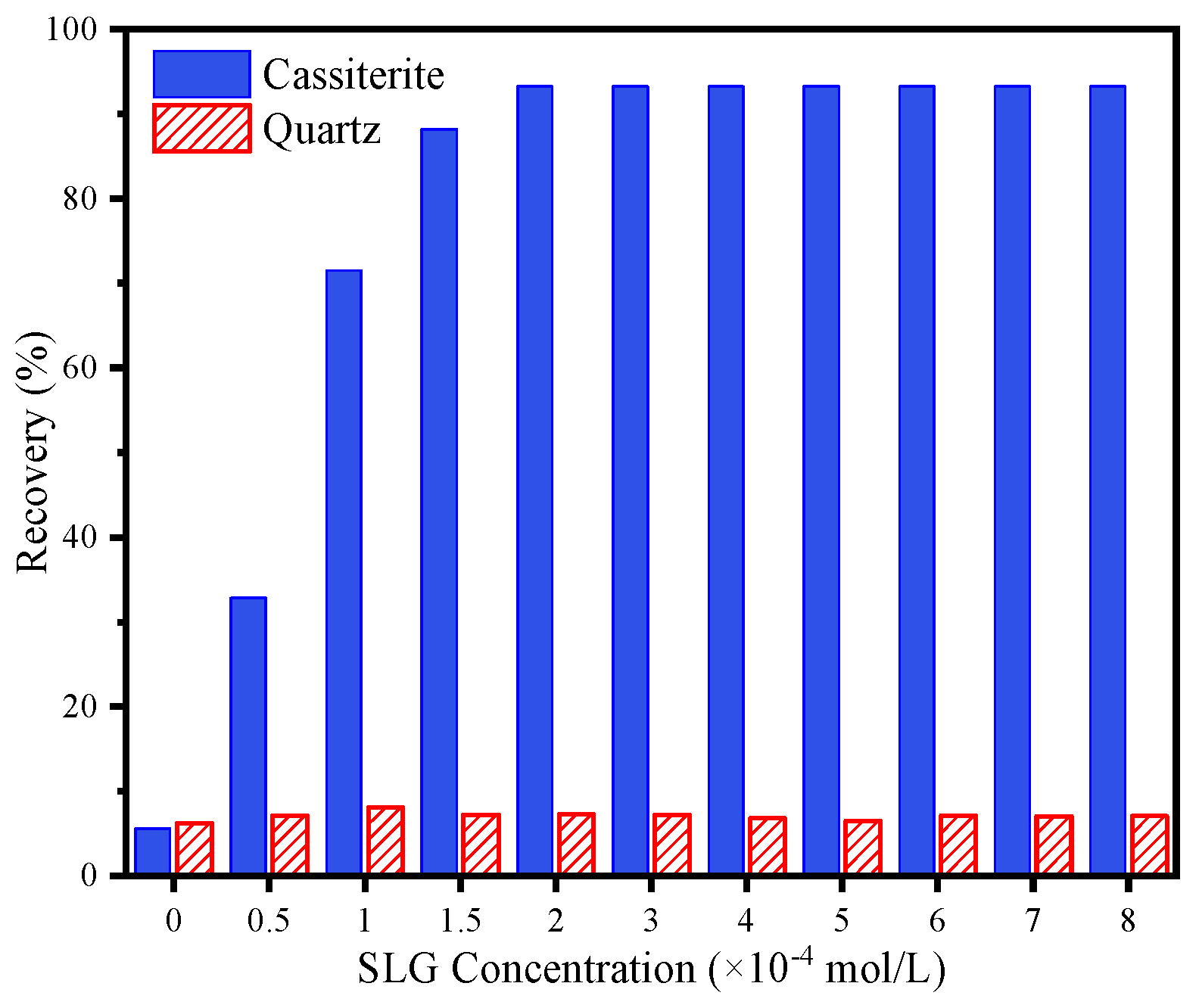

3.1. Micro-Flotation Tests

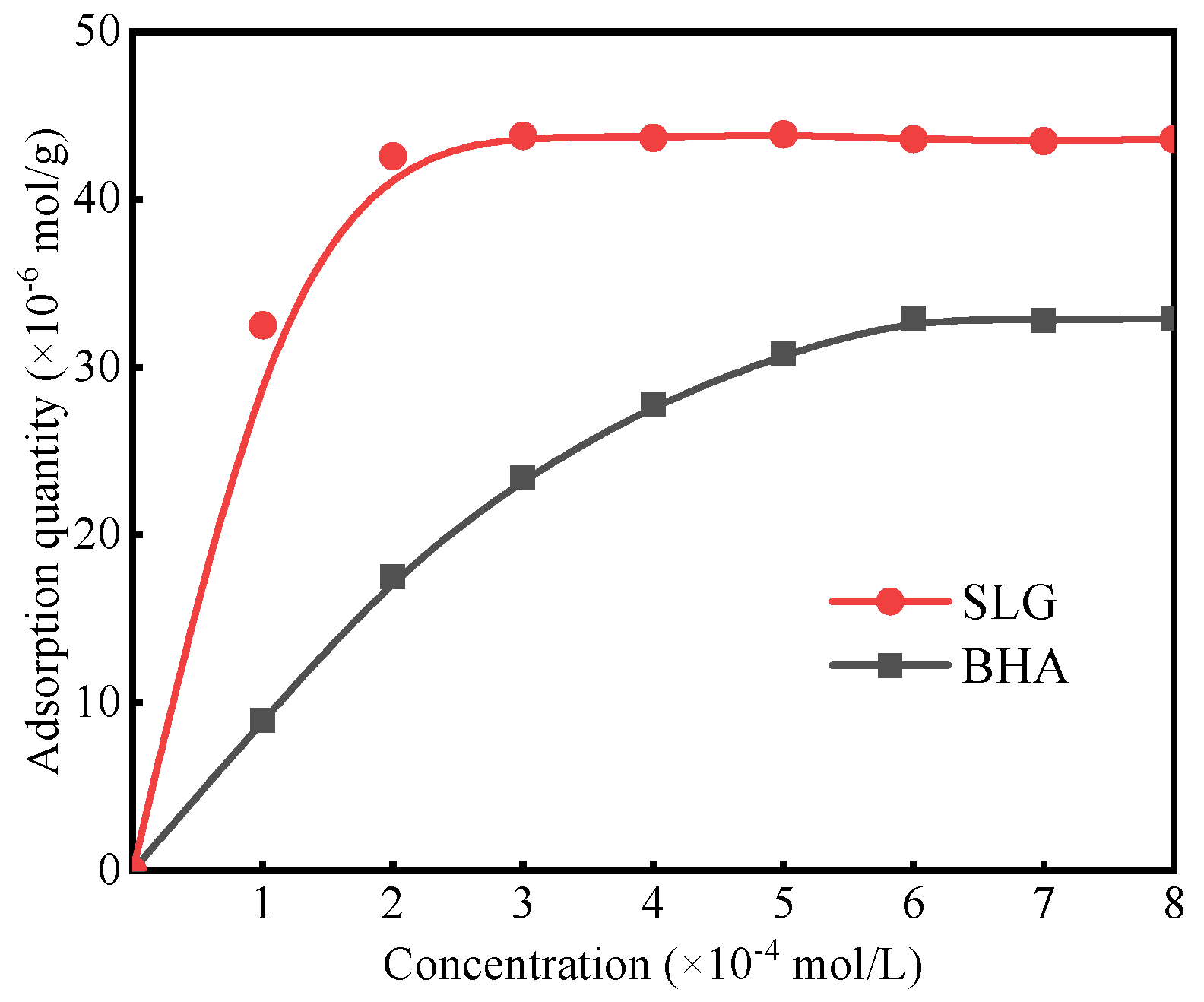

3.2. Adsorption Experiments

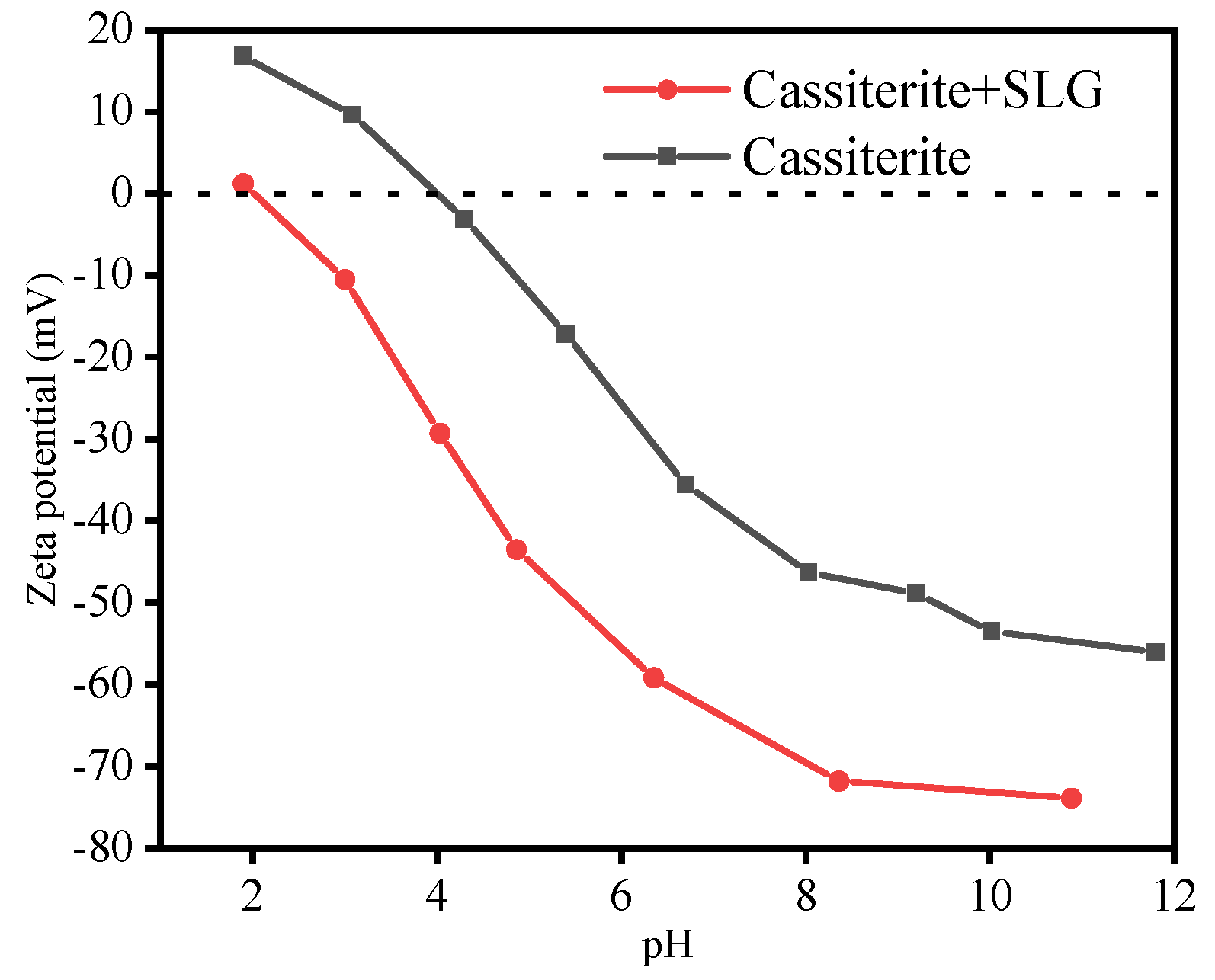

3.3. Zeta Potential Measurements

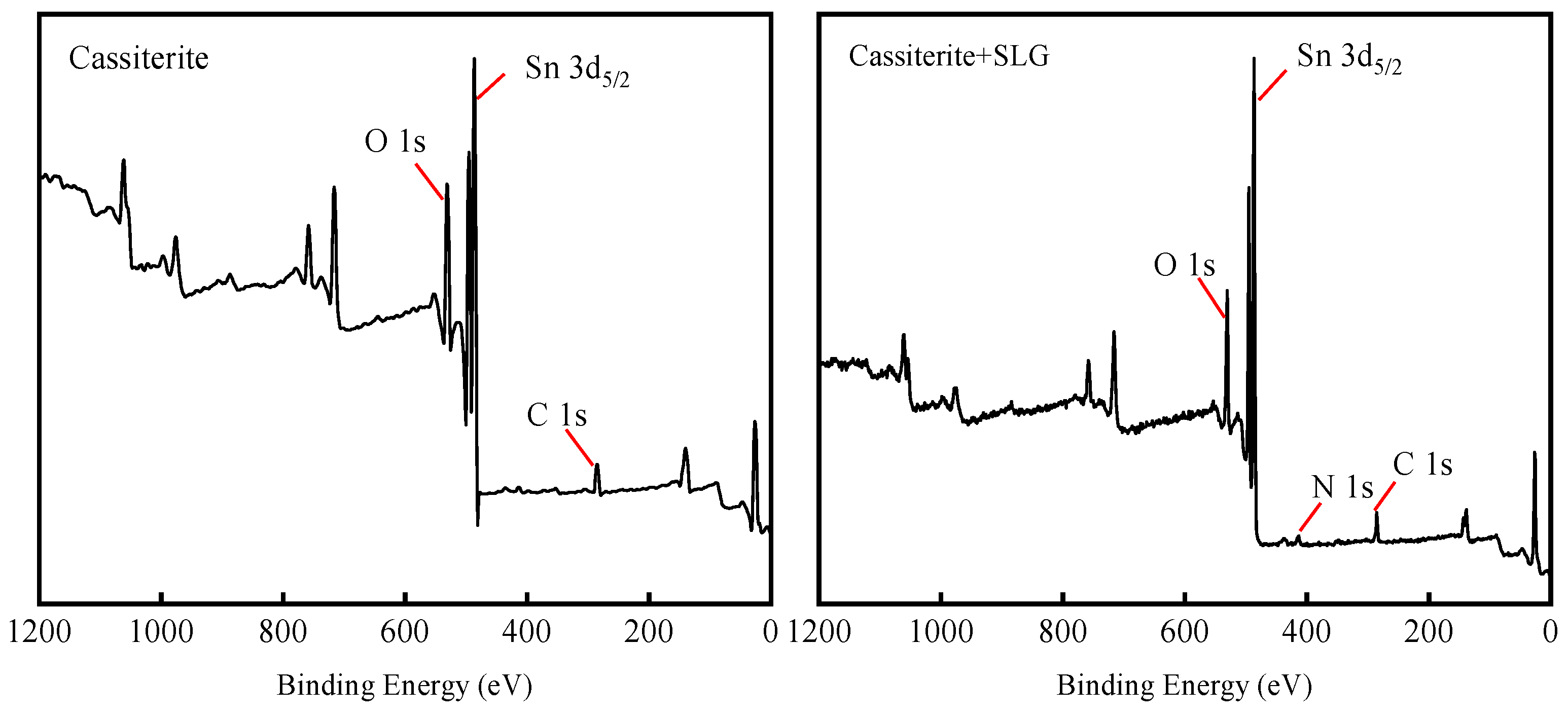

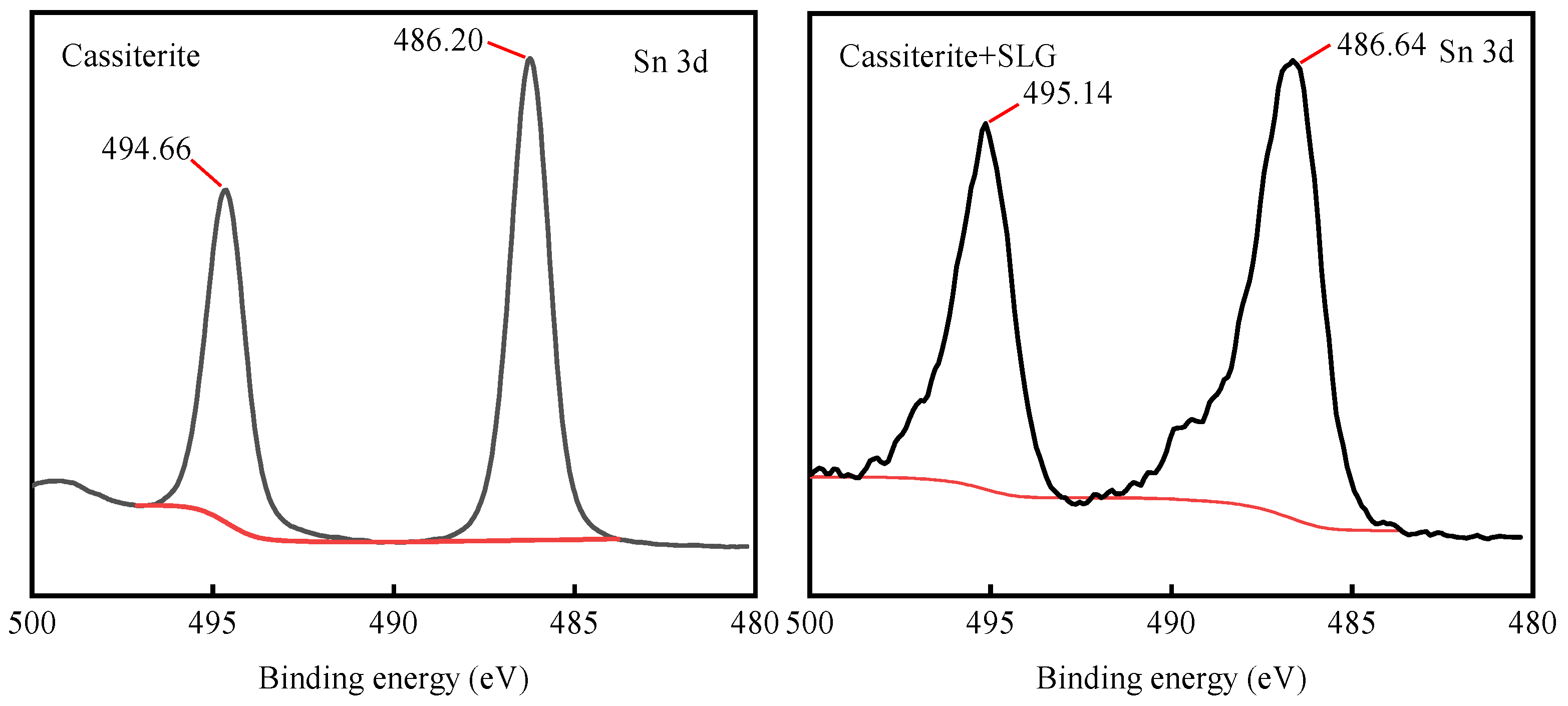

3.4. XPS Analysis

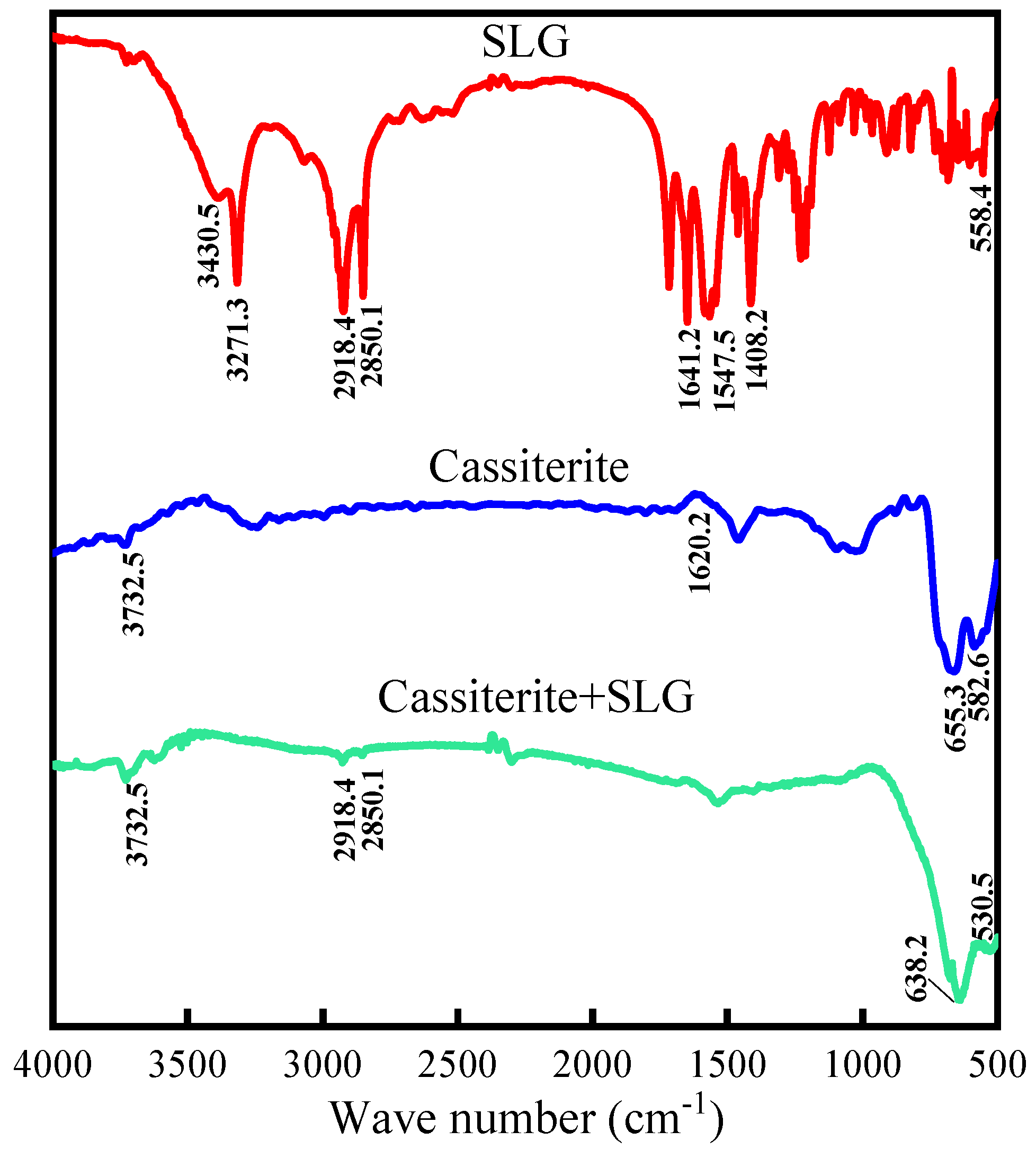

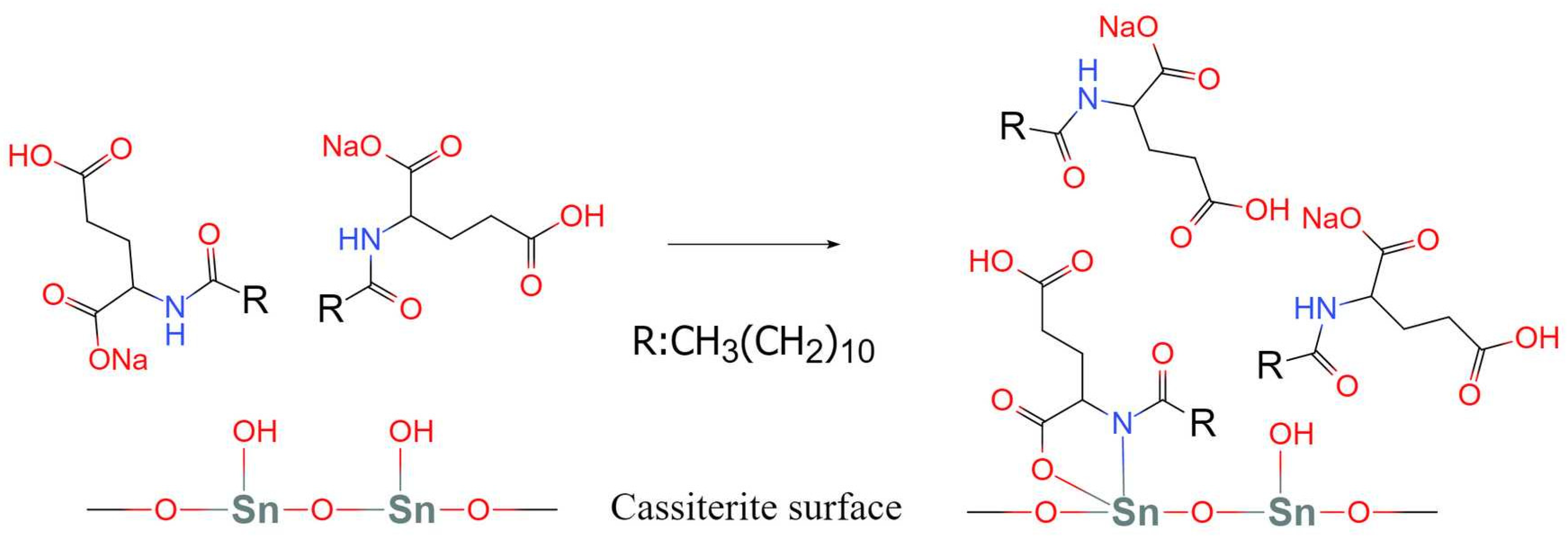

3.5. FTIR Analysis

3.6. Bench-Scale Flotation Tests of Xinzhai Cassiterite

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, Y.; Sun, L.; Gao, Z.; Sun, W.; Cao, X. Activation mechanism of zinc ions in cassiterite flotation with benzohydroxamic acid as a collector. Miner. Eng. 2020, 156, 106523. [Google Scholar] [CrossRef]

- Matveeva, T.N.; Chanturia, V.A.; Gromova, N.K.; Lantsova, L.B. Effect of chemical and phase compositions on absorption and flotation properties of tin–sulphide ore tailings with dibutyl dithiocarbamate. J. Min. Sci. 2018, 54, 1014–1023. [Google Scholar] [CrossRef]

- Yang, C.; Tan, Q.; Zeng, X.; Zhang, Y.; Wang, Z.; Li, J. Measuring the sustainability of tin in China. Sci. Total Environ. 2018, 635, 1351–1359. [Google Scholar] [CrossRef] [PubMed]

- Qi, J.; Liu, S.; Dong, Y.; Liu, G. Revealing the role of dithiocarbamate ester group in hydroxamic acid flotation of cassiterite with in situ AFM, DFT and XPS. Appl. Surf. Sci. 2022, 604, 154521. [Google Scholar] [CrossRef]

- Angadi, S.I.; Sreenivas, T.; Jeon, H.S.; Baek, S.H.; Mishra, B.K. A review of cassiterite beneficiation fundamentals and plant practices. Miner. Eng. 2015, 70, 178–200. [Google Scholar] [CrossRef]

- Sun, L.; Hu, Y.; Sun, W. Effect and mechanism of octanol in cassiterite flotation using benzohydroxamic acid as collector. Trans. Nonferrous Met. Soc. China 2016, 26, 3253–3257. [Google Scholar] [CrossRef]

- Ren, L.; Qiu, H.; Zhang, M.; Feng, K.; Liu, P.; Guo, J.; Feng, J. Behavior of lead ions in cassiterite flotation using octanohydroxamic acid. Ind. Eng. Chem. Res. 2017, 56, 8723–8728. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Zhu, Y.; Li, Y. Adsorption and depression mechanism of an eco-friendly depressant PBTCA on fluorite surface for the efficient separation of cassiterite from fluorite. Miner. Eng. 2021, 171, 107124. [Google Scholar] [CrossRef]

- Richards, R.G.; Machunter, D.M.; Gates, P.J.; Palmer, M.K. Gravity separation of ultra-fine (−0.1 mm) minerals using spiral separators. Miner. Eng. 2000, 13, 65–77. [Google Scholar] [CrossRef]

- Cao, Y.; Tong, X.; Xie, X.; Song, Q.; Zhang, W.; Du, Y.; Zhang, S. Effects of grinding media on the flotation performance of cassiterite. Miner. Eng. 2021, 168, 106919. [Google Scholar] [CrossRef]

- Chen, Y.; Tong, X.; Feng, D.; Xie, X. Effect of Al (III) ions on the separation of cassiterite and clinochlore through reverse flotation. Minerals 2018, 8, 347. [Google Scholar] [CrossRef]

- Li, F.; Zhong, H.; Zhao, G.; Wang, S.; Liu, G. Flotation performances and adsorption mechanism of α-Hydroxyoctyl phosphinic acid to cassiterite. Appl. Surf. Sci. 2015, 353, 856–864. [Google Scholar] [CrossRef]

- Lv, L.; Wang, X.; Ren, H.; Liu, J.; Zhu, Y. Depressing Behaviors and Mechanism of an Eco-Friendly Depressant on Flotation Separation of Cassiterite and Fluorite. J. Mol. Liq. 2021, 322, 114898. [Google Scholar] [CrossRef]

- Wang, X.; Miles, N.J.; Kingman, S. Numerical study of centrifugal fluidized bed separation. Miner. Eng. 2006, 19, 1109–1114. [Google Scholar] [CrossRef]

- Bru, K.; Sousa, R.; Leite, M.M.; Broadbent, C.; Stuart, G.; Pashkevich, D.; Martin, M.; Kern, M.; Parvaz, D.B. Pilot-Scale Investigation of two electric pulse fragmentation (EPF) approaches for the mineral processing of a low-grade cassiterite schist ore. Miner. Eng. 2020, 150, 106270. [Google Scholar] [CrossRef]

- Leistner, T.; Embrechts, M.; Leißner, T.; Chehreh Chelgani, S.; Osbahr, I.; Möckel, R.; Peuker, U.A.; Rudolph, M. A study of the reprocessing of fine and ultrafine cassiterite from gravity tailing residues by using various flotation techniques. Miner. Eng. 2016, 96, 94–98. [Google Scholar] [CrossRef]

- Zhou, Y.; Tong, X.; Song, S.; Wang, X.; Deng, Z.; Xie, X. Beneficiation of cassiterite fines from a tin tailing slime by froth flotation. Sep. Sci. Technol. 2014, 49, 458–463. [Google Scholar] [CrossRef]

- Yuan, Q.; Mei, G.; Liu, C.; Cheng, Q.; Yang, S. A novel sulfur-containing ionic liquid collector for the reverse flotation sepa-ration of pyrrhotite from magnetite. Sep. Purif. Technol. 2022, 303, 122189. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H.; Feng, D.; Tong, X.; Hu, S.; Yang, F.; Wang, G. A recipe of surfactant for the flotation of fine cassiterite particles. Miner. Eng. 2021, 160, 106658. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, P.; Ou, L.; Zhang, Y.; Chen, J. Flotation of cassiterite using alkyl hydroxamates with different Carbon Chain Lengths: A Theoretical and Experimental Study. Miner. Eng. 2021, 170, 107025. [Google Scholar] [CrossRef]

- Gong, G.; Wang, P.; Liu, J.; Han, Y.; Zhu, Y. Effect and mechanism of Cu(II) on flotation separation of cassiterite from fluorite. Sep. Purif. Technol. 2020, 238, 116401. [Google Scholar] [CrossRef]

- Tian, M.; Zhang, C.; Han, H.; Liu, R.; Gao, Z.; Chen, P.; He, J.; Hu, Y.; Sun, W.; Yuan, D. Novel insights into adsorption mechanism of benzohydroxamic acid on lead (II)-activated cassiterite surface: An integrated experimental and computational study. Miner. Eng. 2018, 122, 327–328. [Google Scholar] [CrossRef]

- Feng, Q.; Zhao, W.; Wen, S.; Cao, Q. Activation mechanism of lead ions in cassiterite flotation with salicylhydroxamic acid as collector. Sep. Purif. Technol. 2017, 178, 193–199. [Google Scholar] [CrossRef]

- Sreenivas, T.; Padmanabhan, N.P.H. Surface chemistry and flotation of cassiterite with alkyl hydroxamates. Colloids Surf. A. 2002, 205, 47–59. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, J. Selective flotation of cassiterite with benzohydroxamic acid. Miner. Eng. 2006, 19, 1410–1417. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, S.; Zhong, H. Study on the activation of scheelite and wolframite by lead nitrate. Minerals 2015, 5, 247–258. [Google Scholar] [CrossRef]

- Tian, M.; Gao, Z.; Han, H.; Sun, W.; Hu, Y. Improved flotation separation of cassiterite from calcite using a mixture of lead (II) ion/benzohydroxamic acid as collector and carboxymethyl cellulose as depressant. Miner. Eng. 2017, 113, 68–70. [Google Scholar] [CrossRef]

- Shukla, V.; Shukla, P.; Tiwari, A. Lead Poisoning. Lead poisoning. Indian J. Med. Spec. 2018, 9, 146–149. [Google Scholar] [CrossRef]

- Izard, C.F.; Müller, D.B. Tracking the devil’s metal: Historical global and contemporary U.S. tin cycles. Resour. Conserv. Recycl. 2010, 54, 1436–1441. [Google Scholar] [CrossRef]

- Marques, E.F.; Brito, R.O.; Silva, S.G.; Enrique Rodríguez-Borges, J.; do Vale, M.L.; Gomes, P.; Araújo, M.J.; Söderman, O. Spontaneous vesicle formation in catanionic mixtures of amino acid-based surfactants: Chain length symmetry effects. Langmuir 2008, 24, 11009–11017. [Google Scholar] [CrossRef]

- Islam, M.S.; Shortall, S.M.; Mekhail, G.M.; Callender, S.P.; Madkhali, O.; Bharwani, Z.; Ayyash, D.; Kobernyk, K.; Wettig, S.D. Effect of counterions on the micellization and monolayer behaviour of cationic gemini surfactants. Phys. Chem. Chem. Phys. 2017, 19, 10825–10834. [Google Scholar] [CrossRef]

- Ariki, R.; Hirano, A.; Arakawa, T.; Shiraki, K. Drug solubilization effect of Lauroyl-L-glutamate. J. Biochem. 2012, 151, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Ananthapadmanabhan, K.P. Amino-Acid Surfactants in Personal Cleansing (Review). Tenside Surfactants Deterg. 2019, 56, 378–386. [Google Scholar] [CrossRef]

- Bordes, R.; Holmberg, K.A. Amino acid-based surfactants—Do they deserve more attention? Adv. Colloid Interface Sci. 2015, 222, 79–91. [Google Scholar] [CrossRef]

- Katiyar, S.S.; Kushwah, V.; Dora, C.P.; Patil, R.Y.; Jain, S. Design and toxicity evaluation of novel fatty acid-amino acid-based biocompatible surfactants. AAPS PharmSciTech 2019, 20, 186. [Google Scholar] [CrossRef]

- Sivasamy, A.; Krishnaveni, M.; Rao, P.G. Preparation, characterization, and surface and biological properties of N-stearoyl amino acids. J. Am. Oil Chem. Soc. 2001, 78, 897–902. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, L.; Chen, J.; Min, F.; Lu, F. Study on the influence of particle size on the flotation separation of kaolinite and quartz. Powder Technol. 2022, 408, 897–902. [Google Scholar] [CrossRef]

| Component | SnO2 | Al2O3 | MgO | CaO | TFe | Pb | SiO2 | Else |

|---|---|---|---|---|---|---|---|---|

| Content/% | 97.98 | 0.22 | 0.35 | 0.24 | 0.18 | 0.17 | 0.35 | 0.51 |

| Component | SiO2 | Al2O3 | MgO | CaO | K2O | Na2O | Fe2O3 | Else |

|---|---|---|---|---|---|---|---|---|

| Content/% | 98.68 | 0.41 | 0.08 | 0.13 | 0.21 | 0.06 | 0.21 | 0.22 |

| Element (Atomic %) | Cassiterite | Cassiterite + SLG | Δ |

|---|---|---|---|

| C | 28.5 | 48.9 | 20.4 |

| O | 45.9 | 32.5 | −13.4 |

| Sn | 25.6 | 17.4 | −8.2 |

| N | - | 1.2 | 1.2 |

| Elements | Sn | Pb | Zn | S | Cu | SiO2 | Fe | Else |

|---|---|---|---|---|---|---|---|---|

| Content (wt %) | 0.14 | 0.46 | 6.89 | 21.52 | 0.23 | 37.5 | 30.21 | 3.05 |

| Conditions | Product | Yield | Sn Grade | Sn Recovery |

|---|---|---|---|---|

| BHA | Concentrate | 3.09 | 3.45 | 74.3 |

| Tailings | 96.91 | 0.038 | 25.7 | |

| Raw ore | 100 | 0.144 | 100 | |

| SLG | Concentrate | 3.05 | 4.02 | 85.2 |

| Tailings | 96.95 | 0.022 | 14.8 | |

| Raw ore | 100 | 0.143 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Sun, L.; Cao, Y.; Fan, X.; Sun, W.; Wang, Q. Sodium Lauroyl Glutamate as a Collector in Cassiterite Flotation. Minerals 2023, 13, 61. https://doi.org/10.3390/min13010061

Peng Z, Sun L, Cao Y, Fan X, Sun W, Wang Q. Sodium Lauroyl Glutamate as a Collector in Cassiterite Flotation. Minerals. 2023; 13(1):61. https://doi.org/10.3390/min13010061

Chicago/Turabian StylePeng, Zaihua, Lei Sun, Yang Cao, Xiaohui Fan, Wei Sun, and Qingqing Wang. 2023. "Sodium Lauroyl Glutamate as a Collector in Cassiterite Flotation" Minerals 13, no. 1: 61. https://doi.org/10.3390/min13010061

APA StylePeng, Z., Sun, L., Cao, Y., Fan, X., Sun, W., & Wang, Q. (2023). Sodium Lauroyl Glutamate as a Collector in Cassiterite Flotation. Minerals, 13(1), 61. https://doi.org/10.3390/min13010061