Study on Mechanical Properties of Ring Sandstone Specimen under Temperature and Water Coupling Dynamic Compression

Abstract

:1. Introduction

2. Specimen Processing and Basic Physical Parameter Change

2.1. Preparation of Specimen

2.2. Specimen Coupling Treatment with Temperature and Water

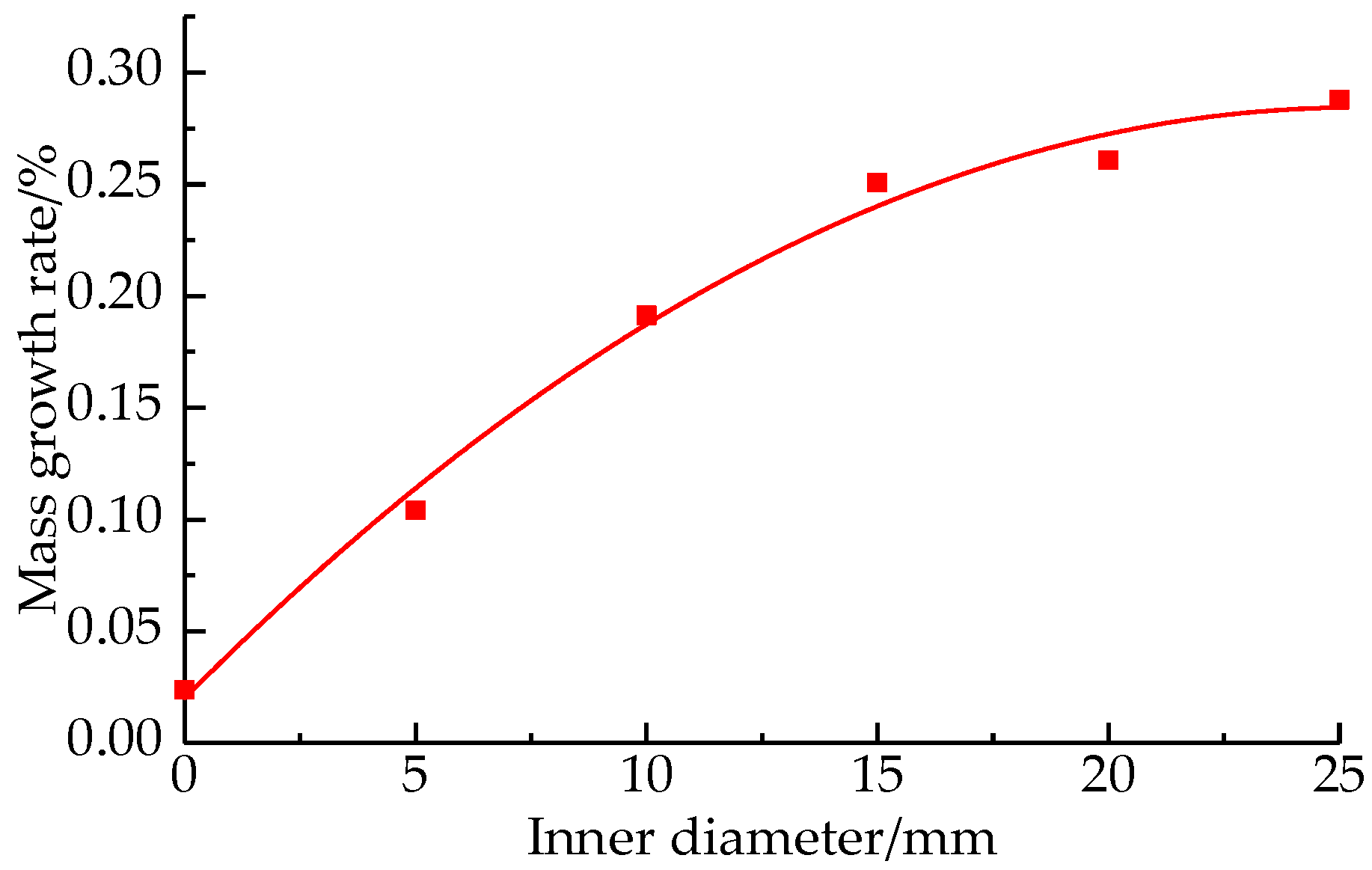

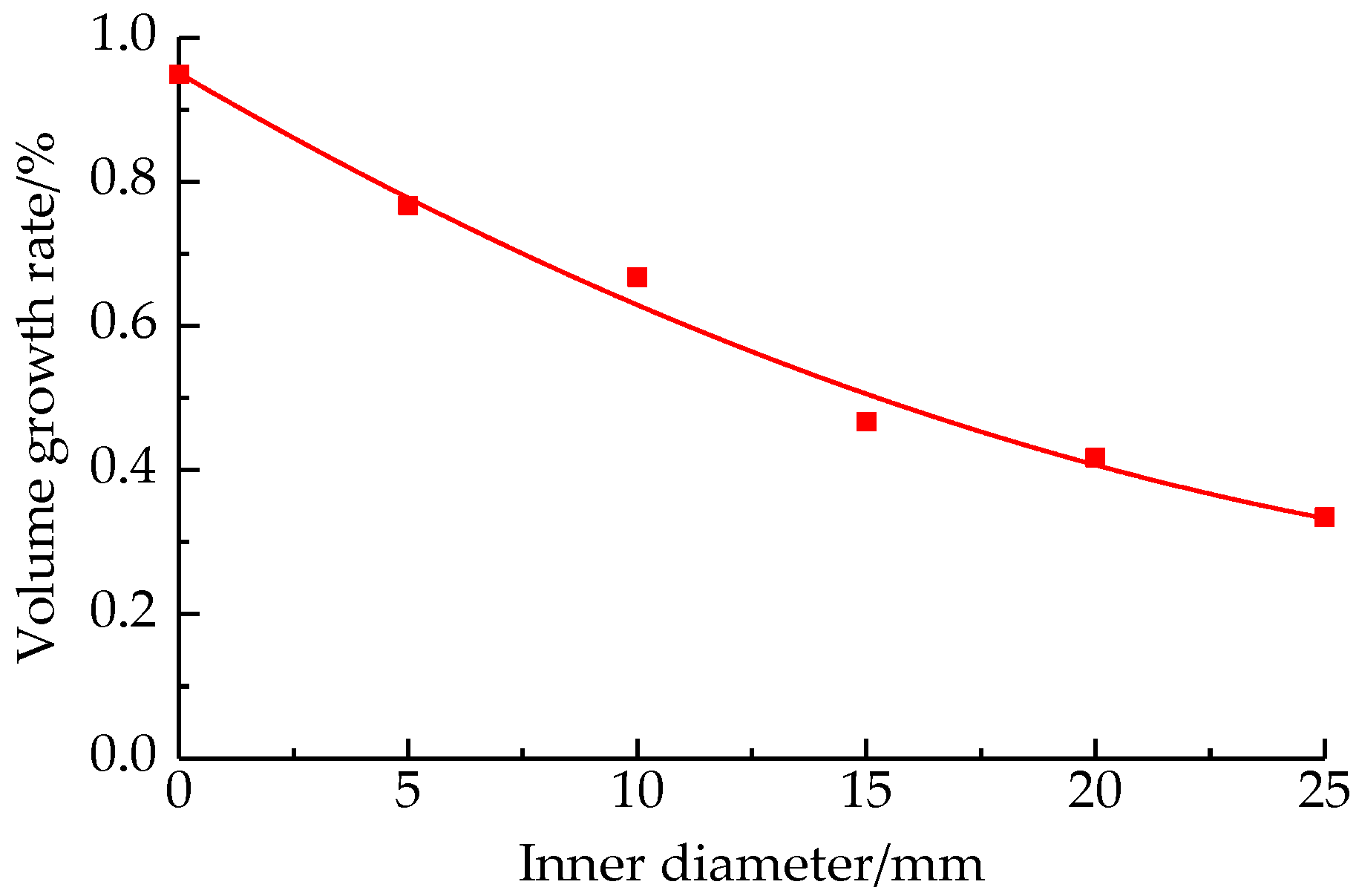

2.3. Basic Physical Parameters of the Specimen

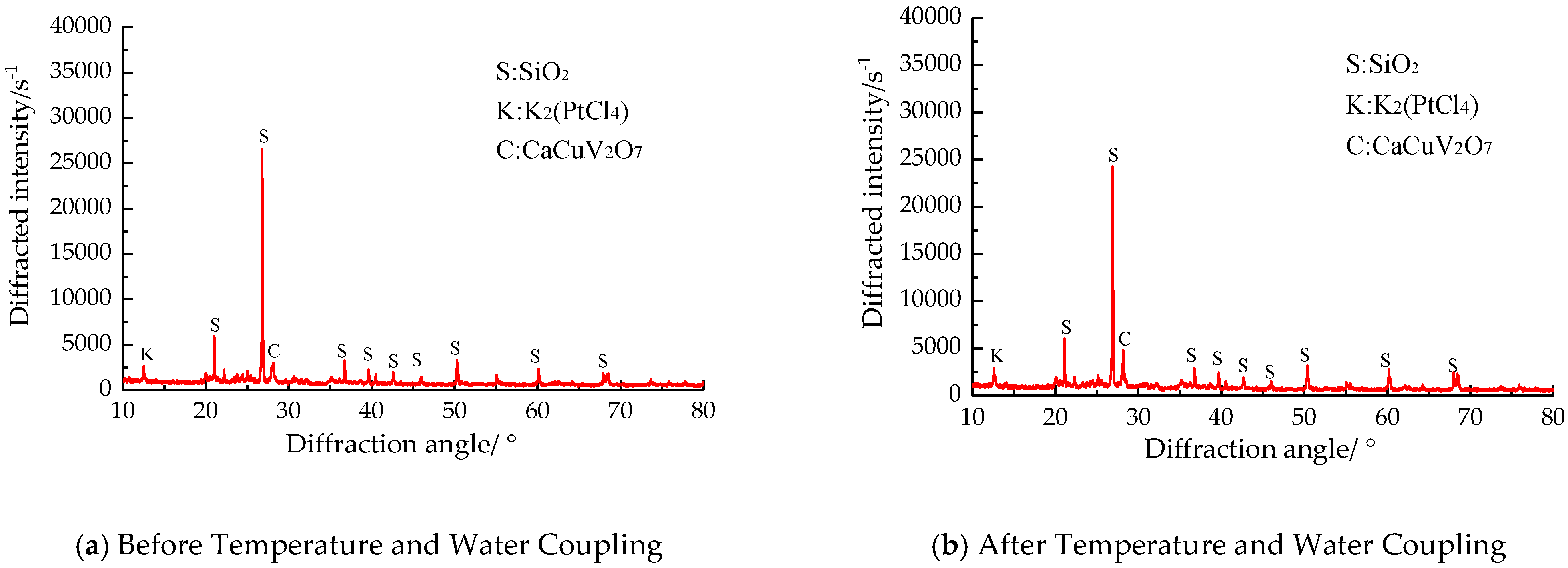

2.4. Microscopic Material Composition

3. Specimen Processing and Basic Physical Parameter Change

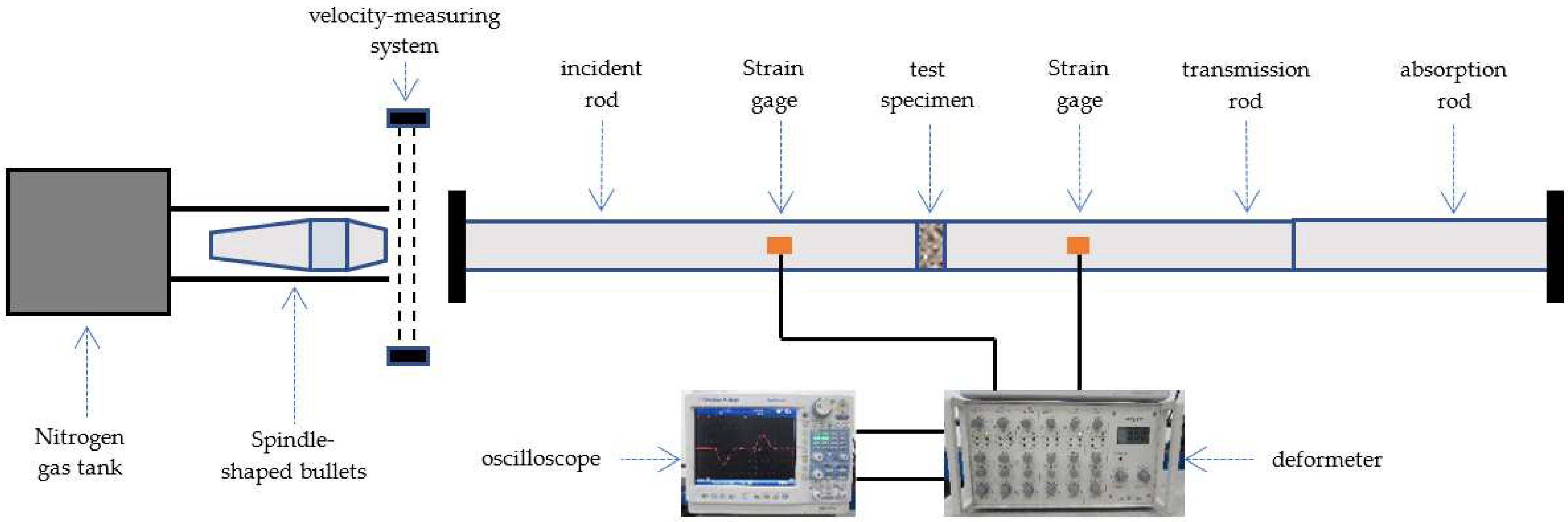

3.1. SHPB Test Facility

3.2. Dynamic Performance Analysis

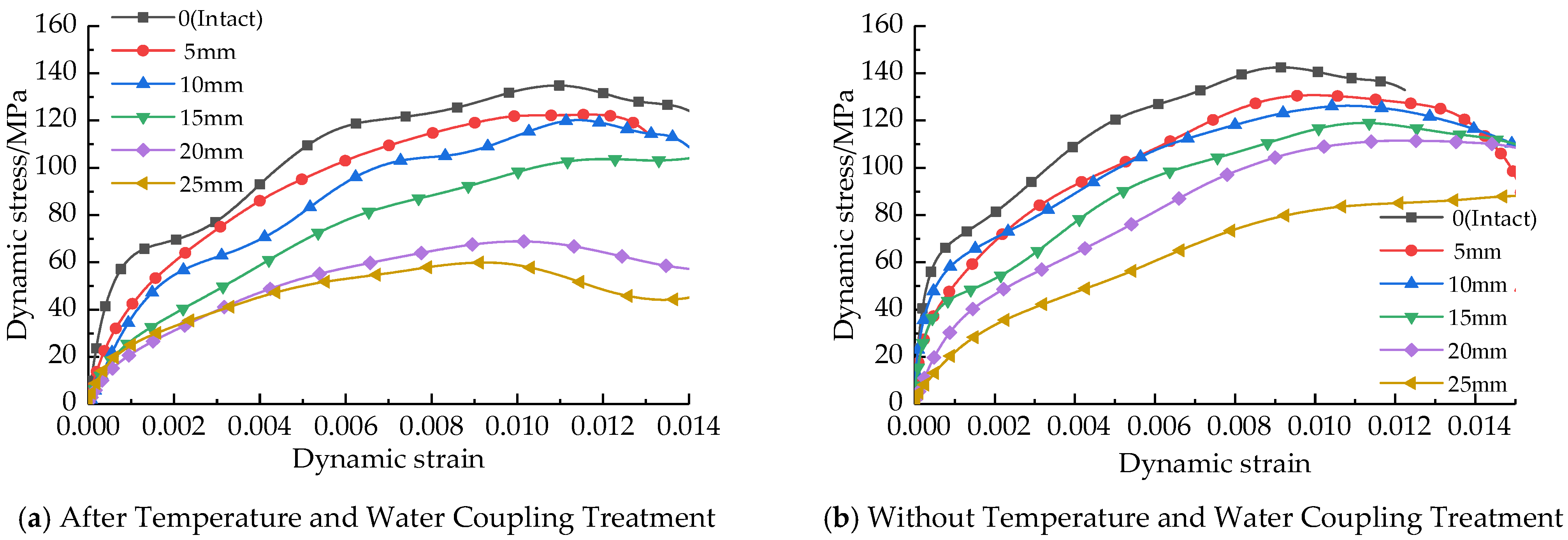

3.2.1. Dynamic Stress-Strain Relationship

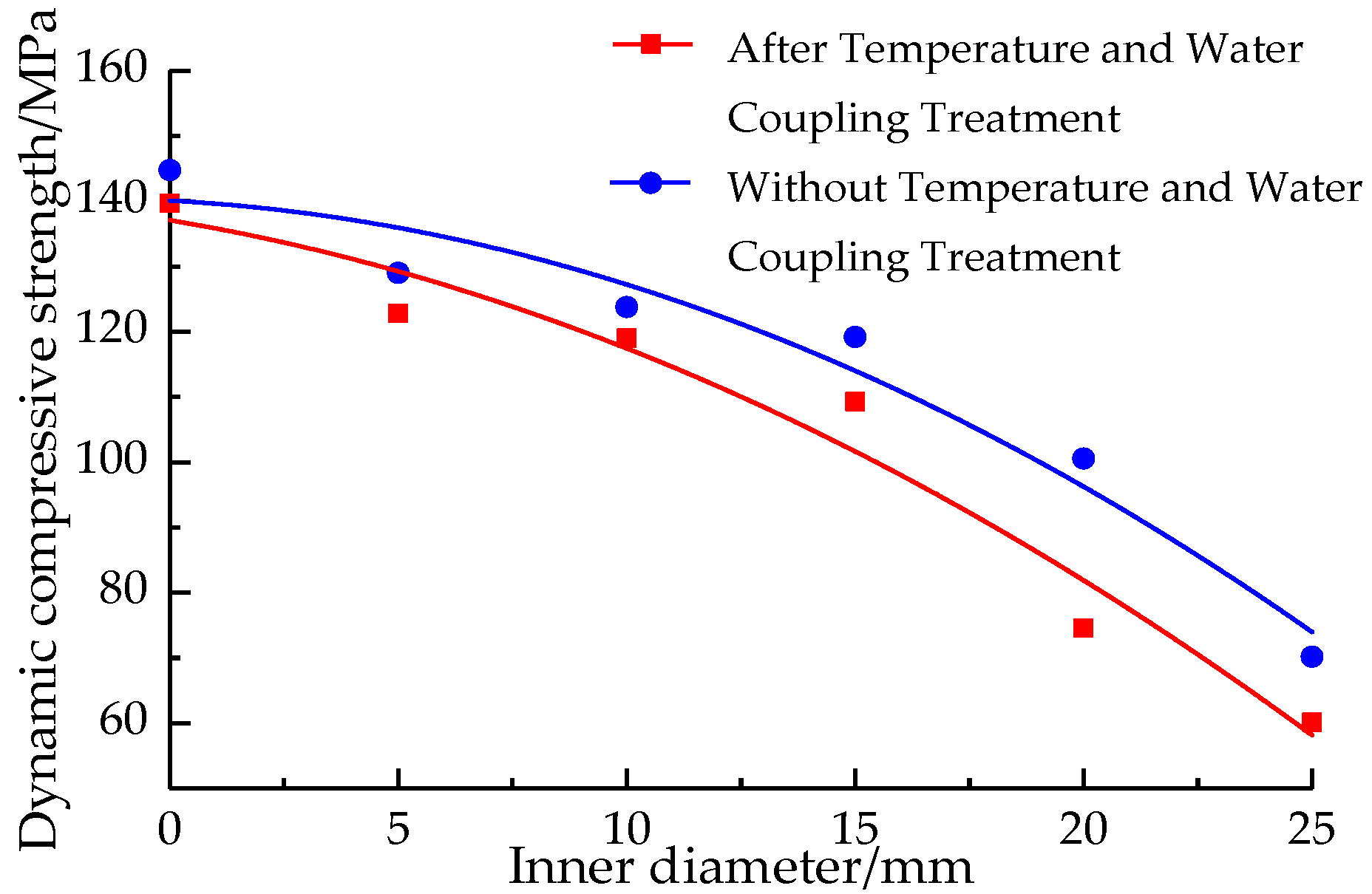

3.2.2. Dynamics Performance

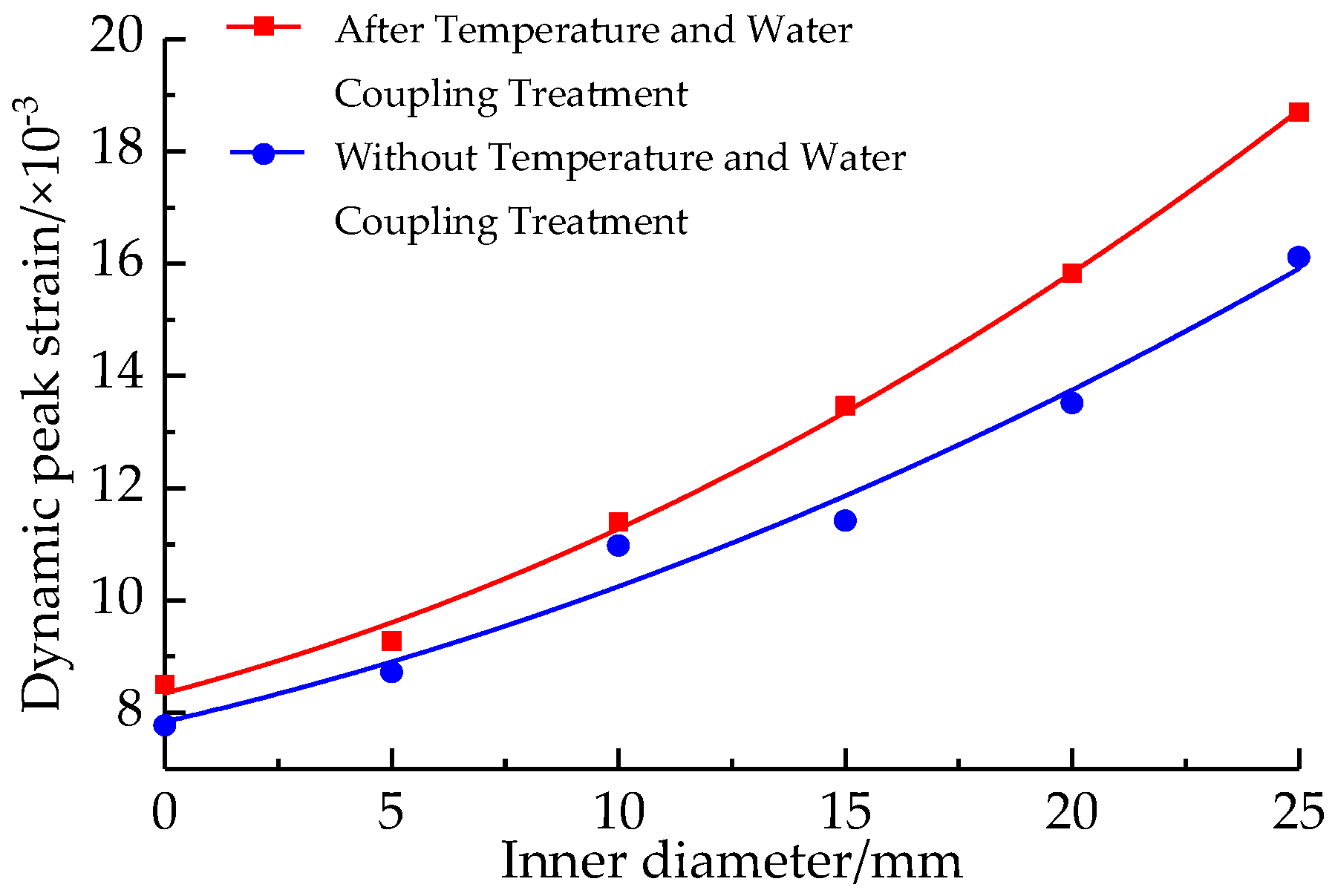

3.2.3. Dynamic Peak Strain

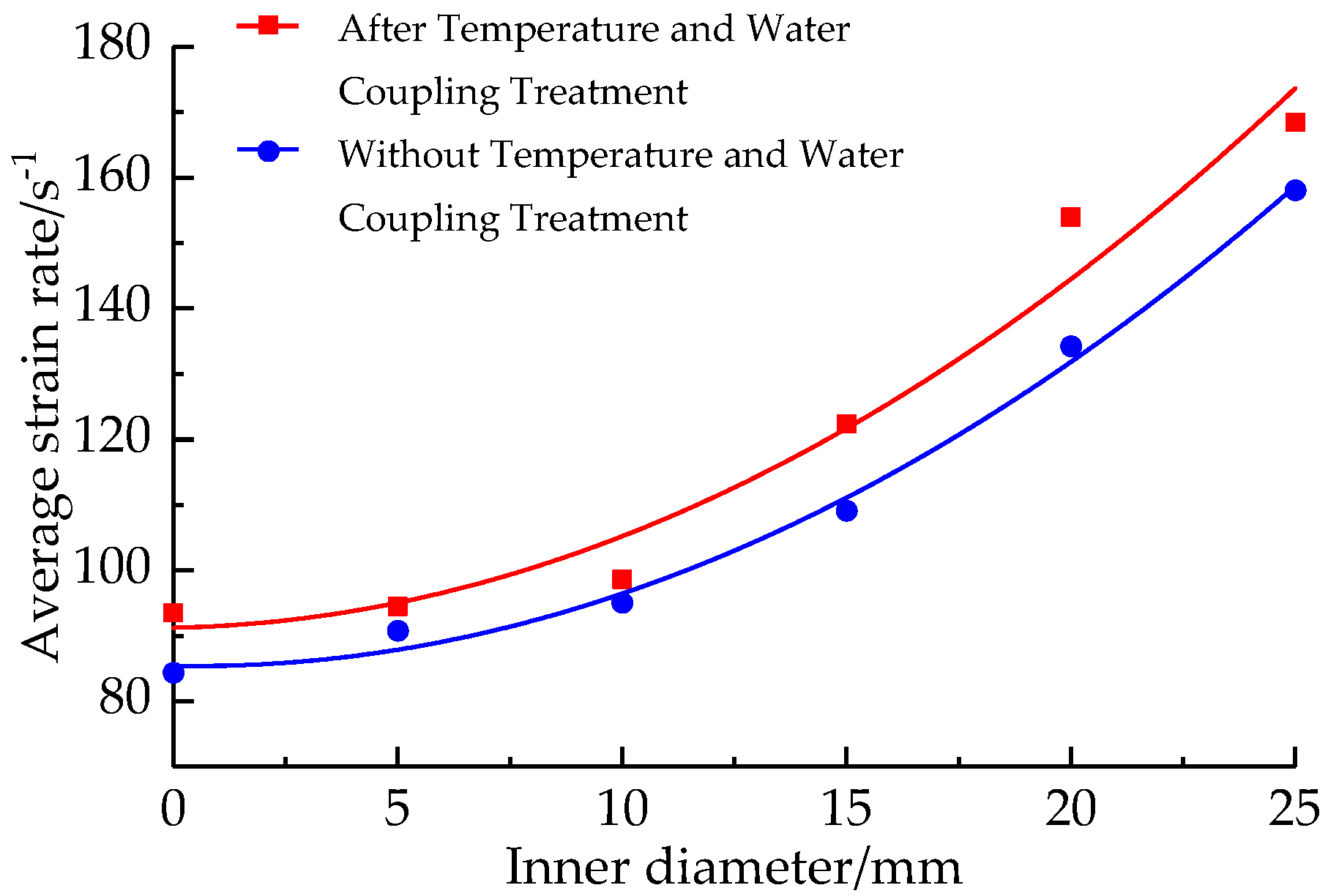

3.2.4. Average Strain Rate

3.2.5. Dynamic Modulus of Elasticity

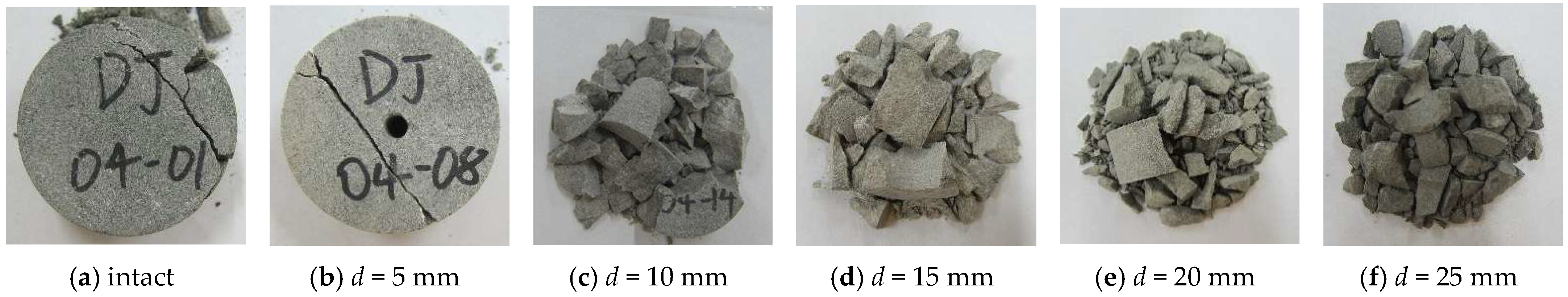

4. Analysis of Fracture Morphology and Energy Dissipation of Specimen

4.1. Fracture Surface

4.2. SHPB Test Facility

4.3. Energy Dissipation Analysis

5. Conclusions

- (1)

- After coupling with temperature and water, the mass growth rate of ring sandstone specimen is about 0.2%; the Density and volume growth rate is about 0.6%. The density showed a decreasing trend with a reduction rate of 0.004%. XRD results show that the material composition of ring sandstone samples does not change under the coupling effect of temperature and water, and no new materials are found.

- (2)

- The dynamic properties of ring sandstone specimens decrease with the increase inin inner diameter. The dynamic properties of the ring sandstone specimen were weakened by temperature and water coupling.

- (3)

- Both dynamic compressive strength and the peak strain show a quadratic function relationship with the increase in inner diameter, and the positive correlation is obvious. The average strain rate and dynamic elastic modulus show a strong quadratic negative correlation with the increase in specimen inner diameter.

- (4)

- Through the microscopic fracture surface analysis, the coupling effect of temperature and water damaged the ring sandstone specimen through degradation, which made the specimen rupture and expansion, and more prone to ring breakage. The crack of the specimen tends to expand, which increases the degree of breakage of the specimen.

- (5)

- Through the energy dissipation analysis, the energy dissipation per unit volume of the ring sandstone specimen increases after the coupling of warm water. The law of energy dissipation is consistent with the broken form of the specimen.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yuan, L. Study on Failure Mechanism and Supporting Technology of Deep Roadway Surrounding Rock. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=SNAD&filename=SNAD000001655646 (accessed on 27 December 2015).

- Lu, C.P.; Liu, G.J.; Liu, Y.; Zhang, N.; Xue, J.H.; Zhang, L. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, B.; Liu, B.; Liu, Y.; Wang, H.Y.; Zhang, H. Anatomy of mining-induced fault slip and a triggered rockburst. Bull. Eng. Geol. Environ. 2019, 78, 5147–5160. [Google Scholar] [CrossRef]

- Ping, Q.; Zhang, C.L.; Sun, H.J. The Dynamic Characteristics of Sandstone after High Temperature Cycle Test Study. J. Min. Saf. Eng. 2021, 38, 1015–1024. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, Z.N.; Chi, X.L.; Lu, X.; Wei, Z.; Liu, W.J. Experimental Study on Crack Evolution and Damage Characteristics of Water-Bearing Sandstone Under Cyclic Loading. Rock Soil Mech. 2022, 43, 1791–1802. [Google Scholar] [CrossRef]

- Xu, P.F.; Deng, H.F.; Zhang, H.B.; Peng, M.; Li, G.Y.; Jiang, Q.; Chen, X.Z. Study on Failure Characteristics of Sandstone under Time-Delayed Uniaxial Compression at Different Stress Levels. Rock Soil Mech. 2021, 42, 3041–3050+3078. [Google Scholar] [CrossRef]

- Jia, P.; Wang, Y.; Li, B.; Qian, Y.J. Experimental Study on Mechanical Properties of Rock Cooled by Water at High Temperature under Cyclic Loading and Unloading [J/OL]. Trans. Beijing Inst. Technol. 2022, 126–134. [Google Scholar] [CrossRef]

- Ping, Q.; Gao, Q.; Wang, C.; Wu, Y.L.; Zhang, C.L.; Qi, D.Z.; Diao, Q.; Zang, L.; Su, Z.Q. Study on Physical and Dynamic Splitting Mechanical Properties of Temperature-Water Coupled Sandstone. IOP Conf. Ser. Earth Environ. Sci. 2021, 861, 042077. [Google Scholar] [CrossRef]

- Deng, C.F.; Liu, J.F.; Chen, L.; Li, Y.; Xiang, G. Fracture Mechanical Behavior and Acoustic Emission Characteristics of Granite with Different Water Content. Chin. J. Geotech. Eng. 2017, 39, 1538–1544. [Google Scholar] [CrossRef]

- Ai, D.H.; Zhao, Y.C.; Wang, Q.F.; Li, C.W. Crack Propagation and Dynamic Properties of Coal under SHPB Impact Loading: Experimental Investigation and Numerical Simulation. Theor. Appl. Fract. Mech. 2020, 105, 102393. [Google Scholar] [CrossRef]

- Ping, Q.; Fang, Z.H.; Ma, D.D.; Zhang, H. Coupled Static-Dynamic Tensile Mechanical Properties and Energy Dissipation Characteristic of Limestone Specimen in SHPB Tests. Adv. Civ. Eng. 2020, 2020, 7172928. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q.; Zhang, Y.L. Combined Effects of Salt, Cyclic Wetting and Drying Cycles on the Physical and Mechanical Properties of Sandstone. Eng. Geol. 2018, 248, 70–79. [Google Scholar] [CrossRef]

- He, J.J.; Shi, J.P. Shear Failure Characteristics of Sandstone with Different Water-Bearing States after Freeze-Thawing. Chin. J. Rock Mech. Eng. 2005, 2018, 1350–1358. [Google Scholar] [CrossRef]

- Wang, C.; Lai, Y.M.; You, Z.M.; Yang, Y.; Yu, D.H.; Liu, G.H. Experimental Study on Effects of Temperature and Water Content on Rock Splitting Strength. Glacial Permafr. 2016, 38, 1317–1324. [Google Scholar]

- Wang, Q.; Hu, X.L.; Zheng, W.B.; Li, L.X.; Zhou, C.; Ying, C.Y.; Xu, C. Mechanical Properties and Permeability Evolution of Red Sandstone Subjected to Hydro-mechanical Coupling: Experiment and Discrete Element Modelling. Rock Mech. Rock Eng. 2021. prepublish. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Tang, J.Z.; Chen, Y.; Zhang, L.Y.; Wang, W.J.; Wan, W.; Liao, L.P. Hydromechanical coupling tests for mechanical and permeability characteristics of fractured limestone in complete stress–strain process. Environ. Earth Sci. 2017, 76, 24. [Google Scholar] [CrossRef]

- Chen, G.Q.; Jian, D.H.; Chen, Y.H.; Li, Y.; Lin, Z.H. Shear Creep Characteristics of Red Sandstone After Freeze-Thaw with Different Water Content. Chin. J. Geotech. Eng. 2021, 43, 661–669. [Google Scholar]

- Yang, Y.; Zhang, N.N.; Wang, J.G. A Study on the Dynamic Strength Deterioration Mechanism of Frozen Red Sandstone at Low Temperatures. Minerals 2021, 11, 1300. [Google Scholar] [CrossRef]

- Xue, J.H.; Zhao, Z.H.; Dong, L.J.; Jin, J.F.; Zhang, Y.B.; Tan, L.; Cai, R.Y.; Zhang, Y.H. Effect of Chemical Corrosion and Axial Compression on the Dynamic Strength Degradation Characteristics of White Sandstone under Cyclic Impact. Minerals 2022, 12, 429. [Google Scholar] [CrossRef]

- Ping, Q.; Wang, C.; Gao, Q.; Shen, K.F.; Wu, Y.L.; Wang, S.; Sun, S.J. Experimental Study on Dynamic Mechanical Properties of Sandstone Corroded by Strong Alkali. Appl. Sci. 2022, 12, 7635. [Google Scholar] [CrossRef]

- Li, X.; Huang, S.; Yin, T.B.; Li, X.B.; Peng, K.; Fan, X.D.; Huang, L.C. Dynamic Properties of Thermal Shock Treated Sandstone Subjected to Coupled Dynamic and Static Loads. Minerals 2021, 11, 889. [Google Scholar] [CrossRef]

- Fan, X.; Lin, H.; Xiong, W.; Zhong, W.W. Influence of Water Absorption Rate and Water Absorption Time on Schmidt Hardness of Red Sandstone. J. China Univ. Min. Technol. 2015, 44, 233–240. [Google Scholar] [CrossRef]

- Laubach, S.E.; Olson, J.E.; Dewers, T.; Fisher, D.; Bodnar, R.; Evans, B.; Dove, P.; Bonnell, L.M.; Marder, M.P.; Pyrak-Nolte, L. The Role of Chemistry in Fracture Pattern Development and Opportunities to Advance Interpretations of Geological Materials. Rev. Geophys. 2019, 57, 1065–1111. [Google Scholar] [CrossRef] [Green Version]

- Ping, Q.; Wang, S.; Wu, Y.L.; Sun, S.J.; Shen, K.F.; Wang, C.; Gao, Q.; Fang, C.L. Study on Mechanical Properties and Energy Consumption of Fissured Sandstone with Different Dip Angles under Impact Load. Shock Vib. 2022, 2022, 5335357. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, C.S.; Wang, Y.X.; Lin, H. Shear-related roughness classification and strength model of natural rock joint based on fuzzy comprehensive evaluation. Int. J. Rock Mech. Min. Sci. 2020. prepublish. [Google Scholar] [CrossRef]

- Yang, C.; Xu, S.L.; Yi, H.S. Study on Compression Deformation Characteristics of Ring under Impact Load. Vib. Shock 2021, 43, 661–669. [Google Scholar] [CrossRef]

- Qi, P.; Gao, Q.; Wu, Y.; Wang, C.; Shen, K.; Wang, S.; Wu, S.; Xu, Y. Study on the Dynamic Splitting Mechanical Properties of Annular Sandstone Specimens with Temperature–Water Coupling in a Coal Mine. Appl. Sci. 2022, 12, 4608. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.B.; Xiong, Z.Q.; Wang, C.; Cheng, L.P.; Zhan, S.F. Experimental Study on Mechanical Characteristics of Annular Granite Under Temperature and Humidity Circulation. J. Rock Mech. Eng. 2020, 39, 3260–3270. [Google Scholar] [CrossRef]

- Wu, Q.H.; Zhao, F.J.; Li, X.B.; Wang, S.M.; Wang, B.; Zhou, Z.H. Study on Mechanical Properties of Circular Sandstone Samples under Radial Compression. Rock Soil Mech. 2018, 39, 3969–3975. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yang, S.Q. Experimental Study on Tensile Mechanical Properties of Pore-Bearing Granite After High Temperature. J. China Univ. Min. Technol. 2017, 46, 783–791. [Google Scholar] [CrossRef]

- Li, D.Y.; Wang, T.; Cheng, T.J.; Sun, X.L. Static and Dynamic Tensile Failure Characteristics of Rock Based on Splitting Test of Circular Ring. Trans. Nonferrous Met. Soc. China 2016, 26, 1912–1918. [Google Scholar] [CrossRef]

- Yang, S.Q.; Li, Y.; Huang, Y.H. Particle Flow analysis of Micromechanical Properties of Single-Hole Disk Splitting Test. J. China Univ. Min. Technol. 2019, 48, 984–992. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Liao, J.; Liu, Q.; Yang, L.; Cheng, J.C. Comparison of Mechanical Properties of Channel Sandstone Under Hydro-Mechanical Coupling and Isolation. J. China Coal Soc. 2020, 45, 3973–3983. [Google Scholar] [CrossRef]

- Wang, Y.X.; Wang, Z.Q.; Zhang, W.; Liu, F.F. Experimental study on Fracture of Concrete with Precast Cavity. J. Beijing Inst. Technol. 2019, 39, 1232–1238. [Google Scholar] [CrossRef]

- Ulusay, R. The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer International Publishing: Cham, Switzerland, 2015; pp. 51–68. [Google Scholar]

- T/CSRME001-2019; Technical Specification for Testing Method of Rock Dynamic Properties. Chinese Society of Rock Mechanics and Engineering: Beijing, China, 2019.

- Ping, Q.; Qi, D.Z.; Diao, Q.; Zhang, C.L.; Gao, Q.; Wu, Y.L. Experimental Study on Physical and Dynamic Mechanical Properties of Temperature-Water Coupled Sandstone. Shock Vib. 2021, 2021, 6568436. [Google Scholar] [CrossRef]

| Inner Diameter (mm) | Specimen Number | Before Temperature and Water Coupling | After Temperature and Water Coupling | ||||

|---|---|---|---|---|---|---|---|

| Mass (g) | Volume (mm3) | Density (g/mm3) | Mass (g) | Volume (mm3) | Density (g/mm3) | ||

| 0 (Intact) | DJ04-01 | 125.92 | 49.06 | 2.57 | 125.95 | 49.53 | 2.54 |

| DJ04-02 | 125.39 | 49.02 | 2.56 | 125.42 | 49.50 | 2.53 | |

| DJ04-03 | 126.92 | 49.27 | 2.58 | 126.95 | 49.73 | 2.55 | |

| 5 | DJ04-07 | 125.39 | 48.56 | 2.58 | 125.55 | 48.95 | 2.57 |

| DJ04-08 | 124.39 | 48.55 | 2.56 | 124.60 | 48.91 | 2.55 | |

| DJ04-09 | 126.36 | 48.56 | 2.60 | 126.38 | 48.95 | 2.58 | |

| 10 | DJ04-13 | 121.69 | 47.31 | 2.57 | 121.86 | 47.62 | 2.56 |

| DJ04-14 | 118.25 | 46.99 | 2.52 | 118.52 | 47.32 | 2.50 | |

| DJ04-15 | 121.56 | 47.17 | 2.58 | 121.81 | 47.48 | 2.57 | |

| 15 | DJ04-19 | 114.55 | 44.75 | 2.56 | 114.77 | 44.98 | 2.55 |

| DJ04-20 | 114.59 | 44.66 | 2.57 | 114.88 | 44.88 | 2.56 | |

| DJ04-21 | 114.00 | 44.76 | 2.55 | 114.35 | 44.94 | 2.54 | |

| 20 | DJ04-25 | 103.42 | 41.23 | 2.51 | 103.67 | 41.42 | 2.50 |

| DJ04-26 | 103.07 | 41.03 | 2.51 | 103.36 | 41.20 | 2.51 | |

| DJ04-27 | 100.25 | 40.96 | 2.45 | 100.51 | 41.11 | 2.45 | |

| 25 | DJ04-31 | 92.36 | 36.72 | 2.52 | 92.64 | 36.85 | 2.51 |

| DJ04-32 | 90.98 | 36.77 | 2.47 | 91.24 | 36.89 | 2.47 | |

| DJ04-33 | 91.17 | 36.83 | 2.48 | 91.42 | 36.95 | 2.47 | |

| Inner Diameter (mm) | Specimen Number | After Temperature and Water Coupling Treatment | Specimen Number | Without Temperature and Water Coupling Treatment | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Peak Stress (MPa) | Average Strain Rate (s−1) | Dynamic Modulus of Elasticity (GPa) | Peak Strain (×10−3) | Peak Stress (MPa) | Average Strain Rate (s−1) | Dynamic Modulus of Elasticity (GPa) | Peak Strain (×10−3) | |||

| 0 (Intact) | DJ04-01 | 123.46 | 8.40 | 13.07 | 94.70 | DJ04-04 | 145.70 | 7.62 | 14.41 | 87.60 |

| DJ04-03 | 122.20 | 8.60 | 13.04 | 92.30 | DJ04-06 | 143.85 | 7.93 | 15.01 | 81.00 | |

| 5 | DJ04-07 | 123.46 | 9.62 | 14.30 | 91.10 | DJ04-11 | 126.26 | 8.83 | 14.45 | 89.70 |

| DJ04-08 | 122.20 | 8.93 | 10.67 | 97.80 | DJ04-12 | 131.77 | 8.62 | 13.88 | 91.80 | |

| 10 | DJ04-13 | 117.10 | 11.45 | 12.36 | 96.60 | DJ04-17 | 127.04 | 10.77 | 13.49 | 95.30 |

| DJ04-15 | 120.95 | 11.35 | 12.24 | 100.60 | DJ04-18 | 120.50 | 11.18 | 13.51 | 94.70 | |

| 15 | DJ04-19 | 107.42 | 14.81 | 10.11 | 126.40 | DJ04-22 | 135.24 | 11.48 | 12.76 | 106.50 |

| DJ04-20 | 111.10 | 12.12 | 10.82 | 118.40 | DJ04-23 | 103.17 | 11.36 | 10.11 | 111.60 | |

| 20 | DJ04-25 | 69.66 | 15.72 | 8.80 | 161.70 | DJ04-28 | 112.13 | 11.73 | 9.65 | 129.00 |

| DJ04-26 | 79.39 | 15.93 | 7.39 | 146.20 | DJ04-30 | 89.00 | 15.30 | 9.12 | 139.40 | |

| 25 | DJ04-31 | 60.44 | 18.85 | 8.03 | 173.20 | DJ04-34 | 89.00 | 15.30 | 8.12 | 158.40 |

| DJ04-33 | 59.80 | 18.55 | 7.17 | 163.70 | DJ04-35 | 51.30 | 16.93 | 9.00 | 157.70 | |

| Inner Diameter (mm) | Specimen Number | After Temperature and Water Coupling Treatment | Specimen Number | Without Temperature and Water Coupling Treatment | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Incident Energy (J) | Reflected Energy (J) | Transmitted Energy (J) | Absorbed Energy (J) | Incident Energy (J) | Reflected Energy (J) | Transmitted Energy (J) | Absorbed Energy (J) | |||

| 0 (Intact) | DJ04-01 | 104.46 | 29.66 | 53.22 | 21.58 | DJ04-04 | 117.76 | 39.33 | 60.37 | 18.06 |

| DJ04-03 | 100.36 | 28.75 | 51.32 | 20.29 | DJ04-06 | 114.44 | 33.31 | 62.35 | 18.78 | |

| 5 | DJ04-07 | 95.77 | 28.92 | 45.12 | 21.74 | DJ04-11 | 113.82 | 36.11 | 58.69 | 19.02 |

| DJ04-08 | 107.12 | 30.92 | 55.69 | 20.58 | DJ04-12 | 113.04 | 36.17 | 57.94 | 18.92 | |

| 10 | DJ04-13 | 106.00 | 31.21 | 52.05 | 21.74 | DJ04-17 | 112.51 | 38.16 | 54.61 | 19.74 |

| DJ04-15 | 103.53 | 34.48 | 46.67 | 22.38 | DJ04-18 | 110.81 | 35.06 | 55.86 | 19.89 | |

| 15 | DJ04-19 | 107.32 | 38.08 | 46.62 | 22.62 | DJ04-22 | 113.63 | 41.19 | 52.28 | 20.16 |

| DJ04-20 | 105.70 | 37.74 | 45.03 | 22.93 | DJ04-23 | 114.52 | 43.07 | 50.73 | 20.72 | |

| 20 | DJ04-25 | 104.95 | 43.25 | 38.06 | 23.64 | DJ04-28 | 115.42 | 45.96 | 47.65 | 21.82 |

| DJ04-26 | 101.19 | 43.45 | 34.66 | 23.08 | DJ04-30 | 113.71 | 45.35 | 45.94 | 22.42 | |

| 25 | DJ04-31 | 105.68 | 51.58 | 29.50 | 24.60 | DJ04-34 | 112.66 | 49.02 | 40.98 | 22.66 |

| DJ04-33 | 105.90 | 51.12 | 30.61 | 24.17 | DJ04-35 | 112.00 | 47.93 | 40.72 | 23.36 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ping, Q.; Gao, Q.; Wu, S. Study on Mechanical Properties of Ring Sandstone Specimen under Temperature and Water Coupling Dynamic Compression. Minerals 2023, 13, 119. https://doi.org/10.3390/min13010119

Ping Q, Gao Q, Wu S. Study on Mechanical Properties of Ring Sandstone Specimen under Temperature and Water Coupling Dynamic Compression. Minerals. 2023; 13(1):119. https://doi.org/10.3390/min13010119

Chicago/Turabian StylePing, Qi, Qi Gao, and Shiwei Wu. 2023. "Study on Mechanical Properties of Ring Sandstone Specimen under Temperature and Water Coupling Dynamic Compression" Minerals 13, no. 1: 119. https://doi.org/10.3390/min13010119

APA StylePing, Q., Gao, Q., & Wu, S. (2023). Study on Mechanical Properties of Ring Sandstone Specimen under Temperature and Water Coupling Dynamic Compression. Minerals, 13(1), 119. https://doi.org/10.3390/min13010119