Research on Roof Load Transfer by Passing Coal Pillar of Working Face in Shallow Buried Closely Multiple-Seam

Abstract

1. Introduction

2. Physical Simulation Experiment

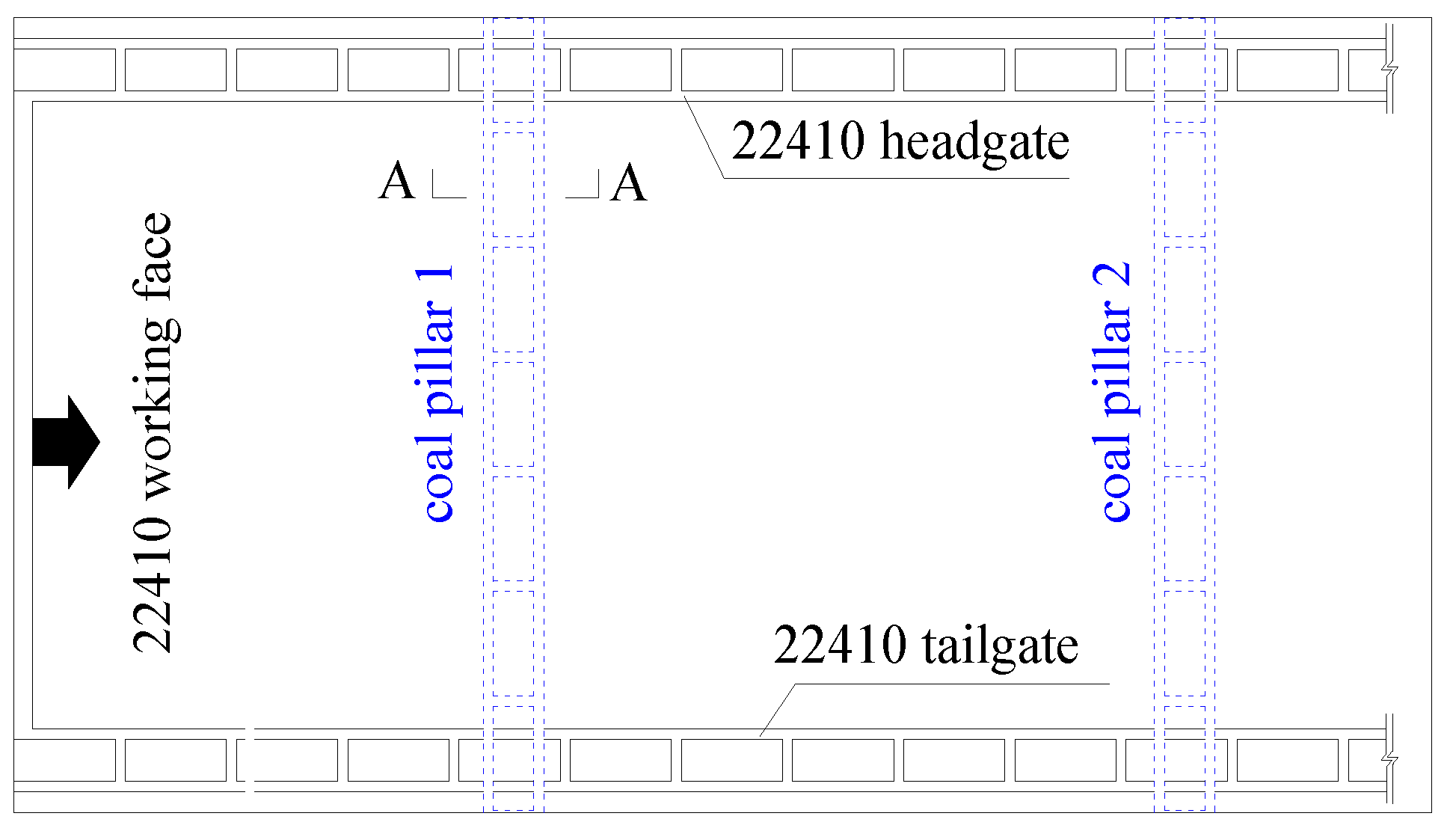

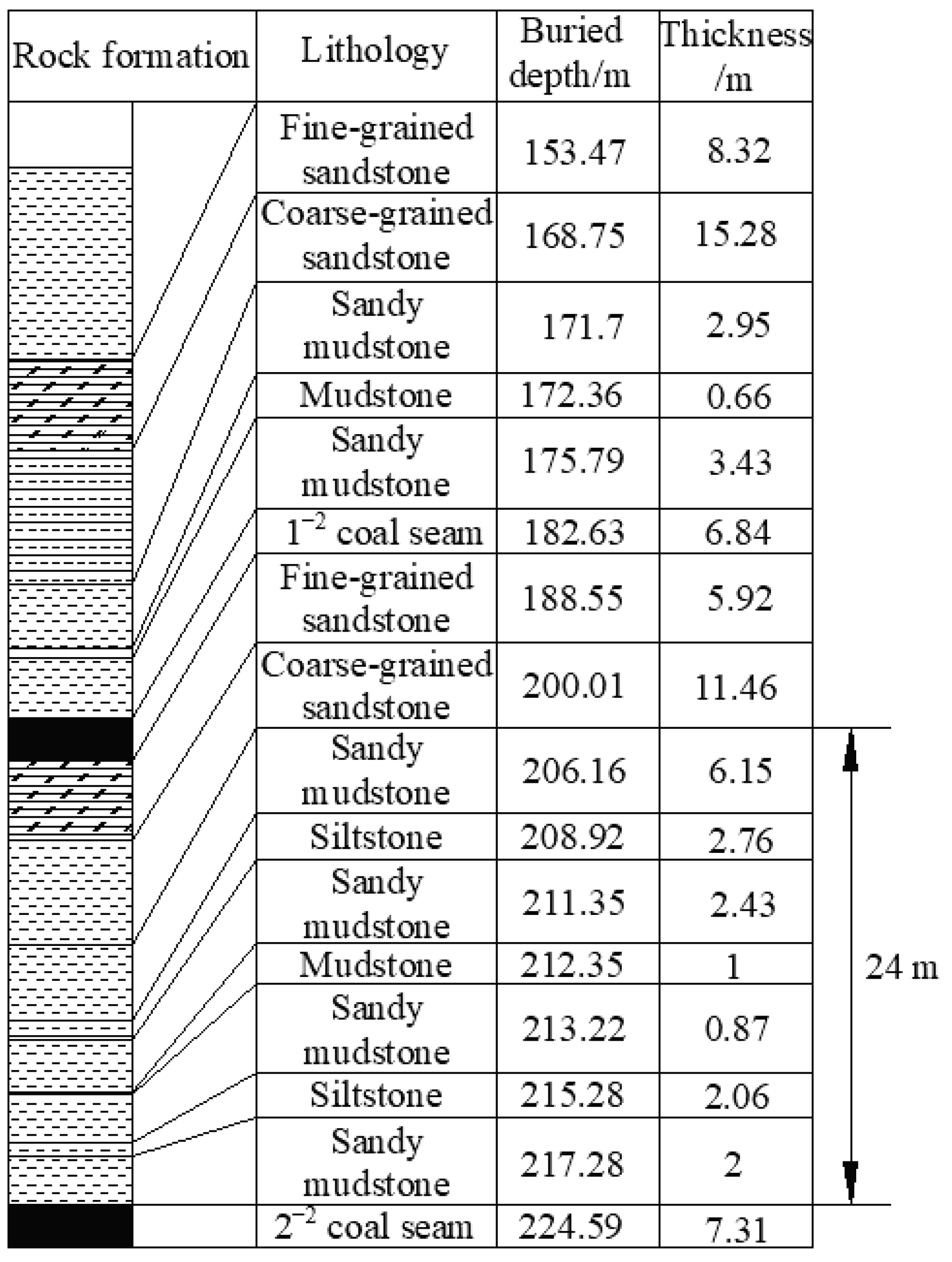

2.1. Overview of the Background

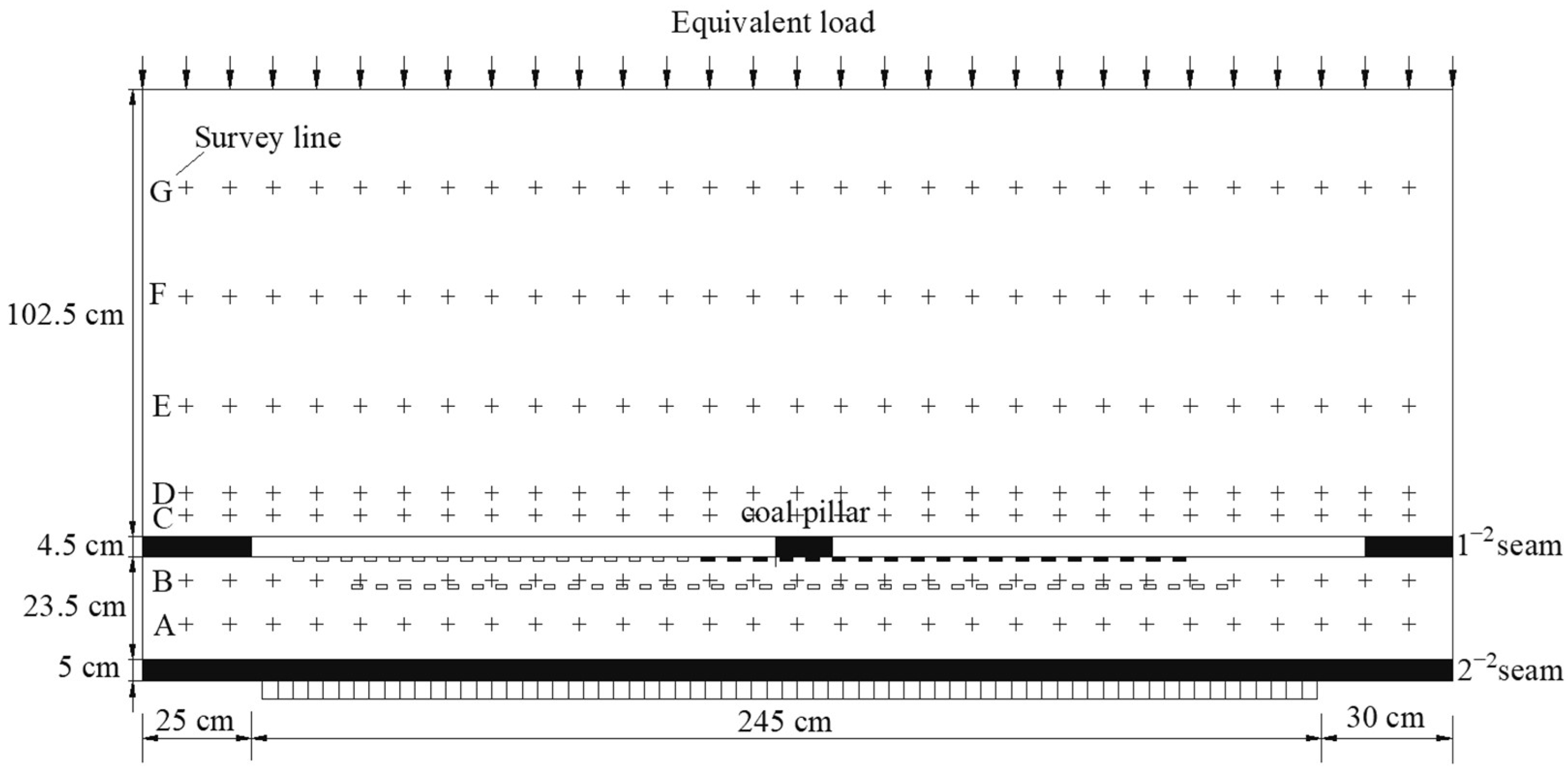

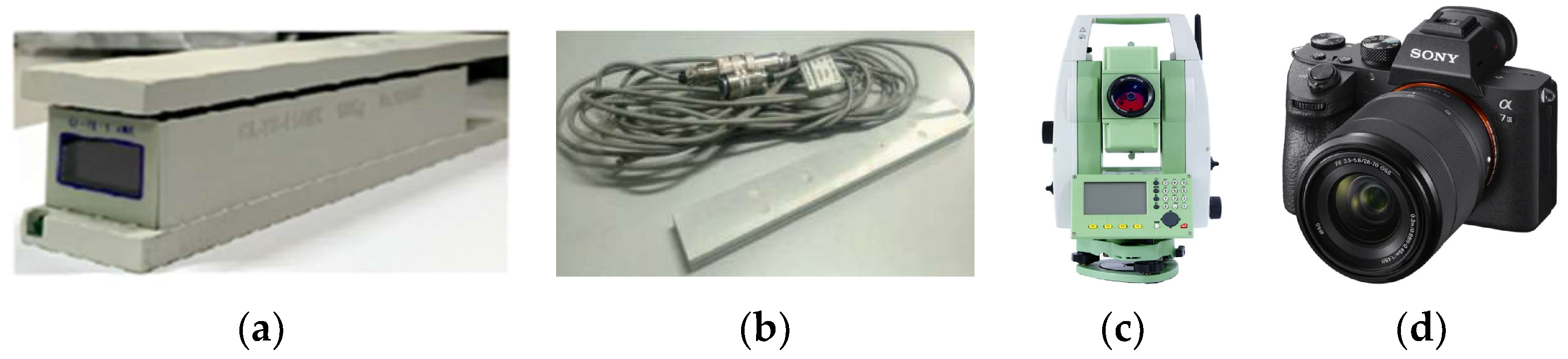

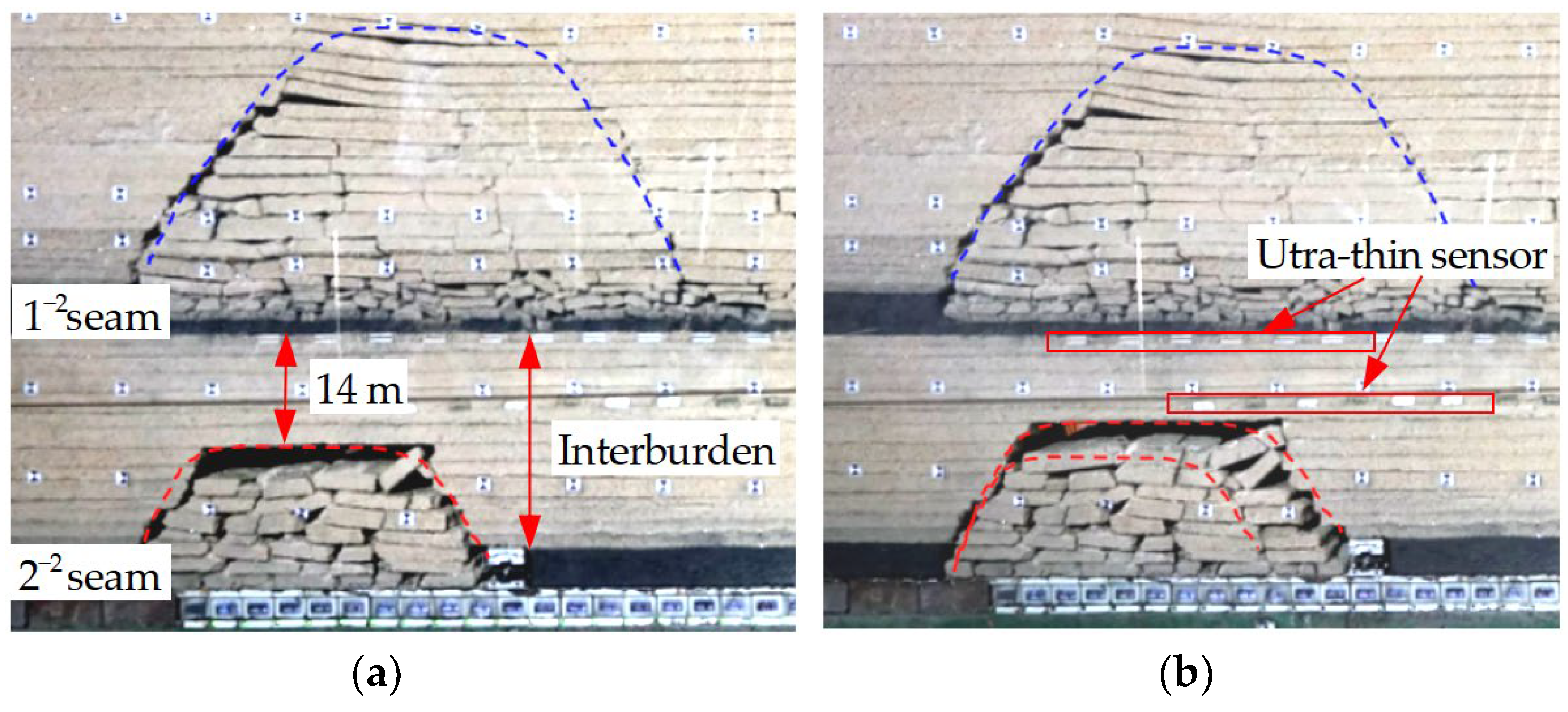

2.2. Monitoring Methods of Interburden Structure and Load Transfer

- (1)

- Fractured structure of the overburden: using fixed-point photography to obtain the fracture and structural characteristics of the overburden at different stages in the mining.

- (2)

- Used the ultra-thin pressure sensors (the thickness of ultra-thin stress sensor is 1 cm), to continuously monitor the law of dynamic load transfer during the mining process. The stress box and ultra-thin pressure sensors on the floor of the 1−2 coal seam every 3 cm to monitor the concentrated stress of the coal pillars in the goaf (Figure 3). The ultra-thin sensors every 3 cm at 5 cm below the 1−2 coal seam, to monitor the stress transfer of the interburden.

- (3)

- Used the developed wireless pressure sensor and fast data acquisition system, laying wireless pressure sensors on the floor of 2−2 coal seam to monitor the law of the FAP during the mining of the 2−2 coal seam.

- (4)

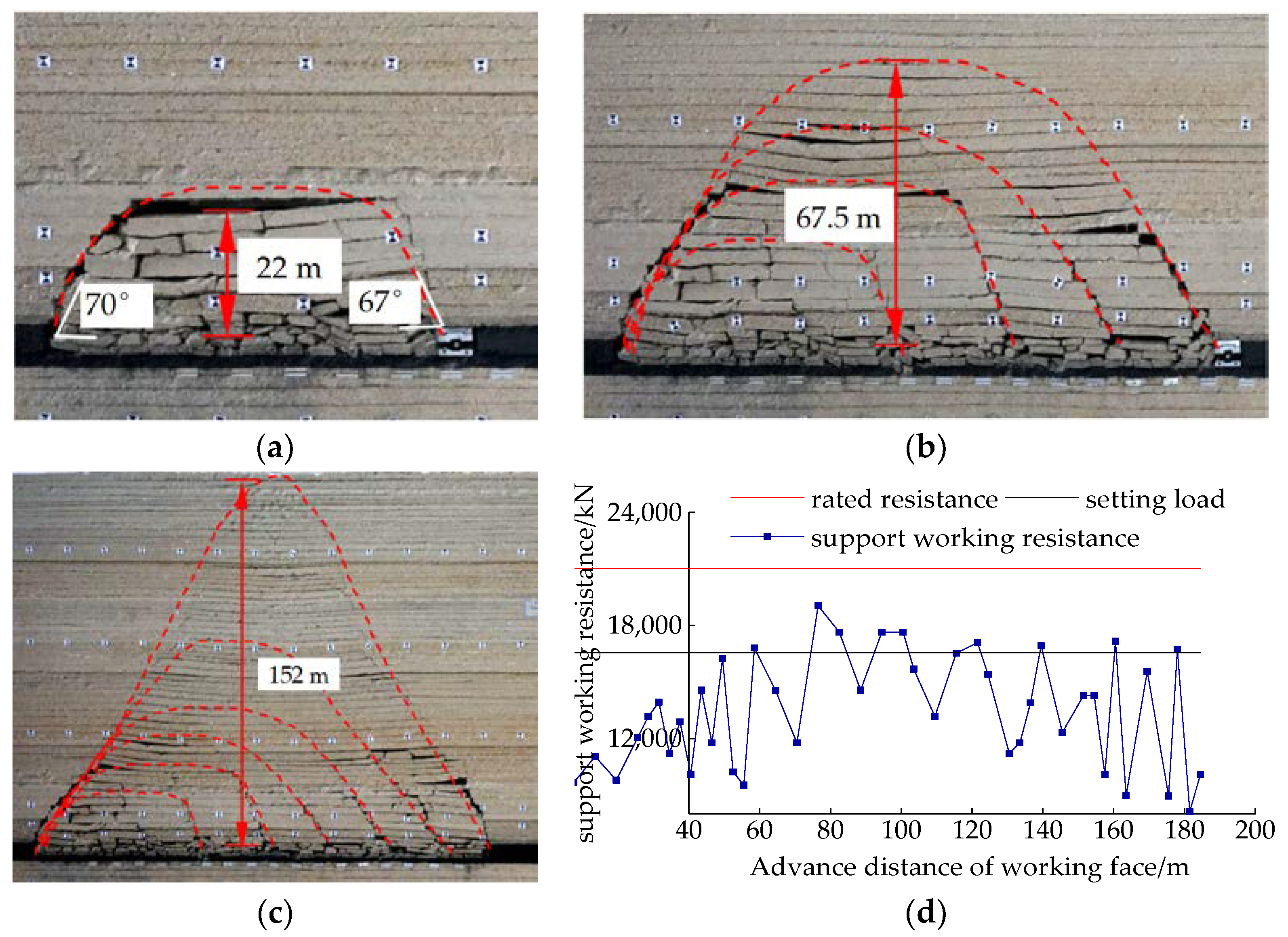

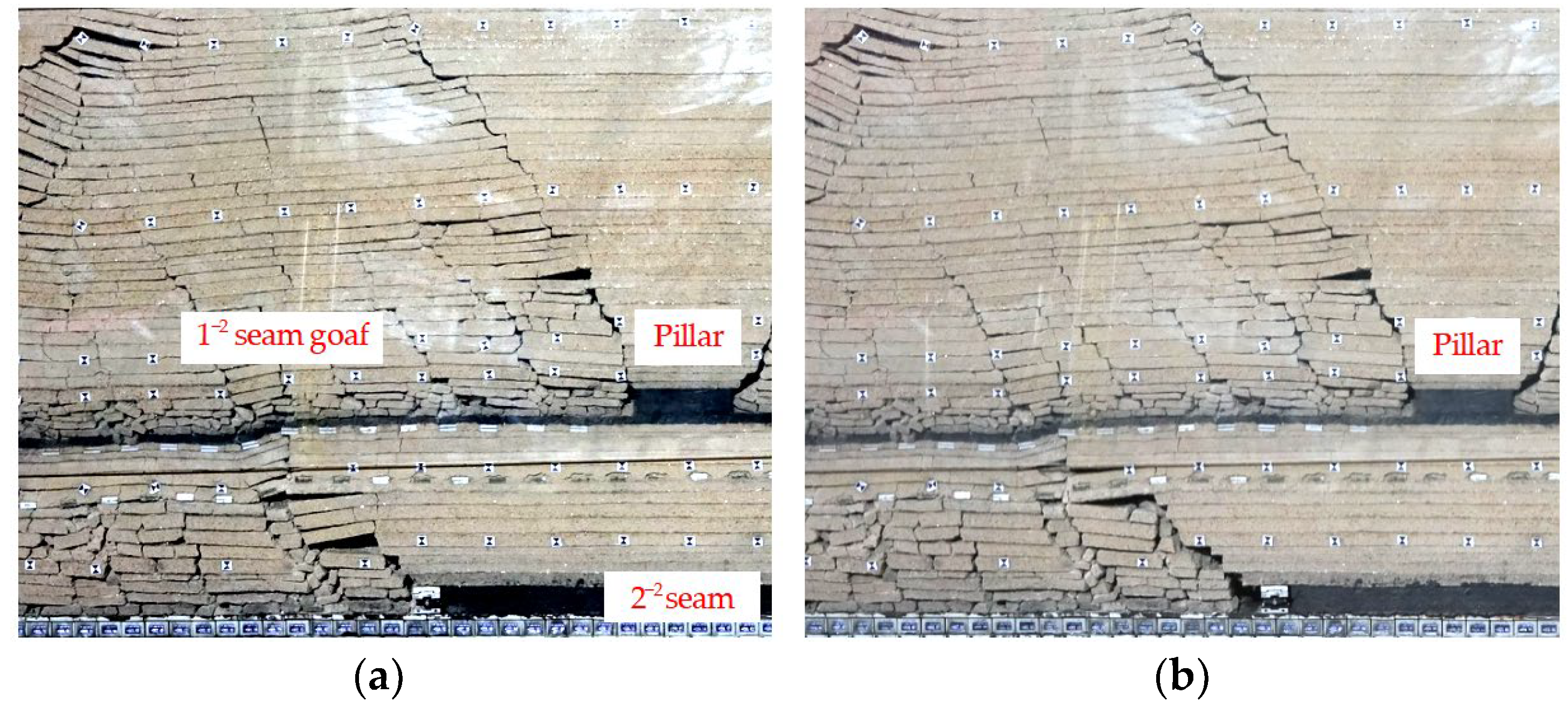

3. Overburden Characteristics of Upper Coal Seam Mining

3.1. Characteristics of Roof Caving and Weighting

3.2. Evolution of Stress Distribution in the Goaf and Coal Pillar

4. Physical Experiment of Characteristics of Interburden

4.1. During Interburden Unbroken Mining Process

4.2. When the Interburden Is Broken, Upper and Lower Goaf Are Connected

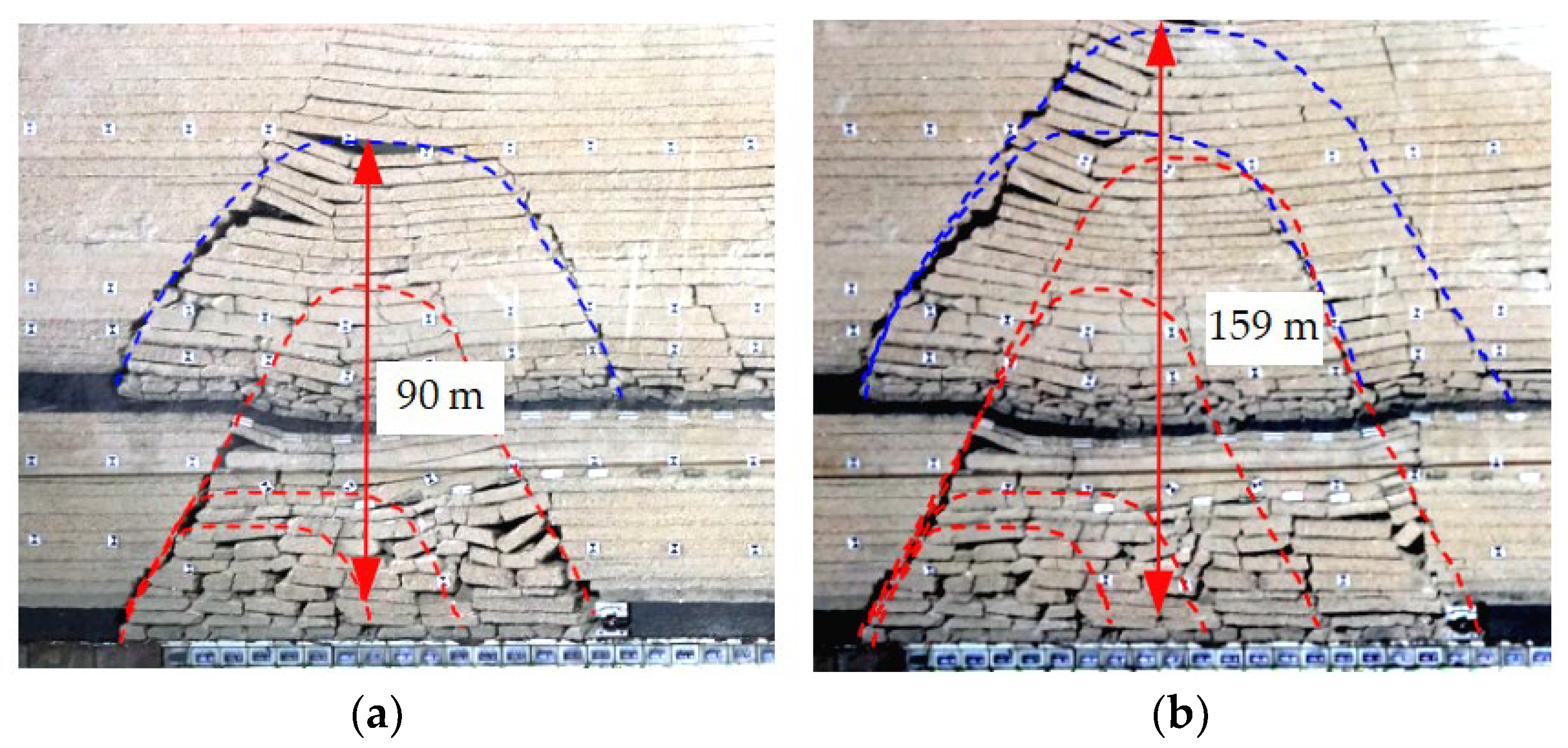

4.3. The Dynamic Load Evolution of the FAP and the 24 m Layer Stress in the Lower Seam Mining

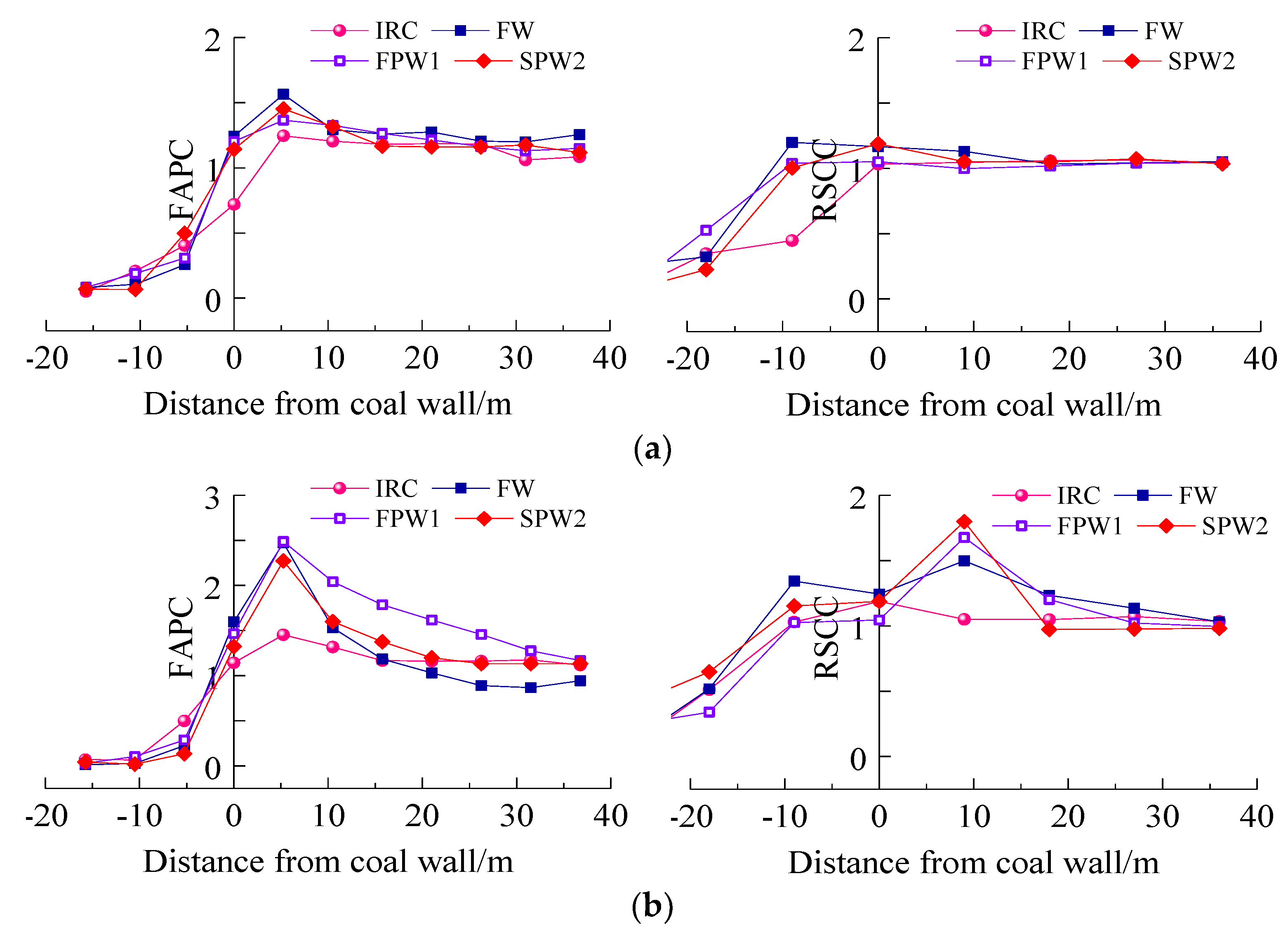

- ①

- Before the interburden unbroken: during the FW and FPW1 of the lower coal seam, the FAPC increased from 1.24 to 1.56, an increase of 26%, as shown in Figure 11a. The 24 m layer RSCC is basically equal to the original rock stress, indicating that the mining has little disturbance to the interburden. During the FW period, the roof belongs to the unloading damage, and the damage of the roof develops from the low level to the high level. Under the influence of the breaking angle, the movement of high level has a certain hysteresis compared with coal rib, but the change is not significant, as shown in Figure 11b.

- ②

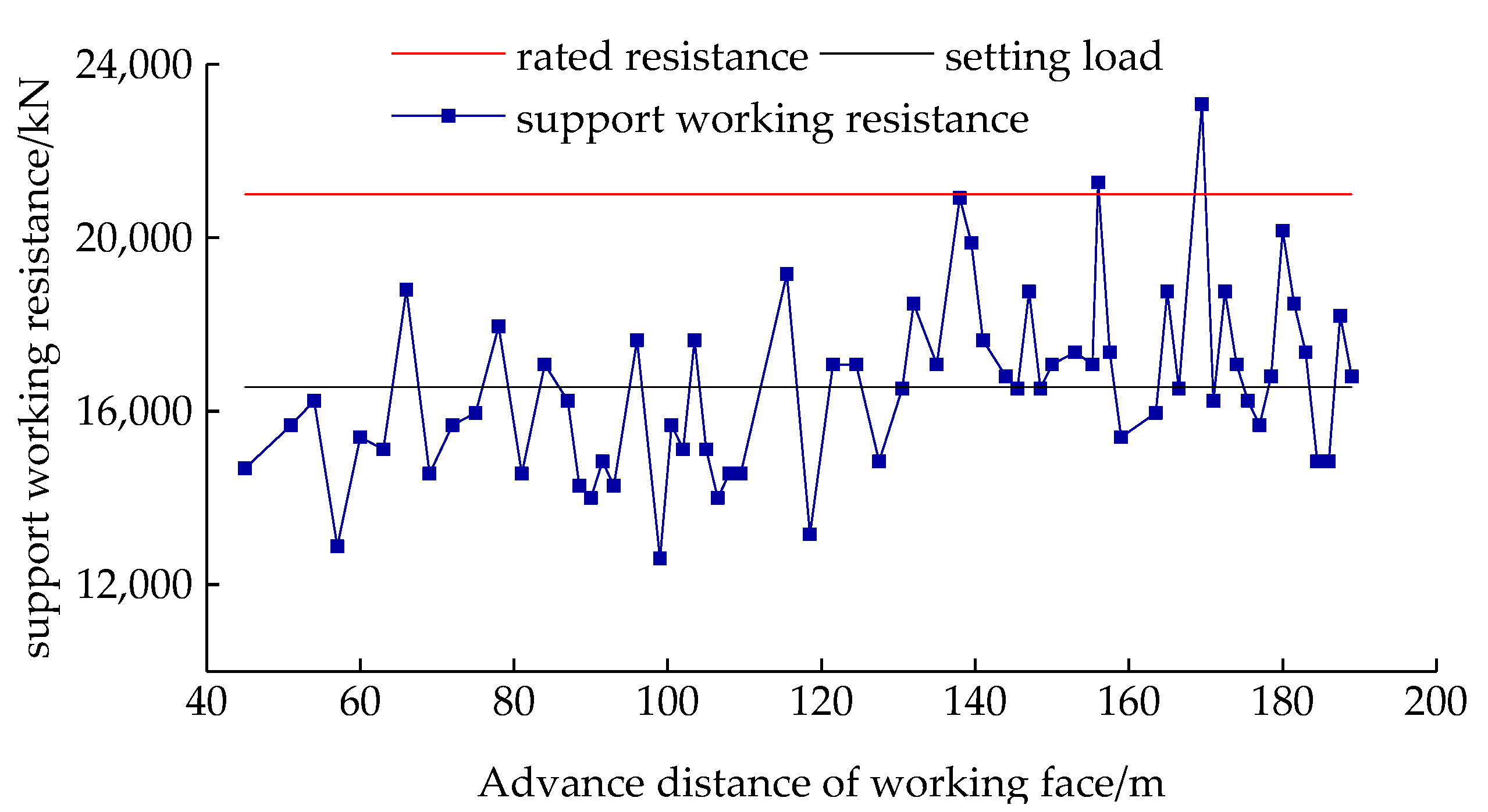

- After the interburden collapsed: in the analysis of the results from the SPW2 to FPW5, we found the FAPC increased from 1.45 to 2.47, an increase of 70.3%. The 24 m layer RSCC is increased from 1.05 to 1.80, an increase of 71.4%. It is shown that after the interburden is broken, the upper and lower goaf are connected, and the load of the collapsed roof in the upper goaf will be transmitted to the lower working face, causing the WR increase, as shown in Figure 10. Combined with the physical experiment, the WR during the SPW2 is 17,640 kN/frame, and the average WR during the TPW3 to FPW5 is 19,146 kN/frame, the WR increases by 8.5%.

- ③

- Experiment shows that during the period of weighting, the breakage of the interburden triggers the “activation” of the caved roof, which causes the FAP and WR of the working face to rise, indicating the “activation” of the roof has a load transfer effect on the lower coal seam mining. In addition, the RSCC of the interburden at the 24 m layer increased by 71.4%, and the FAPC increased by 70.3%, indicating that the load of the weighting is almost 100% transferred to the lower coal seam.

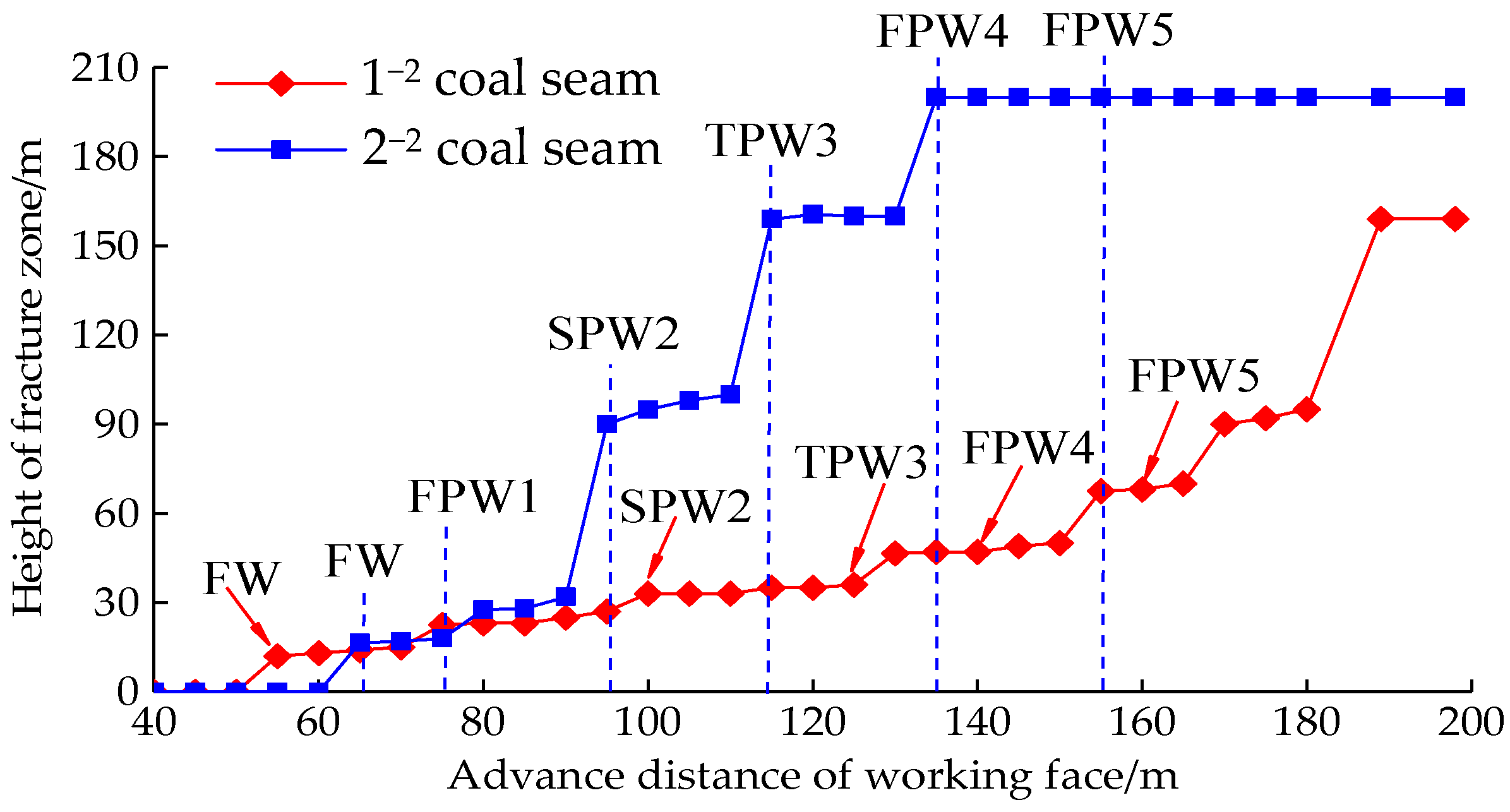

4.4. Development of the Fracture Zone

5. Concentrated Stress Transfer of Coal Pillars and Dynamic Load Characteristics of Supports

5.1. The Pressure Law of the Support at the Stage of Passing the Coal Pillar

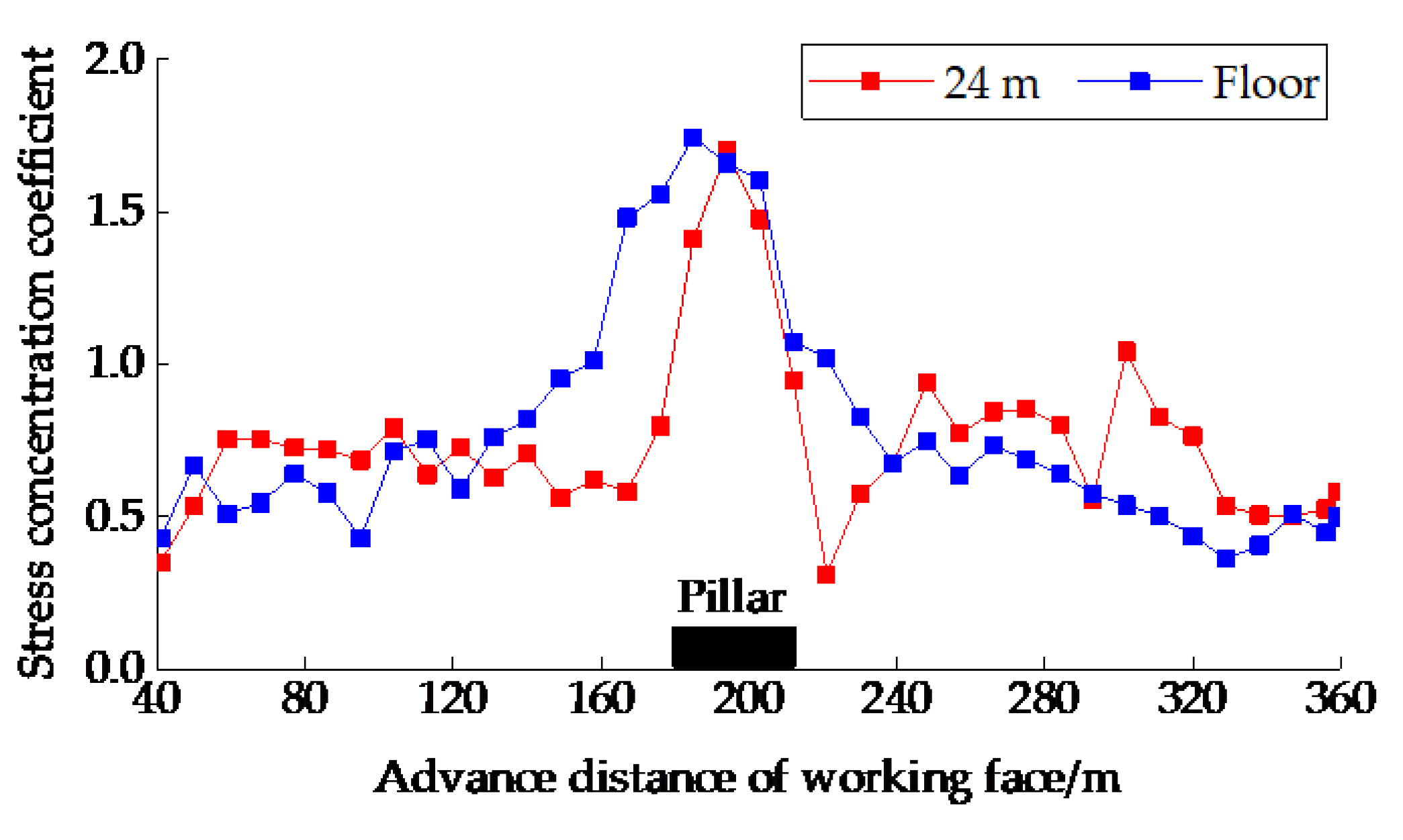

5.2. Law of FAPC and the 24 m Layer RSCC at the Stage of Passing the Coal Pillar

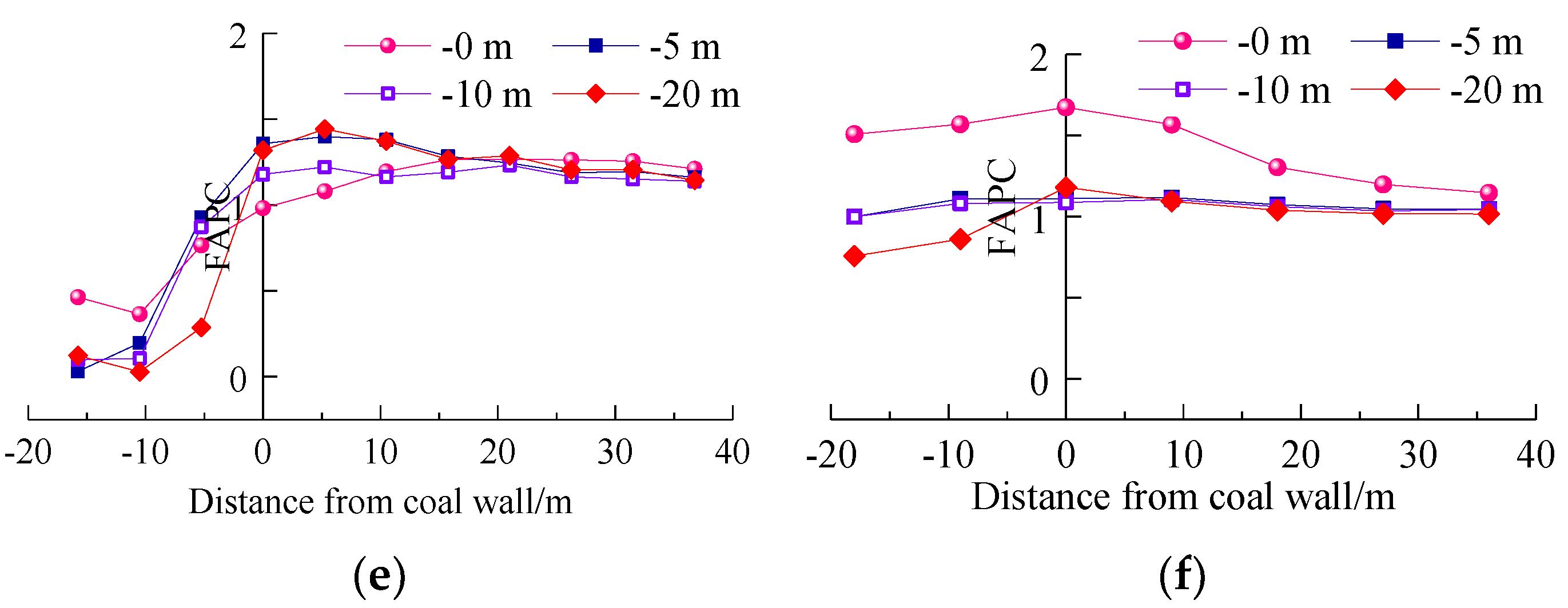

- ①

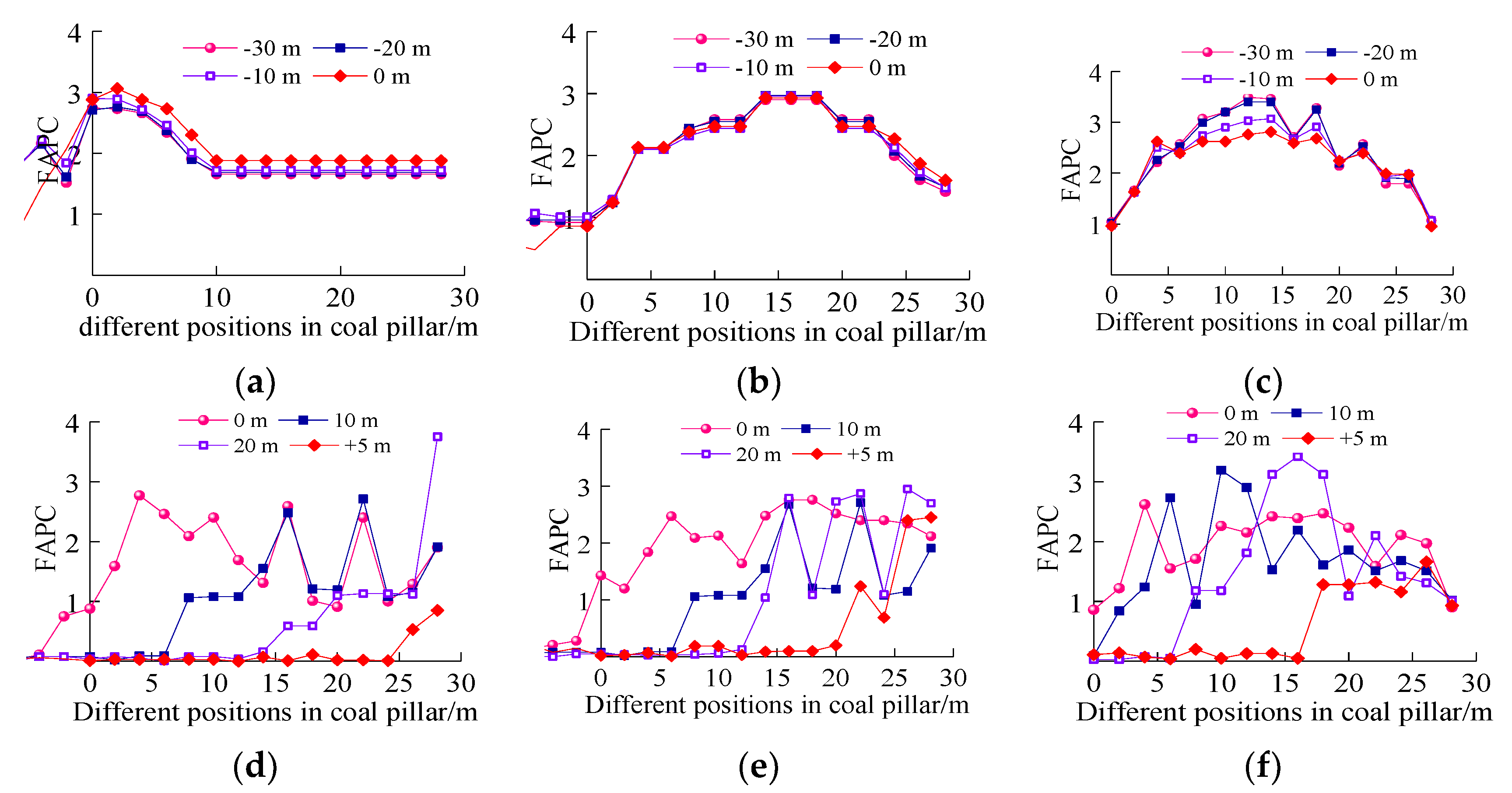

- As the working face passes the coal pillar affected area, the WR slowly increases. Comparing the 20 m before entering the coal pillar and 5 m before entering the coal pillar, the peak of FAPC decreases from 1.99 to 1.19, a decrease of 40.2%. In the range of 0~10 m behind the goaf, the 24 m layer RSCC began to increase, and the peak of 24 m layer RSCC increased from 1.15 to 1.53, an increase of 33%, as shown in Figure 15a,b.

- ②

- During the working face enters 2/3 the width of the coal pillar process, the WR of the support is reduced; comparing the 0 m into the coal pillar and the 3 m before the coal pillar, the FAPC remains basically unchanged. The peak of FAPC at the rear 10 m increased significantly, from 0.27 to 1.19, an increase of 40.2%. In the range of 0~10 m behind the goaf, the 24 m layer RSCC increased from 1.15 to 1.53, an increase of 33%, as shown in Figure 15a–d. At this time, the overall distribution of the FAPC and the RSCC of 24 m layer is increasing.

- ③

- During the peak area of the WR; comparing the 12 m coal pillar entering and 3 m before the coal pillar, the FAPC decreases from 1.22 to 0.57, a decrease of 53.3%. The peak of 24 m layer RSCC increased from 0.99 to 2.13, an increase of 115%, as shown in Figure 15c–f. It shows that during the coal pillar stage, the FAPC is reduced, the 24 m layer RSCC is increased, and the load of the interburden is increased, which is the main reason for the increase of the WR.

- ④

- When the working face passes the coal pillar, the WR slowly decreases. Comparing the coal pillar 0~20 m, the FAPC increases from 1.08 to 1.44, an increase of 33.3%, the 24 m layer RSCC is reduced from 1.6 to 1.09, a decrease of 31.9%. We compare past the coal pillar 5 m and 20 m, the FAPC and RSCC basically remain unchanged, as shown in Figure 15e,f. It needs to be dealt with in production practice, we should reduce the sinking space and the weighting interval of key stratum, make better use of the self-supporting capacity of surrounding rock and reduce the pressure of the period weighting.

5.3. Load Transfer and Stress Evolution

- (1)

- Before the coal pillar (coal pillar affected area to the coal pillar boundary): FAP reduce—WR increase. Before the working face into the coal pillar −htanθ~0 m (h is the thickness of the interburden, h = 35 m; θ is the stress transmission angle, θ = 25°, htanθ = 16, in Figure 16). The stress of the coal pillar is mainly transmitted in FAP, and the FAP begins to rise significantly.

- (2)

- Entering the stage of the coal pillar (under the coal pillar): FAP increases—WR decreases. The working face enters the coal pillar 0~htanθm (approximately equal to 2/3 the width of the coal pillar). The stress transferred by the coal pillar is concentrated on the coal rib, leading to the FAP increases, and the WR decreases.

- (3)

- Out coal pillar stage (from behind the coal pillar boundary to the coal pillar affected area): WR increase—FAP reduce. When the working face is approaching the coal pillar stage, the coal pillar and overlying rotate and sink with the lower working face, and most of the stress is transferred to the roof structure behind the coal rib, resulting in the WR still being larger, and the FAP begins to decrease.

6. Numerical Simulation of Load Transfer and Stress Evolution

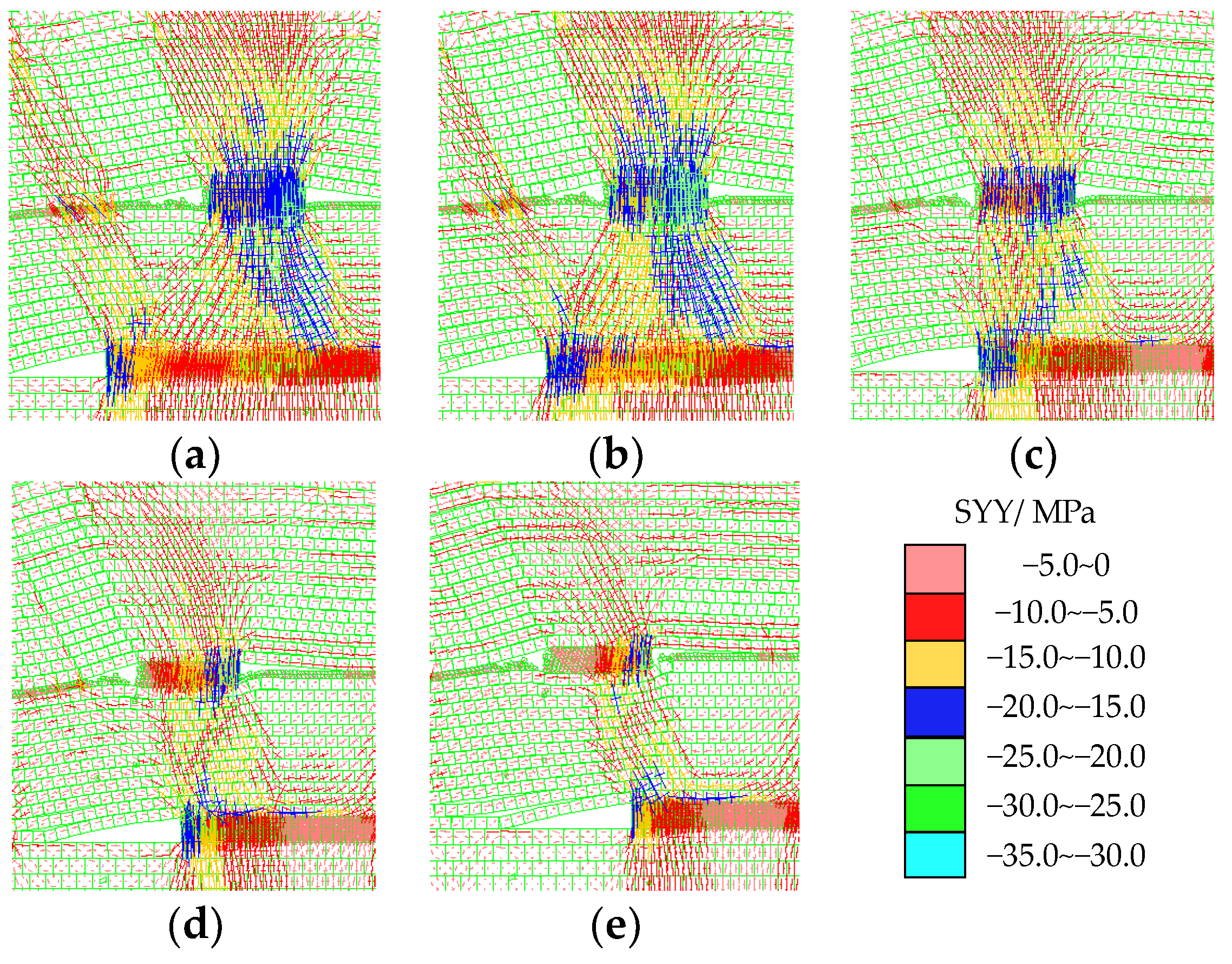

6.1. Interburden Stress by Passing the Coal Pillar

- ①

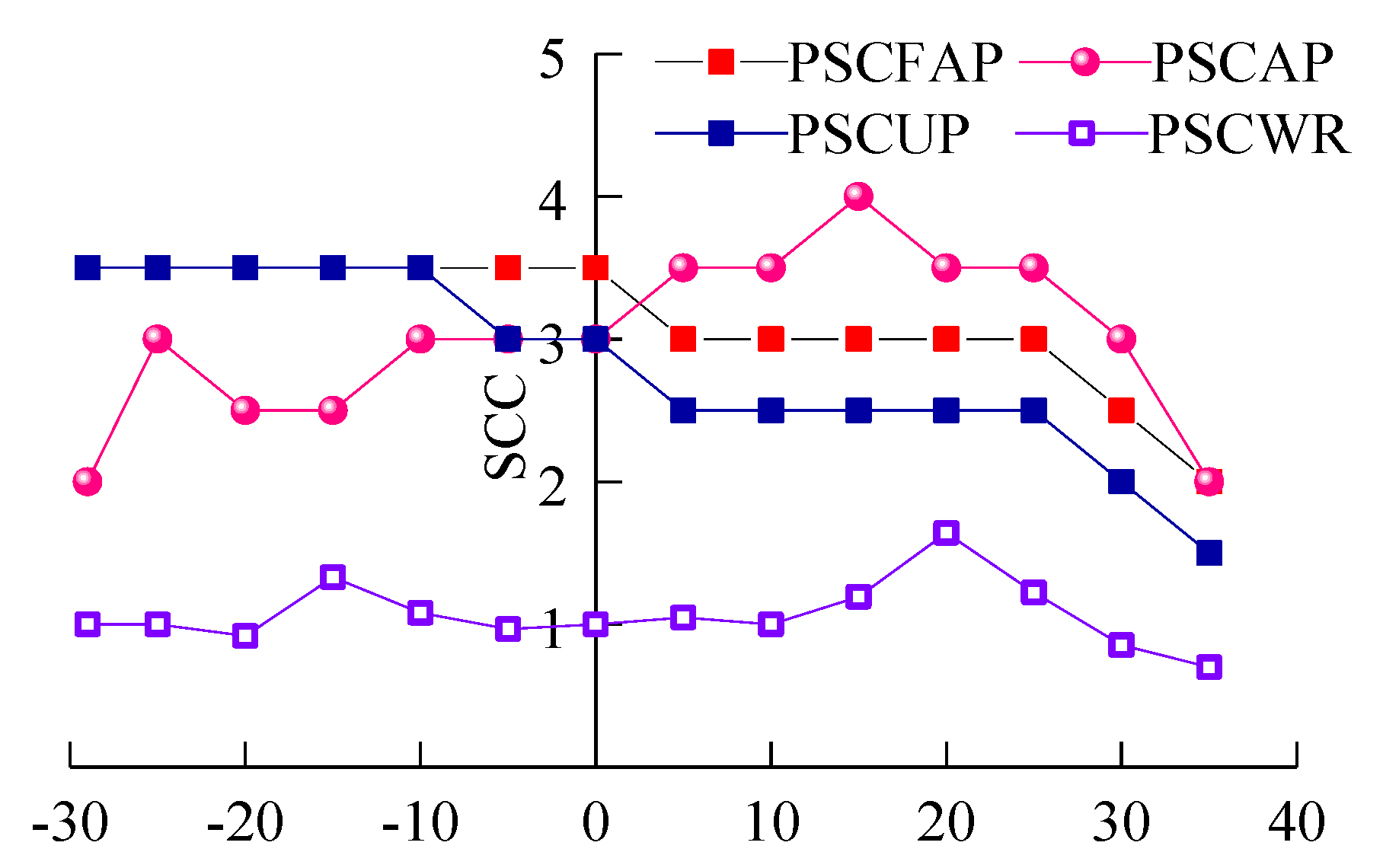

- The peak of stress concentration above the pillar (PSCAP) decreases with the advance of the working face, and the PSCAP before the coal pillar is 3.5, the PSCAP after the coal pillar 10 m is 2.0, and after the coal pillar 20 m is 0.5. It shows that in the stage of coal pillar mining, when the structure of the inverted trapezoid above the coal pillar changes, the load distribution has shifted, as shown in Figure 19. Figure 19 shows the peak of stress concentration front abutment pressure is PSCFAP, the peak of stress concentration under the pillar is PSCUP, and the peak of stress concentration of WR is PSCWR.

- ②

- Before the working face enters the coal pillar, the stress concentration above the pillar is symmetrically distributed, the mining has little effect on the stress of the coal pillar. When the working face enters the mining under the coal pillar, with the working face advances, the influence area of the coal pillar stress decreases, and the PSCAP gradually shifts to the outside of the coal pillar.

- ③

- Due to the stress concentration of the inverted trapezoidal structure of the coal pillar, in the stage of passing the coal pillar, the concentrated stress is transferred to the interburden, coal rib, and support. Combined with the characteristics of the three stages and four regions obtained, when the working face is 5 m ahead of the coal pillar, the concentrated stress of the coal pillar is transferred to the boundary of the coal pillar. At this moment, the peak of the WR reaches the maximum, and the working faces is cut by the concentrated stress contour, as shown in Figure 20.

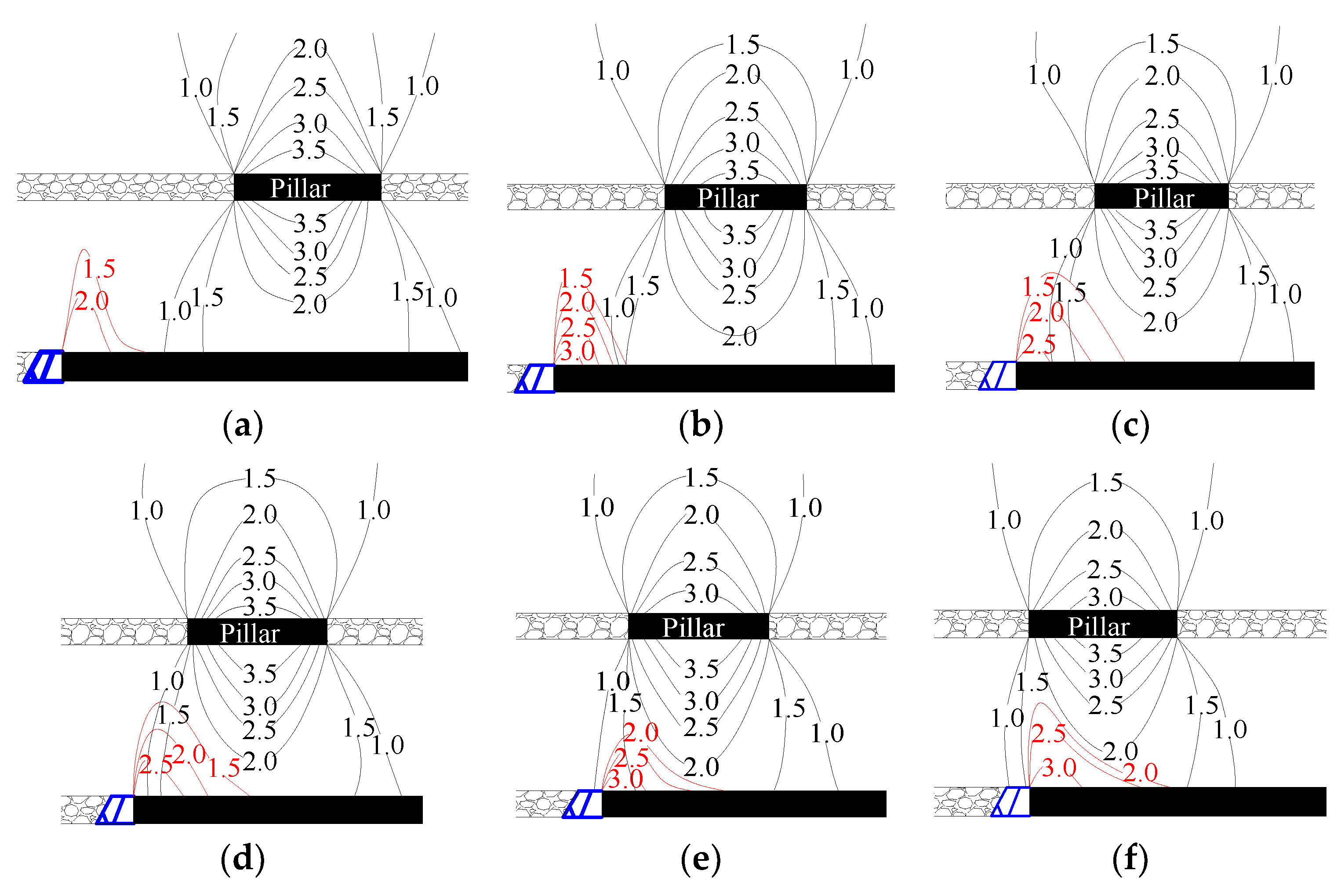

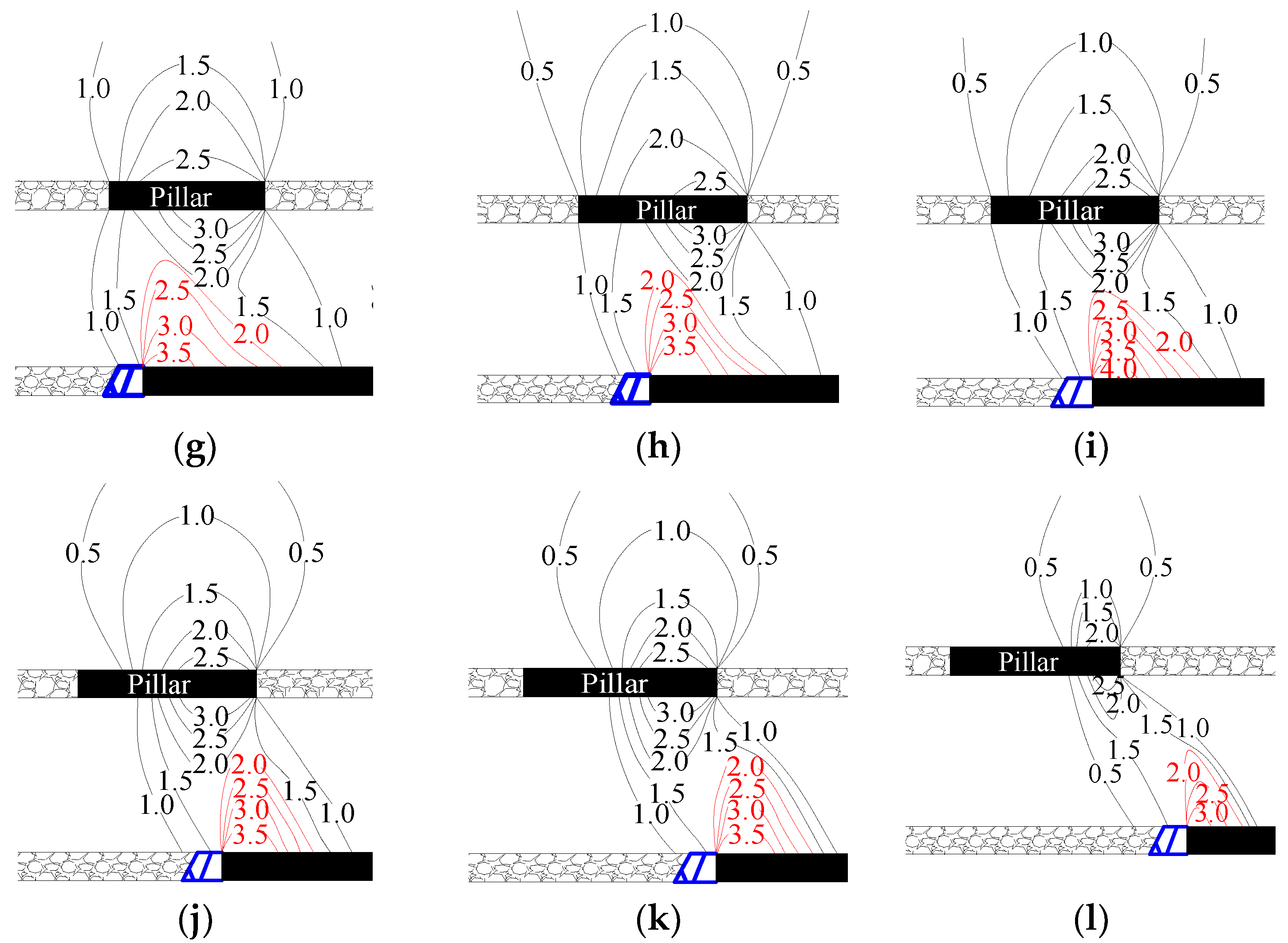

6.2. Results of Numerical Simulation

- ①

- The stress concentration in the 6 m layer mainly affects the FAP, the distribution of 14 m and 24 m layers RSCC are basically symmetrical along the center line of the coal pillar.

- ②

- Before the working face enters the coal pillar: with the decrease of the distance from the coal pillar boundary, the 6 m layer RSCC increases from 2.73 to 3.06, an increase of 12%; the 14 m layer RSCC remains basically unchanged; the 24 m layer RSCC is obviously reduced from 3.46 to 2.31, which is reduced by about 33%. It shows that before entering the coal pillar, mining will lead to a decrease in stress concentration in the upper layer of the interburden, and an increase in stress concentration in the lower layer.

- ③

- After the working face enters the coal pillar: with the different distances of the working face entering the coal pillar, the stress concentration of the roof in different layers of the interburden fluctuates greatly, indicating that the roof stress in the interval strata is redistributed. In the working face into the coal pillar 20 m (pass the coal pillar before 5 m), 6 m, and 24 m layers of the roof stress concentration fluctuations, a wide range of pressure.

7. Conclusions

- (1)

- The collapse movement of the interburden is the cause of the “activation” of the collapsed roof structure in the goaf area of the upper coal seam. The simulation found that when the interburden was broken, the FAPC increased from 1.45 to 2.47, an increase of 70.3%. It shows that the load of the collapsed roof in the upper coal seam goaf will be transmitted to the lower coal seam, causing the WR and FAP to increase, and the development height and range of activated cracks in the overlying increase stepwise.

- (2)

- During the mining of passing the inclined coal pillar, the transfer of the concentrated stress of coal pillars to the roof structure of the working face is the main reason for the strong ground pressure. The coal pillar stress has a transformation process to the FAP, the stress of the interburden, and the WR, it is divided into three stages and four areas: the stage before entering the coal pillar, the FAP reduce—WR increase; entering the stage of the middle stage of the coal pillar, FAP increase—WR reduce, and the peak of FAP—WR rises conversion area; out the coal pillar stage, WR increase—FAP reduce.

- (3)

- Through numerical calculation and analysis, before entering the coal pillar, the stress contour above the coal pillar is symmetrically distributed; as the working face advances, the area affected by the coal pillar stress decreases, the peak of the coal pillar stress shifts to the outside of the coal pillar, and the peak value of the stress concentration factor above the coal pillar decreases. When the working face is 5 m away from the coal pillar, the peak of the supporting stress in front of the coal rib reaches the maximum, and the peak value of the FAP reaches the maximum. When the working face is cutting along the concentrated stress contour, it has a strong ground pressure appears on the working face.

- (4)

- Before entering the coal pillar, mining will lead to the reduction of the stress concentration in the higher layer of the interburden formation, and the increase of the stress concentration in the lower layer. After entering the coal pillar: the roof stress of the different layers of the interburden fluctuates greatly. As the working face enters 20 m under the coal pillar (5 m before the coal pillar), the roof stress concentration of the 6 m and 24 m layers fluctuates greatly, and the working face is expected to occur movement in a wide range.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Q.; He, Y.; Cao, J. Experimental investigation on Cracks Development Characteristics in Shallow Coal Seam Mining, China. Energies 2019, 12, 1302. [Google Scholar] [CrossRef]

- Huang, Q.; Du, J.; Chen, J.; He, Y. Coupling control on pillar stress concentration and surface cracks in shallow multi-seam mining. Int. J. Min. Sci. Technol. 2021, 31, 95–101. [Google Scholar] [CrossRef]

- Fiscor, S. 2020 US longwall census. Coal Age 2020, 1, 16–18. [Google Scholar]

- Peng, S. Longwall Mining, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Holla, L.; Buizen, M. The ground movement, strata fracturing and changes in permeability due to deep longwall mining. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1991, 28, 207–217. [Google Scholar] [CrossRef]

- Sadasivam, S.; Thomas, H.; Zagorscak, R.; Davies, T.; Price, N. Baseline geochemical study of the Aberpergwm mining site in the South Wales Coalfield. J. Geo. Exlpor. 2019, 202, 100–112. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Analysis of the influence of dynamic load on the work parameters of a powered roof support’s hydraulic leg. Sustainability 2019, 11, 2570. [Google Scholar] [CrossRef]

- Ritesh, L.D.; Murthy, V.; Kalendra, S. Semi-empirical model for predicting pot-hole depth in underground coal mining. Curr. Sci. 2018, 115, 1761–1769. [Google Scholar] [CrossRef]

- Maleki, H. Coal pillar mechanics of violent failure in U.S. Mines. Int. J. Min. Sci. Technol. 2017, 27, 387–392. [Google Scholar] [CrossRef]

- Singh, R.; Mandal, P.K.; Singh, A.K.; Kumar, R.; Maiti, J.; Ghosh, A.K. Upshot of strata movement during underground mining of a thick coal seam below hilly terrain. Int. J. Rock Mech. Min. Sci. 2008, 45, 29–46. [Google Scholar] [CrossRef]

- Bryan, A.; Bryan, J.; Fouche, J. Some problems of strata control and support in pillar workings. Min. Eng. 1966, 123, 238–254. [Google Scholar]

- Haycocks, C.; Ehgartner, B.; Karmis, M. Pillar Load Transfer Mechanisms in Multiple-Seam Mining; Society for Mining, Metallurgy, and Exploration, Inc.: Littleton, CO, USA, 1982; pp. 69–82. [Google Scholar]

- Poulsen, B. Coal pillar load calculation by pressure arch theory and near field extraction ratio. Int. J. Rock Mech. Min. Sci. 2010, 47, 1158–1165. [Google Scholar] [CrossRef]

- Singh, R.; Sheorey, P.; Singh, D. Stability of the parting between coal pillar workings in level contiguous seams. Int. J. Rock Mech. Min. Sci. 2002, 39, 9–39. [Google Scholar] [CrossRef]

- Guy, R.; Kent, M.; Russell, F. An assessment of coal pillar system stability criteria based on a mechanistic evaluation of the interaction between coal pillars and the overburden. Int. J. Min. Sci. Technol. 2017, 27, 9–15. [Google Scholar]

- Das, A.; Mandal, P.; Paul, P.; Sinha, R. Generalised analytical models for the strength of the inclined as well as the flat coal pillars using rock mass failure criterion. Rock Mech. Rock Eng. 2019, 52, 3921–3946. [Google Scholar] [CrossRef]

- Frith, R.; Reed, G. Limitations and potential design risks when applying empirically derived coal pillar strength equations to real-life mine stability problems. Int. J. Min. Sci. Technol. 2018, 29, 17–25. [Google Scholar] [CrossRef]

- Quang, P.; Zubov, V.; Duc, T. Design a reasonable width of coal pillar using a numerical model. A case study of Khe Cham basin, Vietnam. In Proceedings of the Fifth International Innovative Mining Symposium, Kemerovo, Russia, 19–21 October 2020; Volume 174, p. 01043. [Google Scholar]

- Yang, J. Dynamic pressure prevention and control technology of coal mining face with shallow depth and contiguous seams passing through overburden goaf and coal pillars. Coal Sci. Technol. 2015, 43, 9–13+40. [Google Scholar] [CrossRef]

- Rashed, G.; Mohamed, K.; Kimutis, R. A coal rib monitoring study in a room-and-pillar retreat mine. Int. J. Min. Sci. Technol. 2021, 31, 127–135. [Google Scholar] [CrossRef]

- Tuncay, D.; Tulu, I.; Klemetti, T. Re-analysis of abutment angle method for moderate and deep cover retreat room and pillar mines and investigation of loading mechanics using finite volume modeling. Rock Mech. Rock Eng. 2021, 54, 3447–3468. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, L.; Zhou, Z.; Shen, B.; Xu, Y. Failure Propagation of Pillars and Roof in a Room and Pillar Mine Induced by Longwall Mining in the Lower Seam. Rock Mech. Rock Eng. 2019, 52, 1193–1209. [Google Scholar] [CrossRef]

- Huang, Q.; Qian, M.; Shi, P. Structural analysis of main roof stability during periodic weighting in longwall face. J. China Coal Soc. 1999, 24, 581–585. [Google Scholar]

- Huang, Q. Study on loading distribution law on key roof and its structure upon mining face under thick sandy horizon. J. China Univ. Min. Technol. 2005, 34, 289–293. [Google Scholar]

- Huang, Q. Experimental research of overburden movement and subsurface water seeping in shallow seam mining. J. Uni. Sci. Technol. Beijing 2007, 14, 483–489. [Google Scholar] [CrossRef]

- Cao, J.; Huang, Q. Roof structure of shallow coal seam group mining in Western China. PLoS ONE 2021, 16, e0255047. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Zhou, J.; Cao, J. Key Stratum structure and support working resistance of longwall face with large mining height in the shallow coal Seams, China. Adv. Civ. Eng. 2020, 2020, 8834403. [Google Scholar] [CrossRef]

- He, Y.; Huang, Q. Research on roof structure and determination of working resistance of shallow buried single key stratum based on grid-drillhole field method. Lithosphere 2022, 4, 4328618. [Google Scholar] [CrossRef]

- Ju, J.; Xu, J. Surface stepped subsidence related to top-coal caving longwall mining of extremely thick coal seam under shallow cover. Int. J. Rock Mech. Min. Sci. 2015, 78, 27–35. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, W.; Wang, X.; Zhang, Z. Influencing mechanism of gully terrain on ground pressure behaviors in shallow seam longwall mining. J. China Coal Soc. 2012, 37, 179–185. [Google Scholar]

- Xu, J.; Zhu, W.; Ju, J. Supports crushing types in the longwall mining of shallow seams. J. China Coal Soc. 2014, 39, 1625–1634. [Google Scholar]

- Li, X.; Chen, S.; Wang, S. Study on in situ stress distribution law of the deep mine taking Linyi Mining area as an example. Adv. Mater. Sci. Eng. 2021, 9, 5594181. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, B.; Li, X. Research on roof damage mechanism and control technology of gob-side entry retaining under close distance gob. Eng. Fail. Anal. 2022, 138, 106331. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Qin, Q. Study on surrounding rock control and support stability of ultra-large height mining face. Energies 2022, 15, 6811. [Google Scholar] [CrossRef]

- Dong, H.; Zhu, W.; Hou, C.; Liu, X. Load transfer behavior during cascading pillar failure: An experimental study. Rock Mech. Rock Eng. 2022, 55, 1445–1460. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, L.; Yang, D.; Jiang, B. Dynamic loading effect of support while roof cutting in shallow coal seam mining. J. China Coal Soc. 2017, 42, 322–327. [Google Scholar]

- Yang, D.; Chen, Z.; Hong, Q.; Zang, S. Catastrophic analysis of support crushing disasters while roof cutting in shallow seam mining. J. Min. Saf. Eng. 2016, 33, 122–127+133. [Google Scholar]

- Zhu, W.B.; Xu, J.M.; Li, Y.C. Mechanism of the dynamic pressure caused by the instability of upper chamber coal pillars in Shendong coalfield, China. Geosci. J. 2017, 21, 729–741. [Google Scholar] [CrossRef]

- Feng, J.; Zhou, Y.; Zhang, K.; Xu, Y.; Li, H. Fracture characteristics of thick key stratum and calculation of shield work load under multiple coal seam mining gobs with shallow depth. J. Min. Saf. Eng. 2018, 35, 332–338. [Google Scholar]

- Yu, D.; Yi, X.; Liang, Z.; Lou, J.; Zhu, W. Research on Strong Ground Pressure of Multiple-Seam Caused by Remnant Room Pillars Undermining in Shallow Seams. Energies 2021, 14, 5221. [Google Scholar] [CrossRef]

| Lithology | Geological Thickness /m | Model Thickness /cm | Model Cumulative Thickness/cm | Proportion | Consumables/kg/cm | ||

|---|---|---|---|---|---|---|---|

| River Sand | Gypsum | White Powder | |||||

| Drift sand | 22.33 | 16 | 151.5 | 919 | 8.64 | 0.10 | 0.86 |

| Sandy mudstone | 15.6 | 10.5 | 135.5 | 928 | 8.64 | 0.19 | 0.77 |

| Mudstone | 4.26 | 3 | 125 | 937 | 8.64 | 0.29 | 0.67 |

| Sandy mudstone | 28.06 | 18.5 | 122 | 928 | 8.64 | 0.19 | 0.77 |

| Fine-grainednsandstone | 4.87 | 3.5 | 103.5 | 837 | 8.53 | 0.32 | 0.75 |

| Sandy mudstone | 5.41 | 3.5 | 100 | 928 | 8.64 | 0.19 | 0.77 |

| Fine-grained sandstone | 6.37 | 4.5 | 96.5 | 837 | 8.53 | 0.32 | 0.75 |

| Sandy mudstone | 9.97 | 6.5 | 92 | 928 | 8.64 | 0.19 | 0.77 |

| Mudstone | 1.6 | 1 | 85.5 | 937 | 8.64 | 0.29 | 0.67 |

| Sandy mudstone | 11.77 | 7.5 | 84.5 | 928 | 8.64 | 0.19 | 0.77 |

| Mudstone | 4.32 | 3 | 77 | 937 | 8.64 | 0.29 | 0.67 |

| Sandy mudstone | 30.59 | 20.5 | 74 | 928 | 8.64 | 0.19 | 0.77 |

| Fine-grained sandstone | 8.32 | 5.5 | 53.5 | 837 | 8.53 | 0.32 | 0.75 |

| Coarse-grained sandstone | 15.28 | 10.5 | 48 | 828 | 8.53 | 0.21 | 0.85 |

| Sandy mudstone | 7.04 | 4.5 | 37.5 | 928 | 8.64 | 0.19 | 0.77 |

| 1−2 coal seam | 6.84 | 4.5 | 33 | 20:1:5:20 | 5.09 | 0.25 | 1.27 |

| Fine-grained sandstone | 5.92 | 4 | 28.5 | 837 | 8.53 | 0.32 | 0.75 |

| Coarse-grained sandstone | 11.46 | 7.5 | 24.5 | 828 | 8.53 | 0.21 | 0.85 |

| Sandy mudstone | 6.15 | 4 | 17 | 928 | 8.64 | 0.19 | 0.77 |

| Siltstone | 2.76 | 2 | 13 | 937 | 8.64 | 0.29 | 0.67 |

| Sandy mudstone | 4.3 | 3 | 11 | 928 | 8.64 | 0.19 | 0.77 |

| Mudstone | 2.06 | 1.5 | 8 | 937 | 8.64 | 0.29 | 0.67 |

| Sandy mudstone | 2 | 1.5 | 6.5 | 928 | 8.64 | 0.19 | 0.77 |

| 2−2 coal seam | 7.31 | 5 | 5 | 20:1:5:20 | 5.09 | 0.25 | 1.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Huang, Q.; Wei, Y.; Du, J. Research on Roof Load Transfer by Passing Coal Pillar of Working Face in Shallow Buried Closely Multiple-Seam. Minerals 2023, 13, 118. https://doi.org/10.3390/min13010118

He Y, Huang Q, Wei Y, Du J. Research on Roof Load Transfer by Passing Coal Pillar of Working Face in Shallow Buried Closely Multiple-Seam. Minerals. 2023; 13(1):118. https://doi.org/10.3390/min13010118

Chicago/Turabian StyleHe, Yanpeng, Qingxiang Huang, Yehao Wei, and Junwu Du. 2023. "Research on Roof Load Transfer by Passing Coal Pillar of Working Face in Shallow Buried Closely Multiple-Seam" Minerals 13, no. 1: 118. https://doi.org/10.3390/min13010118

APA StyleHe, Y., Huang, Q., Wei, Y., & Du, J. (2023). Research on Roof Load Transfer by Passing Coal Pillar of Working Face in Shallow Buried Closely Multiple-Seam. Minerals, 13(1), 118. https://doi.org/10.3390/min13010118