Recovery of Rare Earth Elements Minerals in Complex Low-Grade Saprolite Ore by Froth Flotation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ore Characterization

2.3. Bulk Froth Flotation

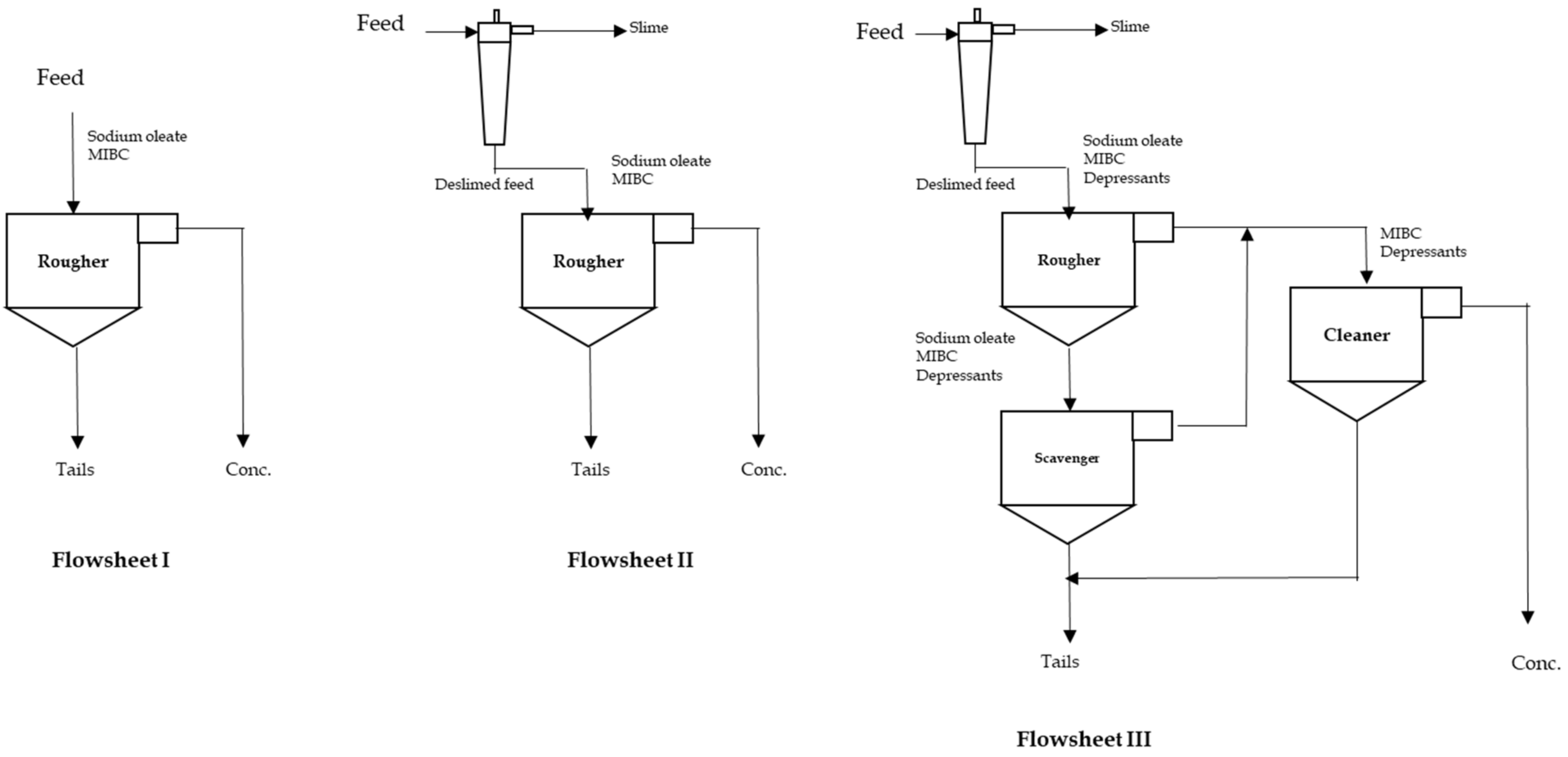

- Flowsheet I: Direct flotation tests were conducted at pulp pH 9 and 10.5 in a single-stage rougher flotation test using 3000 g/t sodium oleate. This was to assess the flotation response of REE and gangue species at pH 9, which has been widely reported in the literature to be suitable for REE recovery using fatty acids as collectors [22,23,24]. Pulp pH 10.5 was selected to assess the feasibility of recovering REE minerals as a by-product of gold leaching, which is typically carried out at pH range of 10–11 [25,26,27].

- Flowsheet II: In this process, the feed was deslimed and subsequently floated at pH 9 and 10.5 in the absence of sodium silicate and starch as depressants, respectively. This was performed with the view of selectively rejecting a significant proportion of the gangue minerals, which were reported into the flotation concentrates generated when Flowsheet I was tested. The aim of this process was to assess the relevance of desliming stage in the recovery of REE minerals in the ore.

- Flowsheet III: A rougher-scavenger-cleaner method was tested on deslimed feed at pulp pH 9 and 10.5 in the presence of depressants to assess any chance of improving REE mineral selectivity. The process commenced with a rougher flotation stage, where 5000 g/t sodium oleate was used in the presence of 1500 g/t sodium silicate and 1500 g/t starch, followed by the scavenging of the rougher tailings. In the final step, the rougher and scavenger concentrates were combined and cleaned with 1500 g/t sodium silicate and 1500 g/t starch.

3. Results

3.1. Physicochemical Characteristics of the Ore

3.1.1. Particle Size Distribution

3.1.2. Chemical Composition

3.1.3. Mineralogical Composition

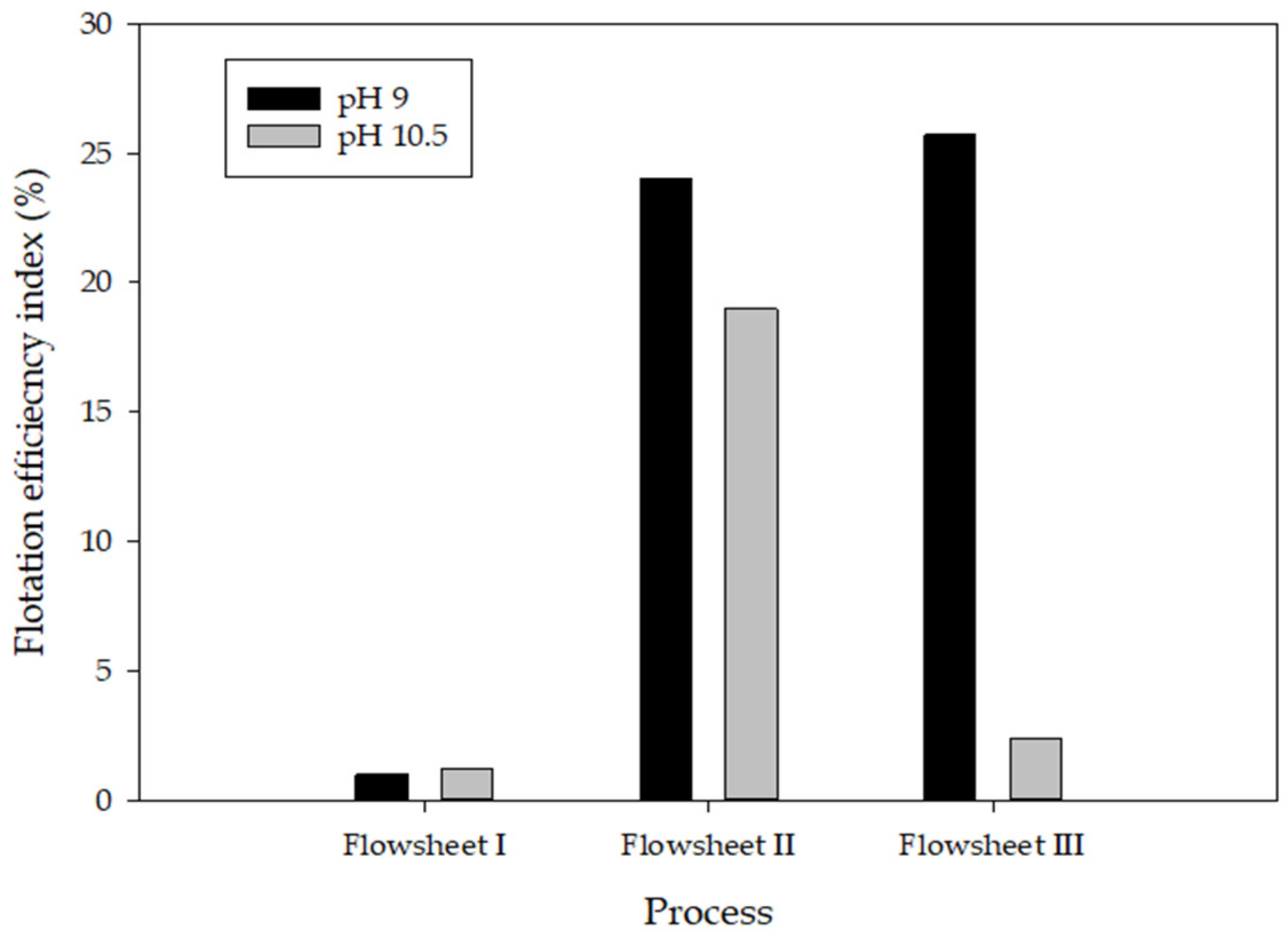

3.2. Froth Flotation

3.2.1. Baseline Flotation (Flowsheet I)

3.2.2. Desliming followed by Flotation (Flowsheet II)

3.2.3. Desliming–Flotation in the Presence of Depressants (Flowsheets III)

Flowsheet III at pH 9

Flowsheet III at pH 10.5

3.3. Mineralogical Composition of Flotation Feed and Concentrate

3.3.1. Modal Mineralogy

3.3.2. Mineral Liberation

3.3.3. Minerals Grain Size

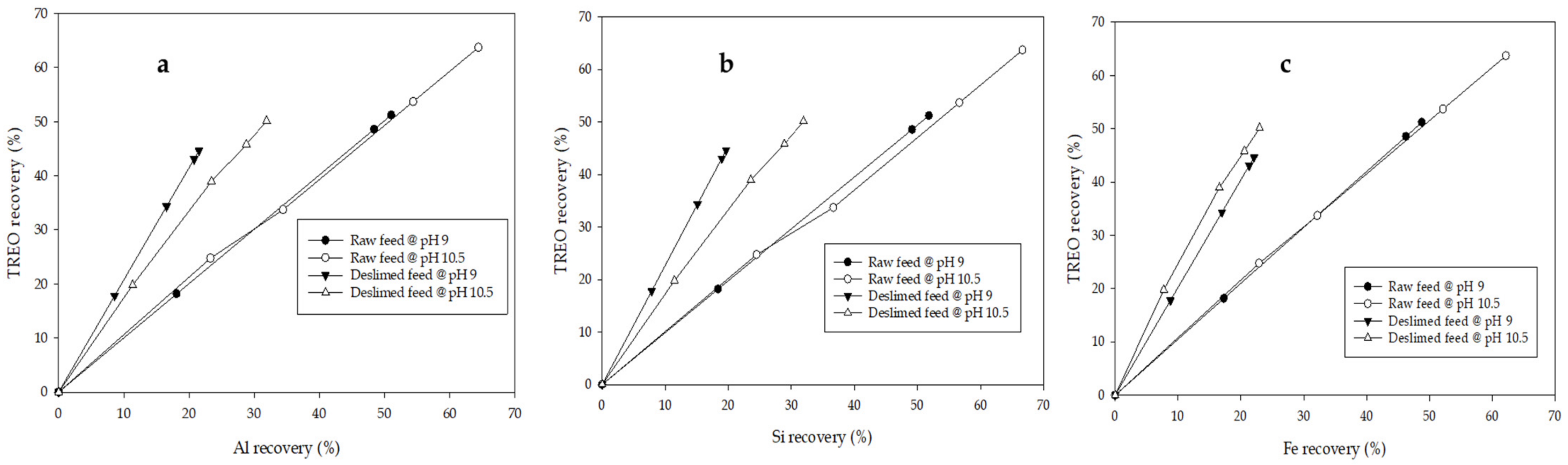

4. Discussion

4.1. The Role of Pulp pH

4.2. Surface Activation of Silicate and Clay Minerals

4.3. Effect of Mineral Grain Size

4.4. Relevance of Desliming

4.5. Effect of Depressants

4.6. TREO Grade–Recovery Relationship and Implications

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abaka-Wood, G.B.; Addai-Mensah, J.; Skinner, W. The Use of Mining Tailings as Analog of Rare Earth Elements Resources: Part 1–Characterization and Preliminary Separation. Miner. Process. Extr. Met. Rev. 2021, 43, 701–715. [Google Scholar] [CrossRef]

- Geoscience-Australia. Australia’s Identified Mineral. Resources 2013; Geoscience Australia: Canberra, Australia, 2014; pp. 107–115. [Google Scholar]

- Dang, D.H.; Thompson, K.A.; Ma, L.; Nguyen, H.Q.; Luu, S.T.; Duong, M.T.N.; Kernaghan, A. Toward the circular economy of Rare Earth Elements: A review of abundance, extraction, applications, and environmental impacts. Arch. Environ. Contam. Toxicol. 2021, 81, 521–530. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Geological Survey. Mineral Commodity Summaries 2022; U.S. Geological Survey: Reston, VA, USA, 2022; p. 206. [Google Scholar]

- Abaka-Wood, G.B.; Ehrig, K.; Addai-Mensah, J.; Skinner, W. Recovery of Rare Earth Elements Minerals from Iron-Oxide-Silicate-Rich Tailings: Research Review. Eng 2022, 3, 259–275. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Z.; Chen, C. Global potential of rare earth resources and rare earth demand from clean technologies. Minerals 2017, 7, 203. [Google Scholar] [CrossRef]

- Barteková, E.; Kemp, R. National strategies for securing a stable supply of rare earths in different world regions. Resour. Policy 2016, 49, 153–164. [Google Scholar] [CrossRef]

- Ilankoon, I.; Dushyantha, N.; Mancheri, N.; Edirisinghe, P.; Neethling, S.; Ratnayake, N.; Rohitha, L.; Dissanayake, D.; Premasiri, H.; Abeysinghe, A.; et al. Constraints to rare earth elements supply diversification: Evidence from an industry survey. J. Clean. Prod. 2022, 331, 129932. [Google Scholar] [CrossRef]

- Kim, H.-M.; Jariwala, D. The Not-So-Rare Earth Elements: A Question of Supply and Demand; University of Pennsylvania: Philadelphia, PA, USA, 2021; p. 20. [Google Scholar]

- Charalampides, G.; Vatalis, K.I.; Apostoplos, B.; Ploutarch-Nikolas, B. Rare earth elements: Industrial applications and economic dependency of Europe. Procedia Econ. Financ. 2015, 24, 126–135. [Google Scholar] [CrossRef]

- Nassar, N.T.; Du, X.; Graedel, T.E. Criticality of the rare earth elements. J. Ind. Ecol. 2015, 19, 1044–1054. [Google Scholar] [CrossRef]

- Imholte, D.; Nguyen, R.; Vedantam, A.; Brown, M.; Iyer, A.; Smith, B.; Collins, J.; Anderson, C.; O’Kelley, B. An assessment of US rare earth availability for supporting US wind energy growth targets. Energy Policy 2018, 113, 294–305. [Google Scholar] [CrossRef]

- Wang, Z.-Y.; Fan, H.-R.; Zhou, L.; Yang, K.-F.; She, H.-D. Carbonatite-related REE deposits: An overview. Minerals 2020, 10, 965. [Google Scholar] [CrossRef]

- Guo, D.; Liu, Y. Occurrence and geochemistry of bastnäsite in carbonatite-related REE deposits, Mianning–Dechang REE belt, Sichuan Province, SW China. Ore Geol. Rev. 2019, 107, 266–282. [Google Scholar] [CrossRef]

- Estrade, G.; Marquis, E.; Smith, M.; Goodenough, K.; Nason, P. REE concentration processes in ion adsorption deposits: Evidence from the Ambohimirahavavy alkaline complex in Madagascar. Ore Geol. Rev. 2019, 112, 103027. [Google Scholar] [CrossRef]

- Jordens, A.; Cheng, Y.P.; Waters, K.E. A review of the beneficiation of rare earth element bearing minerals. Miner. Eng. 2013, 41, 97–114. [Google Scholar] [CrossRef]

- Xu, C.; Zhong, C.; Lyu, R.; Ruan, Y.; Zhang, Z.; Chi, R. Process mineralogy of Weishan rare earth ore by MLA. J. Rare Earths 2019, 37, 334–338. [Google Scholar] [CrossRef]

- Abaka-Wood, G.B.; Zanin, M.; Addai-Mensah, J.; Skinner, W. Recovery of rare earth elements minerals from iron oxide–silicate rich tailings–Part 1: Magnetic separation. Miner. Eng. 2019, 136, 50–61. [Google Scholar] [CrossRef]

- Abaka-Wood, G.; Addai-Mensah, J.; Skinner, W. The concentration of rare earth elements from coal fly ash. J. South. Afr. Inst. Min. Metall. 2022, 122, 21–28. [Google Scholar] [CrossRef]

- Filippov, L.O.; Dehaine, Q.; Filippova, I.V. Rare earths (La, Ce, Nd) and rare metals (Sn, Nb, W) as by-products of kaolin production–Part 3: Processing of fines using gravity and flotation. Miner. Eng. 2016, 95, 96–106. [Google Scholar] [CrossRef]

- Satur, J.V.; Calabia, B.P.; Hoshino, M.; Morita, S.; Seo, Y.; Kon, Y.; Takagi, T.; Watanabe, Y.; Mutele, L.; Foya, S. Flotation of rare earth minerals from silicate–hematite ore using tall oil fatty acid collector. Miner. Eng. 2016, 89, 52–62. [Google Scholar] [CrossRef]

- Pavez, O.; Brandao, P.; Peres, A. Adsorption of oleate and octyl-hydroxamate on to rare-earths minerals. Miner. Eng. 1996, 9, 357–366. [Google Scholar] [CrossRef]

- Chelgani, S.C.; Rudolph, M.; Leistner, T.; Gutzmer, J.; Peuker, U. A review of rare earth minerals flotation: Monazite and xenotime. Int. J. Min. Sci. Technol. 2015, 25, 877–883. [Google Scholar] [CrossRef]

- Abaka-Wood, G.B.; Fosu, S.; Addai-Mensah, J.; Skinner, W. Flotation recovery of rare earth oxides from hematite–quartz mixture using sodium oleate as a collector. Miner. Eng. 2019, 141, 105847. [Google Scholar] [CrossRef]

- Aylmore, M.G.; Muir, D.M. Thiosulfate leaching of gold—A review. Miner. Eng. 2001, 14, 135–174. [Google Scholar] [CrossRef]

- Asamoah, R.K.; Skinner, W.; Addai-Mensah, J. Alkaline cyanide leaching of refractory gold flotation concentrates and bio-oxidised products: The effect of process variables. Hydrometallurgy 2018, 179, 79–93. [Google Scholar] [CrossRef]

- Du Plessis, C.; Lambert, H.; Gärtner, R.S.; Ingram, K.; Slabbert, W.; Eksteen, J.J. Lime use in gold processing—A review. Miner. Eng. 2021, 174, 107231. [Google Scholar] [CrossRef]

- Abaka-Wood, G.B.; Addai-Mensah, J.; Skinner, W. A study of selective flotation recovery of rare earth oxides from hematite and quartz using hydroxamic acid as a collector. Adv. Powder Technol. 2018, 29, 1886–1899. [Google Scholar] [CrossRef]

- Fuerstenau, M.C.; Somasundaran, P. Flotation in Principles of Mineral Processing; Fuerstenau, M.C., Han, K.N., Eds.; SME: New York, NY, USA, 2003; pp. 245–300. [Google Scholar]

- Hoang, D.H.; Heitkam, S.; Kupka, N.; Hassanzadeh, A.; Peuker, U.A.; Rudolph, M. Froth properties and entrainment in lab-scale flotation: A case of carbonaceous sedimentary phosphate ore. Chem. Eng. Res. Des. 2019, 142, 100–110. [Google Scholar] [CrossRef]

- Duarte, A.; Grano, S. Mechanism for the recovery of silicate gangue minerals in the flotation of ultrafine sphalerite. Miner. Eng. 2007, 20, 766–775. [Google Scholar] [CrossRef]

- Taner, H.A.; Onen, V. Control of clay minerals effect in flotation. A review. E3S Web Conf. 2016, 8, 01062. [Google Scholar] [CrossRef]

- Andrews, W.; Collins, D.; Hollick, C. The flotation of rare earths—A Contribution to industrial hygiene. In Proceedings of the 1990 AusIMM New Zealand Branch Annual Conference: The Mineral Industry in New Zealand, Rotorua, New Zealand, 18–21 March 1990. [Google Scholar]

- Pereira, C.A.; Peres, A.E.C. Flotation concentration of a xenotime pre-concentrate. Miner. Eng. 1997, 10, 1291–1295. [Google Scholar] [CrossRef]

- Moldoveanu, G.A.; Papangelakis, V.G. An overview of rare-earth recovery by ion-exchange leaching from ion-adsorption clays of various origins. Miner. Mag. 2016, 80, 63–76. [Google Scholar] [CrossRef] [Green Version]

- Ram, R.; Becker, M.; Brugger, J.; Etschmann, B.; Burcher-Jones, C.; Howard, D.; Kooyman, P.J.; Petersen, J. Characterisation of a rare earth element-and zirconium-bearing ion-adsorption clay deposit in Madagascar. Chem. Geol. 2019, 522, 93–107. [Google Scholar] [CrossRef]

- Feng, X.; Onel, O.; Council-Troche, M.; Noble, A.; Yoon, R.-H.; Morris, J.R. A study of rare earth ion-adsorption clays: The speciation of rare earth elements on kaolinite at basic pH. Appl. Clay Sci. 2021, 201, 105920. [Google Scholar] [CrossRef]

- Gong, J.; Peng, Y.; Bouajila, A.; Ourriban, M.; Yeung, A.; Liu, Q. Reducing quartz gangue entrainment in sulphide ore flotation by high molecular weight polyethylene oxide. Int. J. Miner. Process. 2010, 97, 44–51. [Google Scholar] [CrossRef]

- Corin, K.; McFadzean, B.; Shackleton, N.; O’Connor, C. Challenges related to the processing of fines in the recovery of platinum group minerals (PGMs). Minerals 2021, 11, 533. [Google Scholar] [CrossRef]

- Derhy, M.; Taha, Y.; Hakkou, R.; Benzaazoua, M. Review of the main factors affecting the flotation of phosphate ores. Minerals 2020, 10, 1109. [Google Scholar] [CrossRef]

- Cheng, T.-W.; Holtham, P.; Tran, T. Froth flotation of monazite and xenotime. Miner. Eng. 1993, 6, 341–351. [Google Scholar] [CrossRef]

- Zhang, W.; Honaker, R.; Groppo, J. Concentration of rare earth minerals from coal by froth flotation. Miner. Met. Process. 2017, 34, 132–137. [Google Scholar] [CrossRef]

- Joseph-Soly, S.; Quast, K.; Connor, J.N. Effects of Eh and pH on the oleate flotation of iron oxides. Miner. Eng. 2015, 83, 97–104. [Google Scholar] [CrossRef]

- Fan, G.; Wang, L.; Cao, Y.; Li, C. Collecting agent–mineral interactions in the reverse flotation of iron ore: A brief review. Minerals 2020, 10, 681. [Google Scholar] [CrossRef]

- Jung, R.F.; James, R.O.; Healy, T.W. Adsorption, precipitation, and electrokinetic processes in the iron oxide (Goethite)—Oleic acid—Oleate system. J. Colloid Interface Sci. 1987, 118, 463–472. [Google Scholar] [CrossRef]

- Zhou, C.H.; Keeling, J. Fundamental and applied research on clay minerals: From climate and environment to nanotechnology. Appl. Clay Sci. 2013, 74, 3–9. [Google Scholar] [CrossRef]

- Fuerstenau, M.; Cummins, W. The role of basic aqueous complexes in anionic flotation of quartz. Trans. AIME 1967, 238, 196. [Google Scholar]

- Trahar, W. A rational interpretation of the role of particle size in flotation. Int. J. Miner. Process. 1981, 8, 289–327. [Google Scholar] [CrossRef]

- WAng, L.; Peng, Y.; Runge, K.; Bradshaw, D. A review of entrainment: Mechanisms, contributing factors and modelling in flotation. Miner. Eng. 2015, 70, 77–91. [Google Scholar] [CrossRef]

- Wang, L.; Runge, K.; Peng, Y.; Vos, C. An empirical model for the degree of entrainment in froth flotation based on particle size and density. Miner. Eng. 2016, 98, 187–193. [Google Scholar] [CrossRef]

- Abaka-Wood, G.B.; Zanin, M.; Addai-Mensah, J.; Skinner, W. The upgrading of rare earth oxides from iron-oxide silicate rich tailings: Flotation performance using sodium oleate and hydroxamic acid as collectors. Adv. Powder Technol. 2018, 29, 3163–3172. [Google Scholar] [CrossRef]

- Whitworth, A.J.; Forbes, E.; Verster, I.; Jokovic, V.; Awatey, B.; Parbhakar-Fox, A. Review on advances in mineral processing technologies suitable for critical metal recovery from mining and processing wastes. Clean. Eng. Technol. 2022, 7, 100451. [Google Scholar] [CrossRef]

- Chen, J.; Chimonyo, W.; Peng, Y. Flotation behaviour in reflux flotation cell—A critical review. Miner. Eng. 2022, 181, 107519. [Google Scholar] [CrossRef]

- Jiang, K.; Dickinson, J.; Galvin, K. The kinetics of fast flotation using the reflux flotation cell. Chem. Eng. Sci. 2019, 196, 463–477. [Google Scholar] [CrossRef]

- Eskanlou, A.; Huang, Q.; Zhang, P. De-sliming followed by froth flotation for the recovery of phosphorus and enrichment of rare earth elements from Florida waste clay. Resour. Conserv. Recycl. 2022, 178, 106049. [Google Scholar] [CrossRef]

- Rabatho, J.P.; Tongamp, W.; Shibayama, A.; Takasaki, Y.; Nitta, S.; Imai, T. Investigation of a flotation process with de-sliming and attrition to upgrade and recover Cu and Mo from a Cu-Mo flotation tailing. Mater. Trans. 2011, 52, 746–752. [Google Scholar] [CrossRef] [Green Version]

- Hart, B.R.; Dimov, S.; Xia, L. REE bearing mineral recovery: A microflotation and surface chemistry study using hydroxamate collectors and citric acid. In Proceedings of the XXVII International Mineral Processing Congress, San Tiago, Chile, 20–24 October 2014. [Google Scholar]

- Filippov, L.; Severov, V.; Filippova, I. An overview of the beneficiation of iron ores via reverse cationic flotation. Int. J. Miner. Process. 2014, 127, 62–69. [Google Scholar] [CrossRef]

- Li, R.; Marion, C.; Espiritu, E.; Multani, R.; Sun, X.; Waters, K. Investigating the use of an ionic liquid for rare earth mineral flotation. J. Rare Earths 2021, 39, 866–874. [Google Scholar] [CrossRef]

- Espiritu, E.R.L.; Naseri, S.; Waters, K.E. Surface chemistry and flotation behavior of dolomite, monazite and bastnäsite in the presence of benzohydroxamate, sodium oleate and phosphoric acid ester collectors. Colloids Surf. A Physicochem. Eng. Asp. 2018, 546, 254–265. [Google Scholar] [CrossRef]

- Jordens, A.; Sheridan, R.S.; Rowson, N.A.; Waters, K.E. Processing a rare earth mineral deposit using gravity and magnetic separation. Miner. Eng. 2014, 62, 9–18. [Google Scholar] [CrossRef]

- Park, I.; Kanazawa, Y.; Sato, N.; Galtchandmani, P.; Jha, M.K.; Tabelin, C.B.; Jeon, S.; Ito, M.; Hiroyoshi, N. Beneficiation of low-grade rare earth ore from Khalzan Buregtei deposit (Mongolia) by magnetic separation. Minerals 2021, 11, 1432. [Google Scholar] [CrossRef]

| Rare Earth Oxides | Content (%) | Gangue Species | Content (%) |

|---|---|---|---|

| La2O3 | 0.366 | Al | 13.8 |

| Sc2O3 | 0.002 | Ca | 0.14 |

| CeO2 | 0.092 | Cu | 0.70 |

| Dy2O3 | 0.020 | Fe | 2.83 |

| Er2O3 | 0.008 | K | 1.48 |

| Eu2O3 | 0.012 | Mg | 0.63 |

| Gd2O3 | 0.044 | Na | 1.16 |

| Ho2O3 | 0.003 | P | 0.04 |

| Lu2O3 | 0.001 | Si | 22.25 |

| Nd2O3 | 0.328 | ||

| Pr6O11 | 0.086 | ||

| Sm2O3 | 0.057 | ||

| Y2O3 | 0.113 | ||

| Yb2O3 | 0.005 | ||

| Tb4O7 | 0.005 | ||

| TREO | 1.142 |

| Mineral | Abundance (wt.%) |

|---|---|

| Quartz | 6 |

| Hematite group | <1 |

| Kaolinite-serpentine group | 10 |

| Anatase | <1 |

| Rutile group | 2 |

| Plagioclase | 5 |

| K feldspar | 32 |

| Smectite Group | 6 |

| Barite Group | 1 |

| Mica group | 4 |

| Amorphous | 32 |

| Total | 100 |

| Product | d50 (um) | d80 (um) | Mass (%) | TREO | Si | Fe | Al | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dist. (%) | Grade (%) | Dist. (%) | Grade (%) | Dist. (%) | Grade (%) | Dist. (%) | Grade (%) | ||||

| Underflow | 13.2 | 28.4 | 44 | 89 | 2.71 | 49 | 24.72 | 82 | 5.04 | 40 | 9.92 |

| Overflow | 3.0 | 8.4 | 56 | 11 | 0.26 | 51 | 20.31 | 18 | 2.17 | 60 | 12.75 |

| Feed (calc.) | 7.3 | 33.3 | 100 | 100 | 1.34 | 100 | 22.25 | 100 | 2.70 | 100 | 10.89 |

| Product | Yield (%) | Grade (%) | Recovery (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TREO | Fe | Al | Si | TREO | Fe | Al | Si | ||

| pH 9 | |||||||||

| Feed | 100 | 2.71 | 5.04 | 9.92 | 24.72 | 100 | 100 | 100 | 100 |

| Conc. | 21 | 5.87 | 3.16 | 11.28 | 22.11 | 45 | 13 | 24 | 19 |

| Tails | 79 | 1.87 | 5.54 | 9.56 | 25.43 | 55 | 87 | 76 | 81 |

| pH 10.5 | |||||||||

| Feed | 100 | 2.71 | 5.04 | 9.92 | 24.72 | 100 | 100 | 100 | 100 |

| Conc. | 33 | 4.22 | 2.66 | 10.88 | 23.59 | 51 | 17 | 36 | 31 |

| Tails | 67 | 1.97 | 6.21 | 9.45 | 25.29 | 49 | 83 | 64 | 69 |

| Product | Yield (%) | Grade (%) | Recovery (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TREO | Fe | Al | Si | TREO | Fe | Al | Si | ||

| Rougher | |||||||||

| Feed | 100 | 2.71 | 5.04 | 9.92 | 24.72 | 100 | 100 | 100 | 100 |

| Conc. | 23 | 3.93 | 2.71 | 10.63 | 22.90 | 33 | 12 | 25 | 21 |

| Tails | 77 | 2.35 | 5.74 | 9.71 | 25.28 | 67 | 88 | 75 | 79 |

| Scavenger | |||||||||

| Conc. | 51 | 2.79 | 2.78 | 10.61 | 22.90 | 53 | 28 | 55 | 47 |

| Tails | 26 | 1.48 | 11.53 | 7.94 | 29.94 | 14 | 60 | 20 | 32 |

| Cleaner (Feed comprise rougher and scavenger concentrates) | |||||||||

| Feed | 74 | 3.23 | 2.76 | 10.62 | 22.90 | 86 | 40 | 79 | 69 |

| Conc. | 30 | 5.14 | 2.43 | 9.57 | 21.03 | 55 | 14 | 29 | 26 |

| Tails | 44 | 1.93 | 2.98 | 11.33 | 24.18 | 30 | 26 | 50 | 42 |

| Product | Yield (%) | Grade (%) | Recovery (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TREO | Fe | Al | Si | TREO | Fe | Al | Si | ||

| Rougher | |||||||||

| Feed | 100 | 2.71 | 5.04 | 9.92 | 24.72 | 100 | 100 | 100 | 100 |

| Conc. | 71 | 2.48 | 2.71 | 9.52 | 23.51 | 65 | 38 | 68 | 67 |

| Tails | 29 | 3.28 | 10.74 | 10.90 | 27.72 | 35 | 62 | 32 | 33 |

| Scavenger | |||||||||

| Conc. | 6 | 3.39 | 3.18 | 9.29 | 19.44 | 7 | 4 | 6 | 5 |

| Tails | 23 | 3.25 | 12.72 | 11.32 | 29.88 | 28 | 58 | 26 | 28 |

| Cleaner (Feed comprise rougher and scavenger concentrates) | |||||||||

| Feed | 77 | 2.57 | 2.75 | 9.50 | 23.24 | 72 | 42 | 74 | 72 |

| Conc. | 30 | 2.95 | 2.50 | 9.57 | 23.0 | 32 | 15 | 29 | 28 |

| Tails | 47 | 2.33 | 2.91 | 9.46 | 23.4 | 40 | 27 | 45 | 44 |

| Mineral | Mineral Mass (%) | |

|---|---|---|

| Deslimed Flotation Feed | Flotation Concentrate | |

| Monazite and intergrowths | 0.1 | 0.1 |

| Bastnäsite | 3.0 | 5.6 |

| La-Nd-Si intergrowths | 3.7 | 6.3 |

| La-Fe intergrowths | 0.9 | 1.0 |

| REE intergrowths | 0.8 | 1.3 |

| * Total REE minerals | 8.5 | 14.3 |

| Iron oxide/hydroxide (FeOx/OH) | 0.4 | 0.9 |

| Sulphates | 0.5 | 1.8 |

| Ti minerals | 1.3 | 2.2 |

| Quartz | 7.9 | 7.9 |

| Clays | 22.3 | 21.9 |

| Micas | 19.0 | 18.0 |

| K silicates | 10.0 | 7.2 |

| Fe silicates | 1.9 | 1.8 |

| Na silicates | 24.7 | 20.7 |

| Other silicates | 3.3 | 3.1 |

| Others | 0.2 | 0.3 |

| Total | 100 | 100 |

| Relation | Selectivity Index | R2 | ||

|---|---|---|---|---|

| Raw | Deslimed | Raw | Deslimed | |

| Al-TREO @ pH 9 | 1.00 | 2.07 | 1.00 | 1.00 |

| Al-TREO @ pH 10.5 | 0.98 | 1.57 | 0.99 | 0.99 |

| Si-TREO @ pH 9 | 0.99 | 2.27 | 1.00 | 1.00 |

| Si-TREO @ pH 10.5 | 0.95 | 1.57 | 0.99 | 0.99 |

| Fe-TREO @ pH 9 | 1.05 | 2.02 | 1.00 | 1.00 |

| Fe-TREO @ pH 10.5 | 1.02 | 2.18 | 0.99 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abaka-Wood, G.B.; Johnson, B.; Addai-Mensah, J.; Skinner, W. Recovery of Rare Earth Elements Minerals in Complex Low-Grade Saprolite Ore by Froth Flotation. Minerals 2022, 12, 1138. https://doi.org/10.3390/min12091138

Abaka-Wood GB, Johnson B, Addai-Mensah J, Skinner W. Recovery of Rare Earth Elements Minerals in Complex Low-Grade Saprolite Ore by Froth Flotation. Minerals. 2022; 12(9):1138. https://doi.org/10.3390/min12091138

Chicago/Turabian StyleAbaka-Wood, George Blankson, Bob Johnson, Jonas Addai-Mensah, and William Skinner. 2022. "Recovery of Rare Earth Elements Minerals in Complex Low-Grade Saprolite Ore by Froth Flotation" Minerals 12, no. 9: 1138. https://doi.org/10.3390/min12091138

APA StyleAbaka-Wood, G. B., Johnson, B., Addai-Mensah, J., & Skinner, W. (2022). Recovery of Rare Earth Elements Minerals in Complex Low-Grade Saprolite Ore by Froth Flotation. Minerals, 12(9), 1138. https://doi.org/10.3390/min12091138