Knothe Time Function Optimization Model and Its Parameter Calculation Method and Precision Analysis

Abstract

:1. Introduction

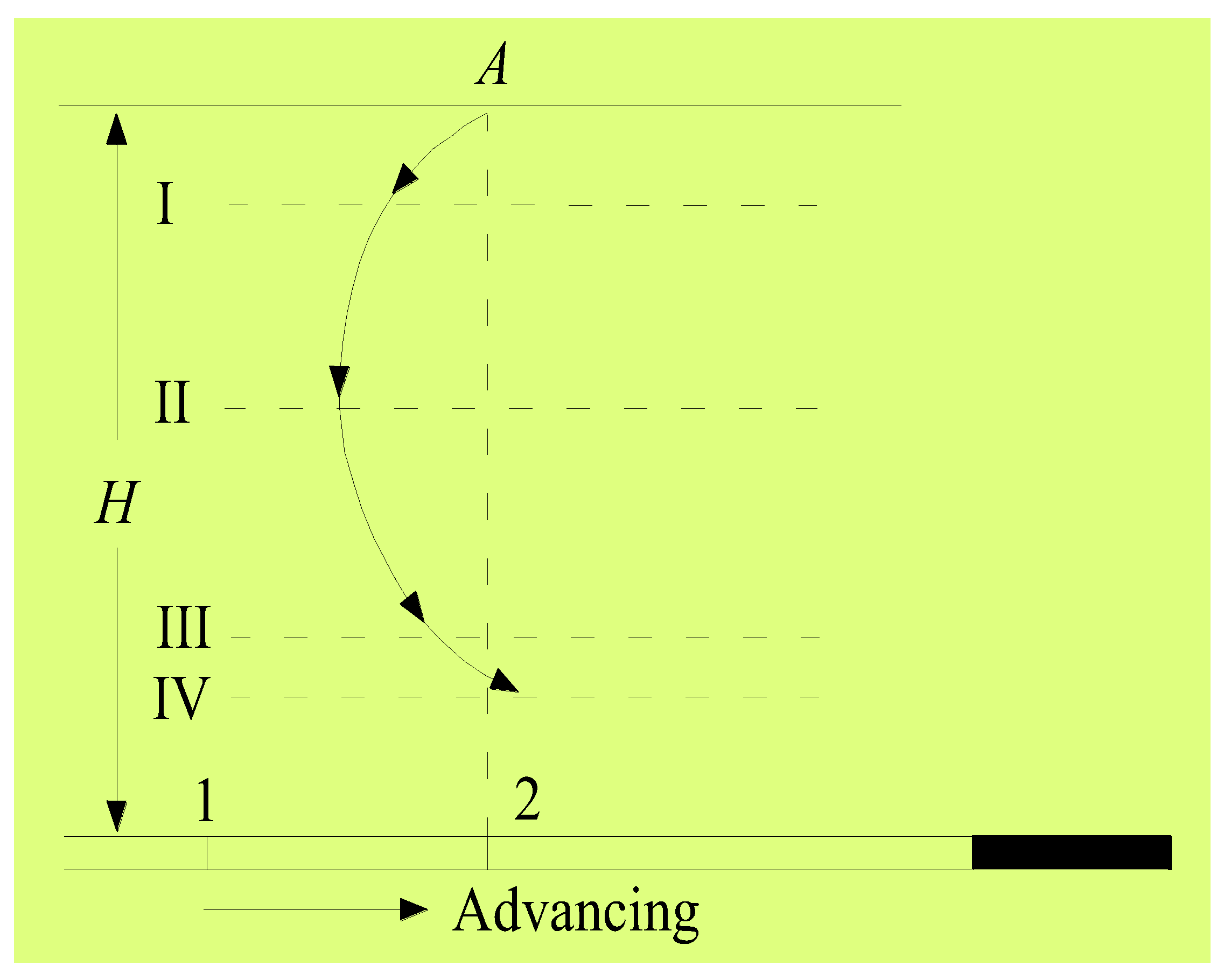

2. Analysis of Surface Point Movement Characteristics in Mining Process

- (1)

- When the working face advances toward Point A, the surface subsidence spreads to point A, the surface subsidence speed increases, and the moving direction of point A is opposite to the advancing direction of the working face. This is the first stage of the movement.

- (2)

- When the working face continues to advance directly below Point A (e.g., location “2” in Figure 1), the surface subsidence rate increases rapidly and gradually reaches the maximum subsidence rate, and Point A moves nearly in the plumb direction. This is the second phase of the movement.

- (3)

- When the working face continues to advance and gradually moves away from Point A, the rate of surface subsidence decreases rapidly, and Point A moves in the same direction as the working face. This is the third stage of the movement.

- (4)

- When the working face is far from the surface point A, the influence of the working face on point A disappears gradually, and the movement of point A finally stops. This is the fourth stage of the movement.

3. Knothe Time Function and Two-Parameter Knothe Time Function

3.1. Knothe Time Function

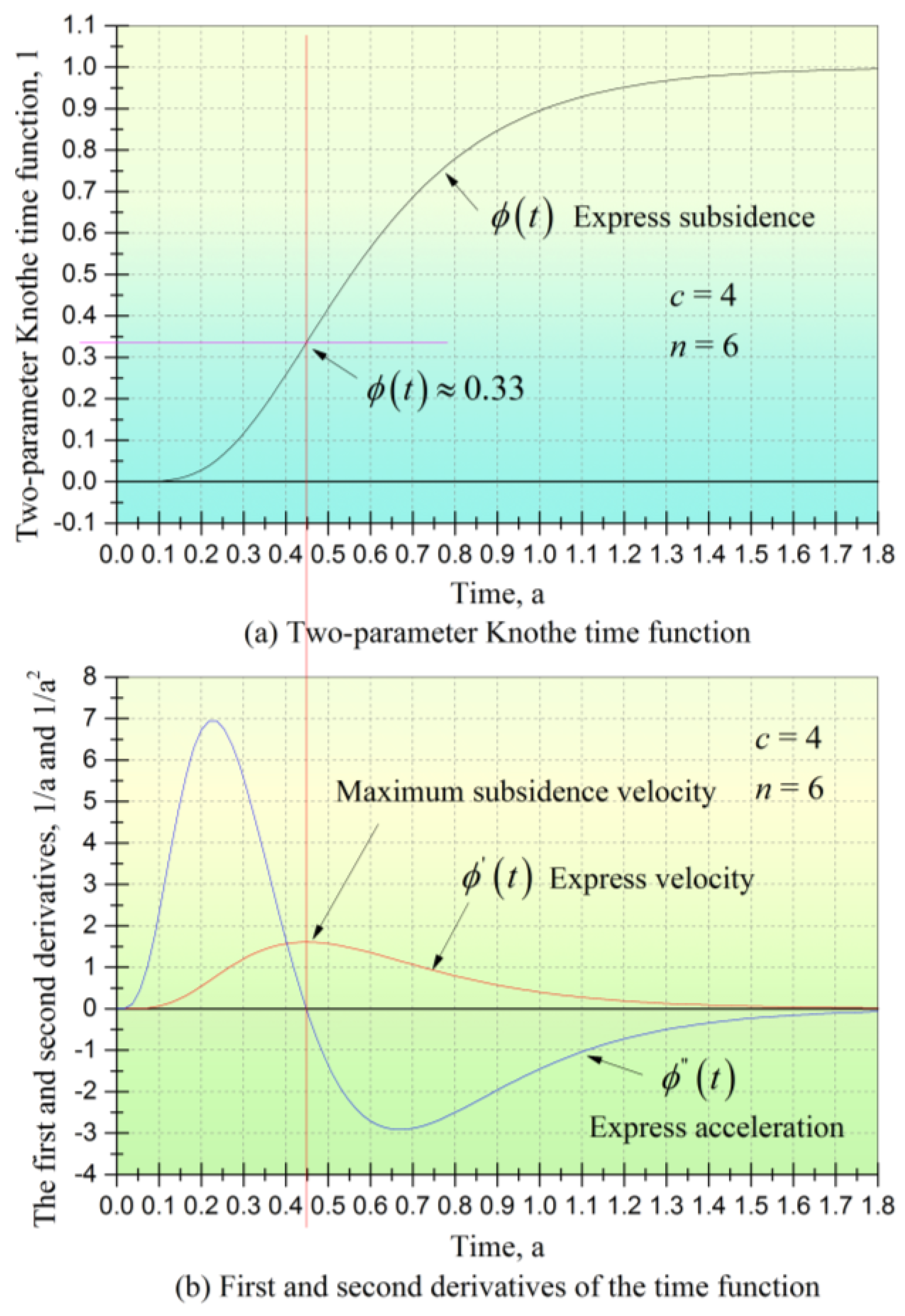

3.2. Two-Parameter Knothe Time Function

4. Establishment of a New Time Function Model and Its Characteristic Analysis

4.1. Model Building

4.2. Characteristic Analysis of New Time Function Model

5. Study on the Method of Model Parameter Estimation

6. Research on Reliability and Effectiveness of Model

6.1. Introduction of Mining Area and Arrangement of Measured Data

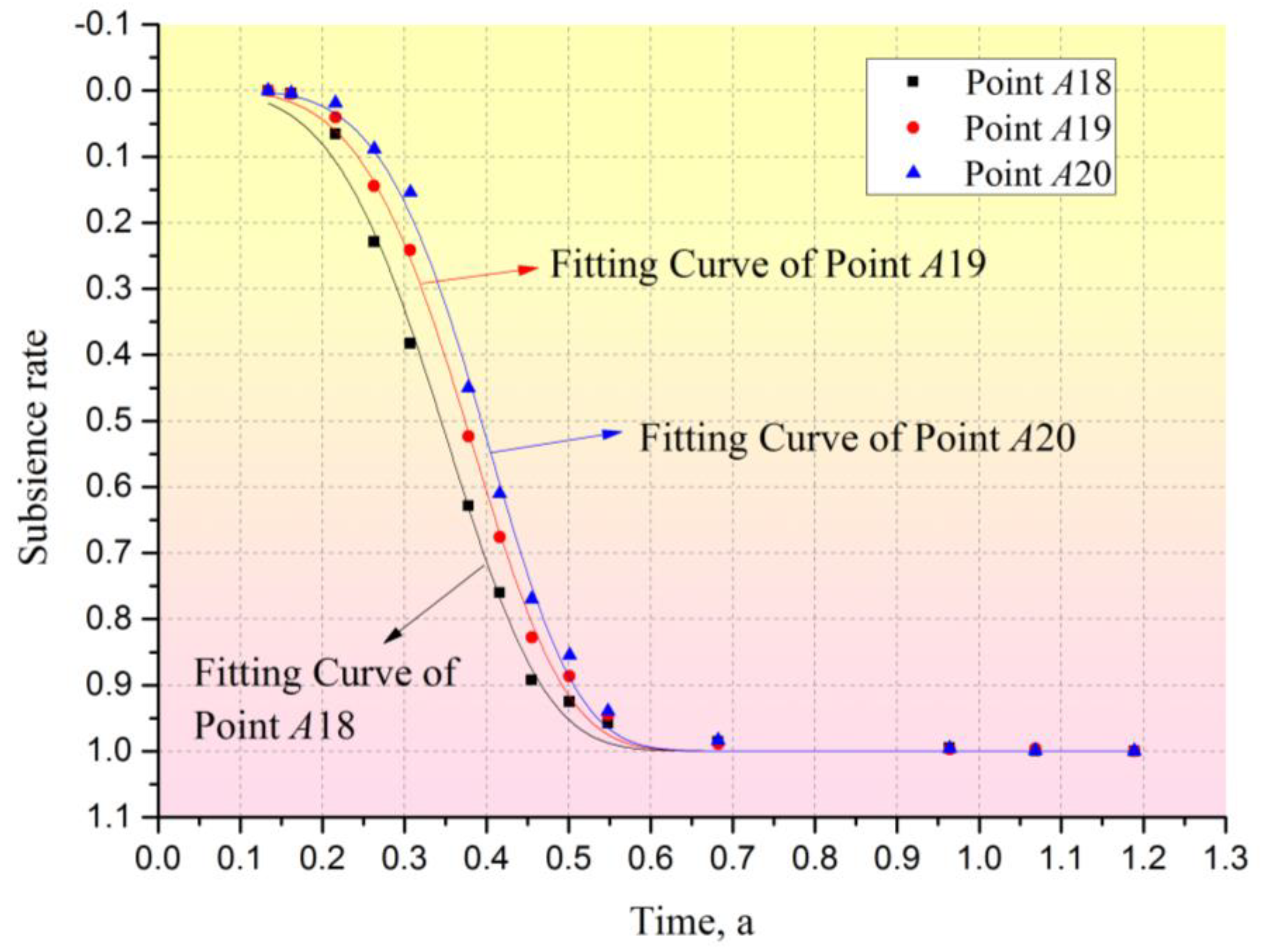

6.2. Reliability Analysis

7. Conclusions

- (1)

- By analyzing the movement characteristics of surface points during mining and the disadvantages of the existing time function, a novel time function for dynamic prediction of mining subsidence was established. An investigation was also conducted to analyze the physical meaning of the parameters of the function and their influence; the results show that the function can effectively express all features of the dynamic surface mining subsidence.

- (2)

- According to the construction process of the Knothe time function, a parameter calculation method was proposed for the new time function on the basis of the normalization method and least square principle.

- (3)

- Taking the measured dynamic subsidence data of 22,618 working faces in a coal mine as an example, the reliability of the model was verified by comparing the measured data with the predicted results. The results show that the average relative root-mean-square error was 5.2%, and the precision was improved compared with the present model.

- (4)

- In the future, we will further study the universal adaptability of the time function model and its parameter estimation method, focusing on the time function estimation method based on a full mining angle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, Q.; Deng, X.; Feng, R.; Li, C.; Wang, X.; Jiang, T. Model for calculating the parameter of the Knothe time function based on angle of full subsidence. Int. J. Rock Mech. Min. Sci. 2015, 78, 19–26. [Google Scholar] [CrossRef]

- Saro, L.; Inhye, P. Application of decision tree model for the ground subsidence hazard mapping near abandoned underground coal mines. J. Environ. Manag. 2013, 127, 166–176. [Google Scholar]

- Tugrul, U.; Hakan, A.; Ozgur, Y. An integrated approach for the prediction of subsidence for coal mining basin. Eng. Geol. 2013, 166, 186–203. [Google Scholar]

- Feng, Y.; Hu, Q.; Deng, X.; Li, L. Study on surface subsidence dynamic prediction system for multi-face mining. Saf. Coal Mines. 2013, 44, 72–75. [Google Scholar]

- Marschalko, M.; Yilmaz, I.; Bednárik, M.; Kubecka, K. Influence of underground mining activities on the slope deformation genesis: Doubrava Vrchovec, Doubrava Ujala and Staric case studies from Czech Republic. Eng. Geol. 2012, 147–148, 37–51. [Google Scholar] [CrossRef]

- Abbas, M.; Ferri, P.; Mehdi, Y. Prediction of the height of distressed zone above the mined panel roof in longwall coal mining. Int. J. Coal Geol. 2012, 98, 62–72. [Google Scholar]

- Wang, Z.; Deng, K. Richards model of surface dynamic subsidence prediction in mining area. Rock Soil Mech. 2011, 32, 1664–1668. [Google Scholar]

- Guo, W.; Chai, H. Coal Mining Damage and Protection; Coal Industry Press: Beijing, China, 2008. [Google Scholar]

- Huang, L.; Wang, J. Research on laws and computational methods of dynamic surface subsidence deformation. J. Chin. Univ. Min. Technol. 2008, 37, 211–215. [Google Scholar]

- Cui, X.; Wang, J.; Liu, Y. Prediction of progressive surface subsidence above longwall coal mining using a time function. Int. J. Rock Mech. Min. Sci. 2001, 38, 1057–1063. [Google Scholar] [CrossRef]

- Liu, T. Surface Movement, Overburden Failures and Its Application; Coal Industry Press: Beijing, China, 1981. [Google Scholar]

- He, G.; Yang, L.; Ling, G.; Jia, F.; Hong, D. Science of Mining Subsidence; China University of Mining and Technology Press: Xuzhou, China, 1994. [Google Scholar]

- Zhang, B.; Cui, X.; Zhao, Y.; Li, C. Parameter calculation method for optimized segmented Knothe time function. J. China Coal Soc. 2018, 43, 3379–3386. [Google Scholar]

- Peng, S. Surface Subsidence Engineering; Society for Mining, Metallurgy, and Exploration, Inc.: Littleton, CO, USA, 1992. [Google Scholar]

- Helmut, K. Mining Subsidence Engineering; Springer: New York, NY, USA, 1983. [Google Scholar]

- Wang, J.; Liu, X.; Li, P.; Guo, J. Study on prediction of surface subsidence in mined—Out region with the MMF Mode. J. China Coal Soc. 2012, 37, 411–415. [Google Scholar]

- Li, C.; Gao, Y.; Cui, X. Progressive subsidence prediction of ground surface based on the normal distribution time function. Rock Soil Mech. 2016, S1, 108–116. [Google Scholar]

- Peng, X.; Cui, X.; Zang, Y.; Wang, Y.; Yuan, D. Time function and prediction of progressive surface movements and deformations. J. Univ. Sci. Technol. Beijing 2004, 26, 341–344. [Google Scholar]

- Cui, X.; Miao, X.; Zhao, Y.; Jin, R. Discussion on the time function of time dependent surface movement. J. China Coal Soc. 1999, 24, 453–456. [Google Scholar]

- Wang, J.; Liu, X.; Liu, X. Dynamic prediction model for mining subsidence. J. China Coal Soc. 2015, 40, 517–521. [Google Scholar]

- Knothe, S. Effect of time on formation of basin subsidence. Arch. Min. Steel Ind. 1953, 1, 1–7. [Google Scholar]

- Lian, X.; Andrew, J.; Jose, S.; Hua, Y. Extending dynamic models of mining subsidence. Trans. Nonferrous Met. Soc. China 2011, 21, 536–542. [Google Scholar] [CrossRef]

- Zhang, B.; Cui, X. Optimization of segmented Knothe time function model for dynamic prediction of mining subsidence. Rock Soil Mech. 2017, 38, 541–548. [Google Scholar]

- Cui, X.; Chen, L. Dynamic Supervision of Large Deformation of Subsidence and Its Stress Analysis; Coal Industry Press: Beijing, China, 2004. [Google Scholar]

- Kowalaki, A. Surface subsidence and rate of its increments based on measurements and theory. Arch. Min. Sci. 2001, 46, 391–406. [Google Scholar]

- Wang, J.; Chang, Z.; Chen, Y. Study on mining degree and patterns of ground subsidence in condition of mining under thick unconsolidated layers. J. China Coal Soc. 2003, 28, 230–234. [Google Scholar]

- Liu, Y.; Zhuang, Y. Model for dynamic process of ground surface subsidence due to underground mining. Rock Soil Mech. 2009, 30, 3406–3410. [Google Scholar]

- Chen, Q.; Niu, W.; Liu, Y.; Chen, Q.; Liu, J.; Fan, Q. Improvement of Knothe model and analysis on dynamic evolution law of strata movement in fill mining. J. China Univ. Min. Technol. 2017, 46, 250–256. [Google Scholar]

- Chen, L.; Zhao, X.; Tang, Y.; Zhang, H. Parameters fitting and evaluation of exponent Knothe model combined with InSAR technique. Rock Soil Mech. 2018, 39, 423–431. [Google Scholar]

- Liu, Y.; Cao, S.; Liu, Y. The improved Knothe time function for surface subsidence. Sci. Surv. Mapp. 2009, 34, 16–17. [Google Scholar]

- Li, D. Influence of cover rock characteristics on time influencing parameters in process of surface movement. Chin. J. Rock Mech. Eng. 2004, 23, 3780–3784. [Google Scholar]

- Hu, Q.; Cui, X.; Kang, X.; Lei, B.; Ma, K.; Li, L. Impact of parameter on Knothe time function and its calculation model. J. Min. Saf. Eng. 2014, 31, 122–126. [Google Scholar]

- Zhang, J. Origin 9.0 Science and Technology Drawing and Data Analysis Super Learning Manual; Posts & Telecom Press: Beijing, China, 2019. [Google Scholar]

| Date | Monitoring Point | |||||

|---|---|---|---|---|---|---|

| A16 | A17 | A18 | A19 | A20 | A21 | |

| 8April 2016 | 0 | 0 | 0 | 0 | 0 | 0 |

| 28 April 2016 | 8 | 7 | 6 | 7 | 6 | 5 |

| 18 May 2016 | 199 | 144 | 87 | 55 | 26 | 17 |

| 4 June 2016 | 502 | 401 | 303 | 197 | 120 | 65 |

| 20 June 2016 | 787 | 644 | 506 | 330 | 209 | 110 |

| 18 July 2016 | 980 | 911 | 831 | 715 | 610 | 459 |

| 20 July 2016 | 1084 | 1054 | 1005 | 923 | 827 | 647 |

| 13 August 2016 | 1188 | 1197 | 1180 | 1130 | 1043 | 835 |

| 20 August 2016 | 1202 | 1225 | 1223 | 1210 | 1158 | 1007 |

| 16 September 2016 | 1216 | 1252 | 1266 | 1290 | 1273 | 1180 |

| 4 November 2016 | 1239 | 1279 | 1303 | 1350 | 1333 | 1274 |

| 15 February 2017 | 1250 | 1292 | 1316 | 1361 | 1349 | 1301 |

| 25 March 2017 | 1250 | 1297 | 1321 | 1360 | 1354 | 1303 |

| 8 May 2017 | 1251 | 1311 | 1322 | 1365 | 1355 | 1307 |

| Time Function | c | n | Adjusted R-Squared | ||

|---|---|---|---|---|---|

| Value | Standard Error | Value | Standard Error | ||

| Knothe time function | 1.99998 | 0.39861 | 0.70314 | ||

| Two-parameter Knothe time function | 12.4335 | 0.52108 | 82.38896 | 16.74915 | 0.99798 |

| New time function | 4.42503 | 0.25762 | 4.37028 | 0.14913 | 0.99835 |

| Monitoring Point | c | n | Adjusted R-Squared | ||

|---|---|---|---|---|---|

| Value | Standard Error | Value | Standard Error | ||

| A18 | 4.43195 | 0.33817 | 4.18217 | 0.18502 | 0.99676 |

| A19 | 4.42503 | 0.25762 | 4.37028 | 0.14913 | 0.99835 |

| A20 | 4.99387 | 0.36582 | 4.50664 | 0.18009 | 0.99801 |

| Mean | 4.61695 | 4.35303 | |||

| Data | Relative Time, a | Point A16, mm | Point A17, mm | Point A21, mm | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Surveyed | Predicted | Error | Surveyed | Predicted | Error | Surveyed | Predicted | Error | ||

| 8 April 2016 | 0.134 | 0 | 38 | 38 | 0 | 27 | 27 | 0 | 3 | 3 |

| 28 April 2016 | 0.162 | 8 | 71 | 63 | 7 | 53 | 46 | 5 | 10 | 5 |

| 18 May 2016 | 0.216 | 199 | 183 | −16 | 144 | 150 | 6 | 17 | 44 | 27 |

| 4 Iune 2016 | 0.263 | 502 | 345 | −157 | 401 | 298 | −103 | 65 | 113 | 48 |

| 20 June 2016 | 0.307 | 787 | 547 | −240 | 644 | 494 | −150 | 110 | 230 | 120 |

| 16 July 2016 | 0.378 | 980 | 901 | −79 | 911 | 867 | −44 | 459 | 534 | 75 |

| 20 July 2016 | 0.416 | 1084 | 1054 | −30 | 1054 | 1045 | −9 | 647 | 734 | 87 |

| 13 August 2016 | 0.455 | 1188 | 1161 | −27 | 1197 | 1179 | −18 | 835 | 935 | 100 |

| 20 August 2016 | 0.501 | 1202 | 1224 | 22 | 1225 | 1267 | 42 | 1007 | 1124 | 117 |

| 16 September 2016 | 0.548 | 1216 | 1246 | 30 | 1252 | 1301 | 49 | 1180 | 1241 | 61 |

| 4 November 2016 | 0.682 | 1239 | 1251 | 12 | 1279 | 1311 | 32 | 1274 | 1307 | 33 |

| 15 February 2017 | 0.964 | 1250 | 1251 | 1 | 1292 | 1311 | 19 | 1301 | 1307 | 6 |

| 25 March 2017 | 1.069 | 1250 | 1251 | 1 | 1297 | 1311 | 14 | 1303 | 1307 | 4 |

| 8 May 2017 | 1.189 | 1251 | 1251 | 0 | 1311 | 1311 | 0 | 1307 | 1307 | 0 |

| RMSE | ±87 | ±58 | ±67 | |||||||

| RRMSE | 6.9% | 4.4% | 5.2% | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Q.; Cui, X.; Liu, W.; Feng, R.; Ma, T.; Yuan, D. Knothe Time Function Optimization Model and Its Parameter Calculation Method and Precision Analysis. Minerals 2022, 12, 745. https://doi.org/10.3390/min12060745

Hu Q, Cui X, Liu W, Feng R, Ma T, Yuan D. Knothe Time Function Optimization Model and Its Parameter Calculation Method and Precision Analysis. Minerals. 2022; 12(6):745. https://doi.org/10.3390/min12060745

Chicago/Turabian StyleHu, Qingfeng, Ximin Cui, Wenkai Liu, Ruimin Feng, Tangjing Ma, and Debao Yuan. 2022. "Knothe Time Function Optimization Model and Its Parameter Calculation Method and Precision Analysis" Minerals 12, no. 6: 745. https://doi.org/10.3390/min12060745

APA StyleHu, Q., Cui, X., Liu, W., Feng, R., Ma, T., & Yuan, D. (2022). Knothe Time Function Optimization Model and Its Parameter Calculation Method and Precision Analysis. Minerals, 12(6), 745. https://doi.org/10.3390/min12060745