Representative-Area Approach to Define Blast-Induced Ground Vibrations—Damage Prevention Criterion Abacus

Abstract

:1. Introduction

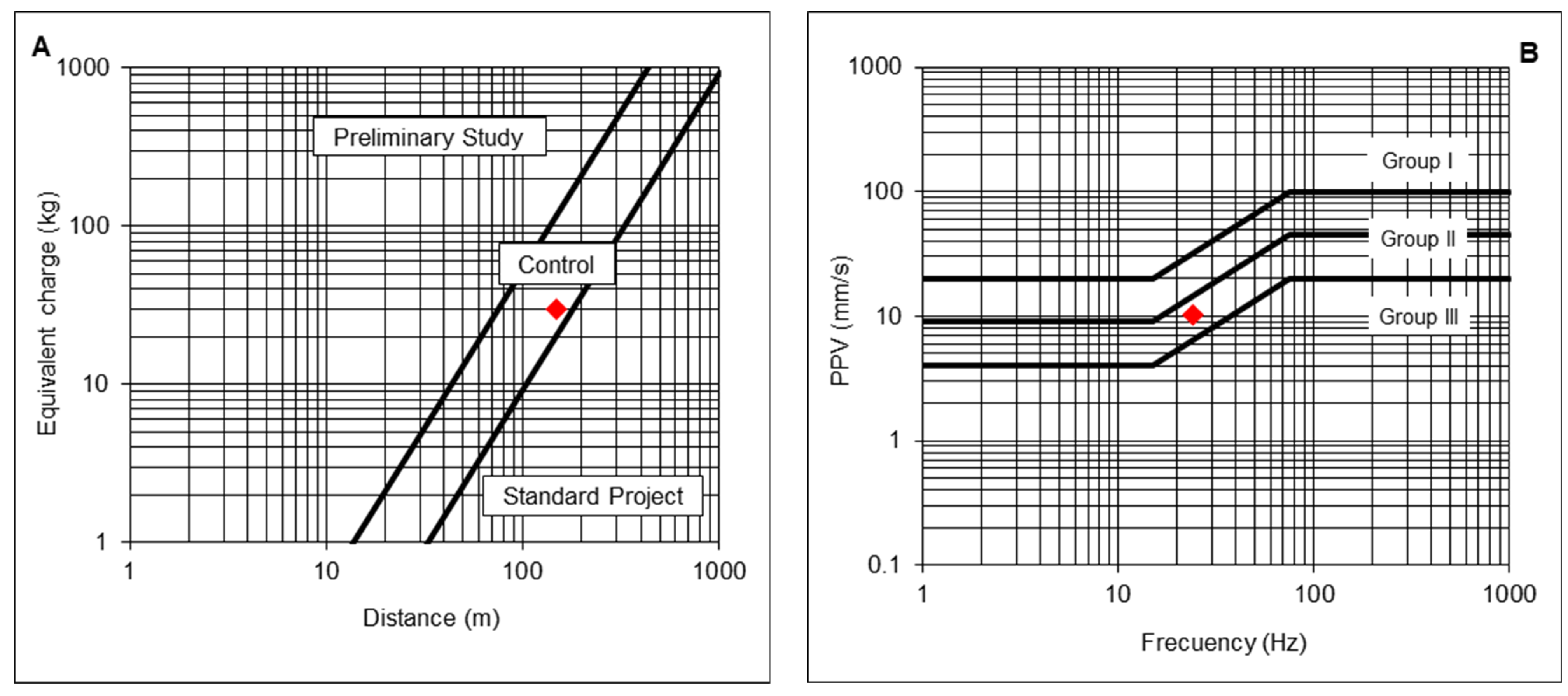

2. Classical Analysis of a Blast Using the Damage Prevention Criteria

2.1. Damage Prevention Criteria

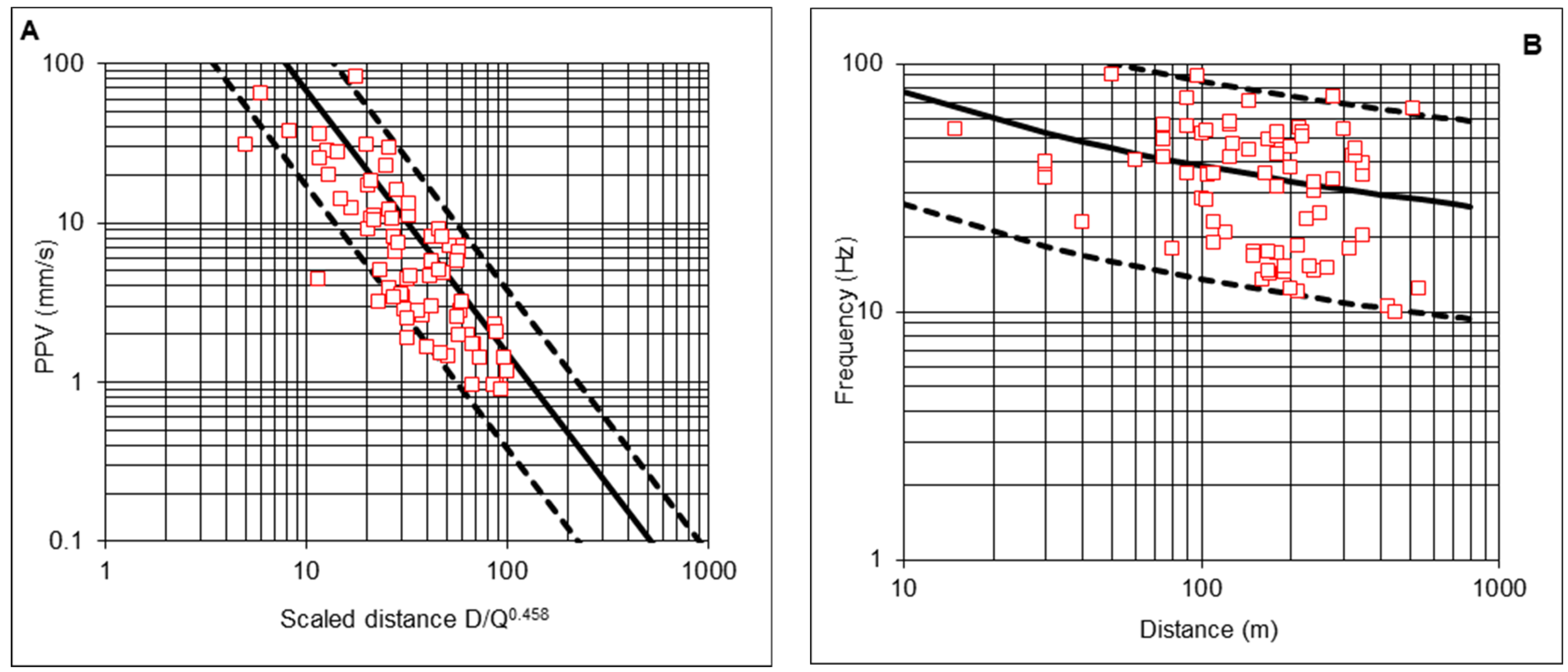

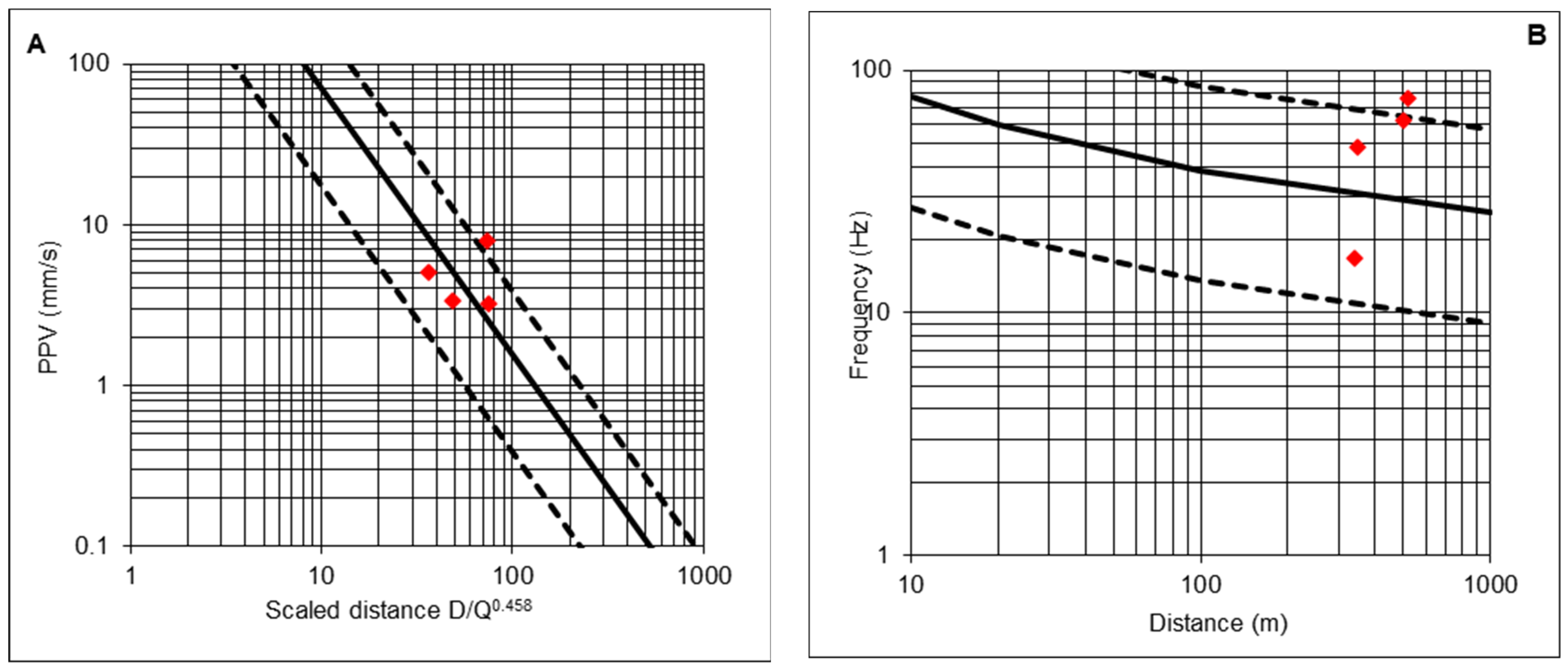

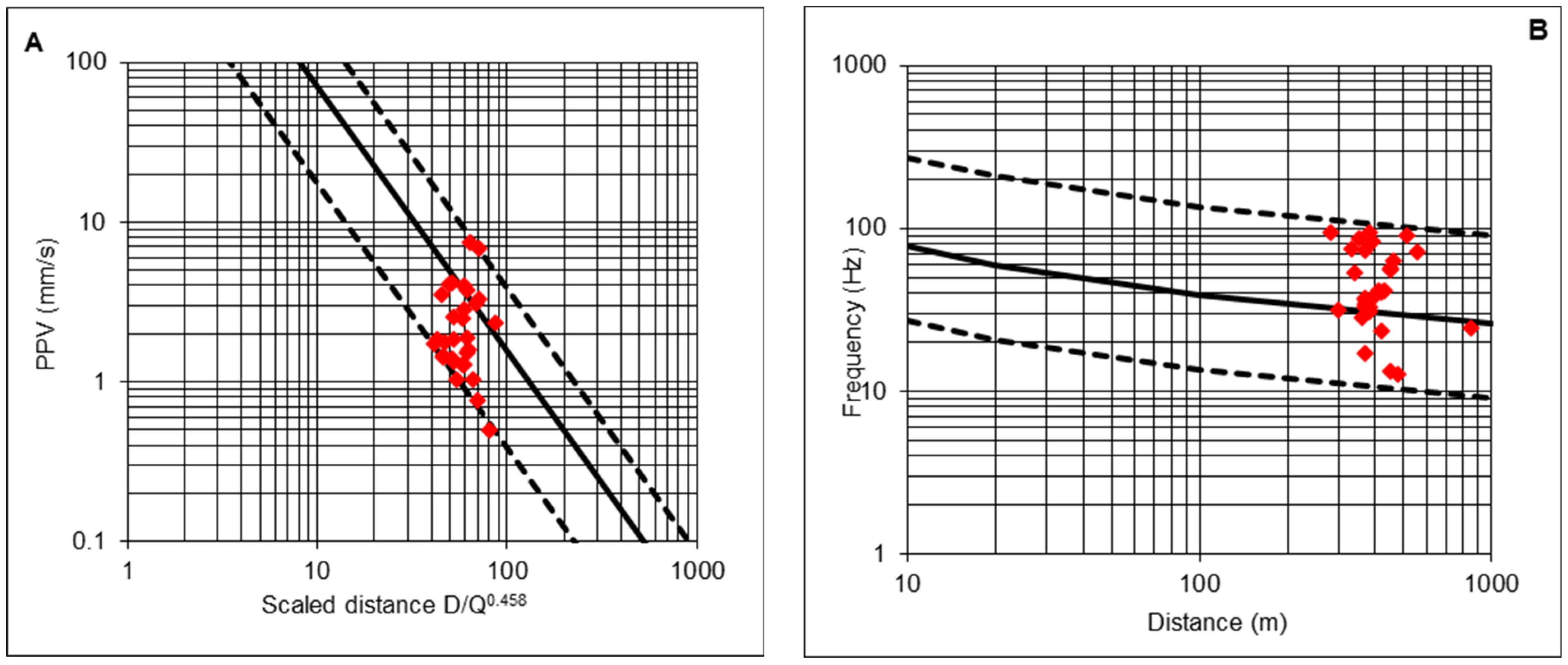

2.2. General Ground Vibration and Frequency Attenuation Laws

2.3. Classical Analysis According to the 22381-93 UNE Standard

3. Conventional Quarry-Blasting Data

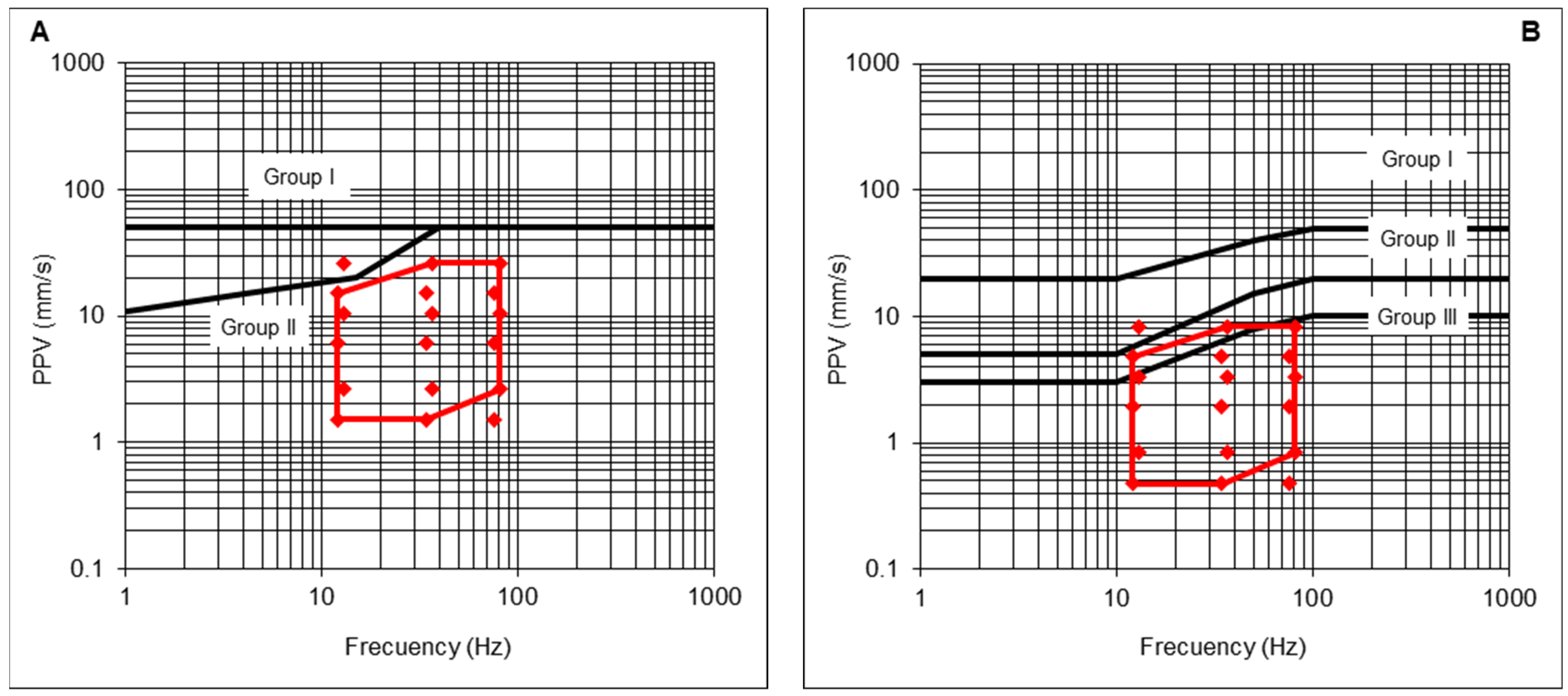

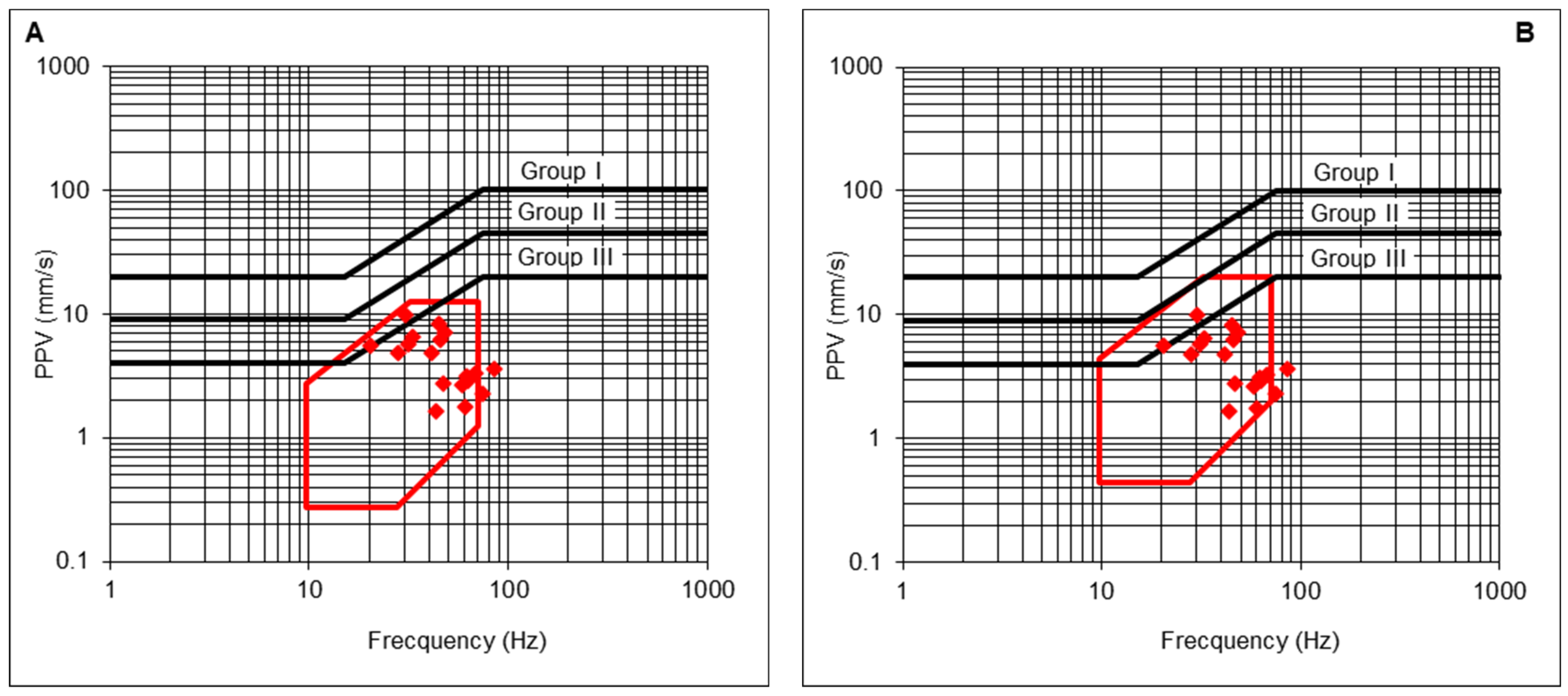

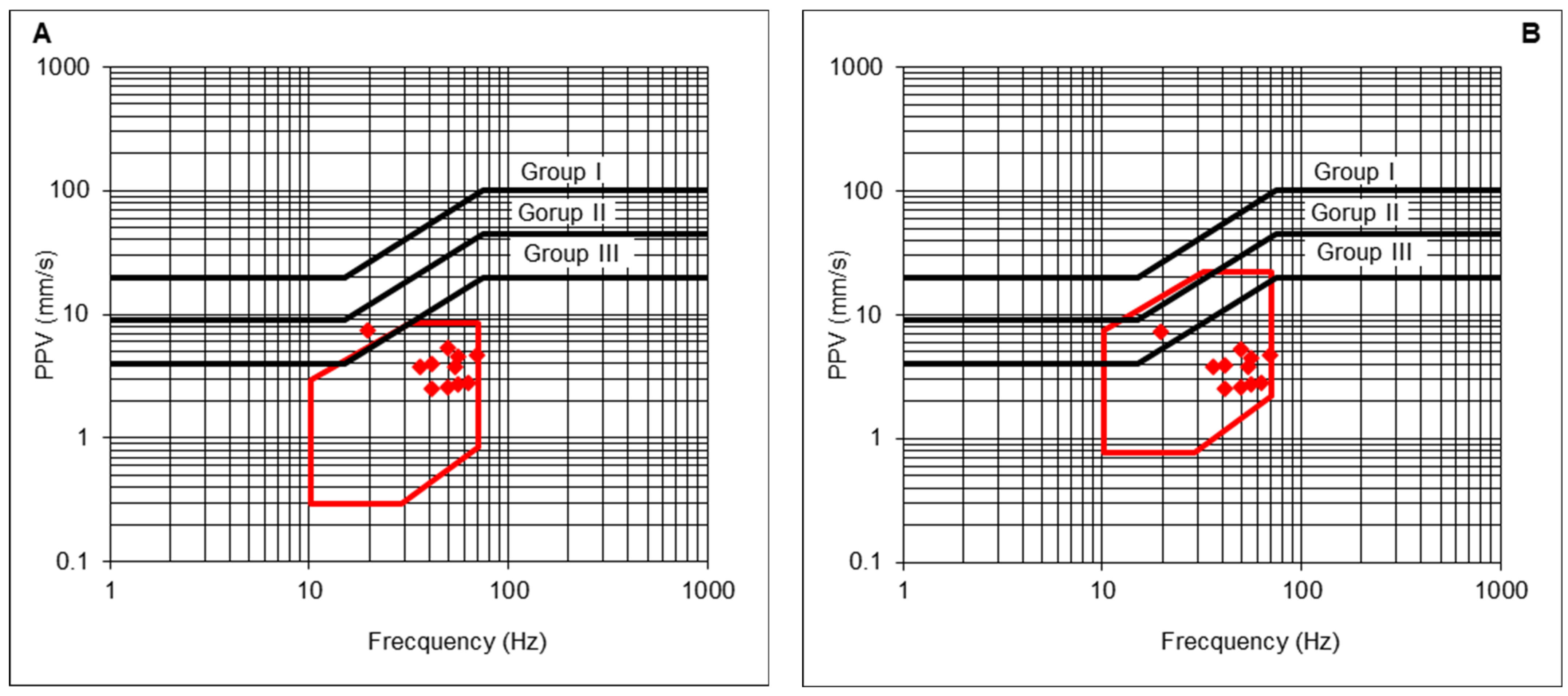

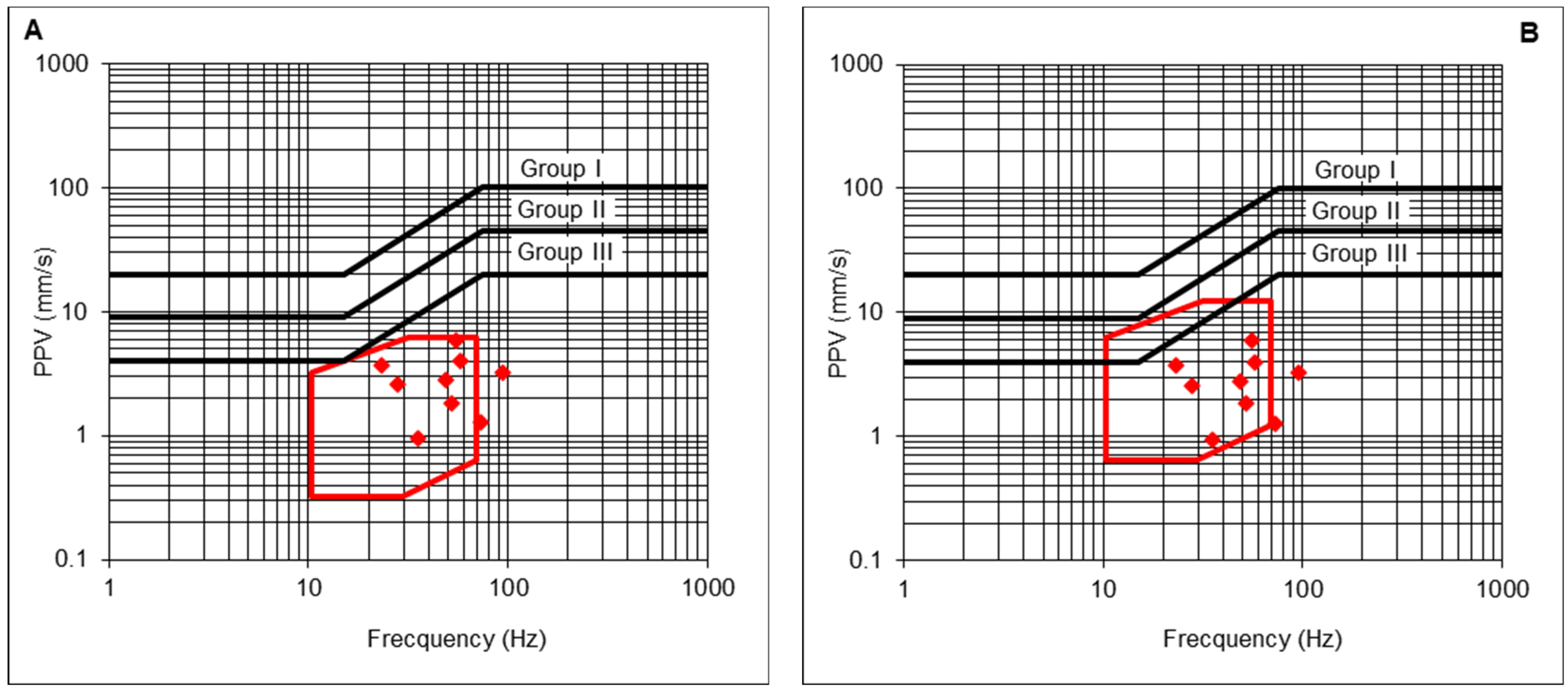

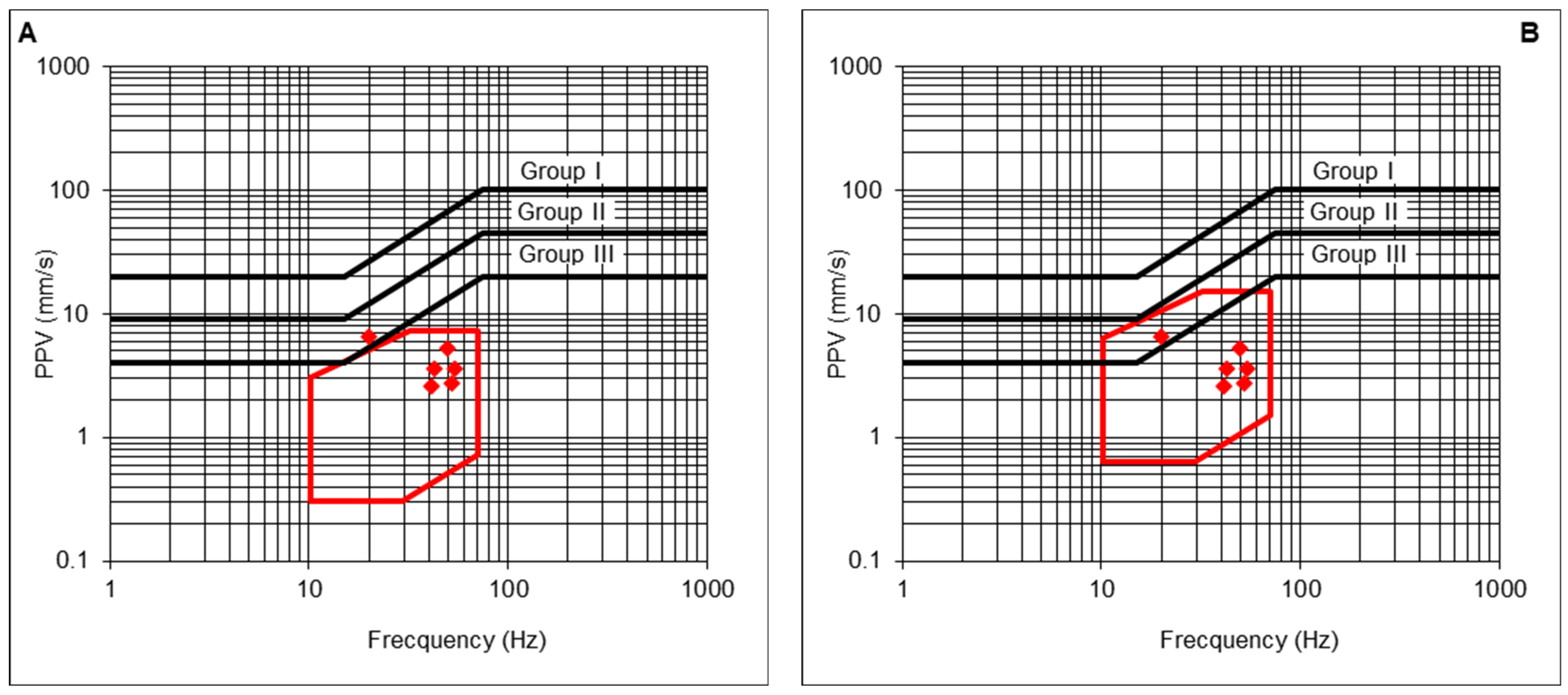

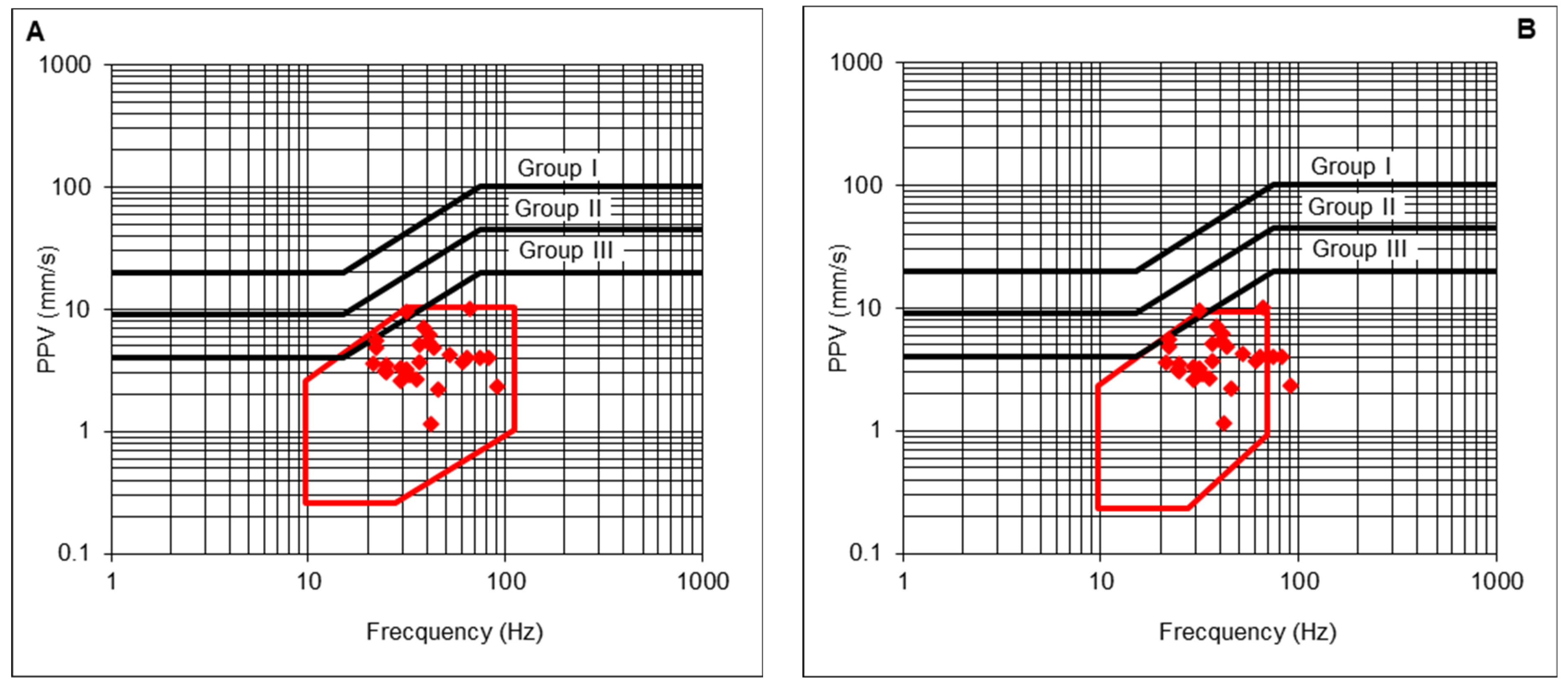

3.1. PPV–Frequency Data

3.2. PPV and Frequency Attenuation Laws in Limestone Rock Masses

4. Definition of a Representative Area of Ground Vibrations Due to Blasting

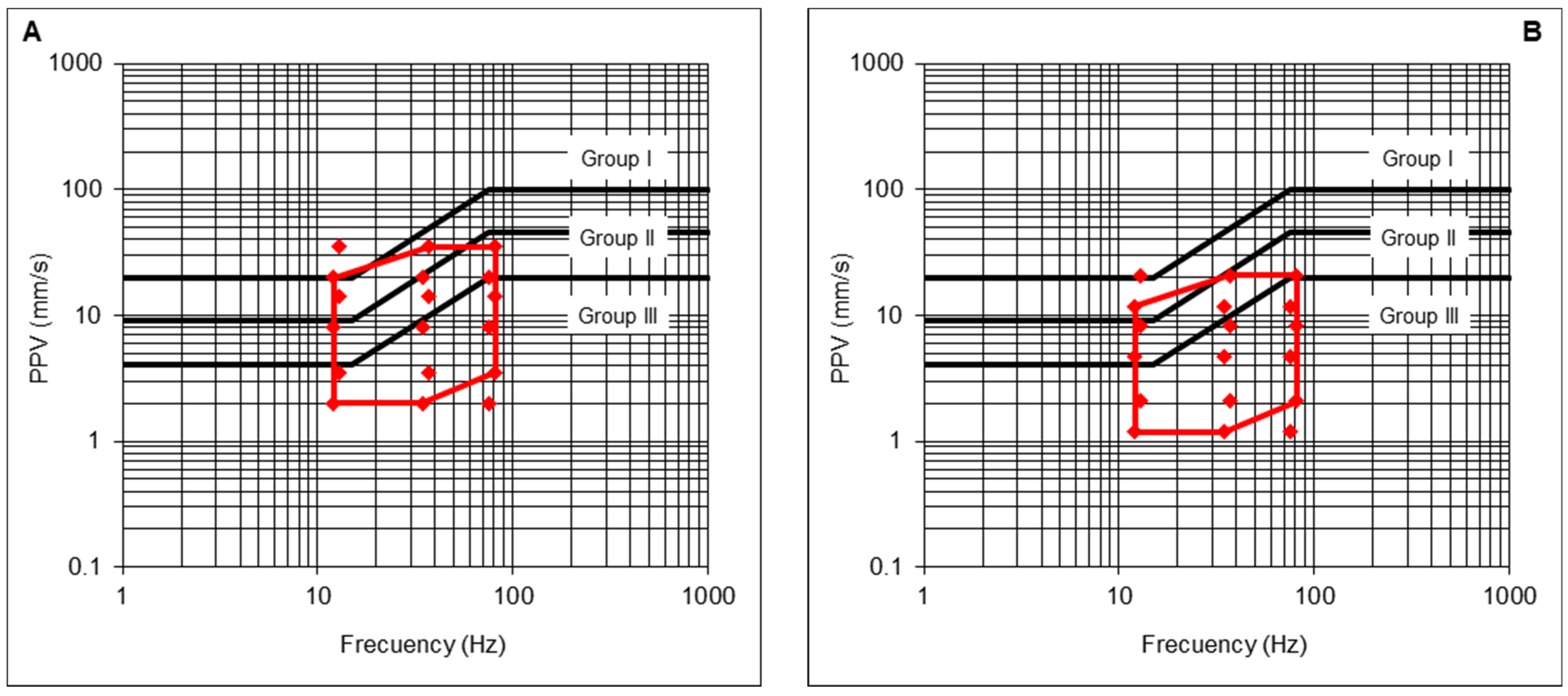

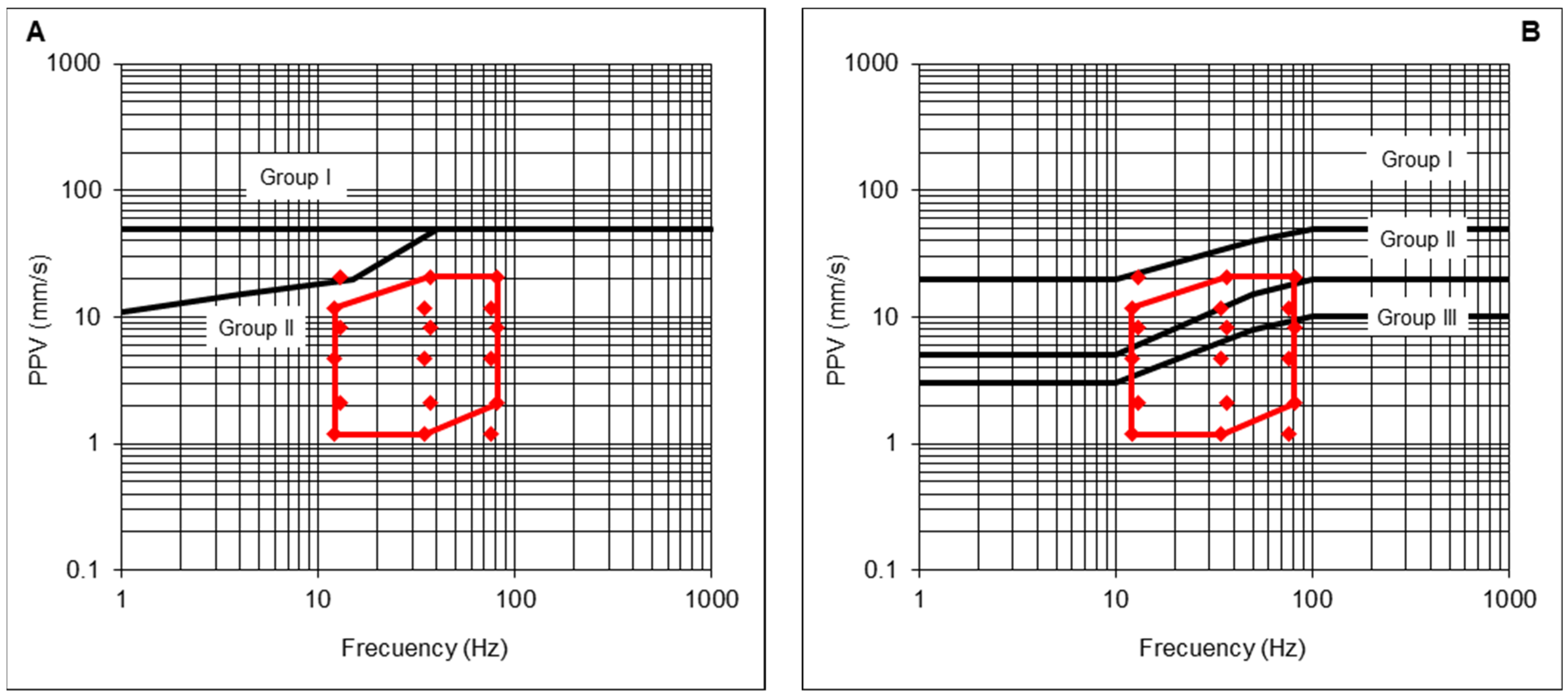

4.1. Definition of the Representative Area Assuming That Q, Dmin and Dmax Are Known

- (a)

- Firstly, the coordinates of the six points that define the border of the representative area are calculated (formulas in Table 4);

- (b)

- Secondly, the envelope defined by those six points is represented in the graph of the damage prevention criterion;

- (c)

- Finally, the result is analyzed from the relative position of the representative area with respect to the limit curves of the damage criterion.

4.2. Definition of the Representative Area When Charge per Delay Q Is Unknown

- Dmin and Dmax are the distances from the buildings to the closest and farthest projected blasts for any given year. It is always assumed that they are known because they can be determined from mine planning;

- Mean frequency fmed is determined from experimental data. If fmed is unknown, a rock-mass behavior must be assumed, giving a value to Kf and then estimating fmed as shown in Equations (17)–(19);

- 3.

- The most unfavorable frequency is determined, which is the minimum fmin detailed in Equation (20);

- 4.

- The maximum PPV admissible for the protection of Group II structures, with its corresponding frequency vGII, is determined from the prevention criterion defined in the UNE 22381 [44] standard (Equation (21)). In addition, a reduction coefficient cs could be applied as a more restrictive safety criterion, if needed;

- 5.

- The maximum and minimum charges per delay, Qmax and Qmin, that can be used are determined, so that vlim is not exceeded at distances Dmax and Dmin. Thus, the attenuation vibration law is used, considering that PPV can be cvmax times the value estimated by Equations (22)–(24);

- 6.

- The charge per delay is the average value obtained in the previous step (Equation (25));

- 7.

- The representative area of the blast results is drawn in the damage prevention criterion abacus using Qmed, Dmin and Dmax values.

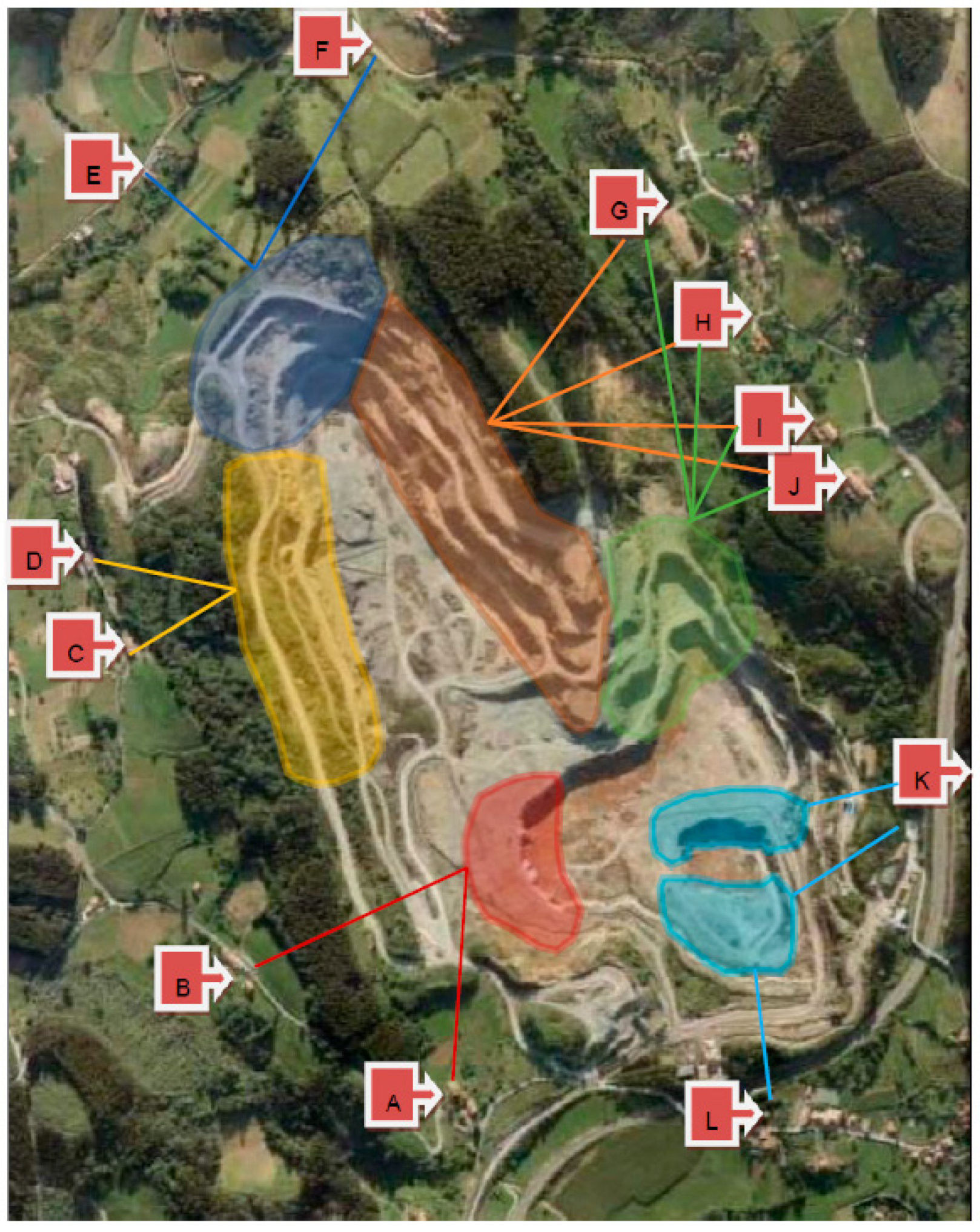

5. Calibration and Usage of the Procedure: El Perecil Quarry

5.1. Direct Use of General PPV and Frequency Attenuation Laws

- PPV attenuation law: Kv = 3085; α = 0.757; β = 1.651; cvmax = 2.5; cvmin = 0.25;

- Frequency attenuation law (low frequencies): Kf = 77.4; cfmax = 2.2; cfmin = 0.35.

5.2. Particularization from the General PPV and Frequency Attenuation Laws

6. Discussion

- (a)

- The variability of the result of a blast can be represented. The presentation of an area as an outcome helps to understand that many different vibration results can be equivalent, and all of them are valid. The difference between them stems from the variability in the blasting process, both due to natural causes (heterogeneity of the rock mass) and due to operational or blasting causes (dispersion in the pyrotechnic detonators, exact geometry of the blastholes, etc.);

- (b)

- It is a method that integrates the use of speed and frequency together. From an exclusively scientific point of view, it is possible to study the variations in both variables independently. However, from a more operational point of view, that of the engineers who design the blasts, a vibration study must necessarily take both variables into account at the same time, because the damage prevention criteria defined in all the standards have been defined as a function of those two variables;

- (c)

- If the method is calibrated, it can be quickly checked whether the blast result is as expected—a large part of the blast results (points) must be within the representative area. In addition, although the max charges per delay are defined based on the distances to the structures, the representative area can be estimated with the distances at which the seismographs have been placed;

- (d)

- The proposed method was designed to be useful and easy to understand for any type of technician. It is relevant because, sometimes, the technicians of the institutions in charge of assessing the environmental impact of the project that requires authorization do not have experience in blasting and/or vibrations;

- (e)

- The method can be used in different ways. If they are blasts where the distances to the structures to be protected are known, the max charge per delay can be chosen, and the method would help us to decide whether or not it is a good option. Likewise, a procedure is proposed to define the representative area of the blast, even if the max charge per delay is not known, since the damage criterion itself indirectly limits the load to be used;

- (f)

- The method allows easy calibration to adapt to the specific conditions of a site;

- (g)

- Finally, although for consistency we used the damage criterion of the UNE [44] standard, the proposed procedure can be used with any damage criterion.

- (a)

- As in any empirical method, the parameters must be defined for each specific place. In principle, the proposed model can only be used in the case of limestone and only as a first approach;

- (b)

- It was shown to be useful in blasting limestone, a rock with medium characteristics, and for this reason, we believe that it could be used in other types of rock; however, we cannot be conclusive, and it is not guaranteed that it can be extended to other types of rock;

- (c)

- Specific PPV and frequency attenuation laws were chosen, but others could have been chosen; no studies have been performed on determining which combination of velocity laws and frequency laws is the best for each case;

- (d)

- Since it is an empirical method that is not based on physical or mathematical laws, fundamental variables might not be taken into account, so it must be used in conditions similar to others in which it has been used successfully;

- (e)

- As with other empirical methods, since it is easy to use, and the results are easy to interpret, it can give a false sense of knowledge about the subject; however, it is not a method that allows technicians to be dispensed with, as the analysis must always be supervised by someone with knowledge of blasting.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- López-Jimeno, C.; López-Jimeno, E.; Bermúdez, P.G. Manual de Perforación, Explosivos y Voladuras: Minería y Obras Públicas; Universidad Politécnica de Madrid, Grupo de Proyectos de Ingeniería: Madrid, Spain, 2017. [Google Scholar]

- Xie, L.; Lu, W.; Gu, J.; Wang, G. Excavation Method of Reducing Blasting Vibration in Complicated Geological Conditions. Shock. Vib. 2018, 2018, 2518209. [Google Scholar] [CrossRef]

- Görgülü, K.; Arpaz, E.; Demirci, A.; Koçaslan, A.; Dilmaç, M.K.; Yüksek, A.G. Investigation of blast-induced ground vibrations in the Tülü boron open pit mine. Bull. Eng. Geol. Environ. 2013, 72, 555–564. [Google Scholar] [CrossRef]

- Hagan, T.N. Rock breakage by explosives. In Proceedings of the National Symposium on Rock Fragmentation, Adelaide, Australia, 26–28 February 1973; pp. 1–17. [Google Scholar]

- Wiss, J.F.; Linehan, P.W. Control of vibration and air noise from surface coal mines III. USBM Rep. 1978, 103, 623. [Google Scholar]

- Massarsch, K.R.; Fellenius, B.H. Pile Vibrations and Building Damage. Deep. Found. 2014, 5, 79–81. [Google Scholar]

- Dobrzycki, P.; Kongar-Syuryun, C.; Khairutdinov, A. Vibration reduction techniques for Rapid Impulse Compaction (RIC). J. Phys. Conf. Ser. 2020, 1425, 012202. [Google Scholar] [CrossRef]

- Herbut, A.; Khairutdinov, M.M.; Kongar-Syuryun, C.; Rybak, J. The surface wave attenuation as the effect of vibratory compaction of building embankments. IOP Conf. Ser. Earth Environ. Sci. 2019, 362, 012131. [Google Scholar] [CrossRef] [Green Version]

- Pal, R.P. Rock Blasting: Effects and Operations; IBH 2005; CRC Press: New Delhi, India, 2005; ISBN 9780415372305. [Google Scholar]

- Kahriman, A.; Ozer, U.; Aksoy, M.; Karadogan, A.; Tuncer, G. Environmental impacts of bench blasting at Hisarcik Boron open pit mine in Turkey. Environ. Geol. 2006, 50, 1015–1023. [Google Scholar] [CrossRef]

- Dowding, C.H. Construction Vibrations; Prentice-Hall: Englewood Cliffs, NJ, USA, 1996; ISBN 9780132991087. [Google Scholar]

- Tripathy, G.R.; Shirke, R.R.; Kudale, M.D. Safety of engineered structures against blast vibrations: A case study. J. Rock Mech. Geotech. Eng. 2016, 8, 248–255. [Google Scholar] [CrossRef] [Green Version]

- Yan, Y.; Hou, X.; Fei, H. Review of predicting the blast-induced ground vibrations to reduce impacts on ambient urban communities. J. Clean. Prod. 2020, 260, 121135. [Google Scholar] [CrossRef]

- Papán, D.; Papánová, Z. Experimental investigation of the seismic effects during blasting works. MATEC Web Conf. 2020, 313, 00019. [Google Scholar] [CrossRef]

- Antón, M.B.; García, J.D. Spatial relation between laws of vibration from blasting. Int. J. Surf. Min. Reclam. Environ. 1995, 9, 161–164. [Google Scholar] [CrossRef]

- Zhou, J.; Li, C.; Koopialipoor, M.; Armaghani, D.J.; Pham, B.T. Development of a new methodology for estimating the amount of PPV in surface mines based on prediction and probabilistic models (GEP-MC). Int. J. Min. Reclam. Environ. 2021, 35, 48–68. [Google Scholar] [CrossRef]

- Filice, A.; Mynarz, M.; Zinno, R. Experimental and Empirical Study for Prediction of Blast Loads. Appl. Sci. 2022, 12, 2691. [Google Scholar] [CrossRef]

- Gonen, A. Investigation of Fault Effect on Blast-Induced Vibration. Appl. Sci. 2022, 12, 2278. [Google Scholar] [CrossRef]

- Nicholls, H.R.; Johnson, C.F.; Duvall, W.I. Blasting Vibrations and Their Effects on Structures; Bulletin 656; U. S. Bureau of Mines: Washington, DC, USA, 1971.

- Studer, J.; Suesstrunk, A. Swiss Standard for Vibration Damage to Buildings. In Proceedings of the Tenth International Conference on Soil Mechanics and Foundation Engineering, Stockholm, Sweden, 15–19 June 1981. [Google Scholar]

- Konon, W. Vibration criteria for historic buildings. J. Constr. Eng. Manag. 1985, 111, 208–215. [Google Scholar] [CrossRef]

- Tripathy, G.R.; Gupta, I.D. Prediction of ground vibrations due to construction blasts in different types of Rock. Rock Mech. Rock Eng. 2002, 35, 195–204. [Google Scholar] [CrossRef]

- Duvall, W.I.; Petkof, B. Spherical Propagation of Explosion of Generated Strain Pulses in Rocks. In Report of Investigation 4583; US Bureau of Mines: Washington, DC, USA, 1959; Volume 21. [Google Scholar]

- Langefors, U.; Kihlstrom, B. The Modern Technique of Rock Blasting; John Wiley & Sons: New York, NY, USA, 1976. [Google Scholar]

- Ak, H. The Investigation of Directional Changes of the Blast Induced Ground Vibration. Ph.D. Thesis, Eskisehir Osmangazi University, Eskişehir, Turkey, 2006. [Google Scholar]

- Yang, J.H.; Lu, W.B.; Zhao, Z.G.; Yan, P.; Chen, M. Safety distance for secondary shotcrete subjected to blasting vibration in Jinping-II deep-buried tunnels. Tunn. Undergr. Space Technol. 2014, 43, 123–132. [Google Scholar] [CrossRef]

- Davies, B.; Farmer, I.W.; Attewell, P.B. Ground vibration from shallow sub-surface blasts. Engineer 1964, 217, 553–559. [Google Scholar]

- Pal Roy, P. Vibration control in an opencast mine based on improved blast vibration predictors. Min. Sci. Technol. 1991, 12, 157–165. [Google Scholar] [CrossRef]

- Liu, D.; Lu, W.; Liu, Y.; Chen, M.; Yan, P.; Sun, P. Analysis of the Main Factors Influencing the Dominant Frequency of Blast Vibration. Shock. Vib. 2019, 2019, 8480905. [Google Scholar] [CrossRef]

- Singh, P.K.; Roy, M.P. Damage to surface structures due to blast vibration. Int. J. Rock Mech. Min. Sci. 2010, 47, 949–961. [Google Scholar] [CrossRef]

- Roy, M.P.; Singh, P.K.; Sarim, M.; Shekhawat, L.S. Blast design and vibration control at an underground metal mine for the safety of surface structures. Int. J. Rock Mech. Min. Sci. 2016, 83, 107–115. [Google Scholar] [CrossRef]

- Zhong, G.; Ao, L.; Zhao, K. Influence of explosion parameters on wavelet packet frequency band energy distribution of blast vibration. J. Cent. South Univ. 2012, 19, 2674–2680. [Google Scholar] [CrossRef]

- Yang, J.H.; Lu, W.B.; Jiang, Q.H.; Yao, C.; Zhou, C.B. Frequency comparison of blast-induced vibration per delay for the full-face millisecond delay blasting in underground opening excavation. Tunn. Undergr. Space Technol. 2016, 51, 189–201. [Google Scholar] [CrossRef]

- Zhou, J.; Lu, W.; Yan, P.; Chen, M.; Wang, G. Frequency-dependent attenuation of blasting vibration waves. Rock Mech. Rock Eng. 2016, 49, 4061–4072. [Google Scholar] [CrossRef]

- Álvarez-Vigil, E.; González-Nicieza, C.; López Gayarre, F.; Álvarez-Fernández, M.I. Predicting blasting propagation velocity and vibration frequency using artificial neural networks. Int. J. Rock Mech. Min. Sci. 2012, 55, 108–116. [Google Scholar] [CrossRef]

- Monjezi, M.; Amiri, H.; Farrokhi, A.; Goshtasbi, K. Prediction of rock fragmentation due to blasting in sarcheshmeh copper mine using artificial neural networks. Geotech. Geol. Eng. 2010, 28, 423–430. [Google Scholar] [CrossRef]

- Khandelwal, M.; Singh, T.N. Prediction of blast-induced ground vibration using artificial neural network. Int. J. Rock Mech. Min. Sci. 2009, 46, 1214–1222. [Google Scholar] [CrossRef]

- Khandelwal, M.; Kankar, P.; Harsha, S. Evaluation and prediction of blast induced ground vibration using support vector machine. Min. Sci. Technol. 2010, 20, 64–70. [Google Scholar] [CrossRef]

- Yu, Z.; Shi, X.; Zhou, J.; Chen, X.; Qiu, X. Effective assessment of blast-induced ground vibration using an optimized random forest model based on a harris hawks optimization algorithm. Appl. Sci. 2020, 10, 1403. [Google Scholar] [CrossRef] [Green Version]

- Valašková, V.; Papán, D.; Drusa, M. Assessment of Blasting Operations Effects During Highway Tunnel Construction. GeoSci. Eng. 2016, 61, 23–28. [Google Scholar] [CrossRef]

- Duvall, W.I.; Fogelson, D.E. Review of Criteria for Estimating Damage to Residences from Blasting Vibrations. In Report of Investigation 5968; US Department of the Interior, Bureau of Mines: Washington, DC, USA, 1962. [Google Scholar]

- Siskind, D.E.; Stagg, M.S.; Kopp, J.W.; Dowing, C.H. Structure Response and Damage Produced by Ground Vibrations from Surface Mine Blasting. In Report of Investigation 8507; U.S. Bureau of Mines: Washington, DC, USA, 1980; Volume 74. [Google Scholar]

- BS 7385; Evaluation and Measurement for Vibration in Buildings—Part 2. British Standards Institution: London, UK, 1993.

- UNE 22-381-93; Control of Vibrations Caused by Blasting. Spanish Association for Standardisation (UNE): Madrid, Spain, 1993.

- DIN 4150; Vibration in Buildings—Part 3: Effects on Structures. Deutsches Institut für Normen, Beuth Verlar GmbH: Berlin, Germany, 1999.

- Ambraseys, N.N.; Hendron, A.J. Dynamic Behavior of Rock Masses: Rock Mechanics in Engineering Practices; Stagg, K., Ed.; J. Wiley & Sons: London, UK, 1968. [Google Scholar]

- Ghosh, A.; Daemen, J.K. A simple new blast vibration predictor. In Proceedings of the 24th U.S. Symposium of Rock Mechanics, College Station, TX, USA, 20–23 June 1983; pp. 151–161. [Google Scholar]

- Ozer, U. Environmental impacts of ground vibration induced by blasting at different rock units on the KadikoyeKartal metro tunnel. Eng. Geol. 2008, 100, 82–90. [Google Scholar] [CrossRef]

- Ak, H.; Konuk, A. The effect of discontinuity frequency on ground vibrations produced from bench blasting: A case study. Soil Dyn. Earthq. Eng. 2008, 28, 686–694. [Google Scholar] [CrossRef]

- Mesec, J.; Kovac, I.; Soldo, B. Estimation of particle velocity based on blast event measurements at different rock units. Soil Dyn. Earthq. Eng. 2010, 30, 10049. [Google Scholar] [CrossRef]

- Kumar, R.; Choudhury, D.; Bhargava, K. Determination of blast-induced ground vibration equations for rocks using mechanical and geological properties. J. Rock Mech. Geotech. Eng. 2016, 8, 341–349. [Google Scholar] [CrossRef] [Green Version]

- Sadovskij, M.A. Evaluation of seismically dangerous zones in blasting, seismic institute of the academy of sciences. In On the Effects of Blast-Induced Vibrations; Bulletin of Subalpina Mining Association, 1966. [Google Scholar]

- Jiao, Y.B. Research on the standard of blasting seismic safety assessment. Blasting 1995, 12, 45–47. [Google Scholar]

- Zhang, L.G.; Yu, Y.L. Research on the relationship of main vibration frequency of blasting vibration and peak particle velocity. Nonferrous Met. 2005, 57, 32–34. [Google Scholar]

- Meng, L.; Guo, F. Experimental research on the master frequency of blasting seismic wave. J. Railw. Eng. Soc. 2009, 11, 81–83. [Google Scholar]

- Li, X.; Li, J.; Li, X.; Xia, W. Application of coupled analysis methods for prediction of blast-induced dominant vibration frequency. Earthq. Eng. Eng. Vib. 2016, 15, 153–162. [Google Scholar] [CrossRef]

- Cardu, M.; Dompieri, M.; Seccatore, J. Complexity analysis of blast-induced vibrations in underground mining, a case study. Min. Sci. Technol. 2012, 22, 125–131. [Google Scholar] [CrossRef] [Green Version]

- Balsa, J. Leyes estadísticas de transmisividad en distintos tipos de rocas. Canteras Y Explot. 1989, 272, 61–73. [Google Scholar]

- Fernández, P.R.; Rodríguez, R.; Bascompta, M. Holistic approach to define the blast design in quarrying. Minerals 2022, 12, 191. [Google Scholar] [CrossRef]

- Ratti, G. On the effects of blast-induced vibrations. Bull. Subalp. Min. Assoc. 1966. [Google Scholar]

- Devine, J.R. Avoiding damage to residences from blasting vibrations. Proc. Natl. Acad. Sci. USA 1966, 135, 35–42. [Google Scholar]

| Blast | Quarry | Region | Type of Blast | D (m) | Q (kg) | PPV (mm/s) | fmed (Hz) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | Asturias | Production | 97 | 30.0 | 9.16 | 88.7 |

| 2 | 144 | 30.0 | 3.39 | 70.7 | |||

| 3 | 125 | 33.0 | 22.80 | 41.7 | |||

| 4 | 240 | 33.0 | 4.85 | 33.0 | |||

| 5 | 164 | 50.0 | 8.20 | 36.0 | |||

| 6 | 350 | 50.0 | 2.77 | 35.7 | |||

| 7 | 213 | 17.3 | 7.06 | 55.3 | |||

| 8 | 322 | 17.3 | 2.27 | 42.3 | |||

| 9 | 125 | 79.5 | 12.21 | 56.3 | |||

| 10 | 60 | 29.1 | 28.28 | 40.7 | |||

| 11 | 300 | 76.1 | 4.64 | 54.3 | |||

| 12 | 30 | 35.7 | 151.99 | 37.0 | |||

| 13 | 105 | 35.7 | 16.94 | 36.0 | |||

| 14 | 30 | 16.8 | 37.19 | 40.0 | |||

| 15 | 105 | 16.8 | 7.51 | 35.3 | |||

| 16 | 75 | 23.3 | 82.12 | 49.7 | |||

| 17 | 75 | 46.6 | 19.89 | 41.7 | |||

| 18 | 347 | 46.6 | 3.19 | 39.7 | |||

| 19 | 167 | 58.3 | 29.79 | 49.3 | |||

| 20 | 128 | 58.3 | 31.09 | 47.7 | |||

| 21 | 30 | 34.6 | 65.41 | 34.7 | |||

| 22 | 15 | 11.1 | 30.70 | 54.7 | |||

| 23 | 104 | 68.6 | 14.19 | 28.3 | |||

| 24 | 104 | 14.0 | 2.85 | 53.3 | |||

| 25 | 329 | 89.2 | 5.72 | 42.7 | |||

| 26 | 329 | 89.2 | 8.08 | 45.7 | |||

| 27 | 218 | 63.0 | 11.05 | 53.0 | |||

| 28 | 218 | 63.0 | 13.16 | 51.0 | |||

| 29 | 278 | 51.4 | 9.06 | 73.0 | |||

| 30 | 278 | 51.4 | 5.01 | 34.0 | |||

| 31 | 2 | Asturias | Production | 100 | 109.1 | 36.29 | 52.0 |

| 32 | 180 | 109.1 | 10.64 | 43.3 | |||

| 33 | 240 | 109.1 | 6.50 | 30.7 | |||

| 34 | 100 | 108.3 | 25.27 | 28.7 | |||

| 35 | 200 | 108.3 | 5.08 | 46.0 | |||

| 36 | 3 | Cantabria | Production | 250 | 62.0 | 2.60 | 34.7 |

| 37 | 425 | 30.0 | 2.03 | 10.5 | |||

| 38 | 450 | 35.0 | 0.95 | 10.0 | |||

| 39 | 350 | 35.0 | 1.71 | 20.4 | |||

| 40 | 4 | Cantabria | Production | 168 | 85.0 | 10.30 | 14.7 |

| 41 | 210 | 85.0 | 3.42 | 18.3 | |||

| 42 | 168 | 92.0 | 18.12 | 17.3 | |||

| 43 | 225 | 92.0 | 16.05 | 23.7 | |||

| 44 | 149 | 42.0 | 10.53 | 16.7 | |||

| 45 | 314 | 42.0 | 5.67 | 18.0 | |||

| 46 | 264 | 42.0 | 8.20 | 15.0 | |||

| 47 | 535 | 42.0 | 1.40 | 12.4 | |||

| 48 | 5 | Burgos | Production | 180 | 15.0 | 7.11 | 51.4 |

| 49 | 180 | 12.0 | 6.60 | 61.3 | |||

| 50 | 190 | 14.0 | 2.54 | 44.2 | |||

| 51 | 200 | 12.0 | 1.97 | 42.1 | |||

| 52 | 180 | 12.0 | 1.97 | 37.0 | |||

| 53 | 75 | 15.0 | 11.07 | 39.7 | |||

| 54 | 110 | 15.0 | 4.38 | 32.7 | |||

| 55 | 80 | 15.0 | 3.15 | 33.3 | |||

| 56 | 145 | 15.0 | 3.00 | 41.7 | |||

| 57 | 515 | 35.0 | 2.31 | 51.3 | |||

| 58 | 90 | 15.0 | 3.87 | 78.3 | |||

| 59 | 125 | 15.0 | 2.77 | 48.7 | |||

| 60 | 110 | 15.0 | 1.89 | 34.7 | |||

| 61 | 90 | 15.0 | 17.00 | 56.7 | |||

| 62 | 50 | 15.0 | 27.80 | 67.0 | |||

| 63 | 40 | 15.0 | 4.38 | 29.7 | |||

| 64 | 110 | 15.0 | 2.52 | 20.7 | |||

| 65 | 90 | 15.0 | 3.87 | 24.0 |

| Blast | Quarry | Region | Type of Blast | D (m) | Q (kg) | PPV (mm/s) | fmed (Hz) |

|---|---|---|---|---|---|---|---|

| 66 | 6 | Navarra | Test | 190 | 9.6 | 1.71 | 14.5 |

| 67 | 240 | 9.6 | 0.95 | 14.6 | |||

| 68 | 180 | 7.2 | 1.40 | 17.1 | |||

| 69 | 230 | 7.2 | 0.89 | 15.3 | |||

| 70 | 160 | 12.0 | 1.46 | 13.4 | |||

| 71 | 210 | 12.0 | 0.95 | 12.1 | |||

| 72 | 150 | 33.6 | 3.56 | 17.3 | |||

| 73 | 200 | 33.5 | 1.65 | 12.4 | |||

| 74 | 120 | 16.8 | 4.64 | 20.8 | |||

| 75 | 170 | 16.8 | 1.52 | 14.2 |

| Point | Q (kg) | D (m) | cv | cf | f (Hz) | PPV (mm/s) |

|---|---|---|---|---|---|---|

| 1 | 30 | 175 | 0.25 | 0.35 | 12.1 | 2.0 |

| 2 | 30 | 125 | 0.25 | 0.35 | 12.9 | 3.5 |

| 3 | 30 | 175 | 0.25 | 1 | 34.5 | 2.0 |

| 4 | 30 | 125 | 0.25 | 1 | 36.9 | 3.5 |

| 5 | 30 | 175 | 0.25 | 2.2 | 75.9 | 2.0 |

| 6 | 30 | 125 | 0.25 | 2.2 | 81.2 | 3.5 |

| 7 | 30 | 175 | 1 | 0.35 | 12.1 | 8.0 |

| 8 | 30 | 125 | 1 | 0.35 | 12.9 | 14.0 |

| 9 | 30 | 175 | 1 | 1 | 34.5 | 8.0 |

| 10 | 30 | 125 | 1 | 1 | 36.9 | 14.0 |

| 11 | 30 | 175 | 1 | 2.2 | 75.9 | 8.0 |

| 12 | 30 | 125 | 1 | 2.2 | 81.2 | 14.0 |

| 13 | 30 | 175 | 2.5 | 0.35 | 12.1 | 20.1 |

| 14 | 30 | 125 | 2.5 | 0.35 | 12.9 | 34.9 |

| 15 | 30 | 175 | 2.5 | 1 | 34.5 | 20.1 |

| 16 | 30 | 125 | 2.5 | 1 | 36.9 | 34.9 |

| 17 | 30 | 175 | 2.5 | 2.2 | 75.9 | 20.1 |

| 18 | 30 | 125 | 2.5 | 2.2 | 81.2 | 34.9 |

| Point | Q (kg) | D (m) | cv | cf | f (Hz) | PPV (mm/s) |

|---|---|---|---|---|---|---|

| 1 | Q | Dmax | cvmin | cfmin | ||

| 2 | Q | Dmax | cvmax | cfmin | ||

| 3 | Q | Dmin | cvmax | cf = 1 | ||

| 4 | Q | Dmin | cvmax | cfmax | ||

| 5 | Q | Dmin | cvmin | cfmax | ||

| 6 | Q | Dmax | cvmin | cf = 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez, R.; Bascompta, M.; Fernández, P.; Fernández, P.R. Representative-Area Approach to Define Blast-Induced Ground Vibrations—Damage Prevention Criterion Abacus. Minerals 2022, 12, 691. https://doi.org/10.3390/min12060691

Rodríguez R, Bascompta M, Fernández P, Fernández PR. Representative-Area Approach to Define Blast-Induced Ground Vibrations—Damage Prevention Criterion Abacus. Minerals. 2022; 12(6):691. https://doi.org/10.3390/min12060691

Chicago/Turabian StyleRodríguez, Rafael, Marc Bascompta, Patricia Fernández, and Pablo R. Fernández. 2022. "Representative-Area Approach to Define Blast-Induced Ground Vibrations—Damage Prevention Criterion Abacus" Minerals 12, no. 6: 691. https://doi.org/10.3390/min12060691

APA StyleRodríguez, R., Bascompta, M., Fernández, P., & Fernández, P. R. (2022). Representative-Area Approach to Define Blast-Induced Ground Vibrations—Damage Prevention Criterion Abacus. Minerals, 12(6), 691. https://doi.org/10.3390/min12060691