Unmanned Amphibious Vehicles (UAmVs), also known as underwater drones, are any submersible vehicles that can operate underwater without the presence of a human operator. UAmVs are commonly used in oceanic research for purposes such as measuring current and temperature, mapping the ocean floor, detecting hydrothermal vents, and so on. To carry out the aforementioned applications, the UAmVs rely heavily on digital cameras, magnetic sensors, ultrasonic imagers, seafloor maps, and bathymetry measurements. Remotely Operated Underwater Vehicles (ROUVs) and Autonomous Underwater Vehicles (AUVs) are two types of UAmVs. A ROUV is an unmanned submersible vehicle that is controlled by a person on a surface vessel using a joystick in the same way that a video game is controlled. The ROUV is connected to the ship by a series of cables, or tethers, which send electrical signals back and forth between the operator and the vehicle. Most ROUVs have at least a still camera, a video camera, and lights, allowing them to transfer images and videos back to the ship. To collect samples, vehicles may be outfitted with additional equipment such as a manipulator or cutting arm, water samplers, and instruments that measure parameters such as water clarity and temperature.

An AUV is an unmanned submersible vehicle that operates autonomously because it does not require real-time input or control from a human operator or driver. Before embarking on any complicated missions, the AUVs are generally programmed with instructions and then deployed into the ocean. AUVs can drift, glide, or propel themselves through the water, depending on their design. Propelled AUVs can travel faster and are more manoeuvrable than non-propelled AUVs, but they have less battery life and are typically used on missions lasting several hours to days. Non-propelled AUVs (drifters or gliders) either drift without power or glide up and down in the water column by changing buoyancy, making them much less manoeuvrable. The AUVs do not require a large and complex support system, but they do carry their energy source and thus do not require external power. The lack of external control lowers the operational cost of employing a human operator: Unlike other unmanned vehicles such as ROUVs, AUVs work without control from an operator, which makes it faster, increasing its data-to-signal ratio makes surveys faster and more accurate. The geographical positions to be followed, navigation requirements for following these positions, measures to avoid obstacles, measures to take if any equipment fails, and payload device operation procedures are all predetermined. For these reasons, the AUV is the most appropriate type for detecting and collecting seabed-based mining available up to 300 m below the water’s surface. As a result, this proposed UAmV is classified as an AUV.

1.1. Literature Review

A literature survey is a collection of previously completed and relevant studies that aid the researcher in gaining a complete picture of the short-listed problems, as well as providing the best methodology for solving the problems. It also provides support for implementing the proposed methodology. The literature review for this project is focused on the following themes: UAmV design and components, computational fluid and vibrational analysis procedures, analytical approach for energy extraction, details of suitable materials for UAmV, and mission execution capability and supporting components.

Muhammad et al. [

1] showed the dynamic stability of an underwater glider, wherein two different forms of wings such as rectangular and tapered on hydrodynamic characteristics were investigated. They also explained the motion, which was based on six degrees of freedom (DOF). A highly manoeuvrable glider requires dynamic stabilities in both horizontal and vertical directions. The stability was controlled by eternal fixed wings and a rudder. The paper also explained the performance of the glider, i.e., glide ratio, horizontal, vertical, and sink were related to its hydrodynamic characteristics. This also provided steady-state CFD analysis to determine the hydrodynamic characteristics and dynamic stability of a glider. It concluded that the glider with tapered wing forms had a positive relationship between the velocities of the glider at the same angle compared to the rectangular wing. The rectangular wing had better dynamic stability with a high lift force. This shows that the CFD simulation results are important for the dynamic stability of the glider. Additionally, we also confirmed which wing form is suitable for our model based on this paper [

1].

Finger [

2] investigated the design space for VTOL (Vertical Take-Off and Landing) UAmVs and evaluated the performance by direct comparison with conventional aircraft. The VTOL combines the helicopter’s ability to take-off and land almost anywhere, with the speed range and load-carrying capability of a fixed-wing aircraft. The paper also showed a different VTOL aircraft that uses single and double propulsive units. The scope of this paper was limited to fixed-wing aircraft that use a propeller to convert the propulsion system’s power into thrust power. The endurance performance, mass fraction model, aerodynamic modelling, propulsion system modelling, propeller efficiency, fuel consumption, maximum engine power, etc. for the models were estimated. In this paper, the effects of the VTOL requirement on aircraft performance were assessed and this work showed that, with today’s technology, VTOL UAmVs are certainly feasible. It is clear from the paper that the VTOL aircraft gives better efficiency compared with conventional aircraft. This present work helps design the UAmV and performance of the UAmV. From this paper [

2], we have finalized the configurations and design parameters for our work.

Chung et al. [

3] defines the design process by defining performance requirements, the wing loading and associated power, the wing area mass and power requirements, motor size, and stability design based on selected material and wing area. The flight duration depends on the energy carried by the UAmV. High-energy fuel density enables lower weight and better performance; therefore, a method was developed by sizing the electric propulsion subsystem. Thus, the performance requirement of an electric-powered UAmV is defined as stall speed, the maximum speed at depth and turning radius, and the absolute ceiling is used to determine the wing load and power load. The UAmV’s wing area and power required can be calculated from weight and loading. The paper also gives a brief description of the conceptual design. The stall speed is a limit to the maximum speed at a safe lift. The cruising speed is 1.15 times the maximum lift-to-drag ratio and the maximum speed is 1.2 times the cruising speed. Then, it also gives the ceiling types and the critical performance. The paper described the weight estimation such as battery weight according to range and endurance, specific payload, and endurance. In aerodynamic configuration and stability design, the wing configuration greatly influences the aircraft’s aerodynamic characteristics and efficiency. It is necessary to understand the wing and aerofoil parameters to ensure that the aircraft has good aerodynamic characteristics under mission requirements. To increase the flying wing UAmV’s lateral stability, its dihedral angle was designed suitably. The manufacturing parameters are also given in this paper. The maximum cruising speed and design for the given payload are designed and reported in this paper. From this paper, the authors can determine the stable hydrodynamic design, the payload which we carry, the absolute ceiling used to determine the depth of the surveillance and energy fuels, and also able to determine its motor size with maximum cruising speed.

The study by Wood [

4] focuses on the reasons for using AUV, highlighting its ability to help scientists carry out complex studies, such as the effects of metals, pesticides, and nutrients on fish abundance, reproductive success, and ability to feed, or on contaminants such as chemicals and biological toxins and the effects of plastics offshore. The paper also mentioned that there are currently over 50 types of AUV’s for research and commercial purposes, including gliders, which are vehicles that glide down slowly to a given depth and then return to the surface with a buoyancy effect. Gliders are capable of travelling in a horizontal path and a typical propeller follows saw tooth, which can descend or ascend vertically. There are several types of gliders. Among them are Slocum gliders, optimized for operation in shallow waters in coastal areas, and spray gliders, which are hydrodynamic in shape and give 50% less drag, so their range is up to 4700 km. Deep gliders are made out of a composite pressure hull of thermoset resin and carbon fibre and operate for one year in 4600 km missions. Both sea and deep gliders have been used in the hydraulic system to control their buoyancy. The military has developed an advanced underwater winged glider based on the air force’s flying wing design. The above paper also presents the systems in hybrid AUV-powered gliders, such as active buoyancy and trim control, fluid intake and sample taking system, communication and navigation, etc, highlighting knowledge about gliders and their types. It also provides the use of controlling the buoyancy to steer underwater. With this in mind, we can define the type of model we to use in our ideas in addition to the system required for underwater purposes and the efficient propulsive system for our requirements.

Abdullah et al. [

5] highlights the convenience of computational methods for solving fluid flow problems. They give a brief definition of the gliders, in which the AUV dive and return with buoyancy and the gliders are mainly used to collect oceanographic data. The Lattice Boltzmann methodology (LBM) is used for the numerical background in place of meshing because the Meshing process is time-consuming. The paper showed that the bell span-load wing (BSW) shape was applied to the existing glider to improve the efficiency of the glider without considering its yaw and roll motion and, hence, the tail was not removed from the glider. The CAD (Computer-Aided Design) of the BSW-shaped glider and the lattice structures around it has been represented. After several calculations, it was shown that the BSW design generated less drag force than the elliptical span-load wings (ESW) design. In this paper, a wing design form was implemented to the benchmark glider design and the computations were taken, in which it was concluded that the lift and drag forces reduce while the stall angle increases. From this, it was seen that BSW provides less drag and lift forces. The variations in the drag and lift forces with the various AOA showed that the BSW shape design increased the stall angle of the vehicle. As shown in this paper, the BSW wing gives minimum drag compared to the ESW design; hence, it is clear that the BSW design is used to obtain better efficiency compared to the ordinary wing design.

Zihao et al. [

6] suggest underwater gliders with low lift-to-drag ratios to solve the targeted problem, developing the flying-wing design. To optimize the shape design using the computational fluid dynamics code, further calculations were undertaken. CFD simulation was performed to investigate the hydrodynamic force at various velocities and angles of attack. It was used to determine the wingspan of the AUV glider. In the flying wing configuration, which was configured to travel farther in horizontal per unit distance and ascend vertically with great gliding efficiency, they used NACA 6 series aerofoil, which provided maximum laminar flow. The reason for selecting laminar flow aerofoil was that the Reynolds’s number of gliders is laminar and the turbulent transition layer in which the winglets under reasonable design can improve glide efficiency. The performance prediction suggested that the flying wing underwater gliders were more suitable for AOA, which was 5 degrees and had a small glide slope angle. The paper concluded that, in the future, further designs of the HFWUG will be carried out. Appendages of the glider, such as a winglet—a flap that can reduce the drag and enhance manoeuvrability—will be developed. It is clear that the flying wing configure improves the performance and is more suitable for big AOA.

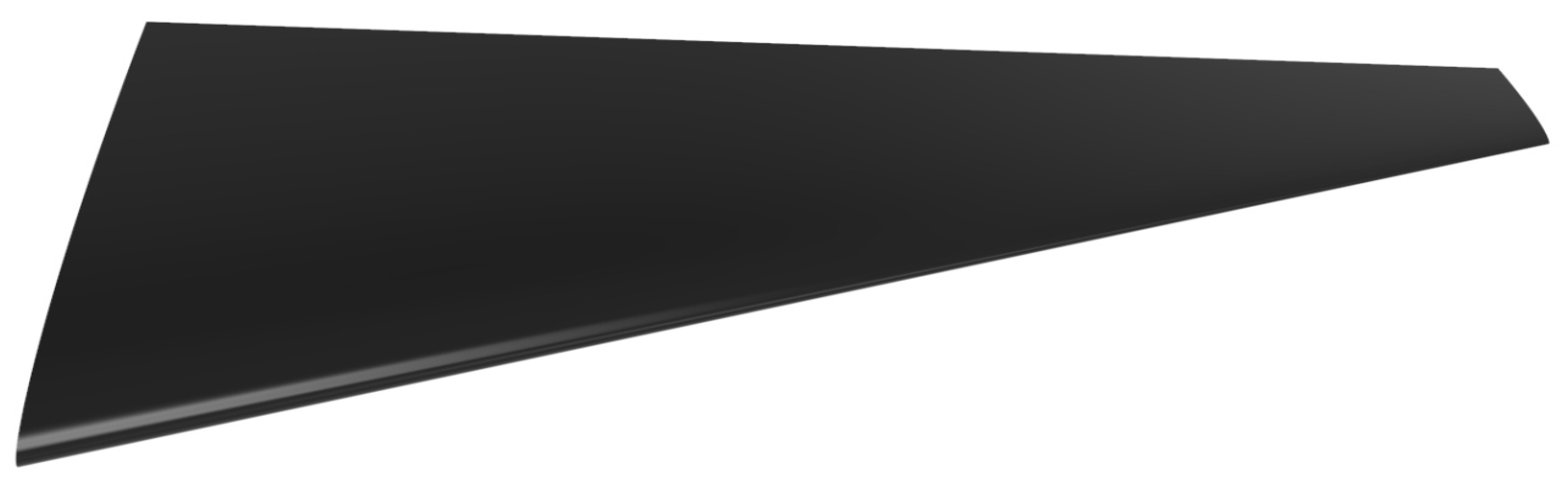

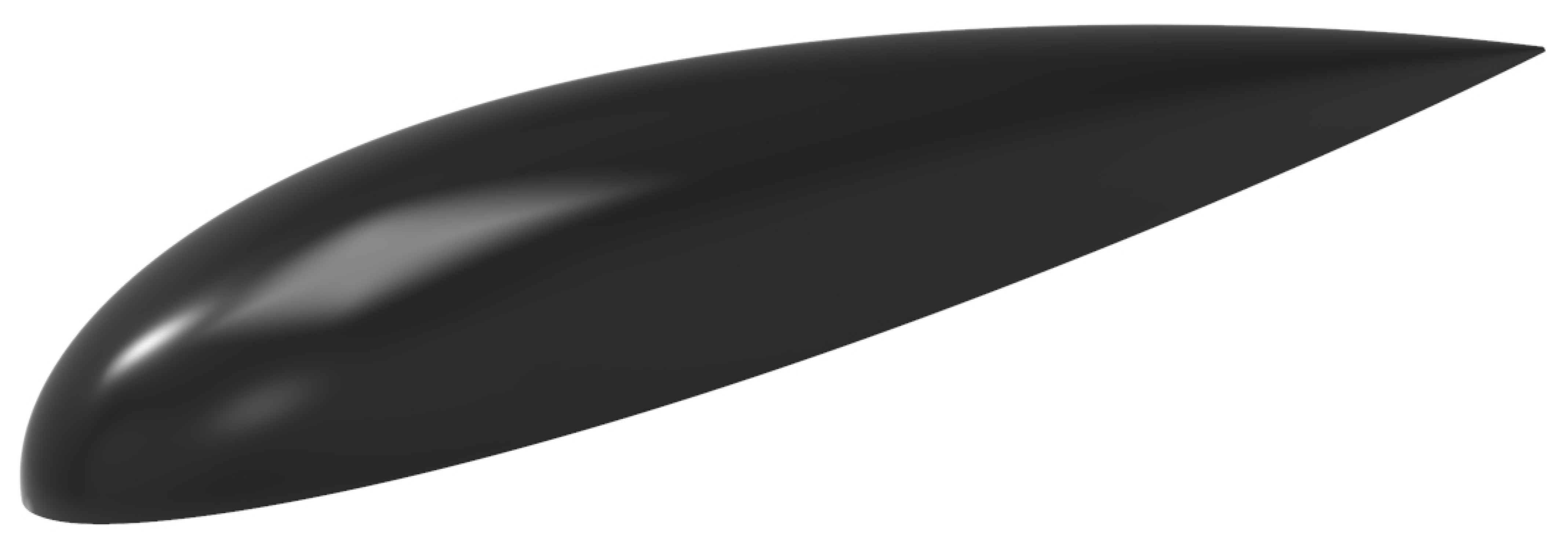

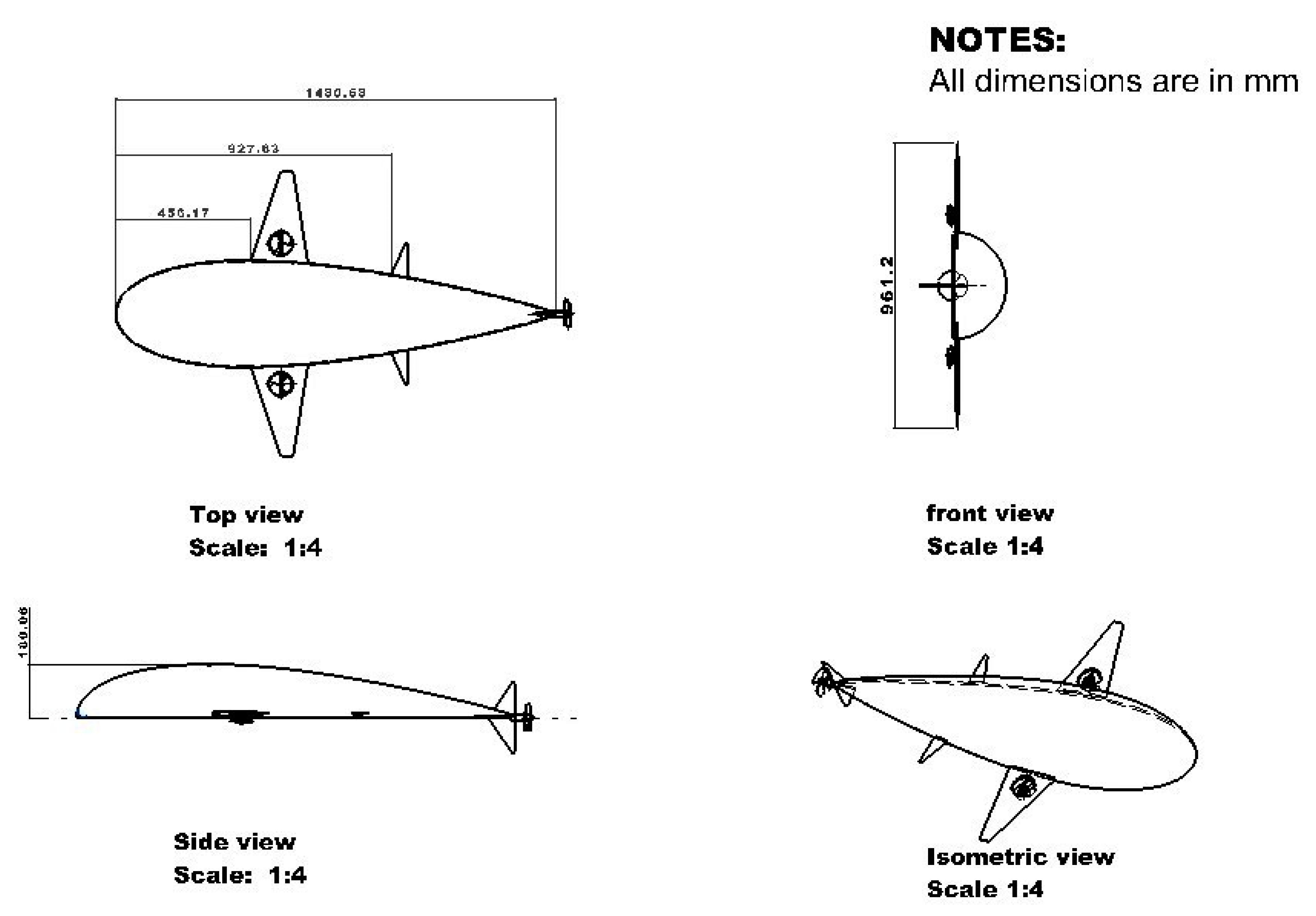

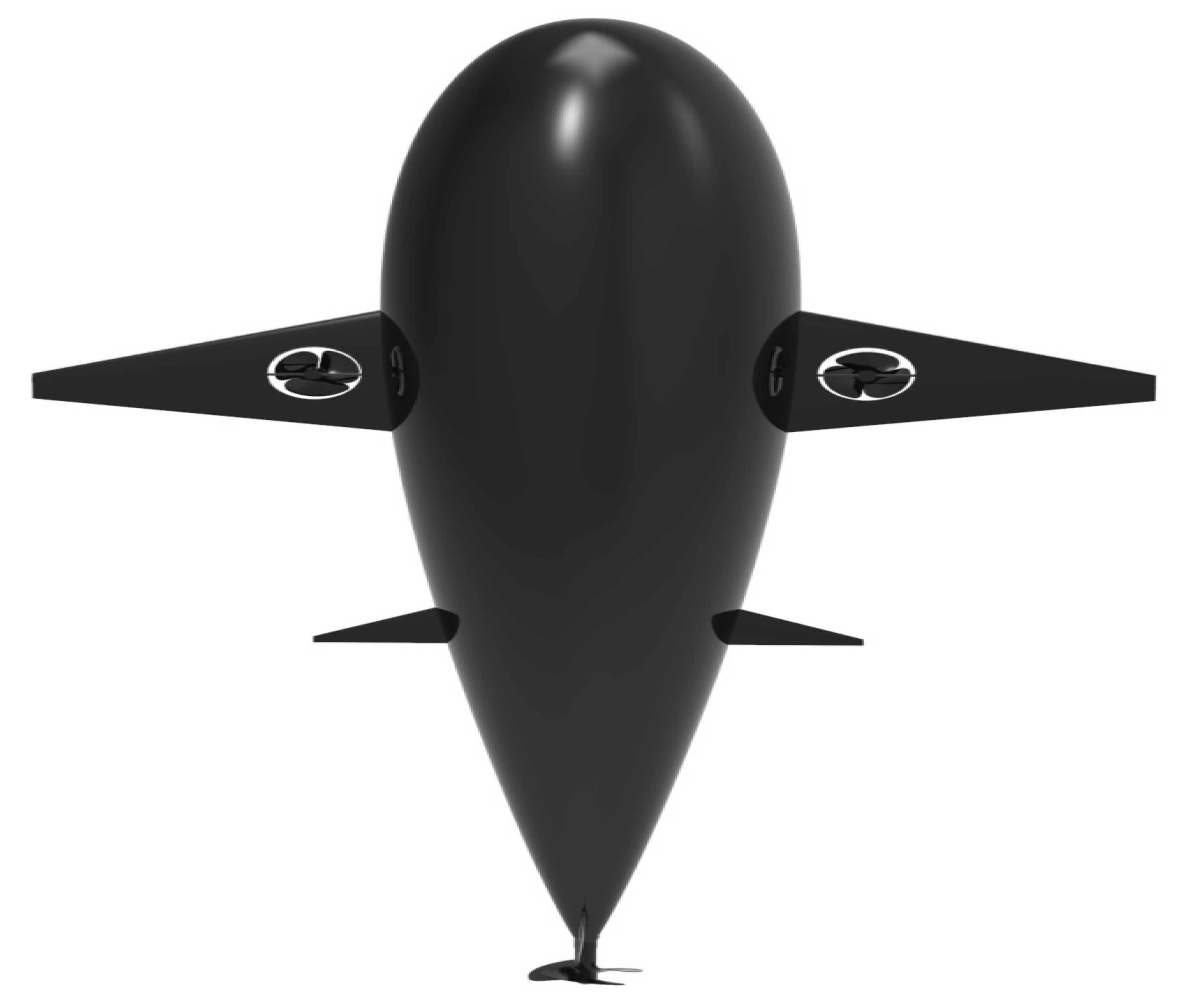

Since the targeted mission location is very dangerous, in order for the UAmV to withstand high hydrodynamic pressures, the need for an efficient, structurally robust, streamlined design is essential. Therefore, this work proposes a design that mimics the appearance and ability of deep-sea fish. According to the data based on the first literature survey, a design based on Rhinaancylostoma was found to be the most suitable to carry out the current investigation [

7,

8,

9,

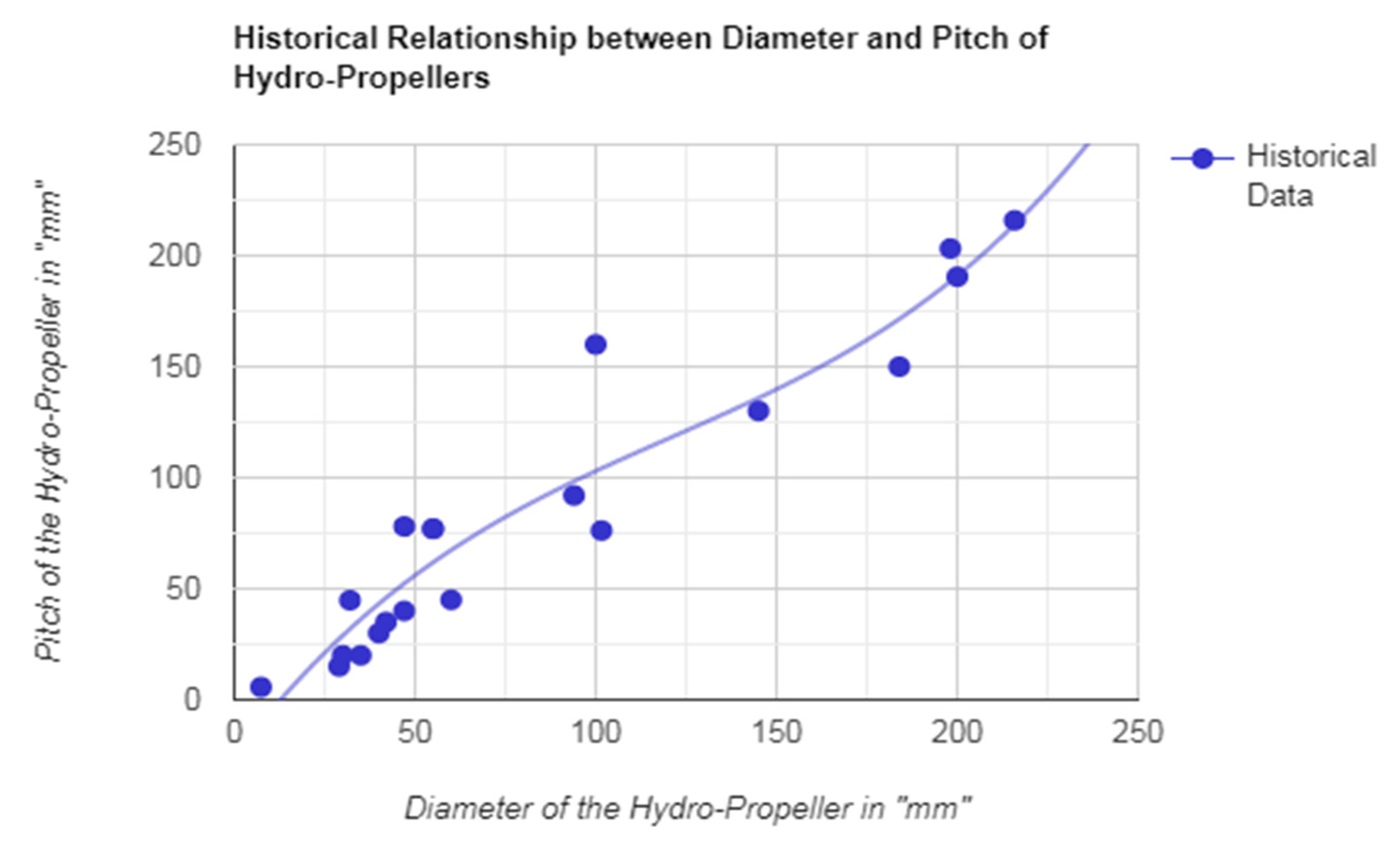

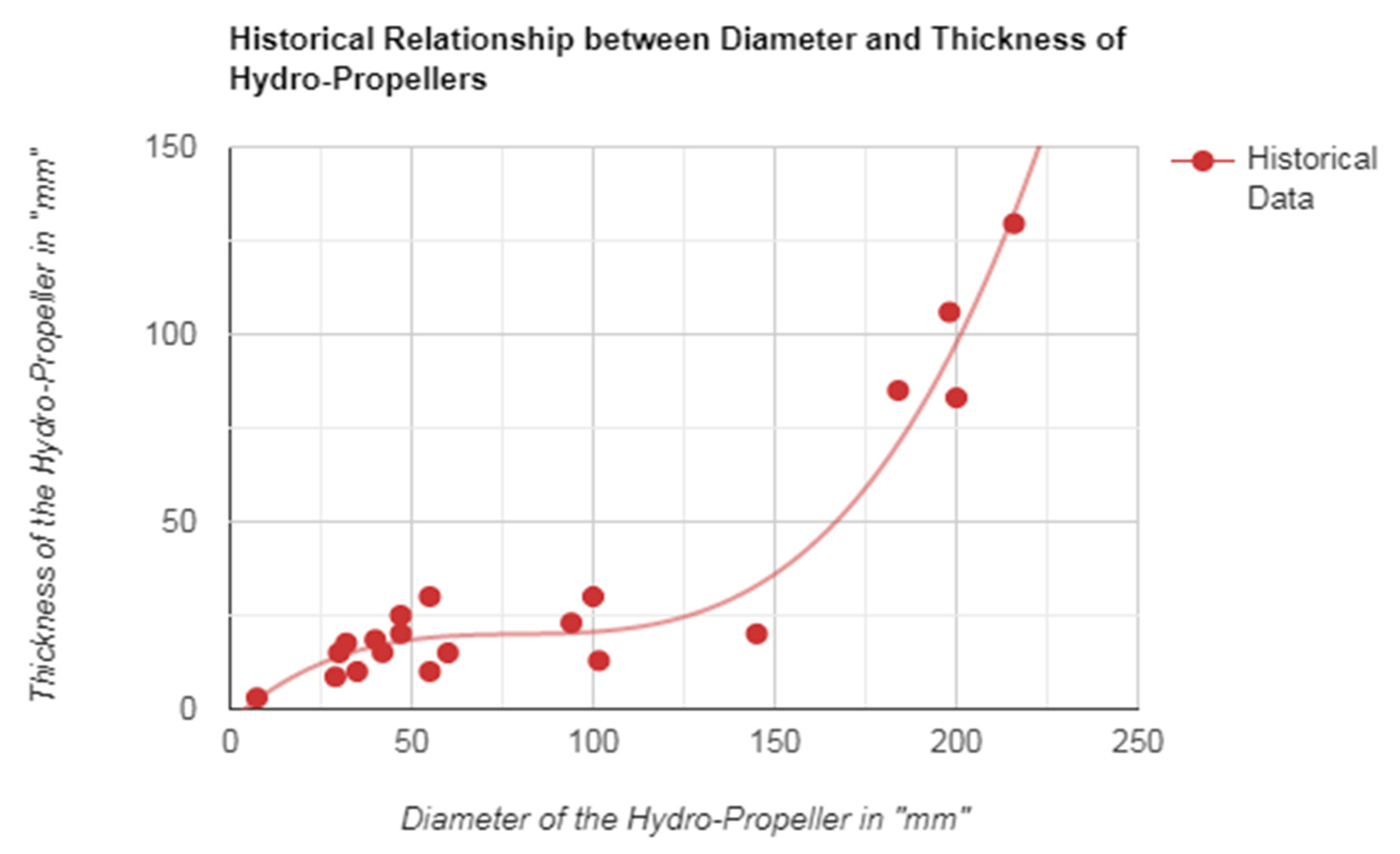

10]. Since the extremities of the UAmV were inspired by Rhinaancylostoma, it was also suggested that the length and breadth of the UAmV also mimic this species. The UAmV was therefore similar in length to Rhinaancylostoma. Additionally, the finalized wing, already introduced in this work, was straight tapered, the finalized horizontal stabilizer shape was straight tapered, and the shortlisted vertical stabilizer design was backward tapered. According to the data based on the second literature survey, conventional analytical approaches were used to design the wings and stabilizers, while the fuselage, forward propeller and vertical propeller were designed following unique analytical approaches [

11,

12,

13,

14,

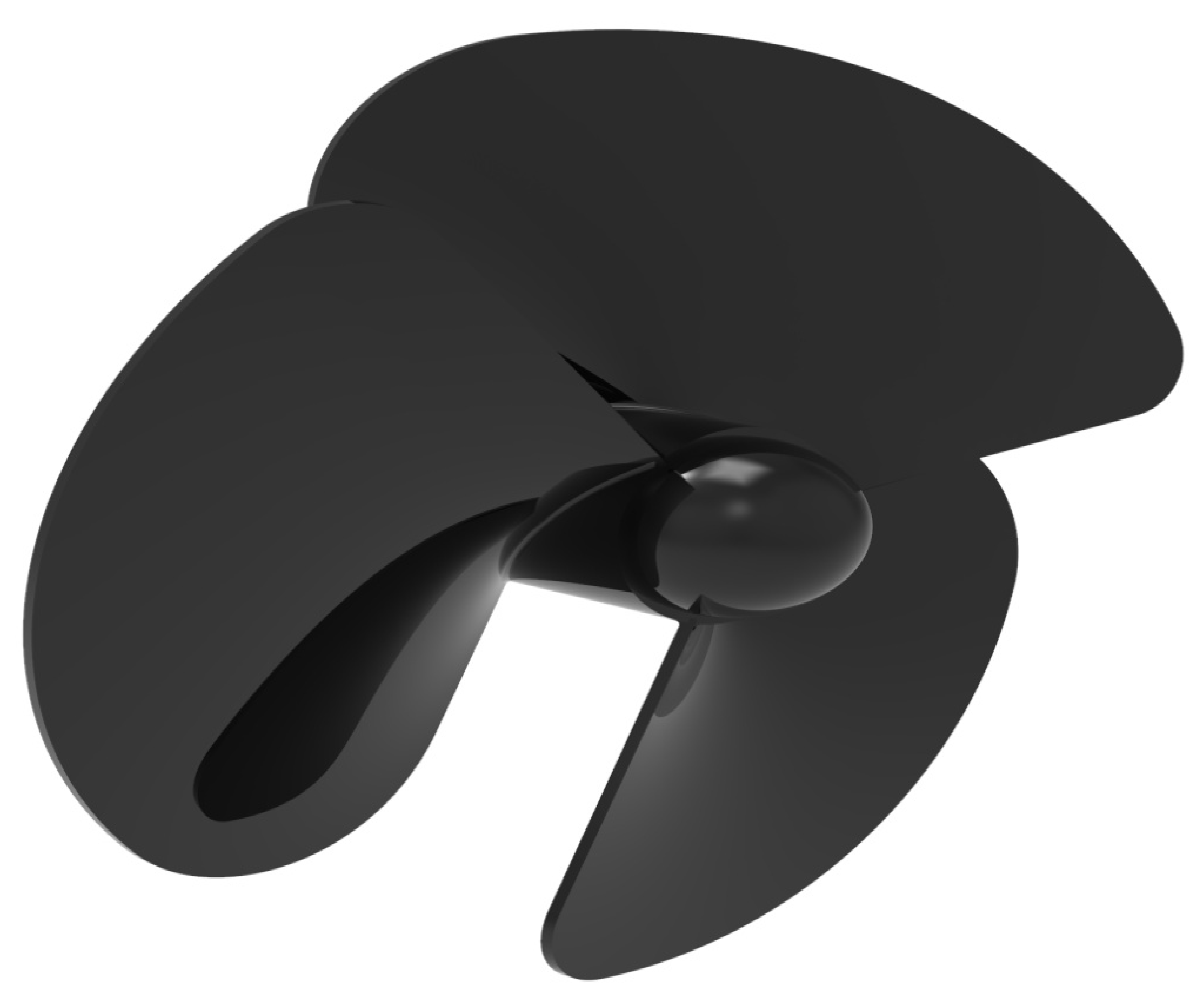

15]. When analysing other studies on the development of unmanned marine vehicles and their components, the authors noticed a few problems. The first problem was that the same propulsive system failed to provide a perfect needful thrust for both the aerodynamic and hydrodynamic environments. The second was that in the previous studies, wings were used instead of fins, but these imposed wings produced an additional lift, causing the smooth flight of the UAmV to collapse. Thus, this work predominantly focused on implementing an optimized wing that could not collapse the smooth lift. This is why this proposed configuration is regarded as the best. Additionally, through CFD, the drag and lift forces at various locations were computed, providing the working conditions and handling capabilities of these components of the UAmV.

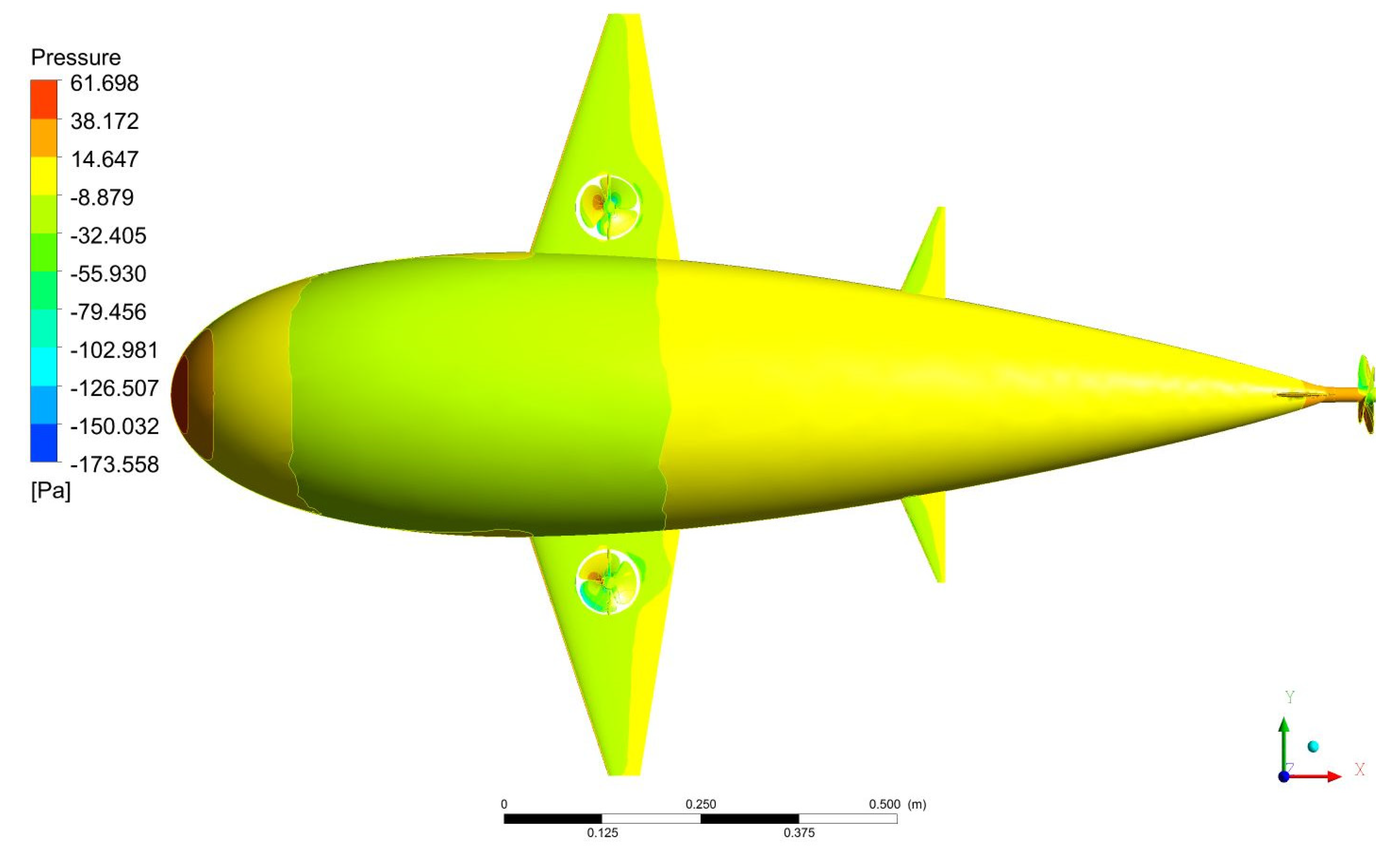

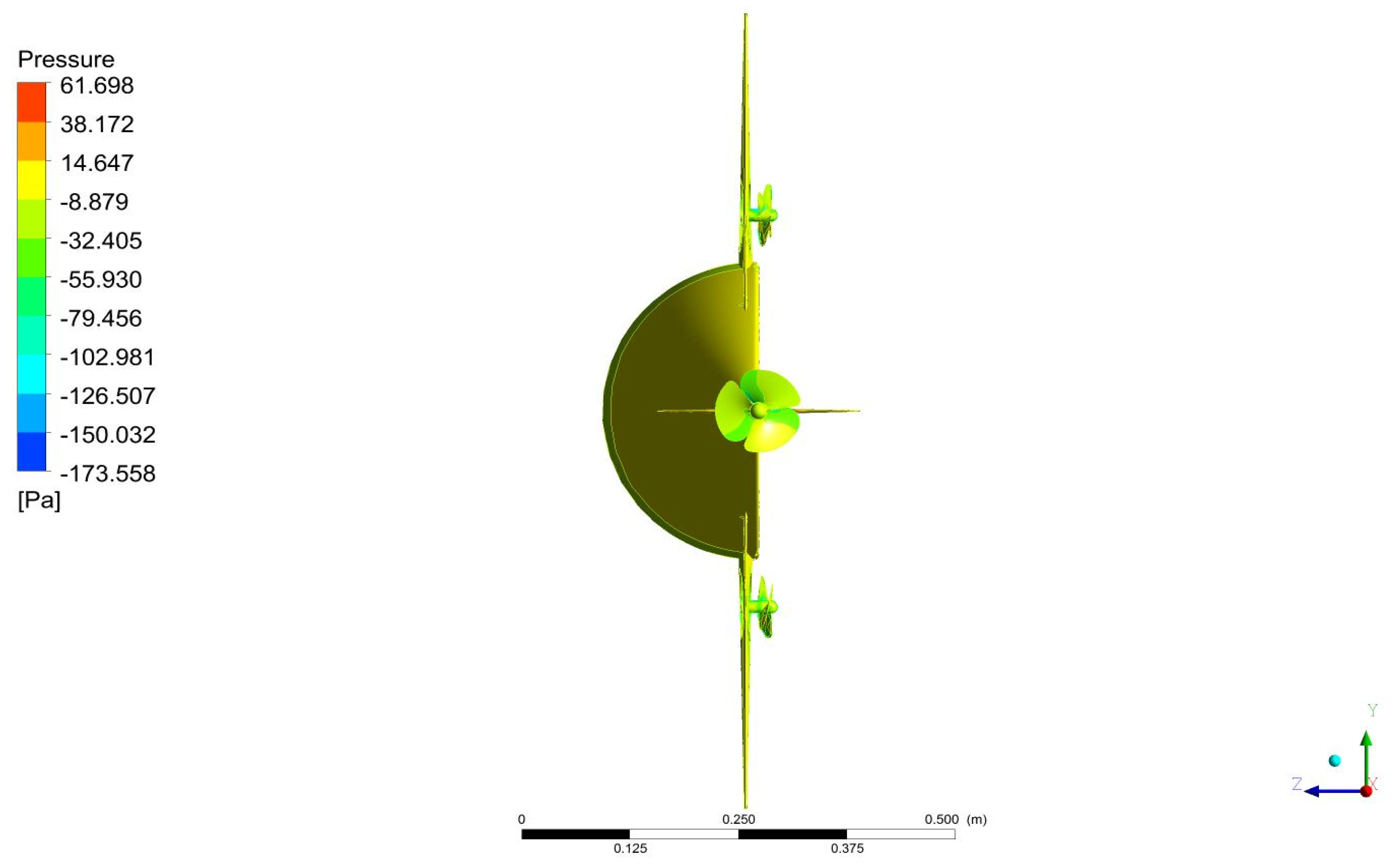

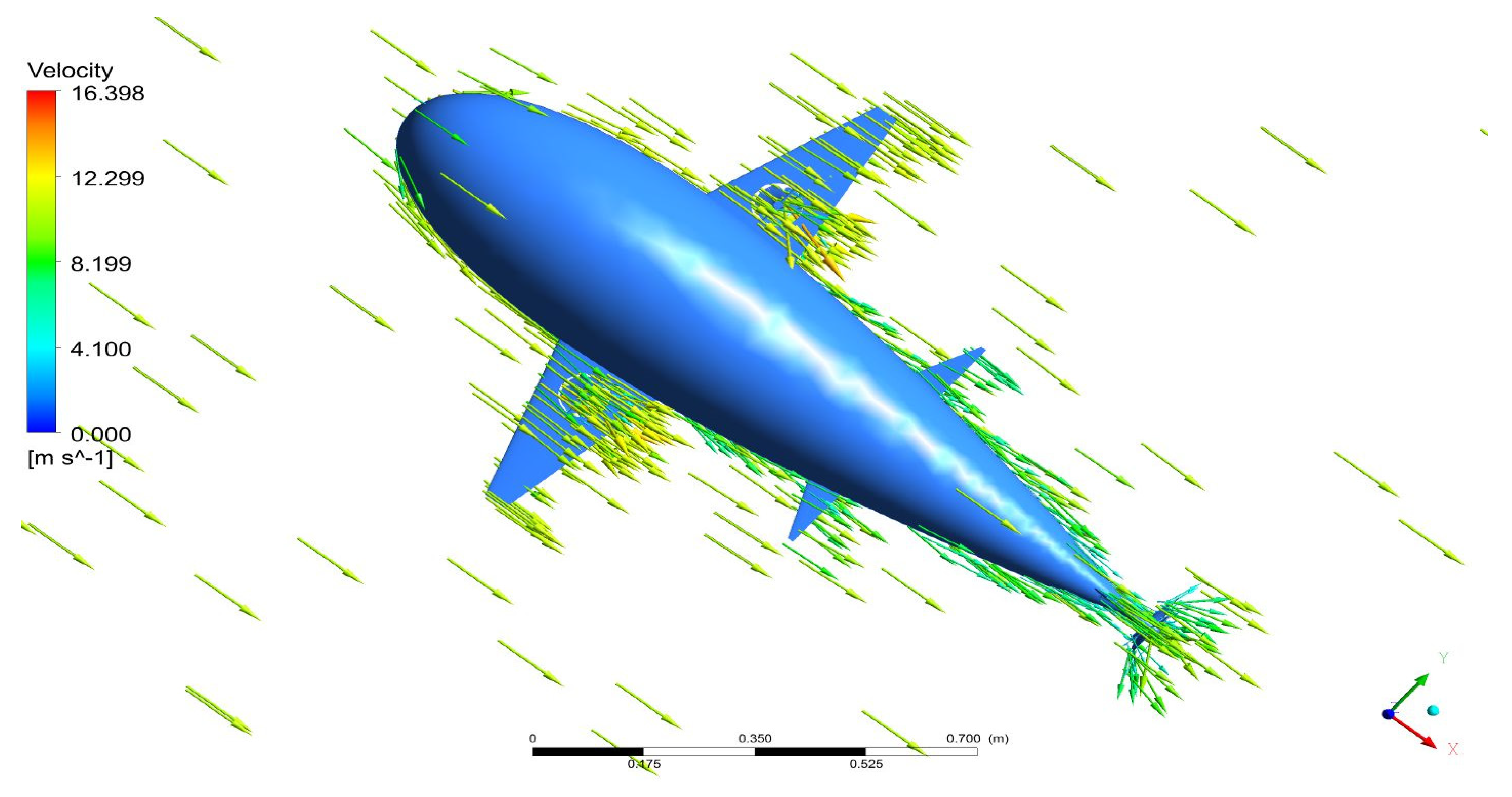

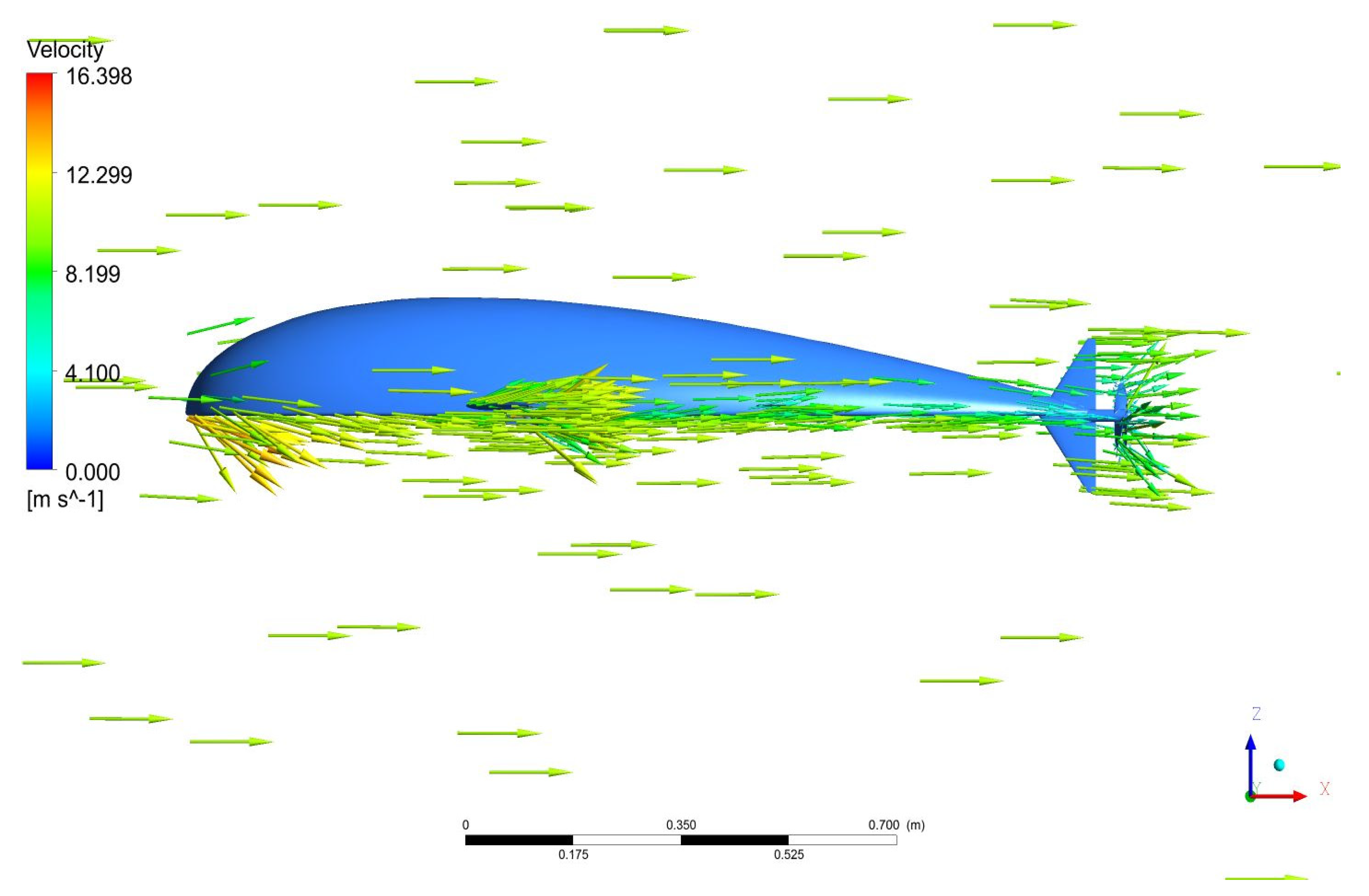

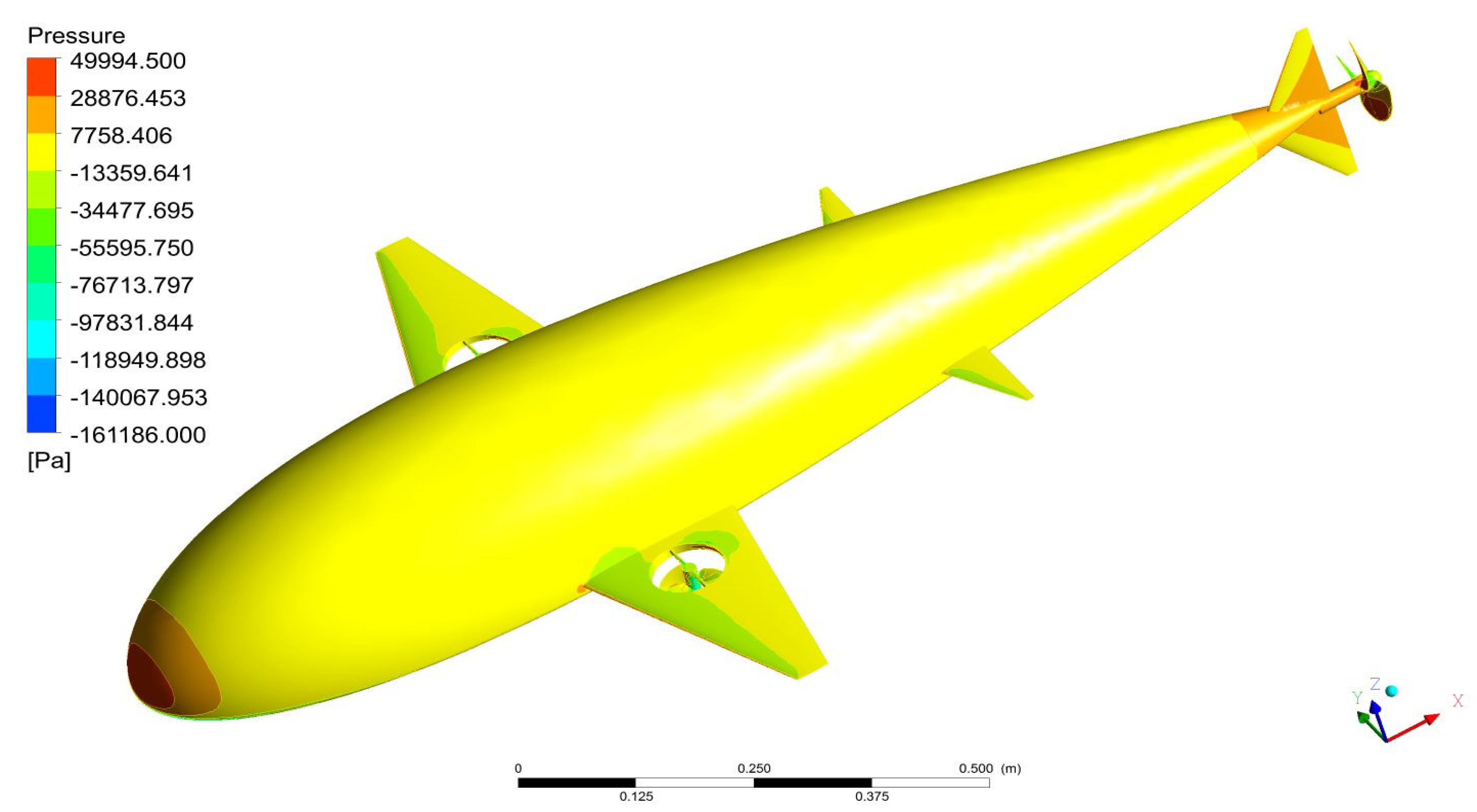

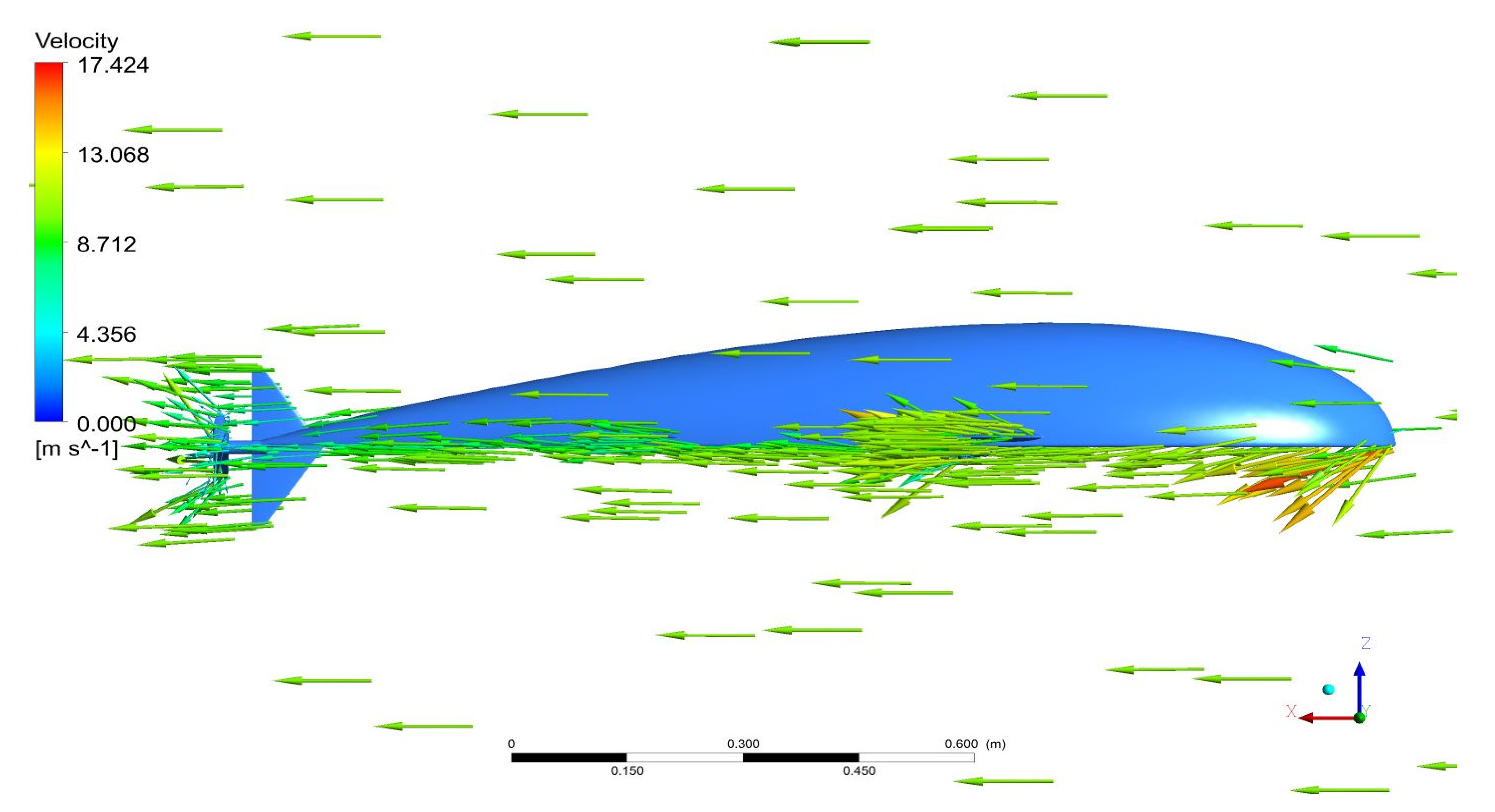

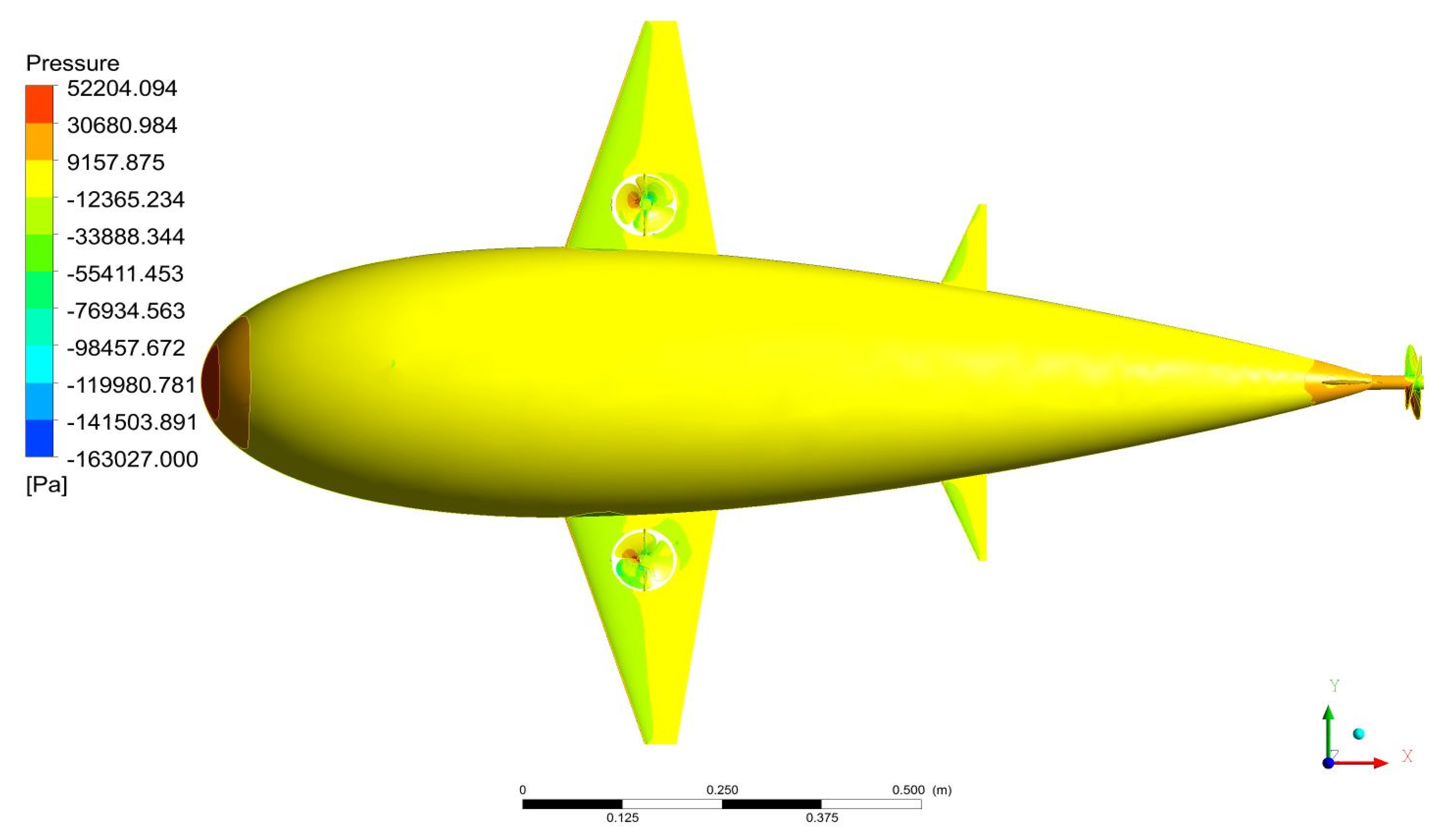

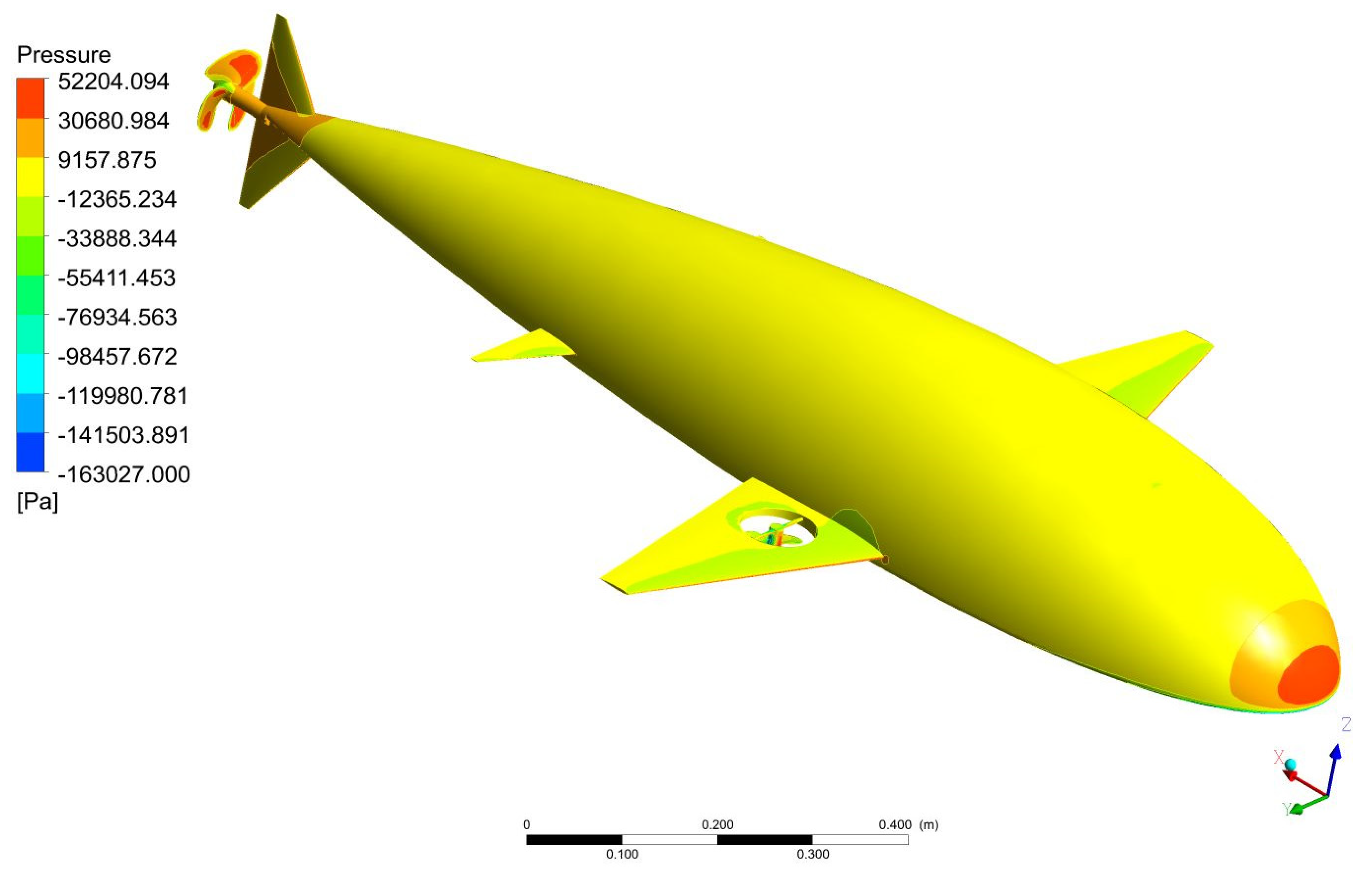

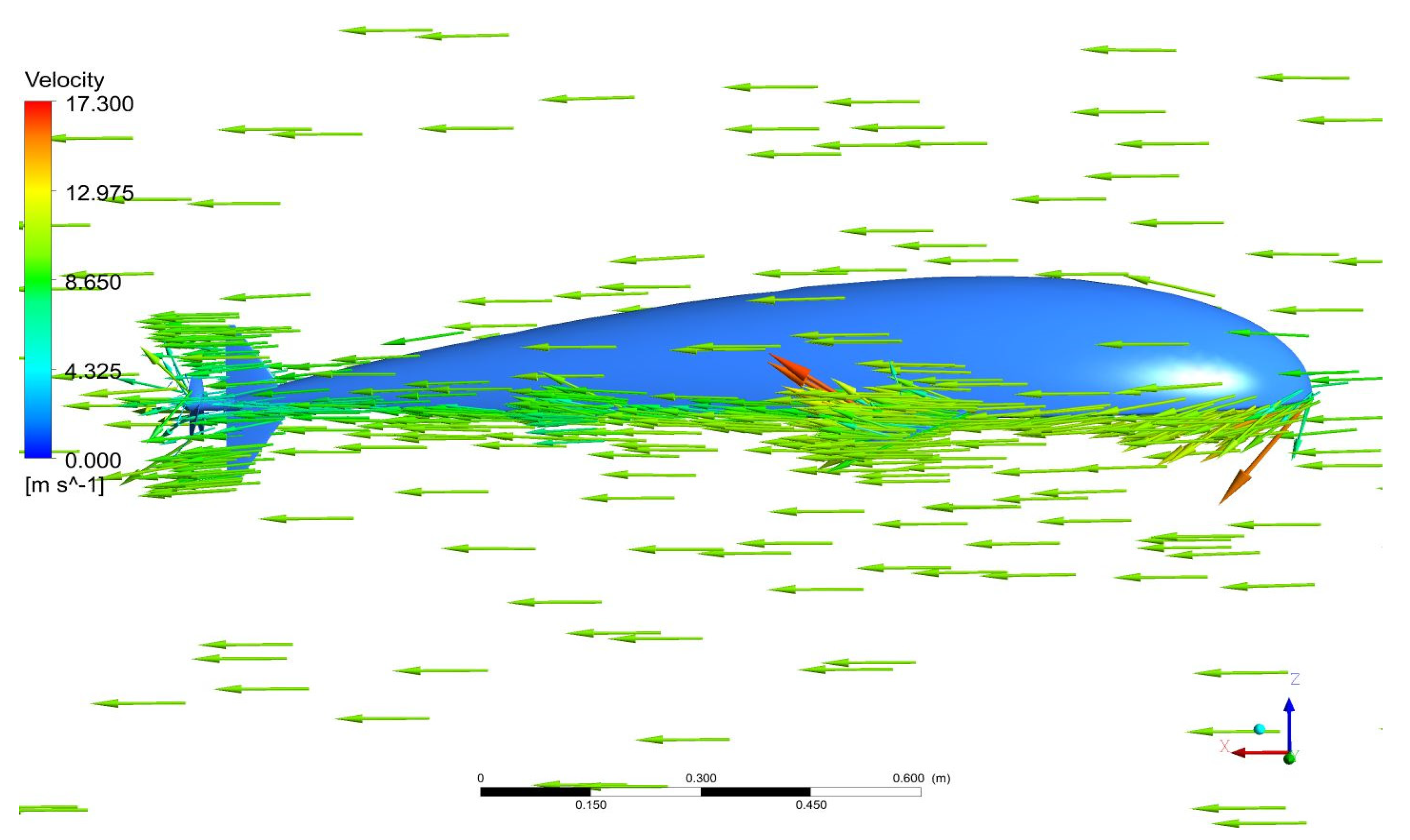

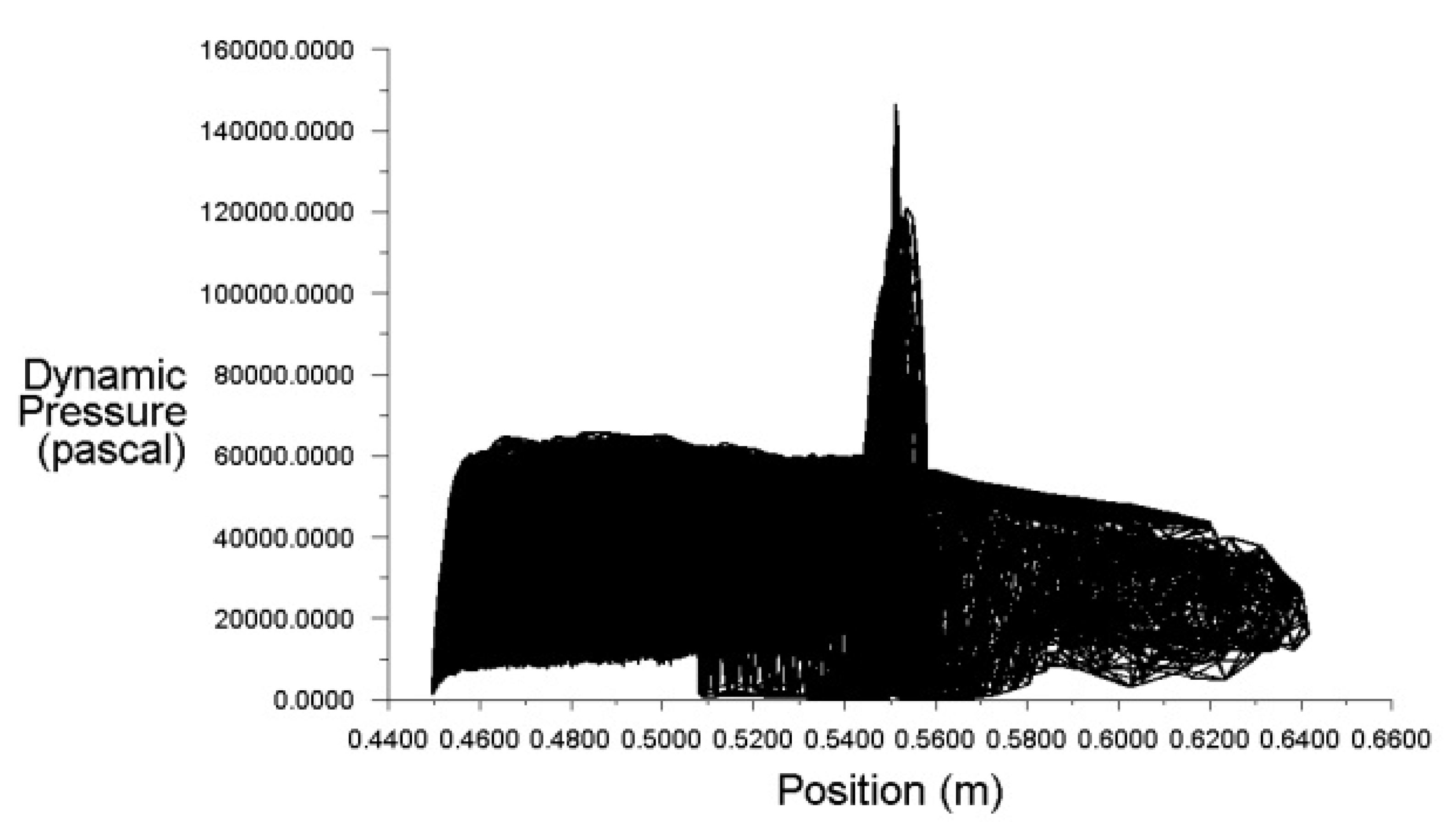

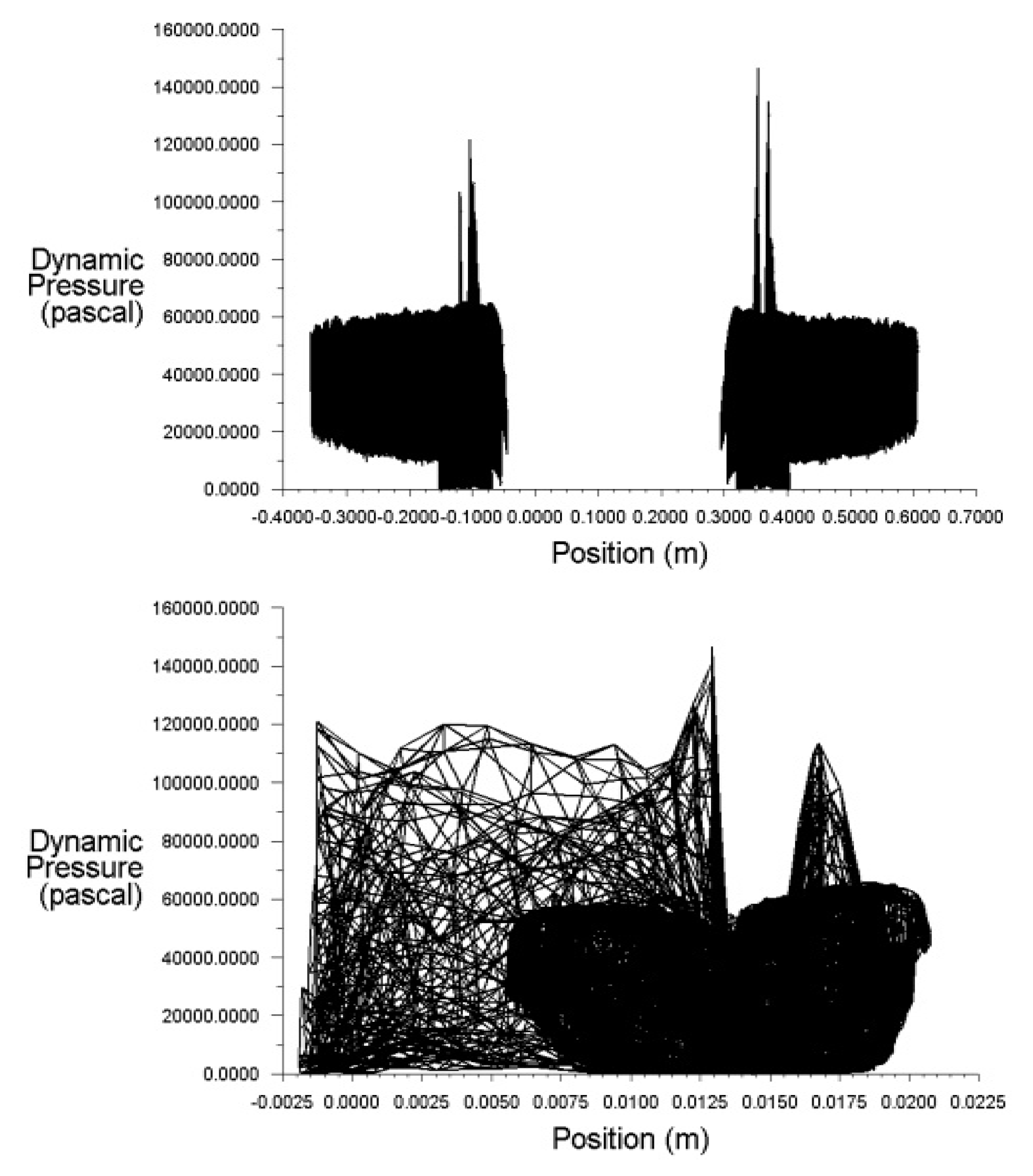

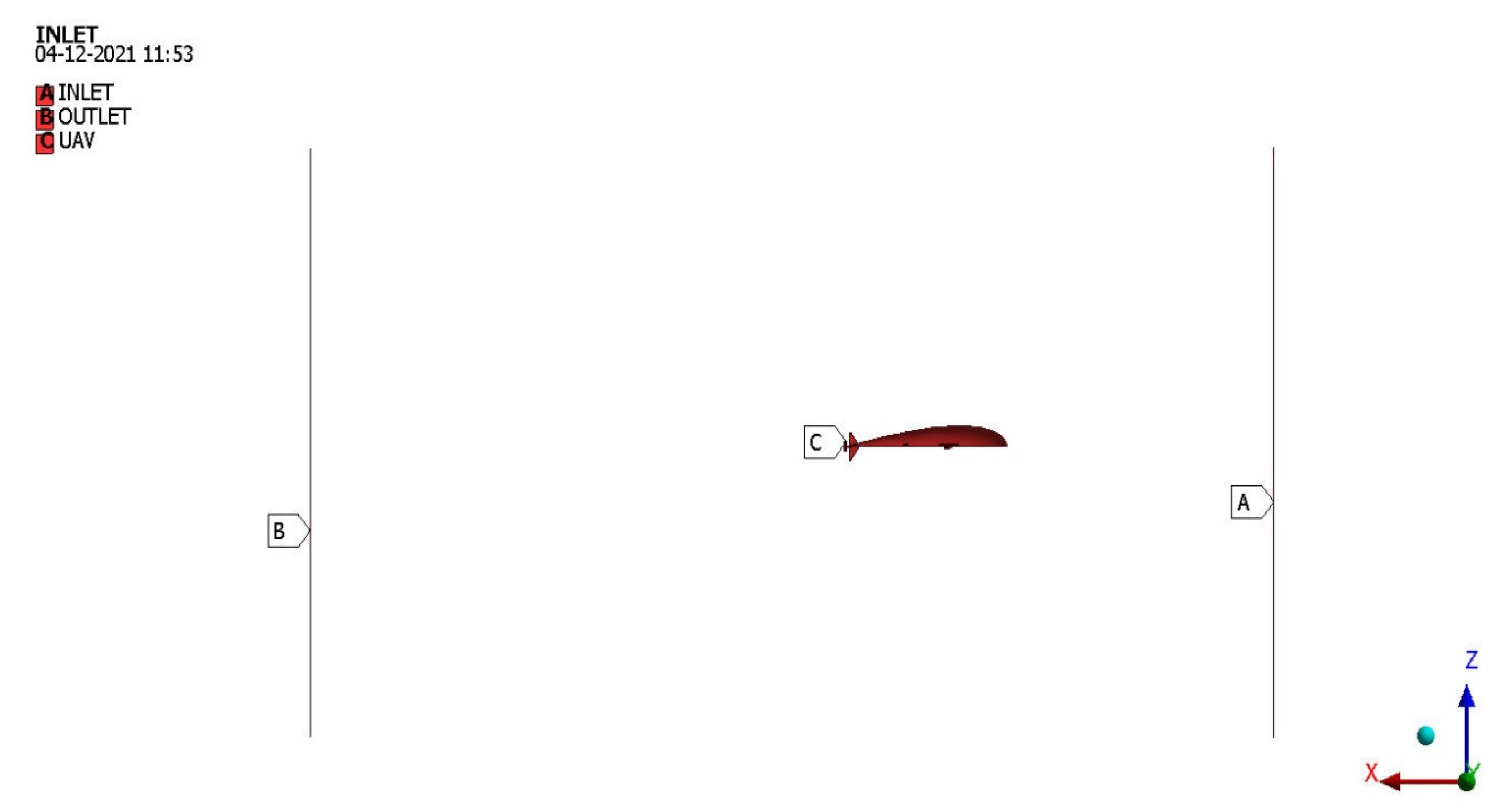

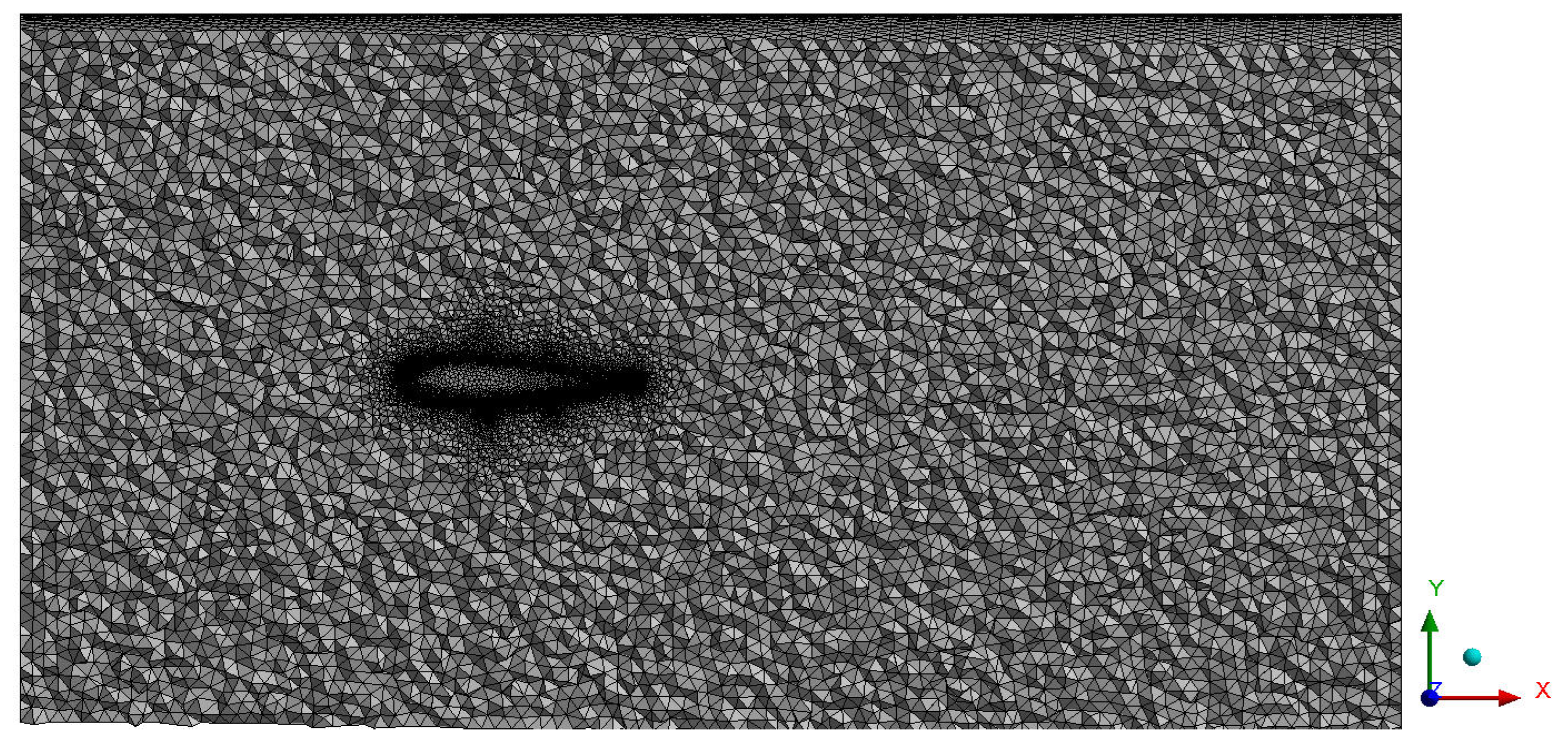

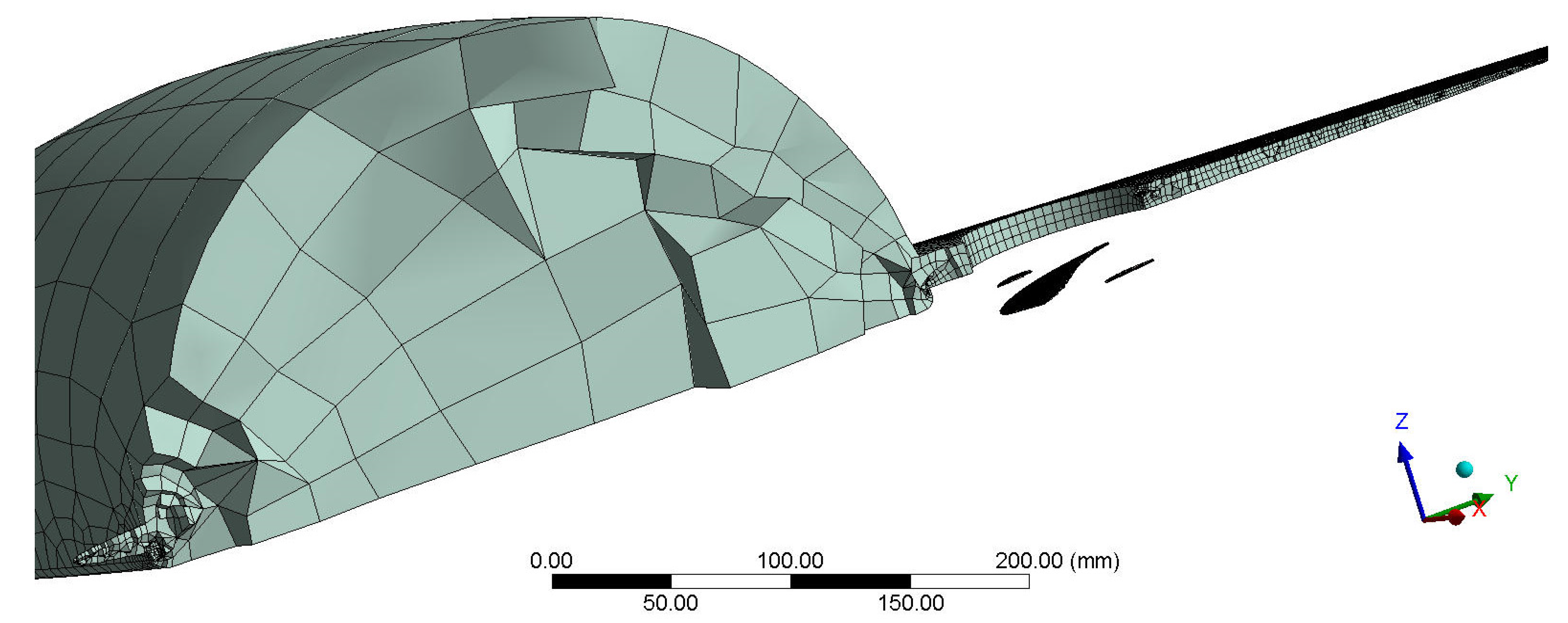

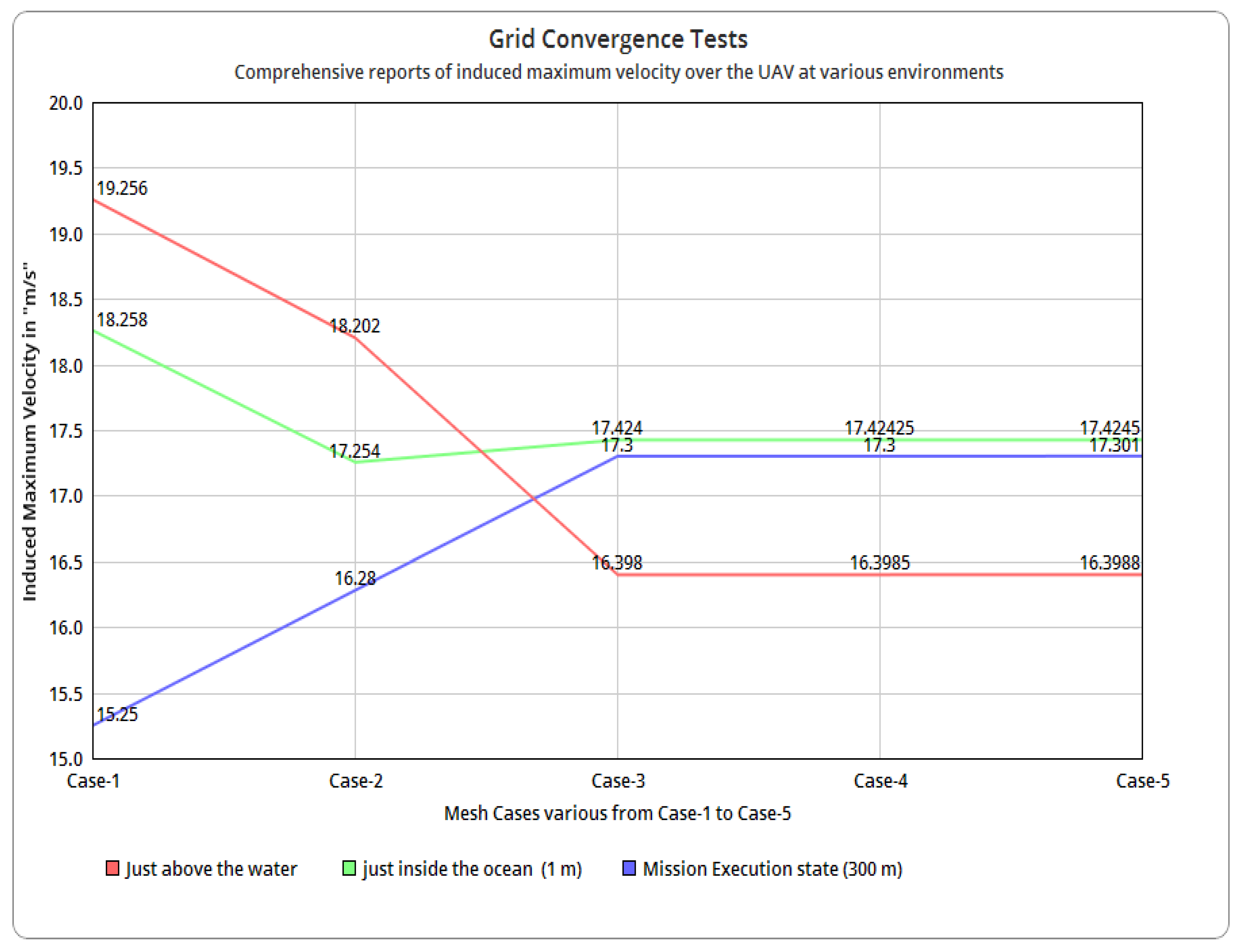

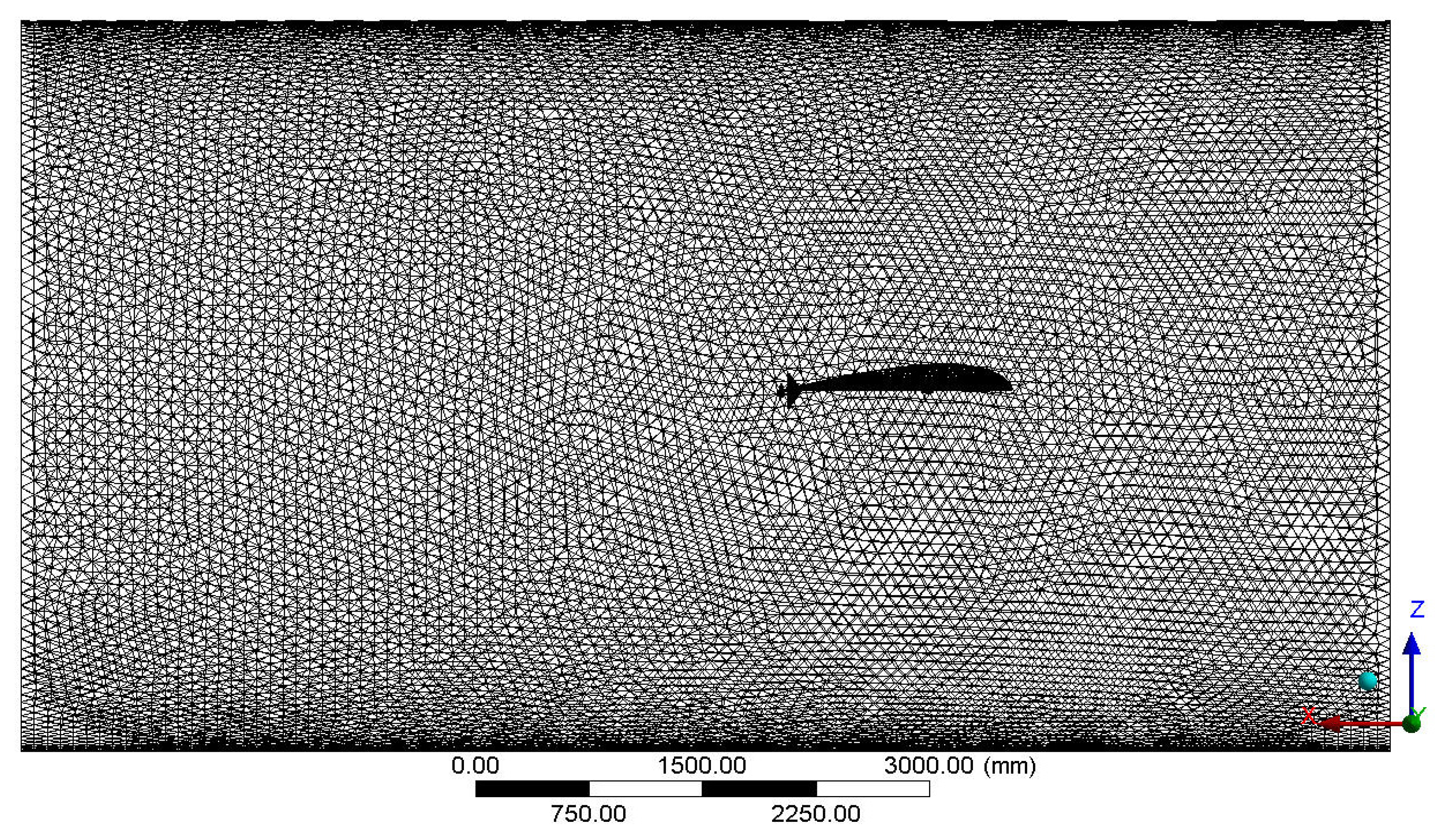

After a method was developed for constructing this UAmV, the next major phase comprised domain preparation, discretization, and computational procedure. These phases are based on data from the third literature survey [

16,

17,

18,

19,

20,

21,

22]. Since the authors of this current work have predominantly relied on the ANSYS Workbench tool for all kinds of computations, this third sub-section is filtered and focused only on obtaining the boundary and initial conditions relevant for the aforesaid computational set-up. The information about the development of control volume, procedures to develop structural meshes, and procedures to attain reliable outcomes for computational hydrodynamic simulations were obtained [

16,

17,

18,

19,

20,

21,

22]. Apart from the primary conditions, the secondary conditions provide significant support in computational fluid dynamic (CFD) simulations. The secondary conditions are a selection of suitable turbulence models and their additional enhancements, such as viscous heating, buoyancy effect consideration, etc., the selection of a suitable coupling scheme between fluid properties, and the provision of perfect values for turbulence models, such as value for viscosity ratio, value for hydraulic diameter, value for eddy length-scale ratio, etc. The incompressible flow-based computations were considered based on data from the fourth literature survey, and so the abovementioned conditions were determined [

23,

24,

25].

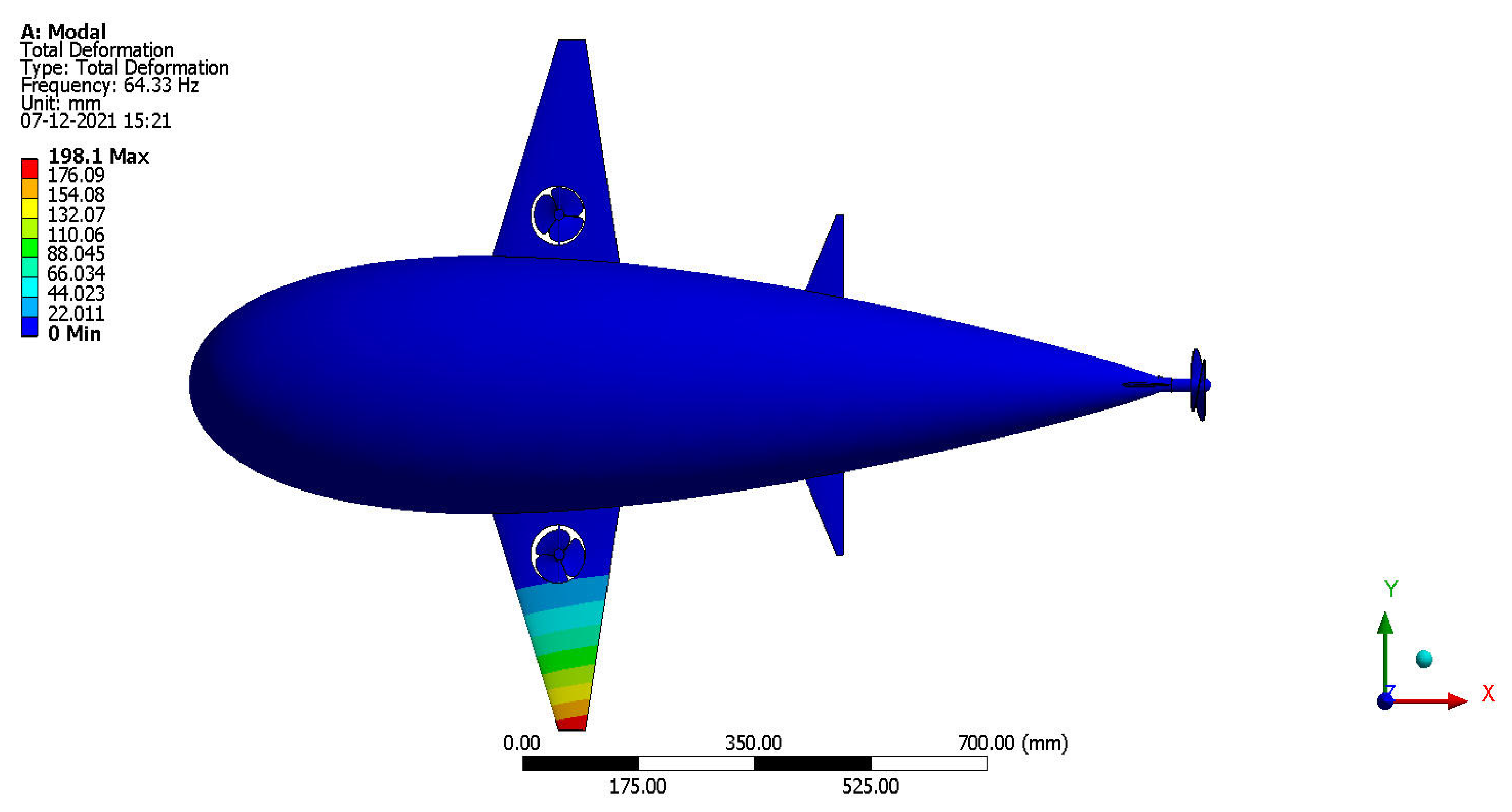

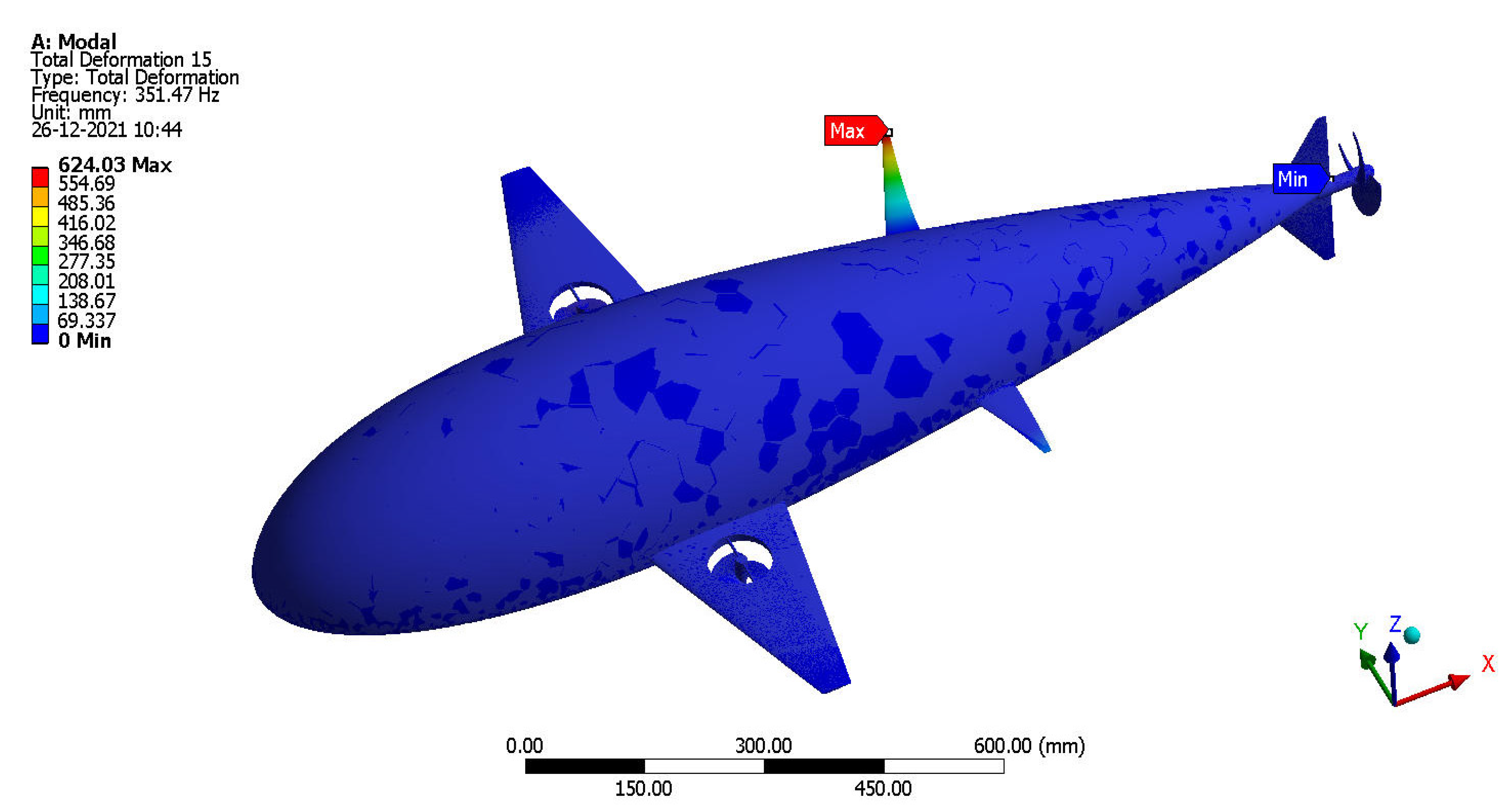

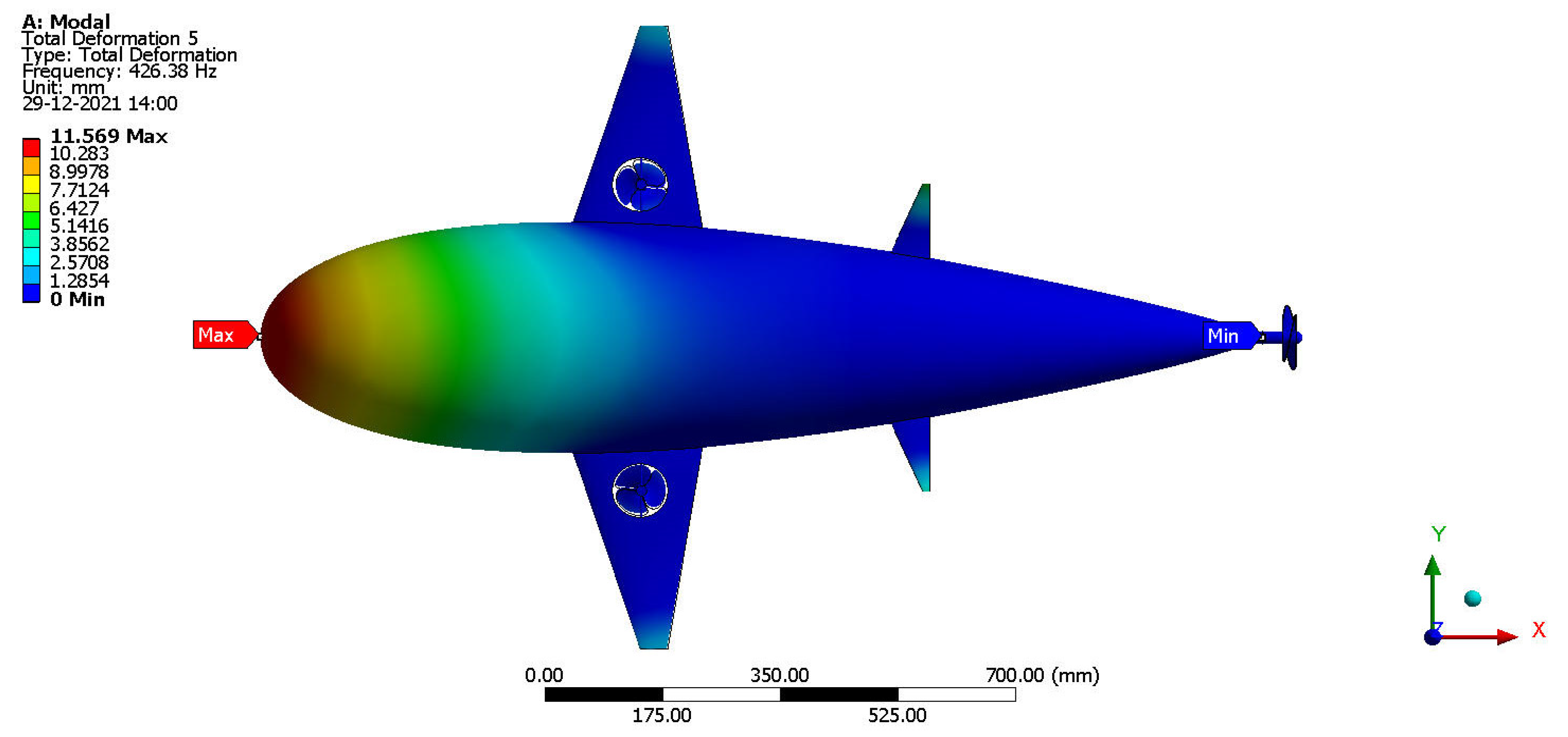

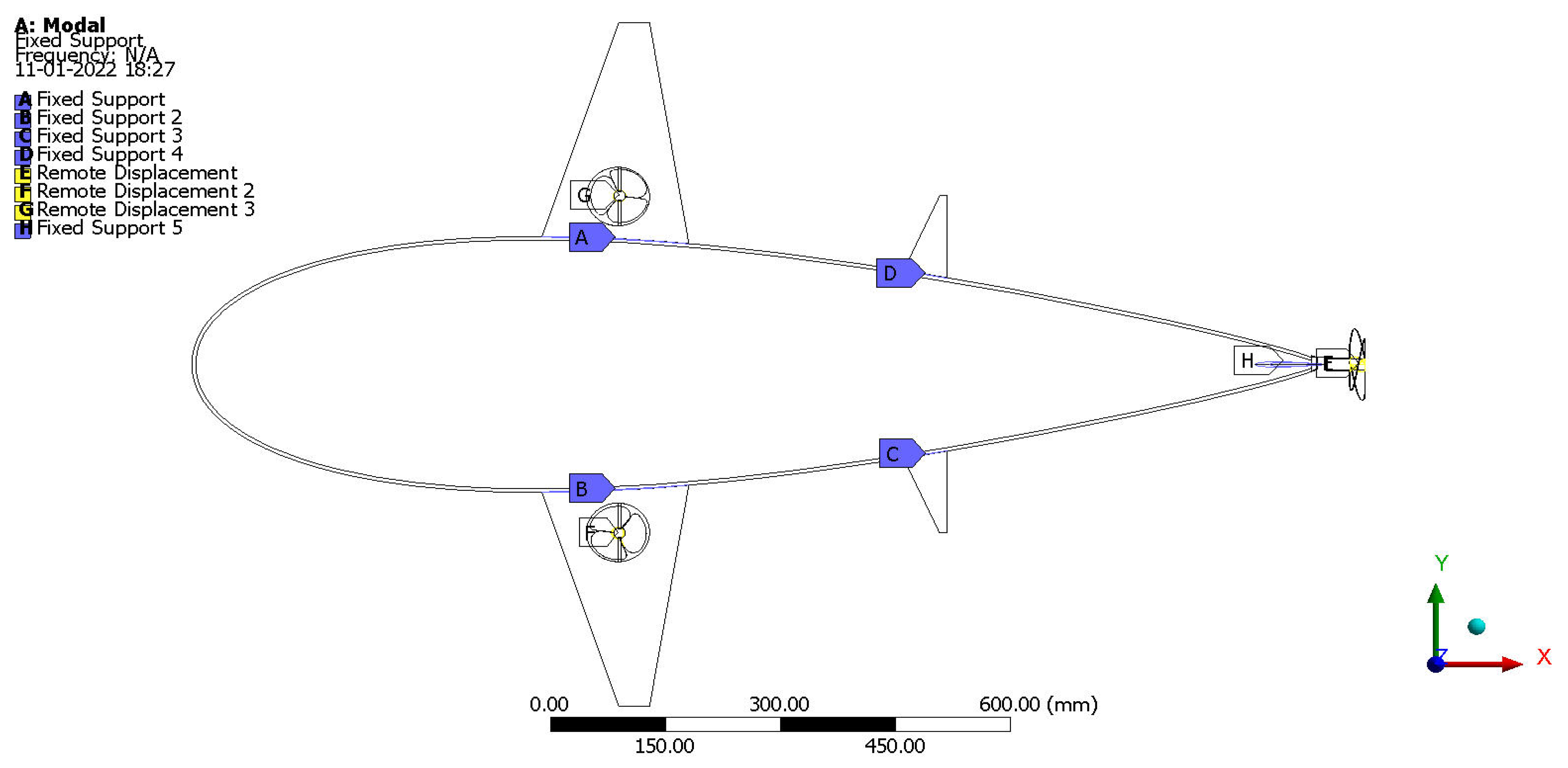

Aside from the CFD observations, computational vibrational analyses (CVA) also play a vital role in this investigation. The essential computational data for CVA were planned to extract from the fifth literature survey. Noted observations from this survey included an analytical approach carried out for the extraction of electrical energy through piezoelectric patches. The formula for this analytical approach included the important supports fixed on the object and the remote displacements implemented on the rotating components [

26,

27,

28,

29,

30,

31]. Additionally, the suitable material to withstand under fluid dynamic loads, as well as a suitable material to undergo high energy extraction-based observations, was executed. Density, young’s modulus, bulk modulus, and Poisson’s ratios, especially, were major focused initial conditions for computational structural analyses. Hence, the works [

32,

33,

34,

35] executed were supported hugely to attain the aforesaid properties. Finally, earlier applications completed by the UAmVs were collected, wherein the involvement of major and minor components for their mission executions were completely recorded. Through these studies [

36,

37,

38,

39,

40,

41,

42], the selection of electrical and electronic components for this current work was executed.

Finally, aerodynamic and hydrodynamic forces generation and their components were studied, wherein the aerofoils imposed on the development of various components of UAmV were focused majorly. Primarily, the authors found that NACA profiles-based aerofoils were implemented on the various kinds of Unmanned Underwater Vehicles, which vary from slow to high-speed operational vehicles, low to heavy payload-based vehicles, short to long-range and endurance-based vehicles. Through focused study, more than twenty-five relevant aerofoils were found to be existing users in the UAmVs. The complete list of relevant aerofoils is listed in

Table 1. Additionally, symmetrical aerofoils were used predominantly in UAmVs rather than unsymmetrical aerofoils. The symmetrical aerofoils implemented in the components of UAmVs were fins, tail portions, and wings. Additionally, the selection of an aerofoils phase was completed with the support of

Table 1.

From

Table 1, it was found that symmetrical characteristics-based NACA aerofoils were used in all kinds of UAmVs. Based on the literature surveys, the authors developed four research articles [

14,

20,

21,

22] that demonstrate the major constraints on the development of symmetrical NACA aerofoils-based UAmVs, wherein the required lifts were achieved in all the cases for the maximum speed of 15 m/s at various angles of attack. Technically, the flow in and over this current UAmV is mostly laminar, so the implementation of low Reynolds Number-based aerofoils in this work has been suggested. Since hybrid configuration is proposed in this work (the separate VTOL propellers for depth increment and decrement, also hovering), the various angle of attack-based computations are avoided.