Creep Constitutive Model and Numerical Realization of Coal-Rock Combination Deteriorated by Immersion

Abstract

:1. Introduction

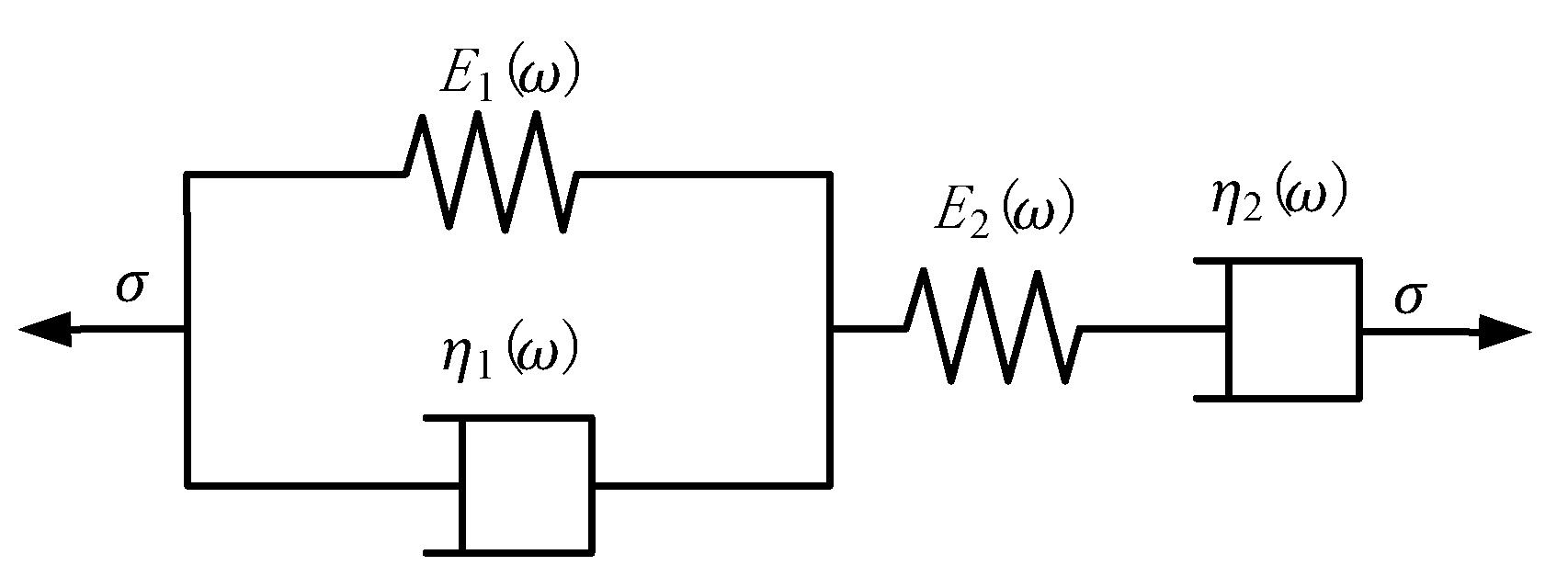

2. Creep Constitutive Model and Numerical Realization

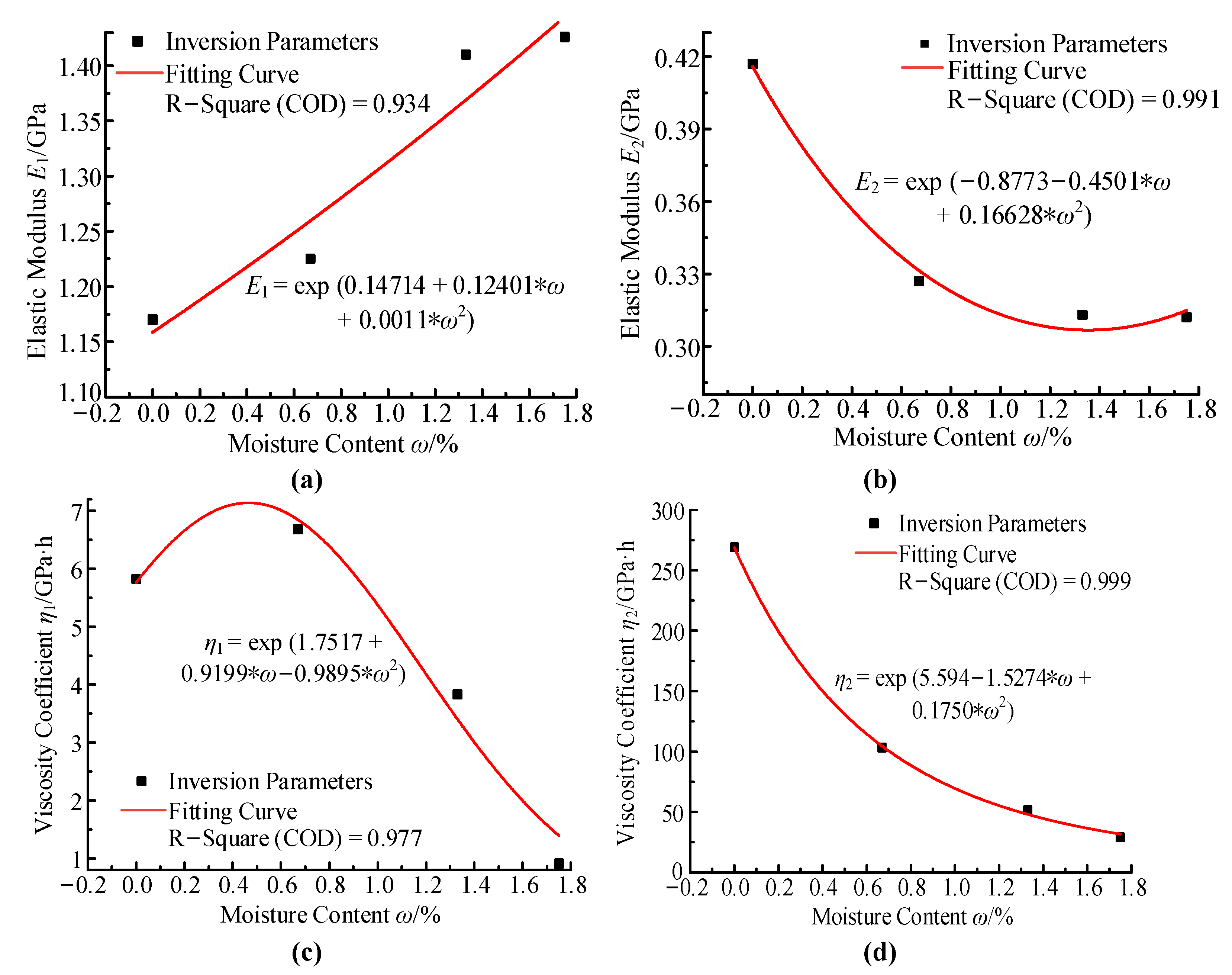

2.1. Creep Constitutive Model of Coal-Rock Combination Considering the Influence of Moisture Content

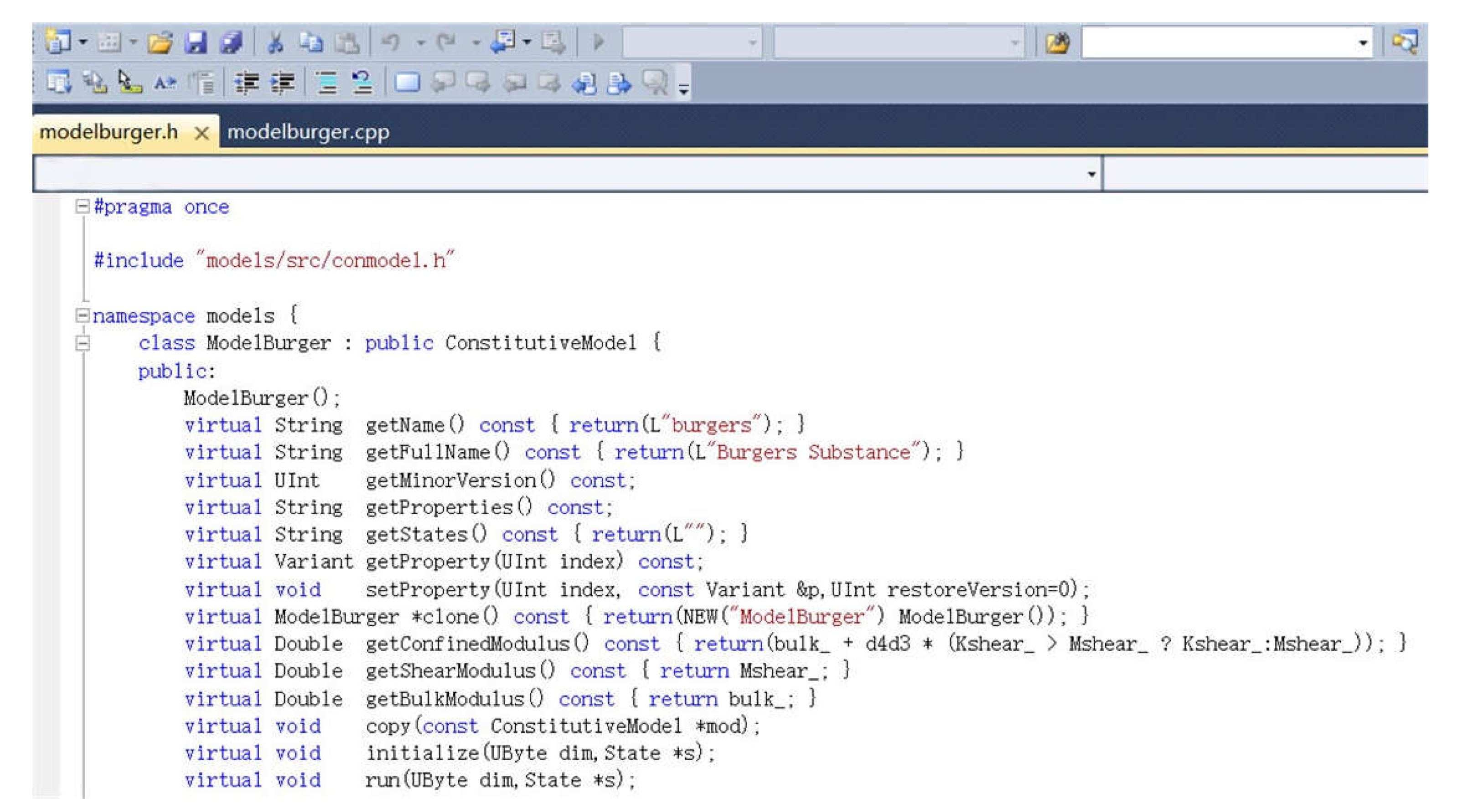

2.2. Numerical Calculation Realization of the Creep Model

3. Numerical Simulation Research

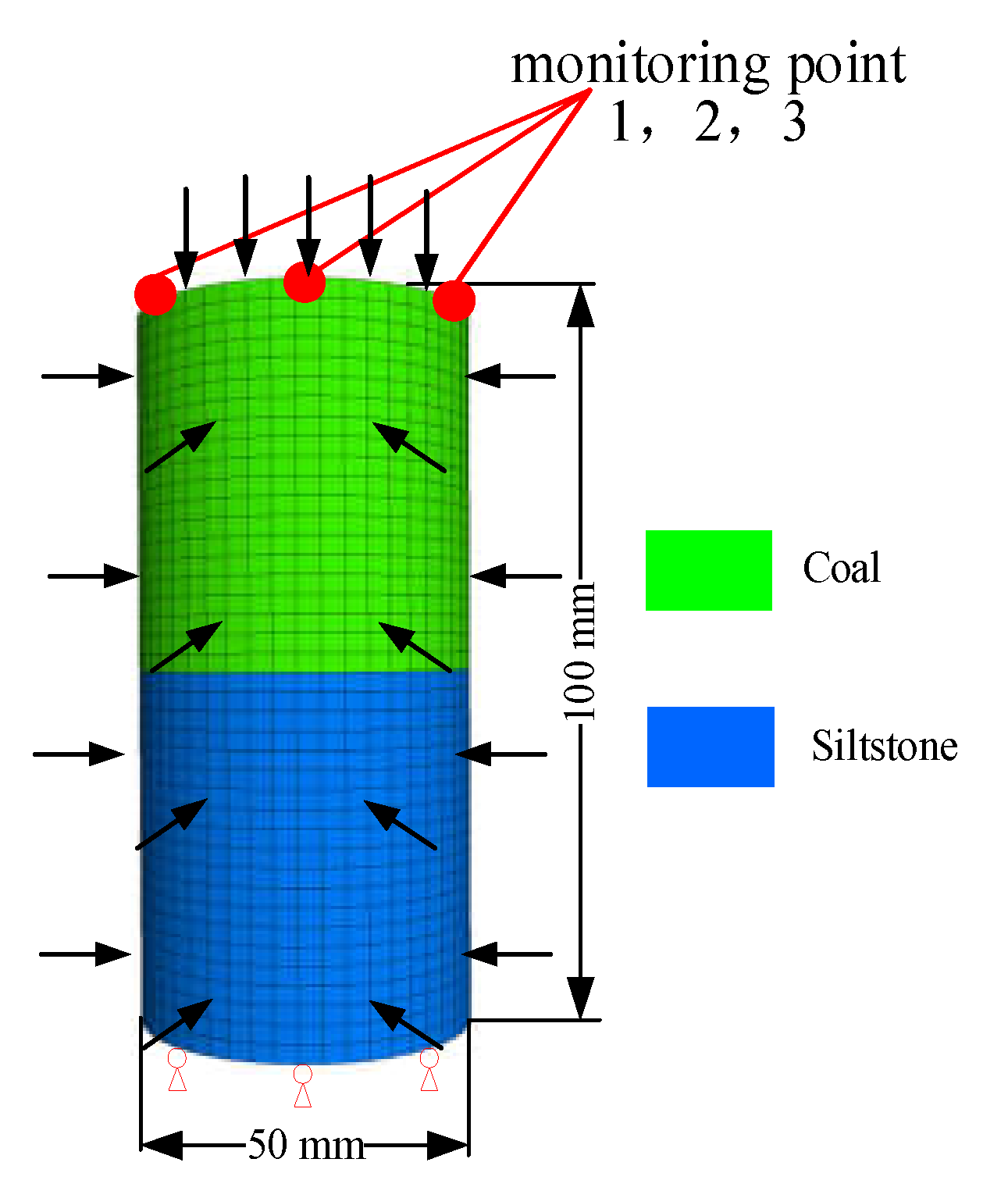

3.1. Simulation Scheme

3.2. Simulation Result Analysis

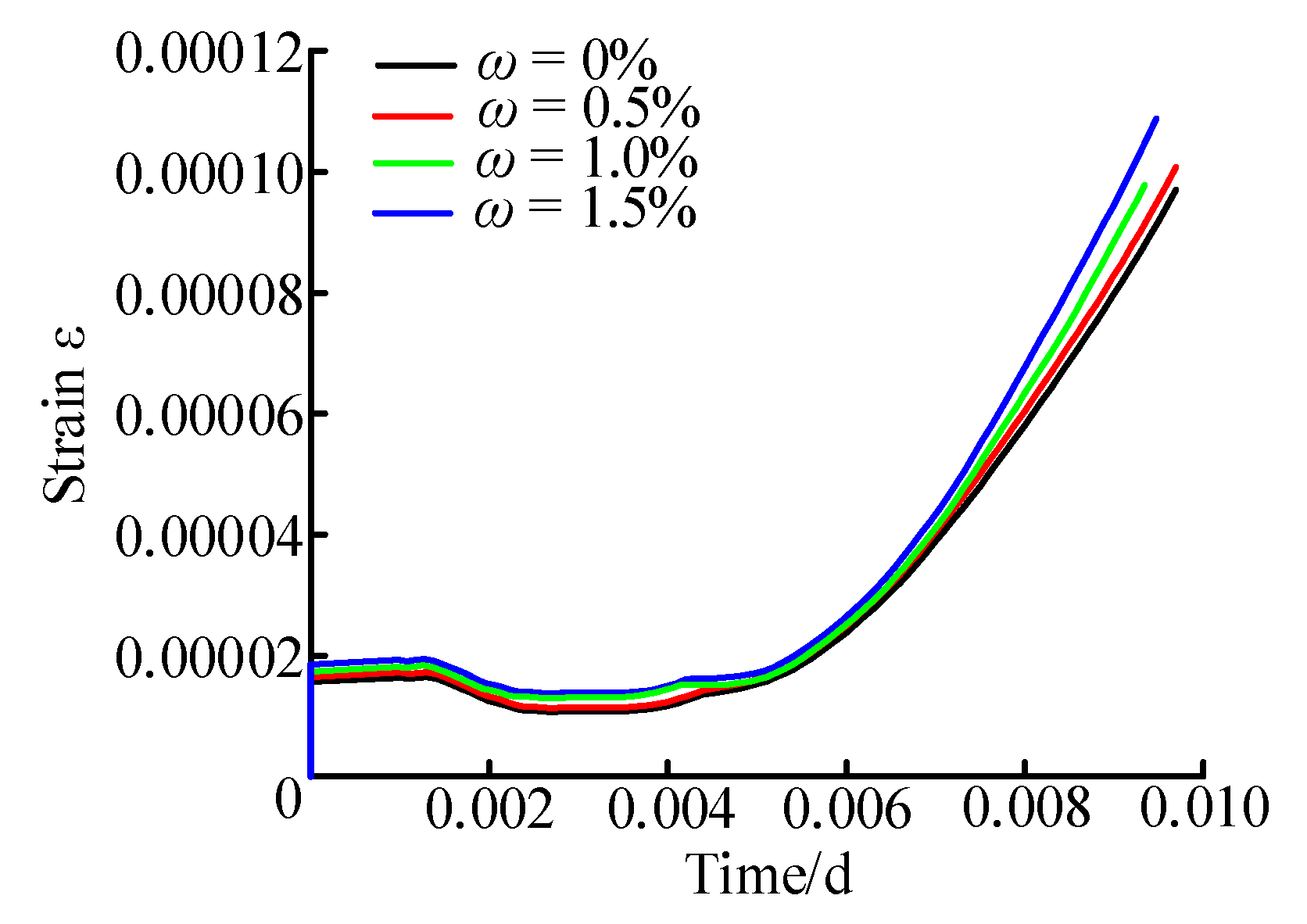

3.2.1. Deformation Characteristics

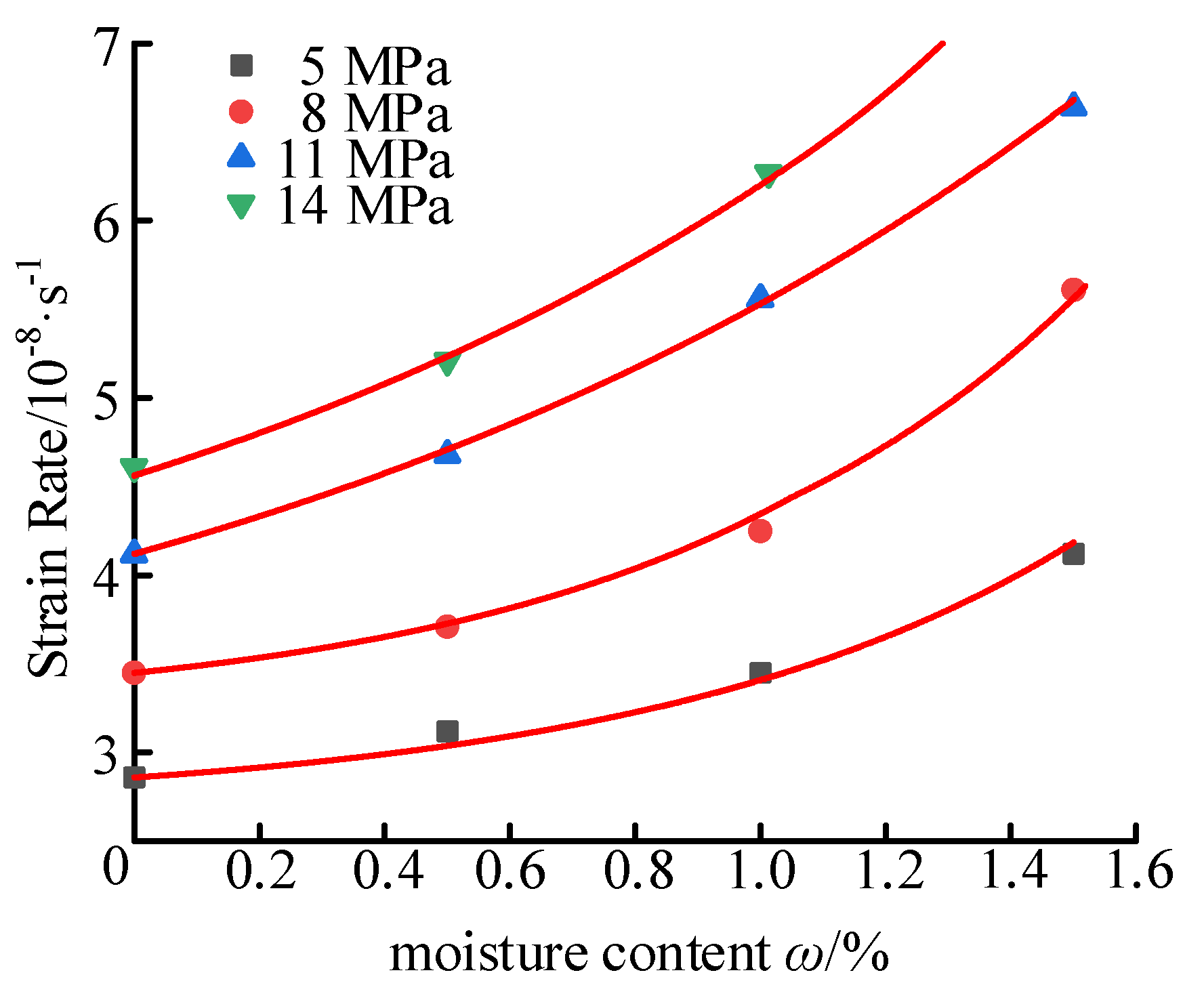

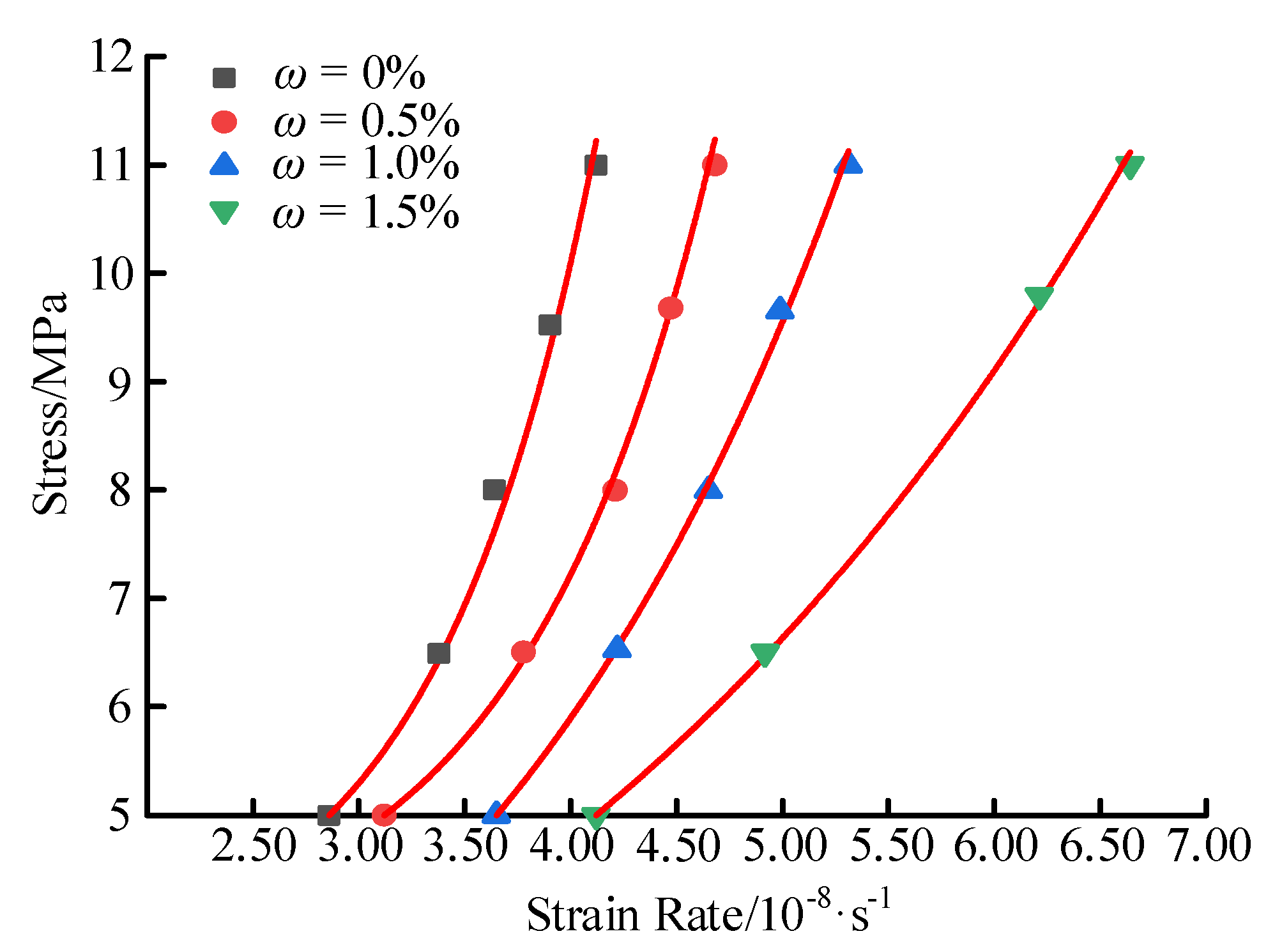

3.2.2. Strain Rate Characteristics

3.2.3. Viscosity Coefficient Characteristics

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, M.C.; Xie, H.P.; Peng, S.P.; Jiang, Y.D. Study on rock mechanics in deep mining engineering. Chin. J. Rock. Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Cao, P.; Wan, L.H.; Wang, Y.X.; Huang, Y.H.; Zhang, X.Y. Viscoelasto-plastic properties of deep hard rocks underwater environment. T. Nonferr. Metal. Soc. 2011, 21, 2711–2718. [Google Scholar] [CrossRef]

- Liu, J.S.; Jing, H.W.; Meng, B.; Wang, L.G.; Zhang, X.D.; Yang, J.J. Research on the effect of moisture content on the creep behavior of weakly cemented soft rock and its fractional-order model. Rock. Soil Mech. 2020, 41, 2609–2618. [Google Scholar]

- Fan, D.Y.; Liu, X.S.; Tan, Y.L.; Song, S.L.; Ning, J.G.; Ma, Q. Numerical simulation research on response characteristics of surrounding rock for deep super-large section chamber under dynamic and static combined loading condition. J. Cent. South Univ. 2020, 27, 3544–3566. [Google Scholar] [CrossRef]

- Sarfarazi, V.; Haeri, H.; Shemirani, A.B.; Hedayat, A.; Hosseini, S.S. Investigation of ratio of TBM disc spacing to penetration depth in rocks with different tensile strengths using PFC2D. Comput. Concr. 2017, 20, 429–437. [Google Scholar]

- Song, S.L.; Liu, X.S.; Tan, Y.L.; Fan, D.Y.; Ma, Q.; Wang, H.L. Study on failure modes and energy evolution of coal-rock combination under cyclic loading. Shock. Vib. 2020, 2020, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.S.; Tan, Y.L.; Ning, J.G.; Lu, Y.W.; Gu, Q.H. Mechanical properties and damage constitutive model of coal in coal-rock combined body. Int. J. Rock. Mech. Min. 2018, 110, 140–150. [Google Scholar] [CrossRef]

- Li, D.Y.; Du, S.H.; Zhang, C.S.; Mao, D.W.; Ruan, B. Time-dependent deformation behavior of completely weathered granite subjected to wetting immersion. Rock. Mech. Rock. Eng. 2021, 54, 6373–6391. [Google Scholar] [CrossRef]

- Li, D.Y.; Wang, W.J. Quantitative analysis of the influence of saturation on rock strength reduction considering the distribution of water. Geomech. Geophys. Geo-Energ. Geo-Resour. 2019, 5, 197–207. [Google Scholar] [CrossRef]

- Yao, Q.L.; Zhu, L.; Huang, Q.H.; Yang, P.; Xu, Z. Experimental study on the effect of moisture content on creep characteristics of fine-grained feldspar lithic sandstone. J. Min. Saf. Eng. 2019, 36, 1034–1042+1051. [Google Scholar]

- Hashiba, K.; Fukui, K. Effect of water on the deformation and failure of rock in uniaxial tension. Rock. Mech. Rock. Eng. 2015, 48, 1751–1761. [Google Scholar] [CrossRef]

- Bukowska, M. Influence of height-to-diameter ratio samples and humidity on the geomechanical properties of sandstones. In Proceedings of the 15th International Multidisciplinary Scientific GeoConference 2015 (SGEM 2015), Albena, Bulgaria, 18–24 June 2015; Volume 3, pp. 391–398. [Google Scholar]

- Li, Y.; Zhu, W.S.; Bai, S.W.; Yang, C.H. Uniaxial experimental study on rheological properties of granite in air-dried and saturated states. Chin. J. Rock. Mech. Eng. 2003, 22, 1673–1677. [Google Scholar]

- Shtumpf, G.G. Water-physical properties of coal-bearing rocks. J. Min. Sci. 1993, 29, 530–536. [Google Scholar] [CrossRef]

- Ojo, O.; Brook, N. The effect of moisture on some mechanical properties of rock. Int. J. Min. Sci. Technol. 1990, 10, 145–156. [Google Scholar] [CrossRef]

- Vásárhelyi, B. Statistical analysis of the influence of moisture content on the strength of the miocene limestone. Rock. Mech. Rock. Eng. 2005, 38, 69–76. [Google Scholar] [CrossRef]

- Vásárhelyi, B.; Ván, P. Influence of water content on the strength of rock. Eng. Geol. 2006, 84, 70–74. [Google Scholar] [CrossRef]

- Okubo, S.; Nishimatsu, Y.; He, C.; Chun, S.Y. Loading rate dependency of uniaxial compressive strength of rock under water-saturated condition. J. Soc. Mater. Sci. Jpn. 1992, 41, 403–409. [Google Scholar] [CrossRef]

- Varun, M.; Eunhye, K. Effects of water on rock fracture properties: Studies of mode I fracture toughness, crack propagation velocity, and consumed energy in calcite-cemented sandstone. Geomech. Eng. 2019, 17, 57–67. [Google Scholar]

- Eunhye, K.; Adriana, G.; Hossein, C. Fragmentation and energy absorption characteristics of Red, Berea and Buff sandstones based on different loading rates and moisture contents. Geomech. Eng. 2018, 14, 151–159. [Google Scholar]

- Edward, M.; Van, E. Mechanisms of strength reduction due to moisture in coal mine shales. Int. J. Rock. Mech. Min. 1976, 13, 61–67. [Google Scholar]

- Liu, X.S.; Tan, Y.L.; Ning, J.G.; Tian, C.L.; Tian, Z.W. Energy criterion of abutment pressure induced strain-mode rockburst. Rock. Soil Mech. 2016, 37, 2929–2936. [Google Scholar]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock. Mech. Min. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Hawkins, A.B.; Mcconnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. Hydrog. 1992, 25, 115–130. [Google Scholar] [CrossRef]

- Gu, H.L.; Tao, M.; Wang, J.X.; Jiang, H.B.; Li, Q.Y.; Wang, W. Influence of water content on dynamic mechanical properties of coal. Geomech. Eng. 2018, 16, 85–95. [Google Scholar]

- Haeri, H.; Shahriar, K.; Marji, M.F.; Vand, P.M. Simulating the bluntness of TBM disc cutters in rocks using displacement discontinuity method. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013; Volume 2, pp. 1414–1423. [Google Scholar]

- Kirby, S.H. Introduction and digest to the special issue on chemical effects of water on the deformation and strengths of rocks. J. Geophys. Res.-Sol. Earth 1984, 89, 3991–3995. [Google Scholar] [CrossRef]

- Afrouz, A.; Harvey, J.M. Rheology of rocks within the soft to medium strength range. Int. J. Rock. Mech. Min. Geo. Abstr. 1974, 11, 281–290. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Shen, B.; Williams, D.J.; Huddlestone-Holmes, C.; Erarslan, N.; Qin, J. Strength reduction on saturation of coal and coal measures rocks with implications for coal pillar strength. Int. J. Rock. Mech. Min. 2014, 71, 41–52. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, C.Q.; Yin, Z.Q.; Hou, J.L. Research on soft coal mechanics characteristic test for moisture content effect. J. Min. Saf. Eng. 2016, 33, 1145–1151. [Google Scholar]

- Talapatra, A.; Karim, M.M. The influence of moisture content on coal deformation and coal permeability during coalbed methane (CBM) production in wet reservoirs. J. Petrol. Explor. Prod. Technol. 2020, 10, 1907–1920. [Google Scholar] [CrossRef]

- Zhang, T.J.; Chen, Z.Y.; Pan, H.Y. Experimental study on the effect of water on the creep acoustic emission characteristics of coal containing pores. Coal. Sci. Technol. 2020, 1–9. Available online: https://kns.cnki.net/kcms/detail/11.2402.TD.20200207.1449.019.html (accessed on 20 October 2021).

- Liu, X.S.; Fan, D.Y.; Tan, Y.L.; Ning, J.G.; Song, S.L.; Wang, H.L.; Li, X.B. New detecting method on the connecting fractured zone above the coal face and a case study. Rock. Mech. Rock. Eng. 2021, 54, 4379–4391. [Google Scholar] [CrossRef]

- Liu, X.S.; Song, S.L.; Tan, Y.L.; Fan, D.Y.; Ning, J.G.; Li, X.B.; Yin, Y.C. Similar simulation study on the deformation and failure of surrounding rock of a large section chamber group under dynamic loading. Int. J. Min. Sci. Technol. 2021, 31, 495–505. [Google Scholar] [CrossRef]

- Tang, Z.H.; Wang, H.J.; Deng, H.; Li, W.C.; He, Y.F.; Li, P.W.; Yang, F. Creep model considering water content and its application in tunnel deformation. Pearl. River. 2020, 41, 73–80. [Google Scholar]

- Yang, W.D.; Zhang, Q.Y.; Zhang, J.G.; He, R.P.; Zeng, J.Q. Second development of improved Burgers creep damage constitutive model of rock based on FLAC3D. Rock. Soil Mech. 2010, 31, 1956–1964. [Google Scholar]

- Xue, D.J.; Lu, L.L.; Yi, H.Y.; Wu, Z.D.; Zhang, Q.S.; Zhang, Z.P. A fractional Burgers model for uniaxial and triaxial creep of damaged salt-rock considering temperature and volume-stress. Chin. J. Rock. Mech. Eng. 2021, 40, 315–329. [Google Scholar]

- Zhao, L.C. Secondary development and engineering application of creep damage model of water bearing sandstone. J. Yangtze River Sci. Res. Inst. 2021, 38, 105–112, 120. [Google Scholar]

- Sun, X.M.; Miao, C.Y.; Jiang, M.; Zhang, Y.; Yang, L.; Guo, B. Experimental and theoretical study on creep behaviors of sandstone with different moisture contents based on modified Nishihara model. Chin. J. Rock. Mech. Eng. 2021, 40, 2411–2420. [Google Scholar]

- Gao, W. Influence of interaction between coal and rock on the stability of strip coal pillar. Geomech. Eng. 2018, 16, 151–157. [Google Scholar]

- Rabat, Á.; Cano, M.; Tomás, R. Effect of water saturation on strength and deformability of building calcarenite stones: Correlations with their physical properties-sciencedirect. Constr. Build. Mater. 2020, 232, 117–259. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.S.; Fan, D.Y.; Tan, Y.L.; Song, S.L.; Li, X.F.; Ning, J.G.; Gu, Q.H.; Ma, Q. Failure evolution and instability mechanism of surrounding rock for close-distance chambers with super-large section in deep coal mines. Int. J. Geomech. 2021, 21, 04021049. [Google Scholar] [CrossRef]

- Li, S.J. Secondary Development and Application of Rock Water-Damage Creep Model Based on FLAC3D. Master’s Thesis, Hefei University of Technology, Hefei, China, March 2018. [Google Scholar]

- Chen, L.W.; Li, S.J.; Chen, Y.F.; Zhang, K.X.; Liu, Y.X. Further development and application of a creep damage model for water-bearing rocks. Chin. J. Solid. Mech. 2018, 39, 642–651. [Google Scholar]

- Kong, J.; Yuan, J.; Pan, X. Secondary development of flac3d and application of naylor K-G constitutive model. Comput. Struct. Eng. 2009, 1267–1273. [Google Scholar] [CrossRef]

- He, J.P.; Chen, W.Z. A simplified concrete damage constitutive model. Adv. Mater. Res. 2013, 671–674, 1663–1671. [Google Scholar] [CrossRef]

- Shi, Y.L.; Li, H.W.; Wang, W.D.; Hou, C. A fiber model based on secondary development of abaqus for elastic–plastic analysis. Int. J. Steel. Struct. 2018, 18, 1560–1576. [Google Scholar] [CrossRef]

- Haeri, H.; Hedayat, A.; Sarfarazi, V.; Shemirani, A.B. A review paper about experimental investigations on failure behaviour of non-persistent joint. Geomech. Eng. 2017, 13, 535–570. [Google Scholar]

- Dai, Z.P.; Zhao, C.; Zhao, C.F. The development and implementation of improved duncan-chang constitutive model in ABAQUS. Appl. Mech. Mater. 2011, 99–100, 965–971. [Google Scholar] [CrossRef]

- Haeri, H.; Sarfarazi, V.; Zhu, Z. Effect of normal load on the crack propagation from pre-existing joints using particle flow code (PFC). Comput. Concr. 2017, 19, 99–110. [Google Scholar] [CrossRef]

- Wang, J.G.; Liang, B.; Tian, M. Study of creep characteristics produced by nonlinear damage of oil shale in hydrous state. J. Exper. Mech. 2014, 29, 112–118. [Google Scholar]

- Yuan, Q.; Tan, C.; Li, L.L. Experimental investigation creep anisotropy characteristics of phyllite on uniaxial compression. Water. Resour. Power. 2019, 37, 148–151+78. [Google Scholar]

| Moisture Content ω (%) | E1 (GPa) | E2 (GPa) | η1 (GPa·h) | η2 (GPa·h) | R2 |

|---|---|---|---|---|---|

| 0 | 1.170 | 0.417 | 5.824 | 268.99 | 0.999 |

| 0.67 | 1.225 | 0.327 | 6.684 | 103.24 | 0.998 |

| 1.33 | 1.410 | 0.313 | 3.83 | 51.64 | 0.998 |

| 1.75 | 1.426 | 0.312 | 0.909 | 29.20 | 0.993 |

| Moisture Content ω (%) | Confining Pressure (MPa) | Axial Stress (MPa) | Creep Time (h) |

|---|---|---|---|

| 0 | 3 | 5 | 12 |

| 0.5 | 3 | 8 | 12 |

| 1.0 | 3 | 11 | 12 |

| 1.5 | 3 | 14 | 12 |

| Lithology | Density (kg/m3) | Cohesion (MPa) | Friction Angle (°) | Poisson’s Ratio | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Coal | 1628 | 3.05 × 106 | 32 | 0.32 | 1.05 × 106 |

| Siltstone | 2637 | 6.51 × 106 | 38 | 0.2 | 5.29 × 106 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, X.; Tan, Y.; Ma, Q.; Wu, B.; Wang, H. Creep Constitutive Model and Numerical Realization of Coal-Rock Combination Deteriorated by Immersion. Minerals 2022, 12, 292. https://doi.org/10.3390/min12030292

Li X, Liu X, Tan Y, Ma Q, Wu B, Wang H. Creep Constitutive Model and Numerical Realization of Coal-Rock Combination Deteriorated by Immersion. Minerals. 2022; 12(3):292. https://doi.org/10.3390/min12030292

Chicago/Turabian StyleLi, Xuebin, Xuesheng Liu, Yunliang Tan, Qing Ma, Baoyang Wu, and Honglei Wang. 2022. "Creep Constitutive Model and Numerical Realization of Coal-Rock Combination Deteriorated by Immersion" Minerals 12, no. 3: 292. https://doi.org/10.3390/min12030292

APA StyleLi, X., Liu, X., Tan, Y., Ma, Q., Wu, B., & Wang, H. (2022). Creep Constitutive Model and Numerical Realization of Coal-Rock Combination Deteriorated by Immersion. Minerals, 12(3), 292. https://doi.org/10.3390/min12030292