Numerical Simulation Study on the Multi-Physical Field Response to Underground Coal and Gas Outburst under High Geo-Stress Conditions

Abstract

:1. Introduction

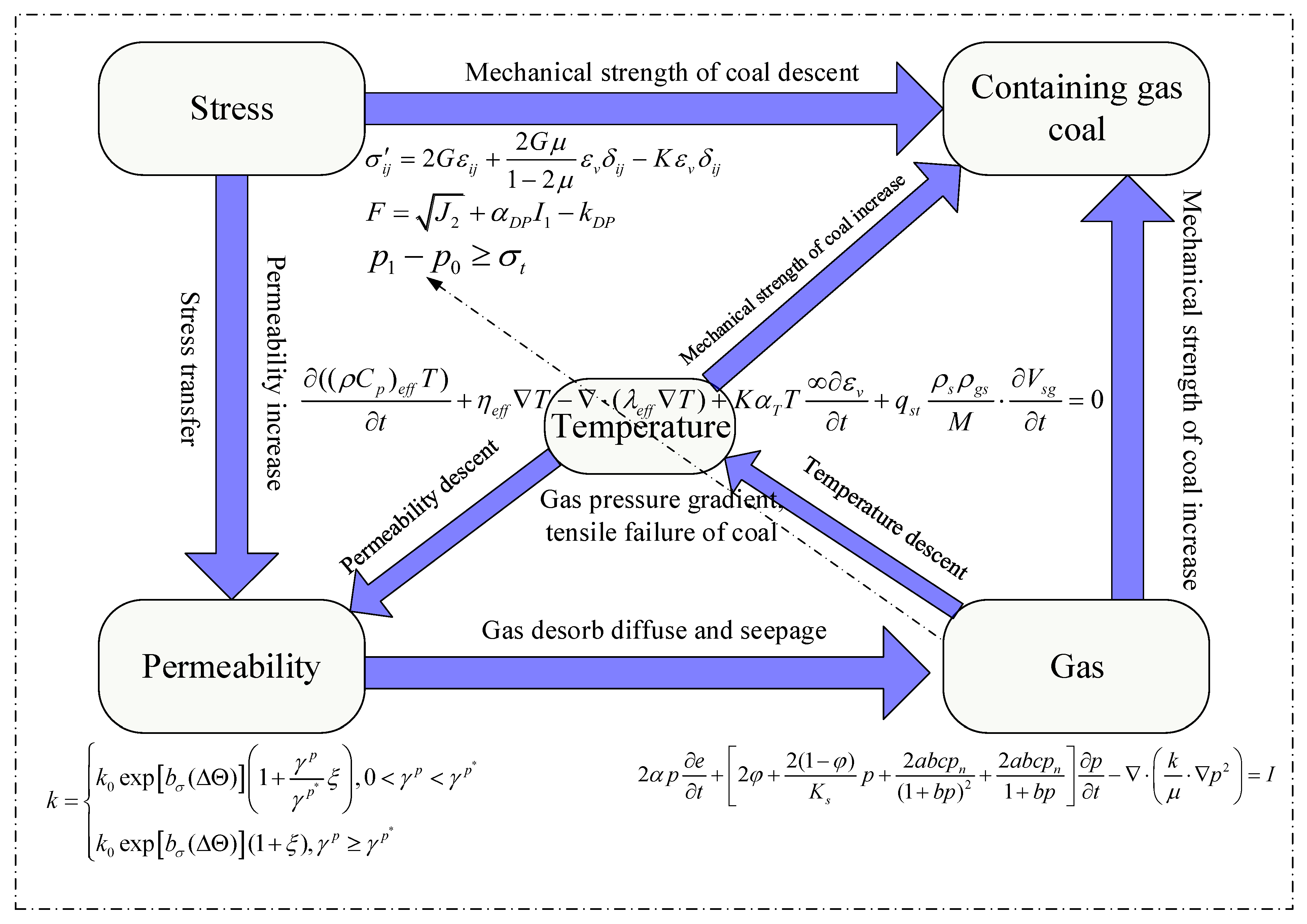

2. Multi-Physics Coupling in the Coal and Gas Outburst Based on Fractal Analysis

2.1. Stress Equation

2.2. Fluid Migration Equation

2.3. Temperature Equation

3. Multi-Physical Field Response of the Outburst Process

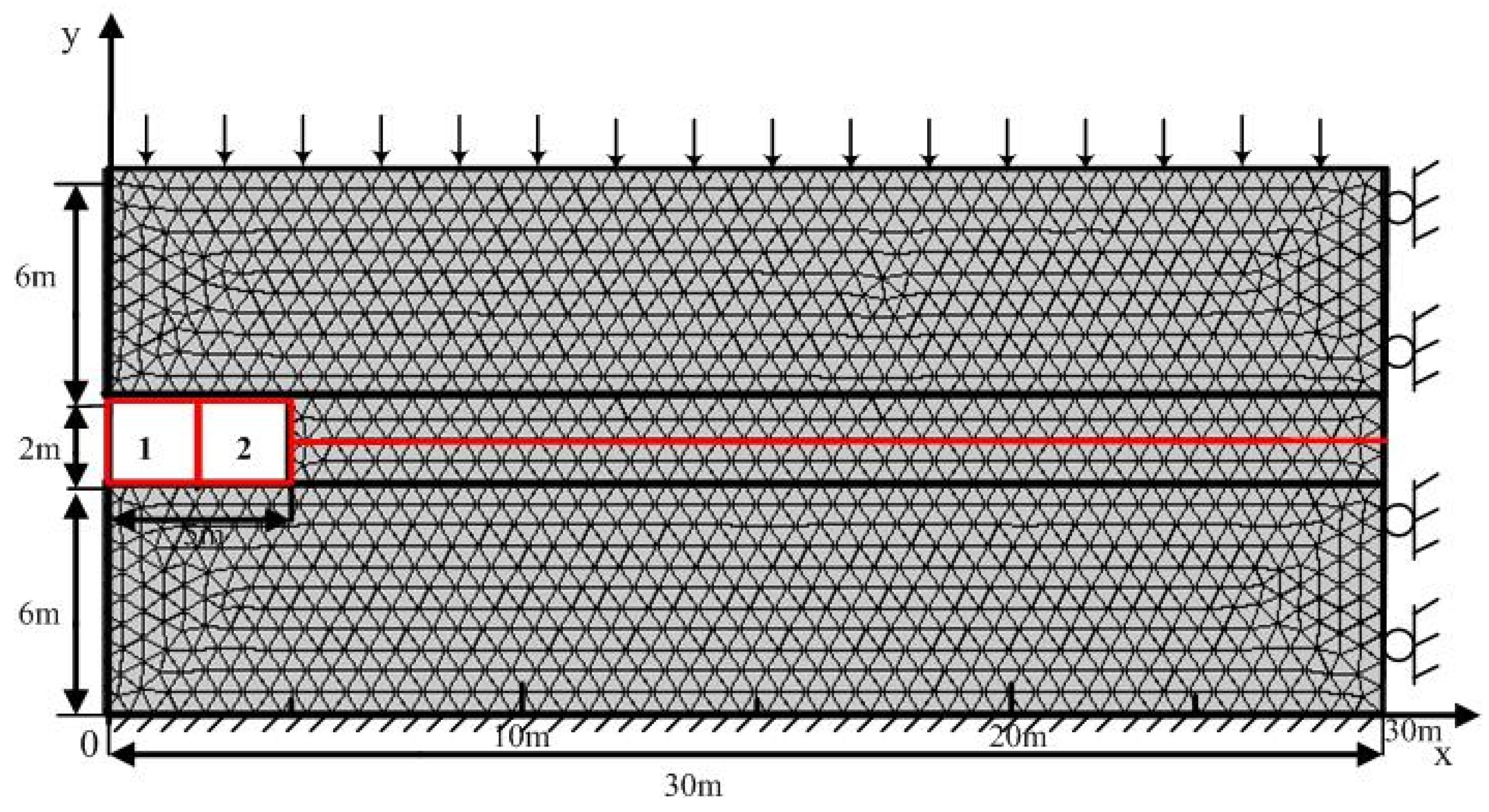

3.1. Geometric Model Construction

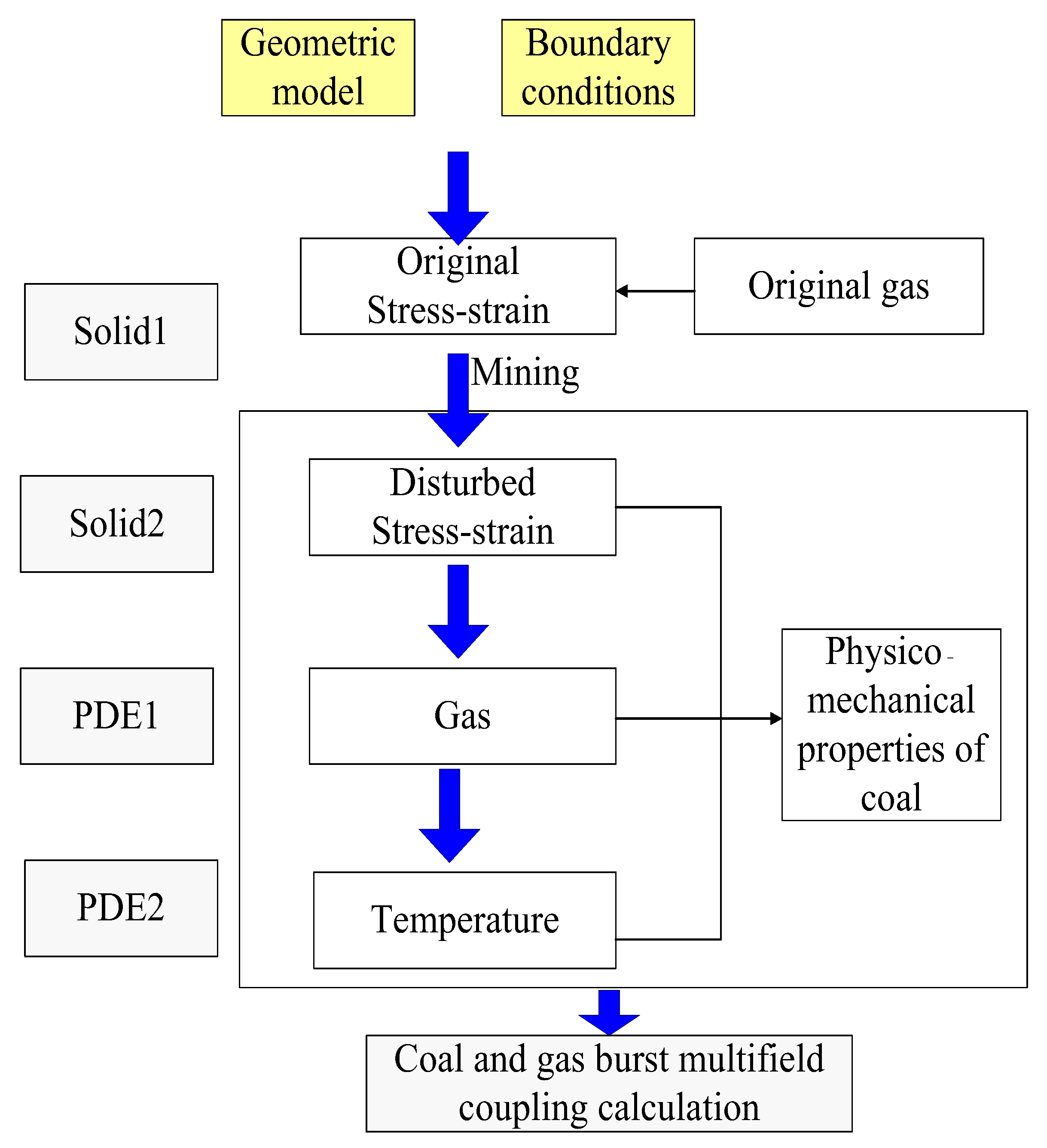

3.2. Calculation Method

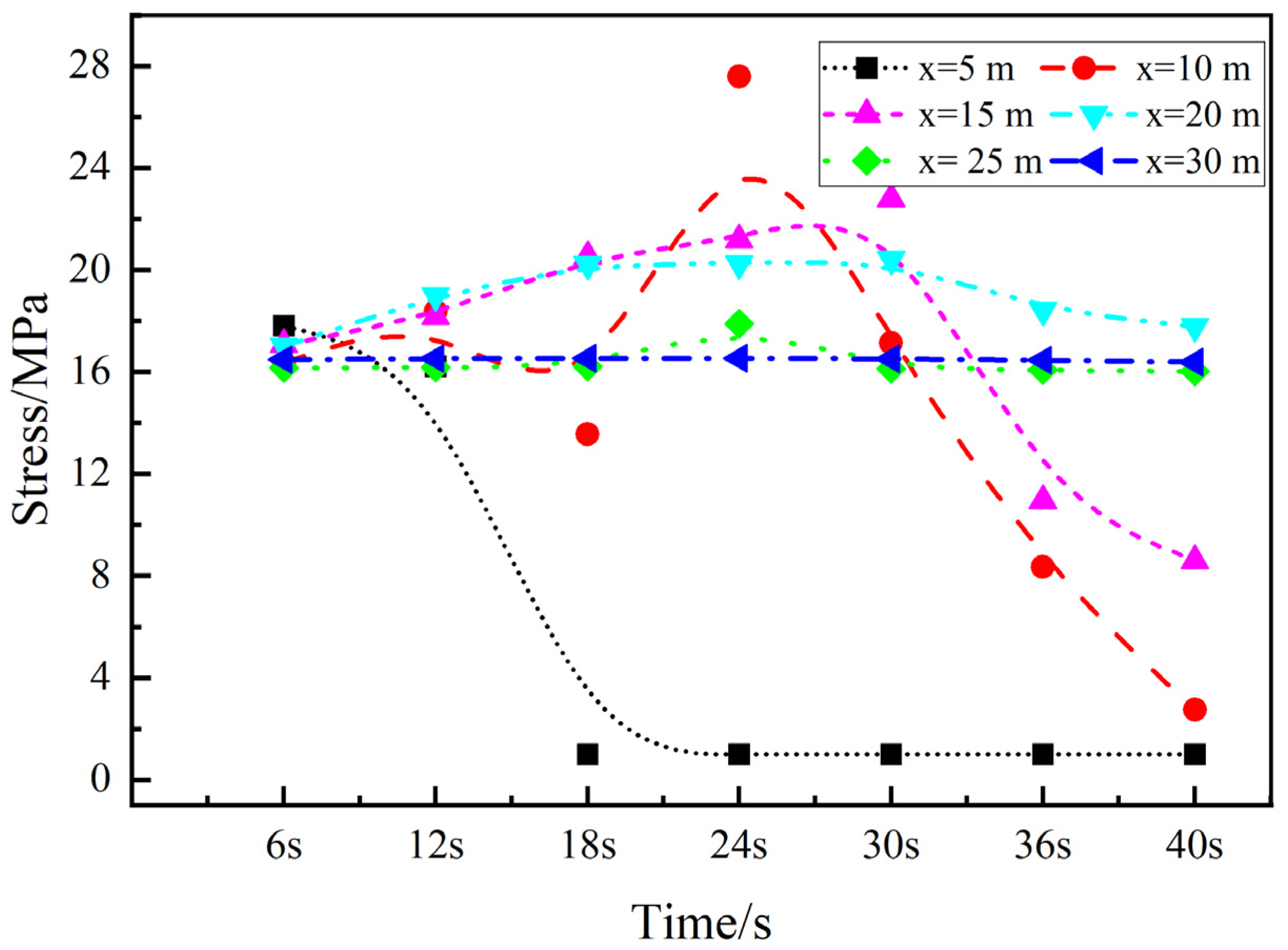

3.3. Stress Field Response in the Whole Outburst

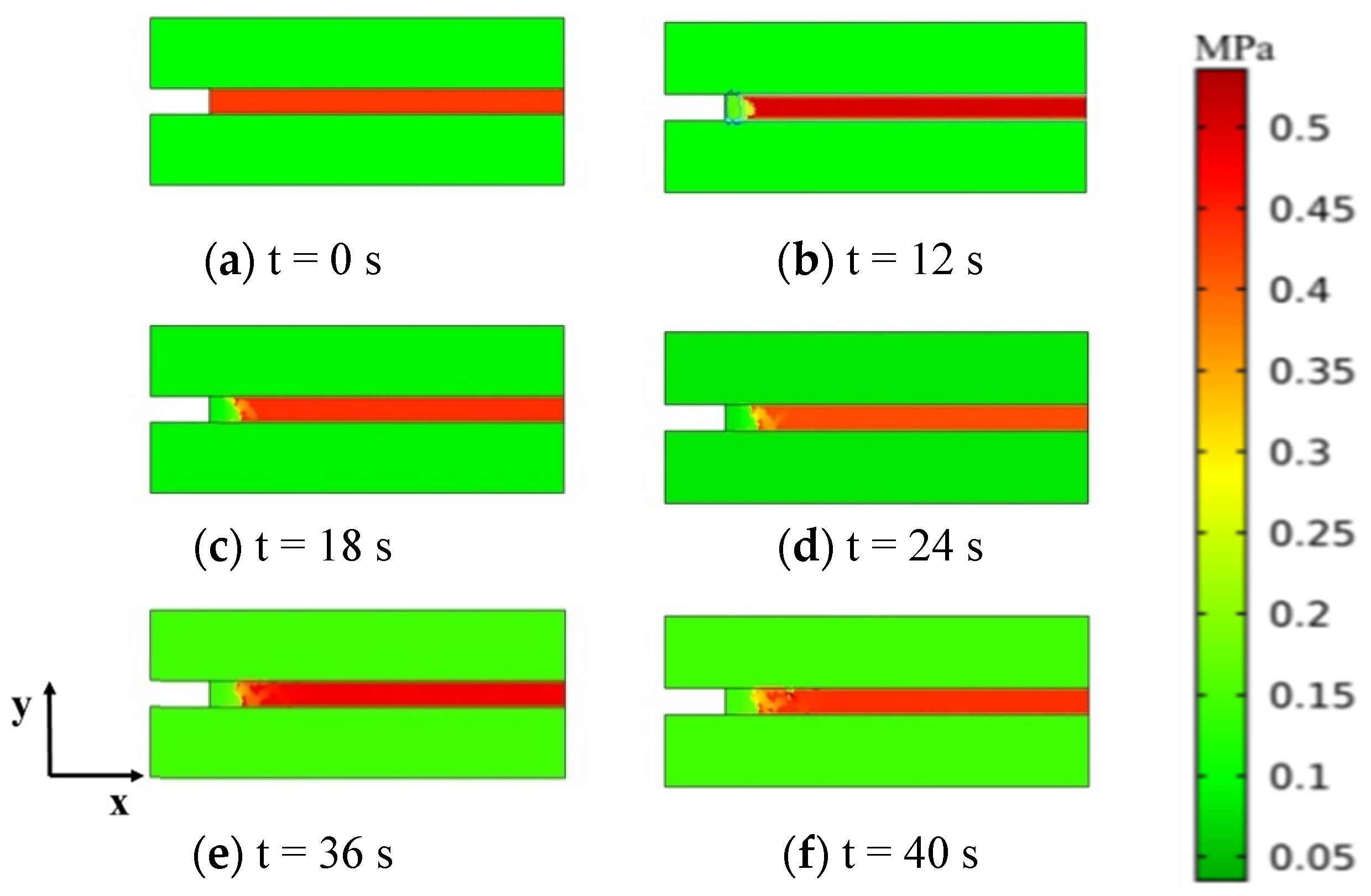

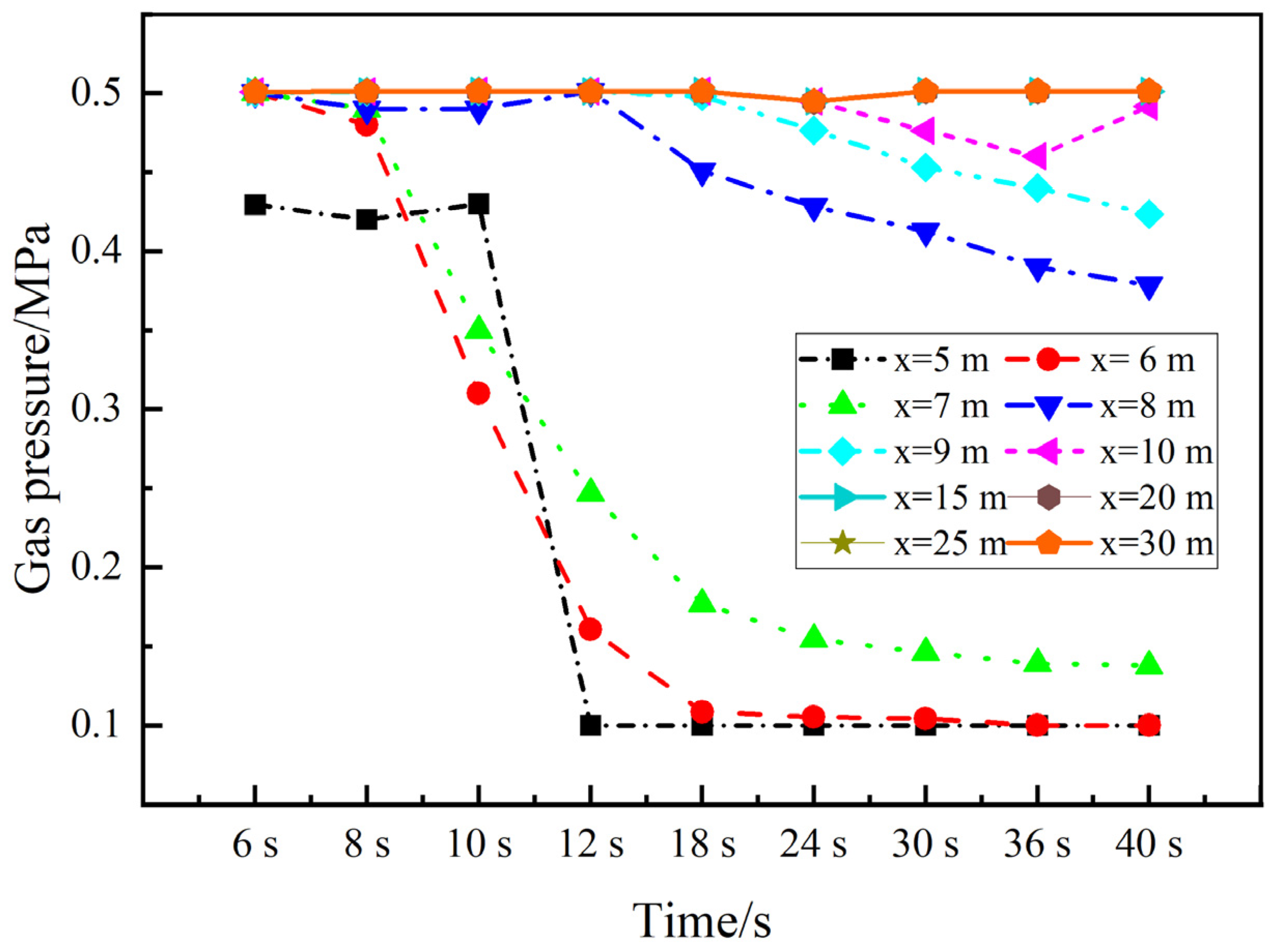

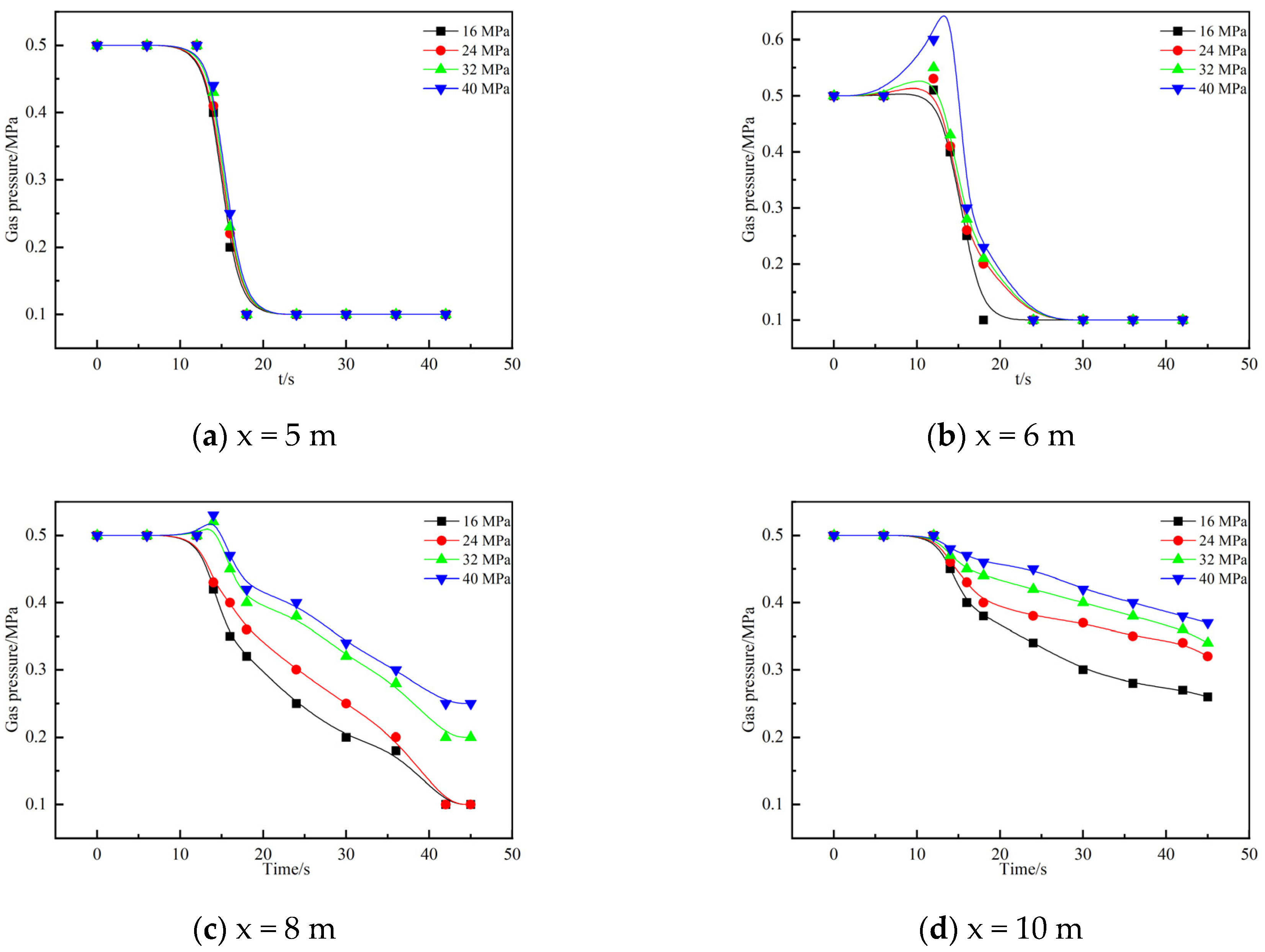

3.4. Gas Pressure Field Response in the Whole Outburst

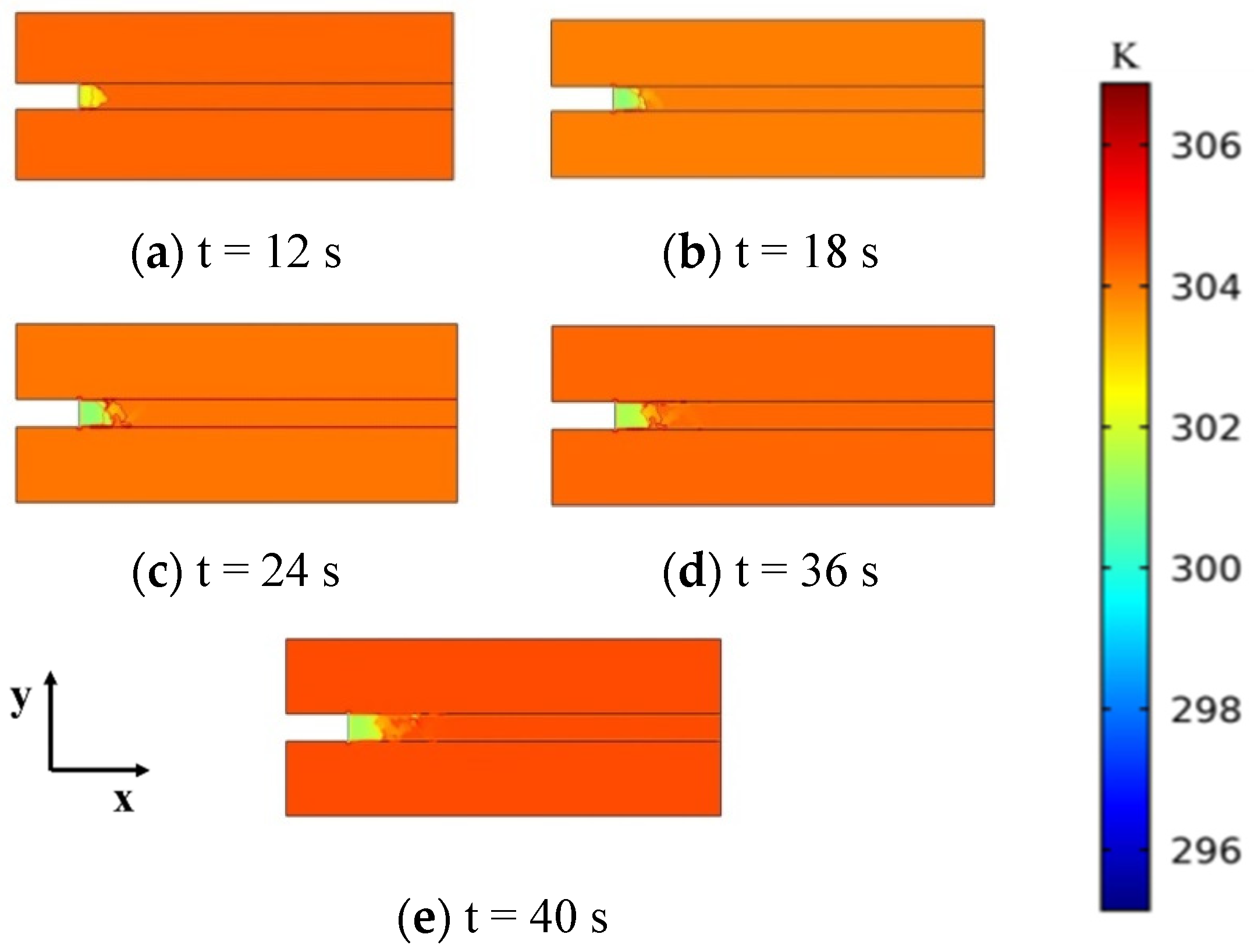

3.5. Temperature Field Response in the Whole Outburst

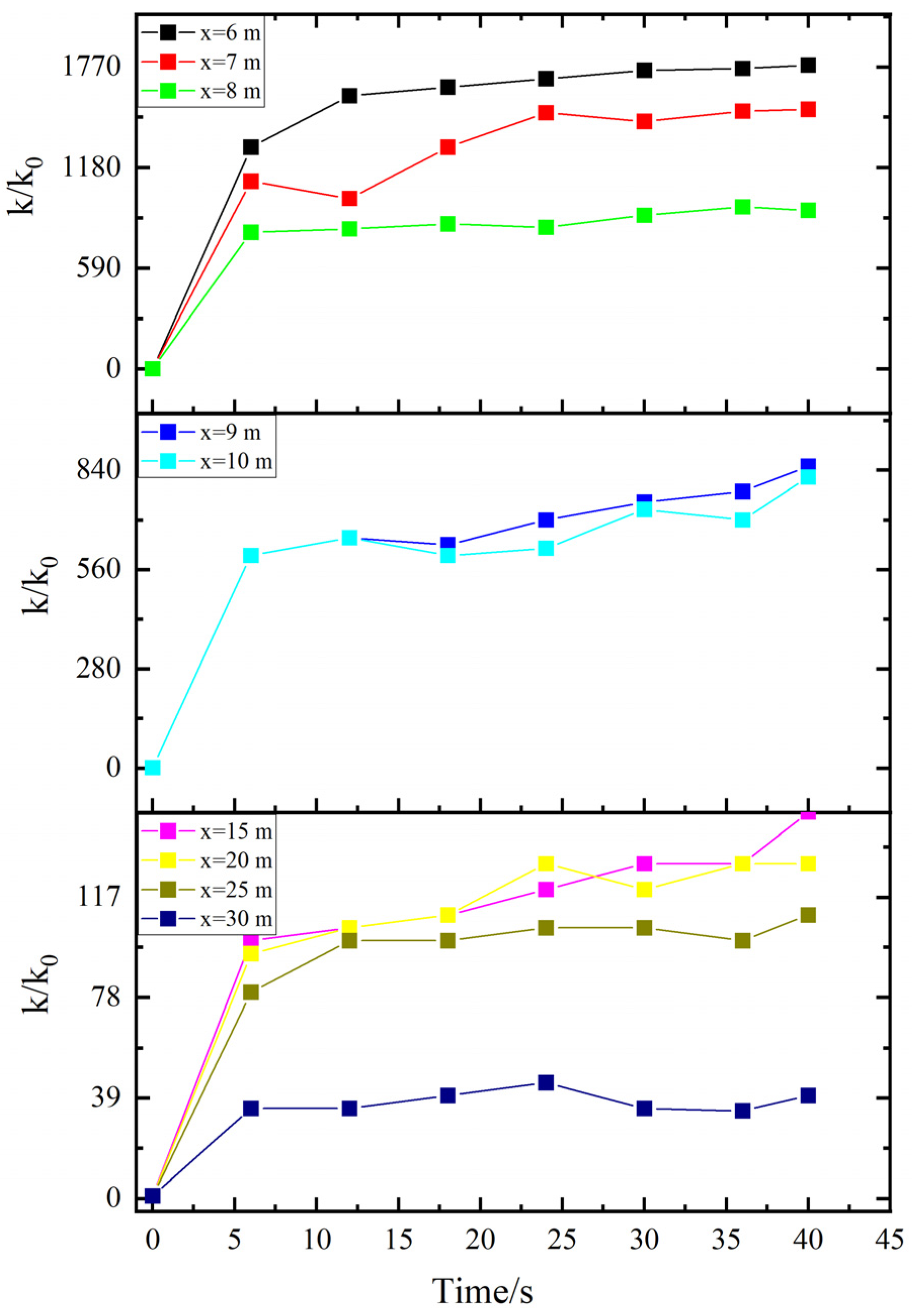

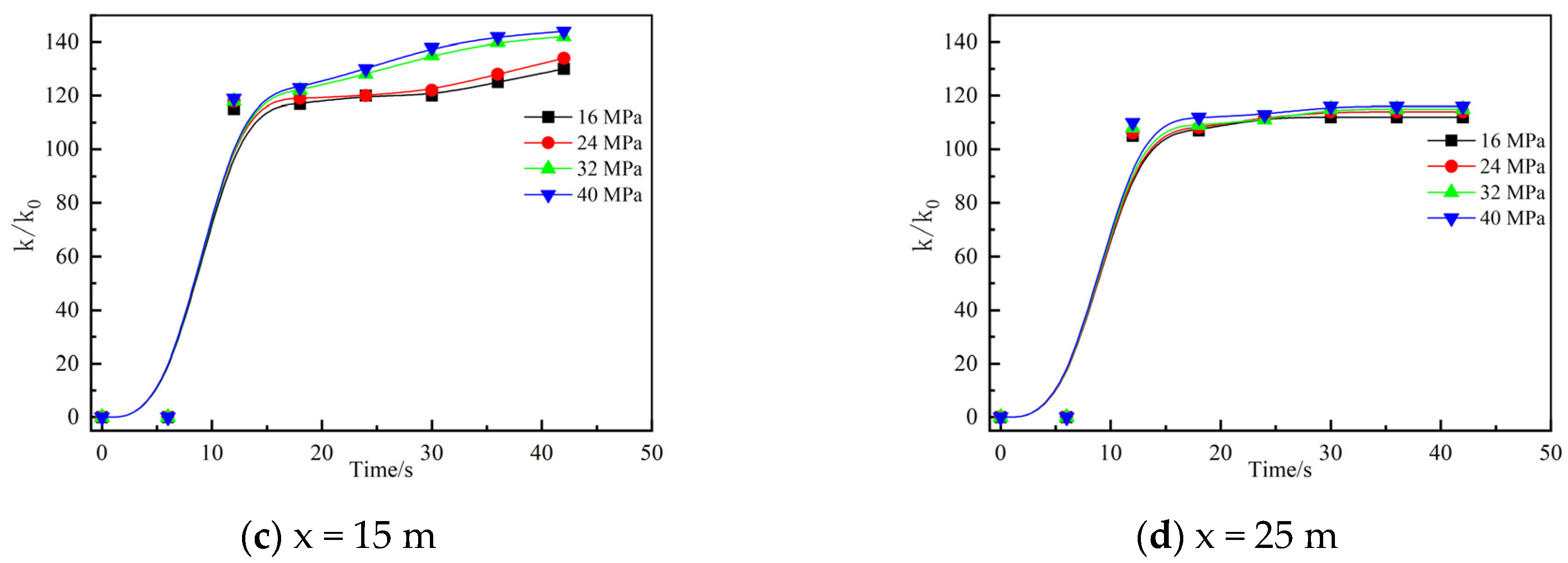

3.6. Seepage Field Response in the Whole Outburst

4. Multi-Physical Field Response of Coal and Gas Outburst under Different Stress Conditions

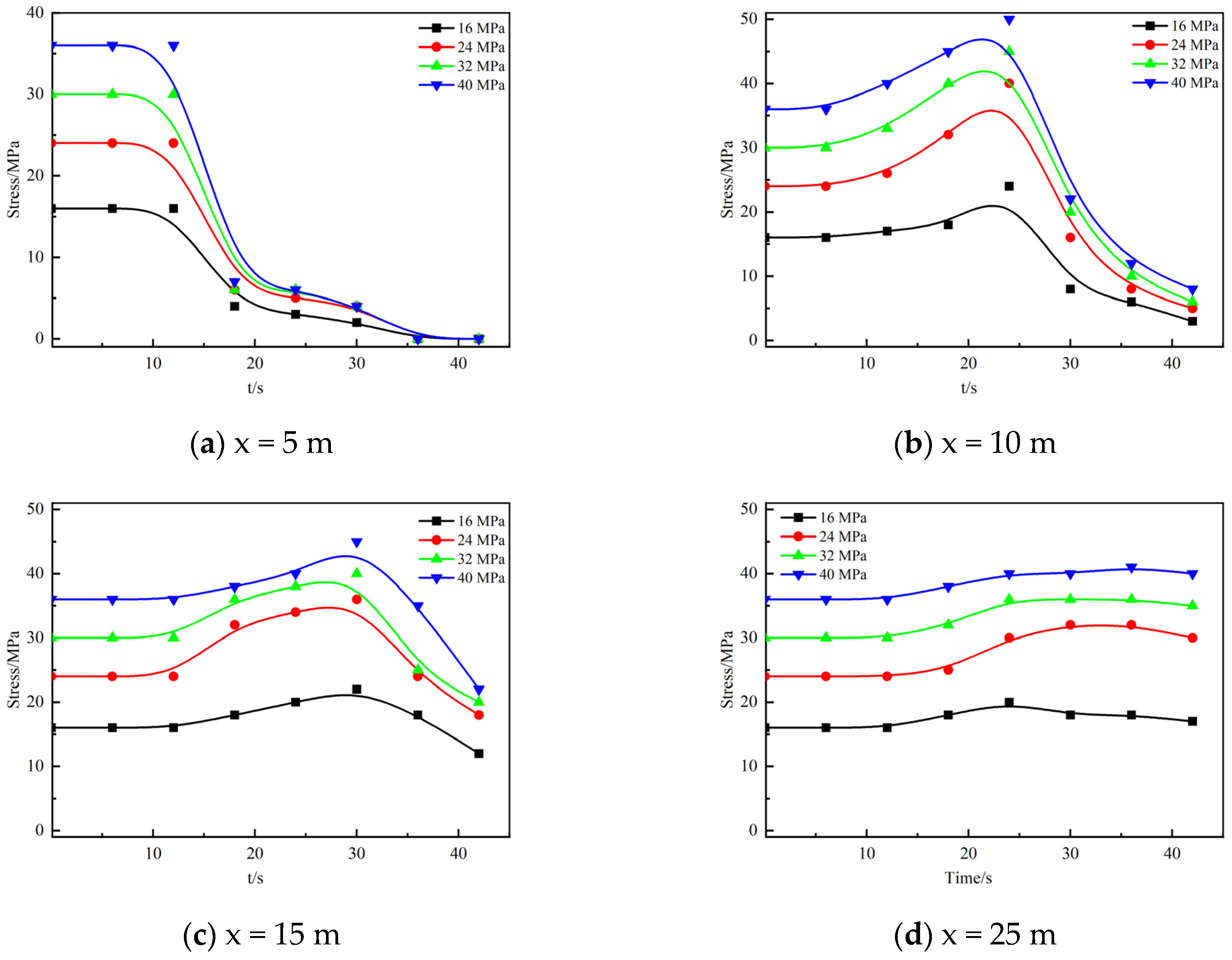

Stress Field Response in the Whole Outburst under Different Stress Conditions

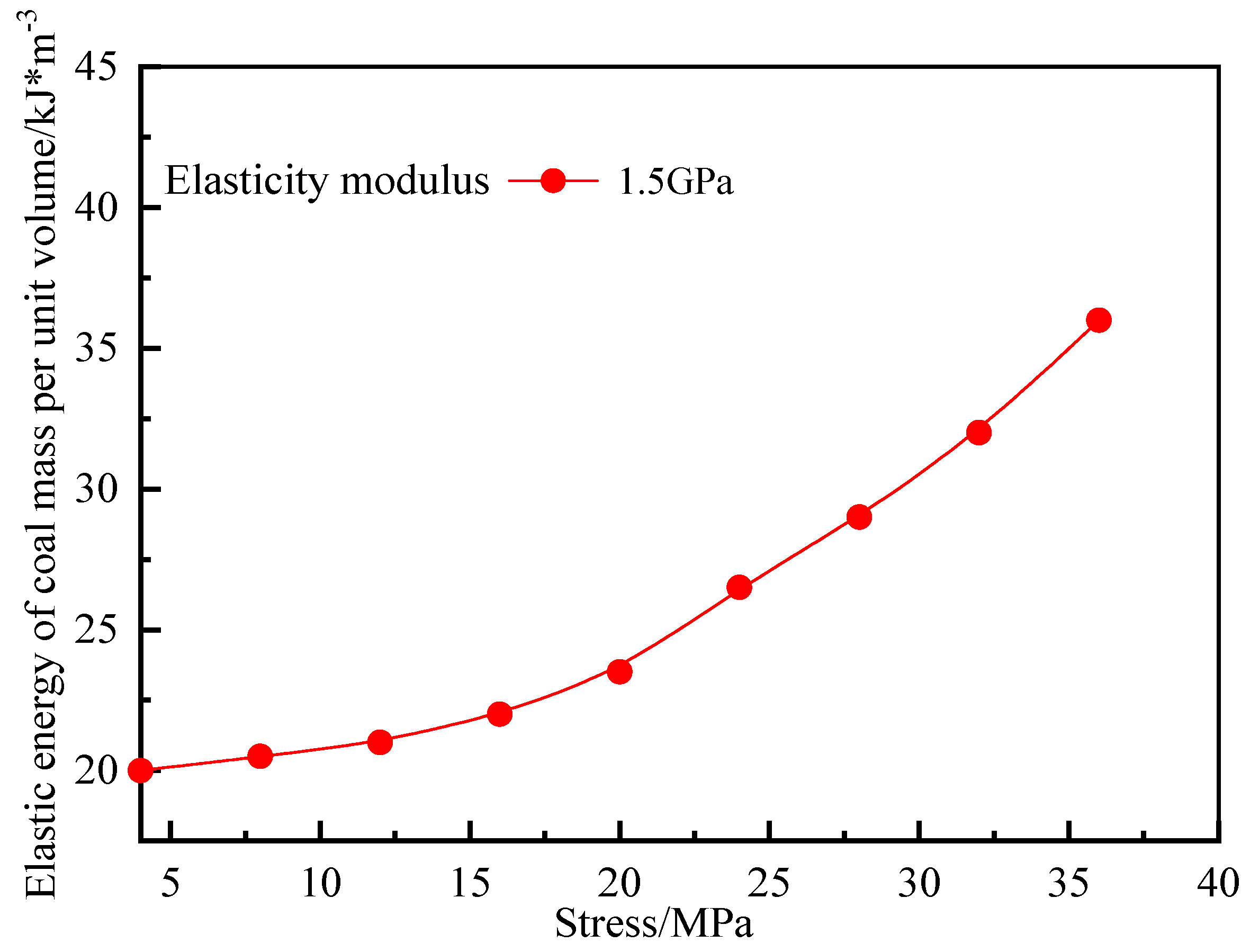

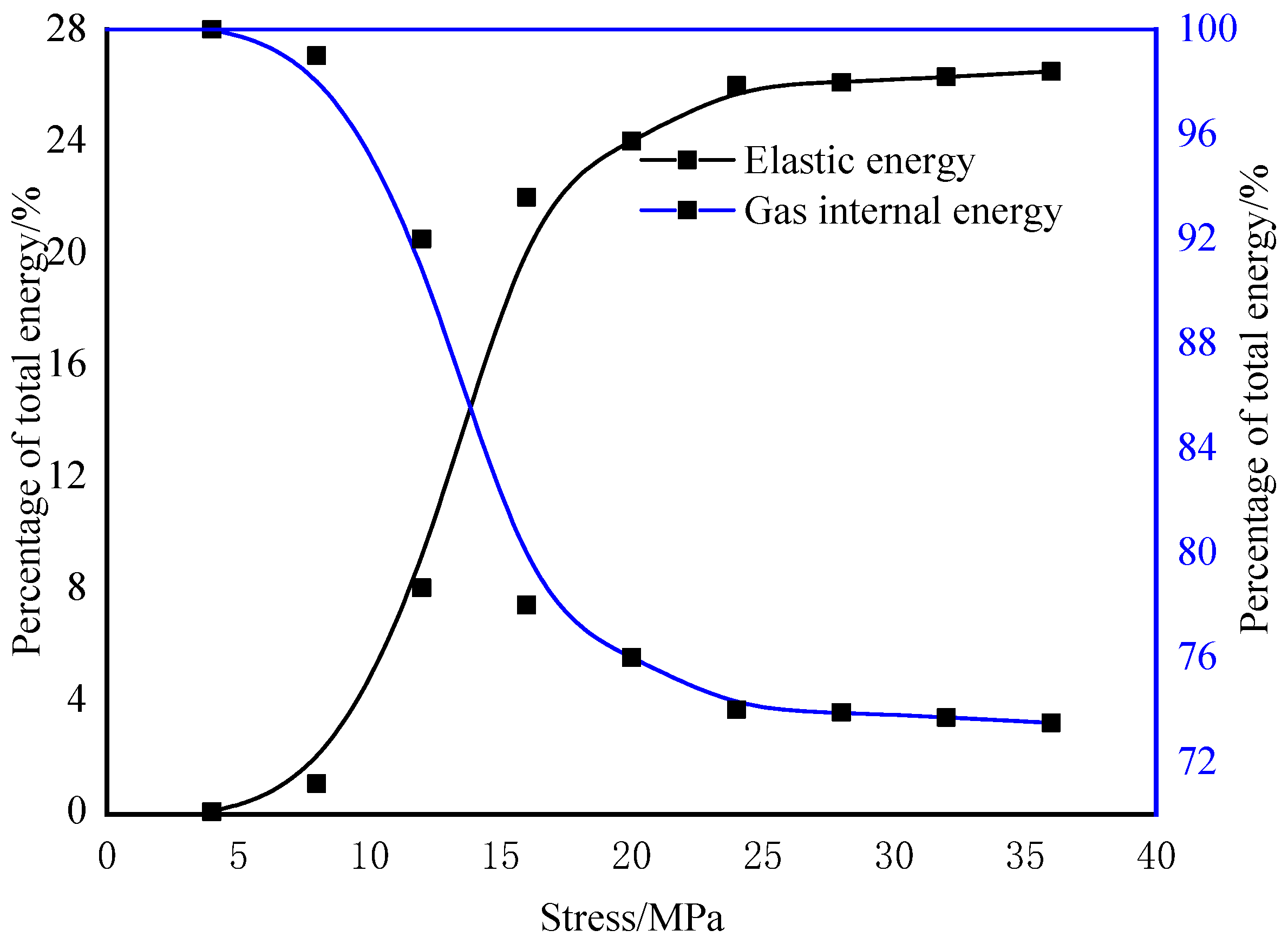

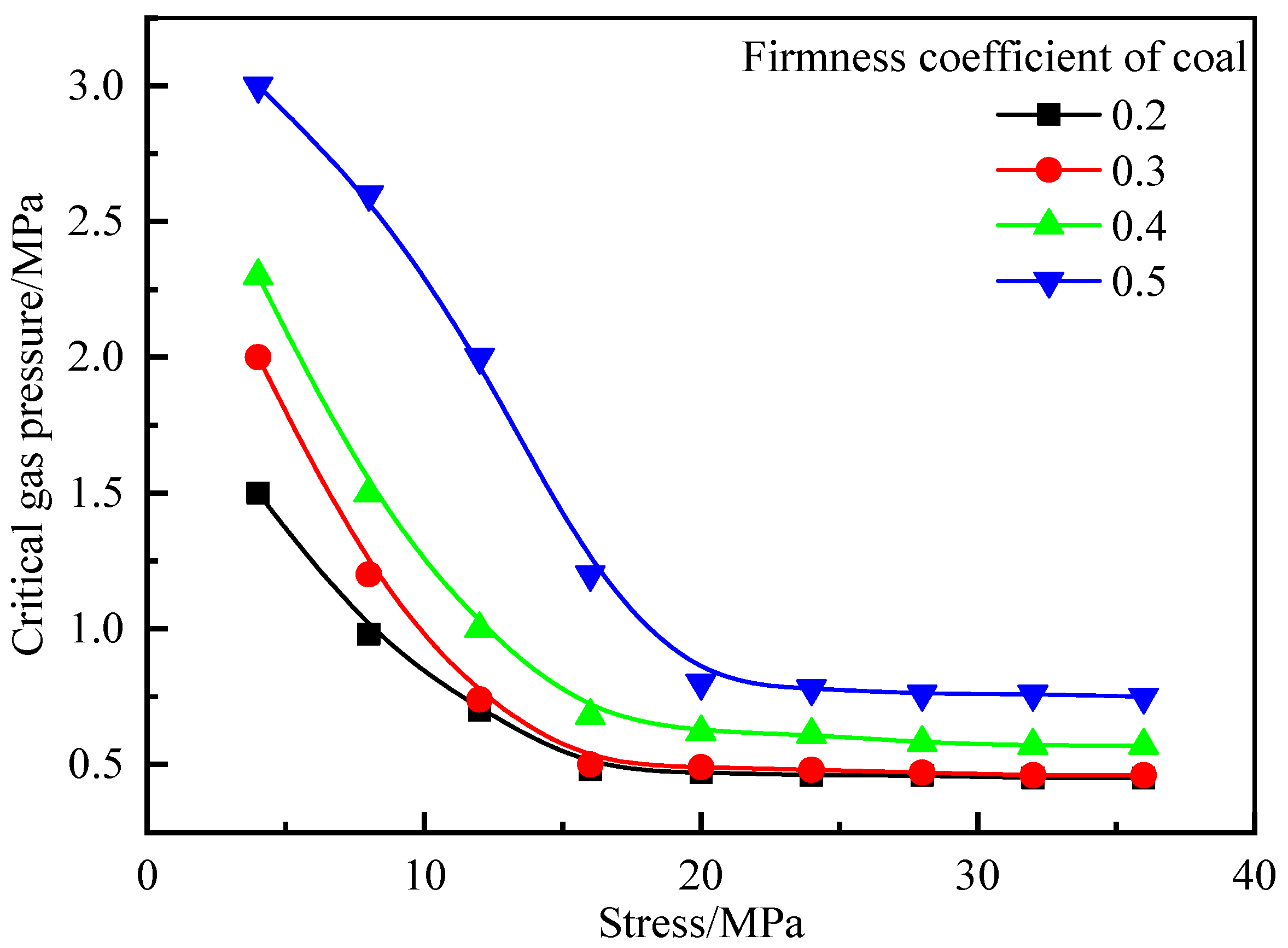

5. Influence of Stress on Energy Condition of Coal and Gas Outburst

6. Conclusions

- The stress field response law of the coal and rock mass around the outburst hole is initial vibration–sudden attenuation–late stability.

- The gas pressure field response law in different areas is that the gas pressure response rate decreases gradually with the increase of distance from the outburst port.

- After the outburst occurs and near the outburst, the adsorbed gas in the broken coal rapidly desorbs and expands to work, which changes the temperature. Most of the gas in the stress area of raw rock far from the outburst does not participate in the outburst work, and only a small part of the gas continues to desorb.

- The permeability changes in front of the driving face have the characteristics of zoning in the process of outburst. After outburst, the permeability changes significantly in front of the driving face under the influence of coal and gas outburst, which can be divided into sudden increase area, medium growth area, and growth area.

- Under the condition of high stress, a small gas pressure can also meet the energy condition of coal and gas outburst, and it also has the risk of coal and gas outburst.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Cheng, Y.; Pan, Z. Reservoir properties of Chinese tectonic coal: A review. Fuel 2019, 260, 116350. [Google Scholar] [CrossRef]

- Kursunoglu, N.; Onder, M. Application of structural equation modeling to evaluate coal and gas outbursts. Tunn. Undergr. Space Technol. 2019, 88, 63–72. [Google Scholar] [CrossRef]

- Jiang, L.; Wu, Q.; Wu, Q.; Wang, P.; Xue, Y.; Kong, P.; Gong, B. Fracture failure analysis of hard and thick key layer and its dynamic response characteristics. Eng. Fail. Anal. 2019, 98, 118–130. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, Y.; Sa, Z.; Si, S. Evaluation of the effect of adsorbed gas and free gas on mechanical properties of coal. Environ. Earth Sci. 2019, 78, 218. [Google Scholar] [CrossRef]

- Zou, Q.; Liu, H.; Zhang, Y.; Li, Q.; Fu, J.; Hu, Q. Rationality evaluation of production deployment of outburst-prone coal mines: A case study of nantong coal mine in Chongqing, China. Saf. Sci. 2020, 122, 104515. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, Y.; Guo, P.; Jin, K.; Tu, Q.; Wang, H. An analysis of the gas-solid plug flow formation: New insights into the coal failure process during coal and gas outbursts. Powder Technol. 2017, 305, 39–47. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Yan, F.; Peng, S.; Gao, Y.; Li, Q.; Cheng, L. Effects of gas pressure on dynamic response of two-phase flow for coal–gas outburst. Powder Technol. 2020, 377, 55–69. [Google Scholar] [CrossRef]

- An, F.; Yuan, Y.; Chen, X.; Li, Z.; Li, L. Expansion energy of coal gas for the initiation of coal and gas outbursts. Fuel 2018, 235, 551–557. [Google Scholar] [CrossRef]

- Yang, W.; Wang, H.; Lin, B.; Wang, Y.; Mao, X.; Zhang, J.; Lyu, Y.; Wang, M. Outburst mechanism of tunnelling through coal seams and the safety strategy by using “strong-weak” coupling circle-layers. Tunn. Undergr. Space Technol. 2018, 74, 107–118. [Google Scholar] [CrossRef]

- Shi, Q.; Qin, B.; Liang, H.; Gao, Y.; Bi, Q.; Qu, B. Effects of igneous intrusions on the structure and spontaneous combustion propensity of coal: A case study of bituminous coal in Daxing Mine, China. Fuel 2018, 216, 181–189. [Google Scholar] [CrossRef]

- Zhao, T.; Guo, W.; Tan, Y.; Yin, Y.; Cai, L.; Pan, J. Case Studies of Rock Bursts Under Complicated Geological Conditions during Multi-seam Mining at a Depth of 800 m. Rock Mech. Rock Eng. 2018, 51, 1539–1564. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Zhou, L.; Yang, Z.; Song, Y. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 2019, 173, 1054–1077. [Google Scholar] [CrossRef]

- Fişne, A.; Esen, O. Coal and gas outburst hazard in Zonguldak Coal Basin of Turkey, and association with geological parameters. Nat. Hazards 2014, 74, 1363–1390. [Google Scholar] [CrossRef]

- Skoczylas, N.; Dutka, B.; Sobczyk, J. Mechanical and gaseous properties of coal briquettes in terms of outburst risk. Fuel 2014, 134, 45–52. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.P.; An, F.-H.; Zhou, H.-X.; Kong, S.-L.; Wang, W. Characteristics of gas disaster in the Huaibei coalfield and its control and development technologies. Nat. Hazards 2013, 71, 85–107. [Google Scholar] [CrossRef]

- Xue, S.; Yuan, L.; Wang, Y.; Xie, J. Numerical Analyses of the Major Parameters Affecting the Initiation of Outbursts of Coal and Gas. Rock Mech. Rock Eng. 2013, 47, 1505–1510. [Google Scholar] [CrossRef]

- Zhang, R.; Jiang, Z.; Zhou, H.; Yang, C.; Xiao, S. Groundwater outbursts from faults above a confined aquifer in the coal mining. Nat. Hazards 2013, 71, 1861–1872. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Q.; Cheng, Y.; Ge, C.; Chen, J. Methane drainage and utilization in coal mines with strong coal and gas outburst dangers: A case study in Luling mine, China. J. Nat. Gas Sci. Eng. 2014, 20, 357–365. [Google Scholar] [CrossRef]

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution during progressive deformation of intact coal and implications for instability in underground coal seams. Int. J. Rock Mech. Min. Sci. 2013, 58, 34–45. [Google Scholar] [CrossRef]

- An, F.; Cheng, Y.; Wang, L.; Li, W. A numerical model for outburst including the effect of adsorbed gas on coal deformation and mechanical properties. Comput. Geotech. 2013, 54, 222–231. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, J.; Ge, Z.; Xia, B.; Liu, Y. Hard rock drilling technique with abrasive water jet assistance. Int. J. Rock Mech. Min. Sci. 2013, 60, 47–56. [Google Scholar]

- Díaz Aguado, M.B.; González Nicieza, C. Control and prevention of gas outbursts in coal mines, Riosa–Olloniego coalfield, Spain. Int. J. Coal geol. 2007, 69, 253–266. [Google Scholar] [CrossRef]

- Wold, M.B.; Connell, L.D.; Choi, S.K. The role of spatial variability in coal seam parameters on gas outburst behaviour during coal mining. Int. J. Coal Geol. 2008, 75, 1–14. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, C.; Li, X.; Chen, Y.; Xie, Q.; Liu, Y.; Tang, J.; Yang, F.-L.; Wang, F.-K.; Deng, S.-H.; et al. Quick determination of gas pressure before uncovering coal in cross-cuts and shafts. J. China Univ. Min. Technol. 2008, 18, 494–499. [Google Scholar]

- Sobczyk, J. The influence of sorption processes on gas stresses leading to the coal and gas outburst in the laboratory conditions. Fuel 2011, 90, 1018–1023. [Google Scholar] [CrossRef]

- Xusheng, Z.; Qianting, H.; Xiaoliang, N. Research on Comprehensive Early-Warning Technology of Coal and Gas Outburst. Procedia Eng. 2011, 26, 2376–2382. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.; Liu, C.; Fu, J.; Guan, H. Hydraulic fracturing after water pressure control blasting for increased fracturing. Int. J. Rock Mech. Min. Sci. 2011, 48, 976–983. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar]

- Lu, T.; Zhao, Z.; Hu, H. Improving the gate road development rate and reducing outburst occurrences using the waterjet technique in high gas content outburst-prone soft coal seam. Int. J. Rock Mech. Min. Sci. 2011, 48, 1271–1282. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, S.; Wen, G.; Dai, L.; Wang, B. Coal-like material for coal and gas outburst simulation tests. Int. J. Rock Mech. Min. Sci. 2015, 74, 151–156. [Google Scholar] [CrossRef]

- Jiang, C.; Xu, L.; Li, X.; Tang, J.; Chen, Y.; Tian, S.; Liu, H. Identification Model and Indicator of Outburst-Prone Coal Seams. Rock Mech. Rock Eng. 2014, 48, 409–415. [Google Scholar] [CrossRef]

- Niu, Q.; Cao, L.; Sang, S.; Zhou, X.; Wang, Z.; Wu, Z. The adsorption-swelling and permeability characteristics of natural and reconstituted anthracite coals. Energy 2017, 141, 2206–2217. [Google Scholar] [CrossRef]

- Qiu, L.; Song, D.; Li, Z.; Liu, B.; Liu, J. Research on AE and EMR response law of the driving face passing through the fault. Saf. Sci. 2019, 117, 184–193. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, Y.; Qi, Y.; Wang, R.; Wang, L.; Jiang, J. Experimental study of pore structure and fractal characteristics of pulverized intact coal and tectonic coal by low temperature nitrogen adsorption. Powder Technol. 2019, 350, 15–25. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, Y.; Pan, Z.; Wang, K.; Liu, S. Gas diffusion in coal particles: A review of mathematical models and their applications. Fuel 2019, 252, 77–100. [Google Scholar] [CrossRef]

- Ding, X.; Xiao, X.; Wu, D.; Lv, X. Mechanical properties and charge signal characteristics in coal material failure under different loading paths. Int. J. Coal Sci. Technol. 2019, 6, 138–149. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Yang, D.; Li, X.; Jiang, C. Experimental analysis of the intensity and evolution of coal and gas outbursts. Fuel 2018, 226, 252–262. [Google Scholar] [CrossRef]

- Jin, K.; Cheng, Y.; Ren, T.; Zhao, W.; Tu, Q.; Dong, J.; Wang, Z.; Hu, B. Experimental investigation on the formation and transport mechanism of outburst coal-gas flow: Implications for the role of gas desorption in the development stage of outburst. Int. J. Coal Geol. 2018, 194, 45–58. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental investigation of N2 injection to enhance gas drainage in CO2-rich low permeable seam. Fuel 2018, 215, 665–674. [Google Scholar] [CrossRef]

- Zhai, C.; Xiang, X.; Xu, J.; Wu, S. The characteristics and main influencing factors affecting coal and gas outbursts in Chinese Pingdingshan mining region. Nat. Hazards 2016, 82, 507–530. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, C.; Tu, S.; Tu, H.; Wang, C. A Study of Directional Permeability and Gas Injection to Flush Coal Seam Gas Testing Apparatus and Method. Transp. Porous Media 2016, 111, 573–589. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, Y. The elimination of coal and gas outburst disasters by long distance lower protective seam mining combined with stress-relief gas extraction in the Huaibei coal mine area. J. Nat. Gas Sci. Eng. 2015, 27, 346–353. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Peng, S.; Yan, F.; Gao, Y.; Li, Q.; Cheng, L. Effects of geo-stress on the dynamic response of multi-physical field parameters during coal and gas outbursts under true triaxial stress. Int. J. Rock Mech. Min. Sci. 2021, 142, 104759. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Peng, S.; Geng, J.; Yan, F. Test system for the visualization of dynamic disasters and its application to coal and gas outburst. Int. J. Rock Mech. Min. Sci. 2019, 122, 104083. [Google Scholar] [CrossRef]

- Koltun, A.P.S.; Lenzi, E.K.; Lenzi, M.K.; Zola, R.S. Diffusion in Heterogenous Media and Sorption—Desorption Processes. Fractal Fract. 2021, 5, 183. [Google Scholar] [CrossRef]

- Posadas-Mondragón, R.; Camacho-Velázquez, R.G. Partially Penetrated Well Solution of Fractal Single-Porosity Naturally Fractured Reservoirs. Fractal Fract. 2019, 3, 23. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Parameters | ||

|---|---|---|---|

| Elastic modulus of rock E | 20 GPa | Density of coal ρ | 1.4 × 103 kg/m3 |

| Poisson’s ratio of rock v | 0.3 | Initial porosity of coal seam | 5.61% |

| Density of rock ρ | 2.5 × 103 kg/m3 | Coal cohesiveness | 20 MPa |

| Cohesion of rock | 20 MPa | Angle of friction in rock | 40° |

| Angle of friction of rock | 40° | Gas dynamic viscosity coefficient η | 11.067 Pa·s |

| Elastic modulus of coal E | 2.3 GPa | Density of gas ρ | 0.716 kg/m3 |

| Working face pressure P | 0.1 MPa | Initial gas pressure P | 0.5 MPa |

| Poisson’s ratio of coal v | 0.192 | Initial temperature of coal T | 305.5 K |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Wen, G.; Nian, J.; Ma, Q.; Fan, C.; Lv, X.; Deng, C. Numerical Simulation Study on the Multi-Physical Field Response to Underground Coal and Gas Outburst under High Geo-Stress Conditions. Minerals 2022, 12, 151. https://doi.org/10.3390/min12020151

Zhao B, Wen G, Nian J, Ma Q, Fan C, Lv X, Deng C. Numerical Simulation Study on the Multi-Physical Field Response to Underground Coal and Gas Outburst under High Geo-Stress Conditions. Minerals. 2022; 12(2):151. https://doi.org/10.3390/min12020151

Chicago/Turabian StyleZhao, Bo, Guangcai Wen, Jun Nian, Qianwei Ma, Chaojun Fan, Xiaobo Lv, and Chunsheng Deng. 2022. "Numerical Simulation Study on the Multi-Physical Field Response to Underground Coal and Gas Outburst under High Geo-Stress Conditions" Minerals 12, no. 2: 151. https://doi.org/10.3390/min12020151

APA StyleZhao, B., Wen, G., Nian, J., Ma, Q., Fan, C., Lv, X., & Deng, C. (2022). Numerical Simulation Study on the Multi-Physical Field Response to Underground Coal and Gas Outburst under High Geo-Stress Conditions. Minerals, 12(2), 151. https://doi.org/10.3390/min12020151