Abstract

Underground coal mining of CH4 gas-rich tectonic coal seams often induces methane outburst disasters. Investigating gas permeability evolution in pores of the tectonic coal is vital to understanding the mechanism of gas outburst disasters. In this study, the triaxial loading–unloading stresses induced gas permeability evolutions in the briquette tectonic coal samples, which were studied by employing the triaxial-loading–gas-seepage test system. Specifically, effects of loading paths and initial gas pressures on the gas permeability of coal samples were analyzed. The results showed the following: (1) The gas permeability evolution of coal samples was correlated with the volumetric strain change during triaxial compression scenarios. In the initial compaction and elastic deformation stages, pores and cracks in the coal were compacted, resulting in a reduction in gas permeability in the coal body. However, after the yield stage, the gas permeability could be enhanced due to sample failure. (2) The gas permeability of the tectonic coal decreased as a negative exponential function with the increase in initial gas pressure, in which the permeability was decreased by 67.32% as the initial gas pressure increased from 0.3 MPa to 1.5 MPa. (3) Coal samples underwent a period of strain development before they began to fail during confining pressure releasing. After the stress releasing-induced yield stage, the coal sample was deformed and cracked, resulting in a quickly increase in gas permeability. With a further releasing process, failure of the sample occurred, and thus induced rapidly increasing gas permeability. These obtained results could provide foundations for gas outburst prevention in mining gas-rich tectonic coal seams.

1. Introduction

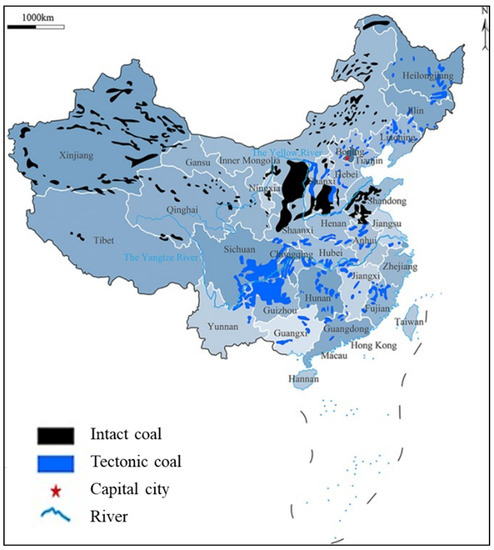

A coalbed methane outburst disaster often threatens the safety mining of coal resources [1,2]. A necessary condition of a gas outburst disaster is the existence of tectonic coal [3]. The original structure of coal, which is affected by tectonism such as faulting, folding and slipping, could be destroyed by tectonic stress, thus causing the coal to be severely crushed or even pulverized [4]. This severely crushed or pulverized coal is commonly known as tectonic coal or tectonically deformed coal and is widely distributed in southwestern and central-eastern China [3] (Figure 1). Compared with primary structure coal, it is more difficult to prevent gas outbursts in tectonic coal due to its higher gas content, lower permeability and lower strength. Furthermore, coal mining induces repeated loading–unloading stress conditions, which could further deform the coal body [5,6], leading to the violent fluctuation of gas permeability. Therefore, studying the gas permeability evolution of tectonic coal, under various initial gas pressures and stress conditions, is of great significance for understanding gas outbursts mechanisms.

Figure 1.

Possibility distribution of tectonic coal in China (from Cheng et al. [3]).

To date, many experimental and numerical studies have been conducted to investigate the CH4 permeability evolutions of intact and fractured coal samples for recovering coalbed methane and reducing the risk of geological catastrophe [7,8,9,10,11,12]. Studies have focused on identifying factors influencing gas permeability through various geological simulations, such as geo-stress, temperature and excavation methods or layouts [13,14,15,16]. Since tectonic coal has been subjected to severe geological structures during its formation, it is more difficult to be sampled. Therefore, many scholars have conducted systematic experimental research on briquette coal samples in order to grasp the basic characteristics of gas seepage in the pores of tectonic coal. Huang et al. [17] investigated the impact of various loading conditions on the permeability of briquette coal samples. They found that confining pressure had a greater effect than axial stress, and the permeability exponentially decreased with increasing stresses. Yin et al. [18] concluded that the gas permeability of briquette coal decreased with increasing confining pressure, due to the compaction effect of applied stress. Yuan et al. [19] studied the impact law of temperatures and effective stresses on briquette coal permeability. Briquette coal permeability decreased with increasing effective stress, while it decreased with increasing temperature. Wierzbicki et al. [20] investigated the permeability evolution of raw coal and briquettes under triaxial stress conditions. They found that the raw coal and briquettes showed similar behavior with increasing confining pressure. The gas permeability of coal briquettes could be decreased by up to one order compared to the three orders in raw coals. This reduction was caused by the presence of stress-sensitive cracks and fissures in the raw coal specimens. Mateusz Kudasik concluded that the values of the Klinkenberg permeability coefficient decreased as the mechanical stress and the corresponding reduction in porosity become greater [21].

However, investigations on the gas permeability evolution and failure response of tectonic coal under various initial gas pressures and stress pathways are scarce. Some previous experimental results showed that it was difficult to reveal the outburst mechanism of coal under dynamic loading and different initial gas pressure conditions. Therefore, in this study, we introduced the coupled mechanical and hydraulic properties of tectonic coal by conducting a triaxial-loading–gas-seepage test. In this study, firstly, the materials and methods are introduced. Afterwards, the effects of stress and initial gas pressure on the gas permeability of coal are presented and analyzed. Finally, some conclusions are drawn. We hope that the findings could help extract coalbed methane and reduce the risk of gas outbursts in tectonic coal seams in underground coal mining systems.

2. Material and Methods

2.1. Sample Preparation

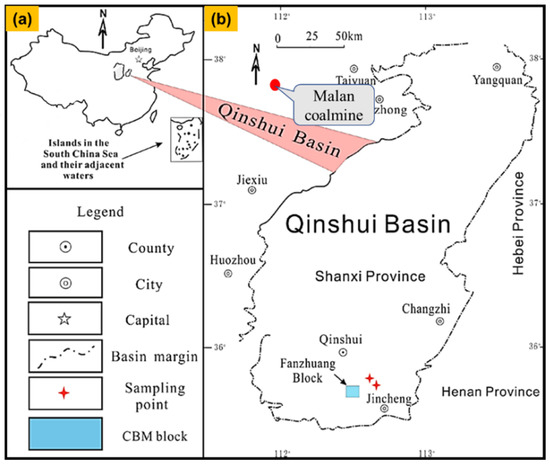

The coal samples were sourced from the Malan coalmine in Xishan Basin, Shanxi, China (Figure 2). The employed coal blocks were taken from the NO. 8 coal seam that is located near the Tunlan river anticline [22]. The maximum gas pressure of this coal seam was 0.47 MPa, and the initial gas release velocity was 8 s to 9 s. According to the identification standard of the NO.8 coal seam, it consists of tectonic coal with outburst hazard tendency. The basic properties of the coal resourced from the NO. 8 coal seam of the Malan coalmine are listed in Table 1 in detail.

Figure 2.

Maps of the Qinshui Basin (a) and the Malan coalmine (b) (modified from [22]).

Table 1.

Basic properties of Malan coal.

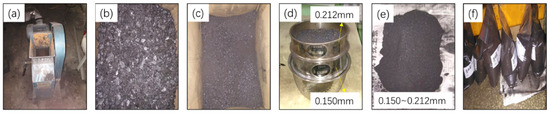

Malan tectonic coal is soft and fragile, making it difficult to prepare raw coal samples. The homogenous briquette coal sample facilitates the analysis of variables in the test process, which was widely employed to investigate the coupled hydro-mechanical properties of coal seams [3,23,24,25,26]. Therefore, the briquette coal samples, instead of raw coal samples, were employed to conduct the test. During the briquette sample preparation, coal mass was crushed twice by a crushing machine to form small particles. Afterwards, two sieves of 60 and 80 mesh per inch were utilized to select the coal powders for bagging and compacting (Figure 3). Finally, coal powders with a particle size of 0.150–0.212 mm were made.

Figure 3.

Preparation of coal powders. (a) Crushing machine; (b) the once-crushed particles of raw coal; (c) the twice-crushed coal fines of raw coal; (d) sieving; (e) coal particles after sieving; (f) pulverized coal stored in bags.

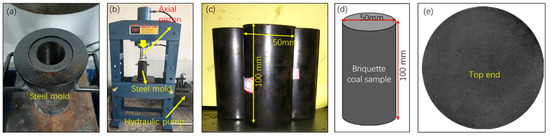

The briquette coal samples were prepared as follows:

- (1)

- The sieved coal powders were put into a steel mold (Figure 4a) layer by layer, and each layer was sprayed with water. Specifically, the mass of water accounted for 10% of the total mass of the sample.

Figure 4. Loading setups for remodeling. (a) Steel mold; (b) compression machine; (c) briquette coal samples; (d) schematic of briquette coal sample; (e) top end of briquette coal sample.

Figure 4. Loading setups for remodeling. (a) Steel mold; (b) compression machine; (c) briquette coal samples; (d) schematic of briquette coal sample; (e) top end of briquette coal sample. - (2)

- The steel mold was placed in the center of a compression machine (Figure 4b).

- (3)

- The compression piston was slowly lowered into the mold to apply compressive stress on the top of sample.

- (4)

- A servo compressive stress of 30 MPa was applied by piston on the top end the sample and the stress was maintained for over 2 h.

- (5)

- The compressed briquette coal sample was taken out and put into an oven (at 50 °C) and dried for 12 h.

- (6)

- (7)

- Due to the unrepeatability of the compression test, which used only one sample, we divided the prepared samples into three groups named A (A1, A2, A3, A4), B (B1, B2, B3) and C (C1, C2, C3) for the gas permeability tests (Table 2). Specifically, samples in group A were used for testing the gas permeability of briquettes under different initial gas pressures. The samples in groups B and C were used for testing the gas permeability of briquettes under different confining pressure-loading conditions and pressure-releasing conditions, respectively.

Table 2. The physical parameters of the briquette coal samples.

Table 2. The physical parameters of the briquette coal samples.

2.2. Experimental Apparatus and Processes

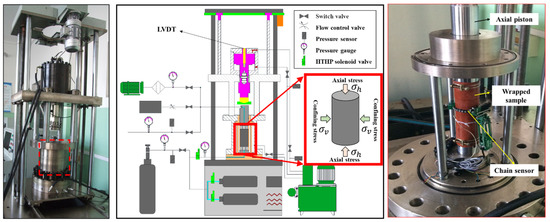

The experiments were conducted by employing the WYS-800 triaxial-loading–gas-seepage test setups. This apparatus consisted of a loading frame, a servo-hydraulic station, an air path system, a triaxial vessel, a constant-temperature oil bath and a data-acquisition system. The schematic diagram of the testing apparatus is displayed in Figure 5. The main technical parameters were as follows: axial stress range 10–800 kN, confining stress range 0–15 MPa and gas pressure range 0–15 MPa. In the aspect of strain measurement, the axial strain usually employed linear variable differential transformer (LVDT) sensors and the radial strains could be measured by chain sensors. The volumetric strain had to be calculated afterwards according to axial and radial strain based on Equation (1):

where, , and are volumetric strain, axial strain and radial strain of samples during the compression test, respectively.

Figure 5.

Picture and structure diagram of the WYS-800 test apparatus.

The experimental processes were as follows. ① For samples in group A (A1, A2, A3 and A4), a confining pressure of 3 MPa was first applied. Afterwards, the initial gas pressures of 0.3, 0.7, 1.1 and 1.5 MPa were filled for samples A1, A2, A3 and A4, respectively. Finally, the gas permeability of the samples was tested under an axial loading rate of 0.05 kN/s until failure. ② For samples in group B (B1, B2 and B3), an initial gas pressure of 1.1 MPa was first applied. Then, the confining pressures were loaded as 3, 4 and 5 MPa for samples B1, B2 and B3, respectively. Finally, the gas permeability of samples was tested under an axial loading rate of 0.05 kN/s until failure. ③ For samples in group C (C1, C2 and C3), the initial gas pressure and constant axial stress was first set as 1.1 MPa and 18 MPa, respectively. Afterwards, the confining pressures were loaded as 3, 4 and 5 MPa for samples C1, C2 and C3, respectively. Finally, the gas permeability of the samples was tested under an unloading confining stress rate of 0.01 MPa/s until sample failure.

The CH4 gas mainly migrated by diffusion into the coal matrix, while it migrated by seepage into pores and fractures in the coal. The speed of gas migration by seepage was much greater than that by diffusion. Generally, gas that flowed into coal pores and fractures obeyed Darcy’s law and the permeability model can be expressed as:

where K is the permeability of gas, 10−3 μm2; P0 is the standard atmospheric pressure, 105 Pa; Q is flow flux, cm3/s; μ is the dynamic viscosity of CH4 gas, which is determined as 1.08 × 10−5 Pa·s at room temperature; P1 and P2 are inlet and outlet gas pressures, respectively, Pa; L is the length of the sample, cm; A is the cross-sectional area of the sample, cm2.

3. Results and Discussion

3.1. Effect of Initial Gas Pressure on the Permeability of Tectonic Coal

3.1.1. Failure Response and Gas Permeability Evolution of Samples

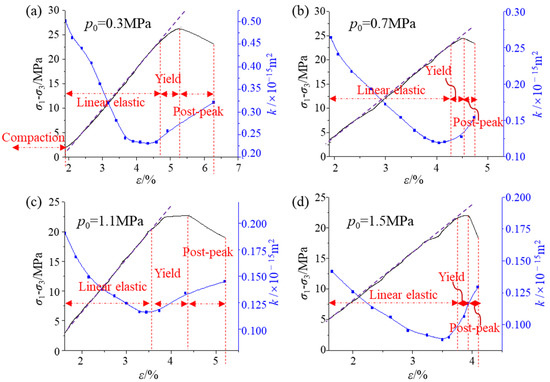

The gas permeability of coal was tested under different gas pressures (0.3, 0.7, 1.1 and 1.5 MPa) and was subject to a constant confining pressure of 3 MPa during axial loading process until failure. The deviator stress–strain versus gas permeability curve under different initial gas pressures are shown in Figure 6.

Figure 6.

Deviatoric stress–strain and permeability evolution of coal under different gas pressures; (a) 0.3 MPa; (b) 0.7 MPa; (c) 1.1 MPa and (d) 1.5 MPa.

The stress–strain curves of coal under different initial gas pressures roughly experienced four stages, i.e., initial compaction stage (compaction process before the test), linear elastic deformation stage, yield stage and post-peak failure stage. Expectedly, samples with a higher initial gas pressure were more likely to be broken. As the gas pressure increased, the axial strain at the peak strength of the coal sample gradually decreased. Peak strengths of samples with initial gas pressures of 0.3, 0.7, 1.1 and 1.5 MPa were 29.5, 27.5, 25.8 and 25.0 MPa, respectively.

The destructive effect of initial gas on the coal sample consisted of two aspects. In the aspect of mechanical behavior, the filled gas provided the pore pressure for samples, and a greater initial gas pressure always implied a higher pore pressure. The pore pressure would limit the triaxial compaction of the coal samples. Furthermore, loadings could promote the deformation of the coal skeleton. This effect would be enhanced under the infilling of stressed gas and thus could cause the decrease in sample strength. In the aspect of coal structures, coal samples could adsorb methane. This would have affected the adhesion between coal particles and caused the coal samples to become cracked and fractured. In our study, the axial strain at peak strength also showed that as the gas pressure increased, the ductility of the coal body decreased. Therefore, a sample with a higher initial gas pressure was easier to be deformed.

The gas permeability curve of coal follows the converse law, as with the deviatoric stress–strain curve. In the elastic stage, the internal pores and cracks of the coal were compacted with the axial stress loading and the coal permeability gradually decreased. When approaching the yielding stage, the coal body was compacted to its maximum, and the permeability dropped to its lowest. As it entered the yielding stage, large deformations occurred and dense new cracks were generated in the coal body, resulting in a sharp increase in gas permeability. Generally, the gas permeability versus axial strain curve showed two stages. Before the peak loading strength, the gas permeability decreased, while after the peak the coal body was destroyed and the permeability increased rapidly.

3.1.2. Gas Permeability Evolution during Sample Deforming

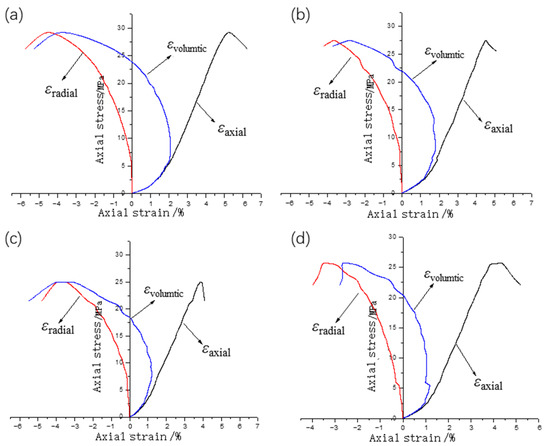

In underground coal mining systems, coal is always compressed to induce the volume deformation. Therefore, it is necessary to understand the relationship between volume deformation and gas permeability of the samples. The volumetric strain of coal samples under triaxial stress consisted of two strain values, i.e., axial strain and radial strain. As mentioned above, the axial and radial components of strain could be measured directly in this test, while volumetric strain usually had to be calculated afterwards according to axial and radial strain.

As shown in Figure 7, in the initial compaction stage, the axial deformation began to develop and the coal sample was compressed. In the linear elastic stage, the radial deformation began to increase and the rate of change was higher than the axial strain, so the volumetric strain of the coal body would begin to develop negatively. After the beginning of the yield stage, the radial deformation would develop rapidly and the axial deformation hardly changed. Therefore, the volumetric strain became negative and increased continuously, showing an obvious expansion in the coal.

Figure 7.

The axial, radial and volumetric strain of coal under compression with different initial gas pressures; (a) 0.3 MPa; (b) 0.7 MPa; (c) 1.1 MPa and (d) 1.5 MPa.

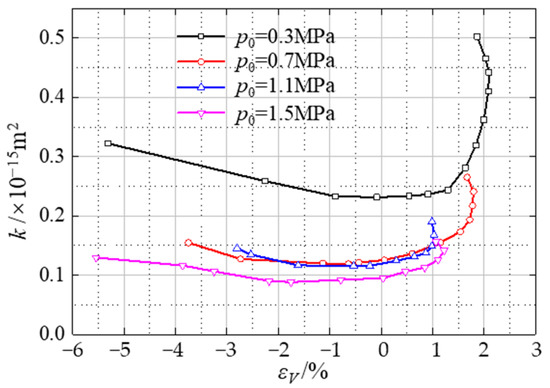

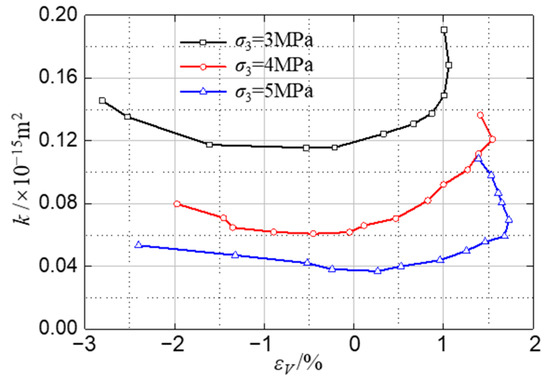

Figure 8 presents the volumetric strain versus gas permeability curve of the coal sample. It could be found that the gas permeability evolution was closely related to the volumetric strain change in the coal sample. From the initial compaction stage to the elastic stage, the coal body was mainly compressed by volume and the pores in the coal body were synchronously compressed. After the yield stage, the radial deformation increased and the volume of the coal sample began to expand, forming new fractured pores and causing the gas permeability increase with the negative increases of volumetric strain.

Figure 8.

Relationship between permeability and volumetric strain of coal.

3.1.3. Relationship between Permeability and Initial Gas Pressure of Coal

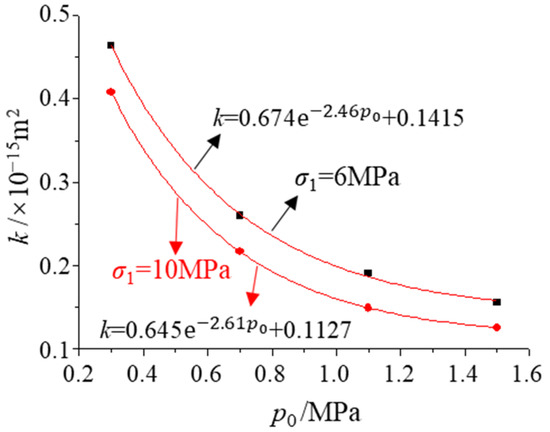

The gas permeability versus initial gas pressure curves of coal samples under confining pressures of 6 MPa and 10 MPa are shown in Figure 9. Generally, a greater confining pressure implied a lower gas permeability. The gas permeability of the coal gradually decreased with the increase in the gas pressure. Under a confining pressure of 6 MPa, the gas permeability was decreased by 67.32% when the initial gas pressure increased from 0.3 MPa to 1.5 MPa. This was due to many gas molecules that accumulated and blocked the gas migration channel. The decreasing trend of gas permeability k under various initial gas pressures p0 could be well fitted by a negative exponential function of , where a, b and c are fitted parameters.

Figure 9.

Gas permeability versus initial gas pressure curves at axial pressures of 6 and 10 MPa.

3.2. Effect of Confining Pressure on the Gas Permeability of Tectonic Coal

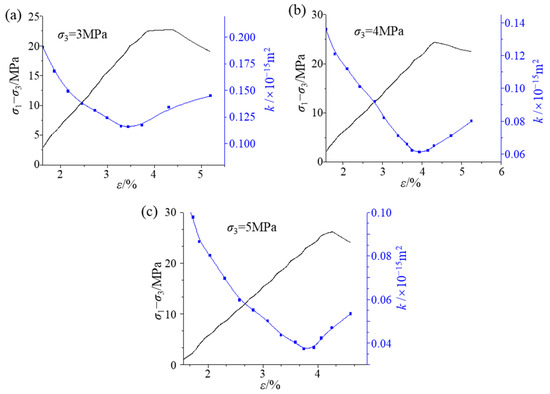

We used samples in group B (i.e., B1, B2 and B3) to study the effect of confining pressure on the gas permeability of tectonic coal. The initial gas pressure was set as 1.1 MPa. Afterwards, the gas permeability of the coal with variable confining pressure (i.e., 3, 4 and 5 MPa) was tested under an axial loading rate of 0.05 kN/s until sample failure. Figure 10 presents the deviatoric stress–strain and gas permeability curves under different confining pressures. With the increase in confining pressure, the peak strength of the coal body gradually increased. The peak strengths under confining pressures of 3, 4 and 5 MPa were 25.5, 28.4 and 31.2 MPa, respectively. This peak-strength-increasing phenomenon was due to the fact that the confining pressure limited the lateral deformation of the coal sample.

Figure 10.

Deviatoric stress–strain (black line) and permeability evolution of coal under confining stresses (blue line); (a) 3 MPa; (b) 4 MPa and (c) 5 MPa.

Confining stress may have had a greater influence on the gas permeability of the coal than that of axial stress. During triaxial compression and gas permeability tests, the gas flow path was consistent with the axial loading direction. The axial loading would generally have two effects on the pore and fissure structure evolution of coal. One effect was to gradually close the pores and cracks and thus weaken the permeability of the coal. Another was that the coal body would produce a certain lateral expansion during loading, which would be helpful in opening the gas flow channel and enhancing the permeability. Therefore, the second effect would release the decreasing trend of gas permeability. In the aspect of the confining effect of the coal samples, the applied confining stress would directly close the cracks and pore structure from the lateral direction and thus weaken gas permeability of the coal samples. Moreover, the confining stress would limit the lateral expansion effect produced by the axial loading, thus further repressing gas flow. Therefore, confining stress had a greater influence on the gas permeability of coal than that of axial stress.

The gas permeability of the coal sample first decreased and then increased with increasing axial stress (Figure 10). In the initial compaction and elastic stages, the pores of the coal sample were closed and the permeability gradually decreased. While after the coal body entered the yielding stage, new fractures in the coal body began to develop and the gas permeability increased. Similarly, as shown in Figure 11, the gas permeability versus volumetric strain curves under different confining pressures had an obvious correlation. As the coal underwent volume compression and expansion, the gas permeability of the coal showed a decreasing trend and then an increasing trend, respectively.

Figure 11.

Volumetric strain versus gas permeability curves under different confining pressures.

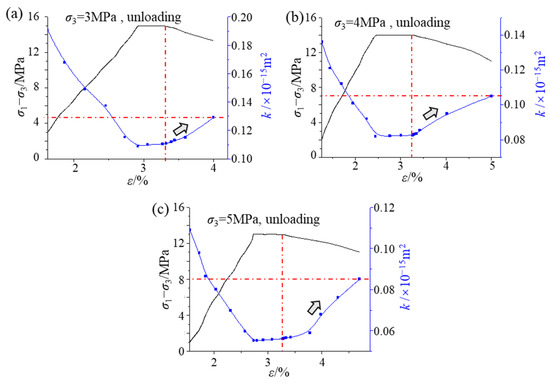

3.3. Gas Permeability Evolution of Tectonic Coal during Confining Pressure Releasing

After loading the sample to an axial stress of 18 MPa, the confining pressure was progressively released. The obtained deviatoric stress–strain versus gas permeability curves of the tectonic coal samples under different unloading confining pressures (3 MPa, 4 MPa and 5 MPa) are shown in Figure 12. In the initial compaction stage and the elastic stage, the coal permeability gradually decreased with the increase in deviatoric stress. During the releasing of confining stress, the gas permeability synchronously changed with the deformation of the coal. Before the yield stage, a small number of cracks were generated in the coal body, but the deformation rate of the coal body was relatively small. Therefore, the gas permeability of the coal increased slowly in the yield stage. In the post-yielding stage, the deformation rate of the coal body increased and the cracks in coal body developed quickly. Therefore, the permeability continued to increase and the speed became faster in the post-yielding stage. After the coal sample entered the stage of instability, the cracks developed and could penetrate the coal body. Large cracks were formed and the permeability increased faster.

Figure 12.

Deviation stress–strain (black line) and permeability curves (blue line) of coal under confining stress releasing conditions.

In the prevention of coal and gas outbursts, before the coal body entered the yield stage, the coal body deformation rate was not large. After the coal body entered the yield stage, the coal body deformed rapidly and became more and more unstable. Therefore, the in-situ support of coal seams should be strengthened before the yield stage. In this period, support strengthen could effectively avoid the mass destruction of coal and rock.

4. Conclusions

Understanding the gas permeability evolution of tectonic coal is significant for the prevention of gas outburst disasters in coal mining systems. In this study, the triaxial gas seepage apparatus was employed to investigate the gas permeability of tectonic coal samples resourced from a Malan coal mine under various stresses, gas pressures and loading–unloading conditions. The following conclusions could be drawn:

- (1)

- The gas permeability of tectonic coal was closely related to the change of volumetric strain during triaxial compression process. In the initial sample compaction stage and the elastic deformation stage, the internal pores and cracks in coal were compacted, resulting in a reduction in gas permeability. However, after the yield stage, cracks developed and the volume strain of the sample increased, which led to the increase in gas permeability of the tectonic coal samples.

- (2)

- The gas permeability of the tectonic coal decreased with the increase in initial gas pressure in a negative exponential manner. The permeability could be decreased by 67.32% when the initial gas pressure increased from 0.3 MPa to 1.5 MPa.

- (3)

- During the confining pressure releasing, the coal underwent a period of strain development before it began to fail. Before the yield stage of sample, a small number of cracks were generated in the coal body and the gas permeability increased slowly. After the yield stage, the coal body deformed severely and the cracks in the coal samples further developed, resulting in the quick increase in gas permeability. With the release of further confining pressure, the coal samples could enter the failure stage, where cracks and fractures rapidly developed and expanded and thus resulted in a rapid increase in the gas permeability of the tectonic coal samples.

Author Contributions

Conceptualization, Y.W.; methodology, Z.L.; investigation, Z.L. and H.Z.; resources, Y.W., Z.C. and Z.L.; data curation, J.W., Q.T., H.Z. and Z.L.; writing—original draft preparation, Z.C., H.Z. and J.W.; supervision, Z.C. and G.L.; funding acquisition, G.L. and H.Z., writing—revision, H.Z., J.W. and M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Natural Science Foundation of Shanxi Province of China, grant number 201901D111005 (ZD); the Innovation Platform Construction Project of Shanxi Province, grant number 202105D121005; the Open Research Fund Program of State Key Laboratory of Coal and CBM Co-mining; the National Natural Science Foundation, grant number 52004011.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Flores, R.M. Coalbed methane: From hazard to resource. Int. J. Coal Geol. 1998, 35, 3–26. [Google Scholar] [CrossRef]

- Wu, C.; Yuan, C.; Wen, G.; Han, L.; Liu, H. A dynamic evaluation technique for assessing gas output from coal seams during commingling production within a coalbed methane well: A case study from the Qinshui Basin. Int. J. Coal Sci. Technol. 2020, 7, 122–132. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.; Pan, Z. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Tu, Q.; Cheng, Y.; Ren, T.; Wang, Z.; Lin, J.; Lei, Y. Role of tectonic coal in coal and gas outburst behavior during coal mining. Rock Mech. Rock Eng. 2019, 52, 4619–4635. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, L.; Wang, Z.; Wang, S. A physical model study of surrounding rock failure near a fault under the influence of footwall coal mining. Int. J. Coal Sci. Technol. 2020, 8, 1–15. [Google Scholar] [CrossRef]

- Xue, D.; Zhou, J.; Liu, Y.; Gao, L. On the excavation-induced stress drop in damaged coal considering a coupled yield and failure criterion. Int. J. Coal Sci. Technol. 2020, 7, 58–67. [Google Scholar] [CrossRef] [Green Version]

- Ju, Y.; Zhang, Q.; Zheng, J.; Wang, J.; Chang, C.; Gao, F. Experimental study on CH4 permeability and its dependence on interior fracture networks of fractured coal under different excavation stress paths. Fuel 2017, 202, 483–493. [Google Scholar] [CrossRef]

- Guo, R.; Akkutlu, K.M.; Kantzas, A. Laboratory investigation on the permeability of coal during primary and enhanced coalbed methane production. J. Can. Pet. Technol. 2008, 47, 27–32. [Google Scholar] [CrossRef]

- Connell, L.D.; Sander, R.; Pan, Z.; Camilleri, M.; Heryanto, D. History matching of enhanced coal bed methane laboratory core flood tests. Int. J. Coal Geol. 2011, 87, 128–138. [Google Scholar] [CrossRef]

- Yan, F.; Xu, J.; Lin, B.; Peng, S.; Zou, Q.; Zhang, X. Changes in pore structure and permeability of anthracite coal before and after high-voltage electrical pulses treatment. Powder Technol. 2019, 343, 560–567. [Google Scholar] [CrossRef]

- Zhang, Z.T.; Ru, Z.; Liu, J.F.; Liu, X.H.; Li, J.W. Permeability evolution of unloaded coal samples at different loading rates. Therm. Sci. 2014, 18, 1497–1504. [Google Scholar] [CrossRef]

- Wu, X.; Peng, Y.; Xu, J.; Yan, Q.; Nie, W.; Zhang, T. Experimental study on evolution law for particle breakage during coal and gas outburst. Int. J. Coal Sci. Technol. 2020, 7, 97–106. [Google Scholar] [CrossRef] [Green Version]

- Valliappan, S.; Wohua, Z. Role of gas energy during coal outbursts. Int. J. Numer. Methods Eng. 1999, 44, 875–895. [Google Scholar] [CrossRef]

- Xinfu, L.; Chunhua, L.; Guoqiang, L. Dynamic behavior of coalbed methane flow along the annulus of single-phase production. Int. J. Coal Sci. Technol. 2019, 6, 547–555. [Google Scholar]

- Zhang, B.; Kang, J.; Kang, T.; Kang, G.; Zhao, G. Molecular dynamics simulations of CH4 diffusion in kaolinite: Influence of water content. Int. J. Coal Sci. Technol. 2019, 6, 556–563. [Google Scholar] [CrossRef] [Green Version]

- Yuan, R.; Chen, C.; Wei, X.; Li, X. Heat–fluid–solid coupling model for gas-bearing coal seam and numerical modeling on gas drainage promotion by heat injection. Int. J. Coal Sci. Technol. 2019, 6, 564–576. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.; Yin, G.; Jiang, Y.; Yi, J. Gas seepage characteristics of briquette samples in a stress field. J. Chongqing Univ. 2008, 31, 1436–1440. [Google Scholar]

- Yin, G.; Jiang, C.; Li, X.; Wang, W.; Cai, B. An experimental study of gas permeabilities of outburst and nonoutburst coals under complete stress-strain process. Rock Soil Mech. 2011, 32, 1613–1619. [Google Scholar]

- Mei, Y.; Zhen, W.; Bobo, L. Experiments study on the briquette permeability with temperature and effective stress change. Saf. Coal Mines 2012, 43, 8–11. [Google Scholar]

- Wierzbicki, M.; Konečný, P.; Kožušníková, A. Permeability changes of coal cores and briquettes under tri-axial stress conditions. Arch. Min. Sci. 2014, 59, 1131–1140. [Google Scholar] [CrossRef] [Green Version]

- Kudasik, M. Investigating permeability of coal samples of various porosities under stress conditions. Energies 2019, 12, 762. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Tang, D.; Qin, Y.; Xu, H.; Liu, Y.; Wu, H. Characteristics of methane (CH4) diffusion in coal and its influencing factors in the Qinshui and Ordos basins. Energy Fuels 2018, 32, 1196–1205. [Google Scholar] [CrossRef]

- Dong, J.; Cheng, Y.; Wang, L.; Guo, P. Establishment of the equivalent structural model for the tectonic coal and some implications for the methane migration. RSC Adv. 2020, 10, 9791–9797. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Wang, J.; Zhang, H.; Shen, W.; Jiang, H. Coupled Effects of Stress, Moisture Content and Gas Pressure on the Permeability Evolution of Coal Samples: A Case Study of the Coking Coal Resourced from Tunlan Coalmine. Water 2021, 13, 1653. [Google Scholar] [CrossRef]

- Geng, J.; Cao, L.; Zhong, C.; Zhang, S. An experimental study on preparation of reconstituted tectonic coal samples: Optimization of preparation conditions. Energies 2021, 14, 2846. [Google Scholar] [CrossRef]

- Gao, D.; Sang, S.; Liu, S.; Geng, J.; Wang, T.; Sun, T. Investigation of the energy evolution of tectonic coal under triaxial cyclic loading with different loading rates and the underlying mechanism. Energies 2021, 14, 8124. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).