Numerical Study on the Vibratory Compaction Mechanism of the Sand-Gabion Backfills in Underground Coal Mines

Abstract

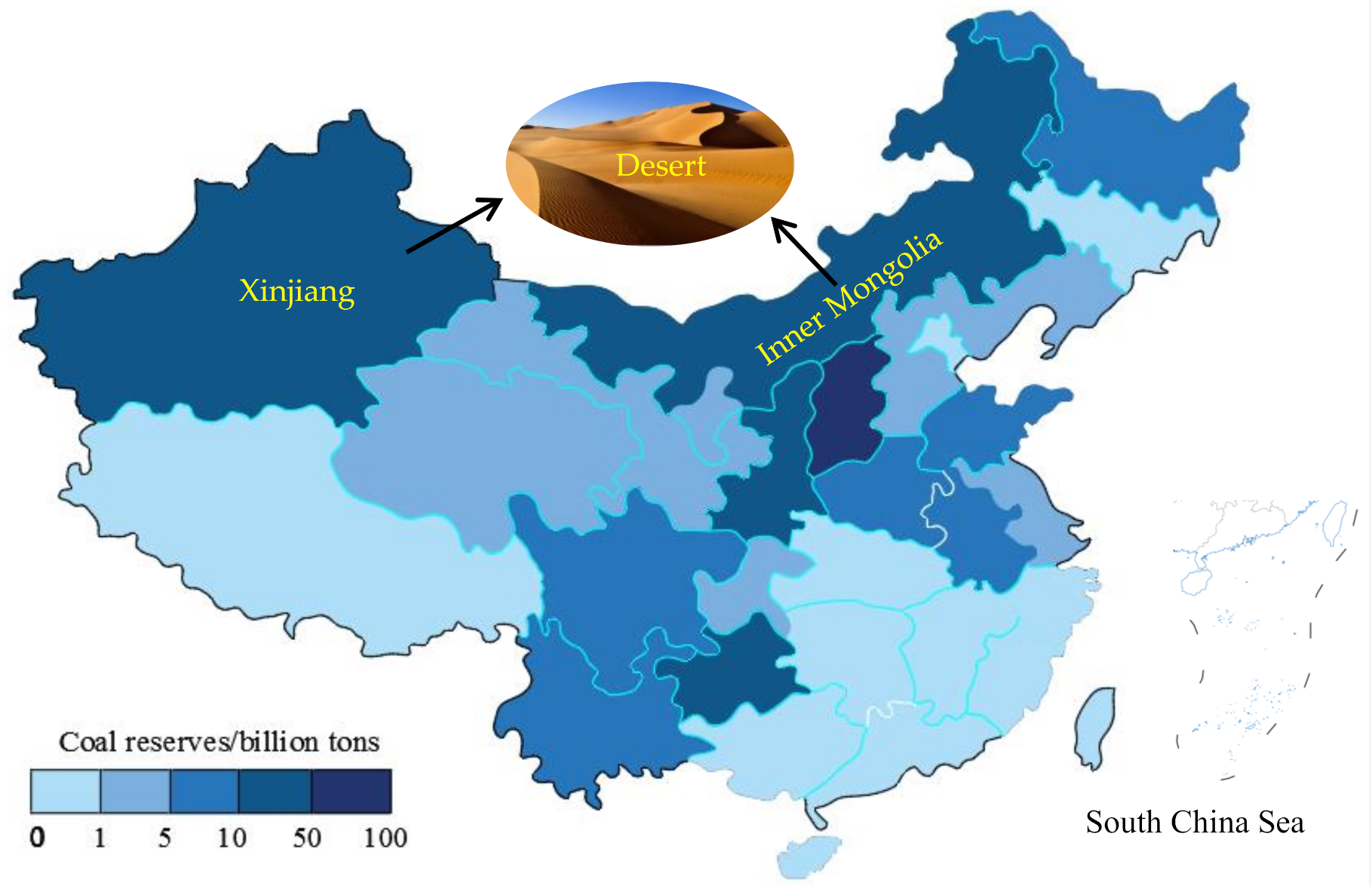

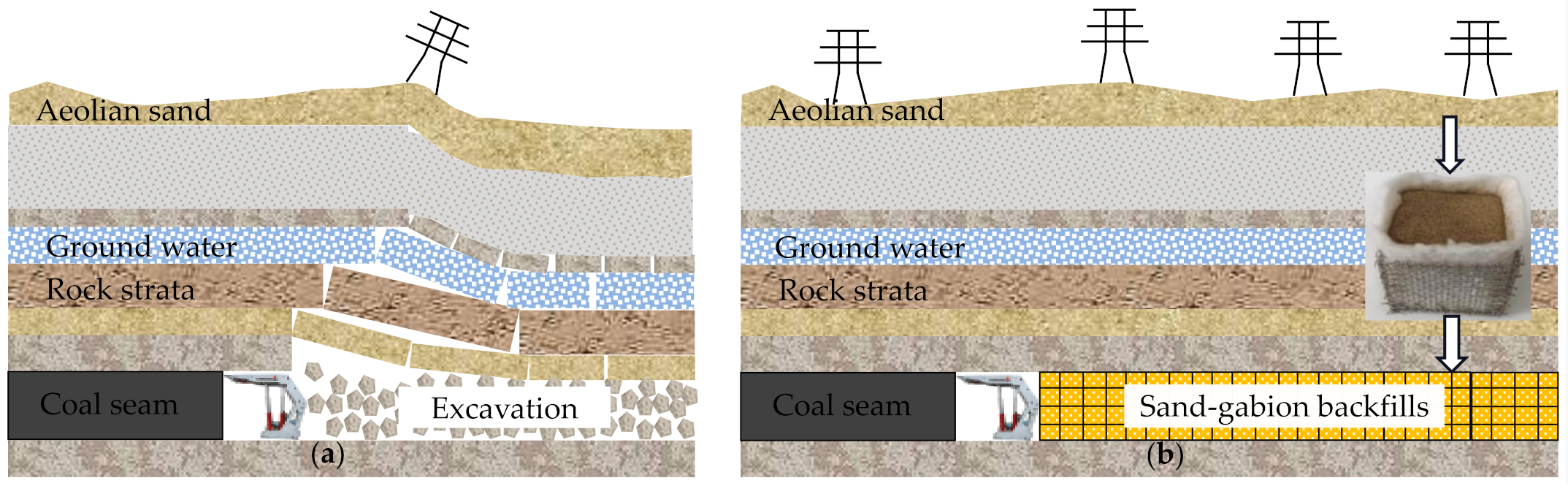

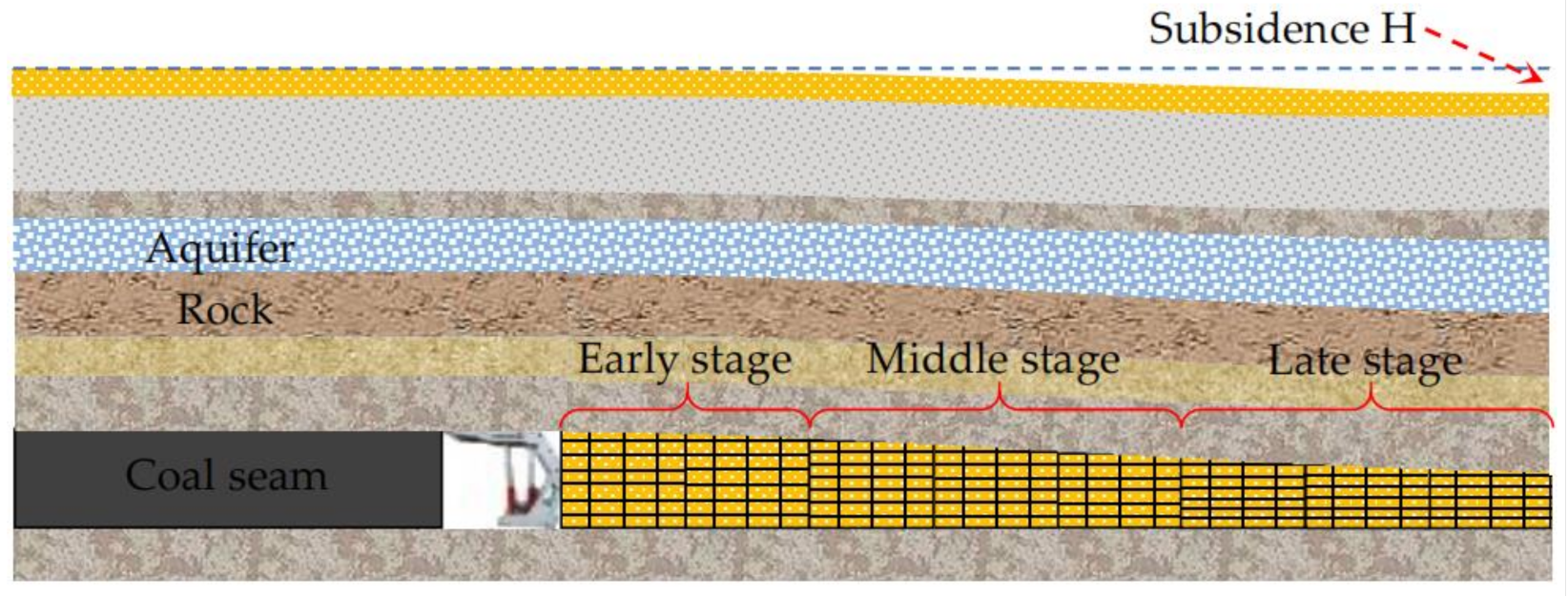

1. Introduction

2. Materials and Methods

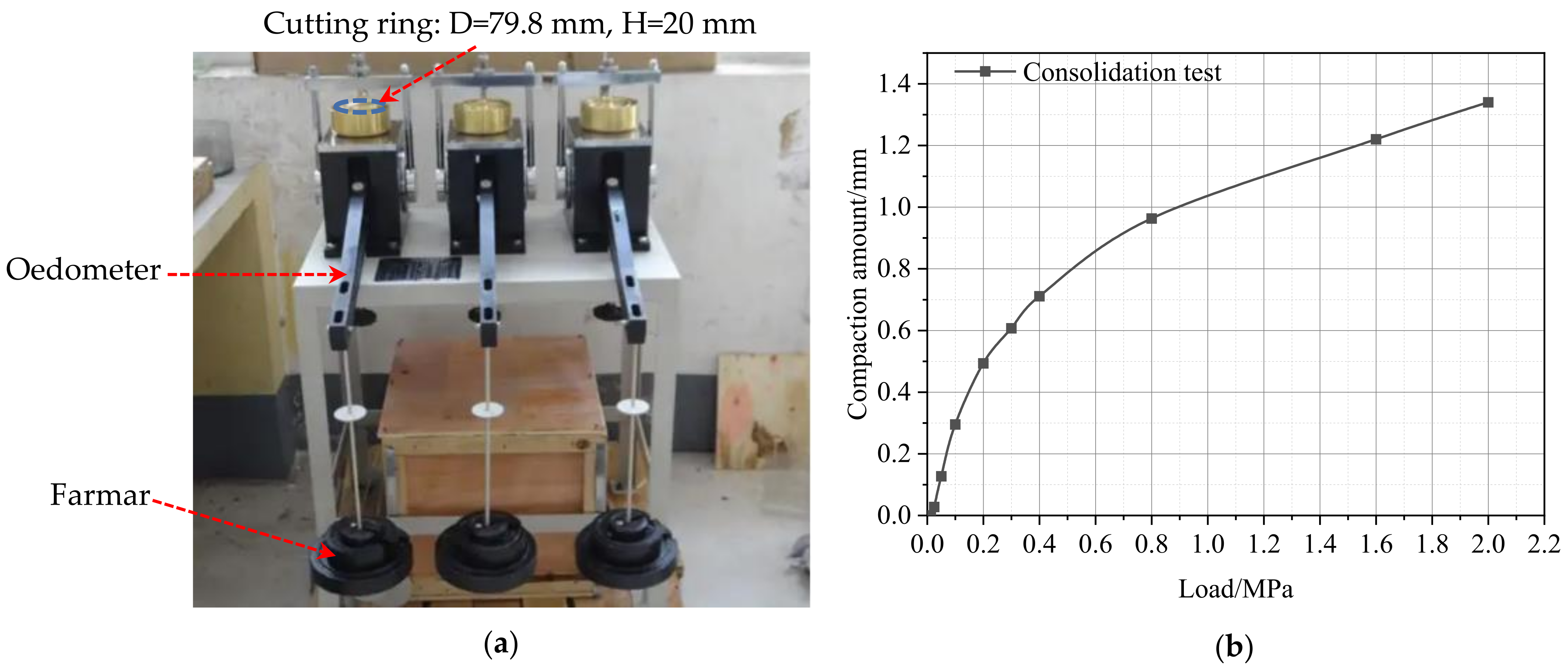

2.1. Consolidation Test of Aeolian Sand

- The aeolian sand is put into the consolidated container, and the protective ring, filter paper, permeable plate, and pressurized cover are placed on the sample successively;

- Place the consolidation container in the pressure frame of the consolidation instrument, install the dial indicator, and apply 1 KPa pre-pressure to set the dial indicator to zero;

- Apply the primary load of 12.5 KPa, record the reading, and then load step by step;

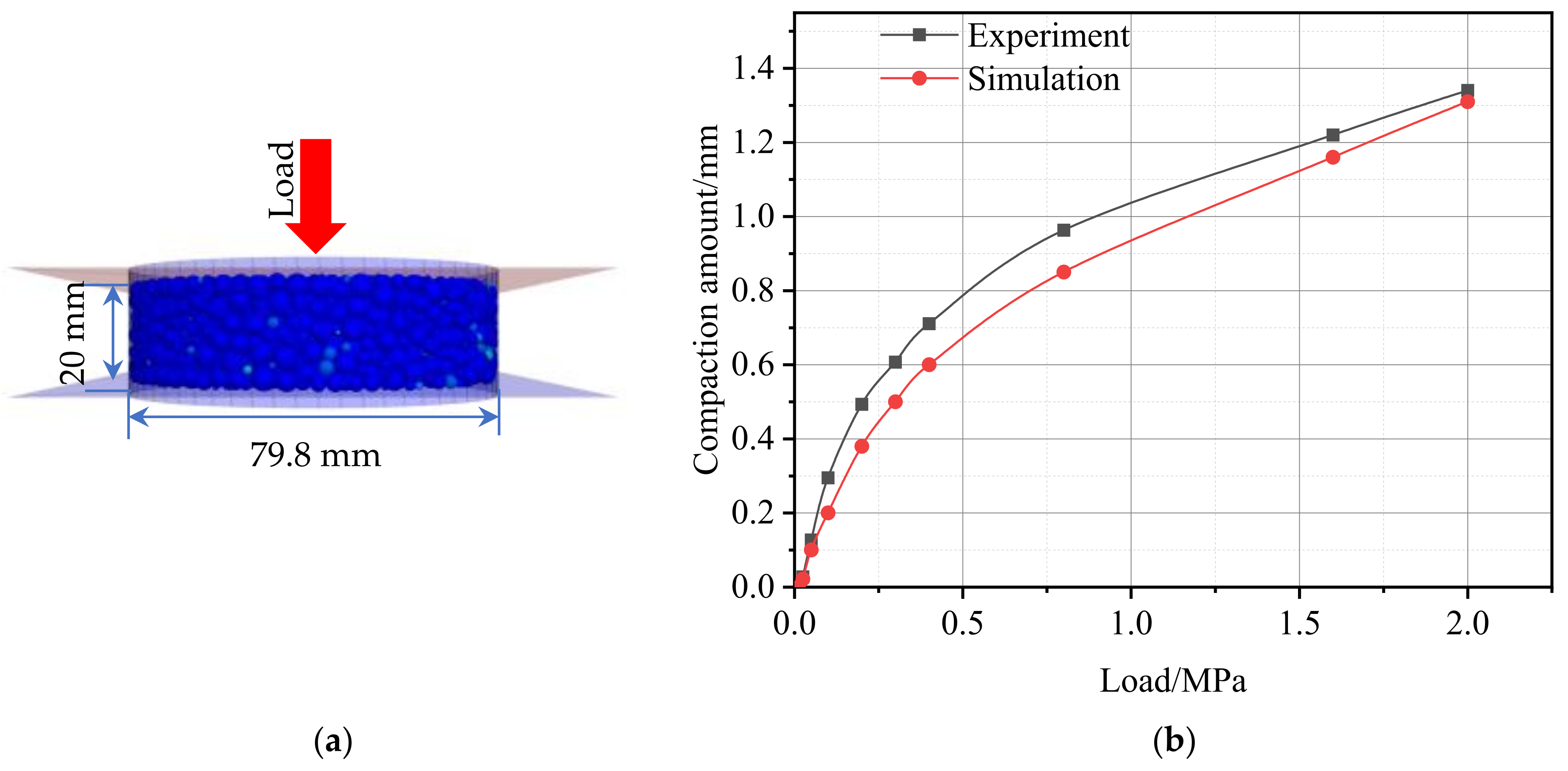

2.2. Numerical Simulation of Consolidation Experiment

2.3. PFC3D Numerical Simulation of Sand-Gabion Backfill Unit

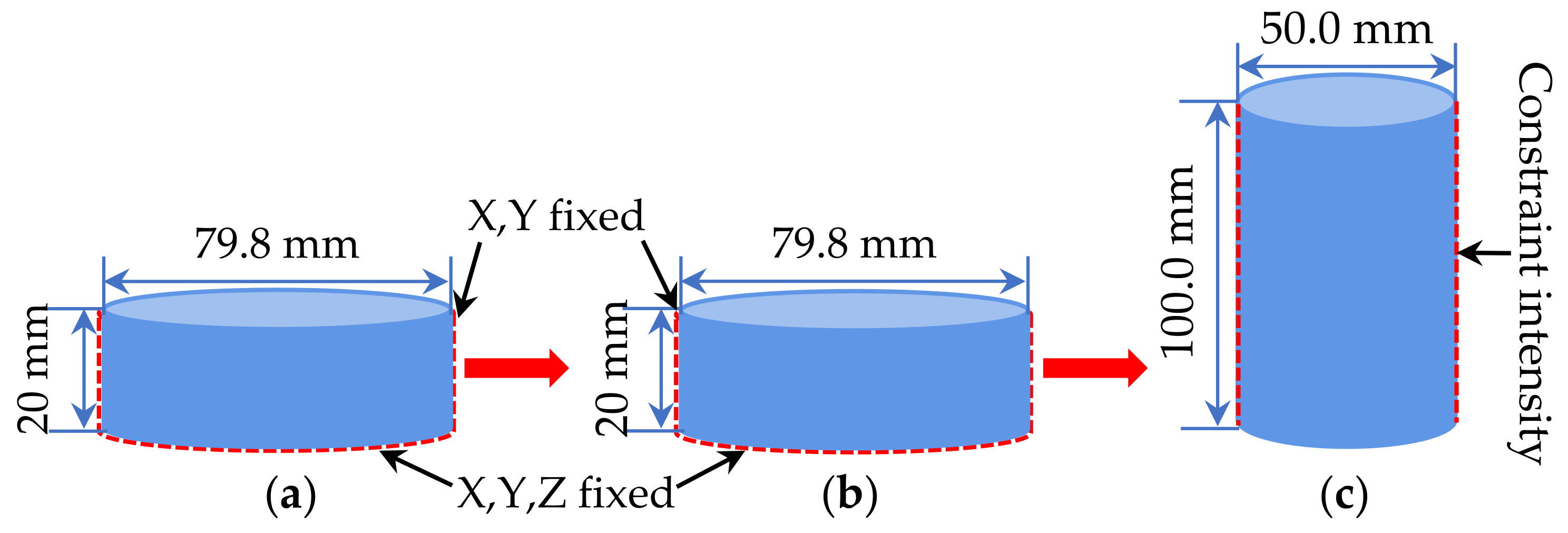

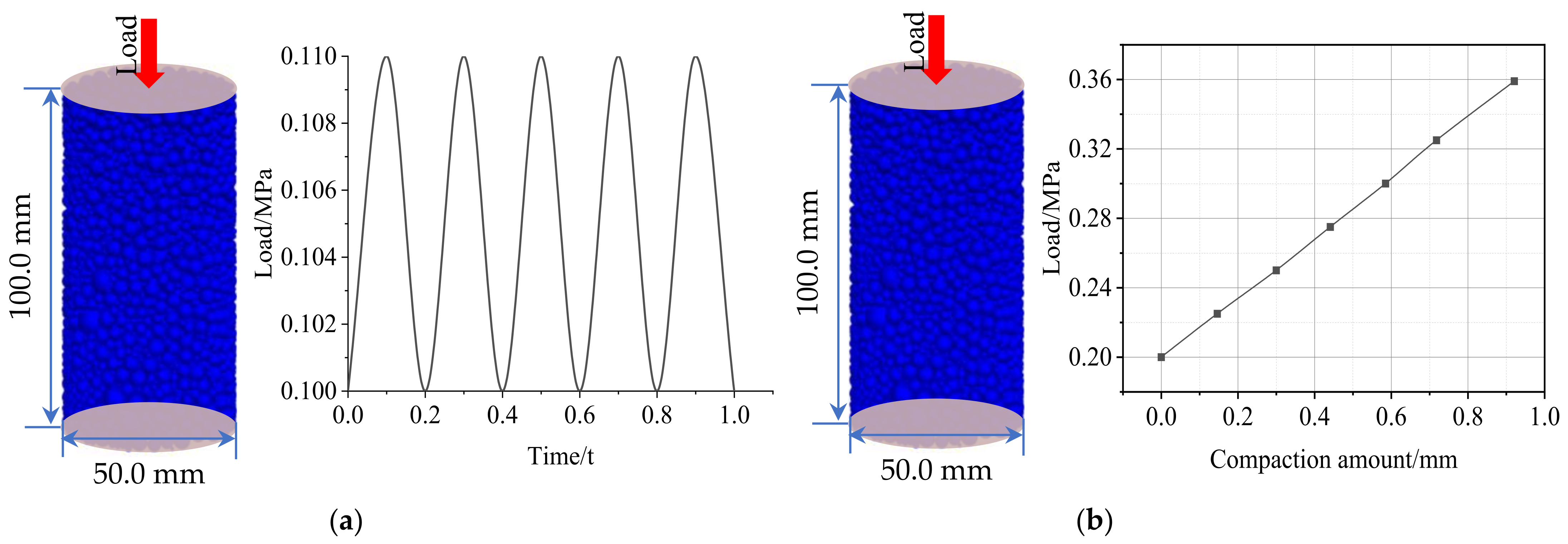

2.3.1. Vibration and Static Load Test

2.3.2. Monitoring Methods and Indicators

- Compaction degree

- 2.

- Porosity and particle transport

- 3.

- Contact force chain

3. Results and Discussions

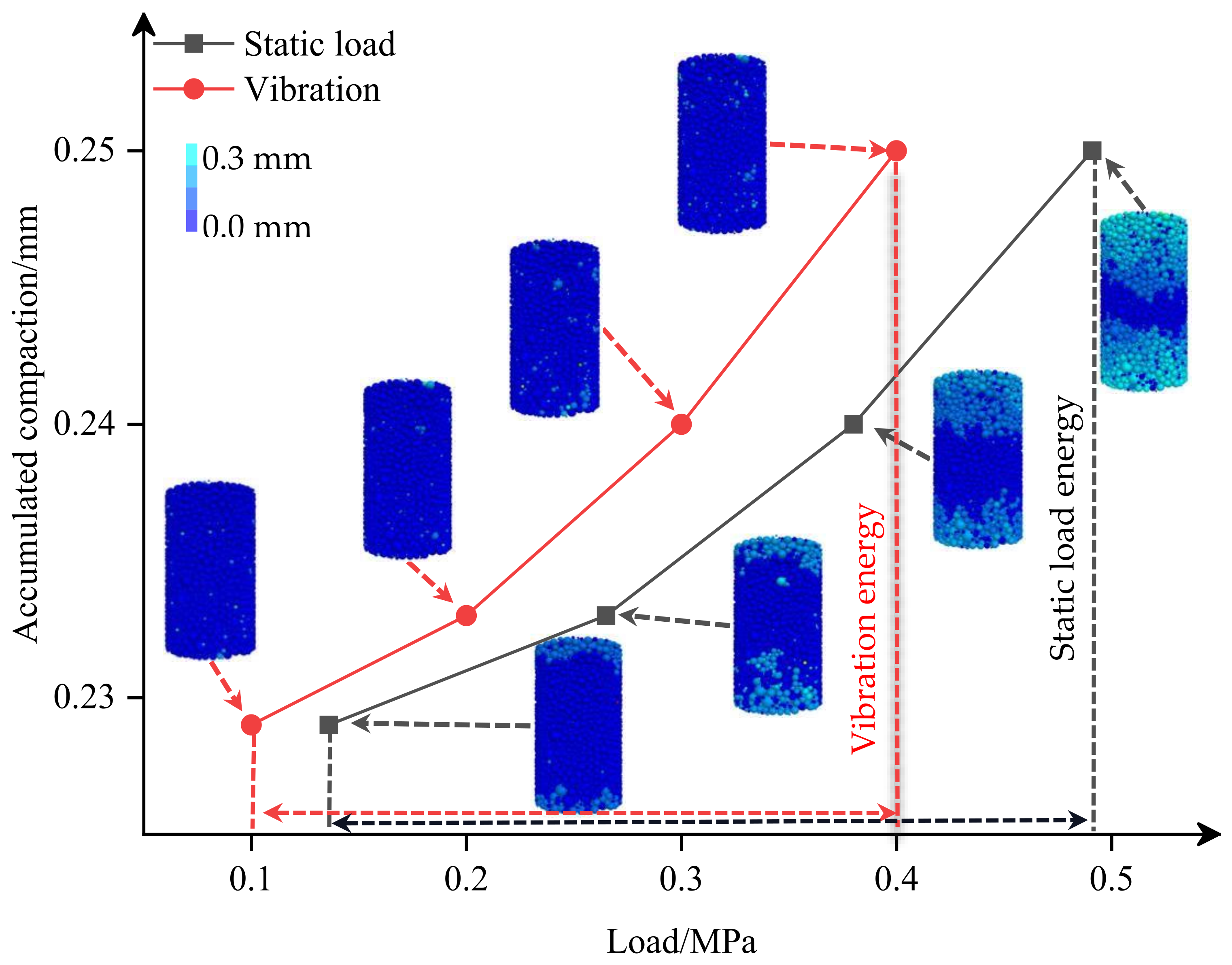

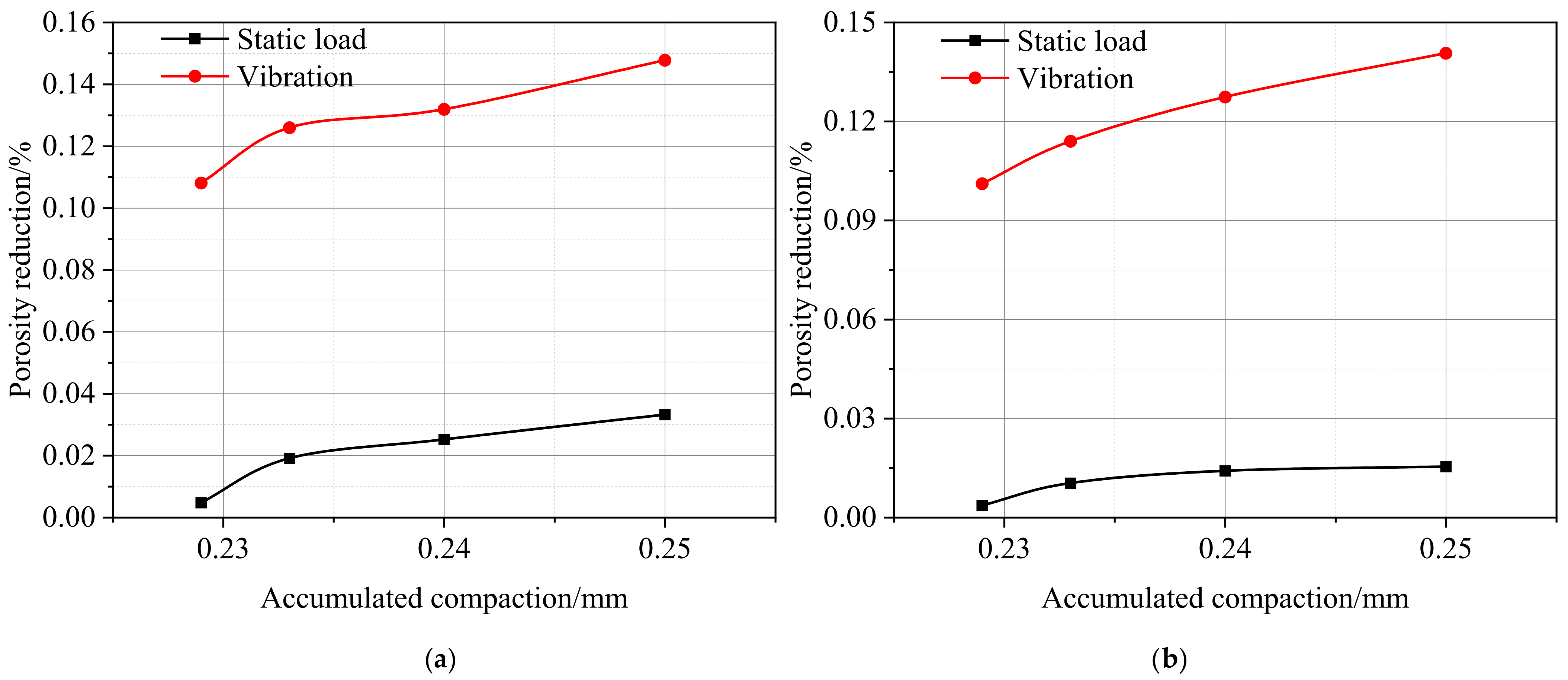

3.1. Comparison between Static and Vibratory Compaction

3.2. Movement Law of the Sand Particles during Vibratory Compaction

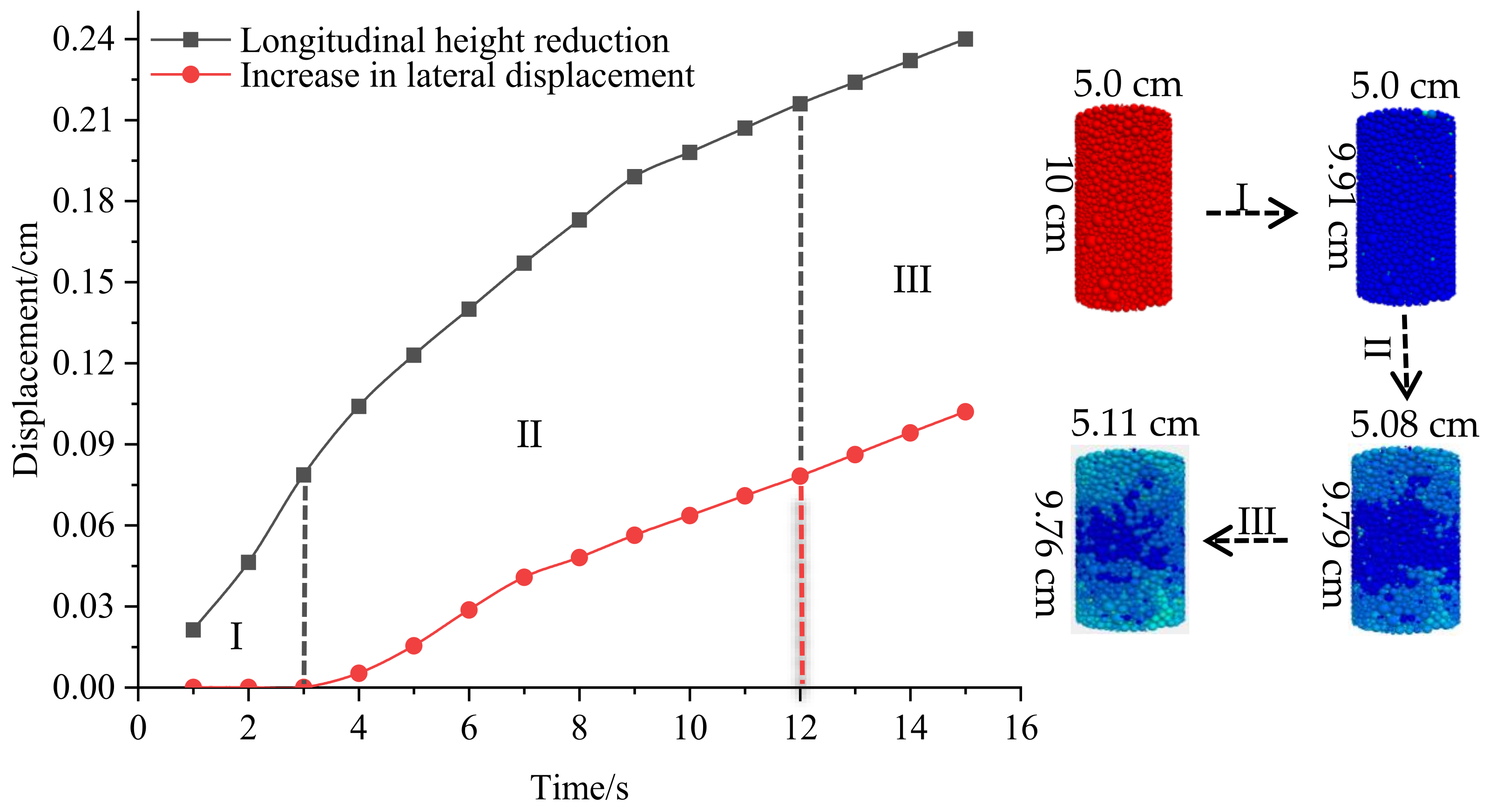

3.2.1. Compactness Process

3.2.2. Movement Law of the Sand Particles

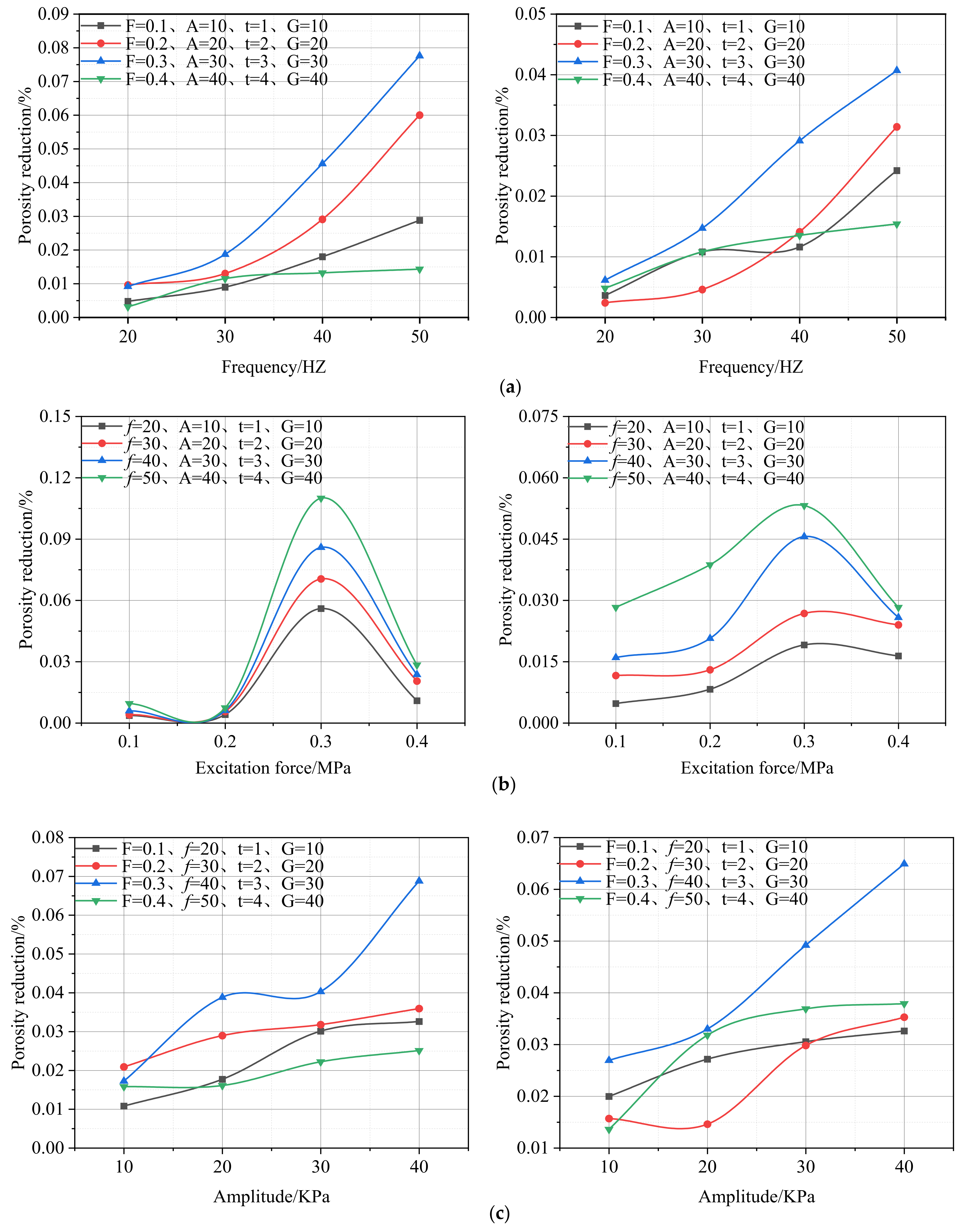

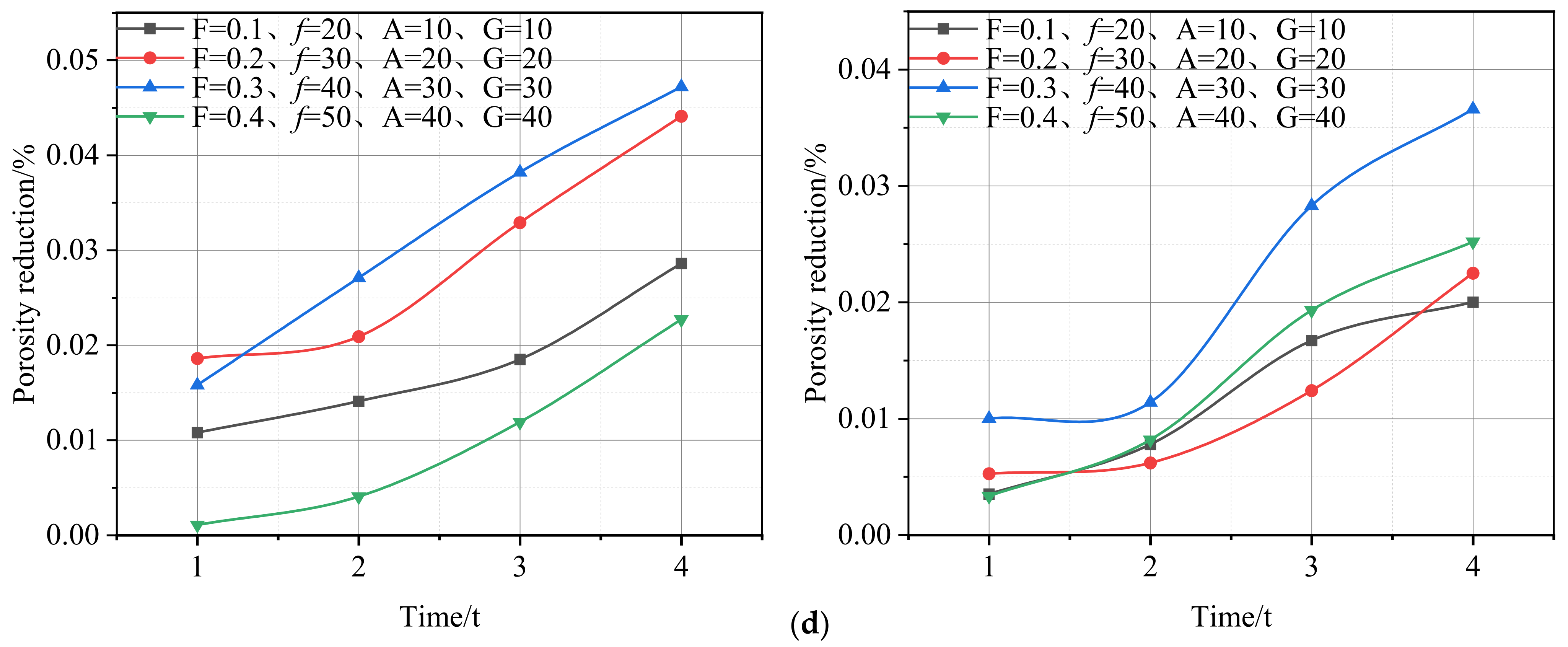

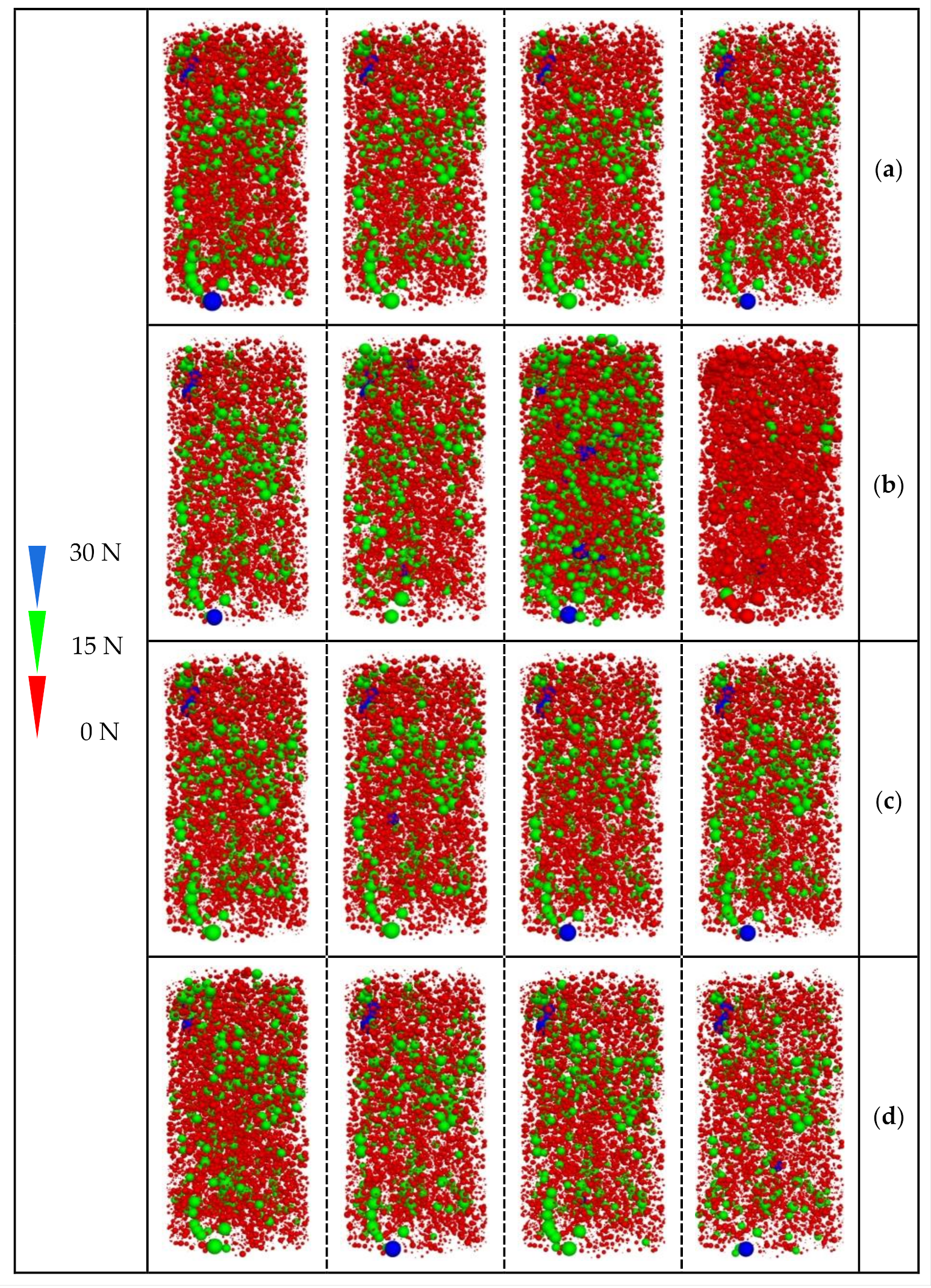

- The influence of vibration parameters on the porosity and particle transport of Sand-gabion backfill material

- 2.

- The influence of vibration parameters on the contact force chain of sand-gabion backfill material

3.3. Influence Law of the Vibratory Parameters on the Ultimate Compactness

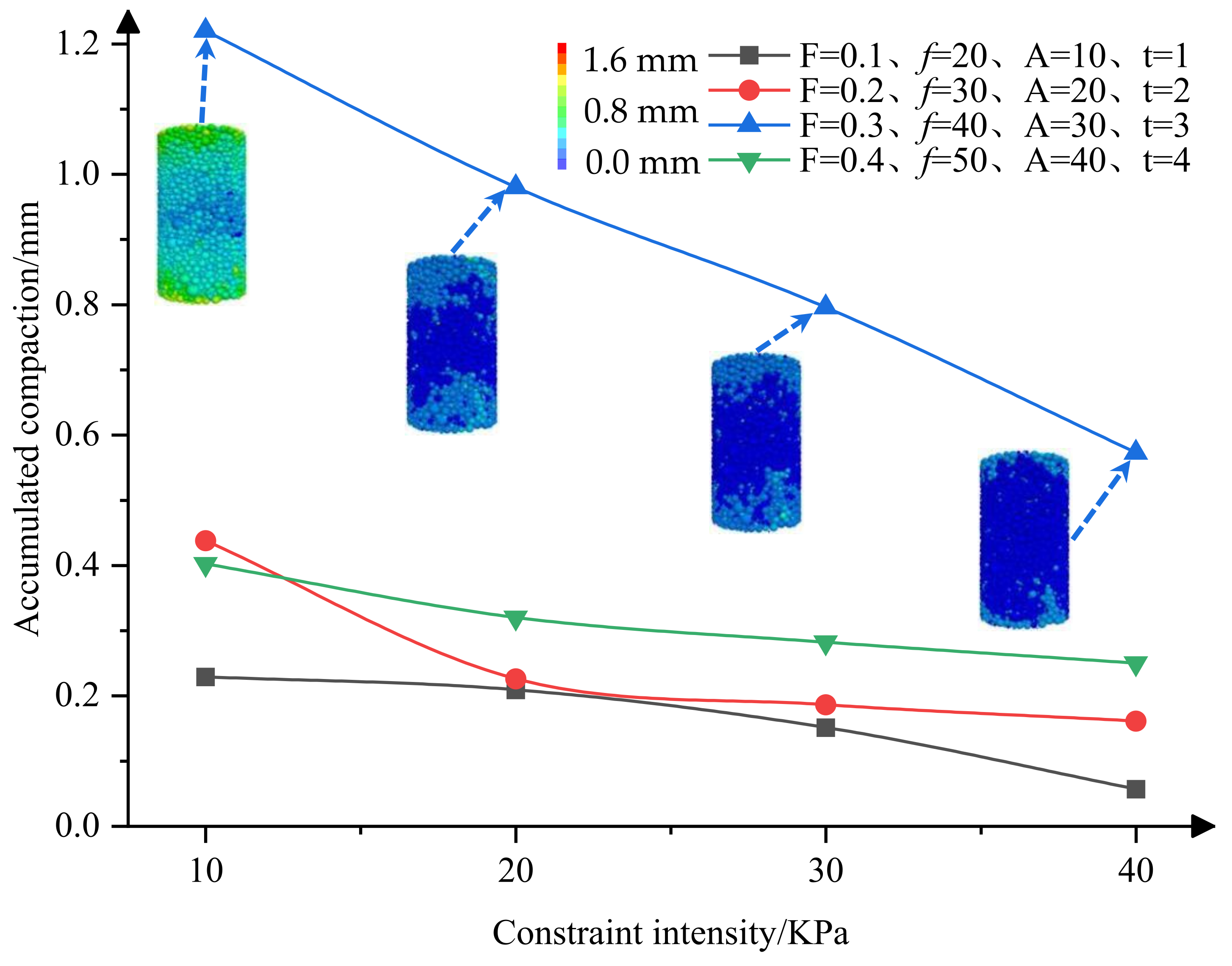

3.4. Influence Law of the Gabion Constraint on the Ultimate Compactness

4. Conclusions

- The compaction effect of aeolian sand under vibration conditions is better than its compaction effect under static load conditions. Under sand-gabion constraints, to obtain compaction of 0.25 mm for a cylindrical aeolian sand specimen with a diameter of 5 cm and a height of 10 cm, the load required for the static method is 1.22 times the excitation force for the vibratory method.

- The typical evolution process of particle contacts force chain network, particle transport, porosity, and other mesoscopic structural characteristic indexes of the aeolian sand samples was quantitatively analyzed. The influence law of frequency, excitation force, amplitude, and vibration time of the sand particles during vibratory compaction has been revealed from the mesoscopic view level. It is considered that when the frequency is 50 HZ, the excitation force is 0.3 MPa, the amplitude is 40 KPa, and the vibration time is 4 s, the denseness of the sand-gabion backfill is the highest.

- Influencing law of the vibration parameters and gabion constraints on the ultimate compactness of the sand-gabion backfills are as follows: The compactness of the sand-gabion showed an increasing trend when the frequency was 20 HZ–50 HZ, the amplitude was 10 KPa–40 KPa, and the time was 1 s–4 s. For excitation forces of 0.1 MPa–0.4 MPa, the compactness of the sand-gabion first increases and then decreases. The compactness of the sand-gabion exhibits a decreasing trend from 10 KPa to 40 KPa in the confinement strength of the cage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, J.; Abulizi, A.; Abliz, A.; Zayiti, A.; Akbar, A.; Ou, B. Construction of Landscape Ecological Security Pattern in the Zhundong Region, Xinjiang, NW China. Int. J. Environ. Res. Public Health 2022, 19, 6301. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Liu, H.; Su, H.; Zeng, Q. Green Mining Takes Place at the Power Plant. Minerals 2022, 12, 839. [Google Scholar] [CrossRef]

- Yu, H.; Li, S.; Wang, X. The Recent Progress China Has Made in the Backfill Mining Method, Part I: The Theory and Equipment of Backfill Pipeline Transportation. Minerals 2021, 11, 1274. [Google Scholar] [CrossRef]

- Li, S.; Zhao, Z.; Yu, H.; Wang, X. The Recent Progress China Has Made in the Backfill Mining Method, Part II: The Composition and Typical Examples of Backfill Systems. Minerals 2021, 11, 1362. [Google Scholar] [CrossRef]

- Li, S.; Zhang, R.; Feng, R.; Hu, B.; Wang, G.; Yu, H. Feasibility of Recycling Bayer Process Red Mud for the Safety Backfill Mining of Layered Soft Bauxite under Coal Seams. Minerals 2021, 11, 722. [Google Scholar] [CrossRef]

- Xie, H.; Ju, Y.; Ren, S.; Gao, F.; Liu, J.; Zhu, Y. Theoretical and Technological Exploration of Deep in Situ Fluidized Coal Mining. Front. Energy 2019, 13, 603–611. [Google Scholar] [CrossRef]

- Jiang, Y.; Misa, R.; Gao, J.; Liu, H.; Sroka, A.; Preusse, A.; Jiang, Y. Non-Pollution Damage Hazard of Underground Mining on Reservoir Ecological Environment. Environ. Earth Sci. 2021, 80, 431. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, W.; Xu, J.; Wu, J.; Li, Y. High-Intensity Longwall Mining-Induced Ground Subsidence in Shendong Coalfield, China. Int. J. Rock Mech. Min. Sci. 2021, 141, 104730. [Google Scholar] [CrossRef]

- Liu, S.; Bai, J.; Wang, G.; Wang, X.; Wu, B. A Method of Backfill Mining Crossing the Interchange Bridge and Application of a Ground Subsidence Prediction Model. Minerals 2021, 11, 945. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, B.; Chen, Q.; Wang, D.; Gao, X. Safety Analysis of Synergetic Operation of Backfilling the Open Pit Using Tailings and Excavating the Ore Deposit Underground. Minerals 2021, 11, 818. [Google Scholar] [CrossRef]

- Shi, P.; Zhang, J.; Yan, H.; Zhang, Y.; Zhang, Q.; Feng, W. Evaluation of Operating Performance of Backfilling Hydraulic Support Using Six Hybrid Machine Learning Models. Minerals 2022, 12, 1388. [Google Scholar] [CrossRef]

- Feng, X.; Ding, Z.; Ju, Y.; Zhang, Q.; Ali, M. “Double Peak” of Dynamic Strengths and Acoustic Emission Responses of Coal Masses Under Dynamic Loading. Nat. Resour. Res. 2022, 6, 1705. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Taheri, A.; Zhang, W.; Wu, Z.; Song, W. Properties and Application of Backfill Materials in Coal Mines in China. Minerals 2019, 9, 53. [Google Scholar] [CrossRef]

- Ning, S.; Lou, J.; Wang, L.; Yu, D.; Zhu, W. Stability Influencing Factors and Control Methods of Residual Coal Pillars with Solid Waste Materials Backfilling Method. Minerals 2022, 12, 1285. [Google Scholar] [CrossRef]

- Shao, X.; Wang, L.; Li, X.; Fang, Z.; Zhao, B.; Tao, Y.; Liu, L.; Sun, W.; Sun, J. Study on Rheological and Mechanical Properties of Aeolian Sand-Fly Ash-Based Filling Slurry. Energies 2020, 13, 1266. [Google Scholar] [CrossRef]

- Shao, X.; Tian, C.; Li, C.; Fang, Z.; Zhao, B.; Xu, B.; Ning, J.; Li, L.; Tang, R. The Experimental Investigation on Mechanics and Damage Characteristics of the Aeolian Sand Paste-like Backfill Materials Based on Acoustic Emission. Materials 2022, 15, 7235. [Google Scholar] [CrossRef]

- Ma, B.; Gao, L.; Cheng, J.; Ding, B.; Ding, L.; Qu, L.; An, Y. Characteristics and Hazards of an Aeolian Sand Environment along Railways in the Southeastern Fringe of the Taklimakan Desert and Sand Control Measures. Appl. Sci. 2022, 12, 9186. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.; Sun, K.; Zhang, S. Influence of Lateral Loading on Compaction Characteristics of Crushed Waste Rock Used for Backfilling. Minerals 2018, 8, 552. [Google Scholar] [CrossRef]

- Li, G.; Wan, Y.; Guo, J.; Ma, F.; Zhao, H.; Li, Z. A Case Study on Ground Subsidence and Backfill Deformation Induced by Multi-Stage Filling Mining in a Steeply Inclined Ore Body. Remote Sens. 2022, 14, 4555. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, Q. The Effect of Backfilling Materials on the Deformation of Coal and Rock Strata Containing Multiple Goaf: A Numerical Study. Minerals 2018, 8, 224. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, Q.; Ali, M. 3D modelling of the strength effect of backfill-rocks on controlling rockburst risk: A case study. Arab. J. Geosci. 2020, 1, 128. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, F.; Bao, Y.; Yuan, H. Research on Dynamic Stress–Strain Change Rules of Rubber-Particle-Mixed Sand. Coatings 2022, 12, 1470. [Google Scholar] [CrossRef]

- Chang, D.-W.; Lu, C.-W.; Tu, Y.-J.; Cheng, S.-H. Settlements and Subgrade Reactions of Surface Raft Foundations Subjected to Vertically Uniform Load. Appl. Sci. 2022, 12, 5484. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J.; Zhao, Q.; Wang, J.; Liu, T.; Zhang, Q. Gradation Design of Phosphorus Tailing–Graded Waste Rock Subgrade Filling Using Discrete Element Method. Minerals 2022, 12, 573. [Google Scholar] [CrossRef]

- Wang, J.Q.; Chang, Z.C.; Xue, J.F.; Lin, Z.N.; Tang, Y. Experimental Investigation on the Behavior of Gravelly Sand Reinforced with Geogrid under Cyclic Loading. Appl. Sci. 2021, 11, 12152. [Google Scholar] [CrossRef]

- Zhang, X.G.; Cai, Q.E.; Liu, J.Y. Study on Method Defining Maximum Dry Density of Aeolian Sand Filler along Tong’e Highway Embankment. Subgrade Eng. 2016, 5, 102. [Google Scholar] [CrossRef]

- Frid, V.; Potirakis, S.M.; Shulov, S. Study of Static and Dynamic Properties of Sand under Low Stress Compression. Appl. Sci. 2021, 11, 3311. [Google Scholar] [CrossRef]

- Miao, Y.; Yu, W.; Hou, Y.; Guo, L.; Wang, L. Investigating the Functions of Particles in Packed Aggregate Blend using a Discrete Element Method. Materials 2019, 12, 556. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R. Effects of Class C and Class F Fly Ash on Mechanical and Microstructural Behavior of Clay Soil—A Comparative Study. Materials 2022, 15, 1845. [Google Scholar] [CrossRef]

- Dun, H.; Yue, P.; Huang, N.; Zhang, J. Discrete Element Simulation on Sand-Bed Collision Considering Surface Moisture Content. Processes 2022, 10, 52. [Google Scholar] [CrossRef]

- Xie, Y.P.; Zhang, C.; Yang, J.S. Study on failure characteristics and reinforcement measures of tunnel’s surrounding rocks in glacial deposits based on coarse-grained dem. Chin. J. Rock Mech. Eng. 2021, 3, 556. [Google Scholar] [CrossRef]

- Rong, H.; Li, G.; Liang, D.; Sun, C.; Zhang, S.; Sun, Y. Numerical Investigation on the Evolution of Mechanical Properties of Rock Affected by Micro-Parameters. Appl. Sci. 2020, 10, 4957. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Chen, Z.; Li, M.; Qiao, M.; Kizil, M. Particle-Crushing Characteristics and Acoustic-Emission Patterns of Crushing Gangue Backfilling Material under Cyclic Loading. Minerals 2018, 8, 244. [Google Scholar] [CrossRef]

- Ji, X.; Lu, H.; Dai, C.; Ye, Y.; Cui, Z.; Xiong, Y. Characterization of Properties of Soil–Rock Mixture Prepared by the Laboratory Vibration Compaction Method. Sustainability 2021, 13, 11239. [Google Scholar] [CrossRef]

- Ding, F.; Song, L.; Yue, F. Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method. Processes 2022, 10, 324. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, Y.; Dai, H.; Zhu, Y.; Wu, T. Stability and Force Chain Characteristics of “Inclined Step Cutting Body” in Stope. Appl. Sci. 2021, 11, 10276. [Google Scholar] [CrossRef]

- Shi, D.; Shi, Q. Study on Mechanical Properties and Mesoscopic Numerical Simulation of Recycled Concrete. Sustainability 2022, 14, 12125. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, Y.; Xu, Q.; Zhang, G.; Wang, Z. Study on Vibration Compaction Energy of Basement Material. Coatings 2022, 12, 1495. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, G.; Chen, W.; Sun, L. Relation between Microstructures and Macroscopic Mechanical Properties of Earthen-Site Soils. Materials 2022, 15, 6124. [Google Scholar] [CrossRef]

- Wang, F.; Shao, J.; Li, W.; Wang, L.; Wang, Y.; Liu, H. Numerical Simulation Study on Lining Damage of Shield Tunnel under Train Load. Sustainability 2022, 14, 14018. [Google Scholar] [CrossRef]

- Beben, D.; Maleska, T.; Bobra, P.; Duda, J.; Anigacz, W. Influence of Traffic-Induced Vibrations on Humans and Residential Building-A Case Study. Int. J. Environ. Res. Public Health 2022, 9, 5441. [Google Scholar] [CrossRef] [PubMed]

- He, Z.L.; Lu, C.P.; Zhang, X.F. Experimental and Numerical Investigations of Dynamic Failure Mechanisms of Underground Roadway Induced by Incident Stress Wave. Appl. Sci. 2022, 12, 10350. [Google Scholar] [CrossRef]

- Sun, B.; Chen, R.; Ping, Y.; Zhu, Z.; Wu, N.; He, Y. Dynamic Response of Rock-like Materials Based on SHPB Pulse Waveform Characteristics. Materials 2022, 15, 210. [Google Scholar] [CrossRef] [PubMed]

- Sanayei, M.; Kayiparambil, P.A.; Moore, J.A.; Brett, C.R. Measurement and prediction of train-induced vibrations in a full-scale building. Eng. Struct. 2014, 7, 77. [Google Scholar] [CrossRef]

- Guo, J.; Xu, L.; Xu, C.; Chen, R.; Lin, J. Dynamic Response Analysis on Stress and Displacement of the Shield Tunnel Structure and Soil Layer under Train-Induced Vibration in Xiamen Metro Line 6. Sustainability 2022, 14, 11962. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Luan, H.; Shi, Y.; Zhang, S.; Yan, P.; Li, B. Discrete Element Simulation of the Macro-Meso Mechanical Behaviors of Gas-Hydrate-Bearing Sediments under Dynamic Loading. J. Mar. Sci. Eng. 2022, 10, 1042. [Google Scholar] [CrossRef]

- Liang, C.; Zhang, H.; Liu, F.; Yan, X.; Bi, H. Simulation Analysis of Cement-Stabilized Macadam Compaction Processing Based on the Discrete Element Method. Appl. Sci. 2022, 12, 8505. [Google Scholar] [CrossRef]

- Zvonarić, M.; Barišić, I.; Galić, M.; Minažek, K. Influence of Laboratory Compaction Method on Compaction and Strength Characteristics of Unbound and Cement-Bound Mixtures. Appl. Sci. 2021, 11, 4750. [Google Scholar] [CrossRef]

- Maksimov, F.; Tombari, A. Derivation of Cyclic Stiffness and Strength Degradation Curves of Sands through Discrete Element Modelling. Modelling 2022, 3, 400–416. [Google Scholar] [CrossRef]

- Chen, X.; Chen, N.; Wei, Z.; Zhang, X.; Yang, F.; Zhao, H.; You, M.; Wang, W. Research on the Influence of Loading Frequency on the Dynamic Response of Concrete Sleepers. Appl Sci 2022, 12, 7245. [Google Scholar] [CrossRef]

- Lian, X.; Zhang, Y.; Yuan, H.; Wang, C.; Guo, J.; Liu, J. Law of Movement of Discontinuous Deformation of Strata and Ground with a Thick Loess Layer and Thin Bedrock in Long Wall Mining. Appl Sci 2020, 10, 2874. [Google Scholar] [CrossRef]

- Germonpré, M.; Degrande, G.; Lombaert, G. A study of modelling simplifications in ground vibration predictions for railway traffic at grade. J. Sound Vib. 2017, 6, 406. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, L.; Wang, Q.; Li, J.; Wang, Y.; Chen, H.; Samosvat, V. Experimental Studies on the Effect of Properties and Micro-Structure on the Creep of Concrete-Filled Steel Tubes. Materials 2019, 12, 1046. [Google Scholar] [CrossRef] [PubMed]

| Contact Model | Normal Stiffness of Wall/N·m−1 | Tangential Stiffness of Wall/N·m−1 | Particle Normal Stiffness/N·m−1 | Tangential Stiffness of Particles/N·m−1 | Friction | Damp | Density (Kg/m3) | Porosity |

|---|---|---|---|---|---|---|---|---|

| Linear contact | 1.8 × 108 | 1.8 × 108 | 1.8 × 108 | 1.8 × 108 | 0.3 | 0.7 | 2600 | 0.35 |

| Component | Frequency /HZ | Excitation Force /MPa | Amplitude /KPa | Vibration time/s | Sand-Gabion/KPa |

|---|---|---|---|---|---|

| 1 | 20,30,40,50 | 0.1 | 10 | 1 | 10 |

| 2 | 20,30,40,50 | 0.2 | 20 | 2 | 20 |

| 3 | 20,30,40,50 | 0.3 | 30 | 3 | 30 |

| 4 | 20,30,40,50 | 0.4 | 40 | 4 | 40 |

| 5 | 20 | 0.1,0.2,0.3,0.4 | 10 | 1 | 10 |

| 6 | 30 | 0.1,0.2,0.3,0.4 | 20 | 2 | 20 |

| 7 | 40 | 0.1,0.2,0.3,0.4 | 30 | 3 | 30 |

| 8 | 50 | 0.1,0.2,0.3,0.4 | 40 | 4 | 40 |

| 9 | 20 | 0.1 | 10,20,30,40 | 1 | 10 |

| 10 | 30 | 0.2 | 10,20,30,40 | 2 | 20 |

| 11 | 40 | 0.3 | 10,20,30,40 | 3 | 30 |

| 12 | 50 | 0.4 | 10,20,30,40 | 4 | 40 |

| 13 | 20 | 0.1 | 10 | 1,2,3,4 | 10 |

| 14 | 30 | 0.2 | 20 | 1,2,3,4 | 20 |

| 15 | 40 | 0.3 | 30 | 1,2,3,4 | 30 |

| 16 | 50 | 0.4 | 40 | 1,2,3,4 | 40 |

| 17 | 20 | 0.1 | 10 | 1 | 10,20,30,40 |

| 18 | 30 | 0.2 | 20 | 2 | 10,20,30,40 |

| 19 | 40 | 0.3 | 30 | 3 | 10,20,30,40 |

| 20 | 50 | 0.4 | 40 | 4 | 10,20,30,40 |

| Accumulated Compaction/mm | 0.285 | 0.6 | 0.75 | 0.87 |

| Vibration load/MPa | 0.1 | 0.2 | 0.3 | 0.4 |

| Static load/MPa | 0.136 | 0.265 | 0.380 | 0.491 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wang, W.; Zhao, B. Numerical Study on the Vibratory Compaction Mechanism of the Sand-Gabion Backfills in Underground Coal Mines. Minerals 2022, 12, 1428. https://doi.org/10.3390/min12111428

Zhang Z, Wang W, Zhao B. Numerical Study on the Vibratory Compaction Mechanism of the Sand-Gabion Backfills in Underground Coal Mines. Minerals. 2022; 12(11):1428. https://doi.org/10.3390/min12111428

Chicago/Turabian StyleZhang, Zhiyi, Wei Wang, and Bo Zhao. 2022. "Numerical Study on the Vibratory Compaction Mechanism of the Sand-Gabion Backfills in Underground Coal Mines" Minerals 12, no. 11: 1428. https://doi.org/10.3390/min12111428

APA StyleZhang, Z., Wang, W., & Zhao, B. (2022). Numerical Study on the Vibratory Compaction Mechanism of the Sand-Gabion Backfills in Underground Coal Mines. Minerals, 12(11), 1428. https://doi.org/10.3390/min12111428