Research on Grinding Law and Grinding Parameters Optimization of Polymetallic Complex Ores

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Batch Grinding Test

2.2.2. Grinding Technical Efficiency

3. Results and Discussion

3.1. Single Factor Grinding Test of Tongkeng Ore

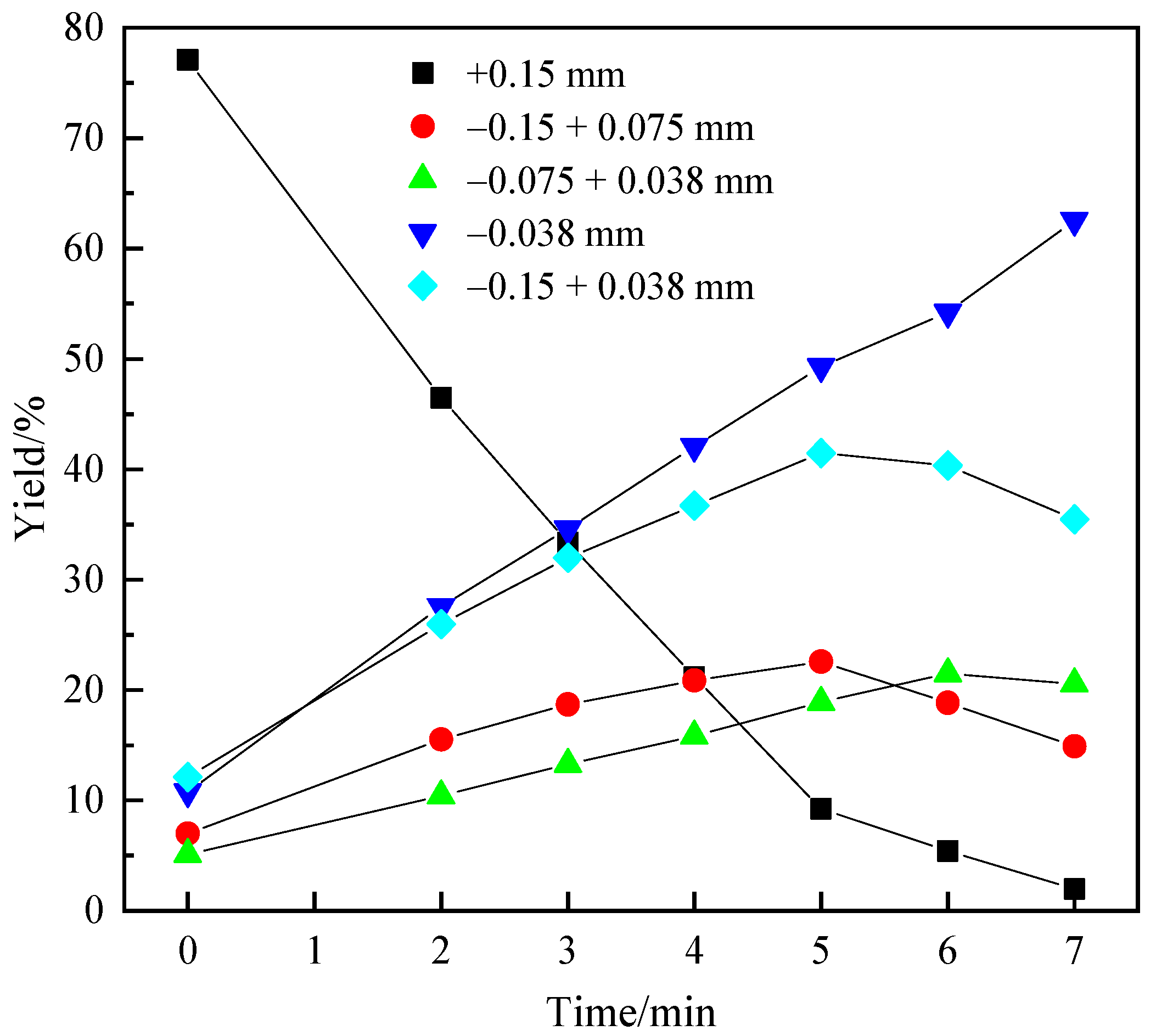

3.1.1. Effect of Grinding Time

3.1.2. Effect of Grinding Concentration

3.1.3. Effect of Filling Ratio

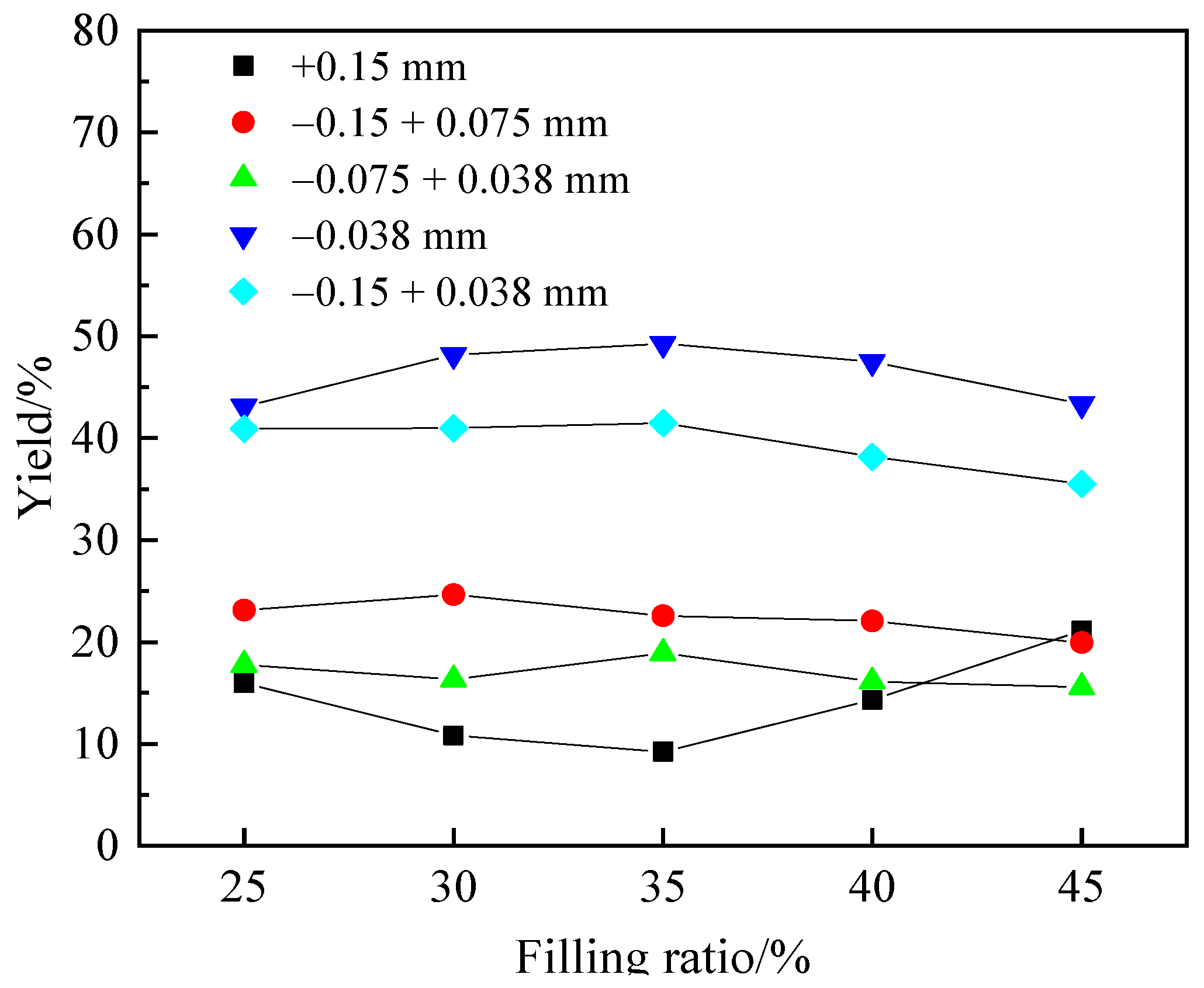

3.1.4. Effect of Rotational Rate

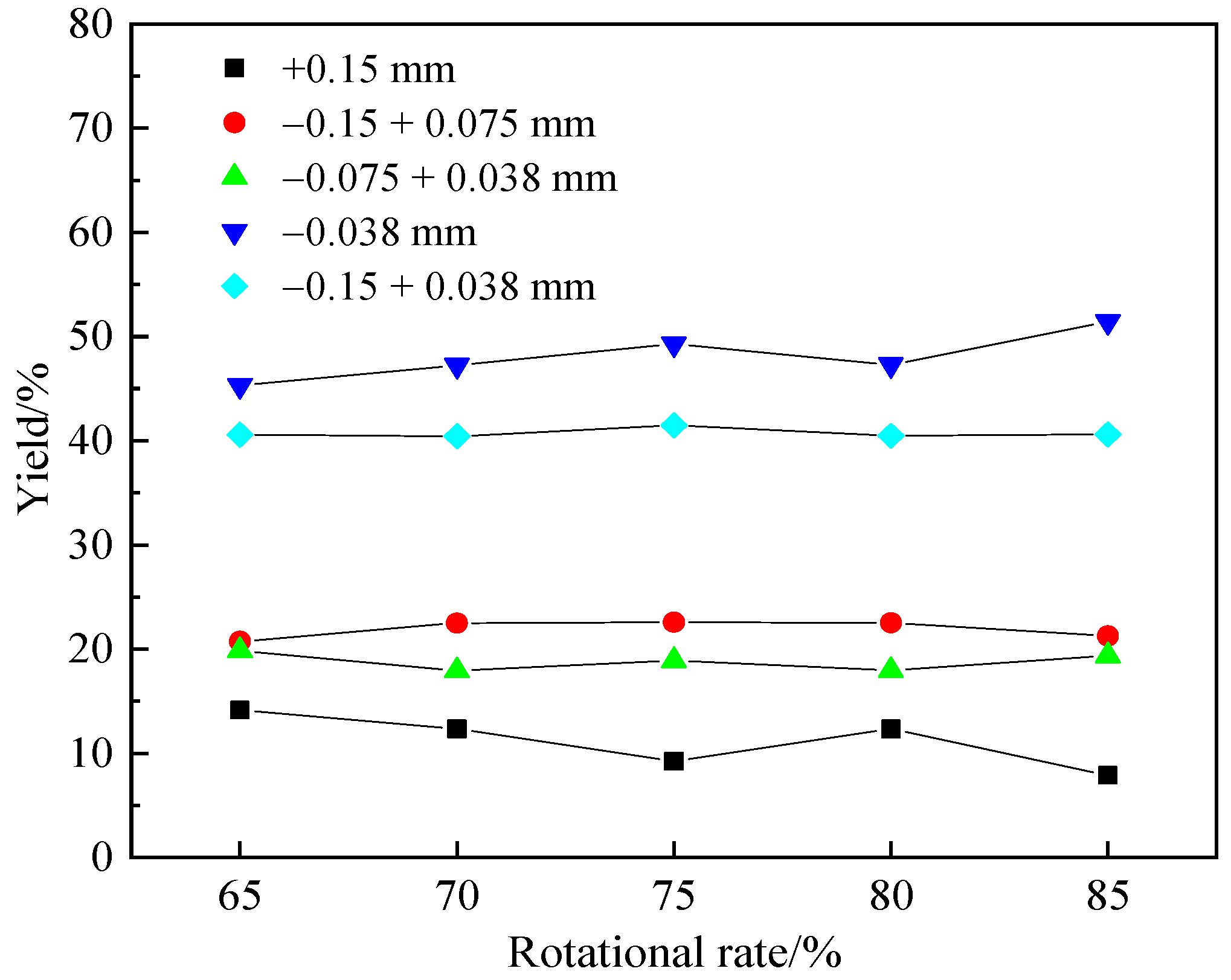

3.2. Single Factor Grinding Test of Gaofeng Ore

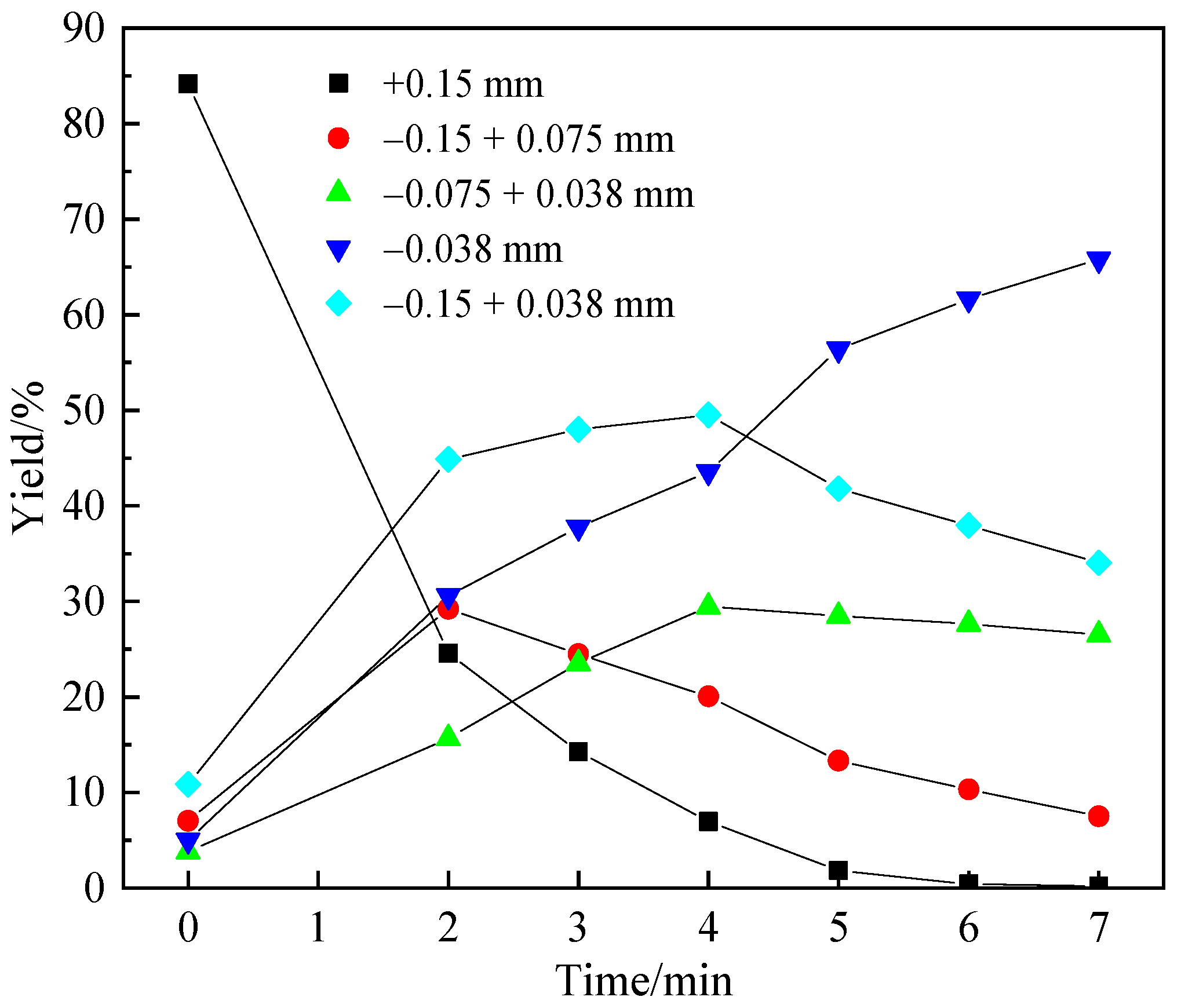

3.2.1. Effect of Grinding Time

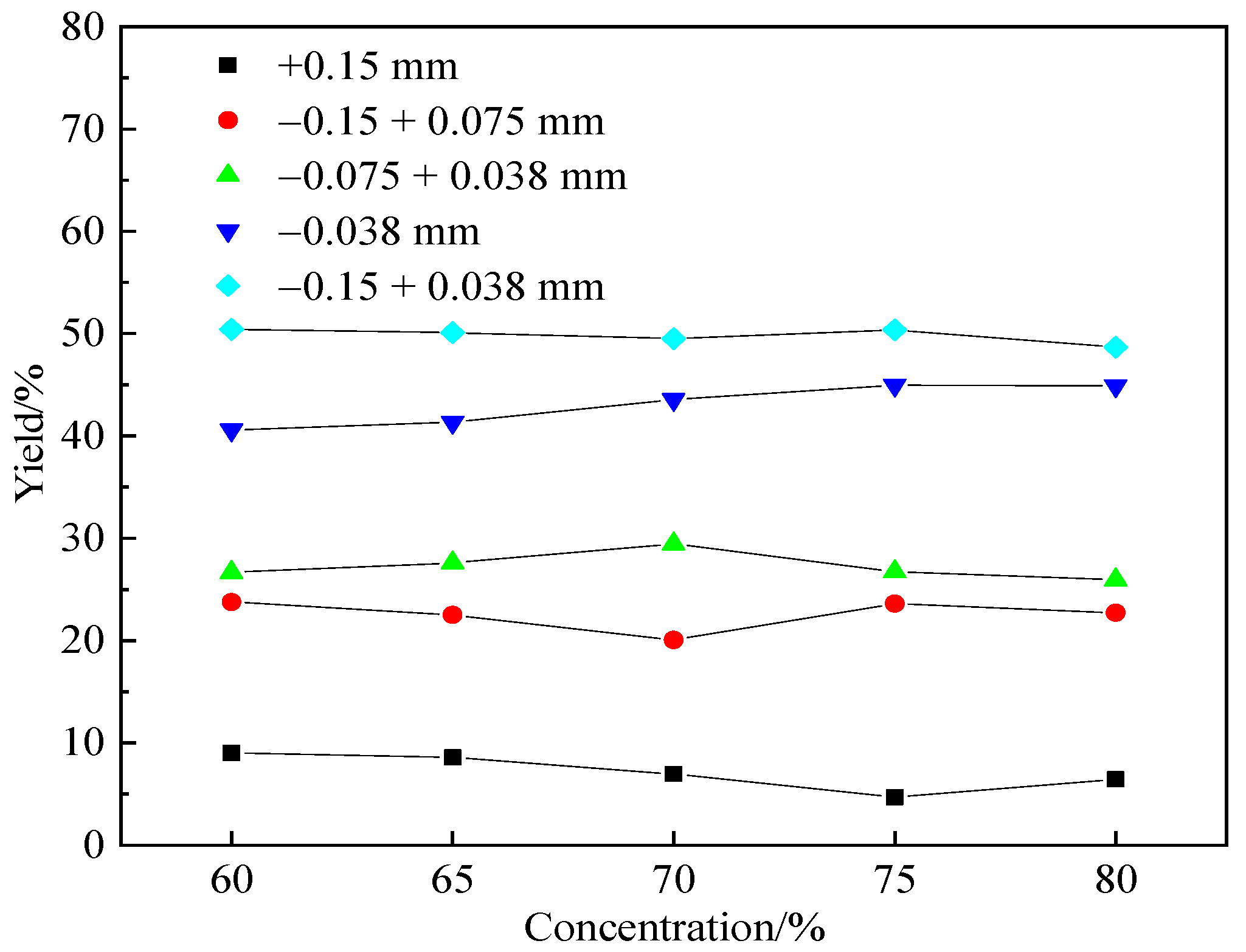

3.2.2. Effect of Grinding Concentration

3.2.3. Effect of Filling Ratio

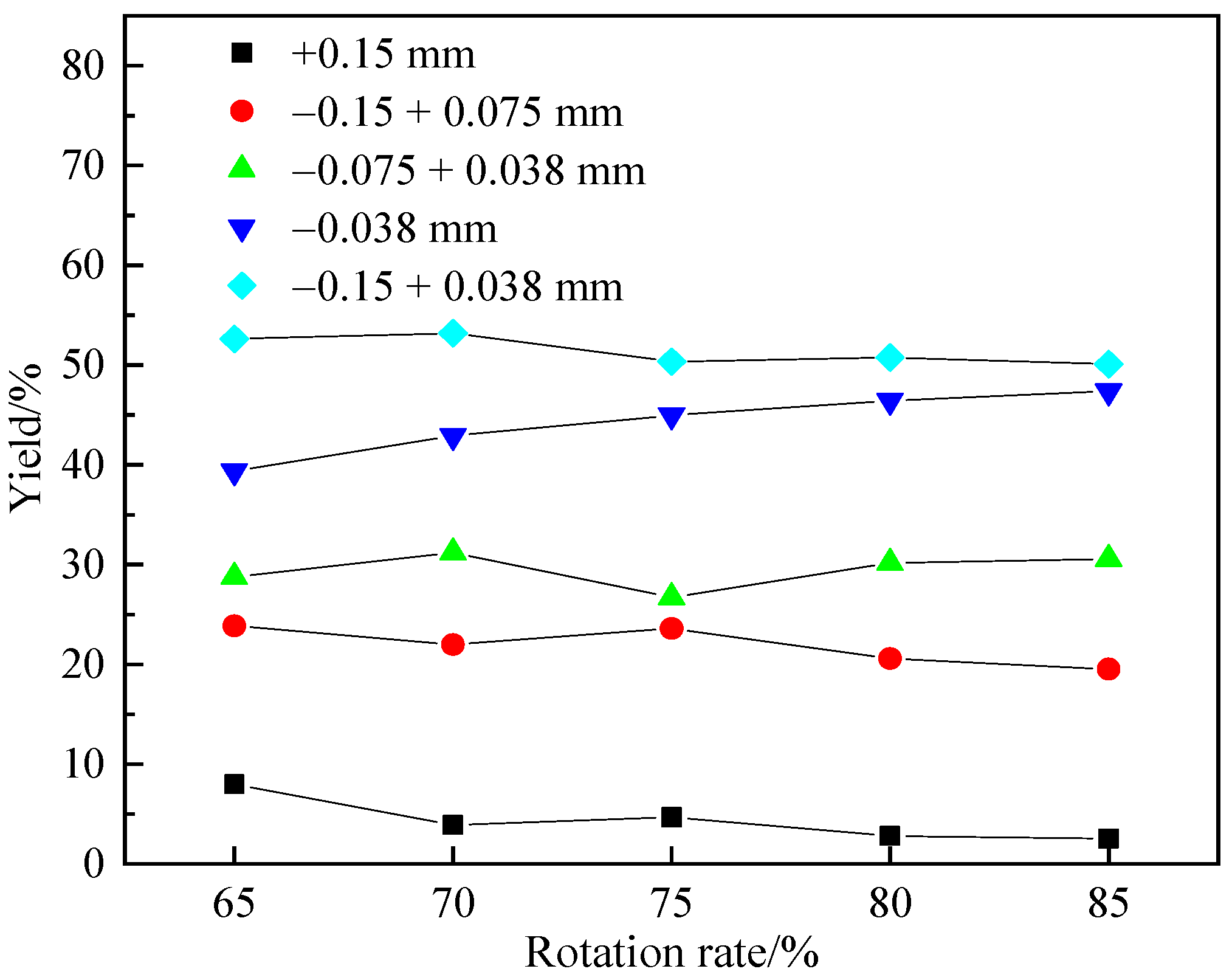

3.2.4. Effect of Rotational Rate

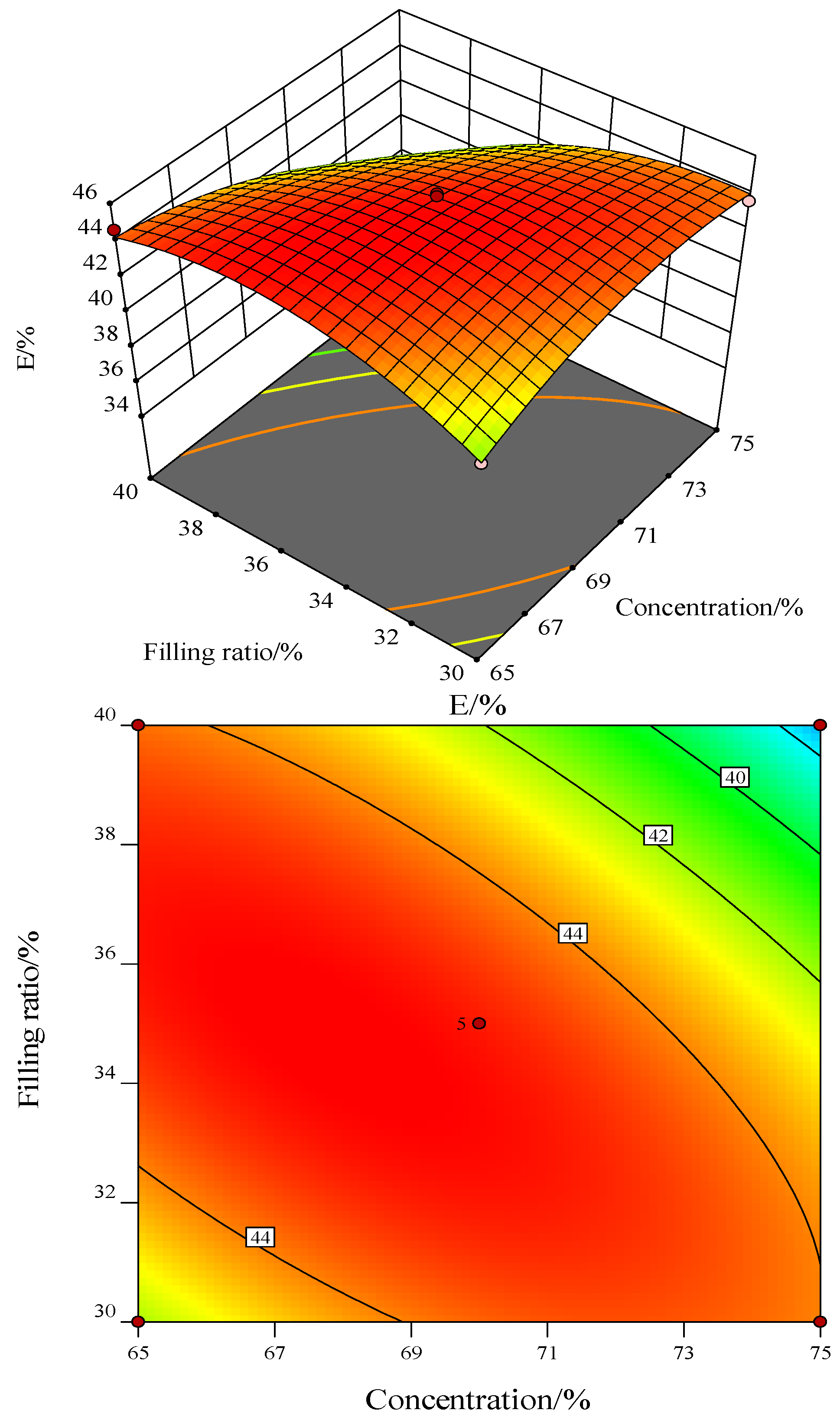

3.3. Grinding Parameters Optimization of Tongkeng Ore

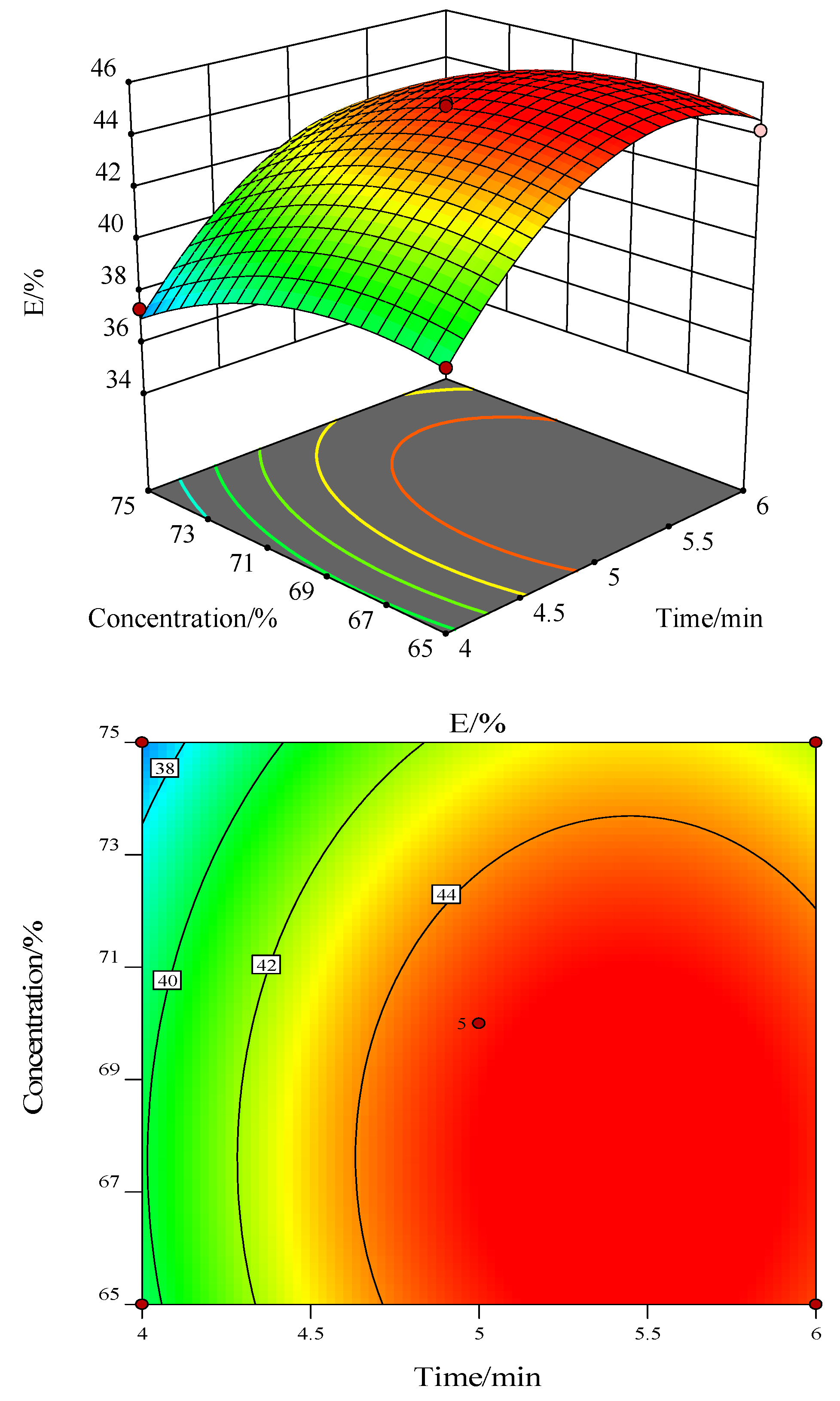

3.3.1. Grinding Parameters Optimization

3.3.2. Verify Grinding Optimization Parameters

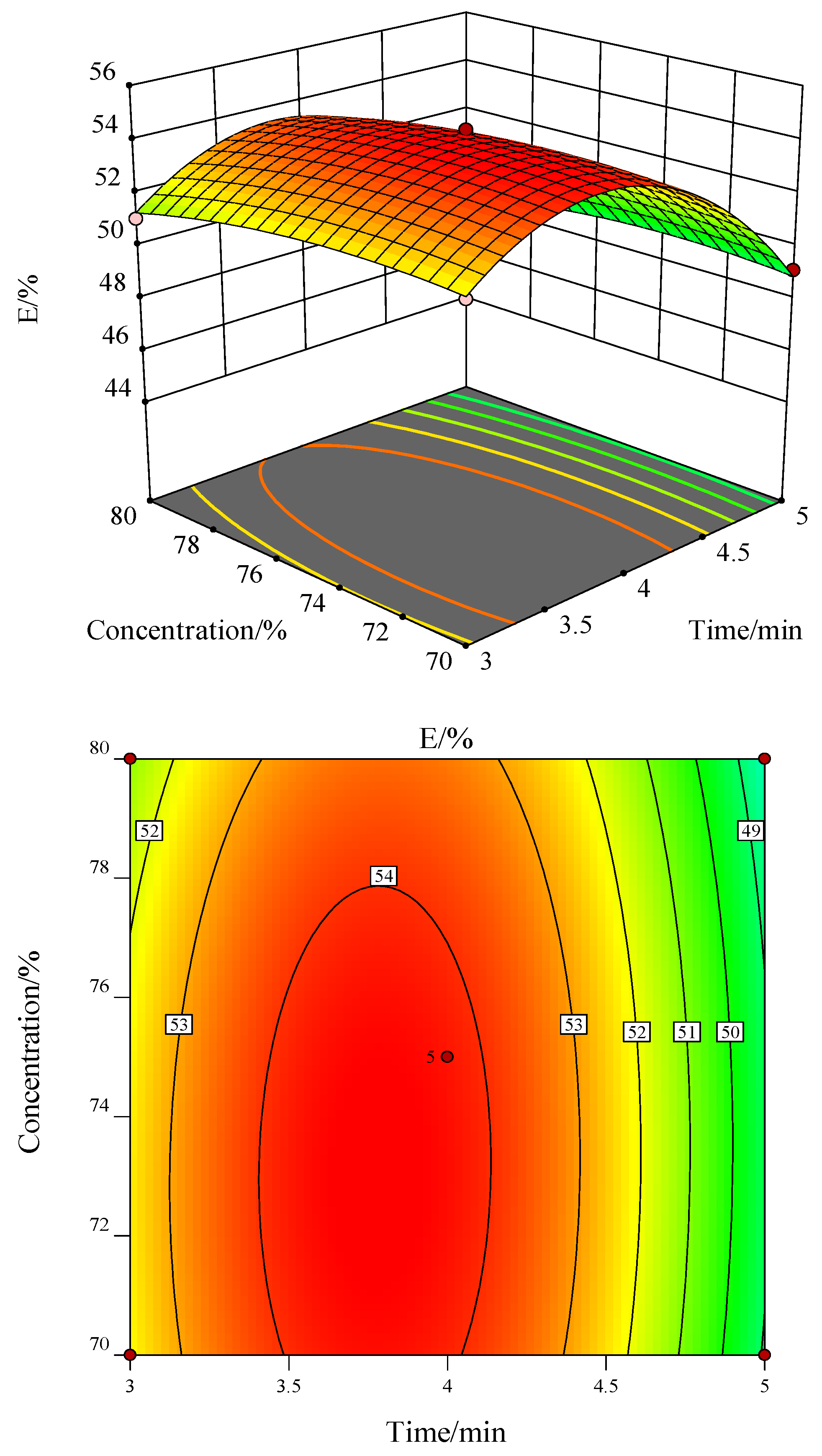

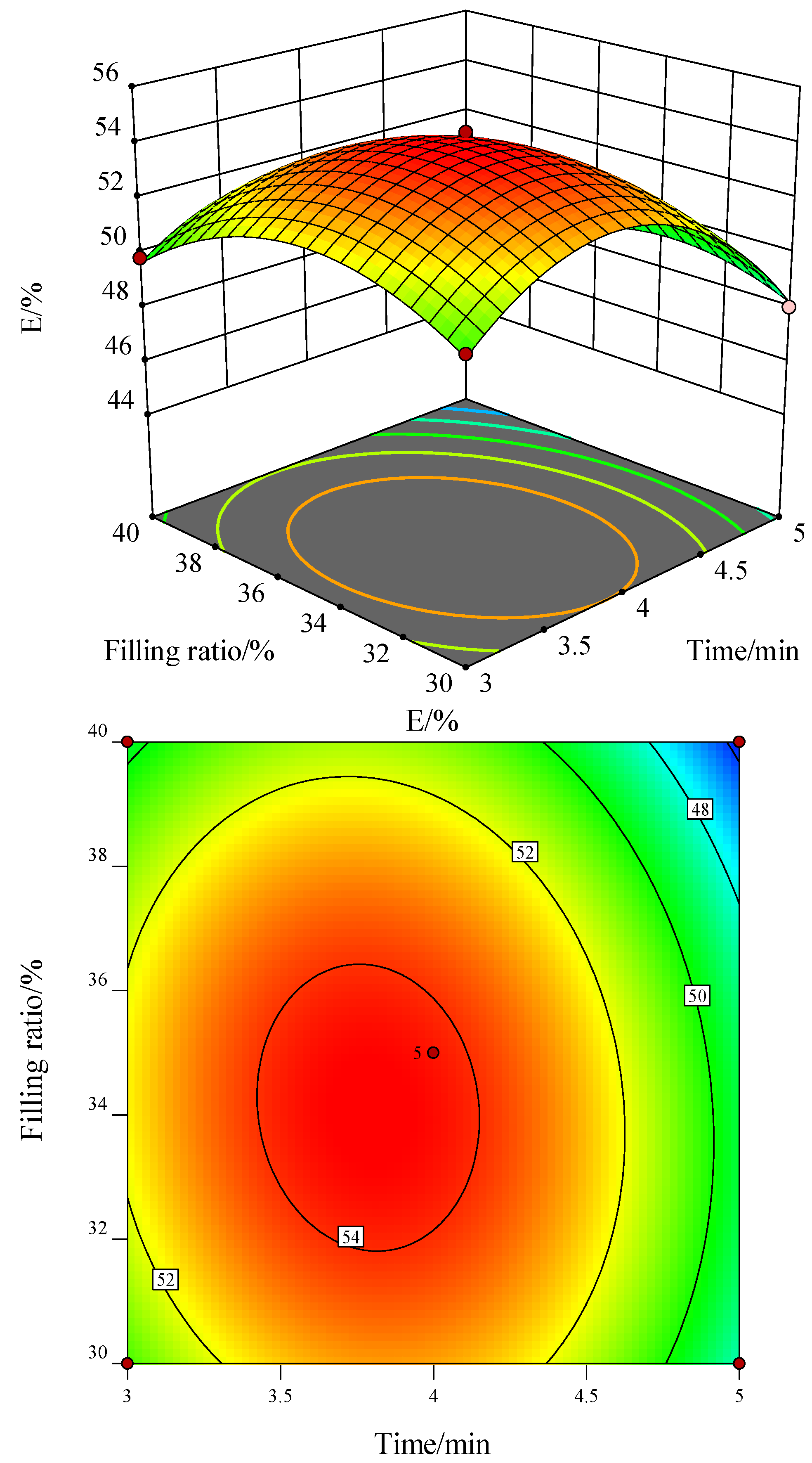

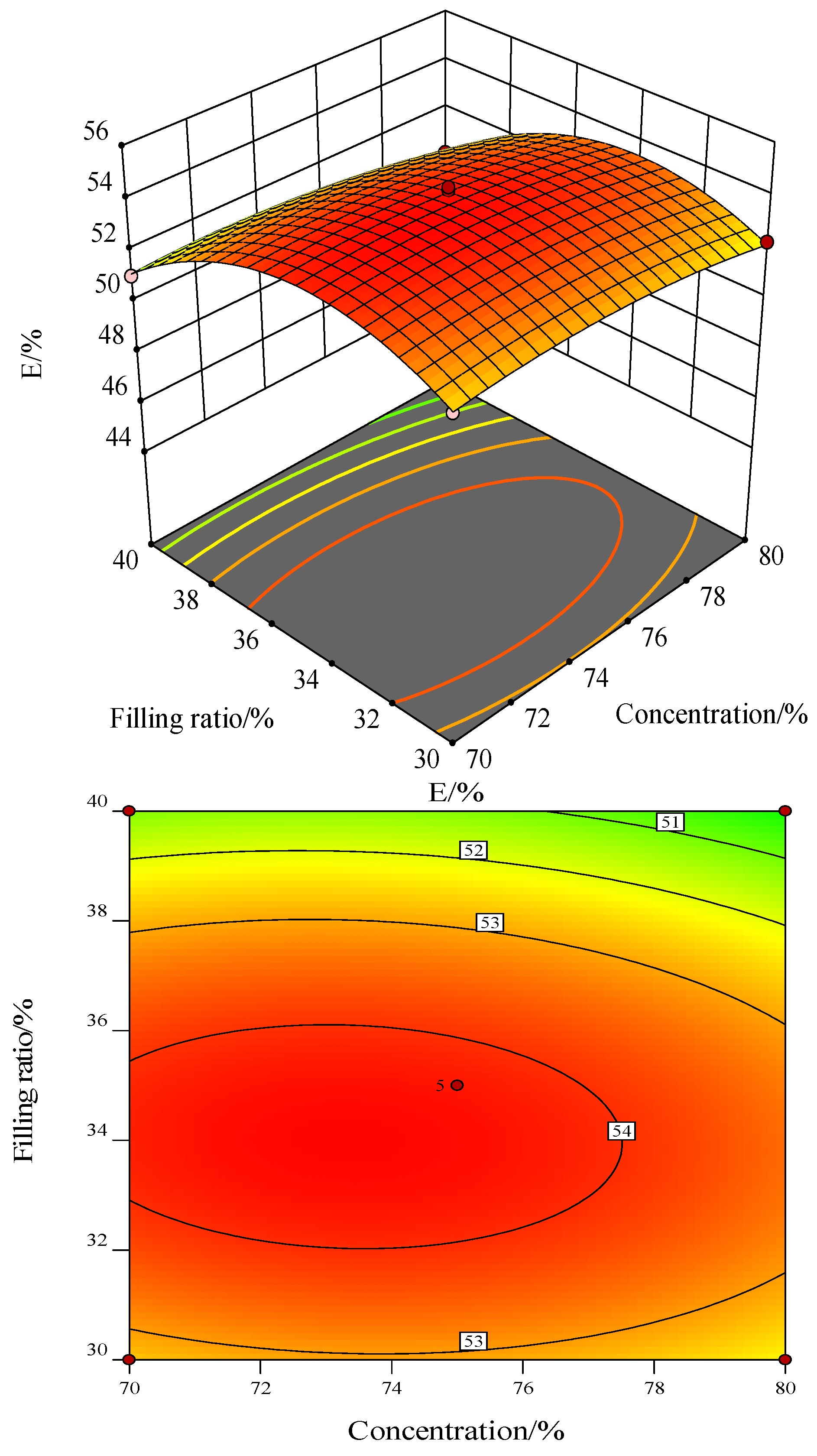

3.4. Grinding Parameters Optimization of Gaofeng Ore

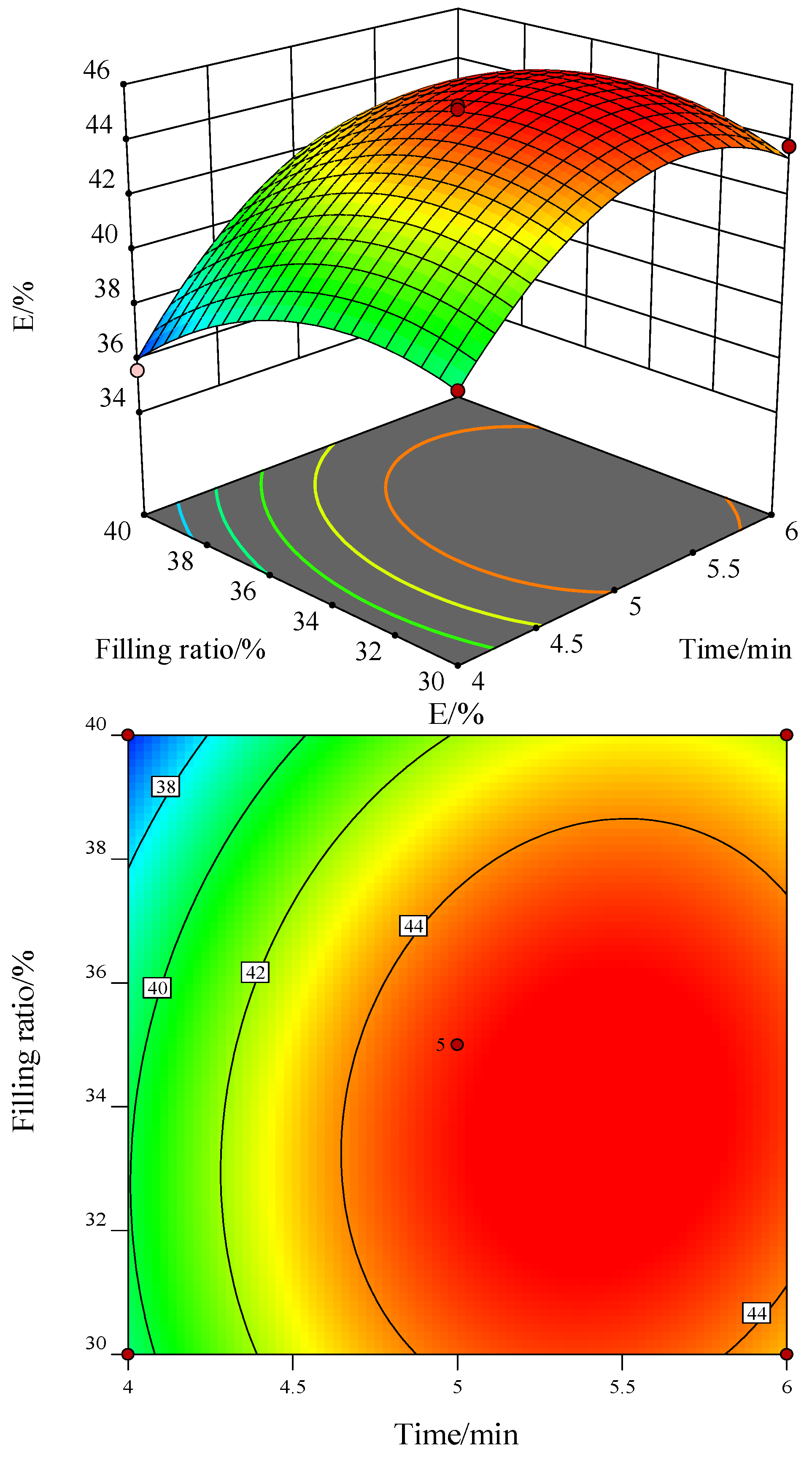

3.4.1. Grinding Parameters Optimization

3.4.2. Verify Grinding Optimization Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sadrai, S.; Meech, J.A.; Ghomshei, M.; Sassani, F.; Tromans, D. Influence of Impact Velocity on Fragmentation and the Energy Efficiency of Comminution. Int. J. Impact Eng. 2006, 33, 723–734. [Google Scholar] [CrossRef]

- Hashim, S.F.S.; Hussin, H. Effect of Grinding Aids in Cement Grinding. J. Phys. Conf. Ser. 2018, 1082, 012091. [Google Scholar] [CrossRef]

- Krishnaraj, L.; Ravichandran, P.T. Investigation on Grinding Impact of Fly Ash Particles and Its Characterization Analysis in Cement Mortar Composites. Ain Shams Eng. J. 2019, 10, 267–274. [Google Scholar] [CrossRef]

- Santosh, T.; Soni, R.K.; Eswaraiah, C.; Rao, D.S.; Venugopal, R. Optimization of Stirred Mill Parameters for Fine Grinding of Pge Bearing Chromite Ore. Particul. Sci. Tec. 2020, 39, 663–675. [Google Scholar]

- Valenzuela, M.A.; Castro, B. Experimental Evaluation of Power Requirements for Wet Grinding and Its Comparison to Dry Grinding. IEEE T. Ind. Appl. 2018, 99, 1. [Google Scholar]

- Huang, K.Q.; Xiao, C.H.; Wu, Q.M. Application of Accurate Ball-load-addition Method in Grinding Production of Some Tailings. Adv. Mat. Res. 2014, 962, 771–774. [Google Scholar]

- Kotake, N.; Kuboki, M.; Kiya, S.; Kanda, Y. Influence of Dry and Wet Grinding Conditions on Fineness and Shape of Particle Size Distribution of Product in a Ball Mil. Adv. Powder Technol. 2011, 22, 86–924. [Google Scholar] [CrossRef]

- Peng, Y.; Grano, S. Effect of Iron Contamination from Grinding Media on the Flotation of Sulphide Minerals of Different Particle Size. Int. J. Miner. Process. 2010, 97, 1–6. [Google Scholar] [CrossRef]

- Malyarov, P.; Dolgov, O.; Kovalev, P. Mineral Raw Material Disintegration Mechanisms in Ball Mills and Distribution of Grinding Energy between Sequential Stages. Miner. Miner. Dep. 2020, 14, 25–33. [Google Scholar] [CrossRef]

- Gupta, V.K.; Sharma, S. Analysis of Ball Mill Grinding Operation using Mill Power Specific Kinetic Parameters. Adv. Powder Technol. 2014, 25, 625–634. [Google Scholar] [CrossRef]

- Erdem, A.S.; Ergün, L. The Effect of Ball Size on Breakage Rate Parameter in a Pilot Scale Ball Mill. Miner. Eng. 2009, 22, 660–664. [Google Scholar] [CrossRef]

- Chimwani, N.; Mohale, T.M.; Bwalya, M.M. Tailoring Ball Mill Feed Size Distribution for the Production of a Size-graded Product. Miner. Eng. 2019, 141, 105891. [Google Scholar] [CrossRef]

- Gupta, V.K. Effect of Size Distribution of the Particulate Material on the Specific Breakage rate of Particles in Dry Ball Milling. Powder Technol. 2017, 305, 714–722. [Google Scholar] [CrossRef]

- Woywadt, C. Grinding Process Optimization-Featuring Case Studies and Operating Results of the Modular Vertical Roller Mill. In Proceedings of the 2017 IEEE-IAS/PCA Cement Industry Technical Conference, Calgary, AB, Canada, 21–25 May 2017. [Google Scholar]

- Hfels, C.; Dambach, R.; Kwade, A. Geometry Influence on Optimized Operation of a Dry Agitator Bead Mill. Miner. Eng. 2021, 171, 107050. [Google Scholar] [CrossRef]

- Xu, T.L. Study on Cassiterite Polymetallic Sulfide Ore Selective Grinding Behavior. Master’s Thesis, Guangxi University, Nanning, China, 2014. (In Chinese). [Google Scholar]

- Xie, H.Y.; Ye, Q.J.; Zhou, P.; Gao, L.K.; Tong, X.; Liu, J.X. Research on Bulk Floatation Discarding Tailing of Copper and Zinc Polymetallic Sulfide Ores. Adv. Mat. Res. 2014, 881–883, 1621–1625. [Google Scholar]

- Zhou, W.T.; Han, Y.X.; Li, Y.J.; Yang, J.L.; Ma, S.J.; Sun, Y.S. Research on Prediction Model of Ore Grinding Particle Size Distribution. J. Disper. Sci. Technol. 2020, 41, 537–546. [Google Scholar]

- Matveeva, T.N.; Getman, V.V.; Karkeshkina, A.Y. Flotation Extraction of Tin from Tailings of Sulfide-tin Ore Dressing Using Thermomorphic Polymer. Eurasian Min. 2021, 2, 46–49. [Google Scholar] [CrossRef]

- Yusupov, T.S.; Kondrat’ev, S.A.; Khalimova, S.R.; Novikova, S.A. Mineralogical and Technological Assessment of Tin–sulfide Mining Waste Dressability. J. Min. Sci. 2018, 54, 656–662. [Google Scholar] [CrossRef]

- Chen, Y.M.; Li, H.; Feng, D.X.; Tong, X.; Hu, S.X.; Yang, F.; Wang, G.C. A Recipe of Surfactant for the Flotation of Fine Cassiterite Particles. Miner. Eng. 2021, 160, 106658. [Google Scholar] [CrossRef]

- Tian, M.J.; Zhang, C.Y.; Han, H.S.; Liu, R.Q.; Gao, Z.Y.; Chen, P.; He, J.Y.; Hu, Y.H.; Sun, W.; Yuan, D.D. Novel Insights into Adsorption Mechanism of Benzohydroxamic Acid on Lead (II)-activated Cassiterite Surface: An Integrated Experimental and Computational Study. Miner. Eng. 2018, 122, 327–338. [Google Scholar] [CrossRef]

- Zhang, L.M.; Khoso, S.A.; Tian, M.J.; Sun, W. Cassiterite Recovery from a Sulfide Ore Flotation Tailing by Combined Gravity and Flotation Separations. Physicochem. Probl. Mi. 2020, 57, 206–215. [Google Scholar] [CrossRef]

- Angadi, S.I.; Sreenivas, T.; Jeon, H.S.; Baek, S.H.; Mishra, B.K. A Review of Cassiterite Beneficiation Fundamentals and Plant Practices. Miner. Eng. 2015, 70, 178–200. [Google Scholar] [CrossRef]

- Liu, S.Q.; Cao, Y.; Tong, X.; Li, P. Beneficiation of a Fine-sized Cassiterite-bearing Magnetite Ore. Mining Metall. Explor. 2011, 28, 88–93. [Google Scholar] [CrossRef]

- Yang, J.L.; Shuai, Z.C.; Zhou, W.T.; Ma, S.J. Grinding Optimization of Cassiterite-polymetallic Sulfide Ore. Minerals 2019, 9, 134. [Google Scholar] [CrossRef]

- Liu, J. Experimental Study on Grinding Materials of a New Medium with Two Spheres in CheHe Concentrator. Master’s Thesis, Guangxi University, Nanning, China, 2013. (In Chinese). [Google Scholar]

- Zhou, W.T.; Han, Y.X.; Li, Y.J.; Sun, Y.S.; Yang, J.L.; Ma, S.J. Process Mineralogy and Grinding Optimization of Cassiterite Polymetallic Sulphide Ore. J. Cent. South. Univ. (Sci. Tech.) 2019, 50, 1271–1277. (In Chinese) [Google Scholar]

- Sreenivas, T.; Padmanabhan, N.P.H. Surface Chemistry and Flotation of Cassiterite with Alkyl Hydroxamates. Colloids Surf. 2001, 205, 47. [Google Scholar] [CrossRef]

- Qin, W.Q.; Xu, Y.B.; Liu, H.; Ren, L.Y.; Yang, C.R. Flotation and Surface Behavior of Cassiterite with Salicylhydroxamic Acid. Ind. Eng. Chem. Res. 2011, 50, 10778. [Google Scholar] [CrossRef]

- Wu, X.Q.; Zhu, J.G. Selective Flotation of Cassiterite with Benzohydroxamic Acid. Min. Eng. 2006, 19, 1410. [Google Scholar] [CrossRef]

- Duan, X.X. Crushing and Grinding; Metallurgical Industry Press: Beijing, China, 2012; pp. 204–218. (In Chinese) [Google Scholar]

- Faria, P.M.C.; Rajamani, R.K.; Tavares, L.M. Optimization of Solids Concentration in Iron Ore Ball Milling through Modeling and Simulation. Minerals 2019, 9, 366. [Google Scholar] [CrossRef]

- Yin, Z.X.; Peng, Y.X.; Zhu, Z.C.; Yu, Z.F.; Li, T.Q.; Zhao, L.L.; Xu, J. Experimental Study of Charge Dynamics in a Laboratory-scale Ball Mill. P. I. Mech. Eng. C J. Mec. 2018, 232, 3491–3499. [Google Scholar] [CrossRef]

- Ucurum, M.; Ozdemir, A.; Teke, C.; Tekin, I. A Novel Approach to Finding Optimum Operating Conditions of Design Factors for the Grinding Experiment. Particul. Sci. Technol. 2021, 39, 204–212. [Google Scholar] [CrossRef]

| Component | SiO2 | CaO | Fe2O3 | SO3 | Al2O3 | ZnO | K2O | MgO |

|---|---|---|---|---|---|---|---|---|

| Content/% | 45.9 | 28.2 | 8.4 | 7.2 | 4.1 | 2.3 | 0.9 | 0.7 |

| Component | SnO2 | As2O3 | PbO | P2O5 | Sb2O3 | MnO | Others | |

| Content/% | 0.5 | 0.5 | 0.3 | 0.4 | 0.4 | 0.1 | 0.1 |

| Component | SiO2 | CaO | Fe2O3 | SO3 | Al2O3 | ZnO | K2O |

|---|---|---|---|---|---|---|---|

| Content/% | 5.0 | 17.0 | 24.2 | 33.5 | 1.3 | 12.2 | 0.4 |

| Component | MgO | PbO | SnO2 | Sb2O3 | MnO | As2O3 | Others |

| Content/% | 2.9 | 1.8 | 0.1 | 1.3 | 0.1 | 0.1 | 0.1 |

| Particle Size/mm | Tongkeng Ore | Gaofeng Ore | ||

|---|---|---|---|---|

| Yield/% | Cumulative Distribution Under Sieve/% | Yield/% | Cumulative Distribution Under Sieve/% | |

| −1.7 + 1.18 | 19.41 | 100.00 | 24.63 | 100.00 |

| −1.18 + 0.85 | 14.56 | 80.59 | 18.18 | 75.37 |

| −0.85 + 0.6 | 12.13 | 66.03 | 13.78 | 57.18 |

| −0.6 + 0.425 | 9.70 | 53.90 | 11.44 | 43.40 |

| −0.425 + 0.3 | 8.09 | 44.20 | 5.57 | 31.96 |

| −0.3 + 0.212 | 7.55 | 36.11 | 5.87 | 26.39 |

| −0.212 + 0.15 | 5.66 | 28.56 | 4.69 | 20.53 |

| −0.15 + 0.106 | 3.77 | 22.90 | 3.81 | 15.84 |

| −0.106 + 0.075 | 3.23 | 19.13 | 3.23 | 12.02 |

| −0.075 + 0.053 | 3.23 | 15.90 | 2.35 | 8.80 |

| −0.053 + 0.038 | 1.89 | 12.67 | 1.47 | 6.45 |

| −0.038 | 10.78 | 10.78 | 4.99 | 4.99 |

| Total | 100.00 | – | 100.00 | – |

| Grinding Time/min | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 0 | 77.10 | 7.00 | 5.12 | 10.78 | 12.12 | 0 |

| 2 | 46.47 | 15.54 | 10.43 | 27.56 | 25.97 | 20.92 |

| 3 | 33.39 | 18.71 | 13.28 | 34.62 | 31.99 | 29.97 |

| 4 | 21.21 | 20.88 | 15.84 | 42.07 | 36.72 | 37.41 |

| 5 | 9.23 | 22.57 | 18.91 | 49.29 | 41.48 | 44.87 |

| 6 | 5.43 | 18.85 | 21.50 | 54.22 | 40.35 | 44.27 |

| 7 | 1.98 | 14.91 | 20.56 | 62.55 | 35.47 | 39.41 |

| Grinding Concentration/% | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 60 | 13.39 | 19.81 | 18.11 | 48.69 | 37.92 | 40.15 |

| 65 | 10.39 | 22.47 | 18.37 | 48.77 | 40.84 | 43.95 |

| 70 | 9.23 | 22.57 | 18.91 | 49.29 | 41.48 | 44.87 |

| 75 | 10.27 | 20.91 | 18.72 | 50.10 | 39.63 | 42.61 |

| 80 | 12.61 | 20.07 | 17.24 | 50.08 | 37.31 | 39.59 |

| Filling Ratio/% | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 25 | 15.99 | 23.13 | 17.78 | 43.10 | 40.91 | 43.04 |

| 30 | 10.83 | 24.65 | 16.33 | 48.19 | 40.98 | 44.02 |

| 35 | 9.23 | 22.57 | 18.91 | 49.29 | 41.48 | 44.87 |

| 40 | 14.32 | 22.06 | 16.12 | 47.49 | 38.18 | 40.27 |

| 45 | 21.13 | 19.94 | 15.57 | 43.37 | 35.51 | 36.07 |

| Rotational Rate/% | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 65 | 14.14 | 20.72 | 19.85 | 45.29 | 40.57 | 42.99 |

| 70 | 12.33 | 22.49 | 17.94 | 47.24 | 40.43 | 43.15 |

| 75 | 9.23 | 22.57 | 18.91 | 49.29 | 41.48 | 44.87 |

| 80 | 12.34 | 22.52 | 17.95 | 47.28 | 40.47 | 43.18 |

| 85 | 7.87 | 21.25 | 19.35 | 51.44 | 40.61 | 44.13 |

| Grinding Time/min | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 0 | 84.16 | 7.04 | 3.81 | 4.99 | 10.85 | 0.00 |

| 2 | 24.58 | 29.21 | 15.65 | 30.56 | 44.86 | 43.88 |

| 3 | 14.25 | 24.48 | 23.50 | 37.77 | 47.98 | 48.57 |

| 4 | 6.95 | 20.05 | 29.45 | 43.55 | 49.5 | 51.15 |

| 5 | 1.83 | 13.33 | 28.47 | 56.37 | 41.80 | 43.74 |

| 6 | 0.4 | 10.31 | 27.63 | 61.66 | 37.94 | 39.87 |

| 7 | 0.19 | 7.52 | 26.5 | 65.79 | 34.02 | 35.78 |

| Grinding Concentration/% | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 60 | 9.00 | 23.76 | 26.66 | 40.58 | 50.42 | 51.84 |

| 65 | 8.58 | 22.50 | 27.59 | 41.33 | 50.09 | 51.56 |

| 70 | 6.95 | 20.05 | 29.45 | 43.55 | 49.50 | 51.15 |

| 75 | 4.68 | 23.63 | 26.73 | 44.96 | 50.36 | 52.37 |

| 80 | 6.42 | 22.71 | 25.95 | 44.92 | 48.66 | 50.35 |

| Filling Ratio/% | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 25 | 10.89 | 26.55 | 22.82 | 39.74 | 49.37 | 50.49 |

| 30 | 4.43 | 23.08 | 21.41 | 51.09 | 44.48 | 46.22 |

| 35 | 4.68 | 23.62 | 26.73 | 44.96 | 50.36 | 52.37 |

| 40 | 5.34 | 22.96 | 17.18 | 54.52 | 40.14 | 41.52 |

| 45 | 14.17 | 22.74 | 15.47 | 47.62 | 38.20 | 38.29 |

| Rotational Rate/% | Yield/% | E/% | ||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | −0.15 + 0.038 mm | ||

| 65 | 9.99 | 22.87 | 27.76 | 39.38 | 50.63 | 52.07 |

| 70 | 5.88 | 20.90 | 30.48 | 42.74 | 51.38 | 53.42 |

| 75 | 4.68 | 23.62 | 26.74 | 44.96 | 50.36 | 52.37 |

| 80 | 2.82 | 20.58 | 30.17 | 46.43 | 50.75 | 53.03 |

| 85 | 2.52 | 19.53 | 30.56 | 47.39 | 50.09 | 52.38 |

| Levels | Grinding Time X1/min | Grinding Concentration X2/% | Filling Ratio X3/% |

|---|---|---|---|

| −1 | 4 | 65 | 30 |

| 0 | 5 | 70 | 35 |

| 1 | 6 | 75 | 40 |

| Serial Number | Grinding Time X1/min | Grinding Concentration X2/% | Filling Ratio X3/% | Grinding Technical Efficiency Y/% |

|---|---|---|---|---|

| 1 | 4 | 65 | 35 | 39.56 |

| 2 | 6 | 65 | 35 | 44.2 |

| 3 | 4 | 75 | 35 | 37.36 |

| 4 | 6 | 75 | 35 | 42.17 |

| 5 | 4 | 70 | 30 | 39.39 |

| 6 | 6 | 70 | 30 | 43.81 |

| 7 | 4 | 70 | 40 | 35.59 |

| 8 | 6 | 70 | 40 | 42.29 |

| 9 | 5 | 65 | 30 | 41.93 |

| 10 | 5 | 75 | 30 | 43.61 |

| 11 | 5 | 65 | 40 | 44.62 |

| 12 | 5 | 75 | 40 | 37.33 |

| 13 | 5 | 70 | 35 | 45.25 |

| 14 | 5 | 70 | 35 | 45.11 |

| 15 | 5 | 70 | 35 | 44.92 |

| 16 | 5 | 70 | 35 | 44.89 |

| 17 | 5 | 70 | 35 | 45.02 |

| Variance Source | Sum of Squares | Degree of Freedom | Standard Deviation | F Value | p Value |

|---|---|---|---|---|---|

| Model | 159.52 | 9 | 17.72 | 118.50 | <0.0001 |

| X1 | 52.89 | 1 | 52.89 | 353.60 | <0.0001 |

| X2 | 12.10 | 1 | 12.10 | 80.91 | <0.0001 |

| X3 | 9.92 | 1 | 9.92 | 66.34 | <0.0001 |

| X1X2 | 0.0072 | 1 | 0.0072 | 0.0483 | 0.8323 |

| X1X3 | 1.30 | 1 | 1.30 | 8.69 | 0.0215 |

| X2X3 | 20.12 | 1 | 20.12 | 134.48 | <0.0001 |

| X12 | 35.63 | 1 | 35.63 | 238.21 | <0.0001 |

| X22 | 7.19 | 1 | 7.19 | 48.05 | 0.0002 |

| X32 | 14.55 | 1 | 14.55 | 97.28 | <0.0001 |

| Residual | 1.05 | 7 | 0.1496 | ||

| Lack of Fit Value | 0.9608 | 3 | 0.3203 | ||

| Pure Error | 0.0863 | 4 | 0.0216 | R2 = 99.35% | |

| Total Deviation | 160.57 | 16 | C.V. = 0.9169% |

| Conditions and Results | Grinding Time 5.4 min, Grinding Concentration 67%, Filling Ratio 35%, Rotational Rate 75% | |||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | E/% | Error Rate/% | |

| Predicted Value | – | – | – | – | 45.896 | – |

| Test Value 1 | 8.79% | 22.48% | 19.50% | 49.23% | 45.504 | 0.86 |

| Test Value 2 | 8.09% | 22.58% | 19.62% | 49.71% | 45.873 | 0.05 |

| Levels | Grinding Time X1/min | Grinding Concentration X2/% | Filling Ratio X3/% |

|---|---|---|---|

| −1 | 3 | 70 | 30 |

| 0 | 4 | 75 | 35 |

| 1 | 5 | 80 | 40 |

| Serial Number | Grinding Time X1/min | Grinding Concentration X2/% | Filling Ratio X3/% | Grinding Technical Efficiency Y/% |

|---|---|---|---|---|

| 1 | 3 | 70 | 35 | 52.13 |

| 2 | 5 | 70 | 35 | 49.13 |

| 3 | 3 | 80 | 35 | 51.08 |

| 4 | 5 | 80 | 35 | 48.41 |

| 5 | 3 | 75 | 30 | 50.65 |

| 6 | 5 | 75 | 30 | 48.05 |

| 7 | 3 | 75 | 40 | 49.86 |

| 8 | 5 | 75 | 40 | 45.51 |

| 9 | 4 | 70 | 30 | 52.58 |

| 10 | 4 | 80 | 30 | 52.25 |

| 11 | 4 | 70 | 40 | 51.08 |

| 12 | 4 | 80 | 40 | 50.18 |

| 13 | 4 | 75 | 35 | 54.26 |

| 14 | 4 | 75 | 35 | 54.15 |

| 15 | 4 | 75 | 35 | 54.20 |

| 16 | 4 | 75 | 35 | 54.09 |

| 17 | 4 | 75 | 35 | 54.39 |

| Variance Source | Sum of Squares | Degree of Freedom | Standard Deviation | F Value | p Value |

|---|---|---|---|---|---|

| Model | 106.55 | 9 | 11.84 | 275.20 | <0.0001 |

| X1 | 19.91 | 1 | 19.91 | 462.78 | <0.0001 |

| X2 | 1.12 | 1 | 1.12 | 26.15 | 0.0014 |

| X3 | 5.95 | 1 | 5.95 | 138.34 | <0.0001 |

| X1X2 | 0.0272 | 1 | 0.0272 | 0.6329 | 0.4524 |

| X1X3 | 0.7656 | 1 | 0.7656 | 17.80 | 0.0039 |

| X2X3 | 0.0812 | 1 | 0.0812 | 1.89 | 0.2118 |

| X12 | 52.10 | 1 | 52.10 | 1211.18 | <0.0001 |

| X22 | 1.11 | 1 | 1.11 | 25.73 | 0.0014 |

| X32 | 20.06 | 1 | 20.06 | 466.32 | <0.0001 |

| Residual | 0.3011 | 7 | 0.0430 | ||

| Lack of Fit Value | 0.2485 | 3 | 0.0828 | ||

| Pure Error | 0.0527 | 4 | 0.0132 | R2 = 99.72% | |

| Total Deviation | 106.85 | 16 | C.V. = 0.4044% |

| Conditions and Results | Grinding Time 3.8 min, Grinding Concentration 73%, Filling Ratio 34%, Rotational Rate 70% | |||||

|---|---|---|---|---|---|---|

| +0.15 mm | −0.15 + 0.075 mm | −0.075 + 0.038 mm | −0.038 mm | E/% | Error Rate/% | |

| Predicted Value | – | – | – | – | 54.528 | – |

| Test Value 1 | 7.80% | 23.62% | 28.78% | 39.80% | 54.091 | 0.81 |

| Test Value 2 | 7.37% | 23.74% | 28.64% | 40.25% | 54.132 | 0.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Li, H.; Shuai, Z.; Yang, J.; Deng, X.; Xu, W. Research on Grinding Law and Grinding Parameters Optimization of Polymetallic Complex Ores. Minerals 2022, 12, 1283. https://doi.org/10.3390/min12101283

Ma S, Li H, Shuai Z, Yang J, Deng X, Xu W. Research on Grinding Law and Grinding Parameters Optimization of Polymetallic Complex Ores. Minerals. 2022; 12(10):1283. https://doi.org/10.3390/min12101283

Chicago/Turabian StyleMa, Shaojian, Hengjun Li, Zhichao Shuai, Jinlin Yang, Xingjian Deng, and Wenzhe Xu. 2022. "Research on Grinding Law and Grinding Parameters Optimization of Polymetallic Complex Ores" Minerals 12, no. 10: 1283. https://doi.org/10.3390/min12101283

APA StyleMa, S., Li, H., Shuai, Z., Yang, J., Deng, X., & Xu, W. (2022). Research on Grinding Law and Grinding Parameters Optimization of Polymetallic Complex Ores. Minerals, 12(10), 1283. https://doi.org/10.3390/min12101283