Research on Automatic Construction Method of Three-Dimensional Complex Fault Model

Abstract

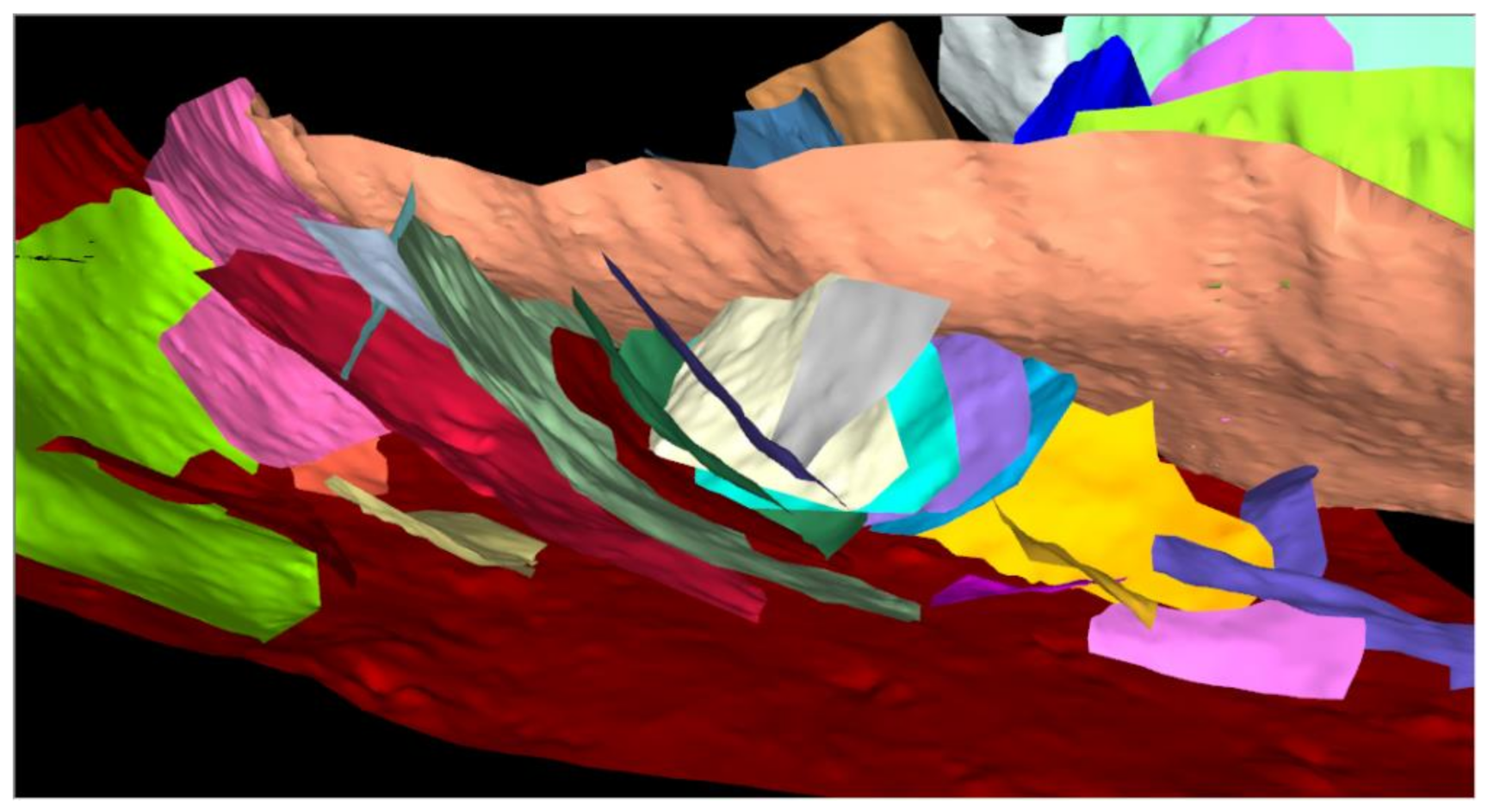

:1. Introduction

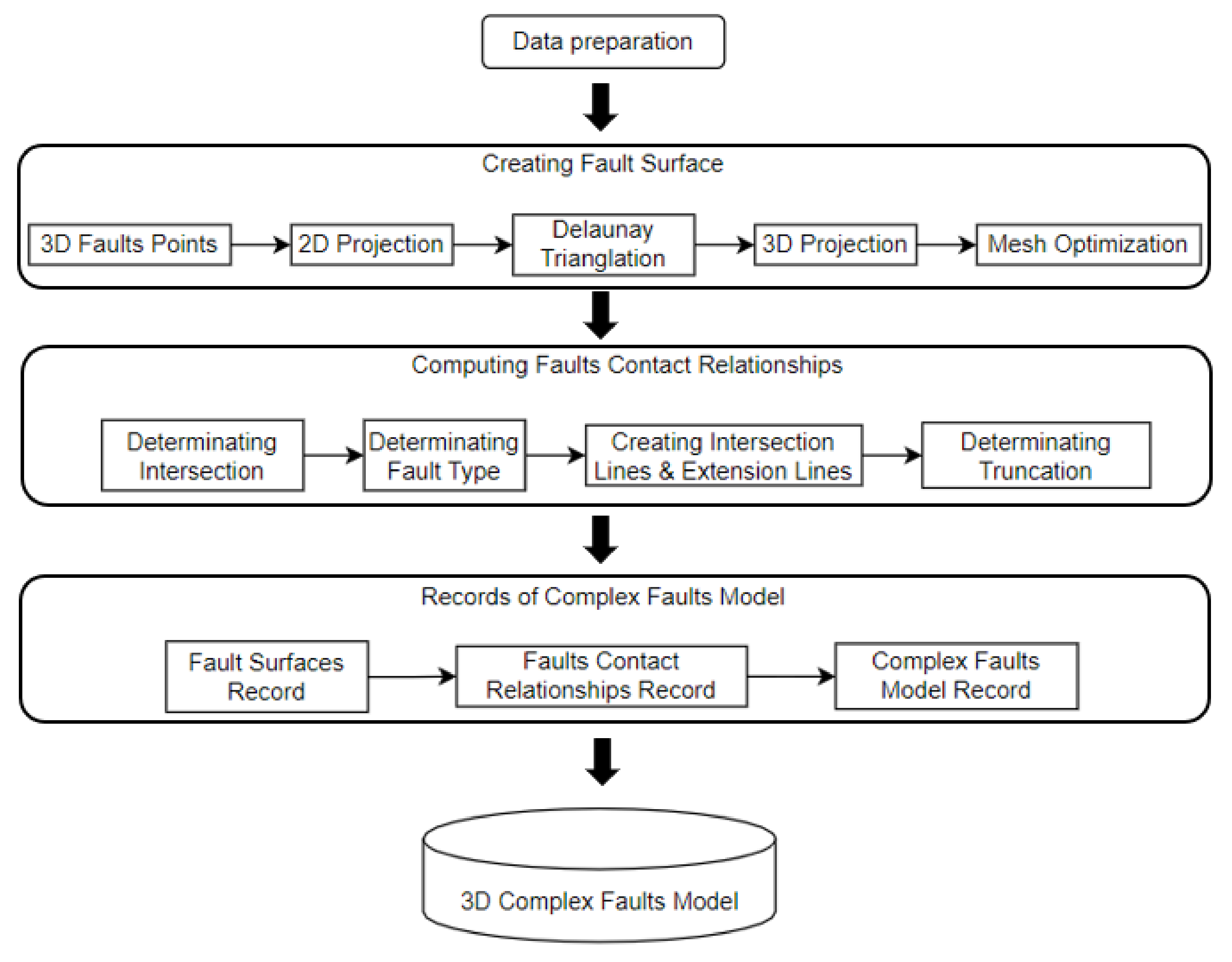

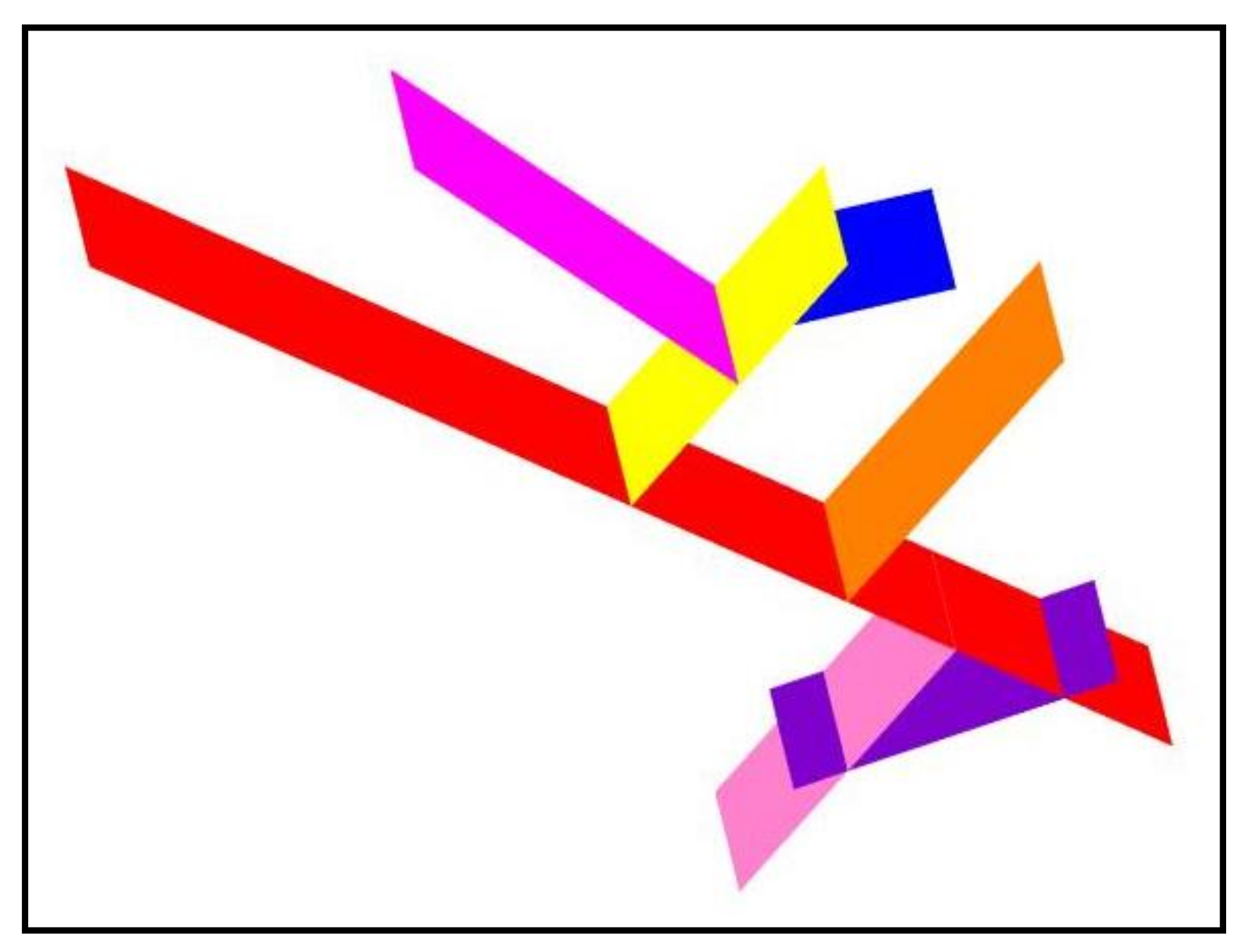

2. Automatic Construction Process of Complex Fault Model

2.1. Data Preparation

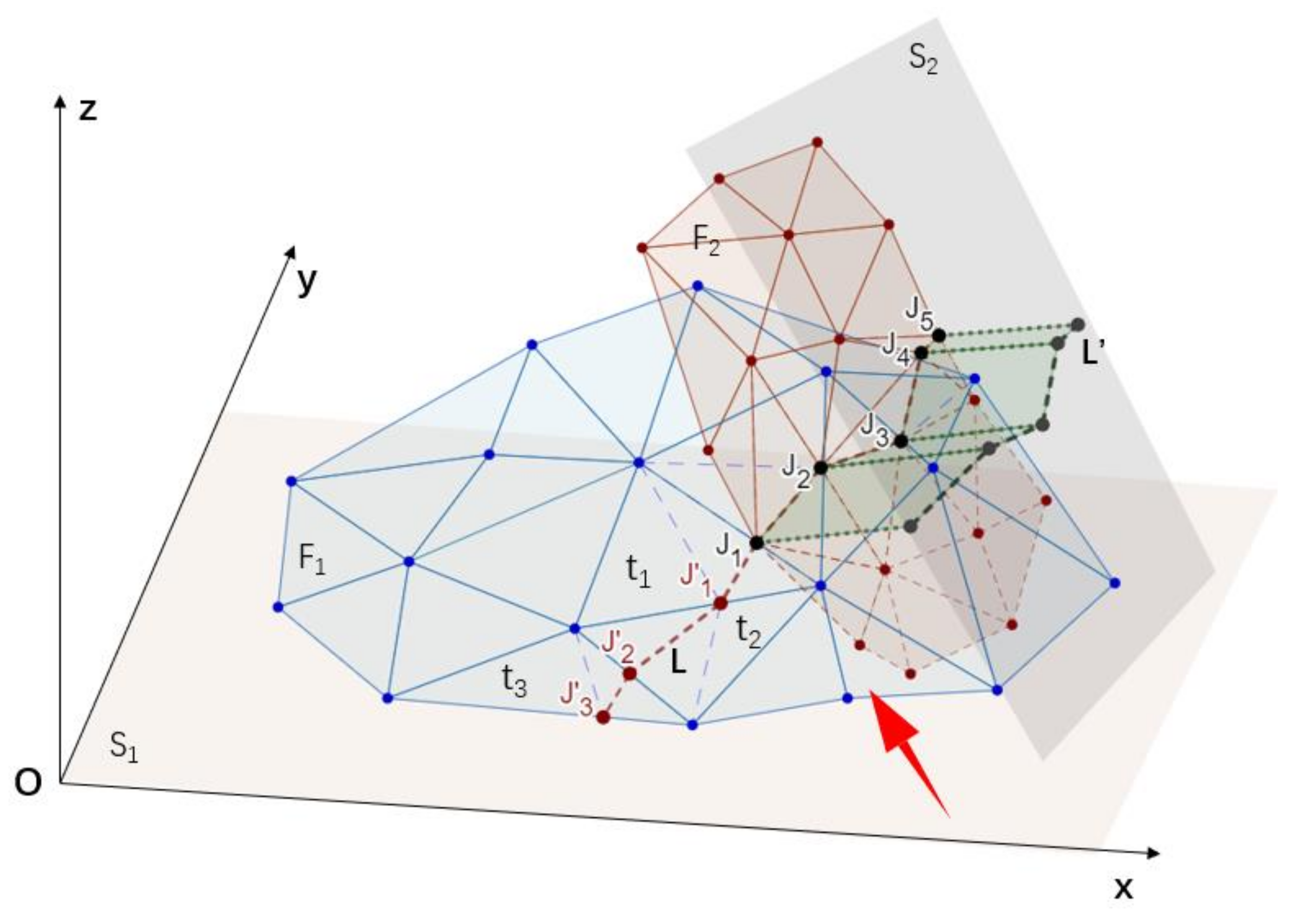

2.2. 3D Fault Surface Model Construction

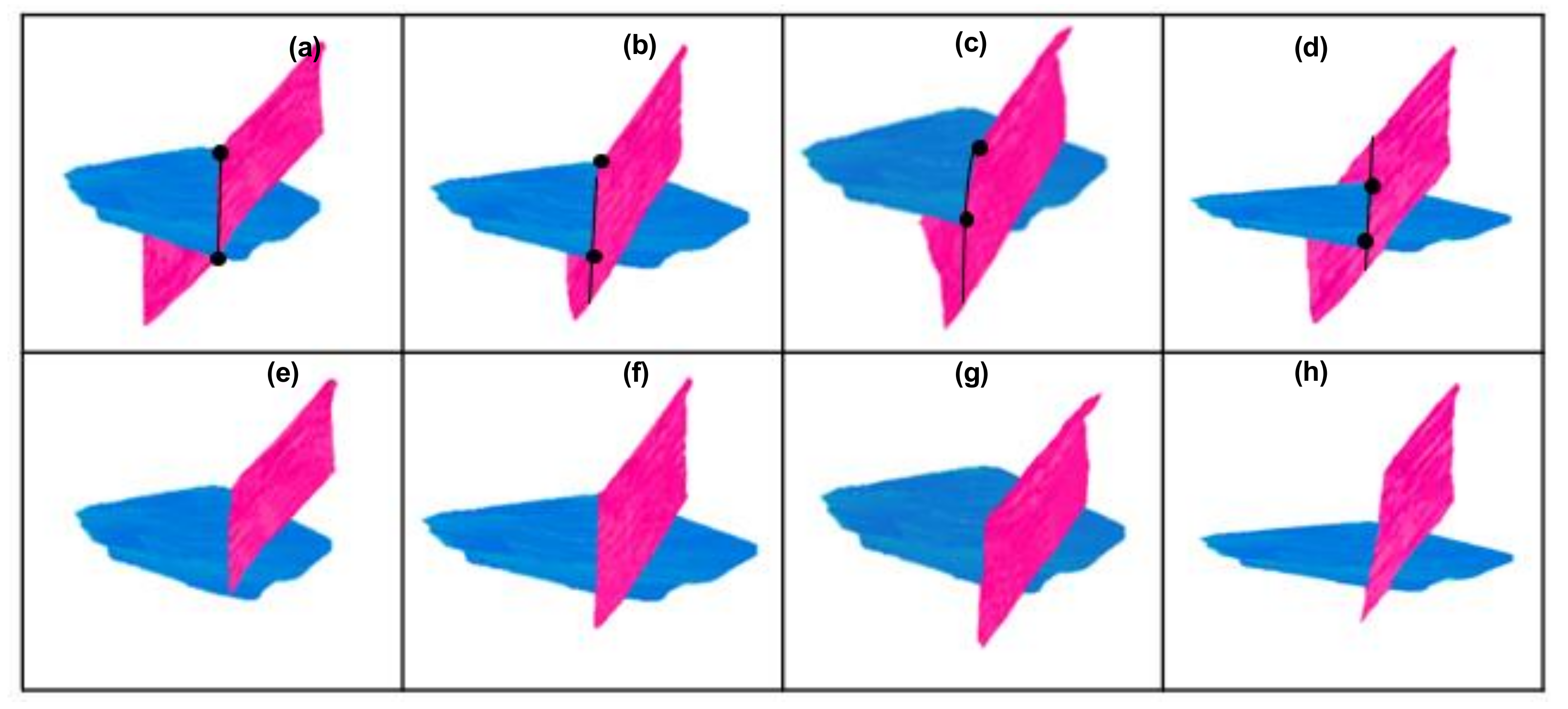

2.3. Determination of Fault-Fault Contact Relationship

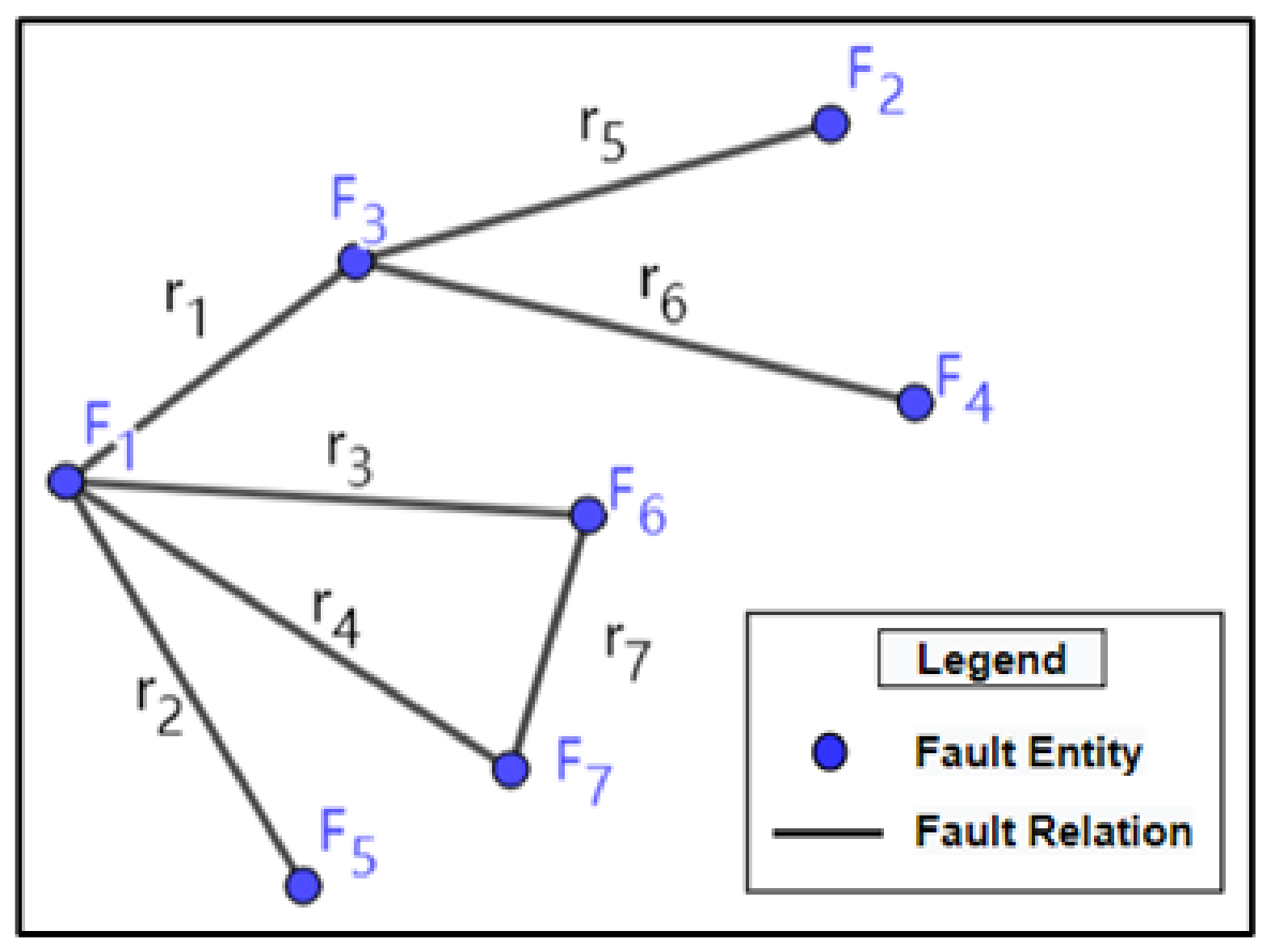

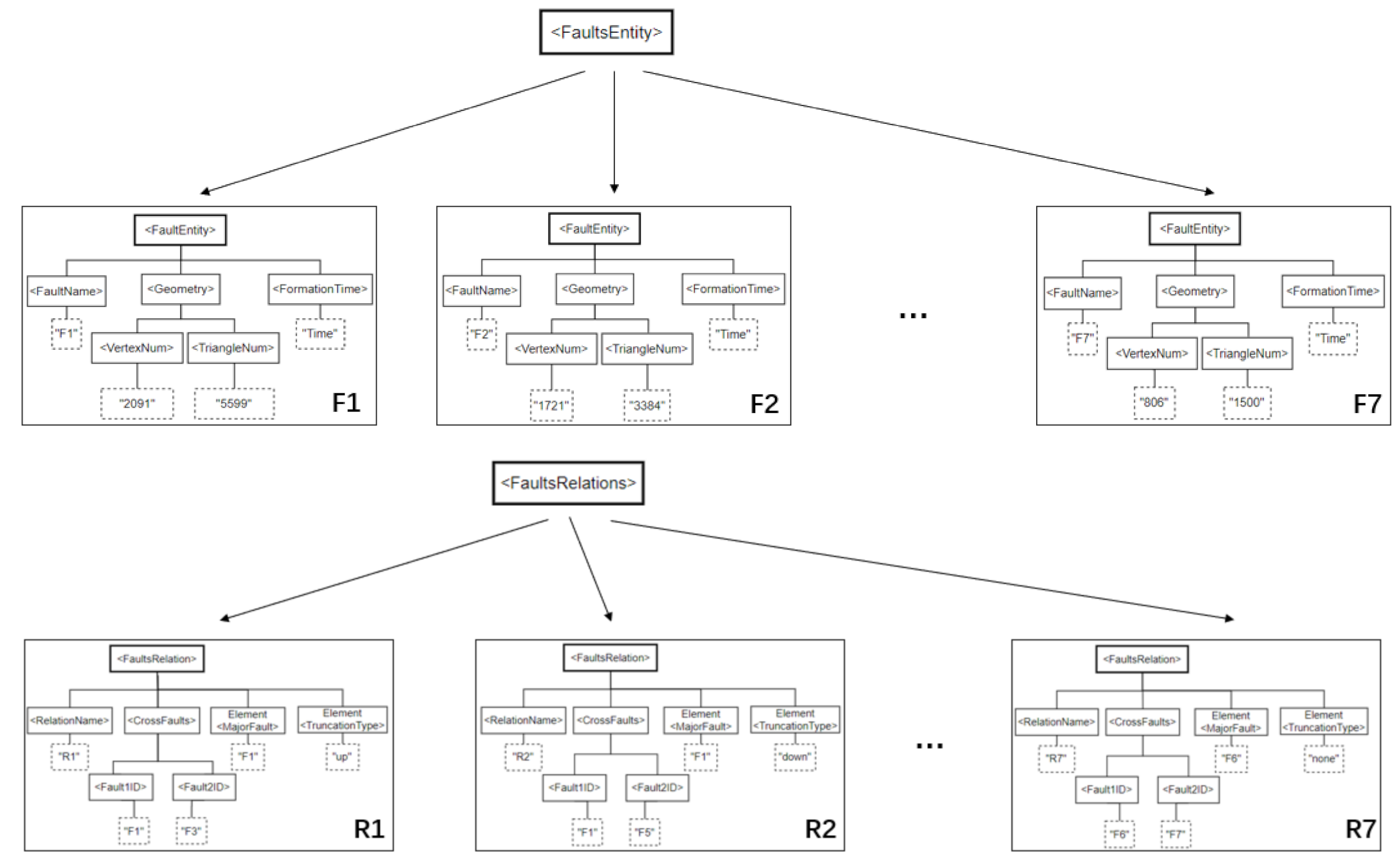

2.4. Recording of Complex Fault Model

3. Automatic Construction Method of Complex Fault Model

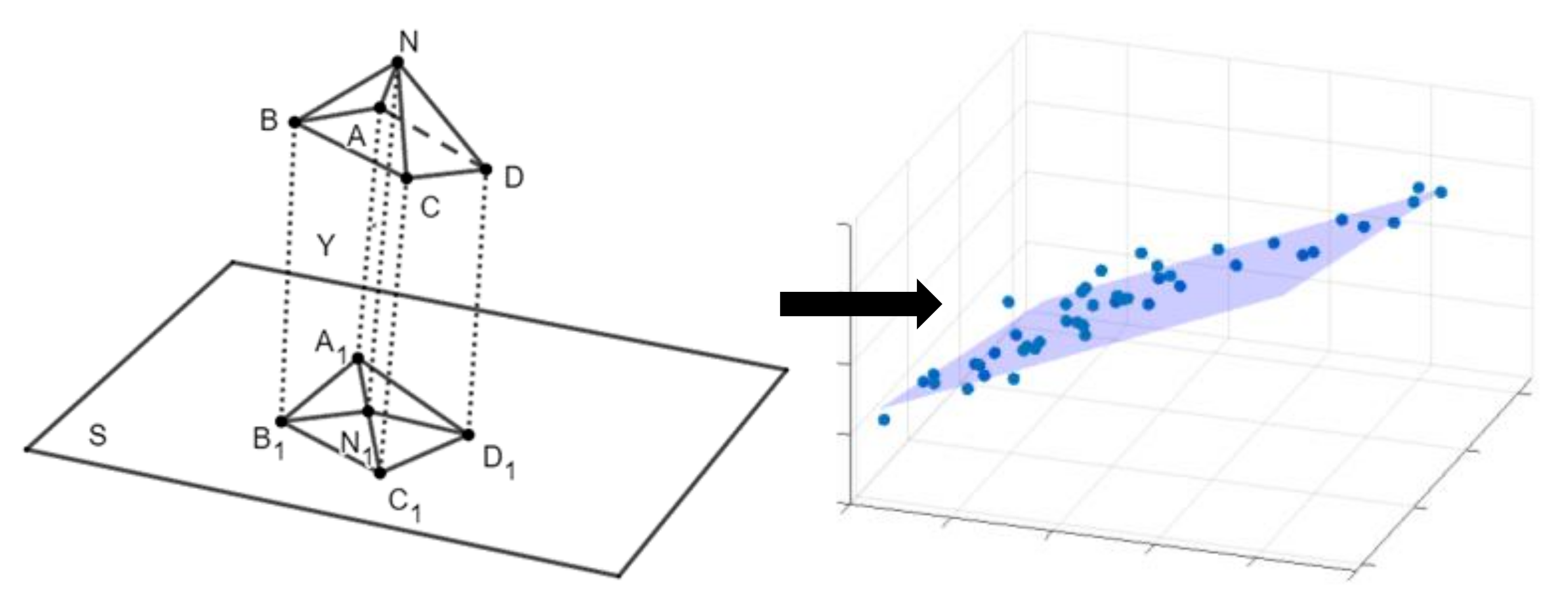

3.1. Automatic Generation Method of Fault Surface

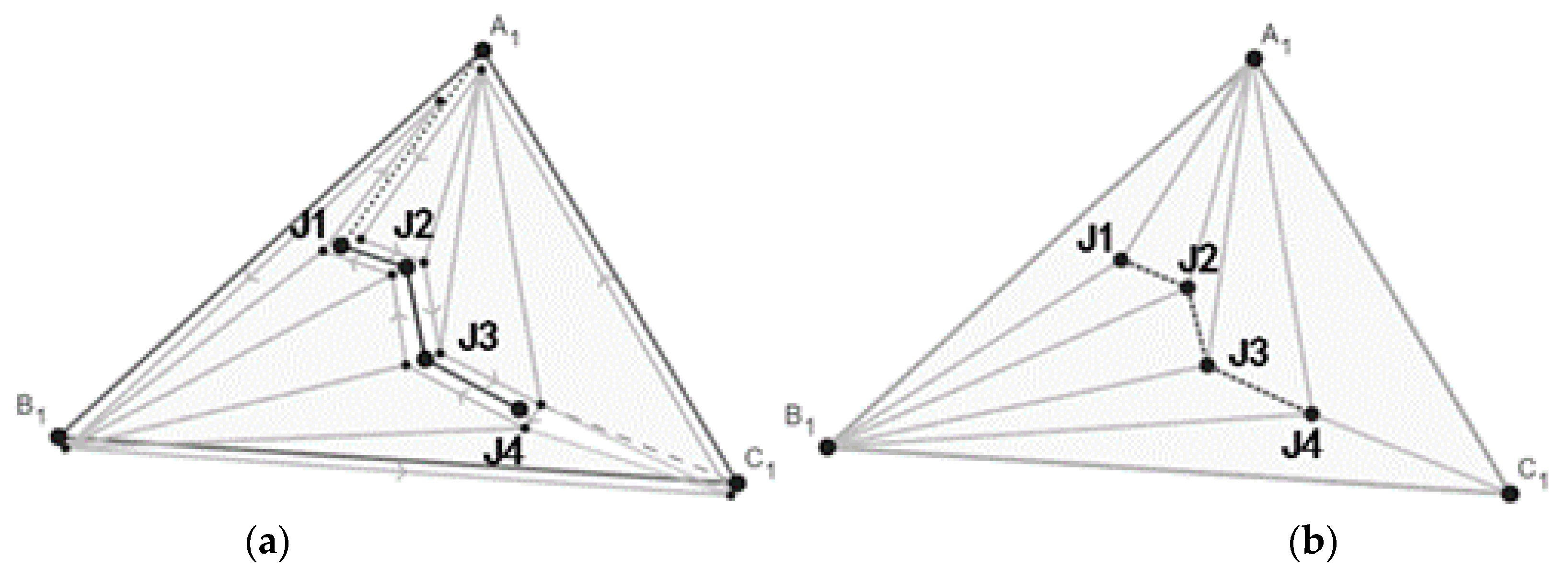

- Calculate the centroid coordinates and 2D fitting plane normal vector of the 3D fault point dataset. The plane equation () can be calculated according to the centroid coordinates and normal vector. Project the 3D points’ set to the 2D surface one by one and perform triangulation to generate a 2D triangular mesh surface.

- Based on the one-to-one correspondence between the points in the 3D space and the 2D space, the topological relationship of the two-dimensional triangulation model is mapped to the 3D space to form a 3D fault surface.

- Optimize the fault surface model, reduce the deformed triangular grid unit, and ensure the quality of the grid.

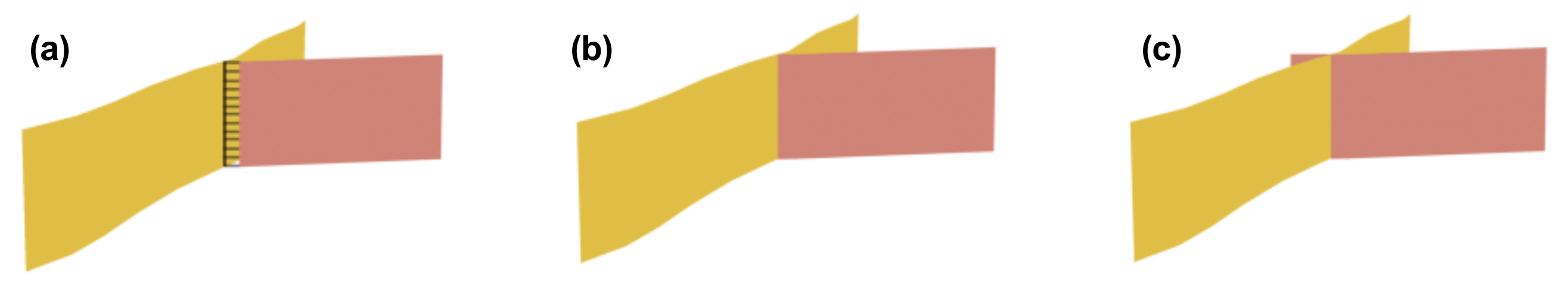

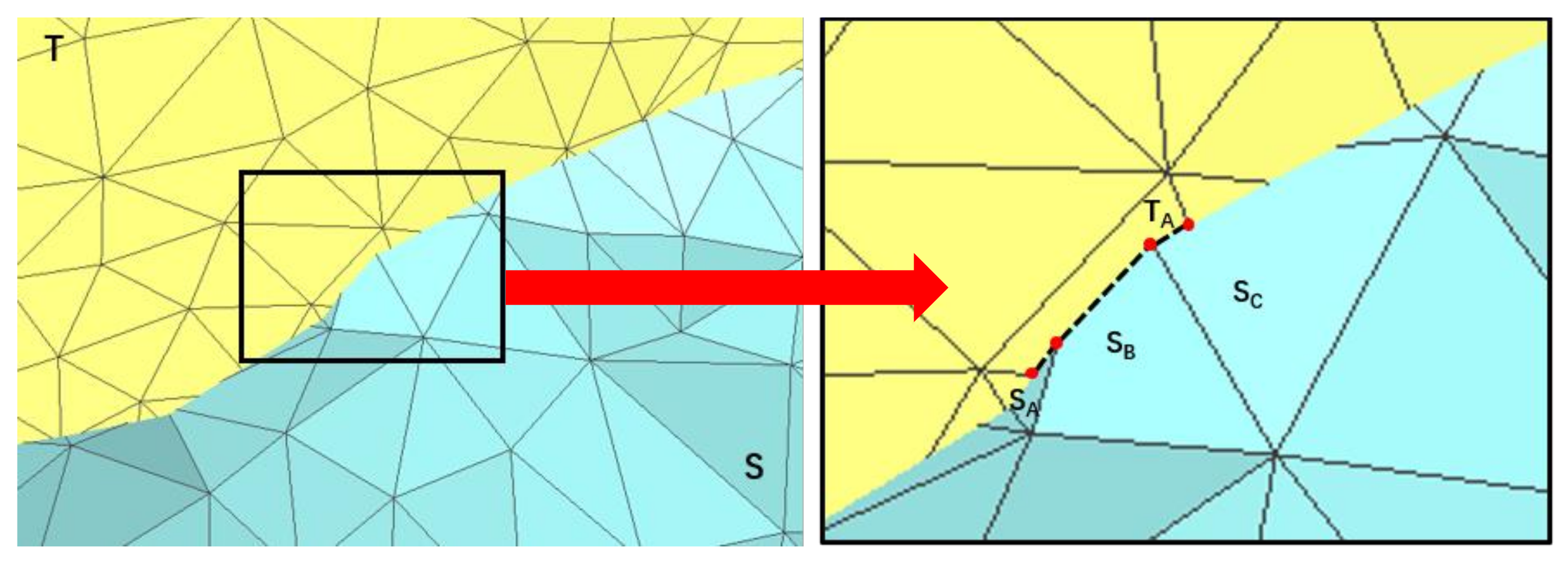

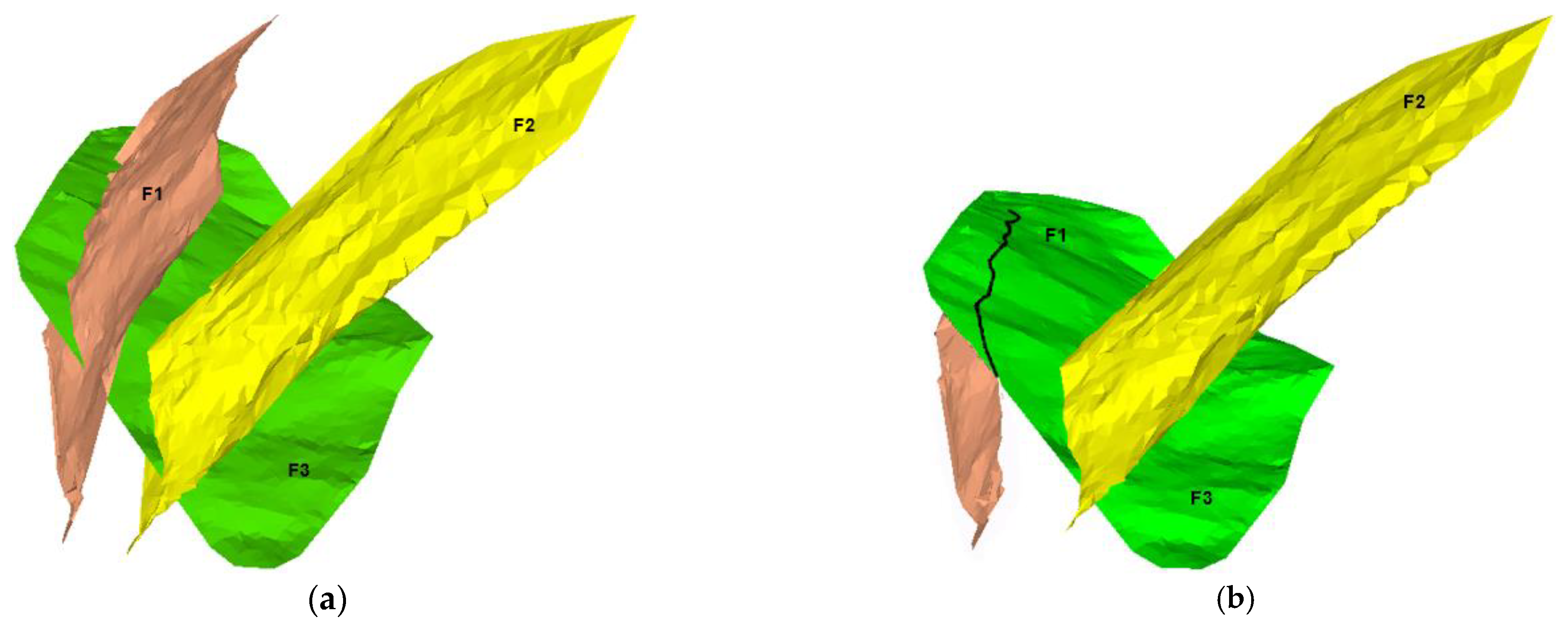

3.2. Automatic Determination Method of Fault-Fault Contact Relationship

3.2.1. Determining the Type of the Fault

3.2.2. Calculation of Intersection & Extension Line of Fault Surface

- Record the intersecting triangle patches in each fault surface.

- Select one of the fault surfaces and calculate the intersection points on each triangle plane recorded in Step 1. One triangular patch may intersect with multiple triangular patches, resulting in multiple intersection points (Figure 6).

- Based on the topological relationship between the triangular patches, all the intersection points on the fault surface are related to generate the intersection line.

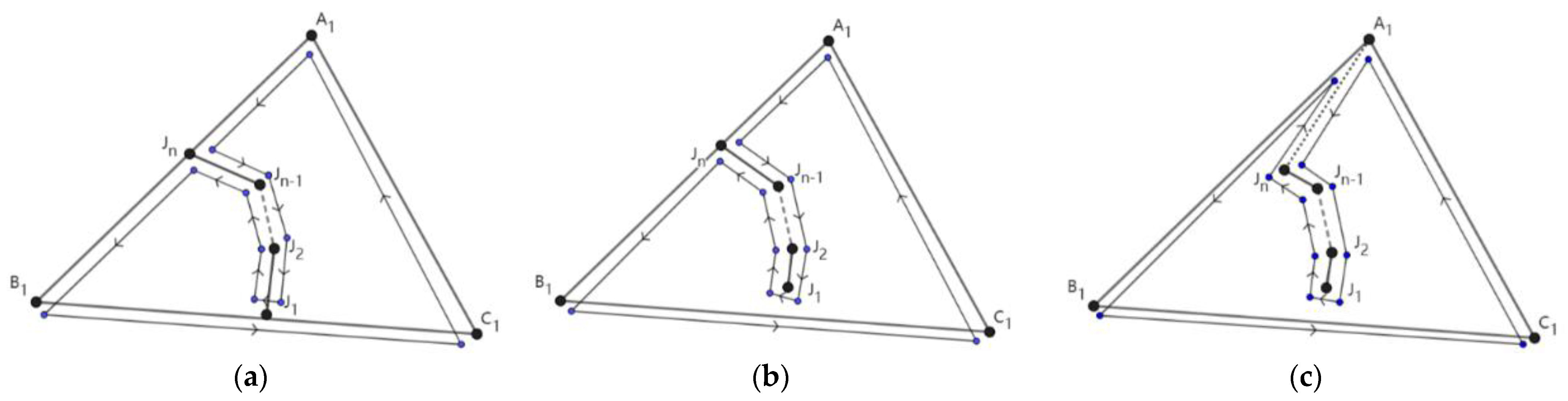

3.2.3. Updating Geometrical Topological Relations with Ear Clipping Algorithm

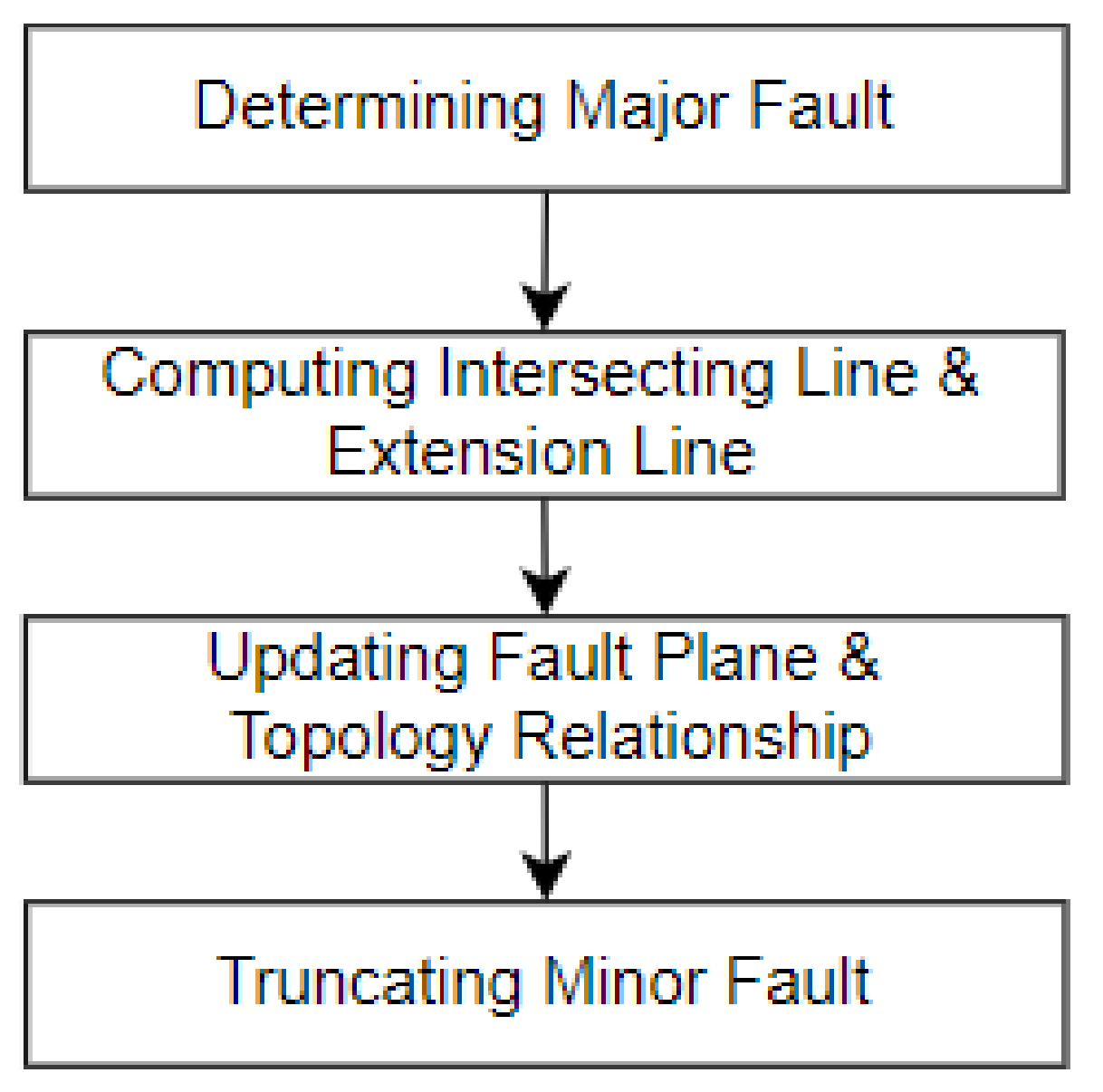

3.2.4. Judging the Truncated Part

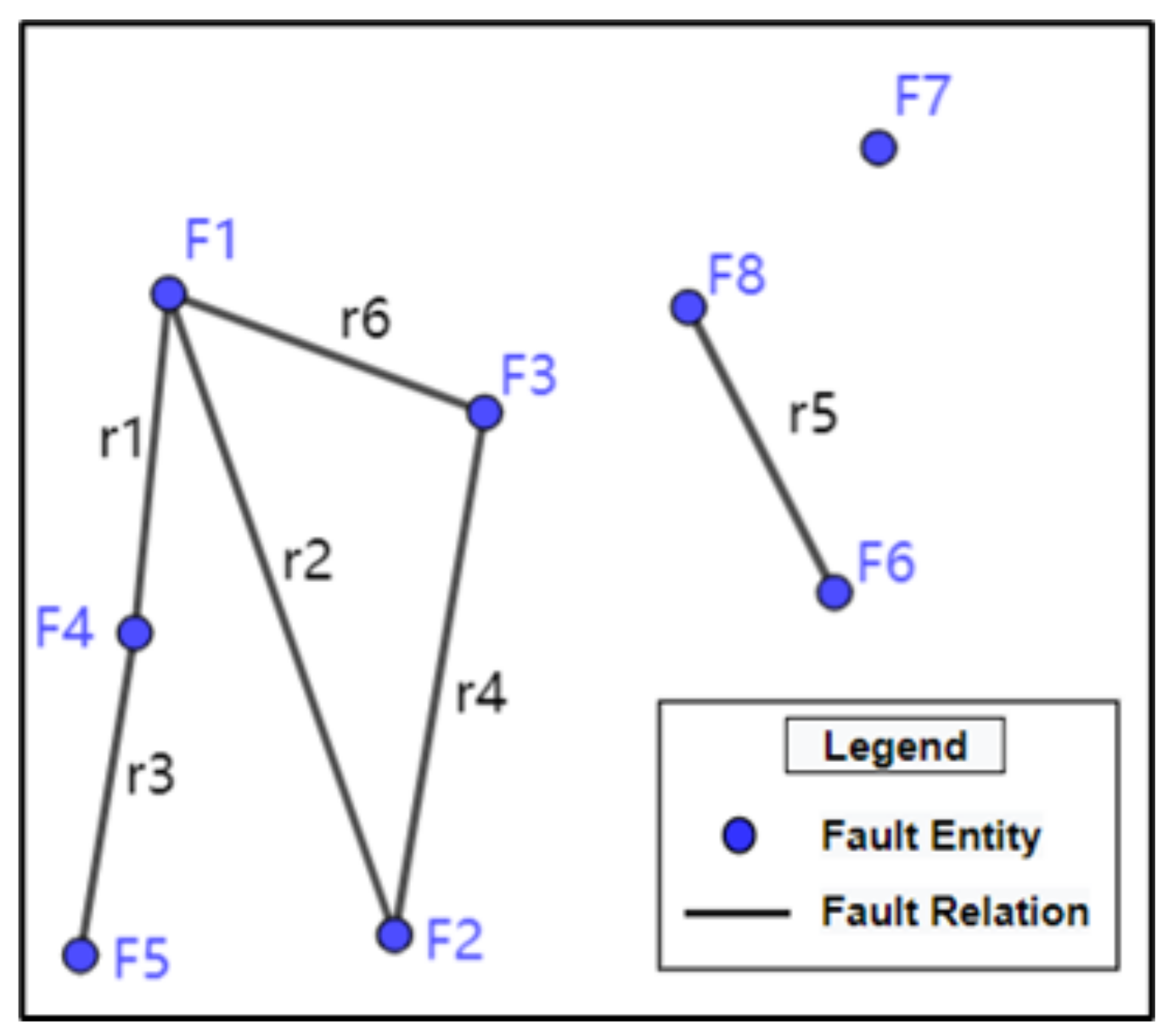

3.3. Complex Fault Model Recording Methods

3.3.1. Record the Fault Surfaces

3.3.2. Record the Fault-Fault Contact Relationship

3.3.3. Record the Complex Fault Model

- Remove isolated fault entity points and fault entity points with only two fault entities connected.

- Process the remaining connected fault entities sequentially. The degree of the fault entity is in the fault-fault contact relationship; if , then is the major fault and is the minor fault; otherwise, it remains unchanged.

- If a circle is present, a self-truncating fault exists. The judgment of major and minor faults of self-truncating faults is too complicated, so they are not truncated, and its truncation label is marked as ‘none.’

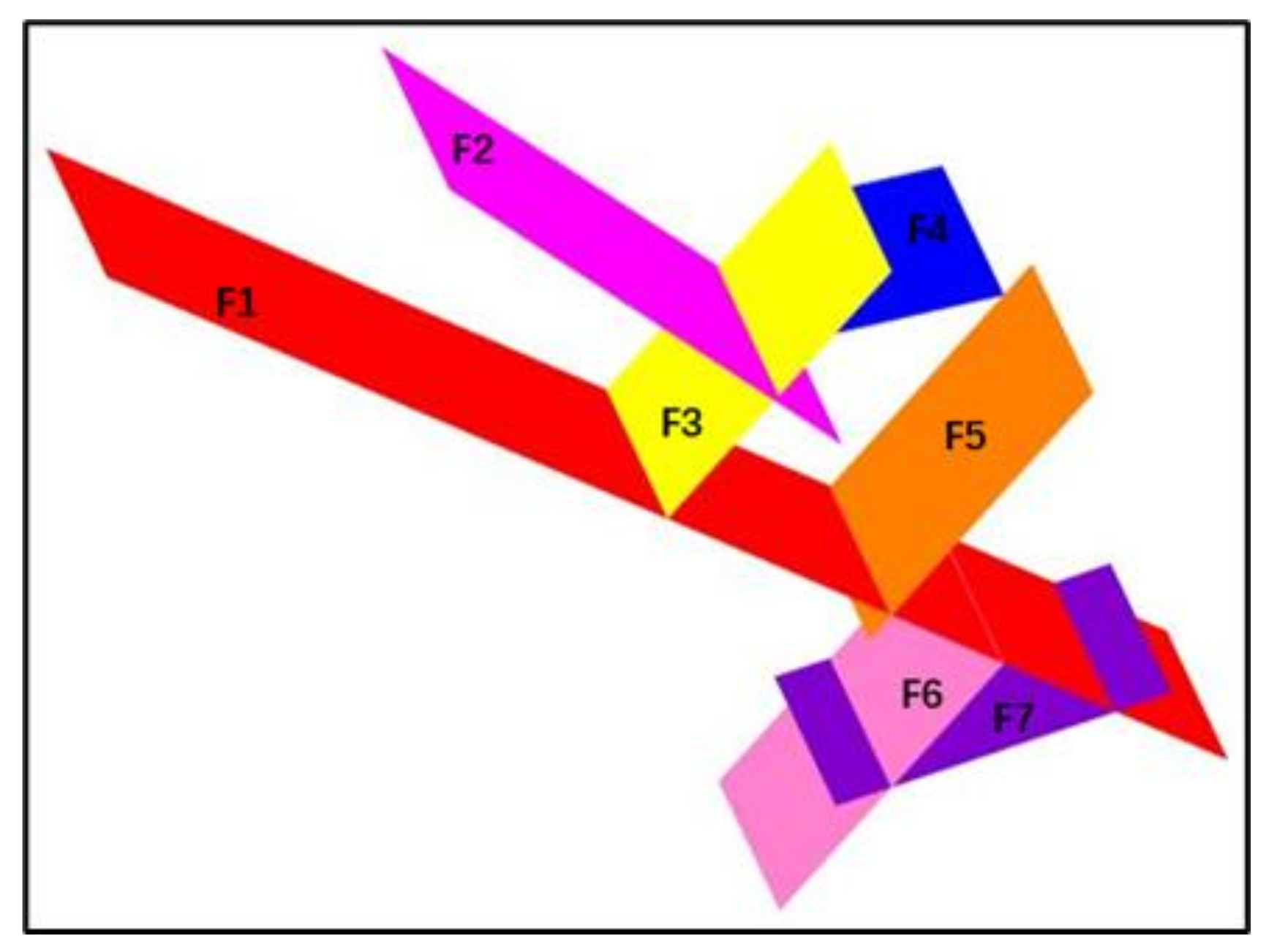

4. Examples of 3D Complex Fault Model Construction

- Generate fault-fault contact relationship entities.

- 2.

- Generate a graph model of a complex fault structure.

- 3.

- Update the label of the major fault and minor fault.

5. Discussion and Conclusions

- It can automatically establish complex fault type such as x-shaped faults, multilevel y-shaped or λ-shaped faults, and self-truncating faults.

- It can automatically determine the fault-fault contact relationship of complex faults and independently truncate the minor faults, which greatly reduces the degree of manual participation in the model building process.

- XML was used to record complex fault models’ information. It can be converted with a graph structure to facilitate the analysis of the contact relationship between faults in a visual environment. Prior geological knowledge can be expressed in XML and directly participate in model construction, simplifying modeling steps and improving modeling efficiency.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Caumon, G.; Collon-Drouaillet, P.; de Veslud, C.L.; Viseur, S.; Sausse, J. Surface-Based 3D Modeling of Geological Structures. Math. Geosci. 2009, 41, 927–945. [Google Scholar] [CrossRef] [Green Version]

- Jessell, M.; Ailleres, L.; De Kemp, E.; Lindsay, M.; Wellmann, F.; Hillier, M.; Martin, R. Next Generation Three-Dimensional Geologic Modeling and Inversion. Soc. Econ. Geol. Spec. Publ. 2014, 18, 261–272. [Google Scholar]

- Wellmann, F.; Caumon, G. 3-D Structural geological models: Concepts, methods, and uncertainties. Adv. Geophys. 2018, 59, 1–121. [Google Scholar]

- Jessell, M.W. “Noddy”—An interactive Map Creation Package. Master’s Thesis, Imperial College of Science and Technology, London, UK, 1981. [Google Scholar]

- Jessell, M.W.; Valenta, R.K. Structural geophysics: Integrated structural and geophysical modelling. Comput. Methods Geosci. 1996, 15, 303–324. [Google Scholar]

- Godefroy, G.; Caumon, G.; Ford, M.; Laurent, G.; Jackson, C.A.L. A parametric fault displacement model to introduce kinematic control into modeling faults from sparse data. Interpret. J. Subsurf. Charact. 2018, 6, B1–B13. [Google Scholar] [CrossRef]

- Grose, L.; Ailleres, L.; Laurent, G.; Caumon, G.; Jessell, M.; Armit, R. Realistic modelling of faults in LoopStructural 1.0. Geosci. Model Dev. Discuss. 2021, 1–26. [Google Scholar] [CrossRef]

- Wang, Z.G.; Qu, H.G.; Wu, Z.X.; Wang, X.H. Geo3DML: A standard-based exchange format for 3D geological models. Comput. Geosci. 2018, 110, 54–64. [Google Scholar] [CrossRef]

- Wang, Z.G.; Qu, H.G.; Wu, Z.X.; Yang, H.J.; Du, Q.L. Formal representation of 3D structural geological models. Comput. Geosci. 2016, 90, 10–23. [Google Scholar] [CrossRef]

- Jessell, M.; Ogarko, V.; Lindsay, M.; Joshi, R.; Pirot, G. Automated geological map deconstruction for 3D model construction. Geosci. Model Dev. Discuss. 2021, 1–35. [Google Scholar] [CrossRef]

- Wu, X.; Hale, D. 3D seismic image processing for faults. Geophysics 2016, 81, IM1–IM11. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Shi, Y.; Fomel, S. Using Synthetic Data Sets to Train a Neural Network for Three-Dimensional Seismic Fault Segmentation. U.S. Patent No. US20210158104A1, 27 May 2021. [Google Scholar]

- Qi, J.; Machado, G.; Marfurt, K. A workflow to skeletonize faults and stratigraphic features. Geophysics 2017, 82, O57–O70. [Google Scholar] [CrossRef]

- Wei, K. 3D Fast Fault Restoration. U.S. Patent No. US 7,480,205 B2, 20 January 2009. [Google Scholar]

- Lepage, F.L.; Souche, A. Faulted Geological Structures Containing Unconformities. U.S. Patent No. 9,378,312, 12 September 2013. [Google Scholar]

- Thom, J.; Hocker, C. 3-D Grid Types in Geomodeling and Simulation–How the Choice of the Model Container Determines Modeling Results Grid Types in Geological Modeling. In Proceedings of the AAPG Annual Convention and Exhibition, Denver, CO, USA, 7–10 June 2009. [Google Scholar]

- Al-shamali, A.; Al-Mayyas, E.A.; Murthy, N.; Verma, N.K.; Al-Sammak, I.; Zhou, C.; Perumalla, S.V.; Shinde, A.L. Geomechanical Characterization of a Matured Deep Jurassic Carbonate Reservoir: Explaining stress effects on production induced Fault Slip and Reservoir Development. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 14–16 September 2015. [Google Scholar] [CrossRef]

- Qu, D.; Roe, P.; Tveranger, J. A method for generating volumetric fault zone grids for pillar gridded reservoir models. Comput. Geosci. 2015, 81, 28–37. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.Y.; Li, Y.H.; Li, Z.Y. Methods of Fault Modeling by Well-to-Seismic Integration. Appl. Mech. Mater. 2015, 733, 178–181. [Google Scholar] [CrossRef]

- Prothro, L.B.; Wagoner, J. Geologic Framework Model for the Dry Alluvium Geology (DAG) Experiment Testbed, Yucca Flat; Nevada National Security Site (NNSS): North Las Vegas, NV, USA, 2020. [Google Scholar] [CrossRef]

- Abbott, W.E. Method and Apparatus for Determining Geologic Relationships for Intersecting Faults. U.S. Patent No. 5,982,707, 9 November 1999. [Google Scholar]

- Caumon, G.; Lepage, F.; Sword, C.H.; Mallet, J.L. Building and editing a sealed geological model. Math. Geol. 2004, 36, 405–424. [Google Scholar] [CrossRef]

- Tertois, A.L.; Mallet, J.L. Editing faults within tetrahedral volume models in real time. Geol. Soc. Lond. Spec. Publ. 2007, 292, 89–101. [Google Scholar] [CrossRef]

- Graf, K.E.; Vassilev, A.T. Automatic Non-Artificially Extended Fault Surface Based Horizon Modeling System, Part I. U.S. Patent No 6,014,343, 11 January 2000. [Google Scholar]

- Hoffman, K.S.; Neave, J.W.; Nilsen, E.H. Building Complex Structural Frameworks. In Proceedings of the International Oil Conference and Exhibition in Mexico, Veracruz, Mexico, 27–30 June 2007. [Google Scholar] [CrossRef]

- Hoffman, K.S.; Neave, J.W. The fused fault block approach to fault network modelling. Geol. Soc. Lond. Spec. Publ. 2007, 292, 75–87. [Google Scholar] [CrossRef]

- Neave, J.W. Analysis and Characterization of Fault Networks. U.S. Patent No. US 7,512,529 B2, 31 March 2009. [Google Scholar]

- Nyberg, B.; Nixon, C.W.; Sanderson, D.J. NetworkGT: A GIS tool for geometric and topological analysis of two-dimensional fracture networks. Geosphere 2018, 14, 1618–1634. [Google Scholar] [CrossRef] [Green Version]

- Sanderson, D.J.; Peacock, D.C.P.; Nixon, C.W.; Rotevatn, A. Graph theory and the analysis of fracture networks. J. Struct. Geol. 2019, 125, 155–165. [Google Scholar] [CrossRef] [Green Version]

- Morley, C.K.; Binazirnejad, H. Investigating polygonal fault topological variability: Structural causes vs image resolution. J. Struct. Geol. 2020, 130, 103930. [Google Scholar] [CrossRef]

- Thiele, S.T.; Jessell, M.W.; Lindsay, M.; Ogarko, V.; Wellmann, F.; Pakyuz-Charrier, E. The topology of geology 1: Topological analysis. J. Struct. Geol. 2016, 91, 27–38. [Google Scholar] [CrossRef]

- Thiele, S.T.; Jessell, M.W.; Lindsay, M.; Wellmann, F.; Pakyuz-Charrier, E. The topology of geology 2: Topological uncertainty. J. Struct. Geol. 2016, 91, 74–87. [Google Scholar] [CrossRef]

- Godefroy, G.; Caumon, G.; Laurent, G.; Bonneau, F. Structural Interpretation of Sparse Fault Data Using Graph Theory and Geological Rules. Math. Geol. 2019, 51, 1091–1107. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Pan, M.; Yang, Y.; Cao, K.; Wu, G. Research and Application of the Three-Dimensional Complex Fault Network Modeling. Acta Sci. Nat. Univ. Pekin. 2015, 51, 79–85. [Google Scholar]

- W3C. Extensible Markup Language (XML); W3C Standards. 2015. Available online: www.w3.org/standards/xml/core (accessed on 17 August 2021).

- Lee, D.T.; Schachter, B.J. Two algorithms for constructing a Delaunay triangulation. Int. J. Parallel Program. 1980, 9, 219–242. [Google Scholar] [CrossRef]

- Mei, G.; Tipper, J.C.; Xu, N. Ear-Clipping Based Algorithms of Generating High-Quality Polygon Triangulation. In Proceedings of the 2012 International Conference on Information Technology and Software Engineering. Lecture Notes in Electrical Engineering; Lu, W., Cai, G., Liu, W., Xing, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 212. [Google Scholar] [CrossRef] [Green Version]

- Barnett, J.H. Early Writings on Graph Theory: Euler Circuits and The Königsberg Bridge Problem An Historical Project; Colorado State University: Pueblo, CO, USA, 2005; Available online: https://www-users.cse.umn.edu/~reiner/Classes/Konigsberg.pdf (accessed on 17 August 2021).

- Thomson, B. Topology vs. Topography: Sometimes Less is More. In Proceedings of the Second EAGE Integrated Reservoir Modelling Conference, Dubai, United Arab Emirates, 16–19 November 2014. [Google Scholar]

| Faults Entity | Information | Details |

|---|---|---|

| Faults entity | Fault name | Fault ID |

| Geometry | Vertexes | |

| Triangles | ||

| Formation time | Time |

| Faults Group ID | Information | Details |

|---|---|---|

| Faults relation | Relation name | Relation ID |

| Cross faults | Fault1 ID | |

| Fault2 ID | ||

| Major fault | Major fault ID | |

| Truncation type | Minor fault Truncation type |

| Fault Entity | New Major Fault |

|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Hou, X.; Pan, M.; Li, Z. Research on Automatic Construction Method of Three-Dimensional Complex Fault Model. Minerals 2021, 11, 893. https://doi.org/10.3390/min11080893

Zhang C, Hou X, Pan M, Li Z. Research on Automatic Construction Method of Three-Dimensional Complex Fault Model. Minerals. 2021; 11(8):893. https://doi.org/10.3390/min11080893

Chicago/Turabian StyleZhang, Chi, Xiaolin Hou, Mao Pan, and Zhaoliang Li. 2021. "Research on Automatic Construction Method of Three-Dimensional Complex Fault Model" Minerals 11, no. 8: 893. https://doi.org/10.3390/min11080893

APA StyleZhang, C., Hou, X., Pan, M., & Li, Z. (2021). Research on Automatic Construction Method of Three-Dimensional Complex Fault Model. Minerals, 11(8), 893. https://doi.org/10.3390/min11080893