Production, Properties and Performance of Slag-Based, Geopolymer Foams

Abstract

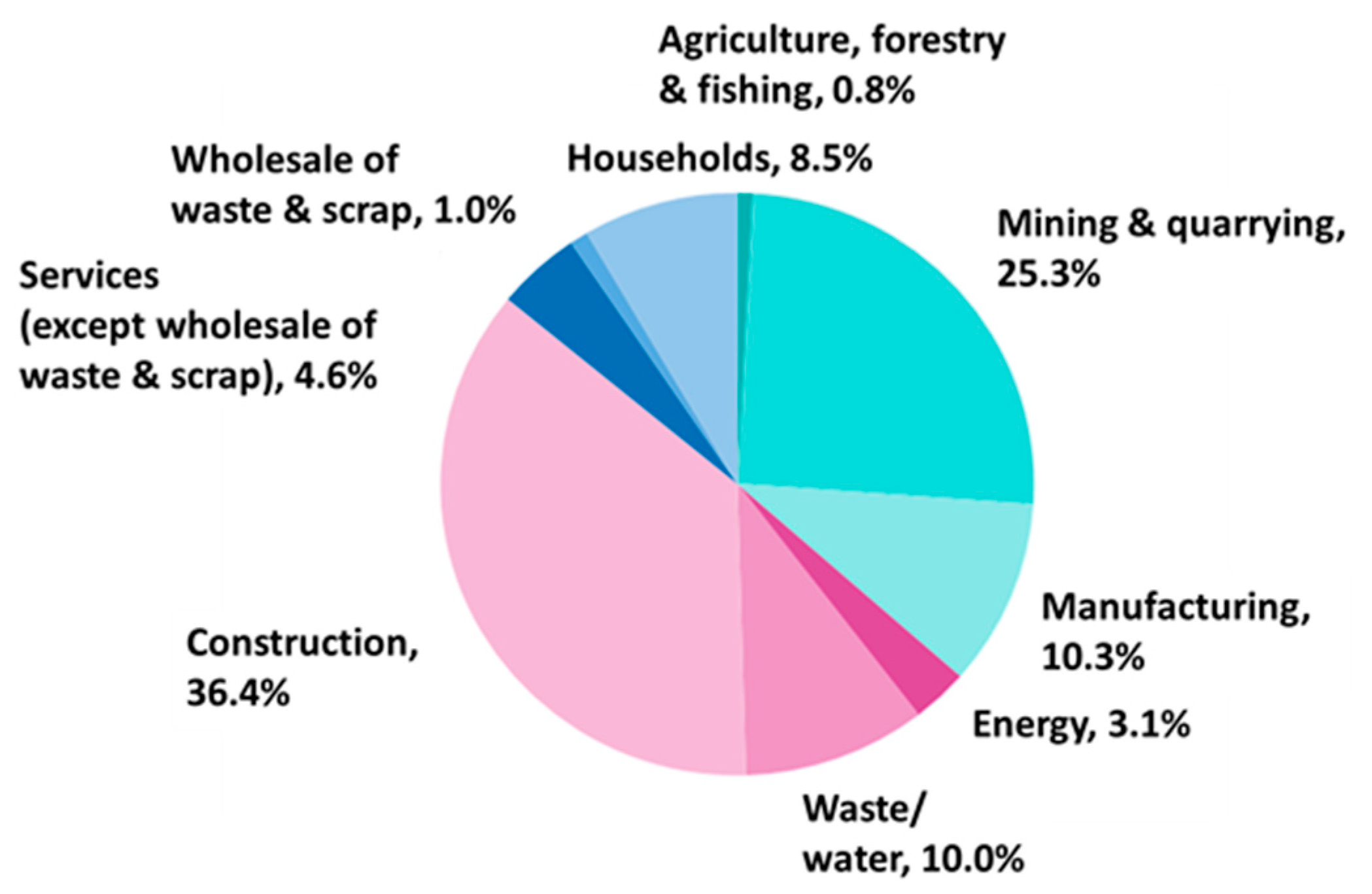

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Paste Preparation and Foaming

2.3. Characterization Methods

2.3.1. Analytical Methods

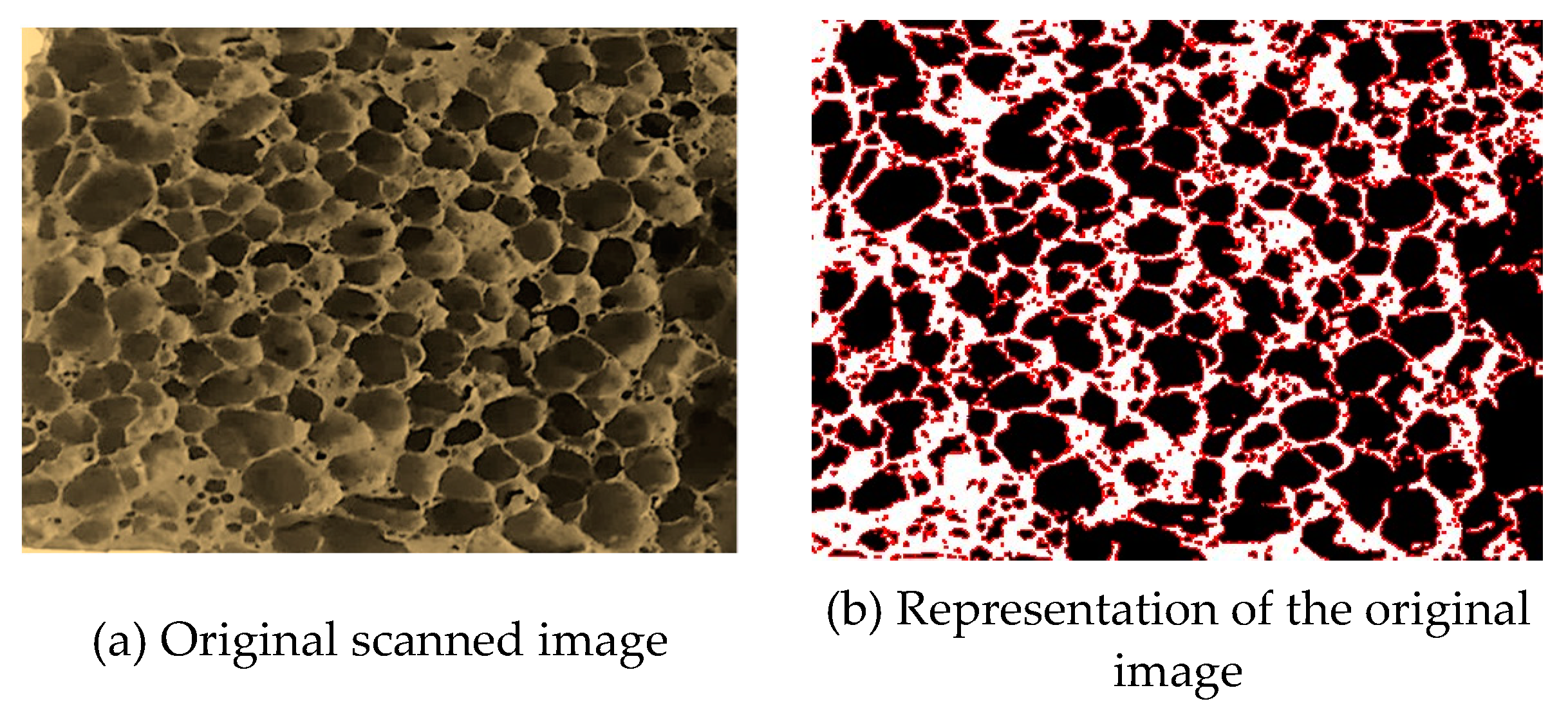

2.3.2. Image Processing Methods

3. Results and Discussion

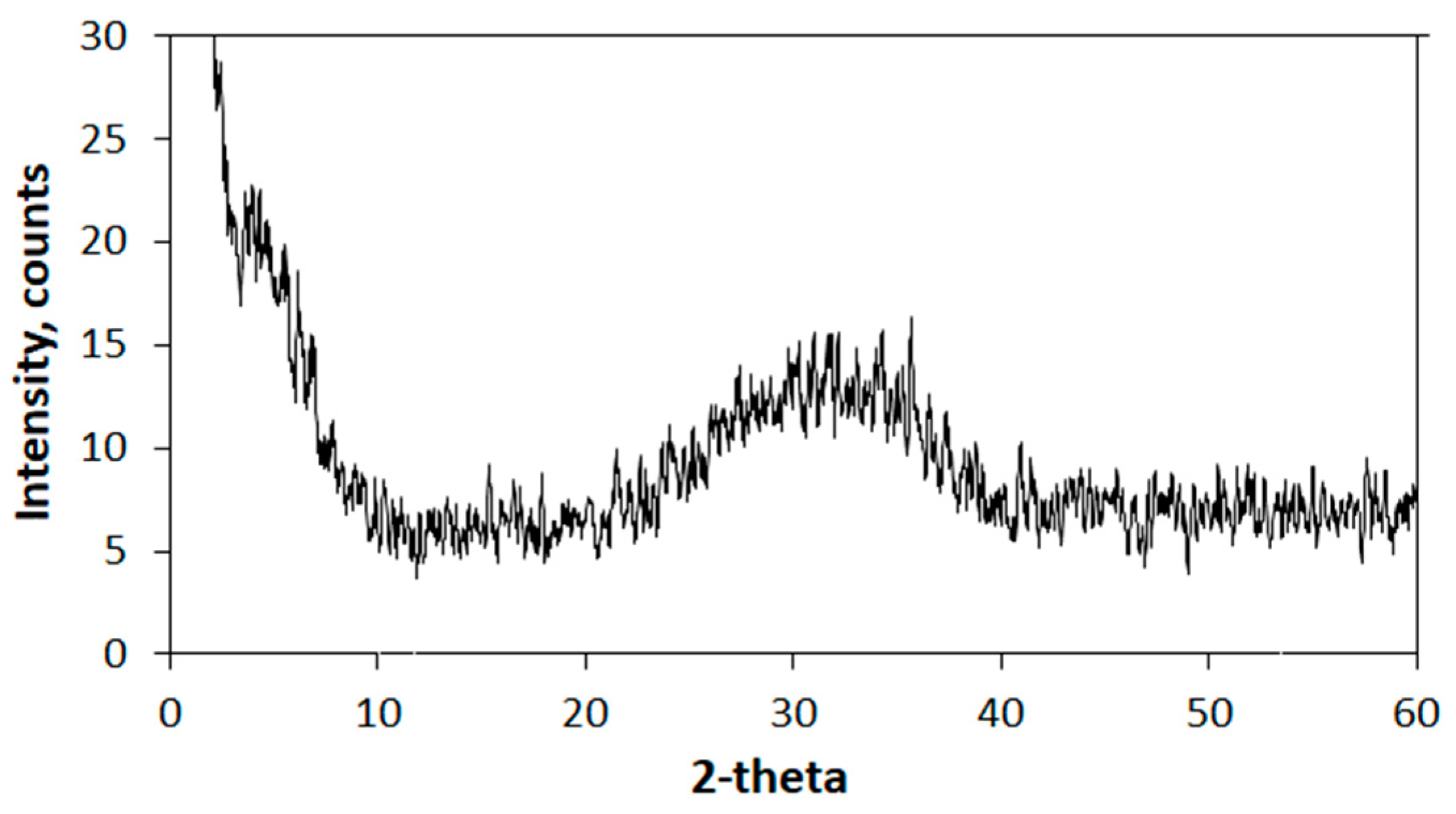

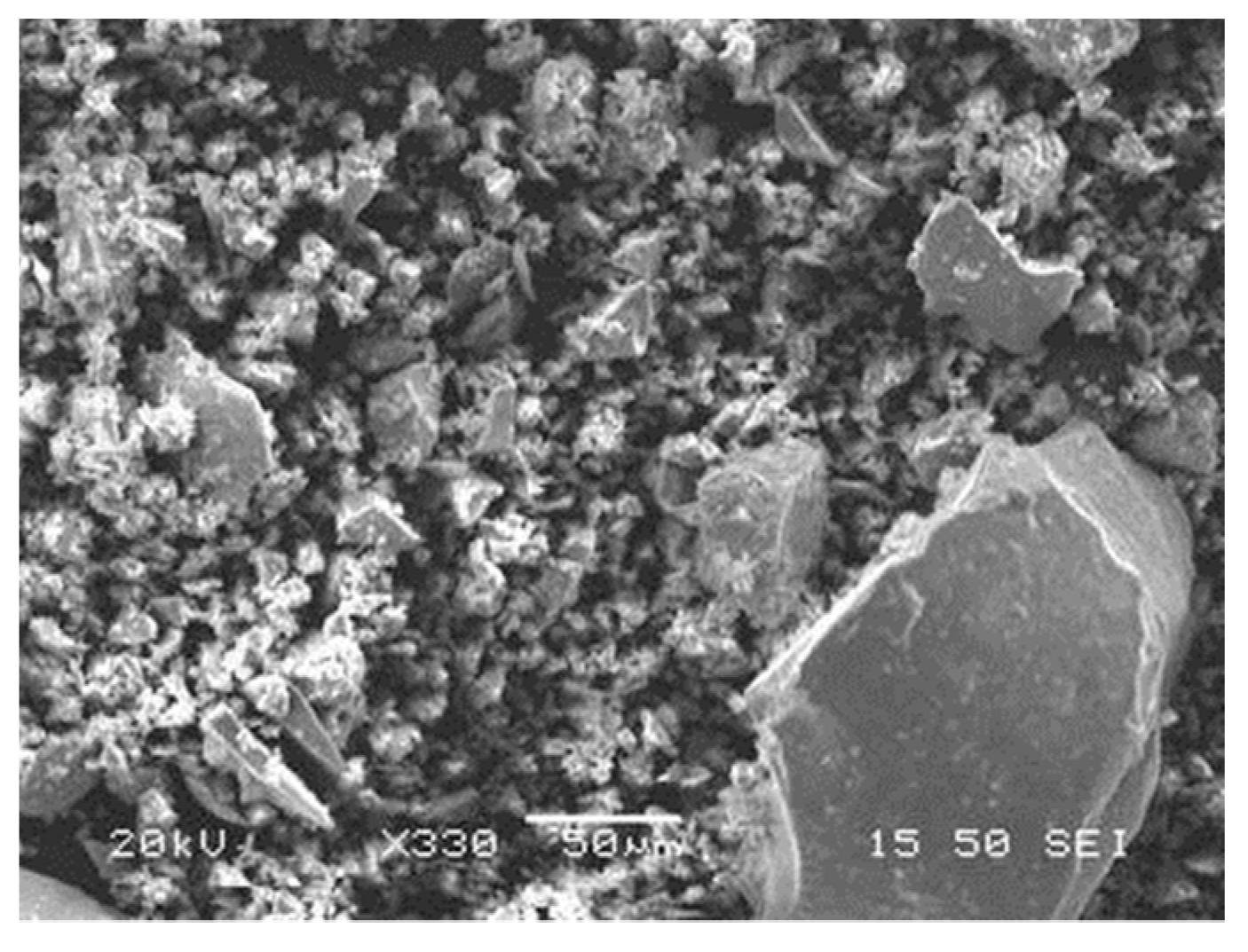

3.1. Characterization of Raw Material (Cu-Slag)

3.2. Properties of Geopolymer Pastes and Foams

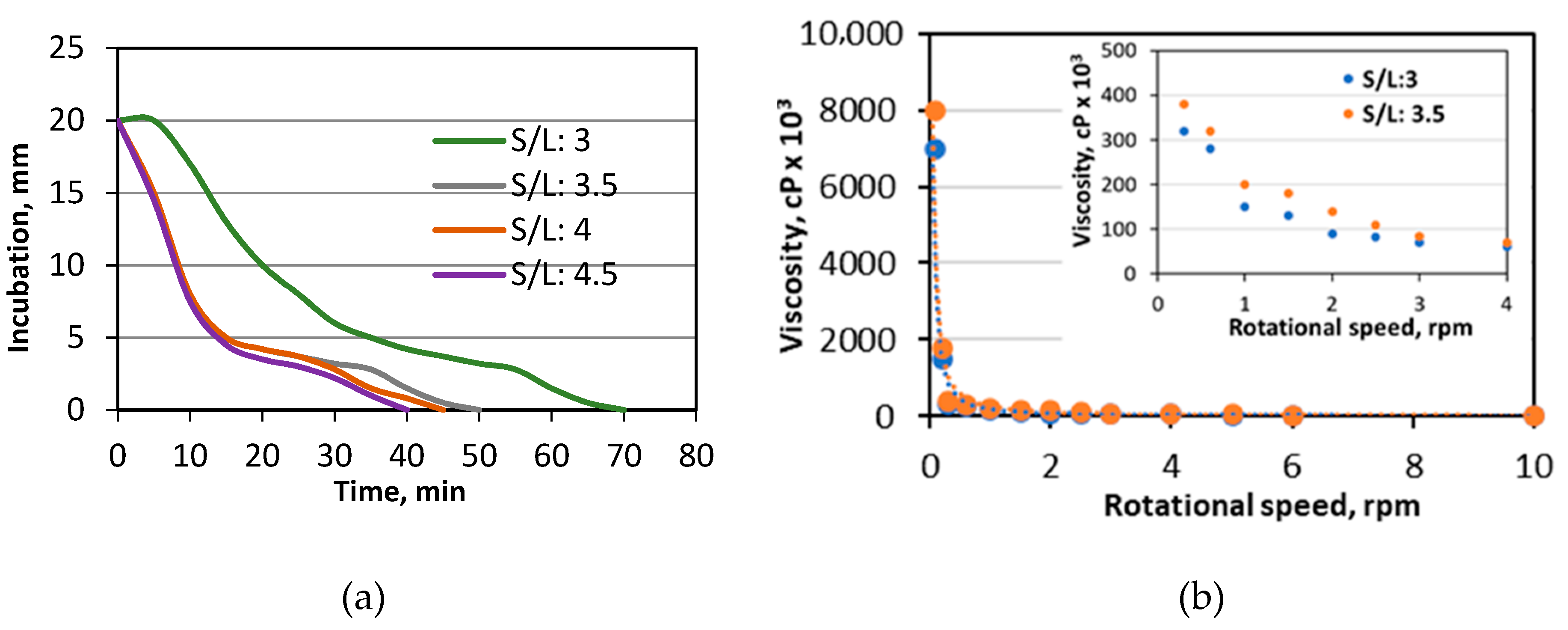

3.2.1. Effect of S/L on Rheological Properties of Geopolymer Pastes

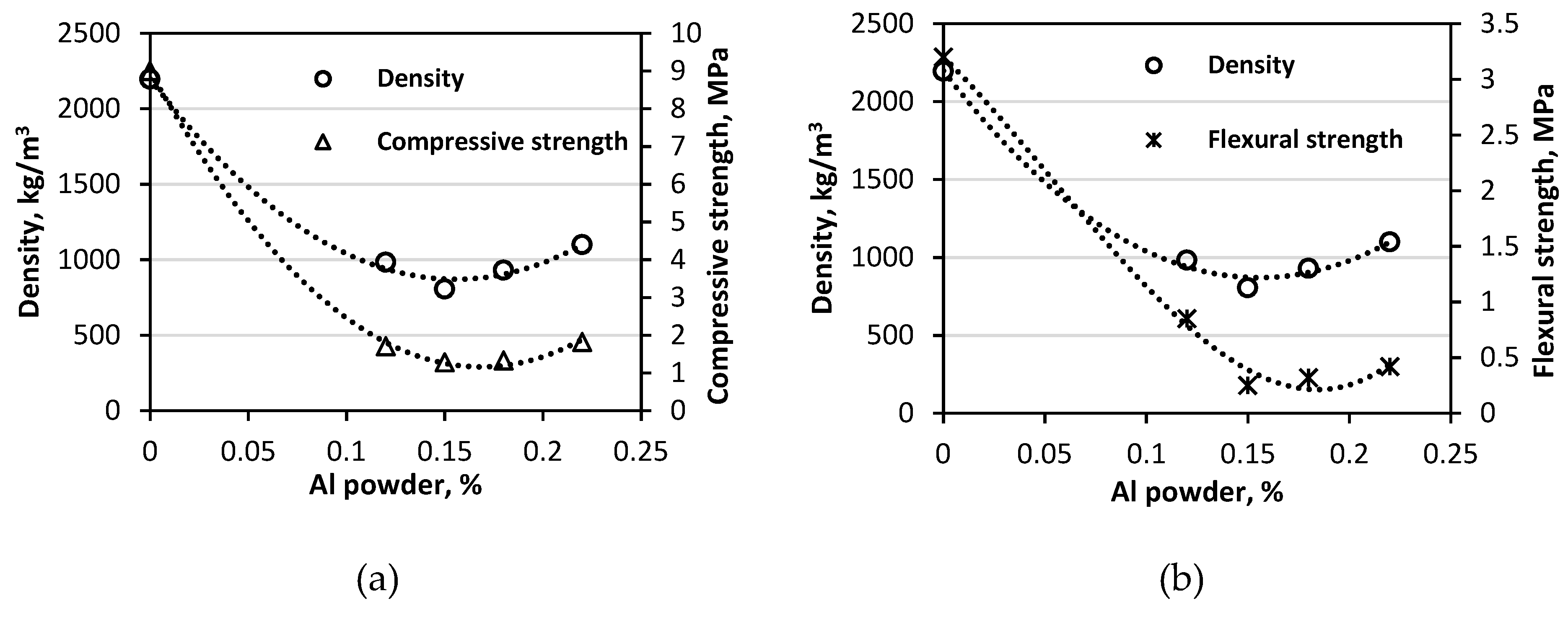

3.2.2. Effect of Al Powder Addition on Geopolymer Foam Properties

3.3. Microstructure and Porosity of Geopolymer Foams

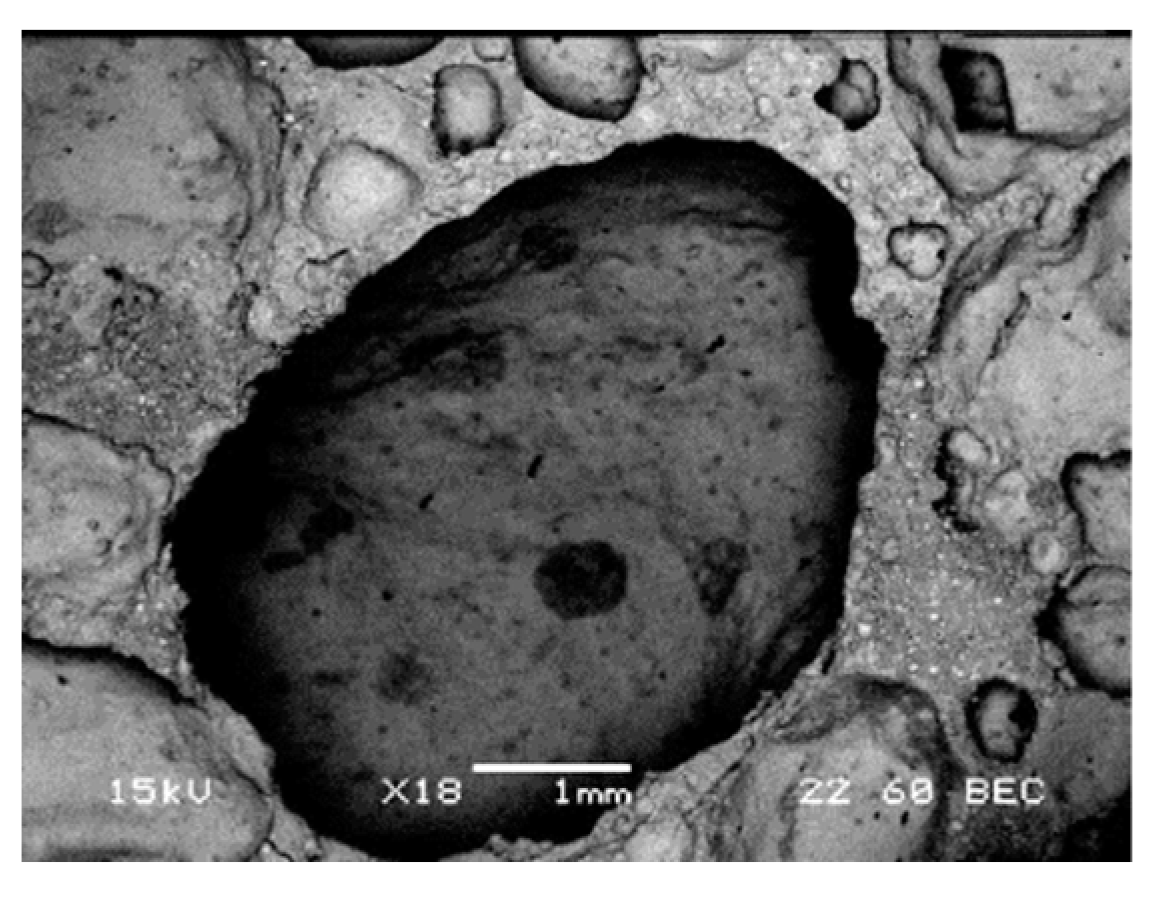

3.3.1. SEM

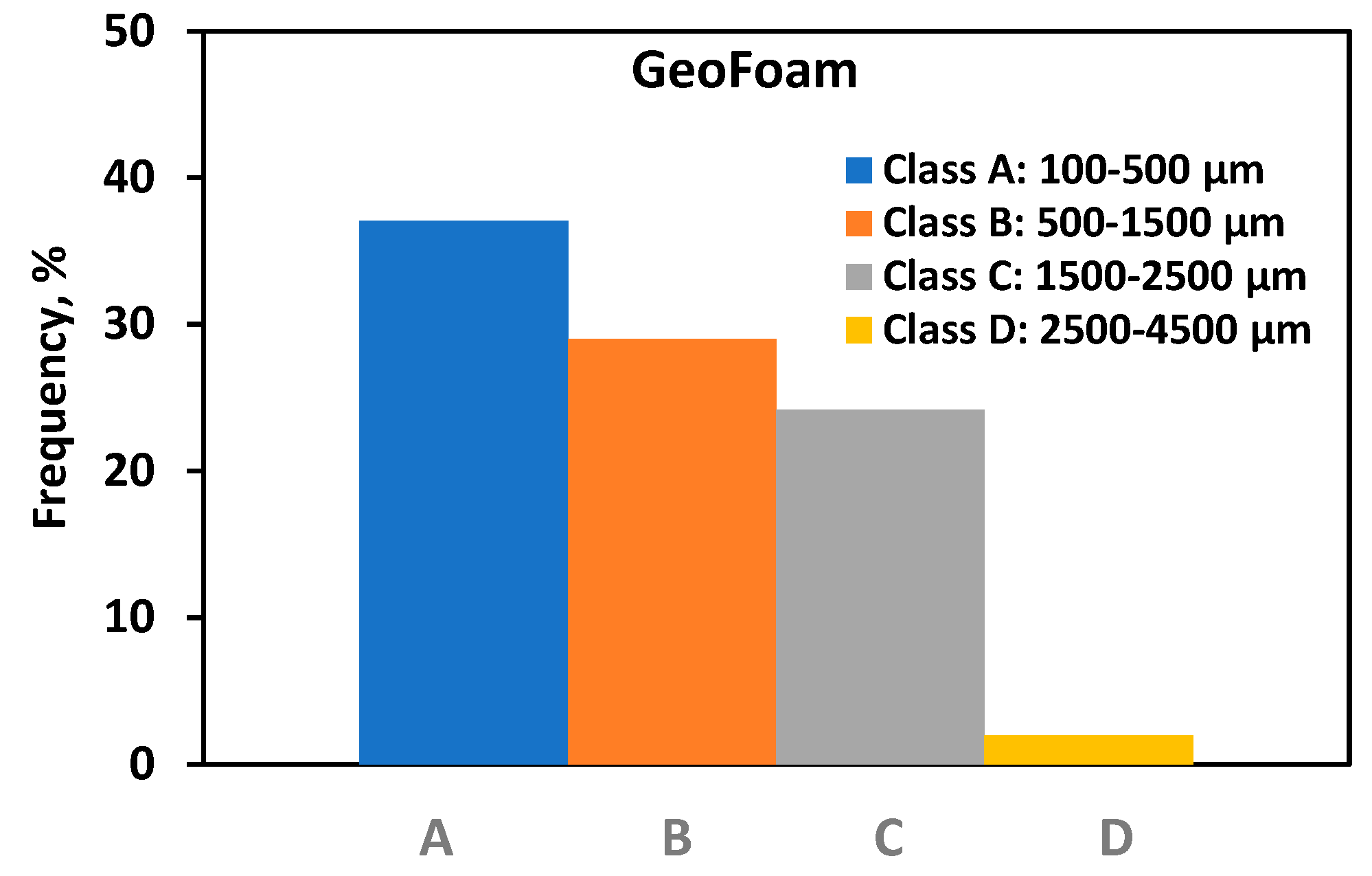

3.3.2. Image J Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eurostat. Statistic Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Waste_generation_by_economic_activities_and_households,_EU-28,_2016_(%25).png&oldid=413561 (accessed on 29 June 2021).

- METGrow. Metal recovery from low grade ore and wastes. In EU Horizon 2020 Research and Innovation Program; GA n° 690088; European Commission: Brussels, Belgium, 2020; Available online: https://cordis.europa.eu/project/id/690088 (accessed on 29 June 2021).

- Panias, D.; Giannopoulou, I.; Perraki, T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids Surf. A 2007, 301, 246–254. [Google Scholar] [CrossRef]

- Maragos, I.; Giannopoulou, I.; Panias, D. Synthesis of ferronickel slag-based geopolymers. Miner. Eng. 2008, 22, 196–203. [Google Scholar] [CrossRef]

- Pontikes, Y.; Machiels, L.; Onisei, S.; Pandelaers, L.; Geysen, D.; Jones, P.T.; Blanpain, B. Slags with a high Al and Fe content as precursors for inorganic polymers. Appl. Clay Sci. 2013, 73, 93–102. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Perdikatsis, V. Effect of synthesis parameters on the compressive strength of low-calcium ferronickel slag inorganic polymers. J. Hazard. Mater. 2009, 161, 760–768. [Google Scholar] [CrossRef]

- Tsaousi, G.M.; Douni, I.; Panias, D. Experimental Evaluation of Efficient Si Dissolution from Perlite at Low Level Activator’s Concentration. Minerals 2018, 8, 160. [Google Scholar] [CrossRef] [Green Version]

- Barbosa, V.F.F.; MacKenzie, K.J.D.; Thaumatutgo, C. Synthesis and characterization of materials based on inorganic polymers of alumina and silica: Sodium polysialate polymers. Int. J. Inorg. Mater. 2000, 4, 309–317. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. The geopolymerization of alumino-silicate minerals. Int. J. Miner. Process. 2000, 3, 247–266. [Google Scholar] [CrossRef] [Green Version]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali activated fly ashes-a cement for the future. Cem. Concr. Res. 1999, 8, 1323–1329. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of geopolymer cements. In Proceedings of the First International Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994; pp. 131–149. [Google Scholar]

- Cundi, W.; Hirano, Y.; Terai, T.; Vallepu, R.; Mikuni, A.; Ikeda, K. Preparation of geopolymeric monoliths from red mud-PFBC ash fillers at ambient temperature. In Proceedings of the World Congress Geopolymer, Saint Quentin, France, 28 June–1 July 2005; pp. 85–87. [Google Scholar]

- Kamseu, E.; Nait-Ali, B.; Bignozzi, M.C.; Leonelli, C.; Rossignol, S.; Smith, D.S. Bulk composition and microstructure dependence of effective thermal conductivity of porous inorganic polymer cements. J. Europ. Ceram. Soc. 2012, 32, 1593–1603. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mat. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Williams, B.H. The thermal decomposition of hydrogen peroxide in aqueous solutions. Faraday Soc. 1928, 24, 245–255. [Google Scholar] [CrossRef]

- Masi, G.; LesVickers, W.; Bignozzi, M.-C.; Riessen, A. A comparison between different foaming methods for the synthesis of lightweight geopolymers. Ceram. Int. 2014, 40 Pt A, 13891–13902. [Google Scholar] [CrossRef] [Green Version]

- Wefers, K.; Misra, C. Oxides and Hydroxides of Aluminum: Technical Report 19—Revised; Alcoa Laboratories: Pittsburgh, PA, USA, 1987; pp. 64–71. [Google Scholar]

- Newman, J.; Owens, P. Properties of lightweight concrete. In Advanced Concrete Technology Part 3: Process; Newman, J., Choo, R.S., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2003; Volume 40. [Google Scholar]

- Hamad, A.J. Materials, Production, Properties and Application of Aerated Lightweight Concrete: Review. Int. J. Mat. Sci. Eng. 2014, 2, 152–157. [Google Scholar] [CrossRef]

- Ducman, V.; Korat, L. Characterization of geopolymer fly-ash based foams obtained with the addition of Al powder or H2O2 as foaming agents. Mat. Charac. 2016, 113, 207–213. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Al-Muhit, B.A.; Jumaat, M.Z.; Liu, M.Y.J. A comparison of the thermal conductivity of oil palm shell foamed concrete with conventional materials. Mat. Des. 2013, 51, 522–529. [Google Scholar] [CrossRef]

- Song, Y.; Li, B.; Yang, E.H.; Liu, Y.; Ding, T. Feasibility study on utilization of municipal solid waste incineration bottom ash as aerating agent for the production of autoclaved aerated concrete. Cem. Concr. Comp. 2015, 56, 51–58. [Google Scholar] [CrossRef]

- Torres, M.L.; García-Ruiz, P.A. Lightweight pozzolanic materials used in mortars: Evaluation of their influence on density, mechanical strength and water absorption. Cem. Concr. Comp. 2009, 31, 114–119. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Santhanam, M.; Jumaat, M.Z.; Mo, K.H. Microstructural investigations of palm oil fuel ash and fly ash based binders in lightweight aggregate foamed geopolymer concrete. Constr. Build. Mat. 2016, 120, 112–122. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospects for the minerals industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Singh, P.S.; Bastow, T.; Trigg, M. Structural studies of geopolymers by 29Si and 27Al MAS-NMR. J. Mater. Sci. 2005, 40, 3951. [Google Scholar] [CrossRef]

- Shi, C.; Hu, S. Cementitious properties of ladle slag fines under autoclave curing condition. Cem. Concr. Res. 2003, 33, 1851–1856. [Google Scholar] [CrossRef]

- Setién, J.; Hernández, D.; González, J.J. Characterization of ladle furnace basic slag for use as a construction material. Constr. Build. Mater. 2009, 23, 1788–1794. [Google Scholar] [CrossRef]

- Tossavainen, M.; Engstrom, F.; Yang, Q.; Menad, N.; Lidstrom, M.; Larsson, M.; Bjorkman, B. Characteristics of steel slag under different cooling conditions. Waste Manag. 2007, 27, 1335–1344. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Parada, S.; Jones, P.T.; Boydens, E.; Van Dyck, J.; Blanpain, B.; Wollants, P. Degradation mechanisms of magnesia-carbon refractories by high-alumina stainless steel slags under vacuum. J. Eur. Ceram. Soc. 2009, 29, 1053–1060. [Google Scholar] [CrossRef]

- CEN. EN 13755: Natural Stone Test. Methods—Determination of Water Absorption at Atmospheric Pressure; CEN: Nashua, MT, USA, 2008. [Google Scholar]

- Kluge, A.L.; Piszora, P.; Darul, J.; Kantel, T.; Gambal, P. Characterization of chemical and physical parameters of post copper slag. Cent. Eur. J. Phys. 2011, 9, 380–386. [Google Scholar] [CrossRef]

- Keeley, P.M.; Rowson, N.A.; Johnson, T.P.; Deegan, D.E. The effect of the extent of polymerisation of a slag structure on the strength of alkali-activated slag binders. Int. J. Miner. Process. 2017, 164, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Mahendran, K.; Arunachelam, N. Study on utilization of copper slag as fine aggregate in geopolymer concrete. Int. J. Appl. Eng. Res. 2015, 10, 53. [Google Scholar]

- Massazza, F. Pozzolana and pozzolanic cements. In Lea’s Chemistry of Cement and Concrete; Hewlett, P., Ed.; Arnold: London, UK, 1998; pp. 471–631. [Google Scholar]

- Panias, D.; Giannopoulou, I. The geopolymerization technology for the utilization of mining and metallurgical solid wastes. In Proceedings of the European Metallurgical Conference, Dusseldorf, Germany, 11–14 June 2007; pp. 625–640. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications, 2nd ed.; Institut Geopolymere: Saint Quentin, France, 2008; Chapter 26; pp. 547–574. [Google Scholar]

- Heah, C.; Kamarudin, H.; Al Bakri, A.M.; Bnhussain, M.; Luqman, M.; Khairul, N.I.; Ruzaidi, C.; Liew, Y. Study of solid-to-liquid and alkaline activator ratios on kaolin based geopolymers. Const. Build. Mater. 2012, 35, 912–922. [Google Scholar] [CrossRef]

- Tsaousi, G.M.; Douni, I.; Panias, D. Characterization of the properties of perlite geopolymer pastes. Mater. Construcc Ión 2016, 66, e102. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Yang, K.H.; Lo, C.W.; Huang, J.S. Production and properties of foamed reservoir sludge inorganic polymers. Cem. Concr. Compos. 2013, 38, 50–56. [Google Scholar] [CrossRef]

- Roviello, G.; Menna, C.; Tarallo, O.; Ricciotti, L.; Messina, F.; Ferone, C.; Asprone, D.; Cioffi, R. Lightweight geopolymer-based hybrid materials. Compos. Part B Eng. 2017, 128, 225–237. [Google Scholar] [CrossRef]

- Tsaousi, G.M.; Douni, I.; Taxiarchou, M.; Panias, D.; Paspaliaris, I. Development of foamed inorganic polymeric materials based on Perlite. Mater. Sci. Eng. 2014, 123. [Google Scholar] [CrossRef]

- Nambiar, E.K.; Ramamurthy, K. Air-void characterisation of foam concrete. Cem. Concr. 2007, Res37, 221–230. [Google Scholar] [CrossRef]

- Soutsos, M.; Boyle, A.P.; Vinai, R.; Hadjierakleous, A.; Barnett, S.J. Factors influencing the compressive strength of fly ash based geopolymers. Constr. Build. Mat. 2016, 110, 355–368. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Comp. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Katarzyna, B.; Le, C.H.; Louda, P.; Michał, S.; Bakalova, T.; Tadeusz, P.; Prałat, K. The fabrication of geopolymer foam composites incorporating coke dust waste. Processes 2020, 8, 1052. [Google Scholar] [CrossRef]

- Lamond, J.F.; Pielert, J.H. Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar] [CrossRef]

- Tsaousi, G.M.; Profitis, E.; Douni, I.; Chatzitheodorides, E.; Panias, D. Development of lightweight insulating building materials from perlite wastes National Technical University of Athens. Mater. Constr. 2019, 69, e175. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Gong, L.; Shi, L.; Cao, W.; Pan, Y.; Cheng, X. Experimental investigation on the influencing factors of preparing porous fly ash-based geopolymer for insulation material. Energy Build. 2008, 168, 9–18. [Google Scholar] [CrossRef]

- Xu, F.; Gu, G.; Zhang, W.; Wang, H.; Huang, X.; Zhu, J. Pore structure analysis and properties evaluations of fly ash-based geopolymer foams by chemical foaming method. Ceram. Int. 2018, 44, 19989–19997. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H. The pore characteristics of geopolymer foam concrete and their impact on the compressive strength and modulus. Front. Mater. 2016, 3, 38. [Google Scholar] [CrossRef] [Green Version]

- Kapat, K.; Kumar, P.; Dhara, S. Coagulant assisted foaming—A method for cellular Ti6Al4V: Influence of microstructure on mechanical properties. Mater. Sci. Eng. A 2017, 689, 63–71. [Google Scholar] [CrossRef]

- Zulkarnain, F.; Ramli, M. Performance of foamed concrete mix design with silica fume for general housing construction. Eur. J. Technol. Adv. Eng. Res. 2011, 1, 18–28. [Google Scholar]

- Singh, N. Fly ash-based geopolymer binder: A future construction material. Minerals 2018, 8, 299. [Google Scholar] [CrossRef] [Green Version]

- Cavallaro, G.; Lazzara, G.; Lisuzzo, L.; Milioto, S.; Parisi, F. Filling of mater-Bi with Nanoclays to enhance the biofilm rigidity. J. Funct. Biomater. 2018, 9, 60. [Google Scholar] [CrossRef] [Green Version]

- Hanzlíček, T.; Perná, I.; Uličná, K.; Římal, V.; Štěpánková, H. The evaluation of clay suitability for geopolymer technology. Minerals 2020, 10, 852. [Google Scholar] [CrossRef]

- Lisuzzo, L.; Cavallaro, G.; Milioto, S.; Lazzara, G. Effects of halloysite content on the thermo-mechanical performances of composite bioplastics. Appl. Clay Sci. 2020, 185, 105416. [Google Scholar] [CrossRef] [Green Version]

| Oxides, % w/w | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| FeO | Al2O3 | SiO2 | Na2O | CaO | ZnO | MgO | CuO | Others | Total, % | S.G, g/cm3 |

| 44.41 | 3.30 | 39.95 | 1.05 | 4.08 | 2.14 | 1.77 | 0.85 | 2.08 | 99.61 | 3.37 |

| S/L, g/mL | 3.5 |

| [KOH], M | 8 |

| Curing time, h | 24 |

| Curing temperature, °C | 70 |

| Material | Density, kg/m3 | Compressive Strength (after 28 Days), MPa | Flexural Strength (after 28 Days), MPa |

|---|---|---|---|

| Geo | 2195 | 9 | 3.2 |

| S/L, g/mL | 3.5 |

| [KOH], M | 8 |

| Al powder, wt.% (to paste) | 0.12, 0.15, 0.18, 0.22 |

| Curing time, h | 24 |

| Curing temperature, °C | 70 |

| Material | Density, kg/m3 | Compressive Strength, MPa | Flexural Strength, MPa | Water Absorption, % | Th. Conductivity W/mK |

|---|---|---|---|---|---|

| GeoFoam | 805 | 1.28 | 0.25 | 42.3 | 0.085 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsaousi, G.-M.; Panias, D. Production, Properties and Performance of Slag-Based, Geopolymer Foams. Minerals 2021, 11, 732. https://doi.org/10.3390/min11070732

Tsaousi G-M, Panias D. Production, Properties and Performance of Slag-Based, Geopolymer Foams. Minerals. 2021; 11(7):732. https://doi.org/10.3390/min11070732

Chicago/Turabian StyleTsaousi, Georgia-Maria, and Dimitrios Panias. 2021. "Production, Properties and Performance of Slag-Based, Geopolymer Foams" Minerals 11, no. 7: 732. https://doi.org/10.3390/min11070732

APA StyleTsaousi, G.-M., & Panias, D. (2021). Production, Properties and Performance of Slag-Based, Geopolymer Foams. Minerals, 11(7), 732. https://doi.org/10.3390/min11070732