Extending the Life Cycle of Cement Binders by Partially Replacing Portland Cement with Different Types Fluidized Bed Combustion Fly Ash

Abstract

:1. Introduction

2. Materials and Methods

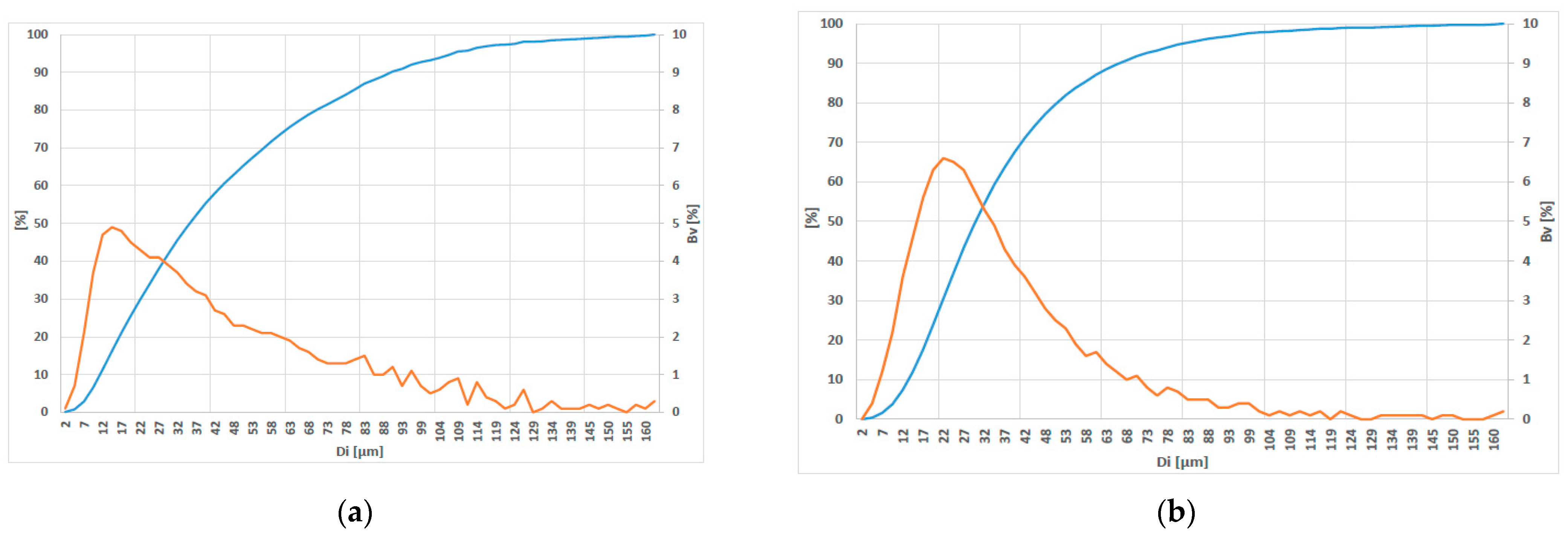

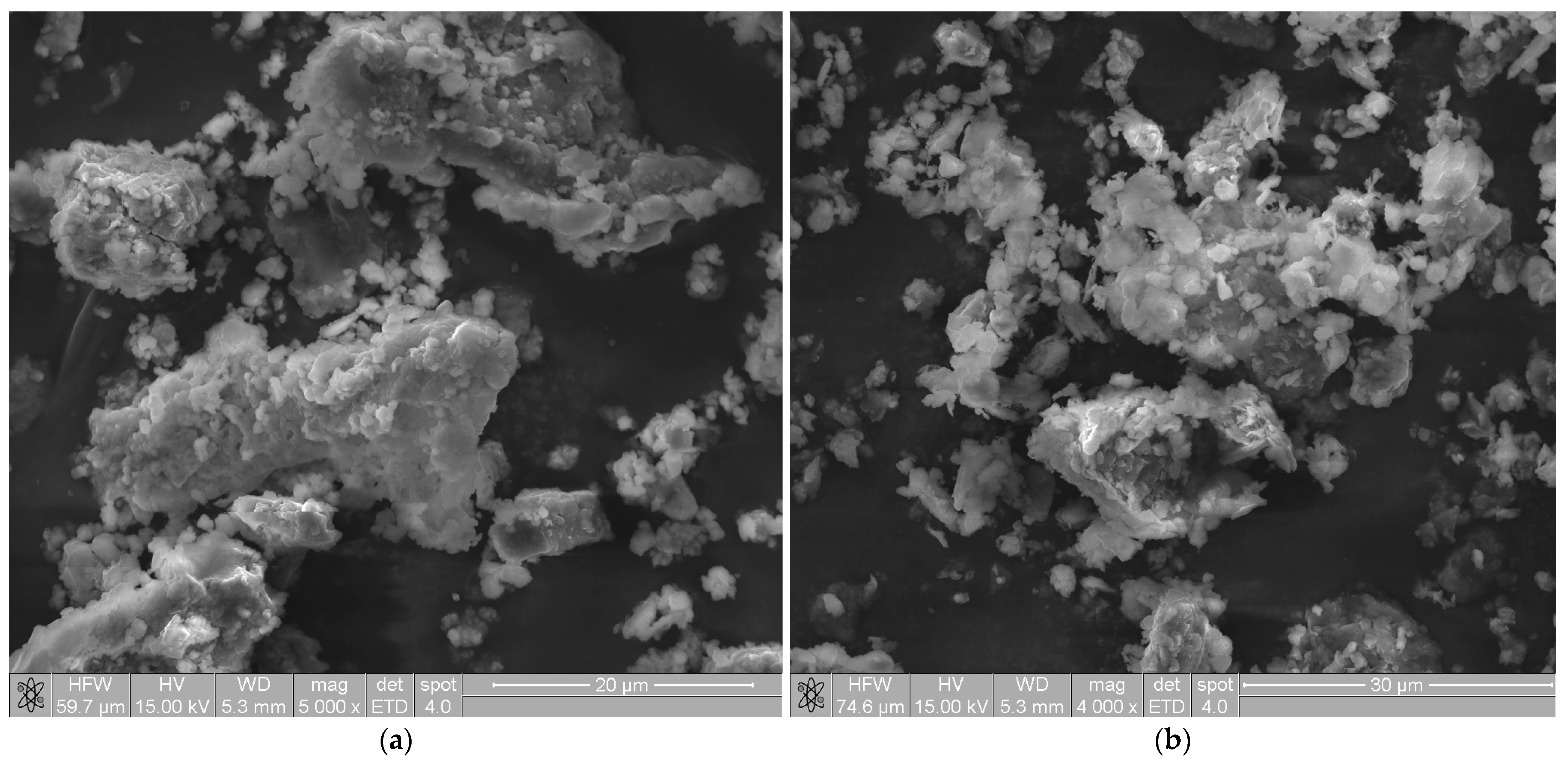

2.1. Materials—FBC Fly Ashes Characteristic

2.2. Materials—Cement Characteristic

2.3. Methods—Setting Time and Compressive Strength Test

2.4. Methods—Linear Changes Test

2.5. Methods—SEM–EDS and XRD Analysis

3. Results

3.1. Physical Properties of FBC Fly Ash-Cements Binders—Setting Time and Compressive Strength

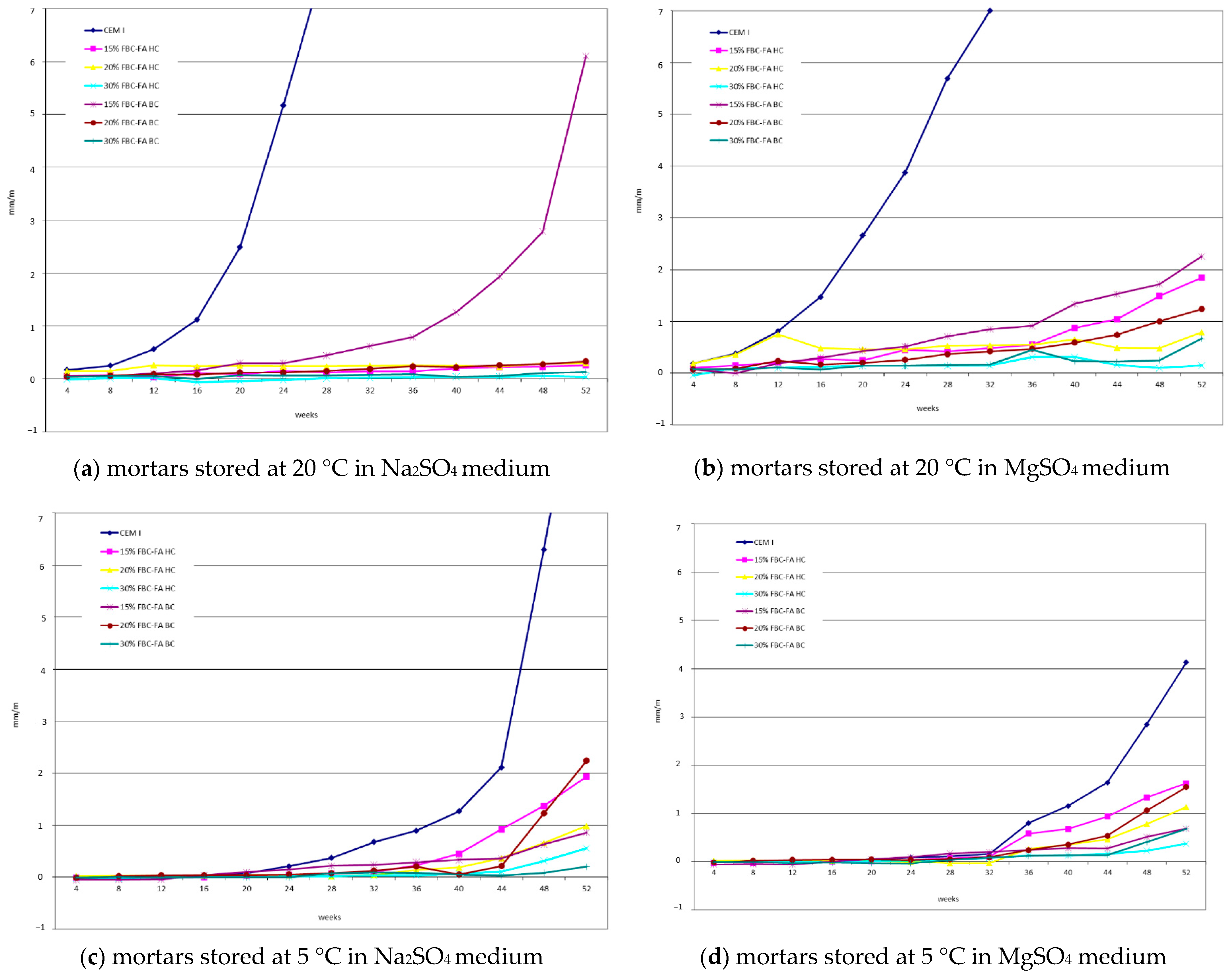

3.2. Sulfate Corrosion Resistance of Blended Fly Ash-Cement Binders—Linear Changes Test

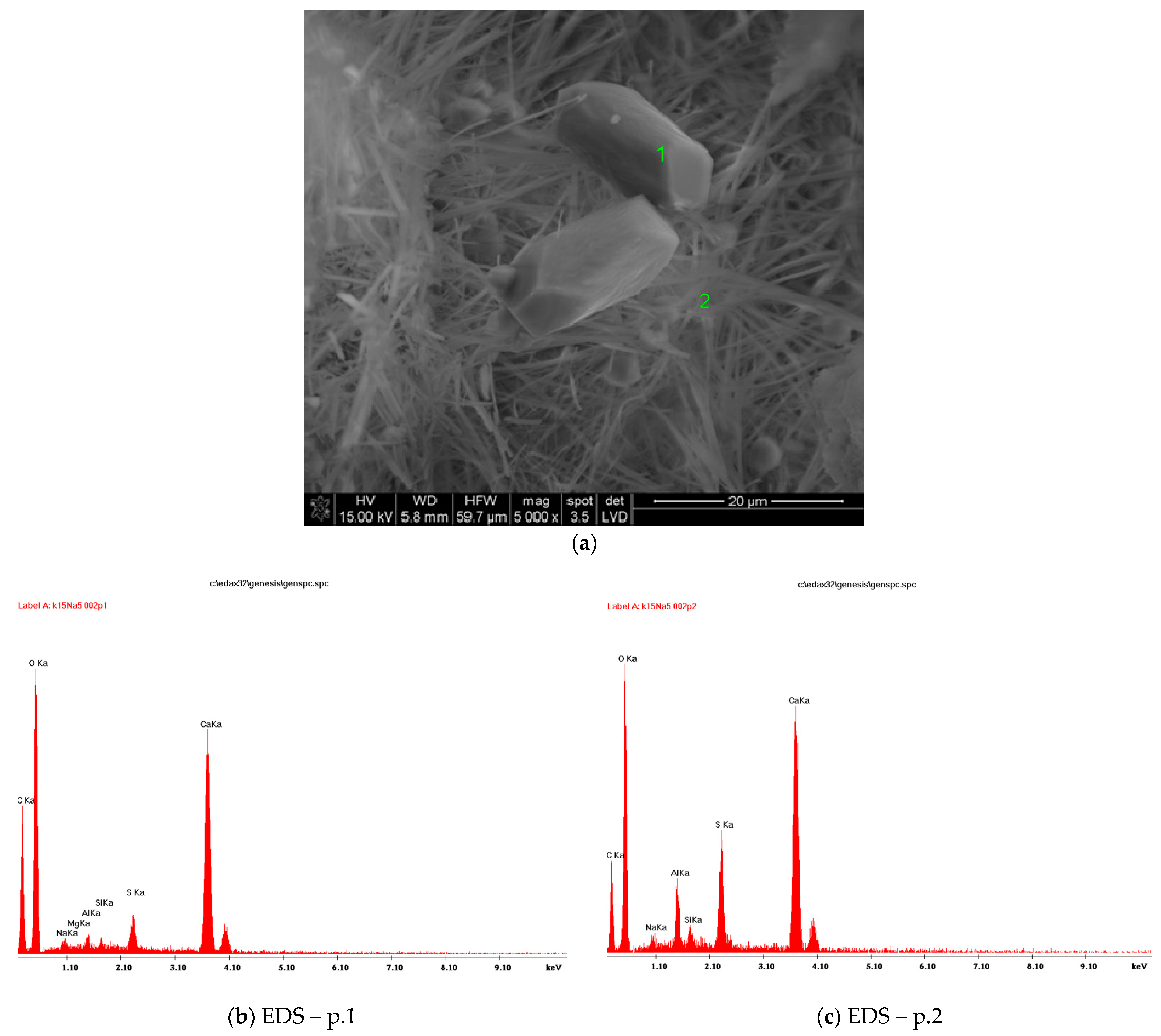

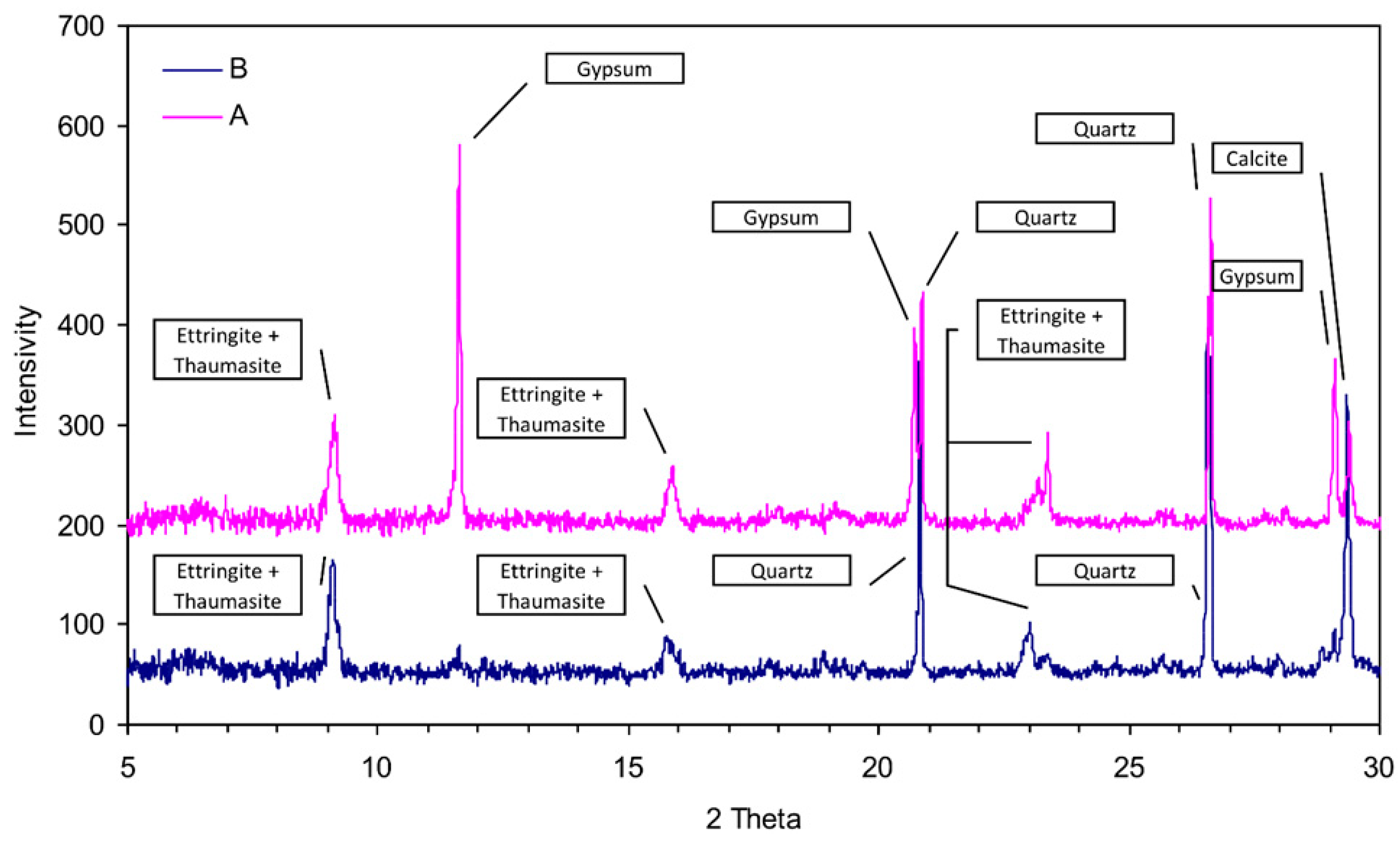

3.3. Sulfate Corrosion Resistance of Blended Fly Ash-Cement Binders—SEM–EDS and XRD Analysis

4. Discussion

5. Conclusions

- The experiments demonstrate that the addition of FBC fly ashes obtained from different types of coal to cements strongly influenced the properties of obtained binders, especially their sulfate-resistance.

- Durability of cement binders in sulfate environment containing a higher amount of FBC fly ash is the more effective, the more fly ash is added into the cement.

- The cement replacement by FBC fly ashes from brown coal combustion in 20%, or by FBC fly ashes from hard coal combustion in 15% meets the requirements for special sulfate-resistant cements according to Polish PN-B-19707 national standard.

- The results of sulfate-resistance tests of samples stored in MgSO4 solution indicate that this medium to a larger degree than Na2SO4 influences the properties of mortars, even then, when the FBC fly ash content is high.

- The content of FBC fly ash in fly ash-cement binders exposed on magnesium sulfate medium should not be less than 15% of binder mass, especially in case of application of FBC fly ashes from brown coal combustion.

- Exposure of mortar samples in Na2SO4 or MgSO4 environments at 5 °C generally increases the linear changes of the tested samples, indicating a higher degree of corrosion processes.

- The bigger expansion of samples stored in Na2SO4 solution in low temperature is defined mainly by ettringite crystallization in contrast to mortars stored in the MgSO4 solution, in which deterioration is probably related to other, additional sulfate corrosion product—thaumasite, which caused in hydrated cement paste considerably lower expansion then ettringite.

- Sulfate-resistance of binders containing FBC fly ashes depends on its chemical composition. The FBC fly ashes with higher SiO2 content and limited amount of CaO exhibit more beneficial properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Polish Cement Association. Neutralność Klimatyczna A Perspektywy Zastosowania Betonu I Cementu W Budownictwie; II Forum Beton w drogownictwie: Ostróda, Poland, 2020. [Google Scholar]

- Gawlicki, M.; Roszczynialski, W. Applicabillity of combustion by-products from fluidized bed as Portland cement components. Ceramics 2003, 80, 681–686. [Google Scholar]

- Sanal, I. Significance of concrete production in terms of carbondioxide emissions: Social and environmental impacts. Politek. Derg. J. Politech. 2018, 21, 369–378. [Google Scholar]

- Minkwan, J.; Kyoungsoo, P.; Won-Jun, P. Mechanical Behavior of Recycled Fine Aggregate Concrete with High Slump Property in Normal- and High-Strength. Int. J. Concr. Struct. Mater. 2019, 13, 61. [Google Scholar]

- Jeong-Eun, K.; Wan-Shin, P.; Young-Li, J.; Sun-Woo, K.; Sun-Woong, K.; Yi-Hyun, N.; Do-Gyeum, K.; Keitetsu, R. Mechanical Properties of Energy Efficient Concretes Made with Binary, Ternary and Quaternary Cementitious Blends of Fly Ash, Blast Furnace Slag and Silica Fume. Int. J. Concr. Struct. Mater. 2016, 10 (Suppl. 3), 97–108. [Google Scholar]

- Kumar, P.; Sikder, P.S.; Pal, N. Biomass fuel cell based distributed generation system for Sagar Island. Bull. Pol. Acad. Sci. Tech. Sci. 2018, 66, 665–674. [Google Scholar]

- Uliasz-Bocheńczyk, A.; Mazurkiewicz, M.; Mokrzycki, E. Fly ash from energy production—A waste, byproduct and raw material. Gospod. Surowcami Miner. Miner. Resour. Manag. 2015, 31, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Gazdič, D.; Fridrichová, M.; Kulísek, K.; Vehovská, L. The Potential Use of the FBC Ash for the Preparation of Blended Cements. Procedia Eng. 2017, 180, 1298–1305. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U. Utilization of blended fluidized bed combustion (FBC) ash and pulverized coal combustion (PCC) fly ash in geopolymer. Waste Manag. 2010, 30, 667–672. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Choi, H.; Sagawa, T.; Hama, Y. Compressive strength development and durability of an environmental load-reduction material manufactured using circulating fluidized bed ash and blast-furnace slag. Constr. Build. Mater. 2017, 146, 102–113. [Google Scholar] [CrossRef]

- Brandt, A. (Ed.) Application of CFBC Fly Ash in Structural Concretes; Collective Work; Polish Academy of Science, Committee of Civil Engineering: Warsaw, Poland, 2010. [Google Scholar]

- Abdulmatin, A.; Tangchirapat, W.; Jaturapitakkul, C. An investigation of bottom ash as a pozzolanic material. Constr. Build. Mater. 2018, 186, 155–162. [Google Scholar] [CrossRef]

- Łagosz, A.; Mróz, R. Durability of Building Materials Based on Mineral Binders Modified By Significant Amounts of Fly Ash from Brown Coal Combustion in Fluidized Bed: Reaktywność Ciał Stałych = Reactivity of Solids/Pod Red; Przybylskiego, K., Polska Akademia Nauk—Oddział w Krakowie, Polskie Towarzystwo Ceramiczne—Prace Komisji Nauk Ceramicznych/Polska Akademia Nauk, Oddział w Krakowie. Ceramika 2013, 115, 259–267. [Google Scholar]

- Li, D.; Sun, R.; Wang, D.; Ren, C.; Fang, K. Study on the pozzolanic activity of ultrafine circulating fluidized-bed fly ash prepared by jet mill. Fuel 2021, 291, 120220. [Google Scholar] [CrossRef]

- Lee, B.Y.; Jeon, S.; Cho, C.G.; Kim, H. Evaluation of time to shrinkage-induced crack initiation in OPC and slag cement matrices incorporating circulating fluidized bed combustion bottom ash. Constr. Build. Mater. 2020, 257, 119507. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D.; Dąbrowski, M. The Influence of Fluidized Bed Combustion Fly Ash on the Phase Composition and Microstructure of Cement Paste. Materials 2019, 12, 2838. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Osholanaa, T.S.; Dludlub, M.K.; Oboirienc, B.; Sadikua, R. Enhanced reactivity of geopolymers produced from fluidized bed combustion bottom ash. South Afr. J. Chem. Eng. 2020, 34, 72–77. [Google Scholar] [CrossRef]

- Liu, Z.; Li, S.; Li, S.; Wang, J.; Zhou, Y.; Wang, D. One-step high efficiency crystallization of zeolite A from ultra-fine circulating fluidized bed fly ash by hydrothermal synthesis method. Fuel 2019, 257, 116043. [Google Scholar] [CrossRef]

- Xun, X.; Zongyue, H.; Liling, D.; Yudong, Z.; Yulong, X.; Weichao, L. Investigation of high volume of CFBC ash on performance of basic magnesium sulfate cement. J. Environ. Manag. 2020, 256, 109878. [Google Scholar] [CrossRef]

- Zahedi, M.; Jafari, K.; Rajabipour, F. Properties and durability of concrete containing fluidized bed combustion (FBC) fly ash. Constr. Build. Mater. 2020, 258, 119663. [Google Scholar] [CrossRef]

- Zahedi, M.; Rajabipour, F. Fluidized Bed Combustion (FBC) Fly Ash and Its Performance in Concrete. ACI Mater. J. 2018, 116, 163–172. [Google Scholar] [CrossRef]

- Chi, M.; Huang, R. Effect of circulating fluidized bed combustion ash on the properties of roller compacted concrete. Cem. Concr. Compos. 2014, 45, 148–156. [Google Scholar] [CrossRef]

- Song, Y.; Guo, C.; Qian, J.; Ding, T. Effect of the Ca-to-Si ratio on the properties of autoclaved aerated concrete containing coal fly ash from circulating fluidized bed combustion boiler. Constr. Build. Mater. 2015, 83, 136–142. [Google Scholar] [CrossRef]

- Drochytkaa, R.; Helanováa, E. Development of microstructure of the fly ash aerated concrete in time. In Proceedings of the 7th Scientific-Technical Conference Material Problems in Civil Engineering (MATBUD’2015); Procedia Engineering, Kraków, Poland, 22–24 June 2015; Volume 108, pp. 624–631. [Google Scholar]

- Xia, Y.; Yan, Y.; Hu, Z. Utilization of circulating fluidized bed fly ash in preparing non-autoclaved aerated concrete production. Constr. Build. Mater. 2013, 47, 1461–1467. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Zieliński, M. The influence of CFBC fly ash addition on phase composition of air-entrained concrete. Bull. Pol. Acad. Sci. Tech. Sci. 2008, 56, 45–52. [Google Scholar]

- Baldermann, C.; Galan, I.; Emmerich, F.; Mittermayr, F. Effect of very high limestone content and quality on the sulfate resistance of blended cements. Constr. Build. Mater. 2018, 188, 1065–1076. [Google Scholar] [CrossRef]

- Sotiriadis, K.; Mróz, R. Simulation of thaumasite sulfate attack on portland cement mixtures using synthesized cement phases. J. Mater. Civ. Eng. 2019, 31, 1–10. [Google Scholar] [CrossRef]

- Haufe, J.; Vollpracht, A. Tensile strength of concrete exposed to sulfate attack. Cem. Concr. Res. 2019, 116, 81–88. [Google Scholar] [CrossRef]

- JCPDS-ICDD (Joint Committee on Powder Diffraction Standards—International Center for Diffraction Data). Available online: https://www.icdd.com/ (accessed on 25 June 2021).

- Lagosz, A.; Mróz, R. Parameters developed durability of building materials based on mineral binders modified by significant amounts of fly ash from brown coal burnt in zfluidized bed combustion. In Proceedings of the XVI French-Polish seminar on Reactivity of solids, Kraków, Poland, 10–12 December 2012. [Google Scholar]

- Brylicki, W.; Małolepszy, J. Properties of cements admixtures with AFBC fly ash. Ceramics 2001, 66, 370–377. [Google Scholar]

- Skalny, J.; Marchand, J.; Odler, I. Sulfate Attack on Concrete; Modern Concrete Technology 10; SPON Press: London, UK; New York, NY, USA, 2002. [Google Scholar]

- Shi, Z.; Ferreiro, S.; Lothenbach, B.; Geikerd, M.R.; Kunther, W.; Kaufmann, J.; Herfort, D.; Skibsted, J. Sulfate resistance of calcined clay—Limestone—Portland cements. Cem. Concr. Res. 2019, 116, 238–251. [Google Scholar] [CrossRef]

| Component | FBC Fly Ash from Brown Coal Combustion (FBC FA BC) | FBC Fly Ash from Hard Coal Combustion (FBC FA HC) |

|---|---|---|

| Wt. % | ||

| LOI, 1000 °C/1 h | 2.73 | 3.40 |

| SiO2 | 36.47 | 47.18 |

| Fe2O3 | 4.40 | 6.80 |

| Al2O3 | 28.40 | 25.62 |

| TiO2 | 3.84 | 1.08 |

| CaO | 15.95 | 5.84 |

| MgO | 1.65 | 0.15 |

| SO3 | 3.80 | 3.62 |

| Na2O | 1.64 | 1.18 |

| K2O | 0.62 | 2.36 |

| Cl- | 0.03 | 0.10 |

| CaOfree | 4.75 | 0.30 |

| Physical Parameters | Results of the Tests | |

|---|---|---|

| FBC Fly Ash from Brown Coal Combustion (FBC FA BC) | FBC Fly Ash from Hard Coal Combustion (FBC FA HC) | |

| Specific density, g/cm3 | 2.75 | 2.68 |

| BET specific surface, m2/g | 12.1 | 13.5 |

| Volume median particle diameter, μm | 37.3 | 31.6 |

| Volume mode particle diameter, μm | 14.3 | 22.0 |

| Water/ash ratio for standardized consistency (analog-like for cement-water paste according to EN 196-3) | 0.746 | 0.732 |

| Phase | FBC Fly Ash from Brown Coal Combustion (FBC FA BC) | FBC Fly Ash from Hard Coal Combustion (FBC FA HC) |

|---|---|---|

| Wt, % | ||

| SiO2 | 1.5 | 15.0 |

| CaSO4 | 6.5 | 6.2 |

| CaO | 4.7 | 0.3 |

| CaCO3 | 4.5 | 1.6 |

| Not burned coal | 0 | 1.7 |

| Amorphous phases | 82.7 | 75.2 |

| Composition of Binder in Standard Cement Mortar | Compressive Strength of Mortars after Two Periods of Hardening, MPa | Activity Index: Compressive Strength of FBC Fly Ash-Cement Mortars to Reference Cement Mortar Ratio, %, after: | ||||

|---|---|---|---|---|---|---|

| 28 Days | 90 Days | 28 Days | Requirements | 90 Days | Requirements | |

| CEM I 42,5R | 45.1 | 49.7 | - | - | - | - |

| 75%–CEM I 42,5R 25%–FBC FA BC | 53.2 | 58.0 | 118 | >75 | 117 | >85 |

| 75%–CEM I 42,5R 25%–FBC FA HC | 57.1 | 58.6 | 127 | 118 | ||

| Chemical Composition of Used Cement—CEM I 32,5R, wt. % | |

|---|---|

| SiO2 | 18.9 |

| Al2O3 | 5.5 |

| Fe2O3 | 2.9 |

| CaO | 63.3 |

| MgO | 1.4 |

| SO3 | 2.84 |

| Na2Oeq | 0.81 |

| Cl– | 0.020 |

| Physical parameters of used cement | |

| Water demand, % | 28.5 |

| Setting time—initial, min | 200 |

| Setting time—final, min | 270 |

| Compressive strength—2 days, MPa | 27.8 |

| Compressive strength—28 days, MPa | 41.4 |

| Binders Composition | Setting Time of FBC Fly Ash Cement Binders, min | Compressive Strength [MPa] of Mortars after: | |||

|---|---|---|---|---|---|

| W/(C+FBC FA) | Initial | Final | 2 Days | 28 Days | |

| 85%–CEM I 32,5R 15%–FBC FA BC | 0.349 | 200 | 250 | 27.4 | 50.6 |

| 80%–CEM I 32,5R 20%–FBC FA BC | 0.382 | 220 | 275 | 29.0 | 53.5 |

| 70%–CEM I 32,5R 30%–FBC FA BC (Additionally for mortars –% wt. of binder: 1.5%—Glenium SKY591(BASF) 0.9%—Liquol BV18 (BASF)) | 0.420 | 230 | 340 | 19.2 | 52.0 |

| 85%–CEM I 32,5R 15%–FBC FA HC | 0.340 | 215 | 255 | 28.8 | 55.2 |

| 80%–CEM I 32,5R 20%–FBC FA HC | 0.374 | 230 | 275 | 29.0 | 58.0 |

| 70%–CEM I 32,5R 30%–FBC FA HC (Additionally for mortars–% wt. of binder: 0.5%—Glenium SKY591(BASF) 0.9%—Liquol BV18 (BASF)) | 0.426 | 275 | 355 | 19.3 | 51.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łagosz, A.; Tracz, T.; Mróz, R. Extending the Life Cycle of Cement Binders by Partially Replacing Portland Cement with Different Types Fluidized Bed Combustion Fly Ash. Minerals 2021, 11, 690. https://doi.org/10.3390/min11070690

Łagosz A, Tracz T, Mróz R. Extending the Life Cycle of Cement Binders by Partially Replacing Portland Cement with Different Types Fluidized Bed Combustion Fly Ash. Minerals. 2021; 11(7):690. https://doi.org/10.3390/min11070690

Chicago/Turabian StyleŁagosz, Artur, Tomasz Tracz, and Radosław Mróz. 2021. "Extending the Life Cycle of Cement Binders by Partially Replacing Portland Cement with Different Types Fluidized Bed Combustion Fly Ash" Minerals 11, no. 7: 690. https://doi.org/10.3390/min11070690

APA StyleŁagosz, A., Tracz, T., & Mróz, R. (2021). Extending the Life Cycle of Cement Binders by Partially Replacing Portland Cement with Different Types Fluidized Bed Combustion Fly Ash. Minerals, 11(7), 690. https://doi.org/10.3390/min11070690