1. Introduction

Afghanistan is a developing nation transitioning towards democracy and peace after decades of civil and international conflict. While some conflict continues between the multitude of actors involved, including the Government of the Republic of Afghanistan, the Taliban, the Islamic State, local communal militias, private security forces, and members of the North Atlantic Treaty Organization (NATO) [

1,

2], the disengagement of international security forces and peace talks between various actors is one indication of progress toward the resolution of conflict. This transition towards peace over the past several decades has prompted the capital, Kabul, to grow from a relatively small city, with a 1970 population of less than 500,000 people, to a sprawling urban center with over 4.2 million people [

3]. Population growth due to in-migration has greatly expanded the need for housing, commercial and industrial buildings, and associated infrastructure. This, in turn, has greatly increased demand for bricks, the primary construction material of the region.

Much research is focused on the brick kilns throughout the “brick belt” of Asia, but there are significant gaps in these studies including a complete lack of statistical data regarding the number and types of brick kilns operating in Afghanistan, despite it being one of the four countries in Asia noted for a large brick making industry [

4]. Specifically, there is a notable lack of data on brick kiln types in operation, their productivity, their location and number, and the number of workers employed. The immense population growth and reconstruction in Kabul and other urban centers in Afghanistan during the past 20 years, which is largely dependent on the supply of low-cost building materials, makes this data gap particularly significant and relevant.

To address these critical gaps in data this study analyzed the scale and scope of the clay quarrying and brick making industry in Kabul over the 53 years between 1965 and 2018. The study investigates how many kilns were operational in Kabul, what type of kiln technology was being utilized, and how these kilns were distributed geographically. Geospatial analysis using very high-resolution satellite imagery together with geologic data provided a better understanding of the mineral resources used in brick making, quantified changes in the industry over time, and provided a baseline dataset of the clay quarrying and brick making industry in Kabul. Further, the number of active kilns was used to estimate how many people were employed by the sector and the production capacity of Kabul’s kiln industry.

1.1. Background

Bricks are one of the most common building materials in developing countries, as they require only readily available resources such as clay, water, and fuel. Various artisanal methods of kiln-firing bricks occur globally, however brick making is predominant throughout Central Asia, due to the prevalence of clay or loess in the surficial geologic sediments and the lack of timber due to prevailing climates [

5,

6]. Along with India, Nepal, and other countries in Central Asia, Afghanistan has traditionally had a substantial brick-making industry located around the periphery of its urban centers [

5,

7,

8].

The brick-making process has four basic steps: clay preparation, molding, drying, and firing [

9]. However, there are a number of kiln styles in different areas of the world that are dependent on local situations and material availability. Brick composition also varies depending on the local availability of raw materials, but some combination of loess, clay, and/or sand, quarried in the immediate vicinity of the kiln, as well as water to bind the materials together, is typical [

10]. Brick furnace designs range from the rudimentary artisanal intermittent ovens such as clamp kilns, to more efficient and complex large-scale kilns such as Bull’s Trench Kilns (BTK) and High/Induced Draught Zigzag kilns. Brick furnace ovens are designed to run either intermittently or continuously at temperatures of approximately 1000 °C [

4,

11].

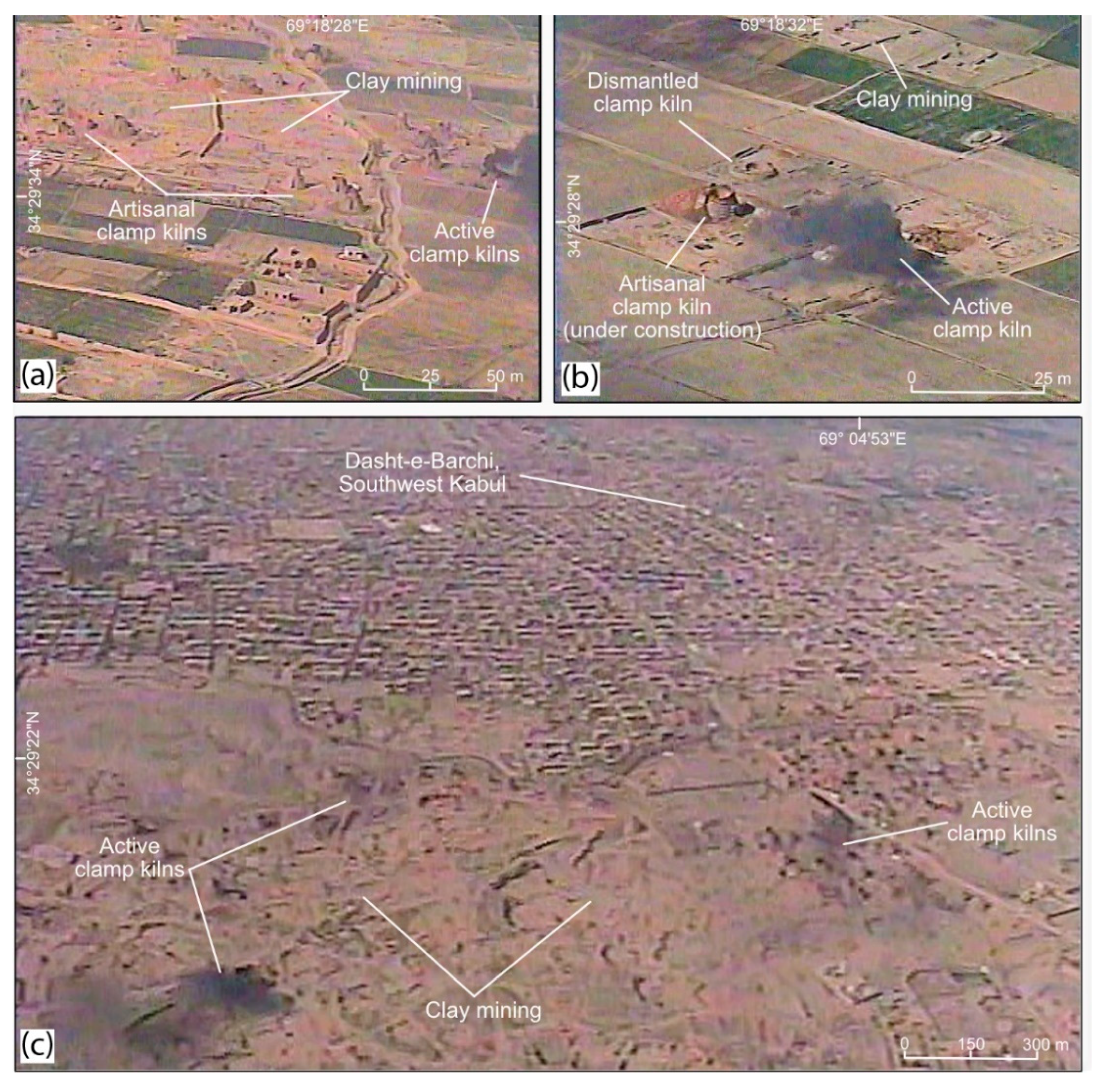

Intermittent kilns fire and cool the bricks in batches, meaning that the kiln must be completely emptied, then refilled, and the fire rekindled for each subsequent batch of bricks [

9]. In its simplest form, such as in clamp kilns, this entails the layering un-fired “green” bricks over top of a fuel source, however more complex versions such as the Hoffman Kiln utilize a flue induced draught and zones of preheating, combustion, and cooling. The primary fuel source for clamp kilns in Afghanistan, which closely resemble mud-walled scove-style clamp kilns, is wood, coal, or agricultural debris. The production capacity of this kiln style is approximately 10,000 bricks per batch (although there are examples of very large intermittent kilns in other regions that have higher production capacities) and each batch may take 10–15 days to complete. Artisanal style clamp kilns in Afghanistan employ approximately 10–12 workers per kiln [

12].

Continuous kilns are larger and more complex, and are built in an elliptical shape around a central ventilation area. The annular space between the kiln’s outer and inner walls is divided into zones of preheating, firing, and cooling. Green bricks are added to this space while firing occurs in another part of the kiln and they are preheated by gases from the firing zone. Fuel is added to this firing zone, and the fire is moved into it by a draught from the chimney. When the fire has progressed onto the next zone, the heated bricks are left to cool, then removed. While the BTK or fixed chimney Bull’s Trench Kiln (FCBTK) are the primary continuous kiln designs in Afghanistan, other continuous kiln styles include the zigzag kiln, vertical shaft, and tunnel kiln. BTKs utilize two moveable chimneys to induce a draught and move the fire around the kiln. However, this two-chimney technology has largely been replaced by the larger central stack of the FCBTK, improving the power of the draught and thereby the efficiency of the kiln. A variety of fuel sources can be used in BTKs and FCBTKs, including wood, coal, agricultural residue, and industrial waste or by-products, however in Afghanistan coal is the primary fuel source. A complete description of BTKs and other kiln styles can be found in [

12].

BTKs and FCBTKs typically produce between 20,000–50,000 bricks per day [

12]. Despite their substantially larger size and production (compared to clamp kilns) FCBTKs are operated entirely manually, meaning that the molding and transport of bricks, the maintenance and fueling of the fire, and the unloading is all done by human labor. Each BTK in Afghanistan typically employs between 30 and 220 workers [

7] depending on its size.

1.2. Impact of the Brick Making Industry

Artisanal brick making is a labor-intensive industry, with strenuous and potentially hazardous work conditions. Kiln-related work has been linked to respiratory and lung diseases due to the particulate and gaseous emissions [

4,

10] and cardiovascular disease, musculoskeletal stress, and other health issues [

10]. In Afghanistan the brick making workforce is made up primarily of bonded and forced labor including child labor [

4,

7]. The difficult working conditions, physical demands, and low profit-margin make it difficult to retain workers. Throughout Central Asia, brick kiln workers constitute one of the poorest and weakest sections of rural society and owners use a system of cash advances and loans that indebts laborers and their families to the kiln owner [

13]. In these situations, both children and adults can work over 70 or more hours per week making bricks or working in the kiln [

7]. This system of bonded labor is perpetuated through poverty, isolation, lack of other employment opportunities, and inheritance of parental debt [

7,

14].

Brick kilns also have a number of direct and indirect impacts on the environment through heat pollution, air pollution, clay quarrying, and groundwater use [

15,

16]. Due in part to the artisanal nature of the industry and in part to its rapid growth, there is minimal governmental oversight regarding emissions from the brick making industry [

16]. Each brick kiln generates a significant amount of particulate matter that is expelled into the lower atmosphere by the kiln ventilation stacks [

10]. These emitted particulates consist of very fine coal and dust particles, organic matter, and trace gases such as sulfur dioxide (SO

2), nitrogen oxides (namely nitric oxide (NO) and nitrogen dioxide (NO

2), hydrogen sulfide (H

2S), and carbon monoxide (CO) [

16]. These emissions have significant and adverse effects on human health [

4], and their wider impacts include reduced crop productivity, contamination of harvested crops, and decreased soil quality and productivity [

8,

17]. Quarrying the clay/silt material for brick production is done locally near the kilns and the topsoil is stripped from the area and the clay/silt material is either dug by hand or removed with the assistance of light machinery. This creates a barren landscape that can no longer be used for agriculture or livestock, and which is at increased risk of erosion and flooding [

4].

2. Study Area

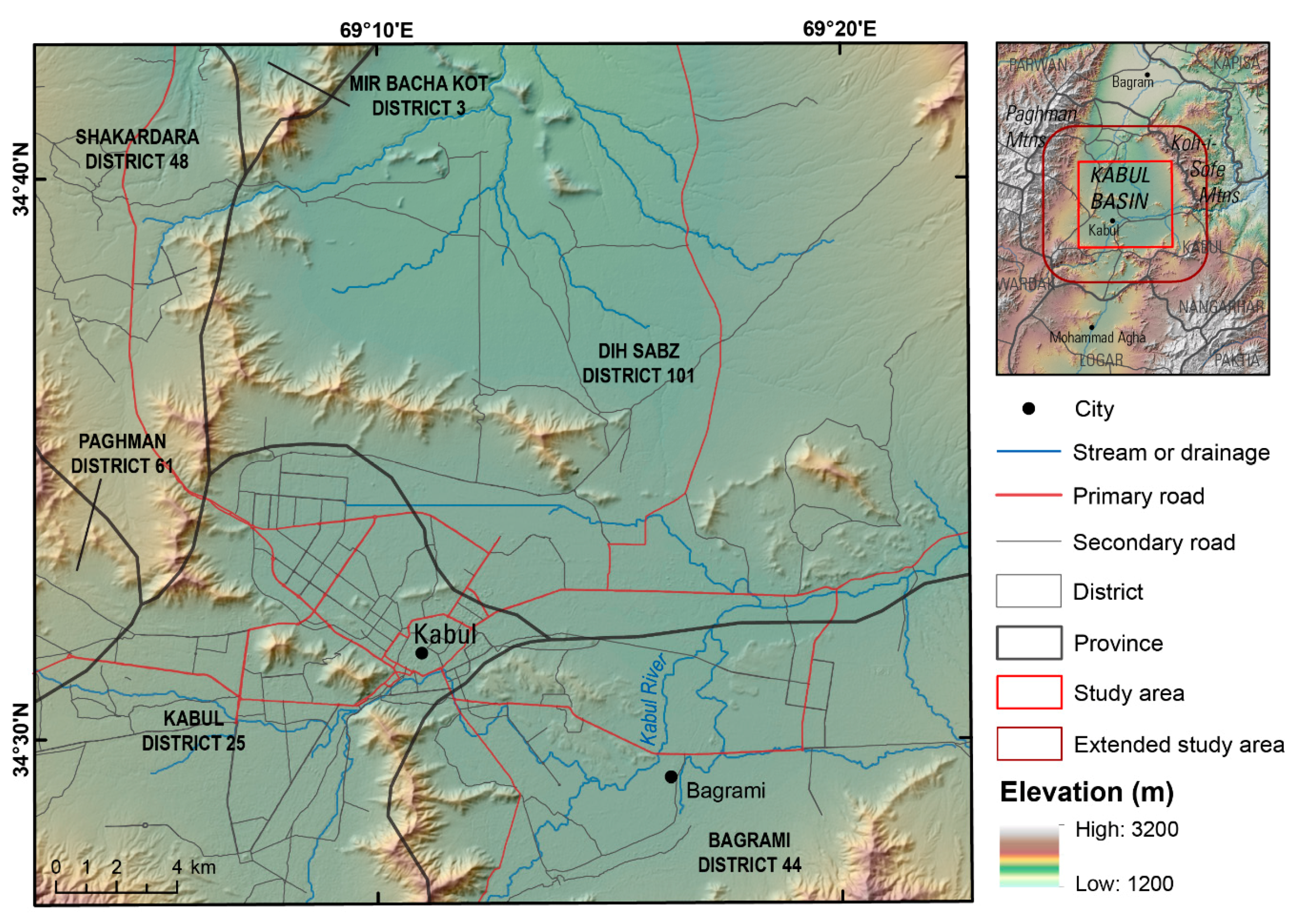

The study area, shown in

Figure 1, encompasses the city, and much of the district of Kabul, Afghanistan, as well as parts of the surrounding districts of Shakardara, Dih Sabz, Paghman, and Bagrami. Located in eastern Afghanistan, this region has an arid continental climate, with cold dry winters, comparatively wet springs, and warm dry summers. It sits in the middle of the Kabul basin, a broad flat area bordered by the Paghman mountain range to the west and the Koh-i-Sofe mountain range to the east. The land is drained primarily by the Kabul River (Kabul Rud), which meanders gently to the east before cutting a deep gorge through the southern part of the Koh-i-Sofe. While the Kabul geologic massif reaches a topographic high above 2000 m in the Koh-i-Sofe range, the Kabul basin in the western half of the massif is situated at around 1700–1800 m.

While the Kabul massif is comprised of multiple geologic formations, the general geologic framework of the Kabul basin is of a crystalline continental basement overlain by Permian to Jurassic marine platform-carbonates, covered by Pleistocene to Holocene aged surficial sedimentary deposits.

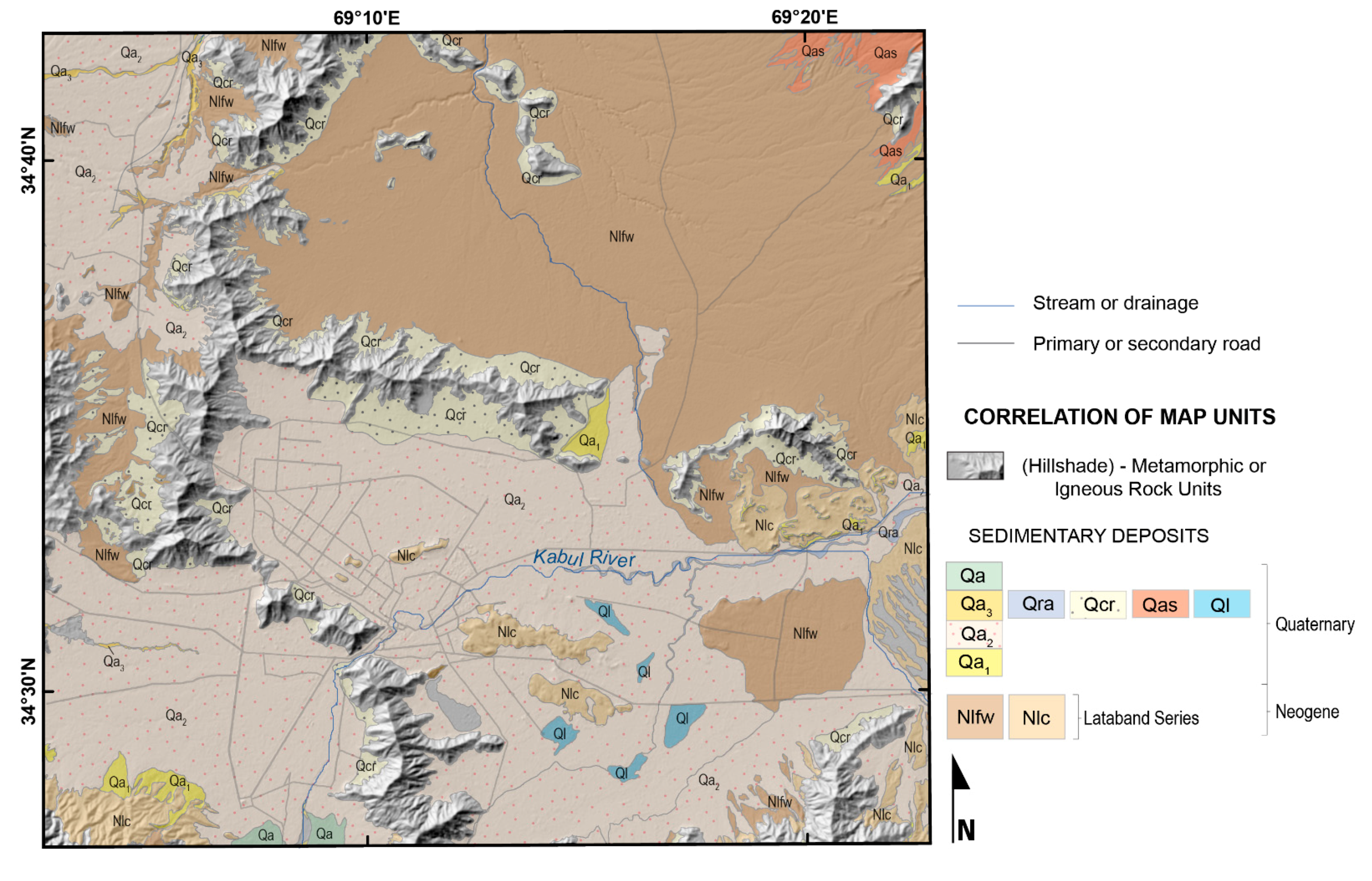

Figure 2 shows the Neogene and Quaternary geologic units of the study area, while

Table 1 provides the unit descriptions. A summary of the geology of the Kabul basin relevant to this study is given below, while a complete review of the geology of the Kabul region can be found in [

18].

Accumulations of eolian desert loess are commonly found on mountain slopes, ridges, flatlands, and valleys throughout the area. Principle among these deposits is the Neogene aged Lataband Series, which consists of Miocene and Pliocene aeolian white silt, sand, and clay (Nlfw) and a pale-grey well-rounded conglomerate (Nlc) visible along the banks of the Kabul River. Quaternary eolian and alluvial materials are also present. These surficial deposits are alluvium of various ages differentiated by the degree of dissection and surface morphology present. Other relevant alluvial units (Qa3, Qa2, Qa1) are distributed more-or-less continuously across the Kabul basin, where each unit is several meters above the next younger unit. Anthropogenic quaternary units produced as a result of development (man-made fill) and agricultural deposits, are also present throughout the study area, though these have not been mapped in any detail.

4. Results

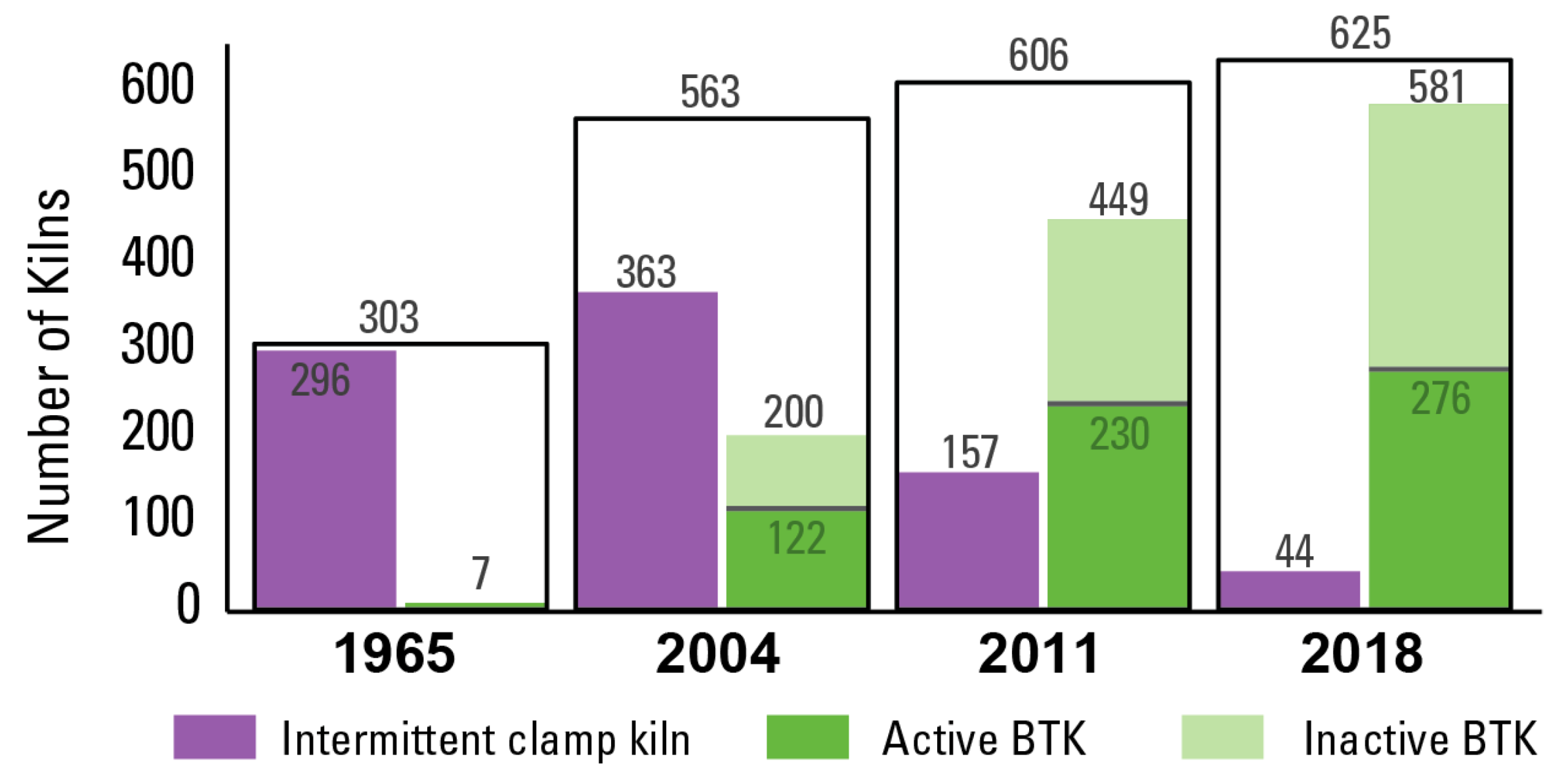

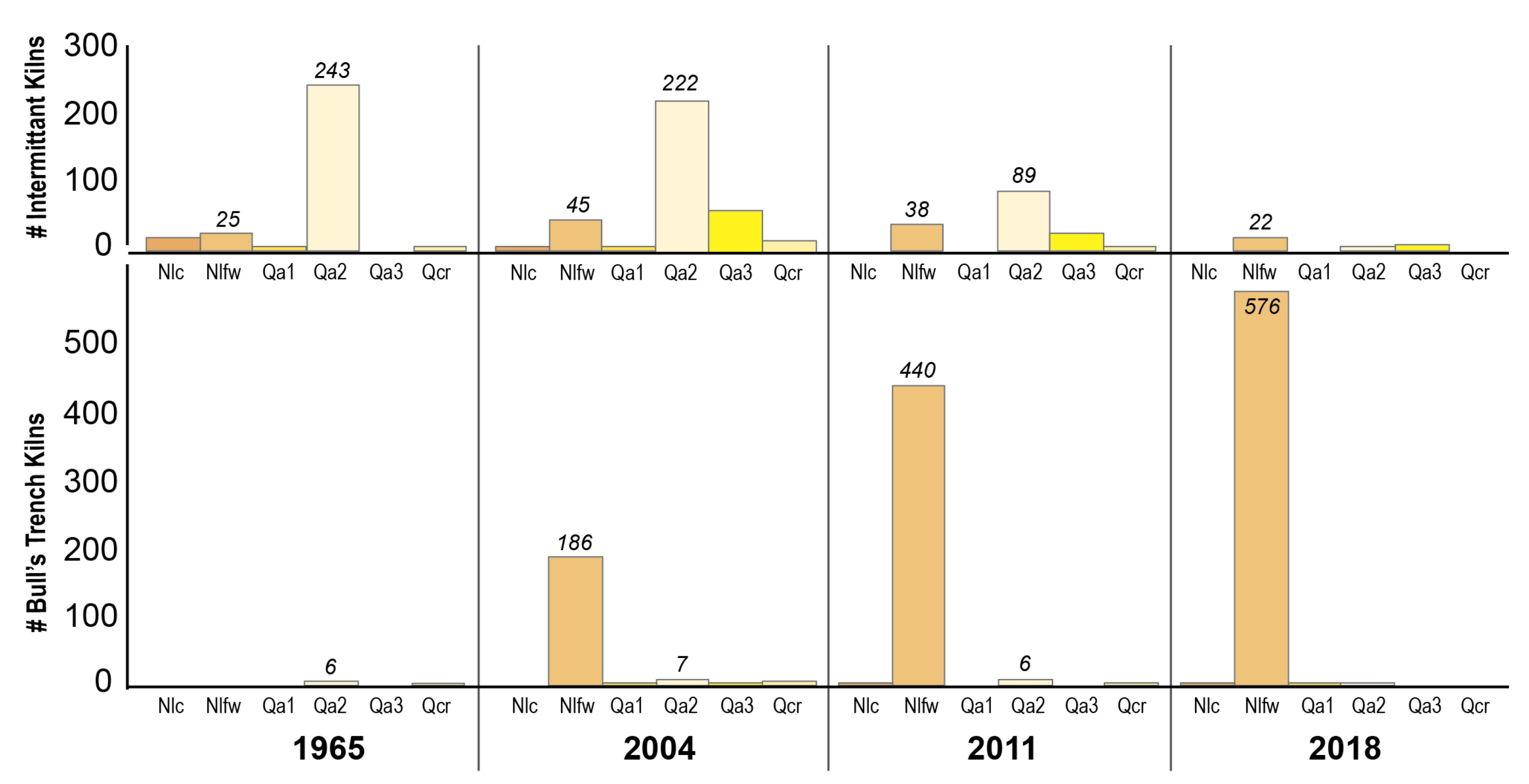

The number of brick kilns observed in the study area increased substantially over the 53-year period of observation from 303 kilns in 1965 to 625 in 2018. However, a substantial number of kilns in each year were interpreted as inactive. In 1965 all 7 BTKs were active, while in 2004 only 61.0% (122 of 2000 kilns) were active. This percentage of active kilns dropped further in 2011 to 51.2% (230 of 449 BTKs), and in 2018 to 47.5% (276 of 581 BTKs). The graph in

Figure 8 shows the number of each type of kiln for each year of observation and indicates the number of active and inactive BTKs for each year.

Figure 9 shows the location of these brick kilns in the study area compared to mapped geologic units.

From the kiln data interpreted for 2018, it was found that active BTKs ranged in length from 48 m to 162 m, with an average length of 85 m. The relationship between each BTK’s length and the estimated number of workers it employs, and its monthly brick production is shown in

Figure 10. Using this relationship, the monthly production of each 2018 active kiln was estimated. Added together, the total monthly production of these active kilns was estimated to be 197,015,000 bricks, with an average of 646,000 bricks per kiln. Assuming that these kilns operated for 8 months of the year, this suggests that in 2018 BTKs in the study area employed an estimated 27,000 workers and produced 1.576 billion bricks. It is also assumed that the 44 clamp kilns observed in 2018 were active, and that each employed 10 workers and produced 20,000 bricks per month (2 batches of 10,000). Within the study area, this brings the total estimated workforce to nearly 27,500 persons, and brick production to 1.579 billion bricks per year.

Although data regarding kiln length was not collected for 1965, 2004, or 2011, kiln status and activity were observed for these years. By applying the 2018 average monthly production per BTK to the count of BTKs in each of these years, the annual brick production of the study area for prior years was estimated. In 1965, production was found to be 59.9 million, which increased to 82.4 million in 2004, and 1.223 billion in 2011.

Figure 11a describes the relationships of observed changes in kiln numbers over time. Overall, there was a linear relationship in the total number of kilns (R

2 = 0.993). This linear relationship is explained by an exponential increase in BTKs (R

2 = 0.995), offset by a decrease in clamp kilns (second order polynomial relationship, R

2 = 0.949). Despite the linear nature of this increase in total kiln numbers, the transition from small clamp style kilns to larger and more efficient BTKs in the early 2000s results in an exponential increase in brick production (shown in

Figure 11b). This trend matches the exponential growth of Kabul’s population since the 1960s (

Figure 11b) and suggests that population growth is a significant factor driving brick demand among other factors.

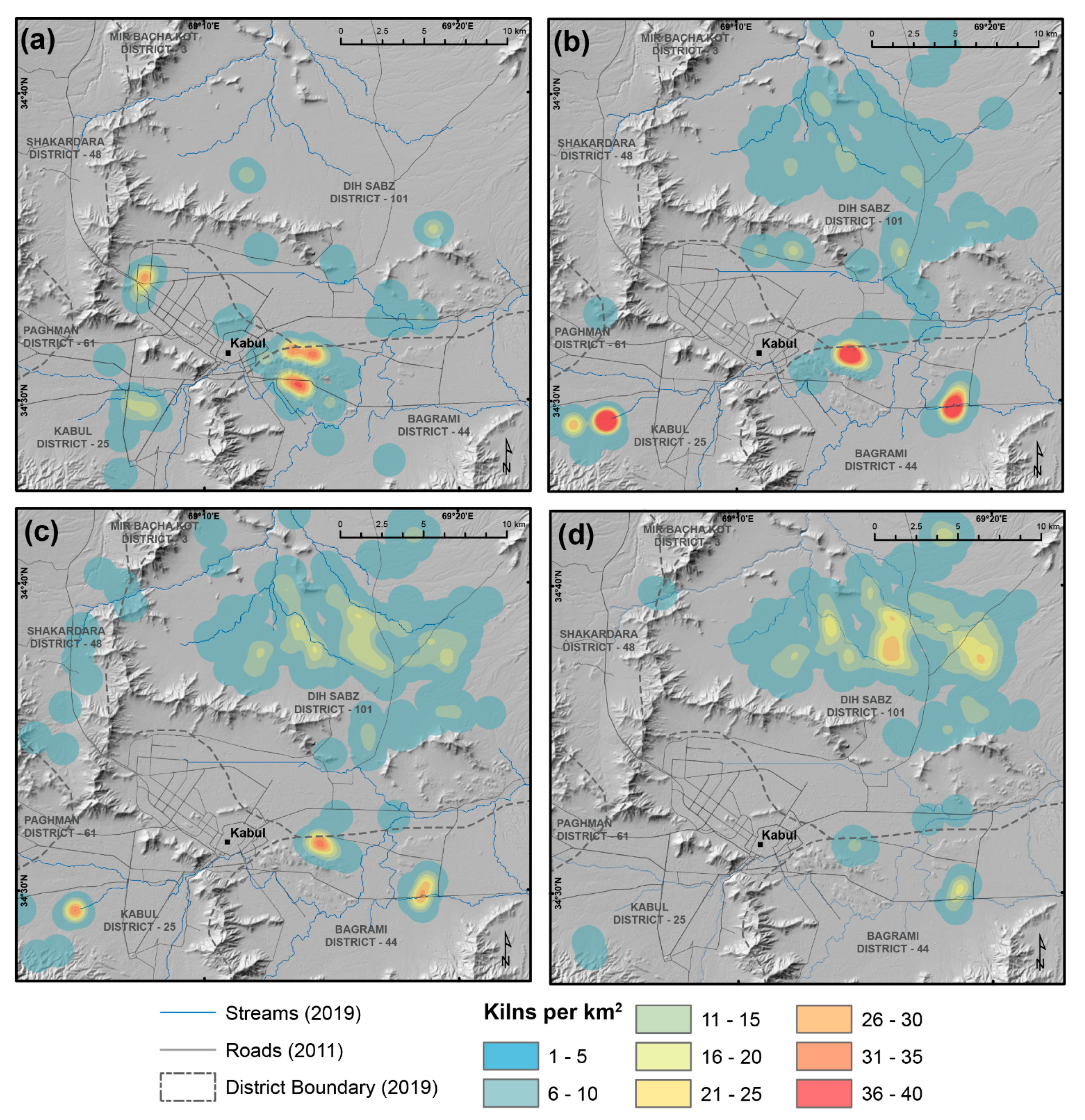

In addition to the increase in the number of brick kilns, the spatial distribution and density of kilns also changed substantially over the period of observation.

Figure 12 shows the results of the kernel density analysis. Kilns in 1965 clustered in various areas of development near the urban core of Kabul. However, by 2004 kilns had migrated out of the Kabul district to the Dih Sabz district along the city’s north-eastern periphery. During this time period, clusters of brick making began to spread to the southeast and west of Kabul. After 2004, the brick-making industry shifted almost exclusively to the northeast of the city.

The results of visual interpretation also point to the adoption of small-scale continuous BTK technology over the artisanal intermittent clamp style kilns. Despite a small increase between 1965 and 2004, over the 53 years covered by the study the number of clamp kilns decreased from 296 to 44. Conversely, BTK style kilns increased during this same period from 7 to 581. The graph in

Figure 8 also shows the number of each type of kiln compared to the total number of kilns for each year of observation. Other technological changes in the brickmaking industry, such as the number of kiln ventilation stacks, were also observed through visual interpretation. While the number of BTKs with 2 or more movable ventilation stacks increased from 74 kilns (2004) to 171 kilns (2011), this diminished to only 16 kilns in 2018.

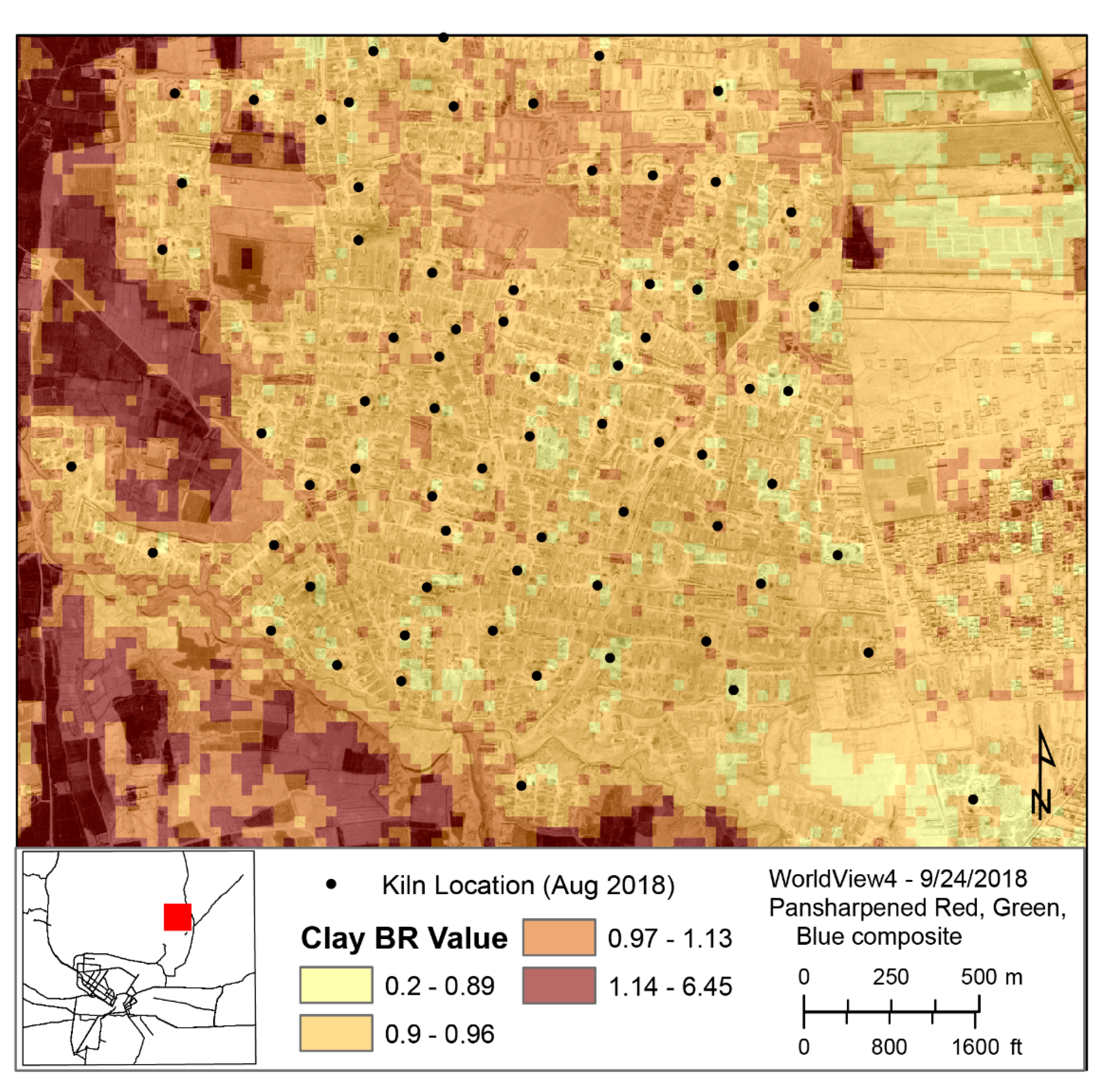

The results of multispectral band ratio analysis of clay quarrying and kiln areas are shown for a small example of the study area in

Figure 13, overlain by kiln locations (black dot). Band ratio values in the study area ranged from 0.2 to 6.45, with an average of 1.14. Summary statistics of the values observed at kiln locations and for surficial geologic units in the study area are shown in

Table 4.

In general, clay band ratio values observed at kiln locations were low compared to those observed in nearby agricultural areas (both vegetated and fallow), and higher clay band ratio values were observed at BTK kilns than at clamp kilns. The Holocene alluvial unit (Qa2) was found to have the highest maximum band ratio value at 6.45, which matches the maximum band ratio value for the study area. The younger alluvial unit (Qa3) was found to have the second highest maximum value at 5.00, and the highest mean value at 1.49. In general, the band ratio values of these young alluvial sediments were somewhat higher than the values of the conglomerate and wind-blown silts of the Lataband geologic units (Nlc and Nlfw). Addressing the latter observation—that higher clay band ratio values were observed at BTKs—it is possible that the transition of BTKs away from the immediate constructions demand in the city necessitated a certain caliber of raw materials. Thus, the different band ratio values observed at the different kiln types may be partially an artifact of development and workforce trends in Kabul.

Brick kilns were located in several geologic units in the Kabul basin, including Qa

1, Qa

2, Qa

3, Qcr, Nlc, and Nlfw. The graph in

Figure 14 shows, for each type of kiln, the number of kilns in each geologic unit. Kiln locations are shown mapped with geologic units in

Figure 9. The description of each of these units is shown in

Table 4, adapted from [

18]. While the landscape position and composition of these units varies, they are almost all (with the exception of the biotite schist) Paleogene to Quaternary in age and primarily composed of sediments derived from alluvial or aeolian processes. The majority of kilns for all years of observation were located in alluvial deposit areas (Qa

2) or wind-blown silt and sand (loess deposits; Nlfw). Detailed spatial analysis of the location of artisanal intermittent clamp style kilns compared to BTKs revealed that the latter are located almost exclusively within the wind-blown silt deposits the northeast of Kabul, while the clamp kilns are found in a variety of different units the majority are located within alluvial deposits (Qa

2).

Hyperspectral analysis conducted by [

23] indicates a difference in the mineral composition of the alluvial and loess units. The alluvial deposits (Qa

2) described by [

18] in the southwest part of Kabul include a mixture of calcite and clay/muscovite with substantial amounts of montmorillonite, muscovite, and illite. The composition of other parts of this unit to the east of Kabul near Bagrami, where clamp kilns were observed in 2004 imagery, indicate a mixture of primarily calcite with calcite and clay/muscovite. By comparison, the composition of the wind-blown silt (Nlfw) supporting the BTKs to the northeast of Kabul includes more muscovite and illite with the calcite and clay/muscovite mixture.

5. Discussion

The clay quarrying and brick making industry is growing substantially in the Kabul region in response to the rapid reconstruction and urbanization. Kabul has experienced rapid population increase in recent years due to the return of refugees, rural to urban in-migration, increased business and work opportunities, and the international investment and spending in the region [

3]. The substantial increase in the number of kilns observed in the region between 2004 and 2018 is evidence of the development and growth in the city. The labor force employed by these kilns is considerable and has been growing. In 2018 there were 587 BTKs and 44 clamp kilns operating in Kabul. Each of the BTK kilns employs between 30 and 220 people [

7] while approximately 10 people are needed to operate an artisanal clamp kiln. Based upon the number and sizes of kilns identified in 2018 and the values observed by [

7], the labor force of the brick making industry in Kabul can be estimated at approximately 27,500 workers. BTKs produce 20,000–50,000 bricks per day and clamp kilns produce approximately 10,000 per batch [

12]. Based upon the number and sizes of kilns identified in 2018 and these production values, the 2018 brick production of the Kabul area is estimated to be over 1.579 billion bricks per year.

Multiple changes in the brick making industry were observed during this study. The change from intermittent clamp style kilns to BTKs is one indicator of the increased demand for bricks in the greater Kabul area. While the intermittent clamp style kilns at one time were capable of providing the necessary bricks for new structures, in the face of the recent rapid development the improved efficiency of the BTK style kiln has led to its almost universal adoption. This demand-driven technological change is evident from the similar exponential increase of the brick production in time with exponential population increase (

Figure 11b). Thus, while the total number of brick kilns (clamp and BTK) has increased linearly (

Figure 11a), brick supply has been able to meet the exponentially increasing demand. The transition of BTKs from multiple ventilation stacks to the more efficient single central ventilation stack is further evidence of technological innovation in response to the huge demand for bricks. This relatively recent shift in BTK technology is also beneficial for the city of Kabul, which has severe air quality problems, because the improved draught of the single central ventilation stack causes the kiln to burn hotter and reduces the emissions and unburned fuel used in the kiln [

8,

10].

Shifts in the location of kilns and brick making throughout the greater Kabul region are another point of interest revealed by this study. The BTKs observed in 2018 imagery are located along the outer, north-eastern periphery of Kabul, in the Dih Sabz district. While the development demands of Kabul have also shifted towards the outskirts of the city, such development also continues far from the Dih Sabz district along the western and southern fringes of the city. This suggests that proximity to development is not a major driver of BTK location. These shifts in the distribution of kilns have serious implications for the health of those living in the Dih Sabz district, as the increased density of brick kilns is likely accompanied by increased pollution from airborne kiln particulate matter. This pollution also potentially affects the productivity of agricultural fields in the vicinity.

In Kabul, a noteworthy factor in determining kiln location appears to be related to the composition of surficial geologic units. The artisanal intermittent clamp kilns were located primarily in areas underlain by alluvial deposits. Hyperspectral analysis of the area of these units suggests that they contain predominantly clay/muscovite, with some areas also containing montmorillonite and illite. These clay components allowed for the adhesion necessary for artisanal and small-batch brick making of the clamp kilns. While this analysis does not indicate the substantial presence of ‘clay’ minerals underlying the locations of newer BTKs, the wind-blown silt (loess) in these locations is suitable and perhaps superior for brick making since hyperspectral analysis indicates the presence of illite, a type of non-expanding clay that would aid in brick cohesion and be less likely to crack or break during firing, in the surficial sediments near BTKs. The extent of these wind-blown silts in the Dih Sabz region is extensive, suggesting the potential for additional expansion of the already sprawling brick making area.

The finding that the surficial material mined for brick making in north-eastern Kabul is not purely ‘clay’ partially explains the extreme difficulty in multispectral classification of these quarrying and brick making areas [

19] and the mixed results of band ratio analysis. While the alluvial deposits (Qa

2, Qa

3, etc.) had higher band ratio values suggesting higher clay content, these units occur in flat areas that have supported significant urban development (

Figure 10). Thus, while alluvial deposit sediments may have been excellent for brick making, the expansion of neighborhoods and commercial space has eclipsed the artisanal clamp style brick kilns in these areas. The increased prevalence of BTKs has occurred primarily within the wind-blown silt deposit (Nlfw) to the northeast of the city. As indicated by the lower band ratio values of this region, clay content in this area may be lower. However, there is plenty of physical space for the expansive BTKs to occupy. Moreover, demand for the space is low due to its aridity. The results of geologic and hyperspectral analysis indicate that both the wind-blown silt and alluvial deposits contain some amount of clay (specifically illite, montmorillonite, or muscovite/clay), however the fine-grained silty material of the Nlfw dominates the spectral signature of the area of BTK expansion. Thus, the clay absorption in the spectral signature of these surficial sediments is muted and not useful for differentiating the excavation and brick making areas from nearby agricultural areas and other areas devoid of vegetation. Moreover, the presence of moisture in these surficial sediments of agricultural areas overrides the clay absorption feature in their spectral signature, making the irrigated agricultural fields more prominent in band ratio analysis than the immediately adjacent brick making areas (visible in

Figure 13). The band ratio values in this region may also be affected by un-examined factors such as absorption of heavy-metals from nearby industrial and developed areas, which has been shown to cause changes in the absorption of NIR and SWIR wavelengths [

25].