Characterization of Fines Produced by Degradation of Polymetallic Nodules from the Clarion–Clipperton Zone

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup and Procedures

2.2. Analytical Methods

3. Results

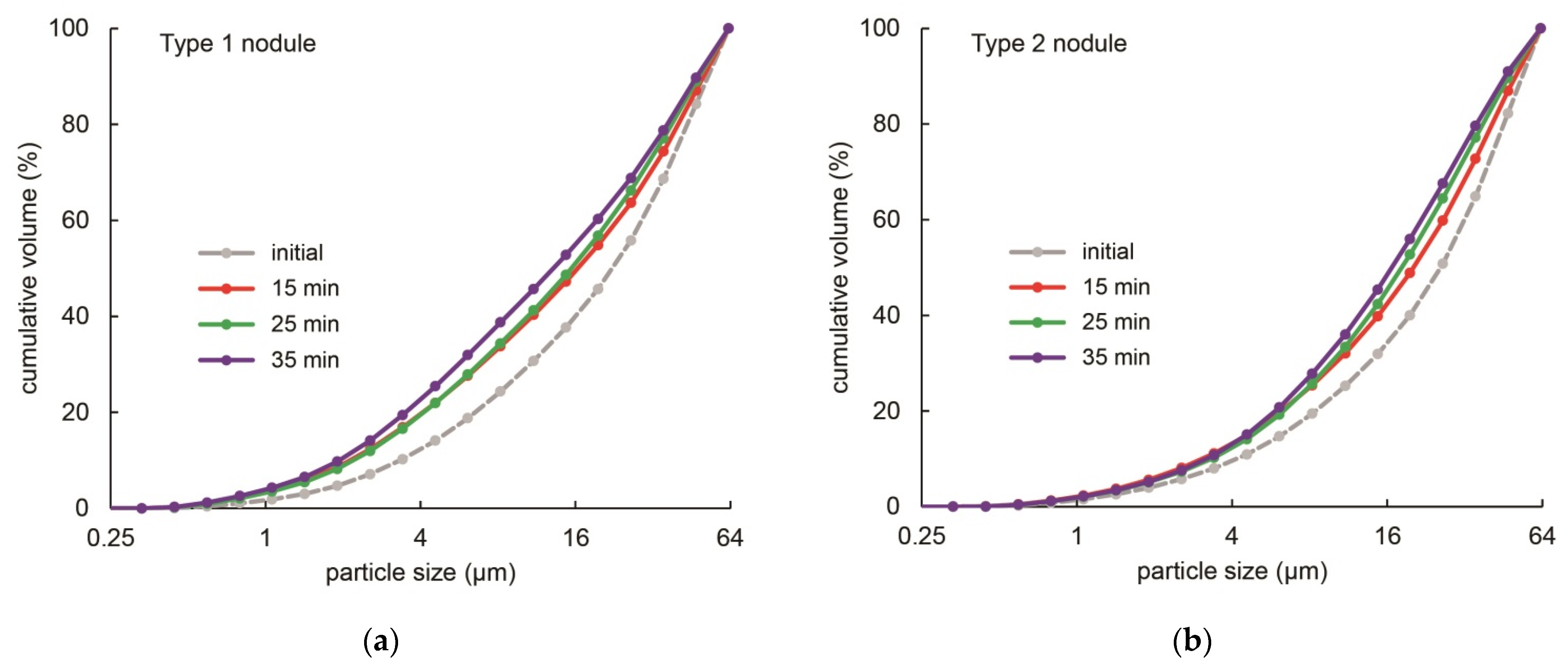

3.1. Particle Size Distribution

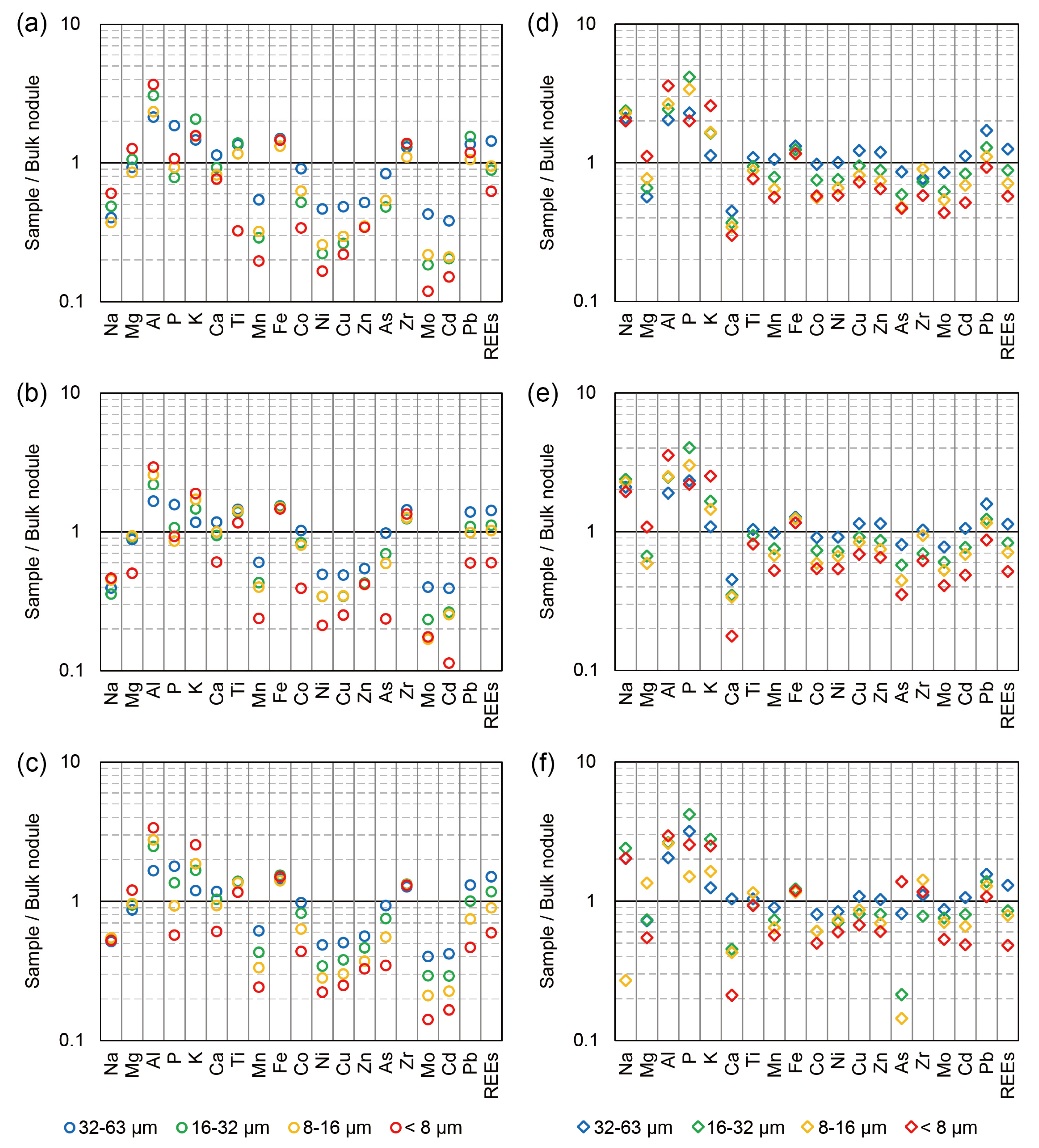

3.2. Chemistry

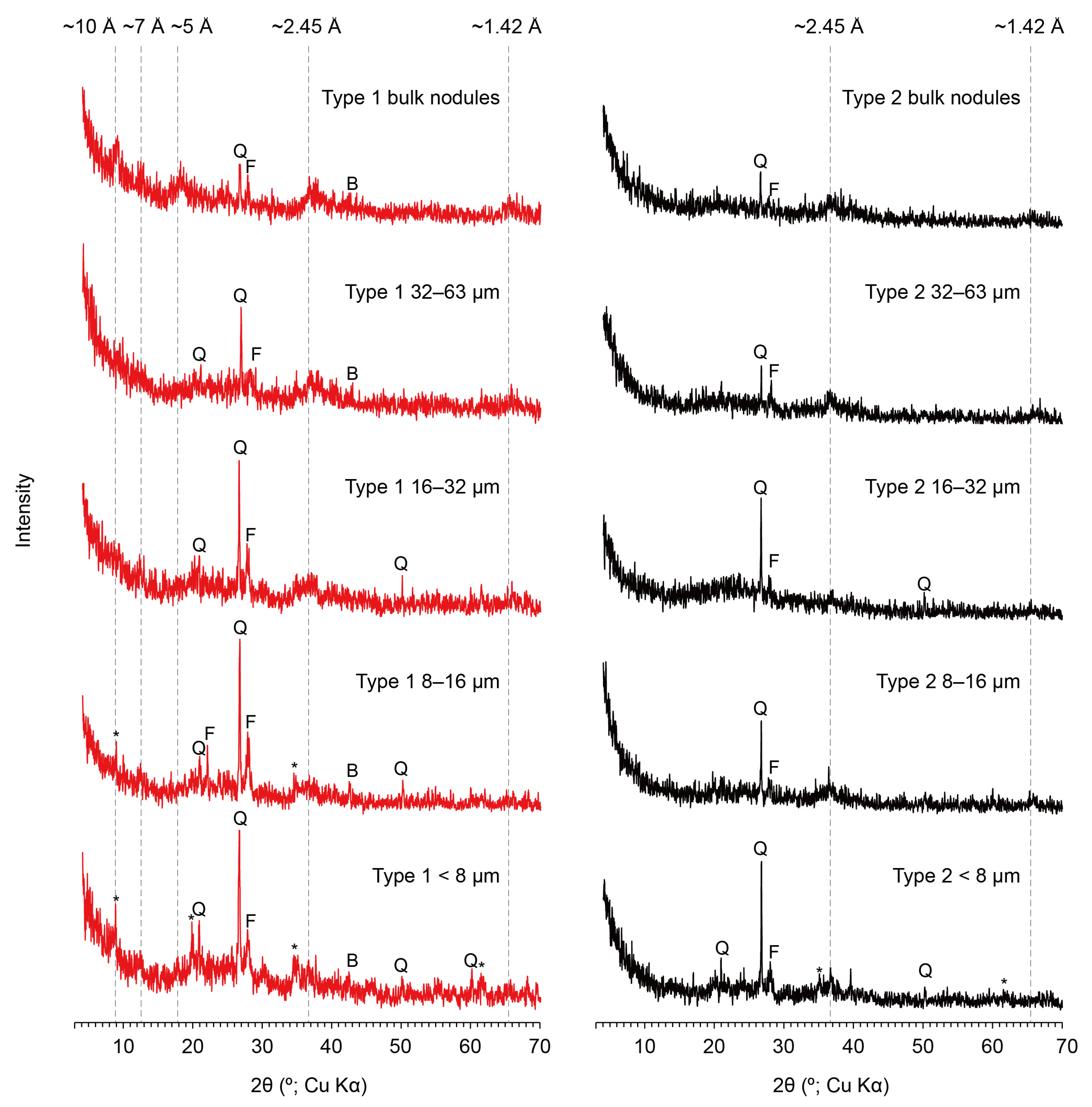

3.3. Mineralogy

4. Discussion

4.1. Causes of Compositional Variation

4.2. Implications on the Nodule Mining

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mero, J.L. The Mineral Resources of the Sea; Elsevier: Amsterdam, The Netherlands, 1965; p. 312. [Google Scholar]

- Amos, A.F.; Roels, O.A. Environment aspects of manganese nodule mining. Mar. Policy 1977, 1, 156–163. [Google Scholar] [CrossRef]

- Sharma, R. Deep-sea impact experiments and their future requirements. Mar. Georesources Geotechnol. 2005, 23, 331–338. [Google Scholar] [CrossRef]

- Sparenberg, O. A historical perspective on deep-sea mining for manganese nodules, 1965–2019. Extr. Ind. Soc. 2019, 6, 842–854. [Google Scholar] [CrossRef]

- Kuhn, T.; Wegorzewski, A.; Rühlemann, C.; Vink, A. Composition, formation, and occurrence of polymetallic nodules. In Deep-Sea Mining; Sharma, R., Ed.; Springer International Publishing: Basel, Switzerland, 2017; pp. 23–63. [Google Scholar]

- Thiel, H.; Tiefsee-Umweltschutz, F. Evaluation of the environmental consequences of polymetallic nodule mining based on the results of the TUSCH Research Association. Deep-Sea Res. Part II—Top. Stud. Oceanogr. 2001, 48, 3433–3452. [Google Scholar] [CrossRef]

- Oebius, H.U.; Becker, H.J.; Rolinski, S.; Jankowski, J.A. Parametrization and evaluation of marine environmental impacts produced by deep-sea manganese nodule mining. Deep-Sea Res. Part II—Top. Stud. Oceanogr. 2001, 48, 3453–3467. [Google Scholar] [CrossRef]

- Schriever, G.; Thiel, H. Tailings and their disposal in deep-sea mining. In Proceedings of the 10th ISOPE Ocean Mining and Gas Hydrates Symposium, Szczecin, Poland, 22–26 September 2013. [Google Scholar]

- Sharma, R. Deep-Sea Mining: Current Status and Future Considerations. In Deep-Sea Mining Resource Potential, Technical and Environmental Considerations; Sharma, R., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 3–21. [Google Scholar]

- Burns, R.E. Assessment of environmental effects of deep ocean mining of manganese nodules. Helgol. Mar. Res. 1980, 33, 433–442. [Google Scholar] [CrossRef]

- Lavelle, J.W.; Ozturgut, E.; Baker, E.T.; Swift, S.A. Discharge and surface plume measurements during manganese nodule mining tests in the North Equatorial Pacific. Mar. Environ. Res. 1982, 7, 51–70. [Google Scholar] [CrossRef]

- International Seabed Authority. Recommendations for the Guidance of Contractors for the Assessment of the Possible Environmental Impacts Arising from Exploration for Polymetallic Nodules in the Area (ISBA/16/LTC/7); International Seabed Authority: Kingston, Jamaica, 2010. [Google Scholar]

- Jones, D.O.; Kaiser, S.; Sweetman, A.K.; Smith, C.R.; Menot, L.; Vink, A.; Trueblood, D.; Greinert, J.; Billett, D.S.M.; Arbizu, P.M.; et al. Biological responses to disturbance from simulated deep-sea polymetallic nodule mining. PLoS ONE 2017, 12, e0171750. [Google Scholar] [CrossRef] [PubMed]

- Christiansen, B.; Denda, A.; Christiansen, S. Potential effects of deep seabed mining on pelagic and benthopelagic biota. Mar. Policy 2020, 114, 103442. [Google Scholar] [CrossRef]

- Beekman, W.J.; Meesters, G.M.; Scarlett, B.; Becker, T. Measurement of granule attrition and fatigue in a vibrating box. Part. Part. Syst. Charact. 2002, 19, 5–11. [Google Scholar] [CrossRef]

- Pitchumani, R.; Zhupanska, O.; Meesters, G.M.; Scarlett, B. Measurement and characterization of particle strength using a new robotic compression tester. Powder Technol. 2004, 143, 56–64. [Google Scholar] [CrossRef]

- Van Wijk, J.M.; De Hoog, E. Size reduction of CCZ polymetallic nodules under repeated impact fragmentation. Results Eng. 2020, 7, 100154. [Google Scholar] [CrossRef]

- Ozturgut, E.; Lavelle, J.W.; Ericson, B.H. Estimated discharge characteristics of a commercial nodule mining operation. Mar. Min. 1981, 3, 1–18. [Google Scholar]

- Yamazaki, T.; Tsurusaki, K.; Handa, K. Discharge from manganese nodule mining system. In Proceedings of the First International Offshore and Polar Engineering Conference, Edinburgh, UK, 11–16 August 1991. [Google Scholar]

- Choi, H.S.; Kang, J.S.; Chang, S.W.; Koh, S.M.; Um, I.K. Shattering ratio of manganese nodule and physical properties of powdered manganese nodule and sea bottom sediment. J. Miner. Soc. Korea 2007, 20, 277–287. [Google Scholar]

- Yoon, C.H.; Kim, J.; Park, H.; Yoo, K. The distribution of particle size and composition of manganese nodule comminuted during lifting. Geosystem Eng. 2015, 18, 348–352. [Google Scholar] [CrossRef]

- Van Wijk, J.M.; Haalboom, S.; De Hoog, E.; De Stigter, H.; Smit, M.G. Impact fragmentation of polymetallic nodules under deep ocean pressure conditions. Miner. Eng. 2019, 134, 250–260. [Google Scholar] [CrossRef]

- De Hoog, E.; Van Wijk, J.M.; Wijnands, J.T.M.; Talmon, A.M. Degradation of polymetallic nodules during hydraulic transport under influence of particle-wall and particle-particle interaction. Miner. Eng. 2020, 155, 106415. [Google Scholar] [CrossRef]

- Wegorzewski, A.V.; Kuhn, T. The influence of suboxic diagenesis on the formation of manganese nodules in the Clarion Clipperton nodule belt of the Pacific Ocean. Mar. Geol. 2014, 357, 123–138. [Google Scholar] [CrossRef]

- Reykhard, L.Y.; Shulga, N.A. Fe-Mn nodule morphotypes from the NE Clarion-Clipperton Fracture Zone, Pacific Ocean: Comparison of mineralogy, geochemistry and genesis. Ore Geol. Rev. 2019, 110, 102933. [Google Scholar] [CrossRef]

- Kim, J.; Hyeong, K.; Lee, H.B.; Ko, Y.T. Relationship between polymetallic nodule genesis and sediment distribution in the KODOS (Korea Deep Ocean Study) area, northeastern Pacific. Ocean Sci. J. 2012, 47, 197–207. [Google Scholar] [CrossRef]

- Rajesh, S.; Gnanaraj, A.A.; Velmurugan, A.; Ramesh, R.; Muthuvel, P.; Babu, M.K.; Ramesh, N.R.; Deepack, C.R.; Atmanand, M.A. Qualification tests on underwater mining system with manganese nodule collection and crushing systems. In Proceedings of the 9th Ocean Mining Symposium, Maui, HI, USA, 19–24 June 2011. [Google Scholar]

- Sung, K.Y.; Min, C.H.; Kim, H.W.; Lee, C.H.; Oh, J.W.; Hong, S. Performance Test for the Manganese Nodule Crushing Equipment of the Deep Seabed Mining Robot ’MineRo’. Ocean Polar Res. 2014, 36, 19–24. [Google Scholar] [CrossRef]

- Hein, J.R.; Koschinsky, A.; Kuhn, T. Deep-ocean polymetallic nodules as a resource for critical materials. Nat. Rev. Earth Environ. 2020, 1, 158–169. [Google Scholar] [CrossRef]

- Wegorzewski, A.V.; Kuhn, T.; Dohrmann, R.; Wirth, R.; Grangeon, S. Mineralogical characterization of individual growth structures of Mn-nodules with different Ni+ Cu content from the central Pacific Ocean. Am. Min. 2015, 100, 2497–2508. [Google Scholar] [CrossRef]

- Chi, S.B.; Hyeong, K.S.; Kim, J.U.; Kim, H.S.; Lee, G.C.; Son, S.K. Classification of deep-sea sediment by geotechnical properties from the KODOS area in the C-C Zone of the northeast equatorial Pacific. Ocean Polar Res. 2003, 25, 529–543. [Google Scholar] [CrossRef][Green Version]

- Chi, S.B.; Lee, H.B.; Hyeong, K.S.; Ju, S.J.; Lee, G.C.; Ham, D.J. Geotechnical properties of pelagic red clay in northeast equatorial Pacific. Sea 2008, 13, 286–294. [Google Scholar]

- Min, W.G.; Kim, D.; Rho, H.S.; Chi, S.B.; Son, S.K. Distribution and variability of the meiobenthic assemblages near the Korean polymetallic nodule claim area of the Clarion-Clipperton Fracture zone (subequatorial NE Pacific). Ocean Sci. J. 2018, 53, 315–336. [Google Scholar] [CrossRef]

- Gillard, B.; Purkiani, K.; Chatzievangelou, D.; Vink, A.; Iversen, M.; Thomsen, L. Physical and hydrodynamic properties of deep sea mining-generated, abyssal sediment plumes in the Clarion Clipperton Fracture Zone (eastern-central Pacific). Elementa 2019, 7, 5. [Google Scholar] [CrossRef]

- Zawadzki, D.; Maciag, Ł.; Abramowski, T.; McCartney, K. Fractionation trends and variability of rare earth elements and selected critical metals in pelagic sediment from abyssal basin of NE Pacific (Clarion-Clipperton Fracture Zone). Minerals 2020, 10, 320. [Google Scholar] [CrossRef]

- Menendez, A.; James, R.H.; Lichtschlag, A.; Connelly, D.; Peel, K. Controls on the chemical composition of ferromanganese nodules in the Clarion-Clipperton Fracture Zone, eastern equatorial Pacific. Mar. Geol. 2019, 409, 1–14. [Google Scholar] [CrossRef]

- Blöthe, M.; Wegorzewski, A.; Müller, C.; Simon, F.; Kuhn, T.; Schippers, A. Manganese-cycling microbial communities inside deep-sea manganese nodules. Environ. Sci. Technol. 2015, 49, 7692–7700. [Google Scholar] [CrossRef]

- Koschinsky, A.; Winkler, A.; Fritsche, U. Importance of different types of marine particles for the scavenging of heavy metals in the deep-sea bottom water. Appl. Geochem. 2003, 18, 693–710. [Google Scholar] [CrossRef]

- Toro, N.; Jeldres, R.I.; Órdenes, J.A.; Robles, P.; Navarra, A. Manganese nodules in Chile, an alternative for the production of Co and Mn in the future—A review. Minerals 2020, 10, 674. [Google Scholar] [CrossRef]

- Rolinski, S.; Segschneider, J.; Sündermann, J. Long-term propagation of tailings from deep-sea mining under variable conditions by means of numerical simulations. Deep-Sea Res. Part II—Top. Stud. Oceanogr. 2001, 48, 3469–3485. [Google Scholar] [CrossRef]

- Cuvelier, D.; Gollner, S.; Jones, D.O.; Kaiser, S.; Arbizu, P.M.; Menzel, L.; Mestre, N.C.; Morato, T.; Pham, C.; Pradillon, F.; et al. Potential mitigation and restoration actions in ecosystems impacted by seabed mining. Front. Mar. Sci. 2018, 5, 467. [Google Scholar] [CrossRef]

- Levin, L.A.; Amon, D.J.; Lily, H. Challenges to the sustainability of deep-seabed mining. Nat. Sustain. 2020, 3, 784–794. [Google Scholar] [CrossRef]

- International Seabed Authority. Draft Regulations on Exploitation of Mineral Resources in the Area (ISBA/25/C/WP.1); International Seabed Authority: Kingston, Jamaica, 2019. [Google Scholar]

- International Seabed Authority. Comments on the Draft Regulations on Exploitation of Mineral Resources in the Area (ISBA/26/C/2); International Seabed Authority: Kingston, Jamaica, 2020. [Google Scholar]

- Jaeckel, A. Strategic environmental planning for deep seabed mining in the area. Mar. Policy 2020, 114, 103423. [Google Scholar] [CrossRef]

- Ginzky, H.; Singh, P.A.; Markus, T. Strengthening the International Seabed Authority’s knowledge-base: Addressing uncertainties to enhance decision-making. Mar. Policy 2020, 114, 103823. [Google Scholar] [CrossRef]

| Element | Bulk Nodule | 15 Min | 25 Min | 35 Min | Surface Sediment 1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 32–63 | 16–32 | 8–16 | <8 μm | 32–63 | 16–32 | 8–16 | <8 μm | 32–63 | 16–32 | 8–16 | <8 μm | |||

| Na (wt %) | 2.16 | 0.87 | 1.05 | 0.8 | 1.3 | 0.85 | 0.77 | 0.97 | 0.11 | 1.11 | 1.16 | 1.18 | 1.13 | - |

| Mg | 1.65 | 1.53 | 1.75 | 1.41 | 2.09 | 1.45 | 1.51 | 1.54 | 0.83 | 1.43 | 1.55 | 1.59 | 1.98 | 1.86 |

| Al | 2.03 | 4.34 | 6.22 | 4.75 | 7.45 | 3.37 | 4.43 | 5.2 | 5.92 | 3.36 | 5.02 | 5.59 | 6.82 | 6.01 |

| P | 0.14 | 0.26 | 0.11 | 0.13 | 0.15 | 0.22 | 0.15 | 0.12 | 0.13 | 0.25 | 0.19 | 0.13 | 0.08 | 0.14 |

| K | 0.93 | 1.36 | 1.92 | 1.45 | 1.46 | 1.09 | 1.36 | 1.59 | 1.75 | 1.11 | 1.55 | 1.73 | 2.36 | 2.03 |

| Ca | 1.32 | 1.5 | 1.22 | 1.08 | 1.01 | 1.55 | 1.24 | 1.32 | 0.8 | 1.55 | 1.36 | 1.23 | 0.8 | 0.81 |

| Ti | 0.31 | 0.42 | 0.43 | 0.36 | 0.1 | 0.45 | 0.43 | 0.44 | 0.36 | 0.43 | 0.43 | 0.42 | 0.36 | 0.3 |

| Mn | 28.55 | 15.47 | 8.22 | 9.12 | 5.6 | 17.2 | 12.26 | 11.41 | 6.77 | 17.52 | 12.29 | 9.5 | 6.9 | 0.43 |

| Fe | 4.48 | 6.7 | 6.55 | 5.9 | 6.52 | 6.89 | 6.84 | 6.7 | 6.56 | 6.47 | 6.88 | 6.28 | 6.71 | 3.82 |

| Co (ppm) | 1589 | 1442 | 826 | 996 | 538 | 1620 | 1326 | 1276 | 624 | 1549 | 1303 | 1004 | 693 | 67 |

| Ni | 12161 | 5657 | 2689 | 3126 | 2017 | 6003 | 4159 | 4176 | 2577 | 5916 | 4163 | 3415 | 2712 | 156 |

| Cu | 9839 | 4753 | 2578 | 2897 | 2152 | 4792 | 3376 | 3397 | 2468 | 4954 | 3736 | 2957 | 2449 | 406 |

| Zn | 1300 | 674 | 451 | 455 | 446 | 705 | 556 | 542 | 545 | 730 | 602 | 482 | 426 | 130 |

| As | 61 | 51 | 29 | 33 | 6 | 59 | 42 | 36 | 14 | 57 | 46 | 34 | 21 | - |

| Zr | 228 | 297 | 310 | 251 | 315 | 330 | 284 | 288 | 306 | 290 | 303 | 299 | 297 | 161 |

| Mo | 694 | 296 | 127 | 151 | 82 | 277 | 162 | 117 | 121 | 278 | 202 | 147 | 98 | - |

| Cd | 19 | 7 | 4 | 4 | 3 | 7 | 5 | 5 | 2 | 8 | 5 | 4 | 3 | - |

| Pb | 200 | 273 | 309 | 211 | 237 | 278 | 219 | 197 | 119 | 262 | 201 | 149 | 93 | 8 |

| La (ppm) | 95 | 129 | 84 | 87 | 66 | 125 | 100 | 92 | 58 | 134 | 106 | 83 | 59 | 39 |

| Ce | 338 | 387 | 261 | 277 | 190 | 441 | 369 | 339 | 195 | 447 | 359 | 282 | 195 | 71 |

| Pr | 32 | 45 | 28 | 30 | 19 | 43 | 33 | 30 | 18 | 46 | 37 | 27 | 18 | 13 |

| Nd | 126 | 190 | 110 | 117 | 79 | 182 | 131 | 120 | 71 | 192 | 143 | 112 | 68 | 54 |

| Sm | 32 | 49 | 29 | 32 | 19 | 46 | 34 | 31 | 17 | 49 | 38 | 27 | 17 | 13 |

| Eu | 8 | 14 | 8 | 9 | 5 | 12 | 9 | 8 | 5 | 13 | 10 | 8 | 5 | 4 |

| Gd | 26 | 47 | 27 | 29 | 16 | 42 | 31 | 28 | 16 | 43 | 34 | 24 | 15 | 14 |

| Tb | 4 | 8 | 4 | 5 | 2 | 7 | 5 | 4 | 2 | 7 | 5 | 4 | 2 | 2 |

| Dy | 23 | 40 | 23 | 25 | 14 | 36 | 26 | 24 | 14 | 38 | 29 | 21 | 13 | 13 |

| Y | 82 | 178 | 101 | 109 | 66 | 154 | 113 | 103 | 63 | 172 | 132 | 97 | 61 | 67 |

| Ho | 4 | 8 | 4 | 5 | 3 | 7 | 5 | 4 | 3 | 7 | 5 | 4 | 2 | 3 |

| Er | 12 | 22 | 12 | 13 | 8 | 19 | 14 | 13 | 7 | 21 | 15 | 11 | 7 | 7 |

| Tm | 2 | 3 | 2 | 2 | 1 | 3 | 2 | 2 | 1 | 3 | 2 | 2 | 1 | 1 |

| Yb | 11 | 20 | 11 | 12 | 7 | 18 | 13 | 12 | 7 | 19 | 14 | 11 | 7 | 7 |

| Lu | 2 | 3 | 2 | 2 | 1 | 3 | 2 | 2 | 1 | 3 | 2 | 2 | 1 | 1 |

| Mn/Fe | 6.37 | 2.31 | 1.25 | 1.55 | 0.86 | 2.50 | 1.79 | 1.70 | 1.03 | 2.71 | 1.79 | 1.51 | 1.03 | 0.02 |

| Element | Bulk Nodule | 15 Min | 25 Min | 35 Min | Surface Sediment 1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 32–63 | 16–32 | 8–16 | <8 μm | 32–63 | 16–32 | 8–16 | <8 μm | 32–63 | 16–32 | 8–16 | <8 μm | |||

| Na (wt %) | 1.41 | 2.95 | 3.33 | 3.21 | 2.82 | 2.94 | 3.34 | 3.2 | 2.73 | 2.85 | 3.38 | 0.38 | 2.86 | - |

| Mg | 0.9 | 0.51 | 0.59 | 0.69 | 1 | 0.53 | 0.6 | 0.53 | 0.97 | 0.65 | 0.66 | 1.21 | 0.49 | 1.86 |

| Al | 1.36 | 2.77 | 3.3 | 3.6 | 4.87 | 2.57 | 3.35 | 3.38 | 4.82 | 2.78 | 3.58 | 3.52 | 3.99 | 6.01 |

| P | 0.44 | 1 | 1.82 | 1.49 | 0.88 | 1.02 | 1.77 | 1.32 | 0.96 | 1.39 | 1.84 | 0.66 | 1.12 | 0.14 |

| K | 0.49 | 0.55 | 0.8 | 0.81 | 1.26 | 0.53 | 0.81 | 0.71 | 1.23 | 0.61 | 1.36 | 0.8 | 1.22 | 2.03 |

| Ca | 2.04 | 0.91 | 0.75 | 0.7 | 0.61 | 0.92 | 0.71 | 0.69 | 0.36 | 2.11 | 0.92 | 0.87 | 0.43 | 0.81 |

| Ti | 0.81 | 0.88 | 0.76 | 0.71 | 0.62 | 0.84 | 0.76 | 0.66 | 0.66 | 0.84 | 0.76 | 0.93 | 0.75 | 0.3 |

| Mn | 16.39 | 17.33 | 12.84 | 10.55 | 9.21 | 16.03 | 12.35 | 11.05 | 8.58 | 14.7 | 11.98 | 10.54 | 9.34 | 0.43 |

| Fe | 13.57 | 17.81 | 16.81 | 15.64 | 15.77 | 17.24 | 16.96 | 16.81 | 15.71 | 16.16 | 16.57 | 15.68 | 16.11 | 3.82 |

| Co (ppm) | 4127 | 4017 | 3088 | 2311 | 2368 | 3746 | 3021 | 2445 | 2235 | 3316 | 2498 | 2512 | 2056 | 67 |

| Ni | 3614 | 3616 | 2732 | 2366 | 2098 | 3306 | 2614 | 2402 | 1946 | 3037 | 2536 | 2636 | 2167 | 156 |

| Cu | 748 | 914 | 708 | 607 | 543 | 855 | 682 | 628 | 514 | 807 | 603 | 647 | 504 | 406 |

| Zn | 512 | 609 | 451 | 377 | 331 | 584 | 442 | 381 | 334 | 525 | 412 | 354 | 309 | 130 |

| As | 175 | 150 | 103 | 84 | 82 | 141 | 101 | 78 | 62 | 142 | 37 | 25 | 242 | - |

| Zr | 310 | 238 | 226 | 279 | 179 | 319 | 215 | 291 | 192 | 342 | 242 | 440 | 361 | 161 |

| Mo | 362 | 306 | 224 | 194 | 157 | 281 | 218 | 190 | 148 | 315 | 274 | 254 | 192 | - |

| Cd | 4 | 4 | 3 | 2 | 2 | 4 | 3 | 2 | 2 | 4 | 3 | 2 | 2 | - |

| Pb | 793 | 1352 | 1020 | 876 | 733 | 1253 | 975 | 917 | 691 | 1235 | 1092 | 1014 | 853 | 8 |

| La (ppm) | 198 | 221 | 138 | 100 | 73 | 201 | 127 | 99 | 68 | 280 | 141 | 103 | 61 | 39 |

| Ce | 615 | 778 | 593 | 515 | 444 | 702 | 572 | 523 | 398 | 681 | 590 | 584 | 380 | 71 |

| Pr | 36 | 44 | 27 | 16 | 11 | 39 | 24 | 15 | 10 | 52 | 22 | 18 | 9 | 13 |

| Nd | 141 | 183 | 113 | 70 | 49 | 165 | 102 | 68 | 44 | 225 | 92 | 77 | 39 | 54 |

| Sm | 28 | 38 | 23 | 17 | 11 | 34 | 21 | 16 | 11 | 45 | 22 | 18 | 9 | 13 |

| Eu | 7 | 10 | 6 | 5 | 3 | 9 | 6 | 4 | 3 | 12 | 6 | 5 | 3 | 4 |

| Gd | 29 | 45 | 29 | 24 | 17 | 41 | 26 | 23 | 16 | 55 | 28 | 26 | 13 | 14 |

| Tb | 5 | 6 | 4 | 3 | 2 | 5 | 3 | 3 | 2 | 7 | 4 | 3 | 1 | 2 |

| Dy | 26 | 34 | 22 | 20 | 14 | 31 | 20 | 18 | 13 | 41 | 23 | 21 | 11 | 13 |

| Y | 154 | 206 | 132 | 90 | 59 | 186 | 115 | 80 | 53 | 315 | 133 | 98 | 45 | 67 |

| Ho | 6 | 7 | 5 | 3 | 2 | 7 | 4 | 3 | 2 | 9 | 5 | 4 | 2 | 3 |

| Er | 17 | 21 | 14 | 11 | 8 | 19 | 13 | 10 | 7 | 27 | 14 | 11 | 6 | 7 |

| Tm | 3 | 3 | 2 | 2 | 1 | 3 | 2 | 2 | 1 | 4 | 2 | 2 | 1 | 1 |

| Yb | 16 | 19 | 13 | 12 | 9 | 17 | 12 | 11 | 8 | 22 | 13 | 13 | 7 | 7 |

| Lu | 2 | 3 | 2 | 2 | 1 | 3 | 2 | 2 | 1 | 4 | 2 | 2 | 1 | 1 |

| Mn/Fe | 1.21 | 0.97 | 0.76 | 0.67 | 0.58 | 0.93 | 0.73 | 0.66 | 0.55 | 0.91 | 0.72 | 0.67 | 0.58 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.G.; Hyeong, K.; Yoo, C.M.; Lee, J.Y.; Seo, I. Characterization of Fines Produced by Degradation of Polymetallic Nodules from the Clarion–Clipperton Zone. Minerals 2021, 11, 205. https://doi.org/10.3390/min11020205

Kim MG, Hyeong K, Yoo CM, Lee JY, Seo I. Characterization of Fines Produced by Degradation of Polymetallic Nodules from the Clarion–Clipperton Zone. Minerals. 2021; 11(2):205. https://doi.org/10.3390/min11020205

Chicago/Turabian StyleKim, Mun Gi, Kiseong Hyeong, Chan Min Yoo, Ji Yeong Lee, and Inah Seo. 2021. "Characterization of Fines Produced by Degradation of Polymetallic Nodules from the Clarion–Clipperton Zone" Minerals 11, no. 2: 205. https://doi.org/10.3390/min11020205

APA StyleKim, M. G., Hyeong, K., Yoo, C. M., Lee, J. Y., & Seo, I. (2021). Characterization of Fines Produced by Degradation of Polymetallic Nodules from the Clarion–Clipperton Zone. Minerals, 11(2), 205. https://doi.org/10.3390/min11020205