Diagnosis and Optimization of Gold Ore Flotation Circuit via Linear Circuit Analysis and Mass Balance Simulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

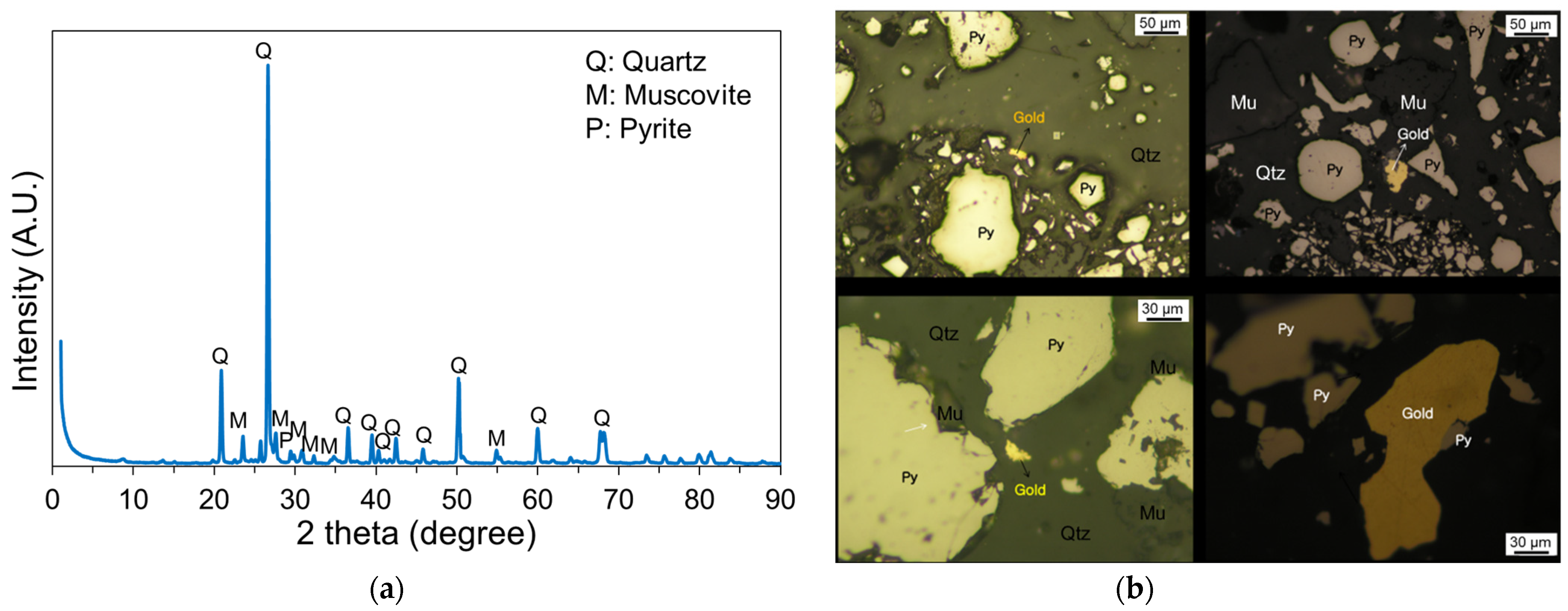

2.2. Characterization of Gold Ores

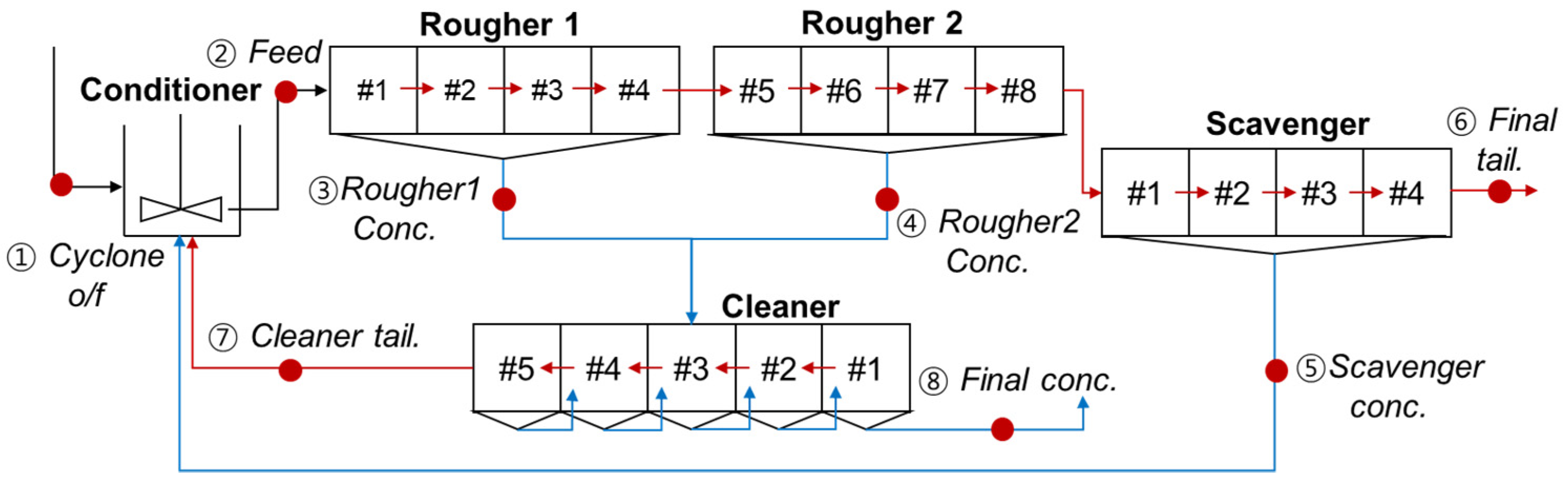

2.3. Flotation Circuit Description

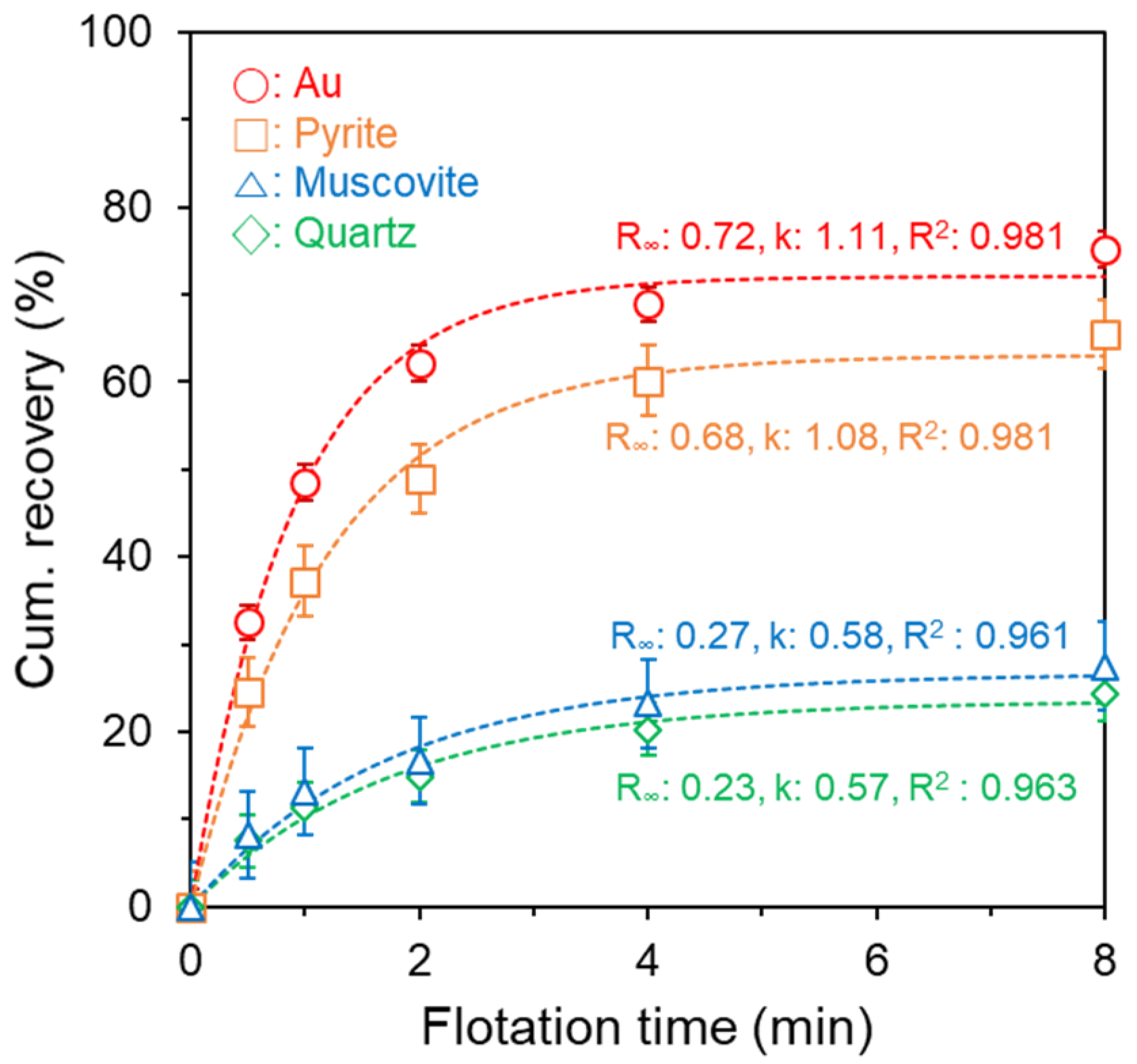

2.4. Measurement of Flotation Rate Constant

2.5. Optimization of Process: Alternative Process Proposal

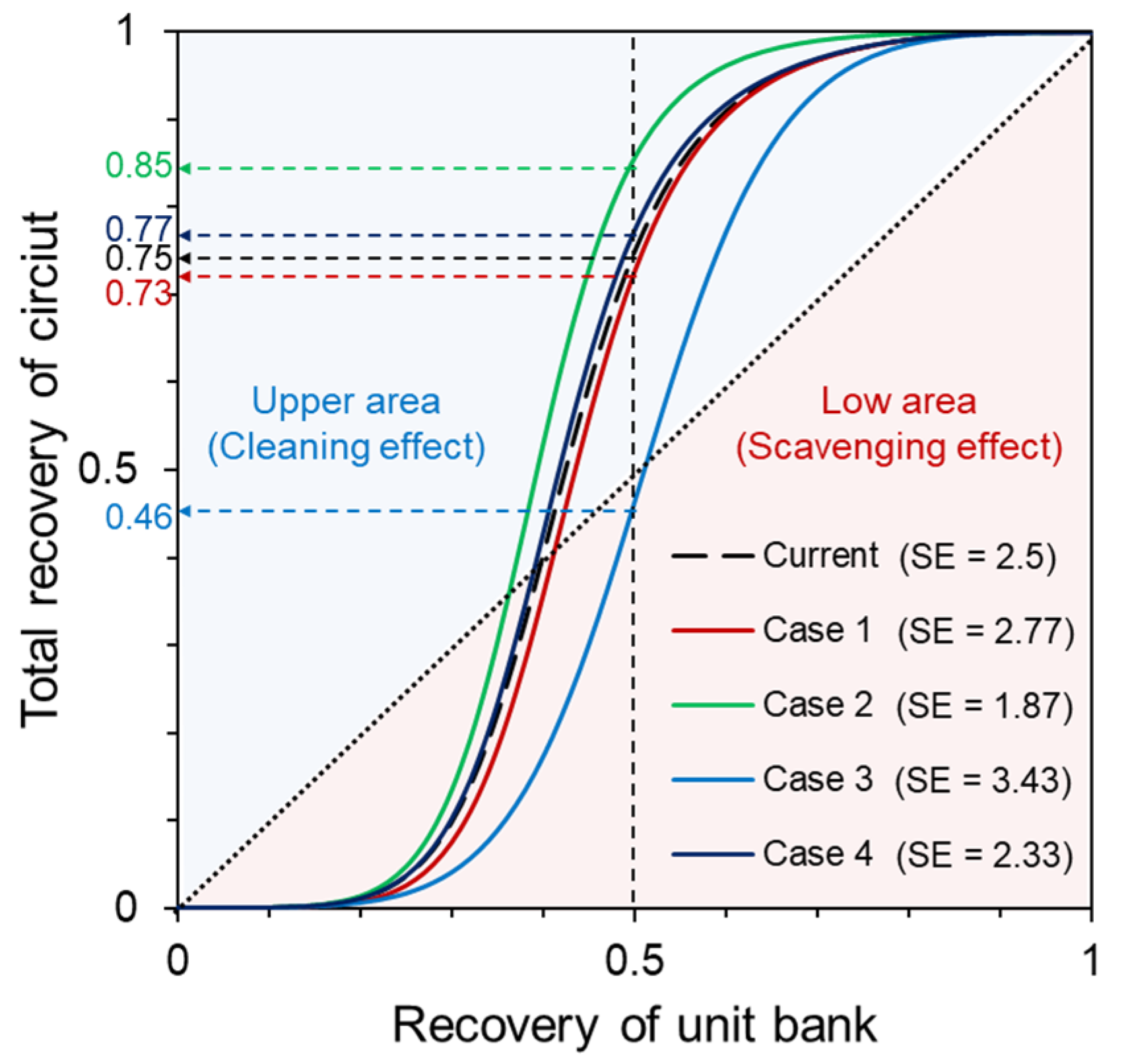

2.6. LCA

2.7. Simulation of Mass Balance

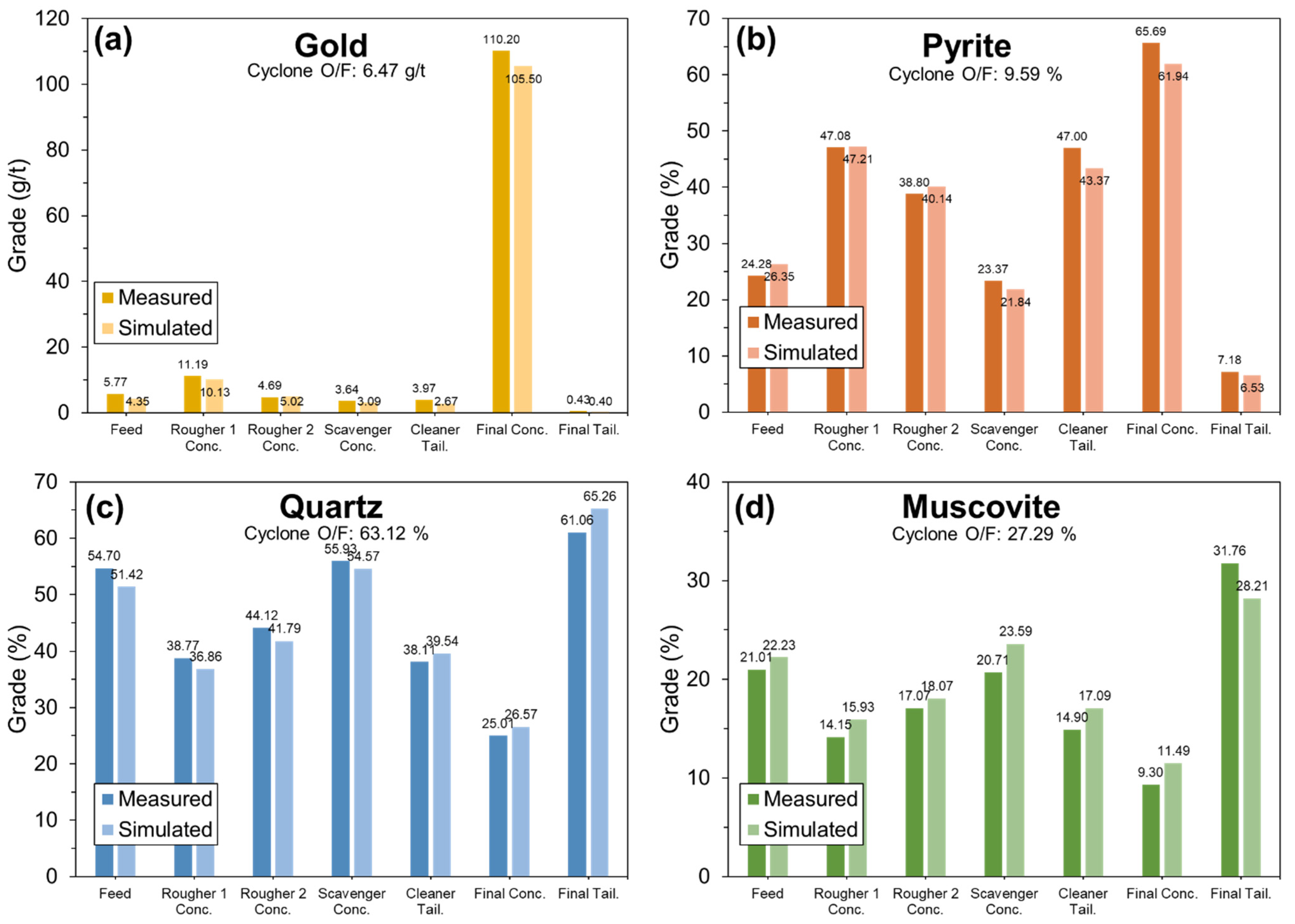

2.8. Validation of Simulation

3. Results and Discussion

3.1. Characterization of Gold Ores

3.2. Flotation Kinetics

3.3. LCAs

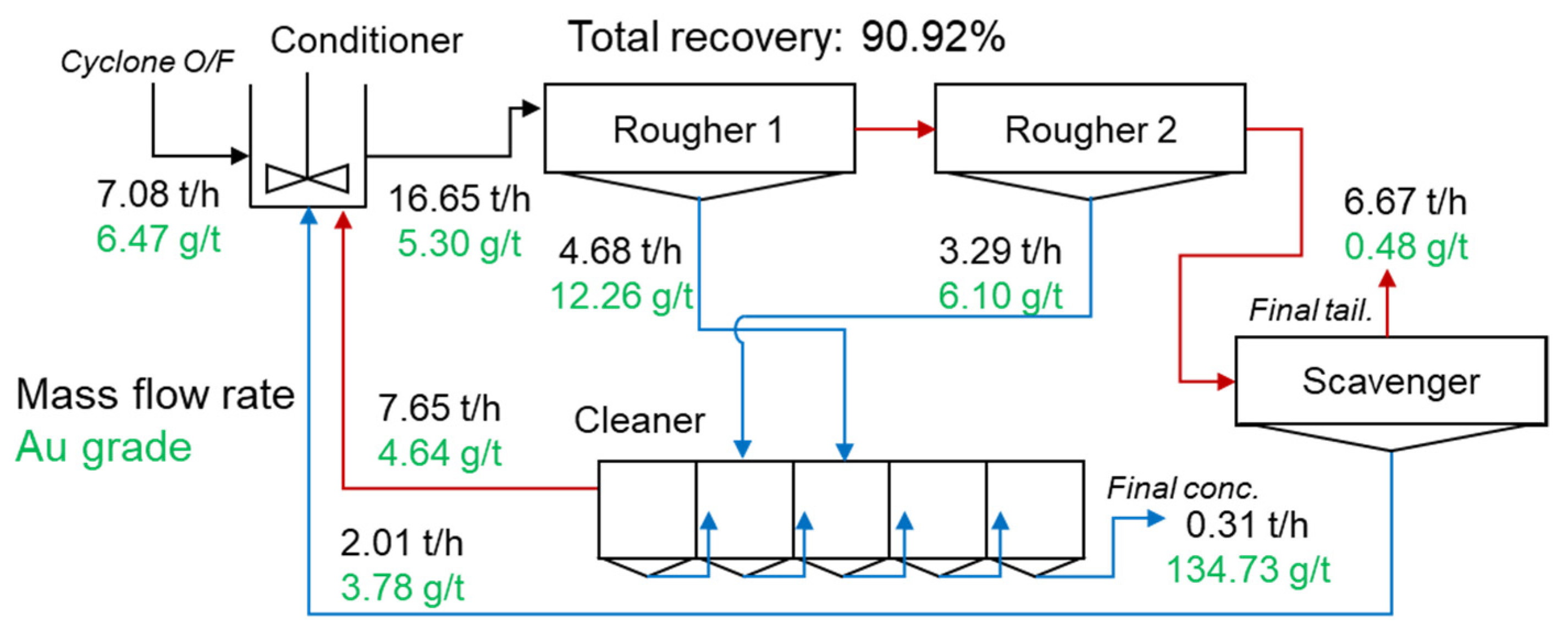

3.4. Mass Balance of Current Flotation Circuit

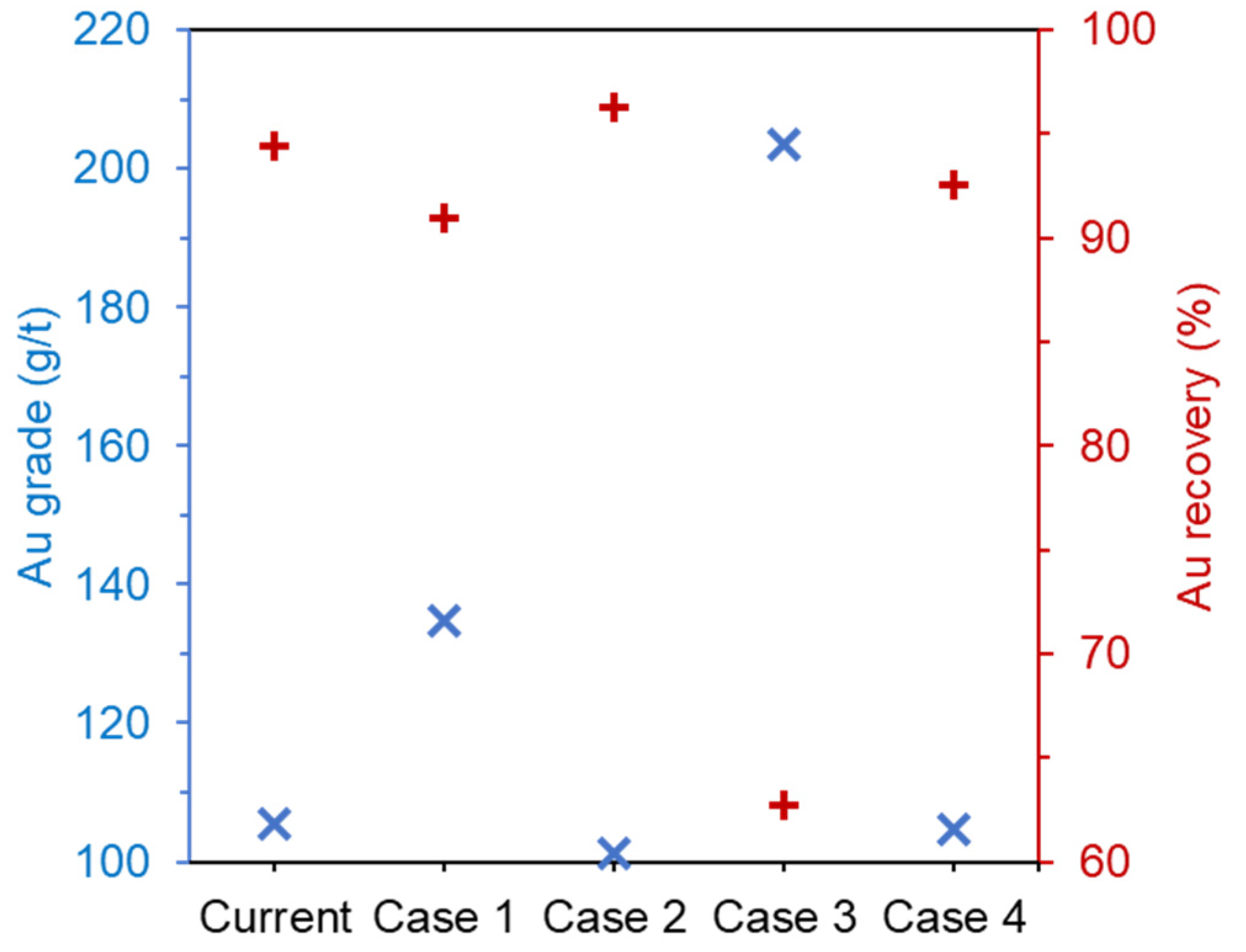

3.5. Comparison between Current Circuit and Alternative Circuits

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hodouin, D. Methods for automatic control, observation, and optimization in mineral processing plants. J. Process Control 2011, 21, 211–225. [Google Scholar] [CrossRef]

- Mendez, A.; Galvez, E.; Cisternas, L. Modeling of grinding and classification circuits as applied to the design of flotation processes. Comput. Chem. Eng. 2009, 33, 97–111. [Google Scholar] [CrossRef]

- Irannajad, M.; Nuri, O.; Allahkarami, E. A new approach in separation process evaluation. Efficiency ratio and upgrading curves. Physicochem. Probl. Miner. Process. 2018, 54, 847–857. [Google Scholar]

- Hodouin, D.; Jamsa-Jounela, S.-L.; Carvalho, M.T.; Bergh, L. State of the art and challenges in mineral processing control. Control Eng. Pract. 2001, 9, 995–1005. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Kim, H.; Park, J. Millimeter-sized spherical ion-sieve foams with hierarchical pore structure for recovery of lithium from seawater. Chem. Eng. J. 2012, 210, 482–489. [Google Scholar] [CrossRef]

- Kim, S.; Park, S.; Han, S.; Han, Y.; Park, J. Silanol-rich ordered mesoporous silica modified thiol group for enhanced recovery performance of Au(III) in acidic leachate solution. Chem. Eng. J. 2018, 351, 1027–1037. [Google Scholar] [CrossRef]

- Kim, Y.; Han, Y.; Kim, S.; Jeon, H. Green extraction of lithium from waste LAS glass ceramics using a water leaching processes. Process Saf. Environ. Protect. 2021, 148, 765–774. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Rajamani, R.; Herbst, J. Optimal control of a ball mill grinding circuit—I. Grinding circuit modeling and dynamic simulation. Chem. Eng. Sci. 1991, 46, 861–870. [Google Scholar] [CrossRef]

- Han, Y.; Kim, S.; Go, B.; Lee, S.; Park, S.; Jeon, H. Optimized magnetic separation for efficient recovery of V and Ti enriched concentrates from vanadium-titanium magnetite (VTM) ore: Effect of grinding and magnetic Intensity. Powder Tech. 2021, 391, 282–291. [Google Scholar] [CrossRef]

- Bouchard, J.; Desbiens, A.; Villar, R.; Nunez, E. Column flotation simulation and control: An overview. Miner. Eng. 2009, 22, 519–529. [Google Scholar] [CrossRef]

- Mehrotra, S.P. Design of optimal flotation circuits—A review. Miner. Metall. Process. 1988, 5, 142–152. [Google Scholar] [CrossRef]

- Welsby, S.D.D.; Vianna, S.M.; Franzidis, J.-P. A continuous pilot-scale flotation rig for the systematic study of flotation variables. Miner. Eng. 2010, 23, 826–829. [Google Scholar] [CrossRef]

- Calisaya, D.; Lopez-Valdivieso, A. A strategy for the identification of optimal flotation circuits. Miner. Eng. 2016, 96–97, 157–167. [Google Scholar] [CrossRef]

- Liu, J.; MacGregor, J. Froth-based modeling and control of flotation processes. Miner. Eng. 2008, 21, 642–651. [Google Scholar] [CrossRef]

- Cisternas, L.; Lucay, F.; Acosta-Flore, R.; Galvez, E. A quasi-review of conceptual flotation design methods based on computational optimization. Miner. Eng. 2018, 117, 24–33. [Google Scholar] [CrossRef]

- Ferreira, J.P.; Loveday, B.K. An improved model for simulation of flotation circuits. Miner. Eng. 2000, 13, 1441–1453. [Google Scholar] [CrossRef]

- Bergh, L.; Yianatos, J. Control of rougher flotation circuits aided by industrial simulator. J. Process Control. 2013, 23, 140–147. [Google Scholar] [CrossRef]

- Vasebi, A.; Poulin, E.; Hodouin, D. Determining a dynamic model for flotation circuits using plant data to implement a Kalman filter for data reconciliation. Miner. Eng. 2015, 83, 192–200. [Google Scholar] [CrossRef]

- Vallejos, P.; Yianatos, J.; Grau, R.; Yanez, A. Evaluation of flotation circuits design using a novel approach. Miner. Eng. 2020, 158, 106591. [Google Scholar] [CrossRef]

- Villeneuve, J.; Guillaneau, J.-C.; Durance, M.-V. Flotation modelling: A wide range of solutions for solving industrial problems. Miner. Eng. 1995, 8, 409–420. [Google Scholar] [CrossRef]

- Yianatos, J.; Carrasco, C.; Bergh, L.; Vinnett, L.; Toress, C. Modelling and simulation of rougher flotation circuits. Int. J. Miner. Process. 2012, 112–113, 63–70. [Google Scholar] [CrossRef]

- Maldonado, M.; Araya, R.; Finch, J. Optimization flotation bank performance by recovery profiling. Miner. Eng. 2011, 24, 939–943. [Google Scholar] [CrossRef]

- Radmehr, V.; Shafaei, S.; Noaparast, M.; Abdollahi, H. Optimizing flotation circuit recovery by effective stage arrangements: A case study. Minerals 2018, 8, 417. [Google Scholar] [CrossRef] [Green Version]

- Gorain, B.K.; Franzidis, J.-P.; Manlapig, E.V. The empirical prediction of bubble surface area flux in mechanical flotation cells from cell design and operating data. Miner. Eng. 1999, 12, 309–322. [Google Scholar] [CrossRef]

- Noble, A.; Luttrell, G. The matrix reduction algorithm for solving separation circuits. Miner. Eng. 2014, 64, 97–108. [Google Scholar] [CrossRef]

- Seppälä, P.; Sorsa, A.; Paavola, M.; Ruuska, J.; Remes, A.; Kumar, H.; Leiviskä, K. Development and calibration of a dynamic flotation circuit model. Miner. Eng. 2016, 96, 168–176. [Google Scholar] [CrossRef]

- Yalcin, E.; Kelebek, S. Flotation kinetics of a pyritic gold ore. Int. J. Miner. Process. 2011, 98, 48–54. [Google Scholar] [CrossRef]

- Lee, W.; Jung, M.; Han, S.; Park, S.; Park, S. Simulation of layout rearrangement in the grinding/classification process for increasing throughput of industrial gold ore plant. Miner. Eng. 2020, 157, 106545. [Google Scholar] [CrossRef]

- Kim, C.; Choi, S.; Choi, S.; Lee, I. Hydrothermal alteration and its genetic implication in the Gasado volcanic-hosted epithermal gold-silver deposit: Use in exploration. J. Miner. Soc. Korea 2002, 15, 205–220. [Google Scholar]

- Kim, S.; Baek, S.; Han, Y.; Jeon, H. Laboratory testing of Scheelite flotation from raw ore in Sangdong mine for process development. Minerals 2020, 10, 971. [Google Scholar] [CrossRef]

- Han, Y.; Han, S.; Kim, B.; Yang, J.; Choi, J.; Kim, H.; You, K.; Kim, H. Flotation separation of quartz from apatite and surface forces in bubble-particle interactions: Role of pH and cationic amine collector contents. J. Ind. Eng. Chem. 2019, 70, 107–115. [Google Scholar] [CrossRef]

- Meloy, T. Analysis and optimization of mineral processing and coal-cleaning circuits—Circuit analysis. Int. J. Miner. Process. 1983, 10, 61–80. [Google Scholar] [CrossRef]

- Meloy, T. Optimizing for grade or profit in mineral processing circuits—Circuit analysis. Int. J. Miner. Process. 1983, 11, 89–99. [Google Scholar] [CrossRef]

- Noble, A.; Luttrrell, G.H.; Amini, S.H. Linear circuit analysis: A tool for addressing challenges and identifying opportunities in process circuit design. Mining. Metall. Explor. 2019, 36, 159–171. [Google Scholar] [CrossRef]

- Yianatos, J.; Vallejos, P.; Grau, R.; Yanez, A. New approach for flotation process modelling and simulation. Miner. Eng. 2020, 156, 106482. [Google Scholar] [CrossRef]

- Moon, D.; Koh, S.; Lee, K. Geochemistry of the Moisan epithermal gold-silver deposit in Haenam area. Econ. Environ. Geol. 2010, 43, 491–503. [Google Scholar]

- Han, I.; Ahn, Y.; Chi, S.; Bae, K.; Kim, H. Froth flotation of Au-Ag ore from epithermal deposit in Haenam. J. Korean Soc. Miner. Energy Resour. Eng. 2011, 48, 701–712. [Google Scholar]

- Lee, W.; Jung, M.; Han, S.; Park, S.; Lim, G.; Park, J. Mathematical modeling and computational simulation on ball milling in domestic goldsilver mineral processing plant. J. Korean Soc. Miner. Energy Resour. Eng. 2017, 54, 502–511. [Google Scholar]

- Han, S.; Jeong, M.; Lee, W.; Lim, G.; Park, J. Simulation of grinding/classification circuit in domestic gold ore processing plant using energy-based grinding model and mathematical classification model. J. Korean Soc. Miner. Energy Resour. Eng. 2018, 55, 8–19. [Google Scholar] [CrossRef]

- Han, S.; You, K.; Kim, K.; Park, J. Measurement of the attachment force between an air bubble and a mineral surface: Relationship between the attachment force and flotation kinetics. Langmuir 2019, 35, 9364–9373. [Google Scholar] [CrossRef]

| Number of Banks | Number of Cells | Cell Size, m3 * | Effective Volume, m3 | |

|---|---|---|---|---|

| Conditioner | - | 1 | 2.4 × 2.4 | 9.8 |

| Rougher | 2 | 4 | 1.5 × 1.3 × 1.2 | 2.1 |

| Scavenger | 1 | 4 | 1.5 × 1.4 × 1.2 | 2.1 |

| Cleaner | 5 | 1 | 1.1 × 1.4 × 0.9 | 1.2 |

| Au (g/t) | Pyrite (wt.%) | Quartz (wt.%) | Muscovite (wt.%) | Others (wt.%) | |

|---|---|---|---|---|---|

| gold ore | 6.8 ± 1.2 | 9.6 ± 0.6 | 63.1 ± 1.1 | 28.0 ± 1.3 | 0.5 ± 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Jung, M.; Lee, W.; Kim, S.; Lee, K.; Lim, G.-t.; Jeon, H.-S.; Choi, S.Q.; Han, Y. Diagnosis and Optimization of Gold Ore Flotation Circuit via Linear Circuit Analysis and Mass Balance Simulation. Minerals 2021, 11, 1065. https://doi.org/10.3390/min11101065

Han S, Jung M, Lee W, Kim S, Lee K, Lim G-t, Jeon H-S, Choi SQ, Han Y. Diagnosis and Optimization of Gold Ore Flotation Circuit via Linear Circuit Analysis and Mass Balance Simulation. Minerals. 2021; 11(10):1065. https://doi.org/10.3390/min11101065

Chicago/Turabian StyleHan, Seongsoo, Minuk Jung, Wonjae Lee, Seongmin Kim, Kyoungmun Lee, Geun-tae Lim, Ho-Seok Jeon, Siyoung Q. Choi, and Yosep Han. 2021. "Diagnosis and Optimization of Gold Ore Flotation Circuit via Linear Circuit Analysis and Mass Balance Simulation" Minerals 11, no. 10: 1065. https://doi.org/10.3390/min11101065

APA StyleHan, S., Jung, M., Lee, W., Kim, S., Lee, K., Lim, G.-t., Jeon, H.-S., Choi, S. Q., & Han, Y. (2021). Diagnosis and Optimization of Gold Ore Flotation Circuit via Linear Circuit Analysis and Mass Balance Simulation. Minerals, 11(10), 1065. https://doi.org/10.3390/min11101065