Abstract

This study investigates the feasibility of using recycled concrete aggregate (RCA) as a partial substitution of natural aggregate in pavement engineering. Despite RCA’s good properties, such as polishing value and freeze-thaw resistance, its use is limited by low resistance to fragmentation and high-water absorption. This paper parent the experimental results of mineralogical-petrographic and physical-mechanical properties of RCA, natural stone (dolerite) and their combination (RCA content—15%, 30%, 45%, and 60%). The tested granular mixtures showed good resistance to fragmentation and wear (LA 22–27%, MDE 14–15%), as well as satisfactory Polished Stone Value of 55–57, which means they can be used in different layers of pavement structures. According to the obtained testing results, the application of RCA is possible in different flexible and rigid pavement layers and for various traffic loads.

1. Introduction

Today’s traffic intensity and the constant tendency for more comfortable and safer driving dictate high demands related to the quality of the flexible and rigid pavement structures. Therefore, engineers must design safe, durable, and cost-effective roads. Choosing the right aggregate, which makes up 93–95% of the weight of the installed asphalt mixture in the wear layer, is also no less a responsible job [1,2]. Mineral raw materials for construction purposes make about 70% of annual world production. The production of geomaterials, on the other side, has severe environmental and social impacts. Besides technical properties, some typical attributes can be given to constructional geomaterials, such as availability (existence in the Earth’s crust and the technological possibility to extract it), sustainability (impacts of their exploitation, especially on ecosystems), and functionality (accessibility, workability, and serviceability) [3].

Over the last decades, numerous researchers have observed a strong relationship between mineral composition, micro-assembly and rock alterations on the one hand and wear resistance (micro-Deval coefficient) and various aggregate strength parameters on the other hand [4,5]. Others investigated the relationships between different technical properties of aggregates in order to establish their mutual correlations [6]. Rigopoulos et al. [7], for example, examined the influence of petrographic characteristics and alterations on the technical properties of dolerite and ultrabasic rocks. Petrographic and microcrack analyses can assist in the selection of acceptable rock types for different structural applications. Factor analysis showed that mafic and fresh ultramafic rocks are most suitable for aggregate production, in contrast to highly serpentinised and tectonic harzburgites [8].

Among many others, the Los Angeles test (LA) is one of the most popular tests for the determination of resistance to fragmentation, i.e., abrasion loss of aggregates. The number of balls and revolutions in the Los Angeles test has a significant effect on the test results. Tunc and Alyamac developed an estimation method for the prediction of the LA abrasion value [9]. This method can be used to classify aggregates approximately, practically and quickly. The micro-Deval test (MDE) is commonly used for the determination of resistance to wear of natural and recycled aggregates. Wang et al. [10] tried to establish a correlation between the micro-Deval test and aggregates with different morphological properties (granite, greywacke, diabase, limestone) and found that the changes in the angularity of the particles mainly cause the mass loss. An experimental study on different rock types and their results were carried out to correlate the micro-Deval and other properties. The proposed models can be used to forecast aggregate quality [6]. Similarities and differences between European (EN) and American Society for Testing and Materials (ASTM) standards and micro-Deval wear are presented by Gökalp et al. [11]. They concluded that these test methods give different results, depending on the aggregate type and grading size. Generally, for the natural aggregates, EN and ASTM gradation A (9.5–19.0 mm) tests results are more similar to each other, but for by-products (slag) EN and ASTM gradation B are more similar (4.75–12.5 mm).

Polishing characteristics measured in the field may be different from the values obtained in laboratory conditions, which can be related to the petrographic characteristics of the rocks. The less durable the aggregate, the higher is the difference in polishing values measured in the laboratory and on the field. It was further determined that smaller fractions have higher Polished stone value (PSV) values compared to larger fractions of the same aggregate, which is explained by the presence of sharper and rougher grains in the finer fraction [12]. It is known that positive impacts on skid resistance (mixed hardness of rock-forming minerals, presence/absence of some phenocrysts) have the opposite effect on wear by studded tires. Despite the effort to divide volcanic rocks into five petrographic-technological subgroups based on their composition, fabric, geological age, and post-genetic history, it was not possible to make a correlation between PSV and resistance to wear by abrasion from studded tires—Nordic test [13].

Sustainable use of geomaterials for construction purposes stimulate a reduction of excavation of primary resources. This approach would minimise impacts on natural systems, and employ materials and technologies that produce less emission of deleterious substances into the atmosphere. The use of secondary materials, such as waste generated during the extraction of primary raw materials and re-use of existing materials, is a modern approach to reducing the pressure on the excavation of primary resources [14]. Aggregates demand in Europe is about 3 × 109 tons per year [15]. At the same time, approximately 8.5 × 108 tons of construction and demolition waste (CDW) are generated annually (road construction and maintenance materials, excavation materials et cetera), amounting to 31% of total waste in Europe [16,17]. Hence, managing this waste, in order to reduce environmental pollution, represents a significant challenge. Keeping in mind that managing CDW primarily means recycling, energy recovery, and disposal, by adhering to sustainability principles [18], the main goal is finding alternative ways of using this material as a resource for the industry. One possible solution is the recycling of CDW and its use as an aggregate in construction [19]. Specifically, pavements are structures in which large amounts of these materials can be used. In order to stimulate the use of alternative materials, many countries have introduced large waste landfilling taxes, and in some cases, taxes on the use of natural aggregates.

Despite this, the scope of alternative material use in pavement structures is still relatively narrow. This is a problem of general perception—Recycled materials are often considered inferior compared with natural ones because of their different and potentially weaker physical-mechanical properties and partly as an economic problem. In countries with significant reserves of natural aggregate (in Serbia, 56% of the territory is covered by mountains [20]), with a total annual production of 2.1 × 107 tons per year [15], the use of alternative materials is usually not profitable because of significant costs associated with the transport and treatment of these materials. Nonetheless, in densely populated areas, the use of such materials is becoming increasingly necessary and profitable. Since the largest share of CDW is waste concrete [21,22], by crushing it, we can produce large quantities of recycled concrete aggregate (RCA).

Until now, RCA was mostly (approximately 85%) used as a material for pavement structures, namely, for upper and lower unbound layers, for soil stabilisation [23], and as aggregate for concrete production [24]. However, because of insufficient quantities and different technical properties of RCA, research on the use of RCA in asphalt mixtures has been, until recently, limited. Encouragingly, a significant number of studies on this topic have been published lately [25,26,27,28,29,30,31]. Radević et al. [32] showed that asphalts of satisfactory quality, especially in terms of fatigue could be produced by partially substituting natural limestone aggregate with RCA [32,33]. The recycled concrete aggregate used in this study was obtained by crushing of the original cement-based concrete slabs (with strength class C35/45, according to Eurocode 2 [34]), after their service life as a sub-structure for the Belgrade city tram tracks.

The study presented in this paper aimed to test the quality of aggregate mixtures consisting of natural—Dolerite (DI-1) and RCA, to be used in the construction or rehabilitation of different pavement layers. Dolerite (DI-1) was chosen as a natural aggregate because of its favorable technical properties [35,36]. The research consisted of testing basic mineralogical-petrographic and physical-mechanical properties of used aggregates. Special attention was paid to the testing of the Polished Stone Value (PSV), as an important property of aggregates used in pavement wear layers. Until recently in Serbia, but also in many other countries, mixtures of RCA and natural crushed stone aggregates were not acknowledged by relevant standards and technical requirements. Having in mind that the application of this type of aggregate in the production of pavement structures depends on the technical regulations of each country, these regulations should be revised in accordance with new research developments.

2. Materials and Methods

The dolerite that was used in this study was from the Divčibare deposit. The production of crushed stone aggregate was performed at the crushing and separation facility within the “Mrčići” quarry. RCA was obtained by crushing 30-year-old concrete slabs which were, during their service life, covered with a protective layer of asphalt. This concrete contained natural river aggregate (Dmax = 16 mm). As the data regarding the mix design and quality of the original concrete were not available, the core samples were taken from the slabs and tested in the laboratory. The average values of density of 2.36 Mg/m3 and compressive strength of 49.3 MPa (corresponding to concrete class C35/45) were obtained.

In order to acquire RCA, the first step was crushing the original concrete by using the mobile jaw crusher KOMATSU BR 380 (KOMATSU Ltd. Tokyo, Japan), equipped with a metal separator (see Figure 1a below). After this procedure, the RCA with grain size 0/100 mm was obtained. In the second phase, the RCA was transported to the aggregate separation facility. There, it was washed and put through a standard set of sieves, using the separation equipment Binder + Co AG Gleisdorf, type KS/DD 1600 × 5. As a result, the RCA was separated into standard aggregate fractions—0/4 mm, 4/8 mm, 8/16 mm and 16/32 mm. In the last phase, the RCA was crushed once more (in order to get an improved percentage of crushed and broken surfaces), by means of laboratory jaw crusher RETSCH BB 300 (RETSCH GMBH, Haan, Germany) (see Figure 1b below). After double crushing, the RCA was ground to a nominal aggregate size of Dmax = 22.4 mm. In regard to its origin, the obtained RCA was exceptionally pure (98% concrete), containing only 1.2% of asphalt and 0.8% of brick debris.

Figure 1.

The aggregate crushing process used to transform concrete waste into recycled concrete aggregate (RCA): (a) mobile jaw crusher; (b) laboratory jaw crusher.

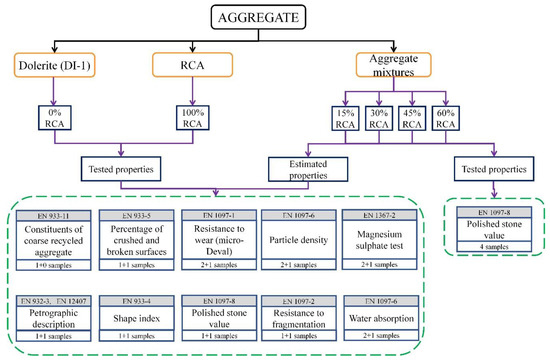

Testing of physical-mechanical properties was performed on natural aggregate—Dolerite (DI-1) and RCA. Both DI-1 and RCA were tested in terms of their mineralogical-petrographic and technical characteristics. The Polished Stone Value (PSV) was measured on both aggregate types, as well as on aggregate mixtures. All tests were performed according to current European (EN) standards. Previously determined technical characteristics of dolerite [35], were added to the analysis. Results of tests on DI-1 and RCA were categorised according to standards for aggregates FprEN 12620 [37] and FprEN 13043 [38]. Figure 2 presents an overview of types of tested aggregates, their properties (tested or estimated), the number of tested samples (RCA + DI-1), as well as the applied test methods/standards.

Figure 2.

Types of aggregate, test methods and the number of test samples (RCA + DI-1) used in the study.

The content of Rc and Ru depends on the particle size of the aggregates (smaller aggregate particles have more residual mortar), but in this study, only a single particle size was tested. The classification test for the constituents of coarse recycled aggregate [39] was carried out on 10/11 mm aggregate particles. From an RCA 10/14 mm fraction, the original natural aggregate particles were extracted, and a qualitative and quantitative assessment of mineral composition was performed on them [40]. For dolerite DI-1, beside a macroscopic assessment of the 10/14 mm fraction [40], standard mineralogical-petrographic tests were carried out using a polarised microscope [41] and SEM-EDS analysis [36]. Geometric properties of DI-1 and RCA were tested using the Shape index [42]. The percentage of crushed and broken surfaces in double crushed aggregate particles was also determined according to [43]. All the applied standards/norms are presented in Figure 2.

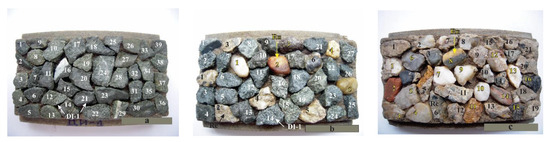

Mechanical properties of aggregates were determined through resistance to fragmentation (Los Angeles test) [44], and resistance to wear (micro-Deval test) [45]. The Polished Stone Value [46] was assessed on specimens with DI-1 and RCA (0% and 100% of RCA, respectively), as well as on specimens with a mixture of DI-1 and RCA—15%, 30%, 45%, and 60% of RCA (see Figure 2). Results of tests on previously defined DI-1 and RCA specimens were compared with the 2011 UK PSV control stone with a specified mean PSV of 49 [47]. Specimens with a mixture of DI-1 and RCA were made using 38 (±2) aggregate particles, on average (see Figure 3). During specimen preparation and selection of RCA particles, care was taken to maintain the inner structure of RCA—Determined according to classification [39] and mineral composition [40], as it is shown in Table 1.

Figure 3.

Test samples for PSV with projected (38 ± 2) aggregate particles: (a) Dolerite; (b) mixtures 30% RCA (six particles Rc, five particles Ru) and 70% DI-1 (27 particles); (c) RCA.

Table 1.

Preparation of PSV test samples according to the RCA and DI-1 mixtures design and RCA structure.

Hence, for specimens with 100% DI-1, 38 (± 2) dolerite particles were needed (Figure 3a), while for the specimen with 30% RCA and 70% of DI-1, 11 particles of RCA were needed (six particles with a residual mortar and five particles of original natural aggregate) and 27 particles of DI-1 (Figure 3b). Finally, for the specimen with 100% of RCA, 38 (± 2) RCA particles were needed (22 particles with a residual mortar and 16 particles of original natural aggregate), Figure 3c. Physical properties of DI-1 and RCA were tested via density and water absorption of the 10/14 mm fraction [48]. The freeze-thaw resistance of the aggregates was determined using a magnesium sulphate test [49].

Except for the PSV, all other technical characteristics were determined only for samples of DI-1 and 100% RCA, i.e., 0% and 100% RCA. From these results, the values for mixtures with 15–60% of RCA were estimated, i.e., calculated by interpolation (see Figure 2).

3. Results

3.1. Mineralogical and Petrographic Properties

Mineralogical-petrographic properties were assessed on samples of DI-1 and RCA (separately for residual mortar and original natural aggregate). By testing the components of coarse RCA in the 10/11 mm fraction [39], it was determined that RCA is mostly comprised of residual mortar (56.8%) and original natural aggregate particles (43.2%), see Table 2. According to norm FprEN 12620 [37], based on the percentage of concrete and residual mortar and original natural aggregate particles, the used aggregate is classified as Rc 50, Ru 43, Rcu 95, and Rcug 90. The tests showed that the RCA sample did not contain any traces of masonry, bitumen, glass, or any other material which can appear in recycled aggregates (steel, wood, gypsum, et cetera); nor did it contain any traces of floating materials. According to these parameters, the used aggregate is classified as Rb 10-, Ra 1-, Rg 2-, X 1-, XRg 0.5-, and FL 0.2- (see Table 2).

Table 2.

Classification and categorisation of coarse RCA.

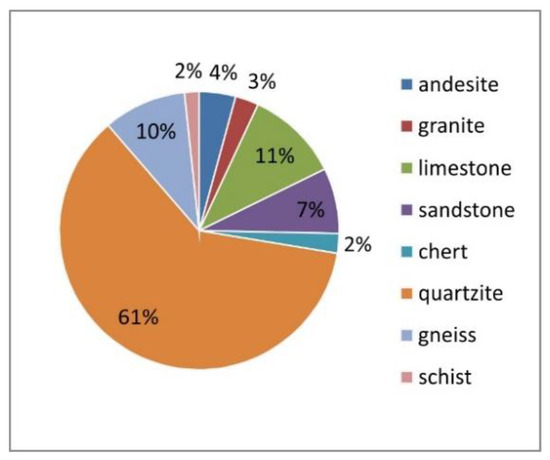

The petrographic tests of the original natural aggregate from RCA (gravel), showed that the 10/14 mm fraction was mostly composed of fragments of metamorphic rocks (73%), see Figure 4. Less prevalent were fragments of sedimentary and igneous rocks—21% and 7%, respectively. Among the fragments of metamorphic rocks, the most abundant were quartzites; besides them, there were fragments of gneisses and schists.

Figure 4.

Petrographic composition of gravel from RCA.

Within the fragments of sedimentary rocks limestones, sandstones with siliceous binders, and a small number of cherts were found. The most abundant igneous rocks were andesite and granites (Figure 4). The crushed gravel consisted mostly of cubic and elongated particles and with rough surfaces. No mineral grains were detected in the tested fraction of gravel. The petrographic composition indicates its origin from the basin of river Velika Morava. Earlier tests of alkali-silica reactivity of cherts from this basin did not show any chemical reactivity [50].

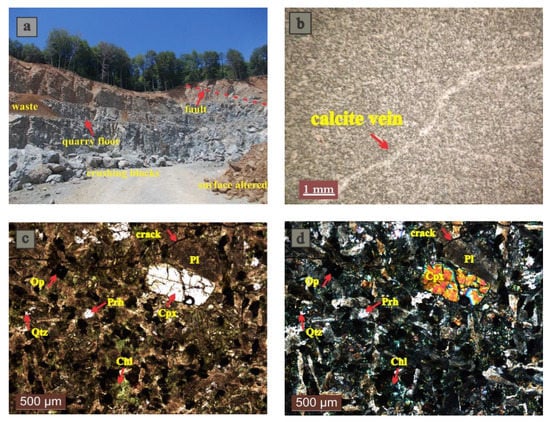

As far as the natural aggregate (dolerite DI-1) is concerned, the deposit is of homogeneous petrographic composition. The central rock mass has a dark green colour and is intersected by calcite or prehnite wires and cracks with an irregular shape. Several floors have been opened in the quarry. In the left and central part of Figure 5a, blasted rocks can be seen which are transported for further processing to a crushing/separation plant in front of the quarry. The sample of dolerite used in this study was taken from this part of the deposit. The macroscopic appearance of the DI-1 sample is shown in Figure 5b with calcite vein. Microscopic tests showed that the dolerites vary in texture from intergranular to fine-grained (grain diameter <0.1 mm), finely ophitic (grain length <0.5 mm), ophitic to subophitic (grain length 0.5–1.0 mm), and locally porphyritic texture (Figure 5c,d).

Figure 5.

“Mrčići” quarry and petrographic properties of the dolerite DI-1 sample: (a) The head of the quarry; (b) macroscopic appearance with calcite veins; (c) microscopic image in ppl of a sample shows finely ophitic, ophitic and porphyritic texture intersecting with crack; (d) microscopic image of the same sample in xpl. Explanation: Chl—chlorite, Cpx—pyroxene, Op—opaque (metallic) mineral, Pl—plagioclase, Prh—prehnite, Qtz—quartz.

They consist of blurred plagioclases (app. 50 vol. %) and clinopyroxene (app. 15–20 vol. %) with small quantities of opaque minerals and titanite (app. 5 vol. %) as main constituents, as well as with various secondary mineral phases—mostly with chlorite and prehnite, and less with quartz and calcite. Minerals are homogeneously distributed in the stone mass [36].

3.2. Technical Properties of Aggregates

Technical properties of dolerite and RCA were determined according to the adopted experimental program (see Figure 2). Using the obtained results, categorisation of these aggregates as construction industry products was carried out according to the Council Directive 89/106/EEC [51], see Table 3. The shape of RCA particles is cubic and elongated. The percentage of particles with an unfavourable shape, i.e., flat shape, is app. 20%. Dolerite particles are cubic and elongated as well; however, the content of particles with an unfavourable shape is lower—13% (see Table 3).

Table 3.

Determined technical properties of aggregates.

RCA is mostly comprised of crushed (Cc 20%) and totally crushed or broken particles (Ctc 61%), i.e., rounded (Cr 11%) and totally rounded gravel particles (Ctr 8%). In order to achieve a more favourable result, the RCA was double crushed, and the testing was repeated. The new results on the percentage of crushed and broken surfaces showed the following: Crushed (Cc 35%) and totally crushed or broken particles (Ctc 60%), i.e., rounded (Cr 5%) and totally rounded gravel particles (Ctr 1%). This ratio of crushed and broken particles in the RCA sample categorises it, according to the newest FprEN 12620 [37] and FprEN13043 [38] standards, into category C 95/1. The dolerite aggregate DI-1 is 100% comprised of completely crushed particles with slightly rough broken surfaces and sharp edges, Table 3. According to the determined geometric properties, it was categorised as C 100/0.

3.3. Properties of Aggregate Mixtures

The previous section presented the results of laboratory tests of RCA and dolerite properties. Before determining an optimal mixture of these aggregates, the changes in their technical properties had to be investigated: This was done for DI-1 and RCA as well as for mixtures with 15%, 30%, 45%, and 60% of RCA (Table 4).

Table 4.

Technical properties of aggregate mixtures and categorisation according to EN standards.

As it was previously explained, the properties of DI-1 and 100% of RCA were determined experimentally, whereas all the properties of aggregate mixtures with 15–60% of RCA (except PSV) were estimated, i.e., calculated by interpolation.

4. Discussion

In this study, attempts have been made to investigate the technical properties of natural and recycled concrete aggregate mixtures, since 100% RCA typically demonstrates low resistance to fragmentation and high-water absorption. By mixing RCA with natural dolerite aggregate in different proportion, the potential for application of these composite aggregates in different pavement structures can be increased.

The grain shape of the aggregate depends on the type of rock and the production technology. Fine-grained silicate rocks are generally hard to break and give more inferior grain shapes than softer rocks. Dolerite (DI-1) used in this study had a grain shape of 3:1 (SI 13), while RCA showed a somewhat worse grain shape (SI 20) which is a consequence of the presence of slate rocks (fragments of gneisses and schists) and some concrete residues with flat grains. Slate or flat rocks, such as gneisses, shists, or flat limestones, will give a poorer grain shape despite the technology applied. Resistance to fragmentation and wear of DI-1 would be better with SI lower than 13% and RCA SI lower than 20% (Table 3). Increasing the RCA content in aggregate mixtures leads to a more unfavourable aggregate shape index; however, this change is relatively small. The transition from category SI 15 to category SI 20 is observed only after the mixture with 45% of RCA (Table 4).

As it can be seen in Table 3, DI-1 has better resistance to fragmentation (LA coefficient 20%) than the applied RCA (LA coefficient 32%). The results are in accordance with the petrographic composition of the rocks: Gravel from RCA has a higher content of strong, but brittle, quartzites (Figure 4) which are more sensitive to the effect of steel balls during the fragmentation test, compared with the dolerites fine-grained to finely ophitic texture. Hence, the resistance to fragmentation category of RCA (LA 35) is lower compared to DI-1 (LA 20). The resistance to wear, determined using the micro-Deval method, is similar for both aggregates—16% and 14% for RCA and DI-1, respectively. Consequently, they are classified into adjacent categories: MDE 20 and MDE 15 for RCA and DI-1, respectively (see Table 3). As far as the aggregate mixtures are concerned, increasing the percentage of dolerite in the mixture improved resistance to fragmentation from category LA 35 for 100% of RCA, to category LA 30 for 60% of RCA, and category LA 25 for 45%, 30%, and 15% of RCA (see Table 4). This mechanical property of aggregates is essential for assessing their possible use in the production of cement and asphalt concretes. Thus, it can be said that improvements gained by using these aggregate mixtures are significant. Resistance to wear of these aggregate mixtures, according to the micro-Deval method, decreases with increasing RCA content. The aggregate category [37,38] has a constant value of up to 60% of RCA (MDE 15) and changes to category MDE 20 only in the case of 100% RCA (Table 4). However, since both aggregates are resistant to wear, their mixtures are resistant as well.

Despite the results of the study, according to which the LA coefficient has the smallest value for those rocks having the highest density, compressive strength, etc. [52], dolerite from the quarry “Mrčići” in Serbia has a higher apparent density (ρa 2.79 Mg/m3) compared to dolerites from ophiolite complexes of Greece 2.50–2.62 Mg/m3, [7,8] but weaker resistance to fragmentation (LA 20% vs. 11–19%) and wear (MDE 14 vs. 6–7%). Dolerites of both complexes have similar values of water absorption (0.5–0.7%) and PSV (55–63). It is known that the technical characteristics of rocks depend on their mineral composition, structure, texture, type and degree of alterations and tectonic deformations [53]. The differences in rock texture and/or the presence of certain mineral phases affect the quality of road aggregates. For example, fine porphyritic andesite can provide better micro-Deval coefficient compared to the coarse porphyritic andesite [54]. The same goes for dolerites with ophitic texture (MDE 14) and gabbro RD-G (MDE 17) [35]. These values indicate that wear resistance depends on the micro-fabric of the intermediate and basic igneous rock. It must be emphasised that the results of laboratory tests among different studies can be compared in cases if the tests are compatible. For example, the results of the micro-Deval test can be compared between RCA (for asphalt mixtures) and armorstone (for harbours), because in both cases a 500 g sample of the 10/14 mm fraction is tested with 12,000 revolutions of drums (EN 1097-1). Silicate aggregates that constituting RCA and DI-1 have better resistance to wear (MDE 16% and 14%—in this study) compared to limestones with different structural characteristics (MDE 20–57%) [4]. On the other hand, the Los Angeles test results cannot be compared for the mentioned aggregates, because the former uses 5 kg of a sample with 500 revolutions of a drum (EN 1097-2) and the latter 10 kg and 1000 revolutions (ASTM C 535). In this case, comparing the results of the same aggregates, it can be wrongly concluded that the dolerite of the ophitic structure (Figure 5c,d) has weaker resistance to fragmentation (DI-1, LA 20) compared to micritic, fossiliferous microsparitic limestone and biosparitic limestone (LA 14–18). Another study [54] indicated that there is no correlation between MDE and LA values. This is because the mechanism of abrasion loss depends not only on the petrographic characteristics and the rock fabric but on the size of steel balls and their impact on aggregate, as well as the presence of water (MDE referent test with the presence of water, while LA test is done without it).

The PSV for the 100% RCA sample amounted to 57 which is considered a medium-high value if compared with the reference value for High Specification Aggregates for Skid-Resistant Road Surfacing of PSV ≥ 58 [55,56]. The same PSV was determined for DI-1 (Table 3). The mixtures of these aggregates with 15%, 30%, 45%, and 60% of RCA, displayed similar PSVs in the range of 55–57. Such high PSVs for RCA are unexpected, taking into account the high percentage of monomineralic rocks in natural aggregate (70% quartzite, sandstone, and chert, Figure 4). However, the dominating content of residual mortar (56.8%) compared with original natural aggregate (43.2% for gravel, Table 2), as well as the existence of differences in hardness between quartz and quartzite, sandstone and chert (7 according to the Mohs scale) compared with calcite from limestone (3 according to the Mohs scale), ensured a micro-rough surface of aggregate particles, i.e., a high PSV for RCA. A slight decrease of PSV values was found in other mixtures: Fifty-six for mixtures with 30%, 60% RCA and 55 for the mixture with 45% of RCA. Generally, it can be concluded that changes in PSV for mixtures of dolerite and RCA are negligible (see Table 4).

RCA showed a somewhat more significant variation in densities between oven-dried particle density which is the real aggregate density—2.40 Mg/m3 (ρrd), saturated and surface-dried particle density—2.49 Mg/m3 (ρssd), and apparent particle density—2.62 Mg/m3 (ρa) (Table 3). This fact is a consequence of RCA’s greater water absorption—3.7%; however, this property does not apply to RCA as an indicator of aggregate freeze-thaw resistance [37,38]. Contrary to RCA, DI-1 showed smaller variations in densities, which ranged between 2.74–2.79 Mg/m3 and lower water absorption of 0.7%. It was classified as category WA24 1 and consequently considered resistant to freeze-thaw action (see Table 3). As the percentage of RCA in the aggregate mixture increases, also water absorption and the difference between apparent (ρa) and oven-dried particle density (ρrd) increase. Besides, a larger content of dolerite (a basic igneous rock with high-density properties), led to an increase in all of the tested densities. The values of oven-dried particle density (real density) for the dolerite and RCA mixtures were higher than 2.00 Mg/m3, and particle densities of recycled aggregate were also higher than 1.50 Mg/m3; hence, it can be concluded that these mixtures represent normal aggregates [37,38].

The magnesium sulphate test showed that only 10% of RCA and 5% of DI-1 was removed after being exposed to salt-action for five cycles. This result has proved that both aggregates are resistant to freeze-thaw action (Table 3), i.e., they were classified into the highest category MS 18. Some decrease in results, negligible for classification purposes, was noticed in freeze-thaw resistance of aggregate mixtures. On the other hand, replacing DI-1 with RCA led to a steady increase of water absorption—1.1%, 1.6%, 2.0%, 2.5%, and 3.7% for 15%, 30%, 45%, 60%, and 100% of RCA, respectively (see Table 4). Since the water absorption test of RCA showed values higher than 2% according to the applied standards [37,38], all aggregate mixtures have been tested on freeze/thaw resistance. The possibility of reducing water absorption in the designed granular mixtures is significant. Silicate aggregates usually have good resistance to frost [5]. However, over time, the technical properties of aggregates can change differently. This change primarily depends on the mineral composition and structure of the aggregate. Thus, for example, amphibole andesite is progressively decomposed in the long-term salt crystallisation test, while micro-Deval initial increase, and then reach a constant value. Pyroxene andesite is also decomposed, due to a salt-action, but aggregate wear remains unchanged [5].

Regarding composite aggregates, it is recommended that more attention should be made because the composite aggregates (basalt, limestone and andesite) can improve or change the volumetric properties of asphalt mixture. Changing the types of coarse aggregates result in more variables than the fine aggregates [57].

In this granular modelling, resistance to fragmentation and water absorption have been improved by adding a certain amount of natural aggregate, which is essential for industrial application (Table 4). On the other hand, knowing that large-scale concrete production leads to the creation of large quantities of construction and demolition waste [58,59], the goal was to increase the use of RCA as much as possible and consequently reduce the waste disposal in the environment. It should be emphasised that some properties of intermediate aggregate blends (15% to 60% RCA addition) were calculated by interpolation from pure NA and 100% RCA results, in order to evaluate their potential to be used in different pavement layers.

The possibility to substitute natural aggregate by RCA and still meet the technical requirements is discussed in the following paragraphs.

In order to conduct a quality assessment of the aggregates, their characteristics were analysed in terms of the current Serbian specification [60], but also according to German specification [61], after which optimal natural aggregate replacement percentages were calculated.

Serbian specification for unbound materials for subbase layers (Table 5), among others, require LA 30 for heavy and medium traffic loading, and LA 35 for low traffic loading. According to that, aggregate mixtures of DI-1 and 15%, 30%, 45% and 60% of RCA fulfil all technical requirements, but 100% RCA can be applied only for low traffic loading. For flexible pavement structures, the application of RCA and dolerite granular mixtures may be permitted even for aggregates with WA24 > 1, if they show satisfactory freeze-thaw resistance. Examined mixtures are resistant to frost (magnesium sulphate 6–8%); they have satisfied other technical properties and can be used for asphalt concrete base and binder courses. Specification requirements for AC (Asphalt concrete) surface, SMA (Stone mastic asphalt), PA (Porous asphalt), MA (Mastic asphalt) are satisfied only by DI-1 for extremely heavy traffic loading, because of the requirement LA 20; other mixtures can be used for lower traffic loadings (see Table 5). For Slurry surfacing, the use of 15–60% RCA aggregate mixtures is possible only in the case of low traffic loading and for bike tracks, parking lots and stopping lanes, while DI-1 can be used for all traffic loadings.

Table 5.

The possibility of using RCA in flexible pavements according to technical requirements in Serbia.

As far as the hydraulically bound materials are concerned, the requirements for subbase layers for heavy traffic loading (LA30) are met by mixtures DI-1 + 15–60% RCA, whereas in case of medium and low traffic loading (LA 35) all aggregate mixtures are suitable. Specification for cement surface concrete pavements requires LA 20 for heavy traffic loading wearing course, which is only fulfilled by DI-1 aggregate. For other traffic loads, aggregate mixtures with 15%, 30% and 45% RCA also fulfil all technical requirements (except WA24 1, which can be substituted by successful MS test). For the cement base, concrete pavements aggregate mixtures with 15%, 30%, 45% and 60% RCA fulfil all technical requirements.

The possible application of RCA in flexible pavements, according to German specification [61], is presented in Table 6. Since the water absorption for all tested aggregate types was greater than required 0.5%, the resistance to freeze-thaw action must be proved according to EN 1367-2 (MS test). Although German technical conditions foresee the possibility of using this method, they do not define the minimum requirements. As can be seen from Table 6, all aggregate mixtures can be used for AC T and AC TD. Dolerite DI-1 and mixtures up to 45% RCA can be used for AC B because the limited requirement is LA 20-25. Specification for AC D, SMA, MA allow the use of DI-1 and 0–60% RCA mixtures because of prescribed resistance to fragmentation LA 20-30. PA requires C 100/0, so the RCA mixtures cannot be used in this case.

Table 6.

The possibility of using RCA in flexible pavements according to technical requirements in Germany.

According to the same German specification, for layers without binder, aggregate mixtures with 15%, 30%, 45%, 60% and 100% RCA fulfil all technical requirements (LA 40—for recycled construction materials). Regarding concrete pavement surfaces and courses with hydraulic binders, all aggregate mixtures fulfil the technical requirements for setting, hydraulically bound base course, concrete base layer and concrete subbase. Aggregate mixtures with up to 30% RCA also fulfil the requirements for top-layer concrete [61].

At the end of the discussion, it should be noted that the RCA used in this study was obtained from a relatively high-quality concrete (compressive strength class C 35/45). If lower quality RCA is to be used, consequently, lower performance of aggregate mixtures may be expected. The obtained results confirm the possibility of using RCA mixtures in different layers of pavement structures, but also pose new questions, such as how to overcome the limitations on the use of RCA in asphalt mixtures arising from the relatively short history of use.

5. Conclusions

Experimental research presented in this paper included testing of mineralogical-petrographic and physical-mechanical properties of natural dolerite aggregate (DI-1) and RCA, as well as their mixtures obtained by partial replacement of natural aggregate with RCA (15%, 30%, 45%, and 60%). The following conclusions can be made regarding the properties of used aggregates:

- Compared with natural dolerite (DI-1) aggregate, RCA has a lower percentage of crushed and broken surfaces, lower resistance to fragmentation, lower density, and higher water absorption. These characteristics of aggregate mixtures can be improved by using higher quantities of dolerite, in order to meet European technical requirements for aggregates to be applied in cement concrete and bituminous mixtures;

- Shape indices of the aggregates and their mixtures (between SI 20 and SI 13 for RCA and DI-1, respectively) are acceptable for their intended use.

- According to the content of crushed and rounded particles, all aggregate mixtures with RCA are classified as category C 95/1. Based on this, it can be said that a relatively large amount of RCA can be added to natural aggregates for use in pavement layers and for the production of rigid pavement structures in which the content of rounded gravel particles is rigorously limited.

- Testing of aggregate mixtures with 15–60% of RCA showed that the increase of RCA quantity leads to the reduction of totally crushed particles (from 94% to 76%), lower resistance to fragmentation (LA coefficient from 22% to 27%), lower resistance to wear (MDE from 14% to 15%), and higher water absorption values (from 1.1% to 2.5%); at the same time, PSV of all aggregate mixtures was in a relatively narrow range (55–57).

- All of the tested aggregate mixtures can also be used for rigid pavement structures, as well as for subbase layers.

- Regarding all the results from the study, it can be concluded that RCA can be a useful resource for producing cement and asphalt concretes.

Author Contributions

Conceptualization, D.Z. and A.R.; methodology, O.Đ., D.Z. and A.R.; formal analysis, O.Đ., and A.R.; investigation, O.Đ., B.Đ. and A.R.; resources, O.Đ. and A.R.; data curation, O.Đ. and A.R.; writing—original draft preparation, O.Đ., D.Z. and A.R.; writing—review and editing, O.Đ., and D.Z.; visualization, O.Đ., and A.R.; supervision, O.Đ., and D.Z.; project administration, D.Z. and B.Đ.; funding acquisition, D.Z. and A.R. All authors have read and agreed to the published version of the manuscript.

Funding

The presented study is a part of the research financially supported by the Ministry of Education, Science, and Technological Development of the Republic of Serbia under the research project TR 36048: “Research on condition assessment and improvement methods of civil engineering structures in view of their serviceability, load-bearing capacity, cost-effectiveness and maintenance” and TR 36017: “Utilisation of by-products and recycled waste materials in concrete composites in the scope of sustainable construction development in Serbia: investigation and environmental assessment of possible applications”.

Acknowledgments

We are thankful to the laboratory for stone and stone aggregates of the Highway Institute Belgrade, for funding part of the laboratory work. The authors also want to express their gratitude to Ivan Polić for helping with laboratory testing and Kristina Šarić for taking microscopic images.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dolan, B. Hot Mix Asphalt Pavement Design Guide. In Requirements for Successful Asphalt Pavement Construction; The Maryland Asphalt Association, Inc.: Glen Burnie, MD, USA, 2008. [Google Scholar]

- Singh, H.; Chopra, T.; Jain, S.; Kaur, A.; Kamotra, S. Effect of aggregate type and polymer modification on the performance of bituminous concrete mixes. Int. J. Appl. Sci. Eng. 2019, 16, 1–13. [Google Scholar] [CrossRef]

- Přikryl, R. Constructional geomaterials: Versatile earth resources in the service of humankind—Introduction to the thematic set of papers on: Challenges to supply and quality of geomaterials used in construction. Bull. Eng. Geol. Environ. 2017, 76, 1–9. [Google Scholar] [CrossRef]

- Ertas, B.; Topal, T. Quality and durability assessments of the armourstones for two rubble mound breakwaters (Mersin, Turkey). Environ. Geol. 2008, 53, 1235–1247. [Google Scholar] [CrossRef]

- Czinder, B.; Török, Á. Effects of long-term magnesium sulfate crystallisation tests on abrasion and durability of andesite aggregates. Bull. Eng. Geol. Environ. 2019. [Google Scholar] [CrossRef]

- Capik, M.; Yilmaz, A.O. Modeling of Micro Deval abrasion loss based on some rock properties. J. Afr. Earth Sci. 2017, 134, 549–556. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. The influence of alteration on the engineering properties of dolerites: The examples from the Pindos and Vourinos ophiolites (northern Greece). Int. J. Rock Mech. Min. Sci. 2010, 47, 69–80. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. Determination of the interrelations between the engineering parameters of construction aggregates from ophiolite complexes of Greece using factor analysis. Constr. Build. Mater. 2013, 49, 747–757. [Google Scholar] [CrossRef]

- Tugrul Tunc, E.; Esat Alyamac, K. A preliminary estimation method of Los Angeles abrasion value of concrete aggregates. Constr. Build. Mater. 2019, 222, 437–446. [Google Scholar] [CrossRef]

- Wang, D.; Wang, H.; Bu, Y.; Schulze, C.; Oeser, M. Evaluation of aggregate resistance to wear with Micro-Deval test in combination with aggregate imaging techniques. Wear 2015, 338–339, 288–296. [Google Scholar] [CrossRef]

- Gökalp, İ.; Uz, V.E.; Saltan, M. Testing the abrasion resistance of aggregates including by-products by using Micro Deval apparatus with different standard test methods. Constr. Build. Mater. 2016, 123, 1–7. [Google Scholar] [CrossRef]

- Erichsen, E. Relationship between PSV and in situ friction: A Norwegian case study. Bull. Eng. Geol. Environ. 2009, 68, 339–343. [Google Scholar] [CrossRef]

- Krutilová, K.; Přikryl, R. Relationship between polished stone value (PSV) and Nordic abrasion value (A N) of volcanic rocks. Bull. Eng. Geol. Environ. 2017, 76, 85–99. [Google Scholar] [CrossRef]

- Přikryl, R.; Török, A.; Theodoridou, M.; Gomez-Heras, M.; Miskovsky, K. Geomaterials in construction and their sustainability: Understanding their role in modern society. Geol. Soc. Spec. Publ. 2016, 416, 1–22. [Google Scholar] [CrossRef]

- UEPG Annual Review 2018–2019; 15340821653-49; EU Transparency Register: Bruxelles, Belgium, 2019; p. 32.

- Sáez, P.V.; del Merino, M.R.; Porras-Amores, C. Managing construction and demolition (C&D) waste—A European perspective. In Proceedings of the 2011 International Conference on Petroleum and Sustainable Development, Dubai, United Arab Emirates, 28–30 December 2011; IACSIT Press: Singapore, 2011; pp. 27–31. [Google Scholar]

- Ecorys. EU Construction & Demolition Waste Management Protocol and Guidelines; European Commission: Bruxelles, Belgium, 2016; ISBN 1866505041. [Google Scholar]

- Brundtland, G.H. Our Common Future: The World Commission on Environment and Development; Oxford University Press: Oxford, UK, 1987; ISBN 019282080X. [Google Scholar]

- Reid, J.M.; Evans, R.D.; Holnsteiner, R.; Wimmer, B.; Gaggl, W.; Berg, F.; Pihl, K.A.; Milvang-Jensen, O.; Hjelmar, O.; Rathmeyer, H.; et al. ALT-MAT Final Report. Contract No.: RO-97-SC.2238. Alt-Mat Altern. Mater. Road Constr. 2001, 1–190. [Google Scholar]

- Cooper, T.; Pezold, T.; Keenleyside, C.; Đorđević-Milošević, S.; Hart, K.; Ivanov, S.; Redman, M.; Vidojević, D. Developing a National Agri—Environment Programme for Serbia; IUCN Programme Office for South-Eastern Europe: Gland, Switzerland; Belgrade, Serbia, 2010; ISBN 978-2-8317-1325-0. [Google Scholar]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef]

- Kim, G.-D.; Kim, T.-B. Development of recycling technology from waste aggregate and dust from waste concrete. J. Ceram. Process. Res. 2007, 8, 82–86. [Google Scholar]

- Wilburn, D.; Goonan, T. Aggregates from Natural and Recycled Sources; Economic Assessments for Construction Applications; A Materials Flow Study in USA; Geological Survey Circular 1176: Washington, UK, 1998; p. 40. [Google Scholar]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Cho, Y.H.; Yun, T.; Kim, I.T.; Choi, N.R. The application of recycled concrete aggregate (RCA) for hot mix asphalt (HMA) base layer aggregate. KSCE J. Civ. Eng. 2011, 15, 473–478. [Google Scholar] [CrossRef]

- Pérez, I.; Pasandín, A.R.; Medina, L. Hot mix asphalt using C&D waste as coarse aggregates. Mater. Des. 2012, 36, 840–846. [Google Scholar] [CrossRef]

- Pourtahmasb, M.S.; Karim, M.R. Utilisation of recycled concrete aggregates in stone mastic asphalt mixtures. Adv. Mater. Sci. Eng. 2014, 1–9. [Google Scholar] [CrossRef]

- Hou, Y.; Ji, X.; Su, X.; Zhang, W.; Liu, L. Laboratory investigations of activated recycled concrete aggregate for asphalt treated base. Constr. Build. Mater. 2014, 65, 535–542. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Pérez, I.; Airey, G.; Thom, N. Stiffness of cold asphalt mixtures with recycled aggregates from construction and demolition waste. Constr. Build. Mater. 2015, 77, 168–178. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, K.; Liu, H.; Deng, Z. Key performance properties of asphalt mixtures with recycled concrete aggregate from low strength concrete. Constr. Build. Mater. 2016, 126, 711–719. [Google Scholar] [CrossRef]

- Wu, S.; Muhunthan, B.; Wen, H. Investigation of effectiveness of prediction of fatigue life for hot mix asphalt blended with recycled concrete aggregate using monotonic fracture testing. Constr. Build. Mater. 2017, 131, 50–56. [Google Scholar] [CrossRef]

- Radević, A.; Đureković, A.; Zakić, D.; Mladenović, G. Effects of recycled concrete aggregate on stiffness and rutting resistance of asphalt concrete. Constr. Build. Mater. 2017, 136, 386–393. [Google Scholar] [CrossRef]

- Radević, A. Properties of Asphalt Concrete Mixtures with Recycled PCC Aggregate. Ph.D. Thesis, The University of Belgrade, Belgrade, Serbia, 2017. [Google Scholar]

- EN 1992-1-1 Eurocode 2: Design of concrete structures—Part 1-1: General rules and rules for buildings. Br. Stand. Inst. 2004, 1, 227.

- Ðokić, O.; Matović, V.; Erić, S.; Šarić, K. Influence of engineering properties on Polished Stone Value (PSV): A case study on basic igneous rocks from Serbia. Constr. Build. Mater. 2015, 101, 1088–1096. [Google Scholar] [CrossRef]

- Đokić, O. Influence of Mineralogical and Petrographical Characteristics on Aggregate Microroughness of Basic Igneous Rocks from Serbia. Ph.D. Thesis, The University of Belgrade, Belgrade, Serbia, 2016. [Google Scholar]

- FprEN 12620 European Standard Emitted by CEN, European Committee for Standardisation: Aggregates for Concrete; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2018; p. 52.

- FprEN 13043 European Standard Emitted by CEN, European Committee for Standardisation: Aggregates for Bituminous Mixtures and Surface Treatments for Roads, Airfields and Other Trafficked Areas; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2018; p. 50.

- EN 933-11 European Standard Emitted by CEN, European Committee for Standardisation: Classification Test for the Constituents of Coarse Recycled Aggregate; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2009; p. 13.

- EN 932-3+A1 European Standard Emitted by CEN, European Committee for Standardisation: Procedure and Terminology for Simplified Petrographic Description; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2003; p. 10.

- EN 12407 European Standard Emitted by CEN, European Committee for Standardisation: Petrographic examination; Technical Committee CEN/TC 246 “Natural Stones”: Brussels, Belgium, 2007; p. 18.

- EN 933-4 European Standard Emitted by CEN, European Committee for Standardisation: Determination of Particle Shape—Shape Index; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2008; p. 11.

- EN 933-5+A1 European Standard Emitted by CEN, European Committee for Standardisation: Determination of Percentage of Crushed and Broken Surfaces in Coarse Aggregate Particles; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2004; p. 10.

- EN 1097-2 European Standard Emitted by CEN, European Committee for Standardisation: Methods for the Determination of Resistance to Fragmentation; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2010; p. 38.

- 1097-1 European Standard Emitted by CEN, European Committee for Standardisation: Determination of the Resistance to Wear (Micro-Deval); Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2011; p. 18.

- EN 1097-8 European Standard Emitted by CEN, European Committee for Standardisation: Determination of the Polished Stone Value; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2009; p. 33.

- Dunford, A. Establishing a New Supply of UK PSV Control Stone Including Results of Supplementary Experiments; Published Project Report PPR603; Transport Research Laboratory: Crothon, UK, 2013; p. 20. [Google Scholar]

- EN 1097-6 European Standard Emitted by CEN, European Committee for Standardisation: Determination of Particle Density and Water Absorption; Technical Committee CEN/TC154 “Aggregates”: Brussels, Belgium, 2013; p. 51.

- EN 1367-2 European Standard Emitted by CEN, European Committee for Standardisation: Magnesium Sulfate Test; European Committee for Standardisation: Brussels, Belgium, 2009; p. 17.

- Bilbija, N. The alkali-silica reactivity of the aggregate from the main streams in the Great Morava basin. In The Alkali-Silica Reactivity in Concrete; Highway Institute: Belgrade, Serbia, 1984; pp. 117–134. [Google Scholar]

- European Commission. Regulation (EU) no 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC. Off. J. Eur. Union 2011, 88, 39. [Google Scholar]

- Ugur, I.; Demirdag, S.; Yavuz, H. Effect of rock properties on the Los Angeles abrasion and impact test characteristics of the aggregates. Mater. Charact. 2010, 61, 90–96. [Google Scholar] [CrossRef]

- Hartley, A. A review of the geological factors influencing the mechanical properties of road surface aggregates. Q. J. Eng. Geol. Hydrogeol. 1974, 7, 69–100. [Google Scholar] [CrossRef]

- Török, Á.; Czinder, B. Relationship between density, compressive strength, tensile strength and aggregate properties of andesites from Hungary. Environ. Earth Sci. 2017, 76. [Google Scholar] [CrossRef]

- Thompson, A.; Burrows, A.; Flavin, D.; Walsh, I. The Sustainable Use of for Skid-Resistant Road Surfacing in England High Specification Aggregates; Capita Symonds Ltd.: East Grinstead, UK, 2004; p. 167. [Google Scholar]

- Smith, M.; Collis, L. Aggregates: Sand, Gravel and Crushed Rock Aggregates for Construction Purposes, 3rd ed.; The Geological Society: London, UK, 2001; ISBN 1862390797. [Google Scholar]

- Kong, D.; Xiao, Y.; Wu, S.; Tang, N.; Ling, J.; Wang, F. Comparative evaluation of designing asphalt treated base mixture with composite aggregate types. Constr. Build. Mater. 2017, 156, 819–827. [Google Scholar] [CrossRef]

- Mustafa, S.; Khan, M.A.; Khan, M.R.; Hameed, F.; Mughal, M.S.; Asghar, A.; Niaz, A. Geotechnical study of marble, schist, and granite as dimension stone: A case study from parts of Lesser Himalaya, Neelum Valley Area, Azad Kashmir, Pakistan. Bull. Eng. Geol. Environ. 2015, 74, 1475–1487. [Google Scholar] [CrossRef]

- Boudlal, O.; Djemai, M.; Hamza, A.; Khattaoui, M. Valorisation de nouveaux matériaux naturels et recyclés dans la construction routière en Algérie. Bull. Eng. Geol. Environ. 2017, 76, 523–535. [Google Scholar] [CrossRef]

- Public Enterprise Roads of Serbia SRCS Technical Conditions for Roads Construction, 2 Special technical Conditions, 2.4 Pavement; Public Enterprise Roads of Serbia: Belgrade, Serbia, 2012; p. 125.

- FGSV 613 E Technical Delivery Terms for Aggregates in Road Construction (TL Gestein-StB 04); German Road and Transportation Research Association (FGSV): Köln, Germeny, 2012; p. 64.

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).