The Effect of Alkali Roasting Pretreatment on Nickel Extraction from Limonite Ore by Using Dissolved SO2-Air

Abstract

1. Introduction

2. Materials and Methods

2.1. Limonite Laterite Nickel Ore

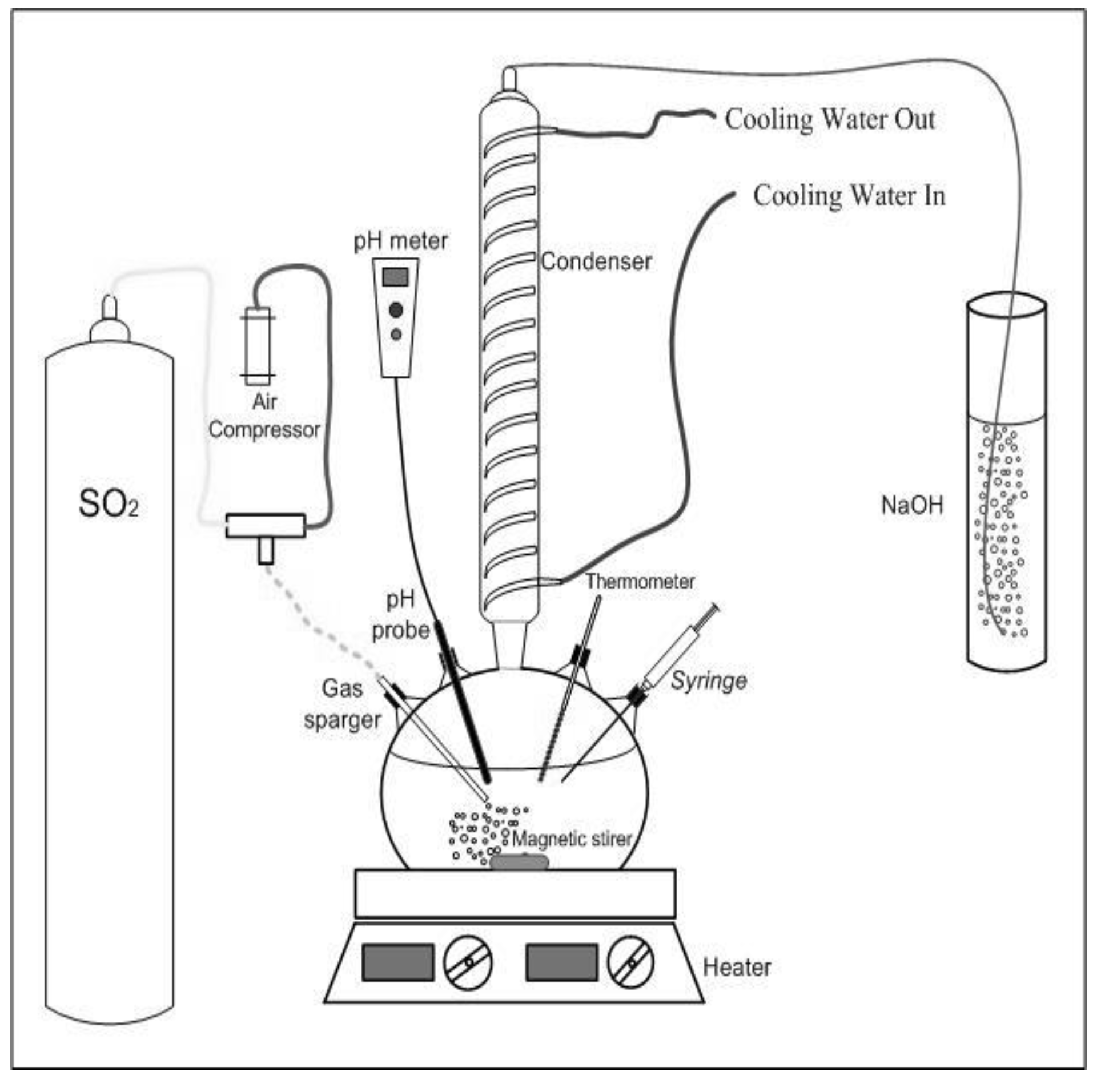

2.2. Method

3. Results and Discussion

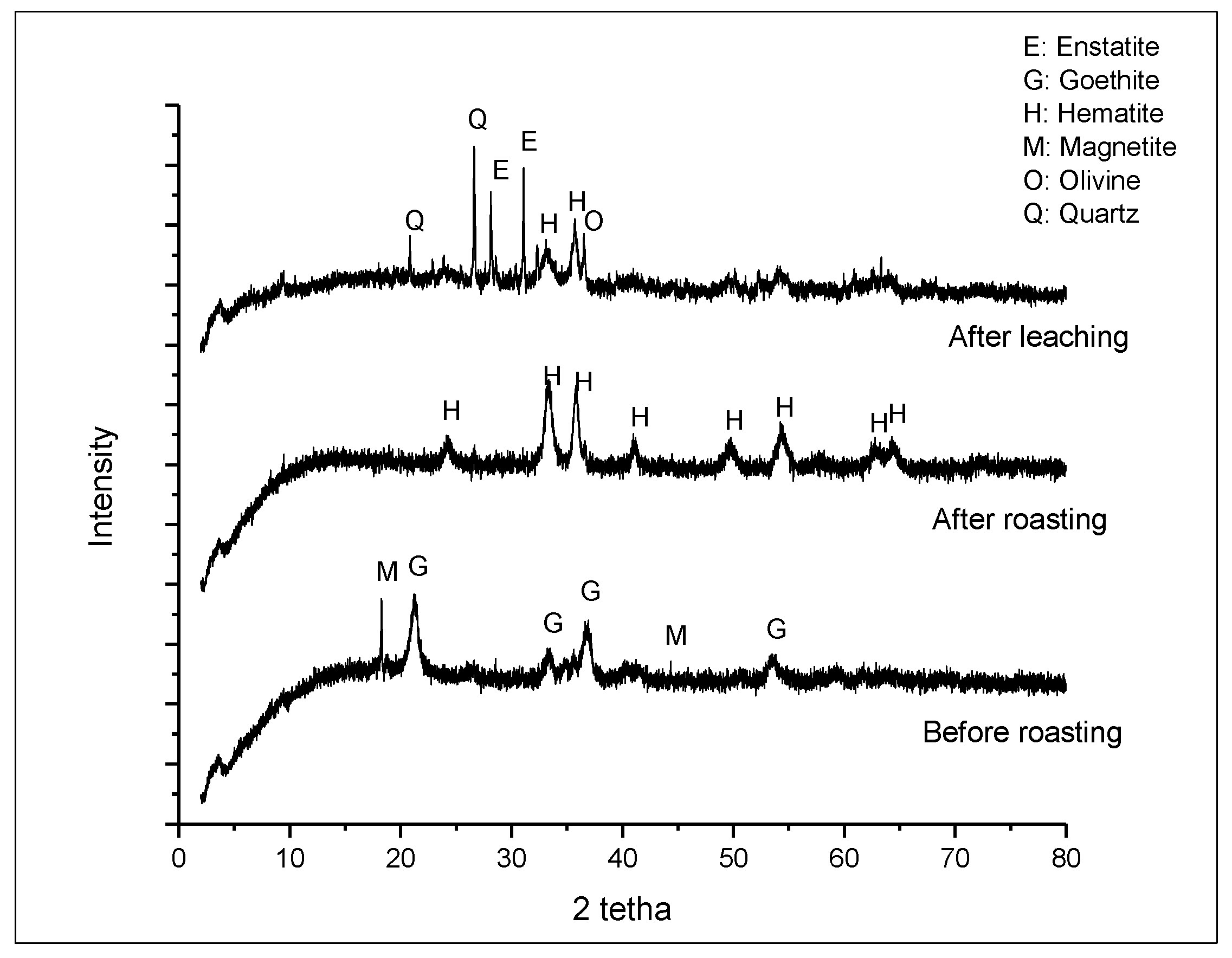

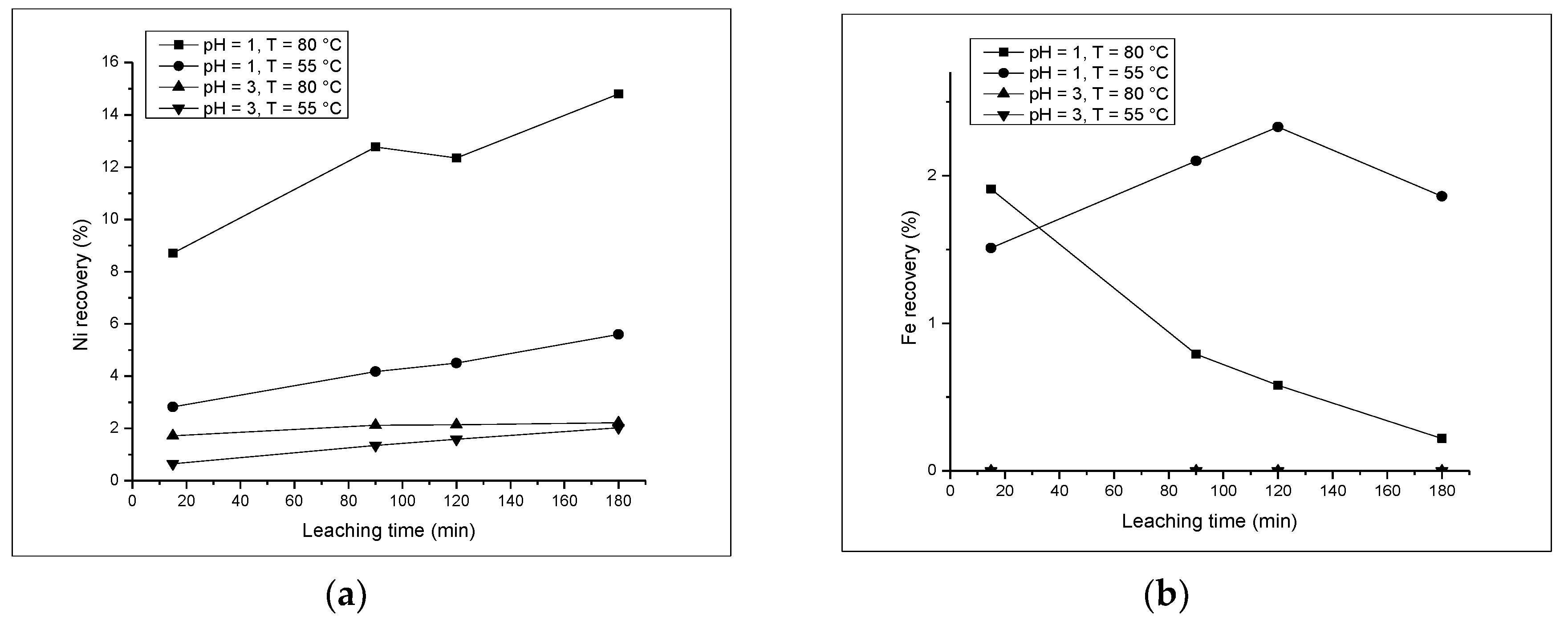

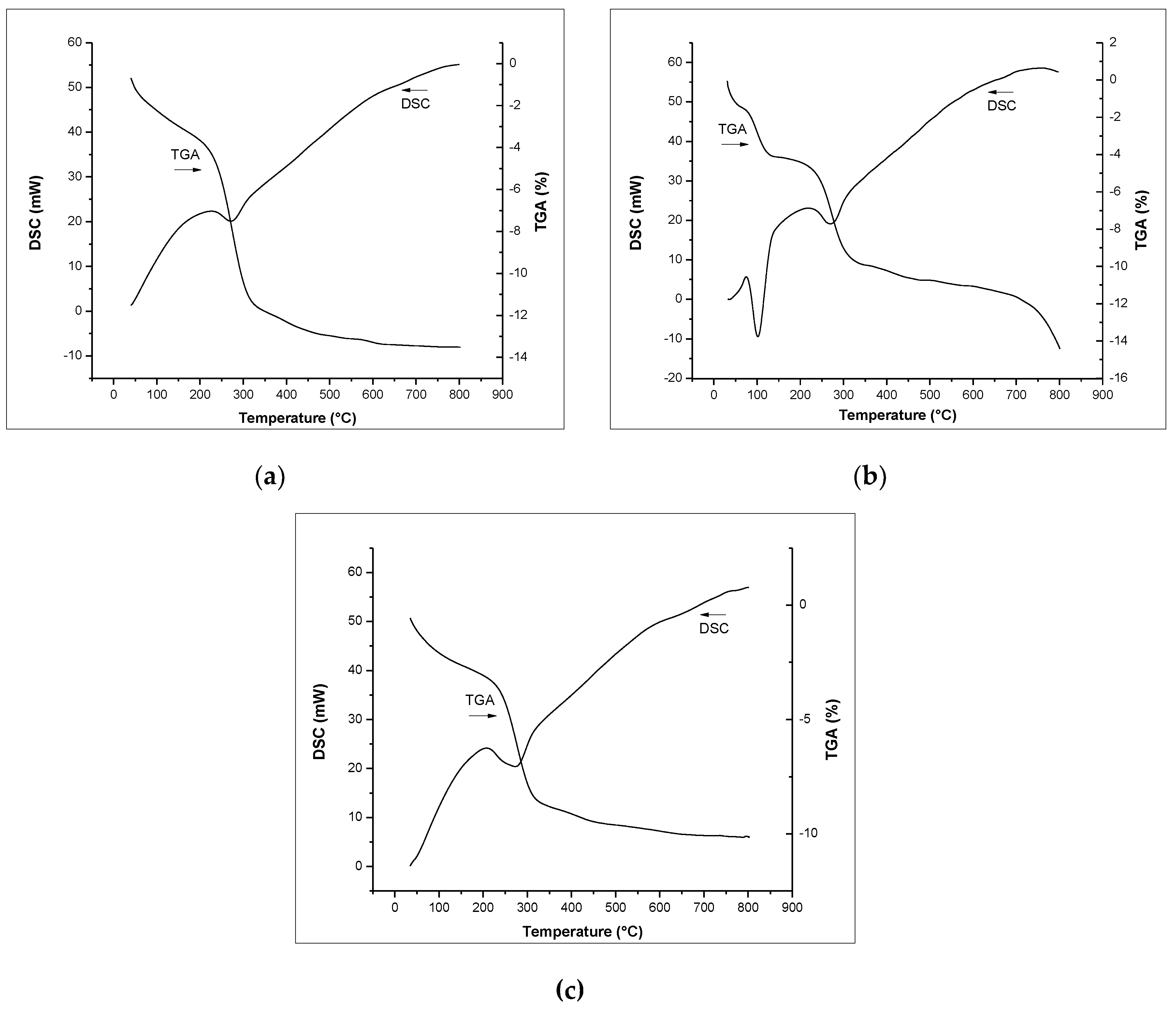

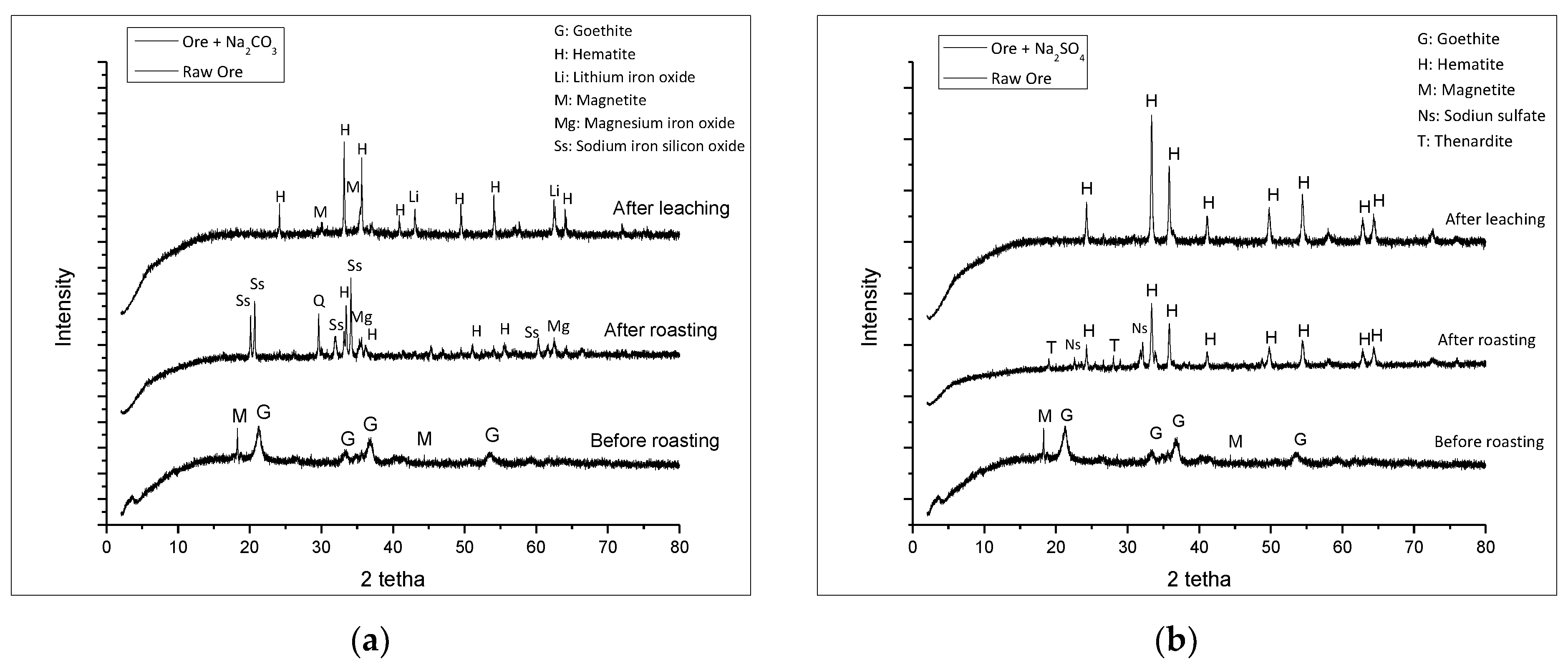

3.1. Roasting (No Alkali) Pretreatment

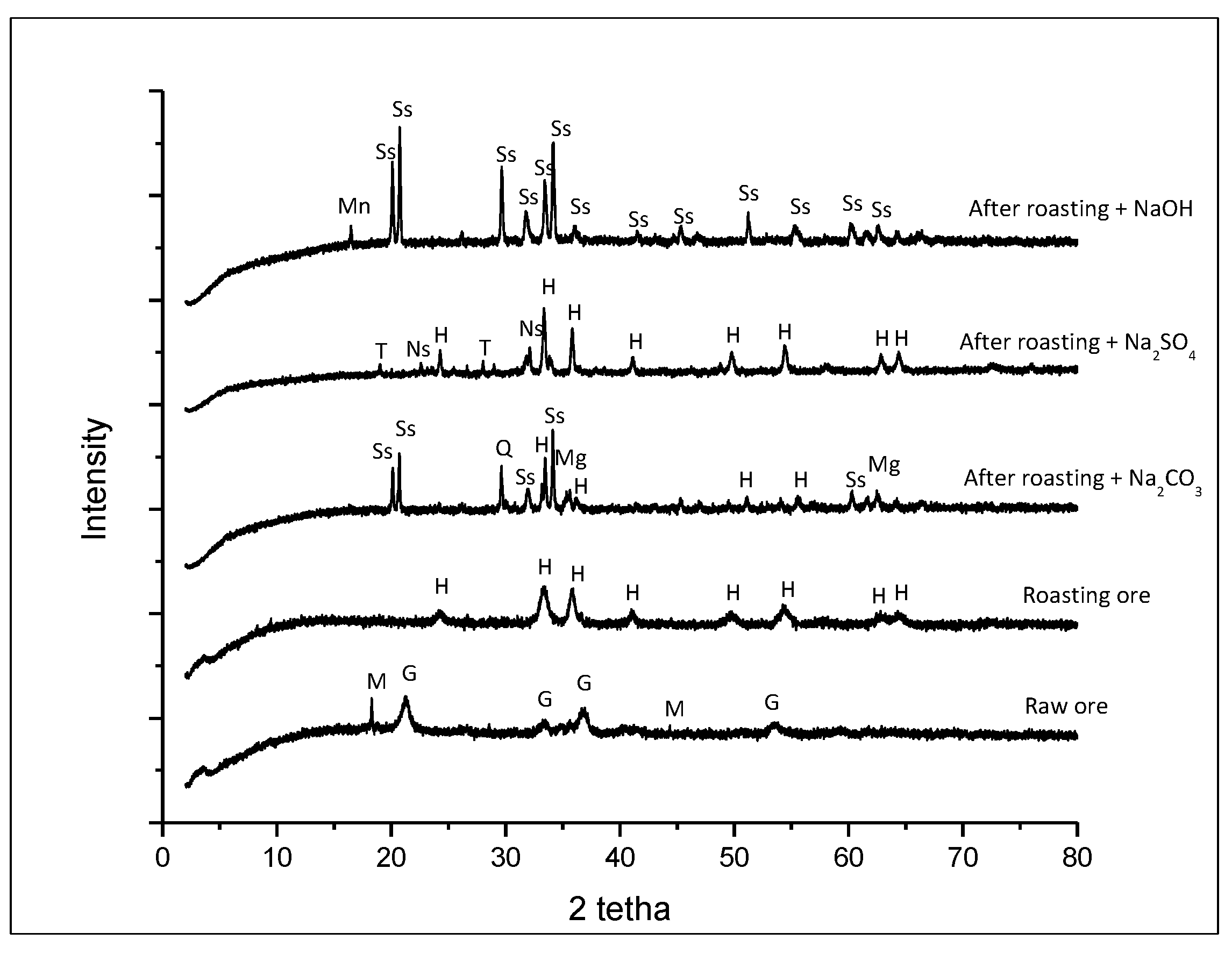

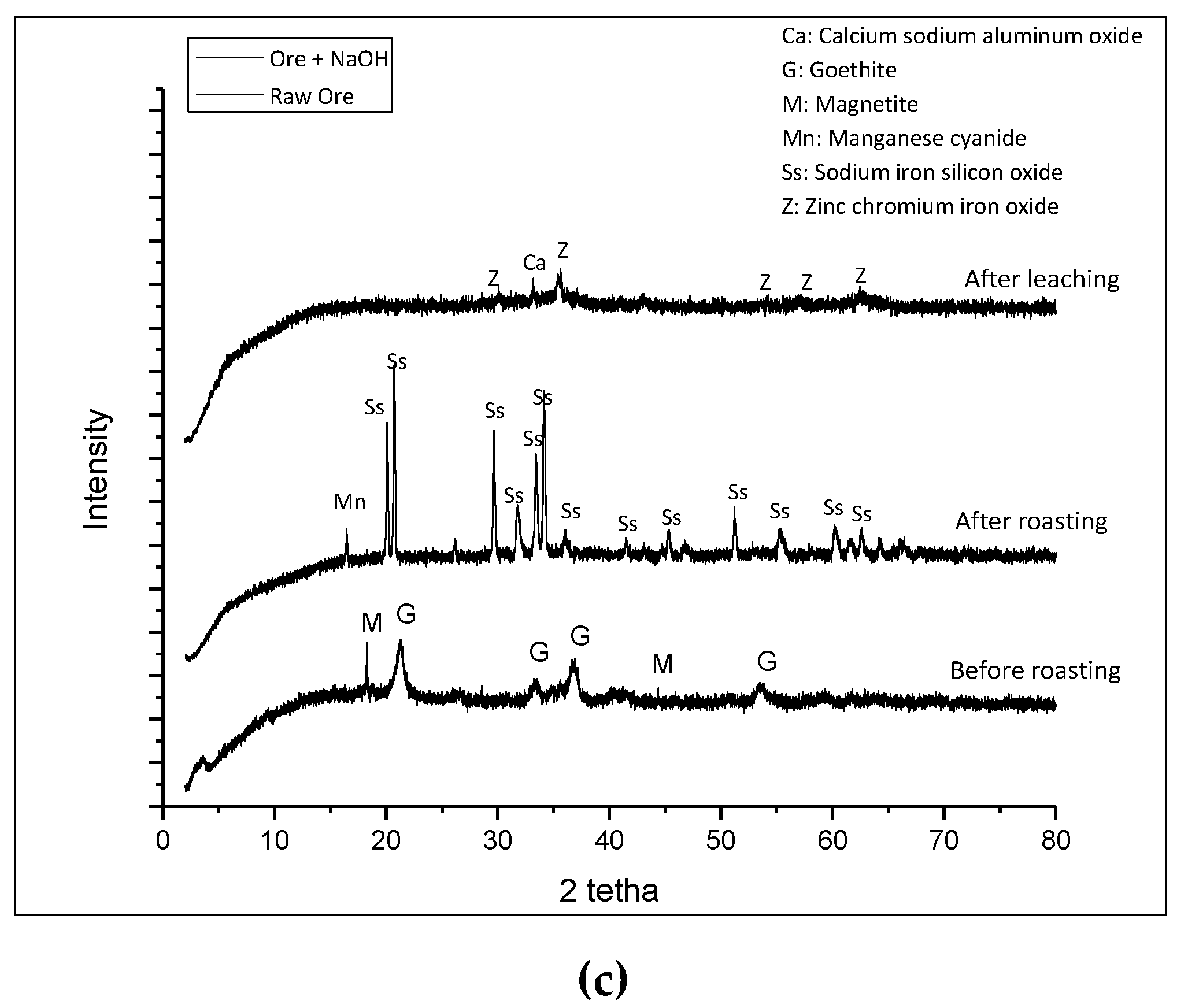

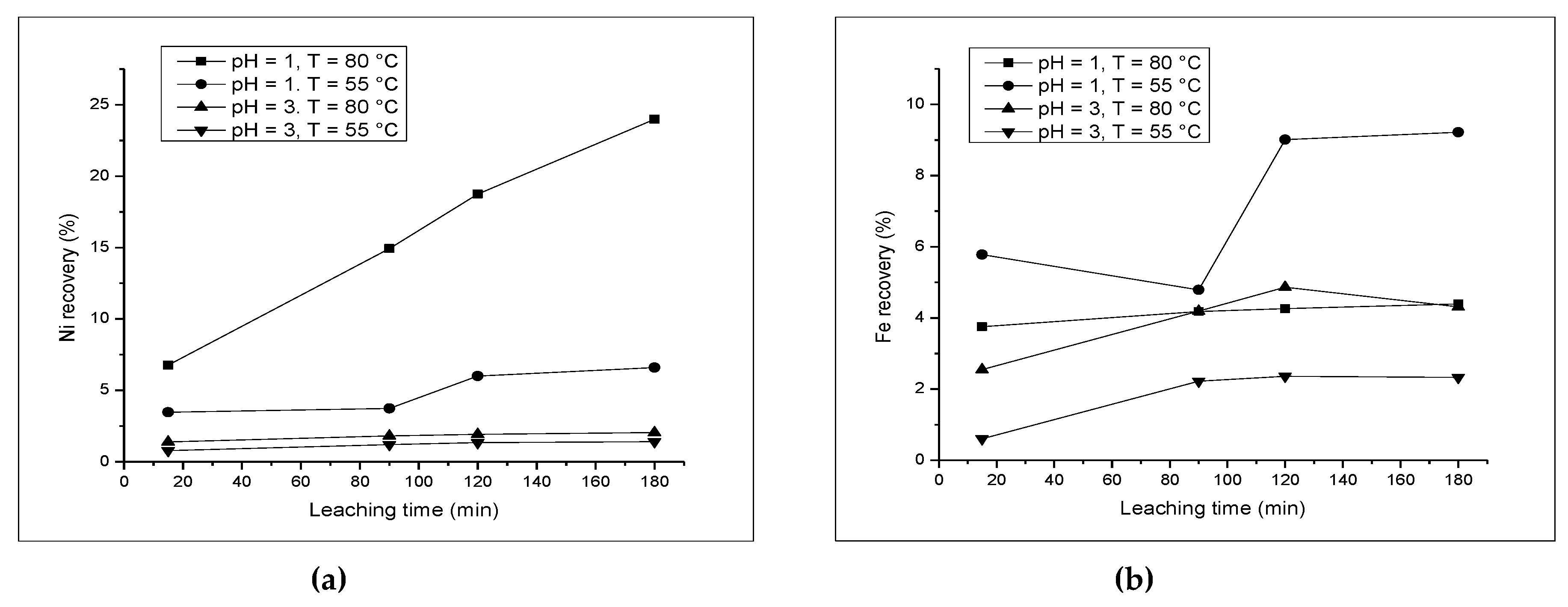

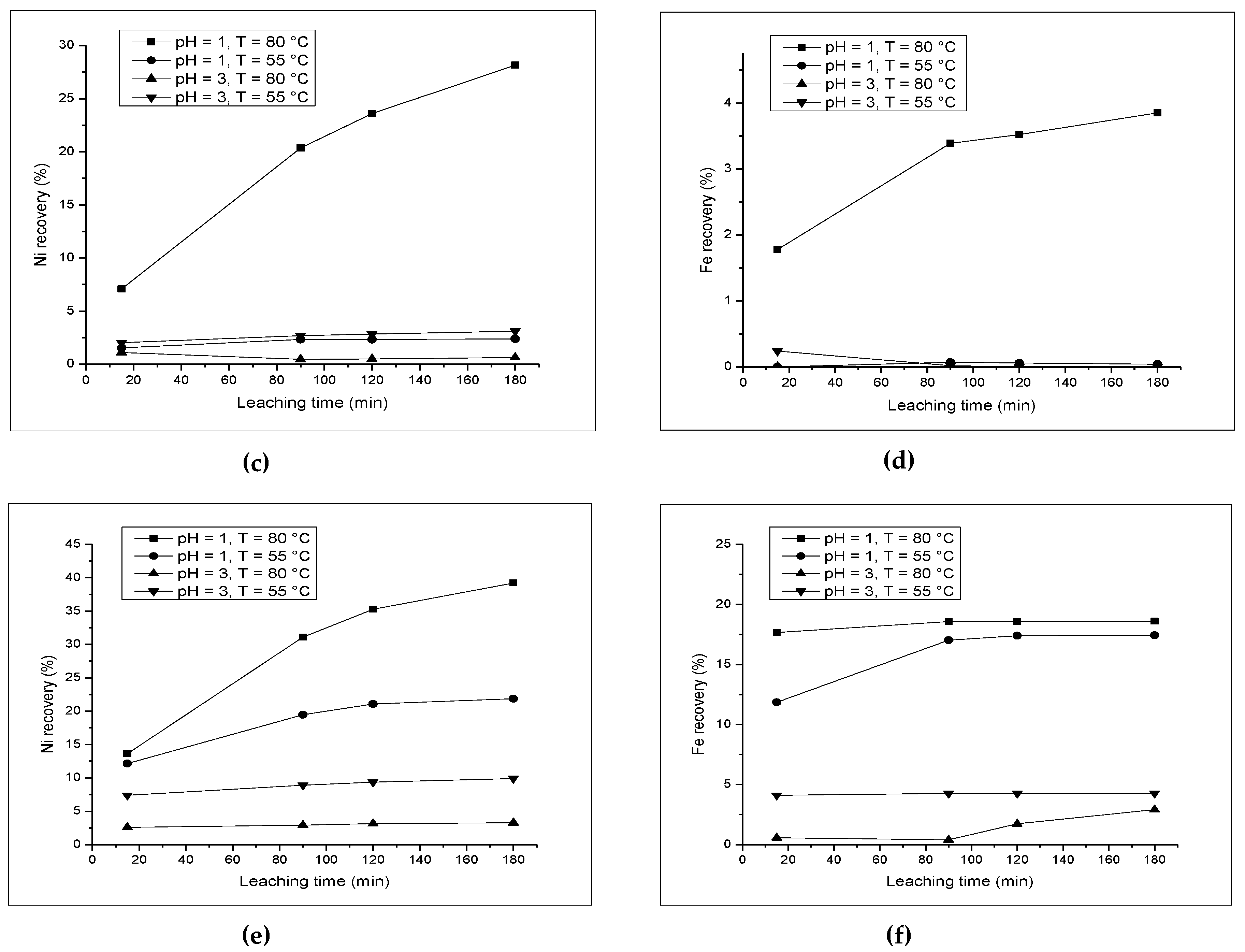

3.2. Alkali Roasting Pretreatment

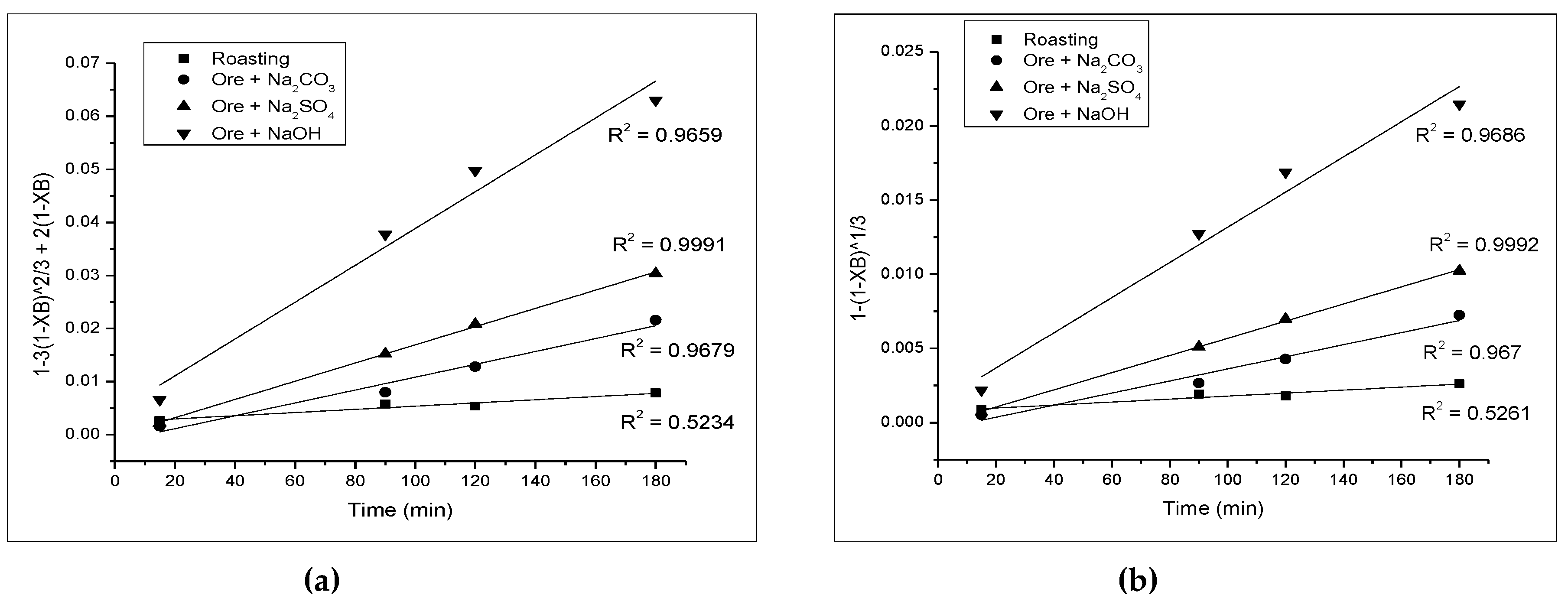

3.3. Kinetic Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mudd, G.M.; Jowitt, S.M. A Detailed Assessment of Global Nickel Resource Trends and Endowments. Econ. Geol. 2014, 109, 1813–1841. [Google Scholar] [CrossRef]

- Fan, R.; Gerson, A.R. Mineralogical characterisation of Indonesian laterites prior to and post atmospheric leaching. Hydrometallurgy 2013, 134, 102–109. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries 2019; U.S. Geological Survey: Hunter Mill, VA, USA, 2019.

- Zhu, D.; Cui, Y.; Hapugoda, S.; Vining, K.; Pan, J. Mineralogy and crystal chemistry of a low grade nickel laterite ore. Trans. Nonferrous Met. Soc. China 2012, 22, 907–916. [Google Scholar] [CrossRef]

- Guo, Q.; Qu, J.K.; Han, B.B.; Wei, G.Y.; Zhang, P.Y.; Qi, T. Dechromization and dealumination kinetics in process of Na2CO3-roasting pretreatment of laterite ores. Trans. Nonferrous Met. Soc. China 2014, 24, 3979–3986. [Google Scholar] [CrossRef]

- Shibayama, K.; Yokogawa, T.; Sato, H.; Enomoto, M.; Nakai, O.; Ito, T.; Mizuno, F.; Hattori, Y. Taganito HPAL Plant Project. Miner. Eng. 2016, 88, 61–65. [Google Scholar] [CrossRef]

- McDonald, R.G.; Whittington, B.I. Atmospheric acid leaching of nickel laterites review: Part II. Chloride and bio-technologies. Hydrometallurgy 2008, 91, 56–59. [Google Scholar] [CrossRef]

- McDonald, R.G.; Whittington, B.I. Atmospheric acid leaching of nickel laterites review: Part I. Sulphuric acid technologies. Hydrometallurgy 2008, 91, 35–55. [Google Scholar] [CrossRef]

- Jang, H.-C.; Valix, M. Overcoming the bacteriostatic effects of heavy metals on Acidithiobacillus thiooxidans for direct bioleaching of saprolitic Ni laterite ores. Hydrometallurgy 2017, 168, 21–25. [Google Scholar] [CrossRef]

- Oxley, A.; Smith, M.E.; Caceres, O. Why heap leach nickel laterites? Miner. Eng. 2016, 88, 53–60. [Google Scholar] [CrossRef]

- Astuti, W.; Hirajima, T.; Sasaki, K.; Okibe, N. Comparison of atmospheric citric acid leaching kinetics of nickel from different Indonesian saprolitic ores. Hydrometallurgy 2016, 161, 138–151. [Google Scholar] [CrossRef]

- Luo, J.; Li, G.; Rao, M.; Peng, Z.; Zhang, Y.; Jiang, T. Atmospheric leaching characteristics of nickel and iron in limonitic laterite with sulfuric acid in the presence of sodium sulfite. Miner. Eng. 2015, 78, 38–44. [Google Scholar] [CrossRef]

- Wang, K.; Li, J.; Mcdonald, R.G.; Browner, R.E. Iron, aluminium and chromium co-removal from atmospheric nickel laterite leach solutions. Miner. Eng. 2018, 116, 35–45. [Google Scholar] [CrossRef]

- Wulandari, W.; Soerawidjaja, T.H.; Alifiani, D.; Rangga, D.A. The effect of pre-treatments to the nickel limonite leaching using dissolved gaseous SO2-air. IOP Conf. Ser. Mater. Sci. Eng. 2018, 285. [Google Scholar] [CrossRef]

- Gbor, P.K.; Ahmed, I.B.; Jia, C.Q. Behaviour of Co and Ni during aqueous sulphur dioxide leaching of nickel smelter slag. Hydrometallurgy 2000, 57, 13–22. [Google Scholar] [CrossRef]

- Mulaudzi, N.; Mahlangu, T. Oxidative precipitation of Mn(II) from cobalt leach solutions using dilute SO2/air mixture. J. South. Afr. Inst. Min. Metall. 2009, 109, 375–382. [Google Scholar]

- Wulandari, W.; Soerawidjaja, T.H.; Joshua, S.; Isradi, H.R. Extraction of nickel from nickel limonite ore using dissolved gaseous SO2-Air. AIP Conf. Proc. 2017, 1805, 070004. [Google Scholar] [CrossRef]

- Guo, Q.; Qu, J.; Qi, T.; Wei, G.; Han, B. Activation pretreatment of limonitic laterite ores. Miner. Eng. 2011, 24, 825–832. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Hu, Q.; Wang, Z.; Zhou, Y.; Zheng, J.; Liu, W.; Li, L. Effect of pre-roasting on leaching of laterite. Hydrometallurgy 2009, 99, 84–88. [Google Scholar] [CrossRef]

- Jiang, M.; Sun, T.; Liu, Z.; Kou, J.; Liu, N.; Zhang, S. Mechanism of sodium sulfate in promoting selective reduction of nickel laterite ore during reduction roasting process. Int. J. Miner. Process. 2013, 123, 32–38. [Google Scholar] [CrossRef]

- Levenspiel, O. Chemical Reaction Engineering. In Chemical Reaction Engineering, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1998; pp. 569–576. [Google Scholar]

- Thubakgale, C.K.; Mbaya, R.K.K.; Kabongo, K. A study of atmospheric acid leaching of a south african nickel laterite. Miner. Eng. 2013, 54, 79–81. [Google Scholar] [CrossRef]

- O’Connor, F.; Cheung, W.H.; Valix, M. Reduction roasting of limonite ores: Effect of dehydroxylation. Int. J. Miner. Process. 2006, 80, 88–99. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Gao, Y.; Zhang, Y.; Chen, Z. Chlorination roasting of laterite using salt chloride. Int. J. Miner. Process. 2016, 148, 23–31. [Google Scholar] [CrossRef]

- Ma, B.; Yang, W.; Pei, Y.; Wang, C.; Jin, B. Effect of activation pretreatment of limonitic laterite ores using sodium fluoride and sulfuric acid on water leaching of nickel and cobalt. Hydrometallurgy 2017, 169, 411–417. [Google Scholar] [CrossRef]

- Li, G.; Shi, T.; Rao, M.; Jiang, T.; Zhang, Y. Beneficiation of nickeliferous laterite by reduction roasting in the presence of sodium sulfate. Miner. Eng. 2012, 32, 19–26. [Google Scholar] [CrossRef]

- Zhang, W.; Singh, P.; Muir, D. Iron(II)/ oxidation by SO2/O2 in acidic media: Part I. Kinetics and mechanism. Hydrometallurgy 2000, 55, 229–245. [Google Scholar] [CrossRef]

| Metal and Oxide | Ni | Co | Fe | SiO2 | CaO | MgO | MnO | Cr2O3 | Al2O3 | P2O5 | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 1.33 | 0.14 | 46.61 | 4.07 | 0.02 | 1.18 | 1.07 | 2.75 | 12.07 | 0.03 | 0.10 | 0.63 |

| Operating Condition | Ni/Fe Selectivity | ||||

|---|---|---|---|---|---|

| pH | T (°C) | Roasting | Na2CO3 Roasting | Na2SO4 Roasting | NaOH Roasting |

| 1 | 55 | 3.02 | 0.71 | 56.66 | 1.25 |

| 80 | 66.71 | 5.47 | 7.31 | 2.11 | |

| 3 | 55 | 10,539 | 0.61 | 16,172.38 | 2.32 |

| 80 | 24,946 | 0.48 | 7024.42 | 1.12 | |

| No. | Method | Type of Ore | Experiment Parameters | Ni Recovery (%) | Reference |

|---|---|---|---|---|---|

| 1 | Atmospheric leaching | Indonesian laterite | T = 90 °C, 30-g/L Na2SO3, t = 6 h, L/S ratio: 10:1. | 82.3 | [12] |

| 2 | Atmospheric leaching | West Papua limonite and saprolite | T = 100 °C, H2SO4/ore ratio = 1.4:1, t (limonite) = 3 h. t (saprolite) = 11 h | Limonite: 85 Saprolite: 50 | [2] |

| 4 | Chlorination roasting and water leaching | Limonite | Roasting T = 1173 K, t = 1.5 h, Chloride agent = NaCl + MgCl2.6H2O (mass ratio of 0.4) | 87 | [24] |

| 5 | Activation pretreatment and NaF and H2SO4 leaching | Philippines limonite | Activation T = 400 °C, t = 60 min, H2SO4 dosage = 500 kg/ton, NaF dosage = 3% | 85.3 | [25] |

| 6 | Pre-roasting and leaching | Yunan, China laterite | T roasting = 300 °C, Ore + 4-mol/L HCl; S/L ratio = 1:6; T = 50 °C; t = 1 h | 93.1 | [19] |

| 7 | Reduction roasting | Sulawesi, Indonesia laterite | Reduction roasting T = 1100 °C, t = 60 min, sodium sulfate = 20 wt% | 83.01 | [26] |

| 8 | Alkali roasting, SO2–air leaching | Indonesia, limonitic | T = 55–80 °C, pH: 1 and 3; t = 3 h | 23.99–39.22 | Current work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wulandari, W.; Kinda, M.M.; Murida, R.; Samadhi, T.W. The Effect of Alkali Roasting Pretreatment on Nickel Extraction from Limonite Ore by Using Dissolved SO2-Air. Minerals 2020, 10, 701. https://doi.org/10.3390/min10080701

Wulandari W, Kinda MM, Murida R, Samadhi TW. The Effect of Alkali Roasting Pretreatment on Nickel Extraction from Limonite Ore by Using Dissolved SO2-Air. Minerals. 2020; 10(8):701. https://doi.org/10.3390/min10080701

Chicago/Turabian StyleWulandari, Winny, Meiyer Marthen Kinda, Rahmaditha Murida, and Tjokorde Walmiki Samadhi. 2020. "The Effect of Alkali Roasting Pretreatment on Nickel Extraction from Limonite Ore by Using Dissolved SO2-Air" Minerals 10, no. 8: 701. https://doi.org/10.3390/min10080701

APA StyleWulandari, W., Kinda, M. M., Murida, R., & Samadhi, T. W. (2020). The Effect of Alkali Roasting Pretreatment on Nickel Extraction from Limonite Ore by Using Dissolved SO2-Air. Minerals, 10(8), 701. https://doi.org/10.3390/min10080701