Evaluation of Recyclability of a WEEE Slag by Means of Integrative X-Ray Computer Tomography and SEM-Based Image Analysis

Abstract

1. Introduction

- Base metals (BMs): Cu, Al, Ni, Sn, Zn, and Fe;

- Precious metals (PMs): Au, Ag, Pd, Pt, Rh, Ir, and Ru;

- Metals of concern (MCs, hazardous): Hg, Be, In, Pb, Cd, As, and Sb;

- Scarce elements (REEs): Te, Ga, Se, Ta, and Ge.

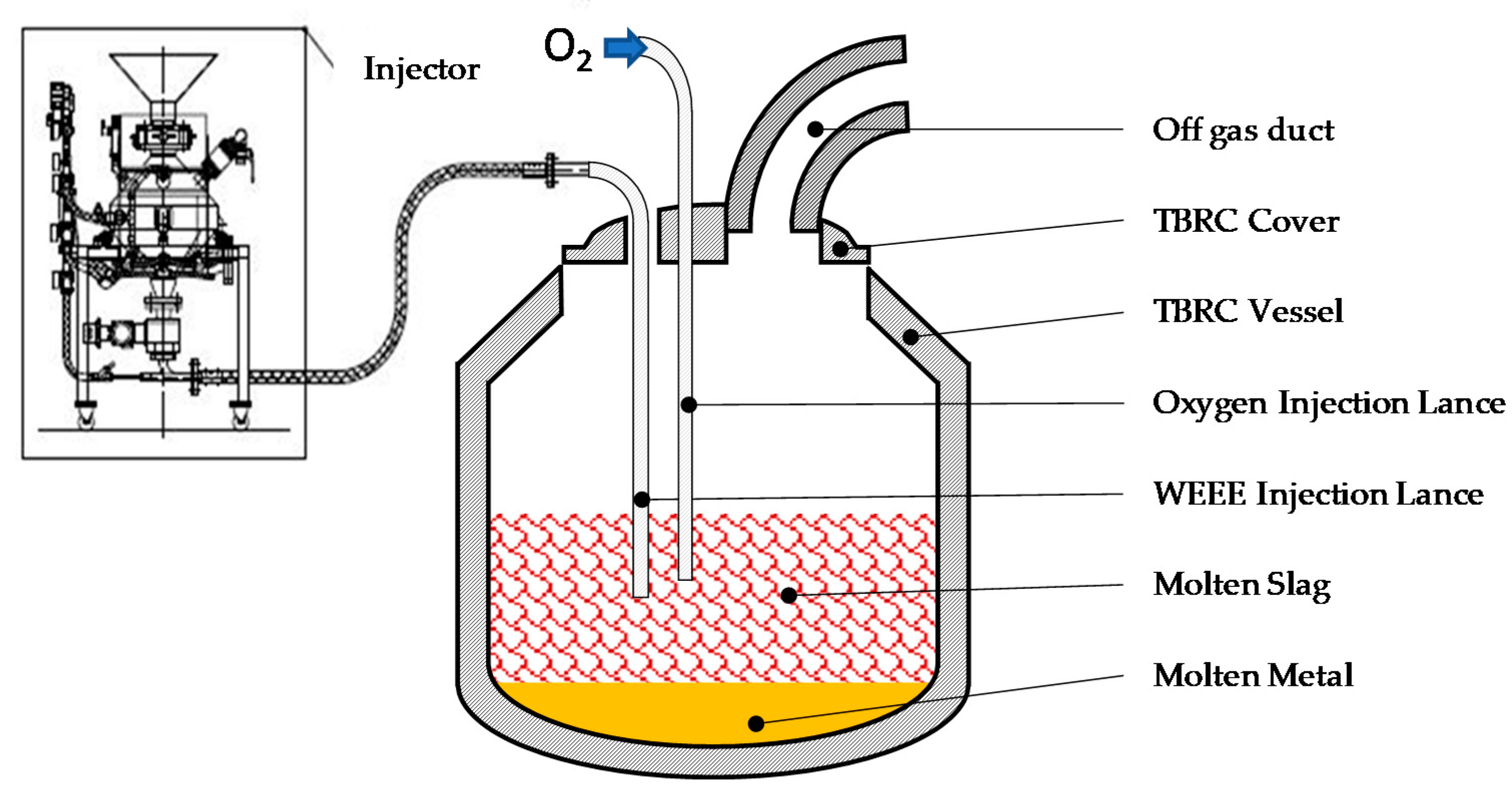

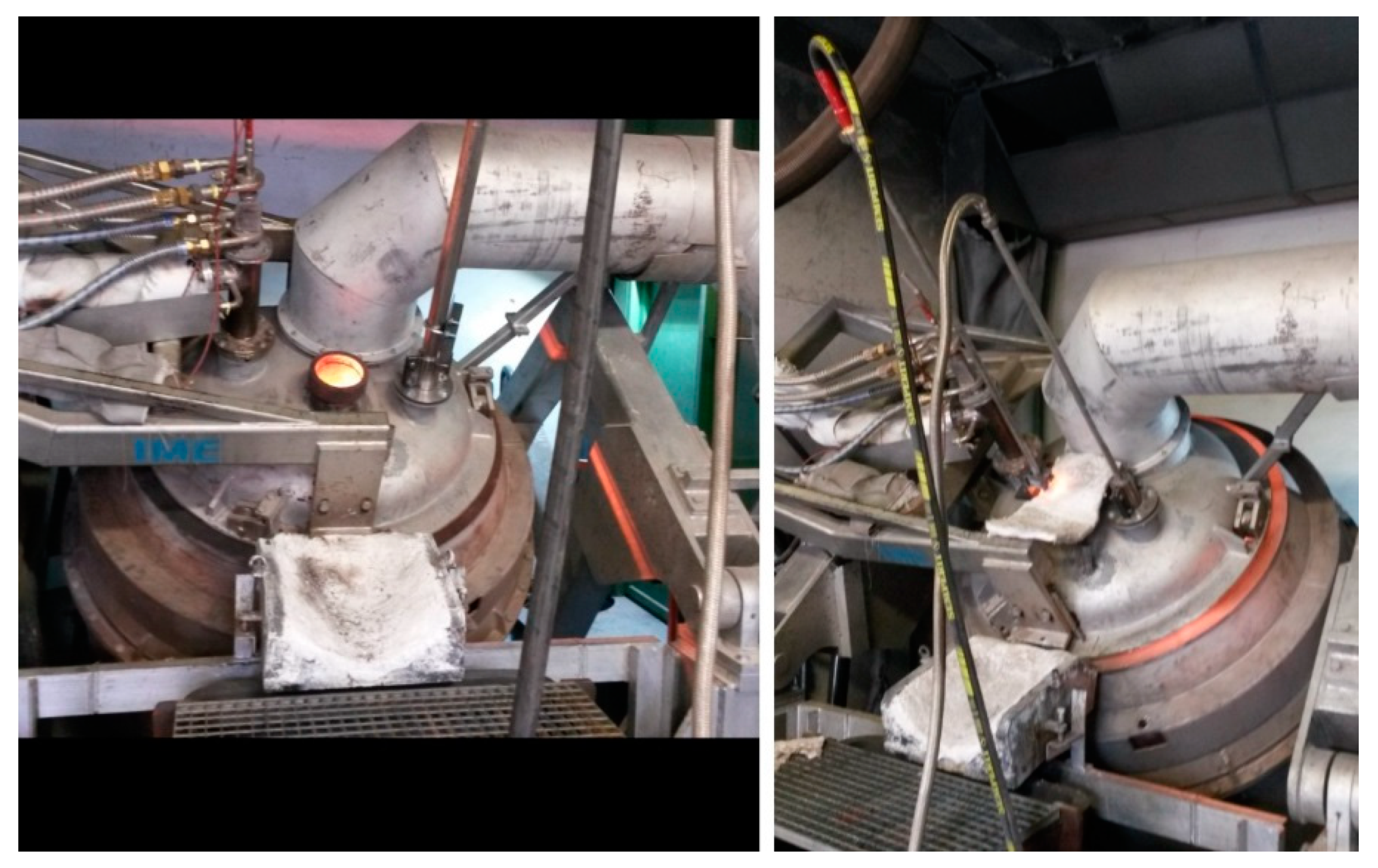

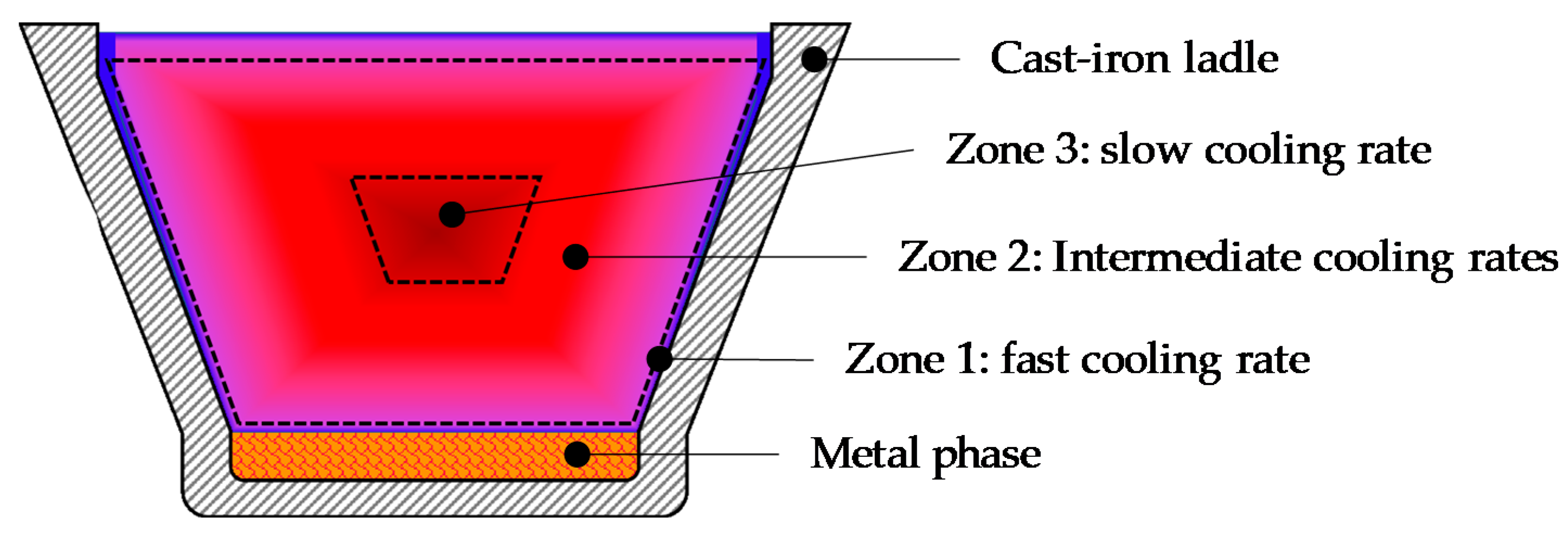

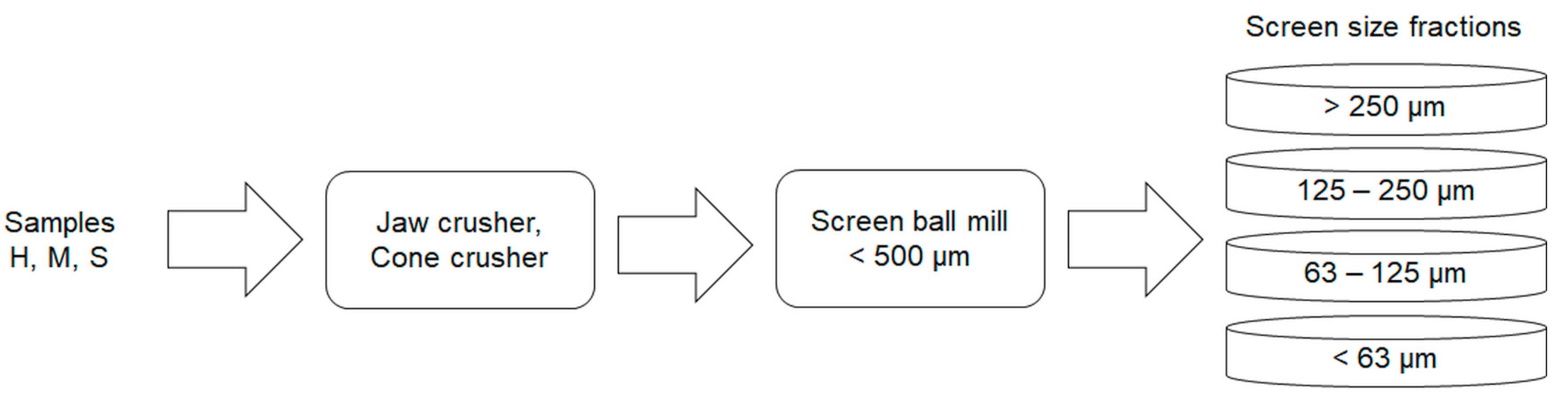

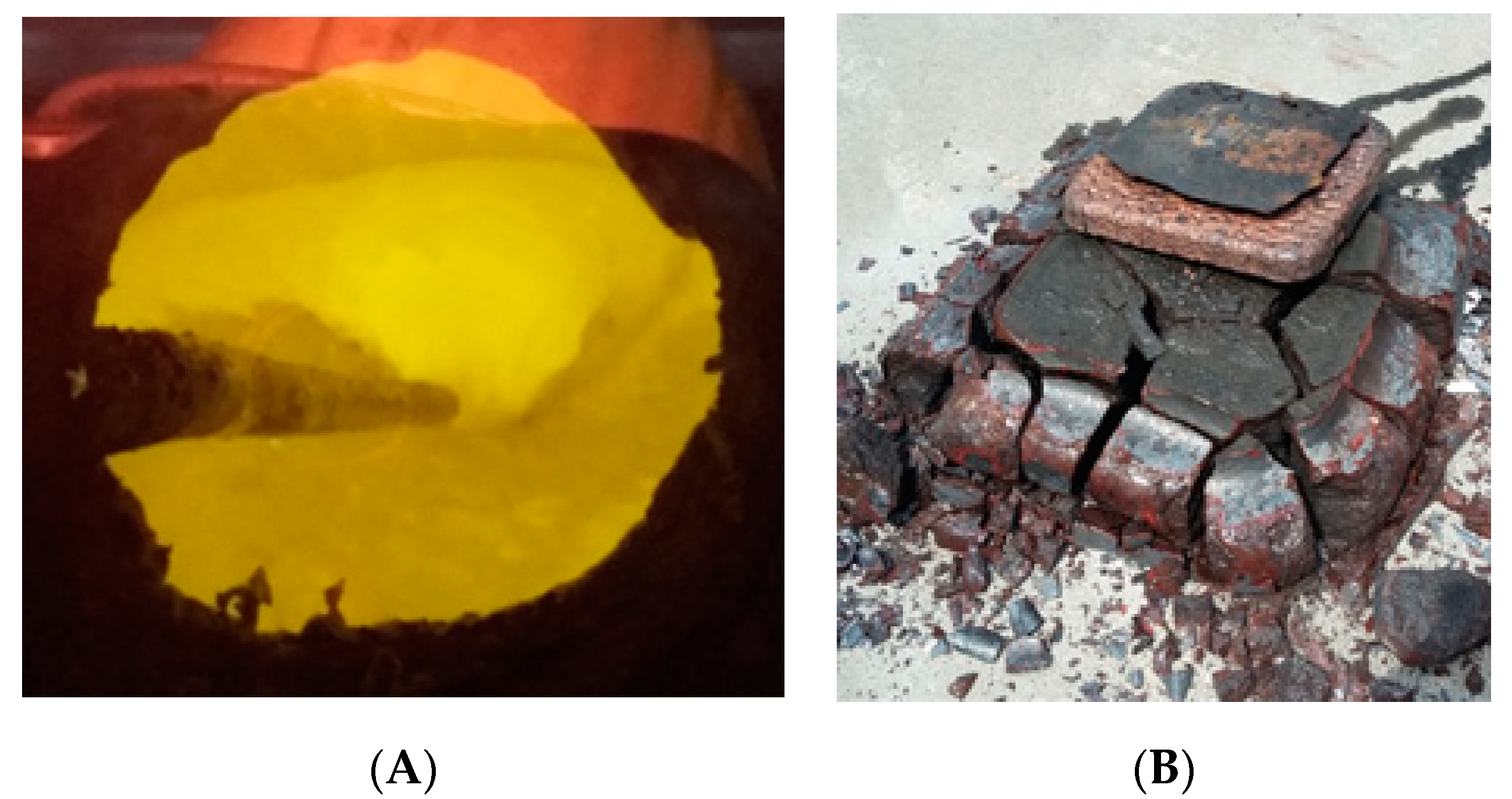

2. Materials and Methods

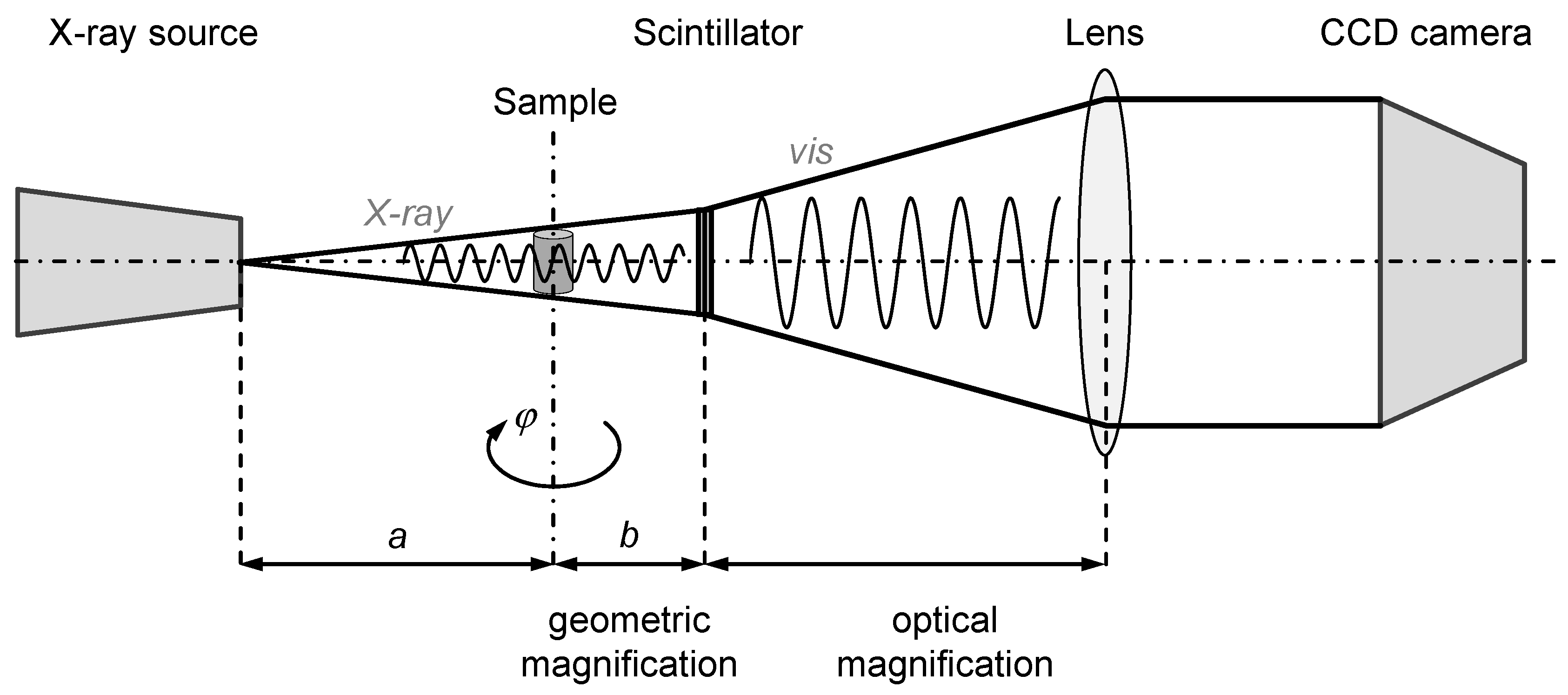

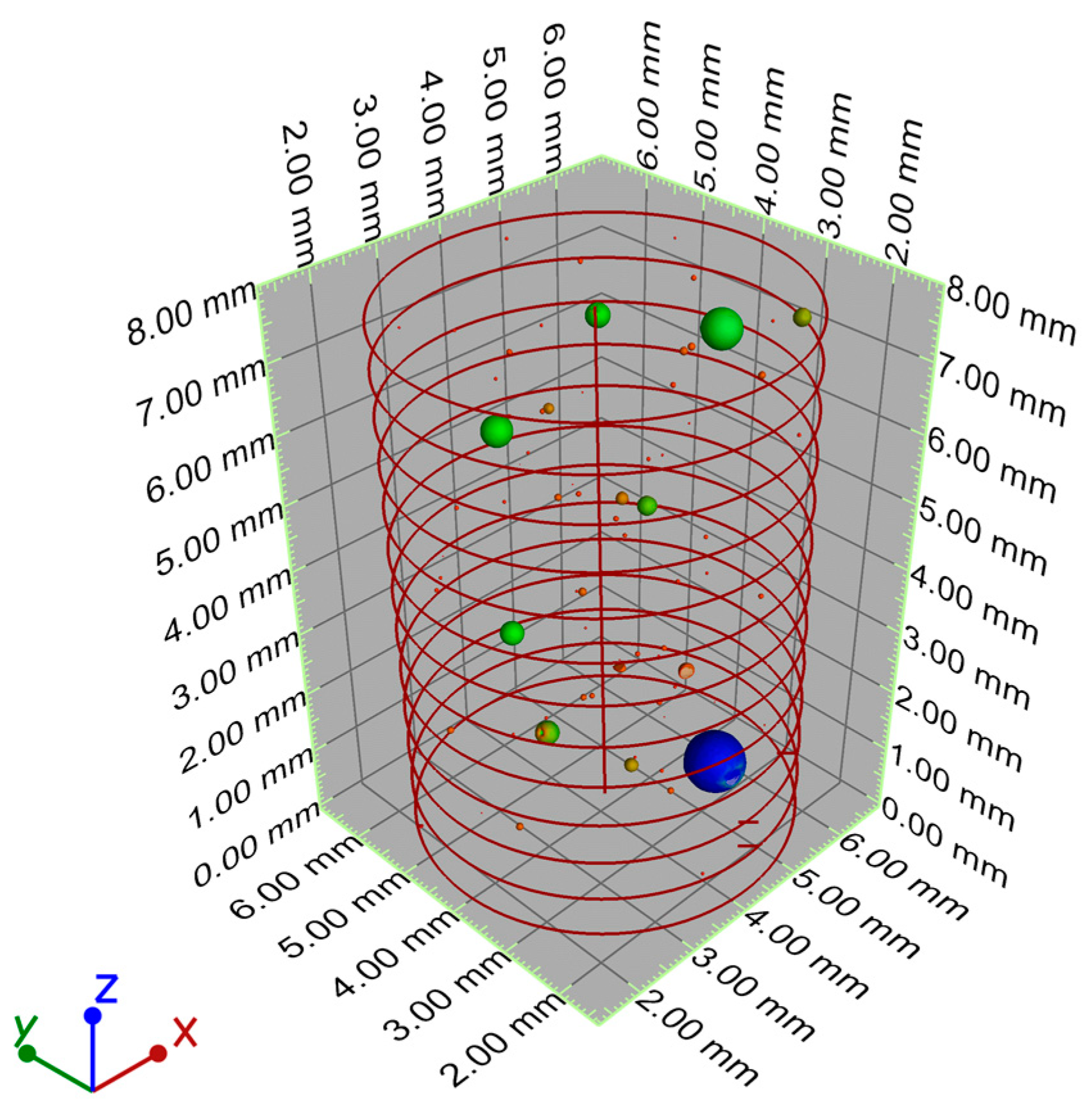

2.1. X-Ray Computed Tomography

2.2. Scanning Electron Microscopy-Based Mineralogical Analysis

3. Results

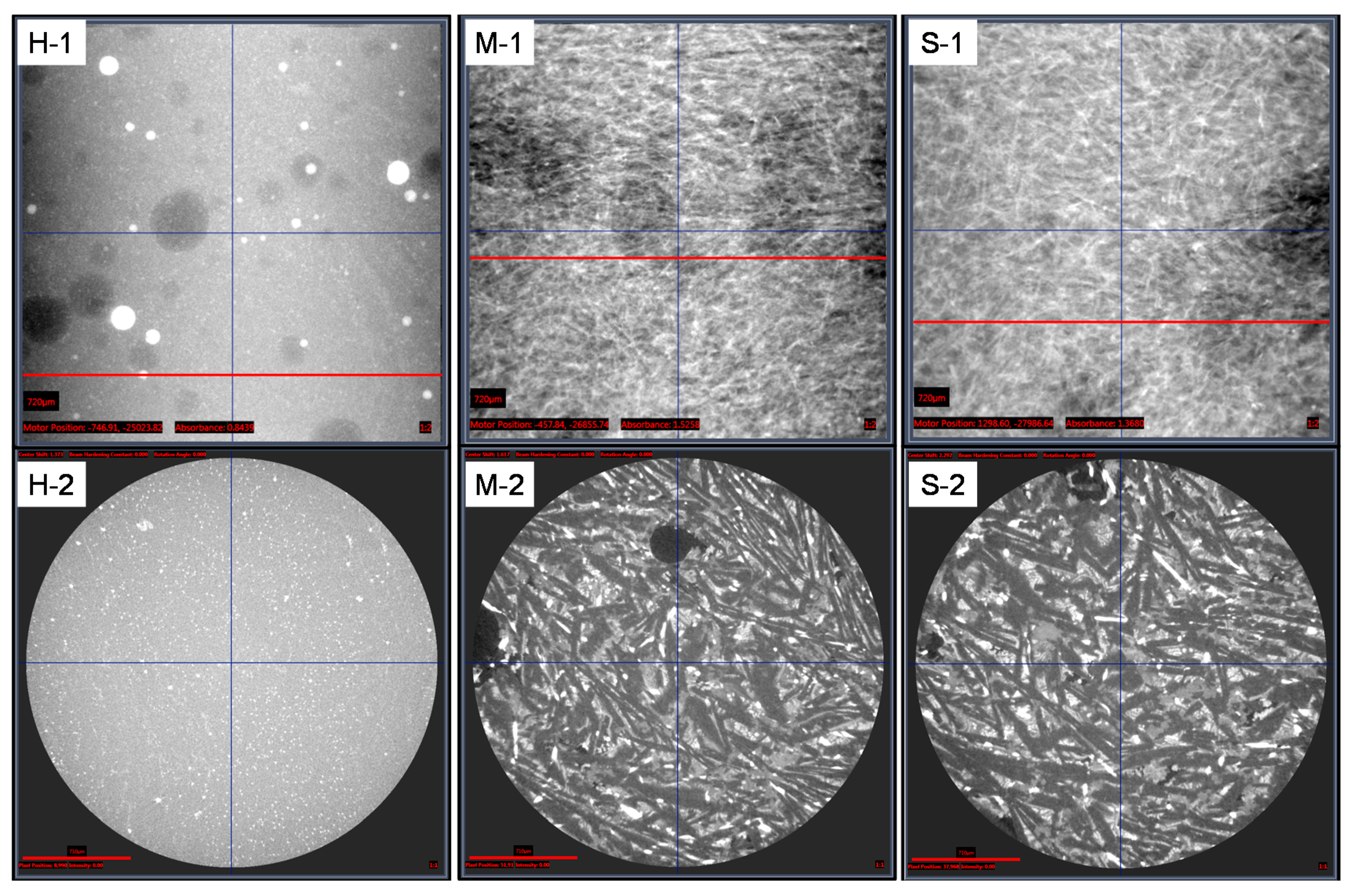

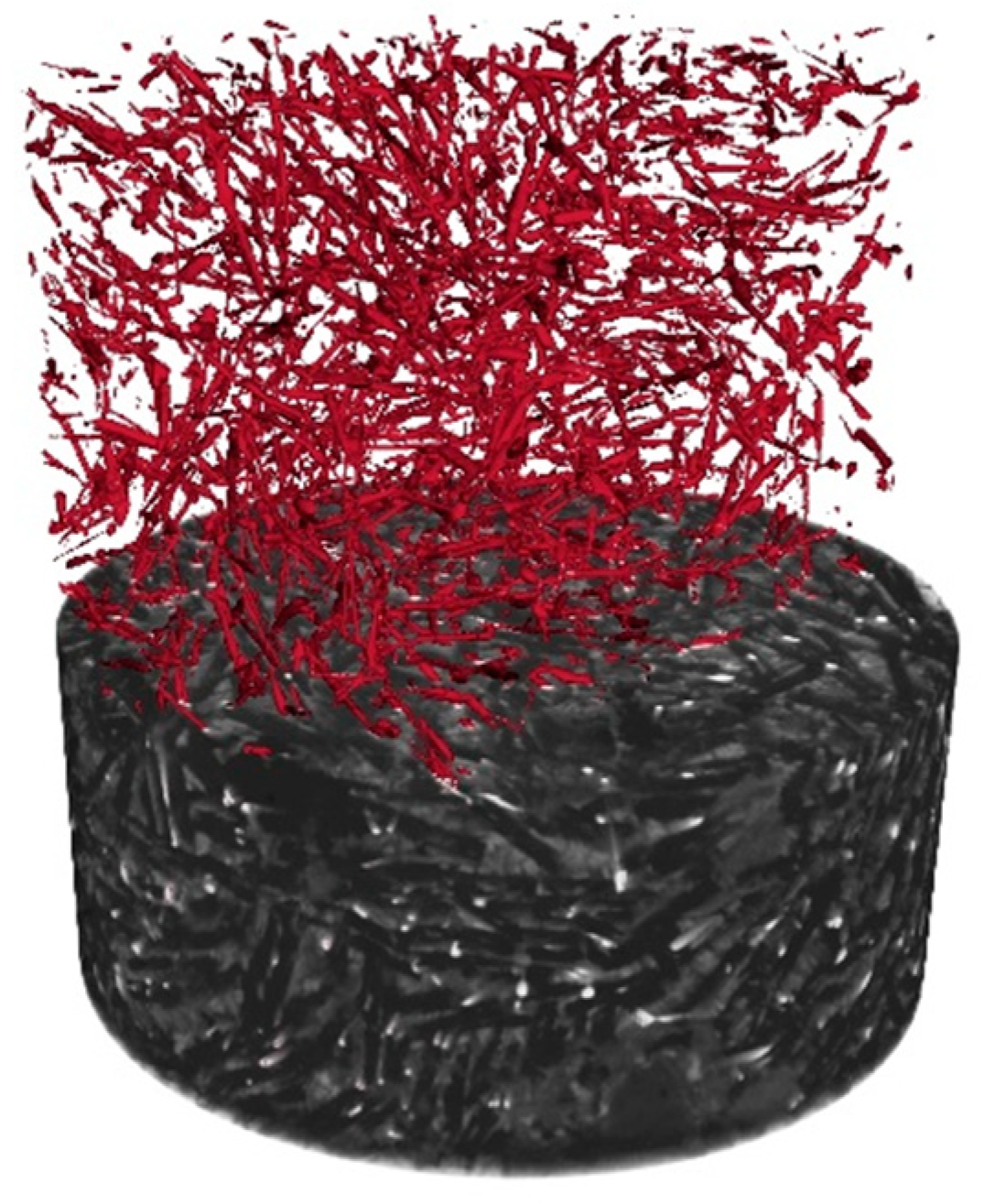

3.1. Results of Computer Tomography

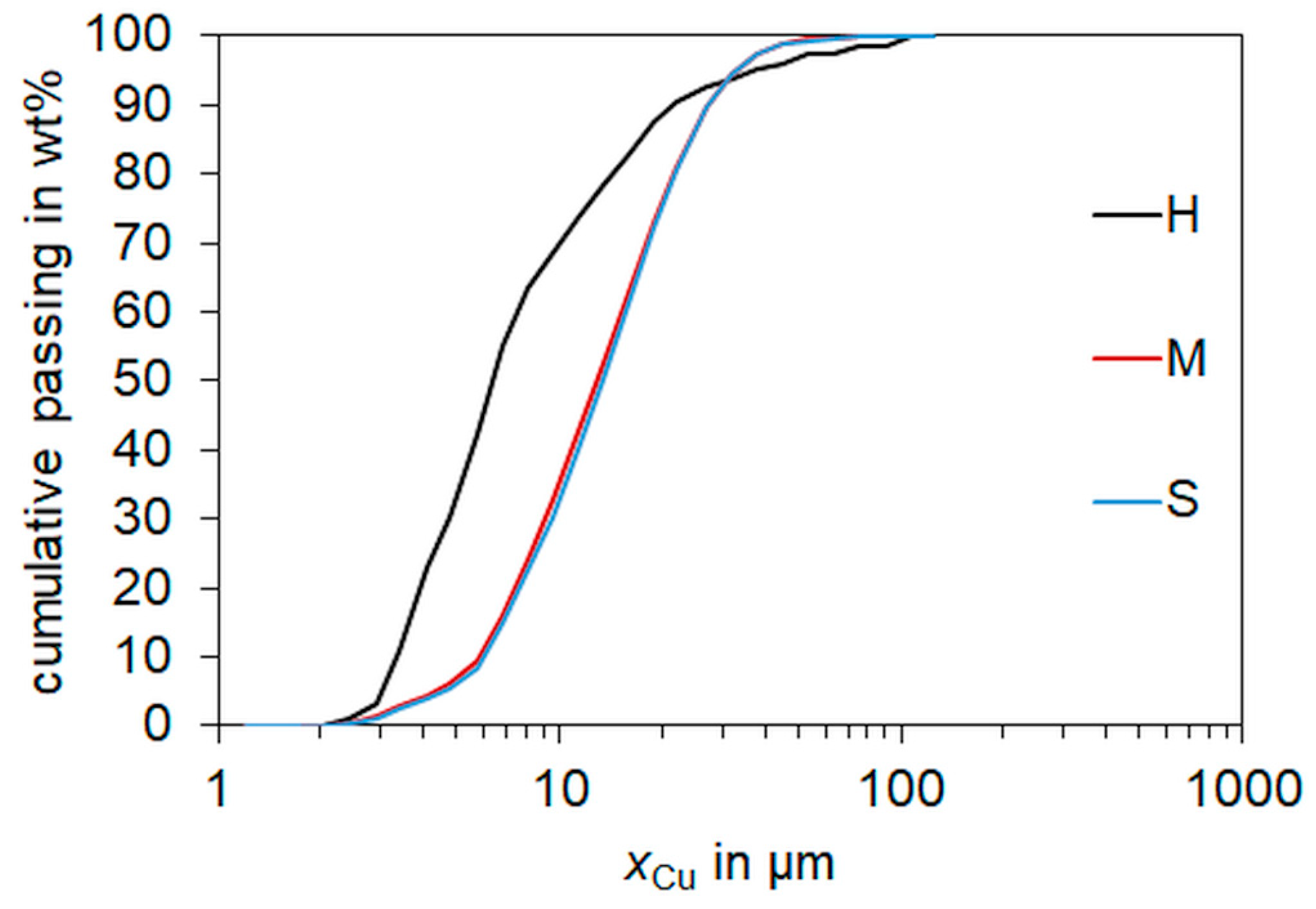

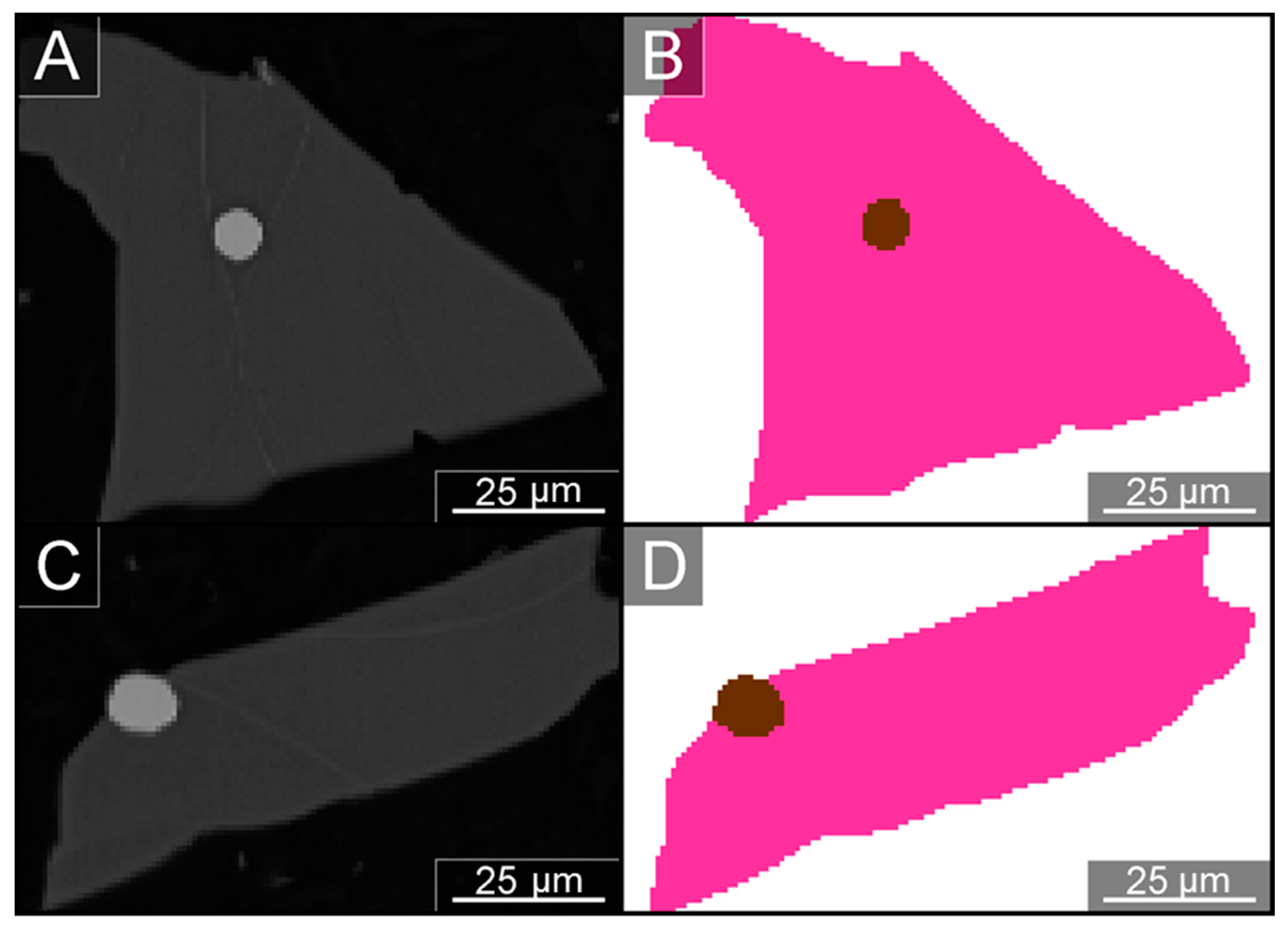

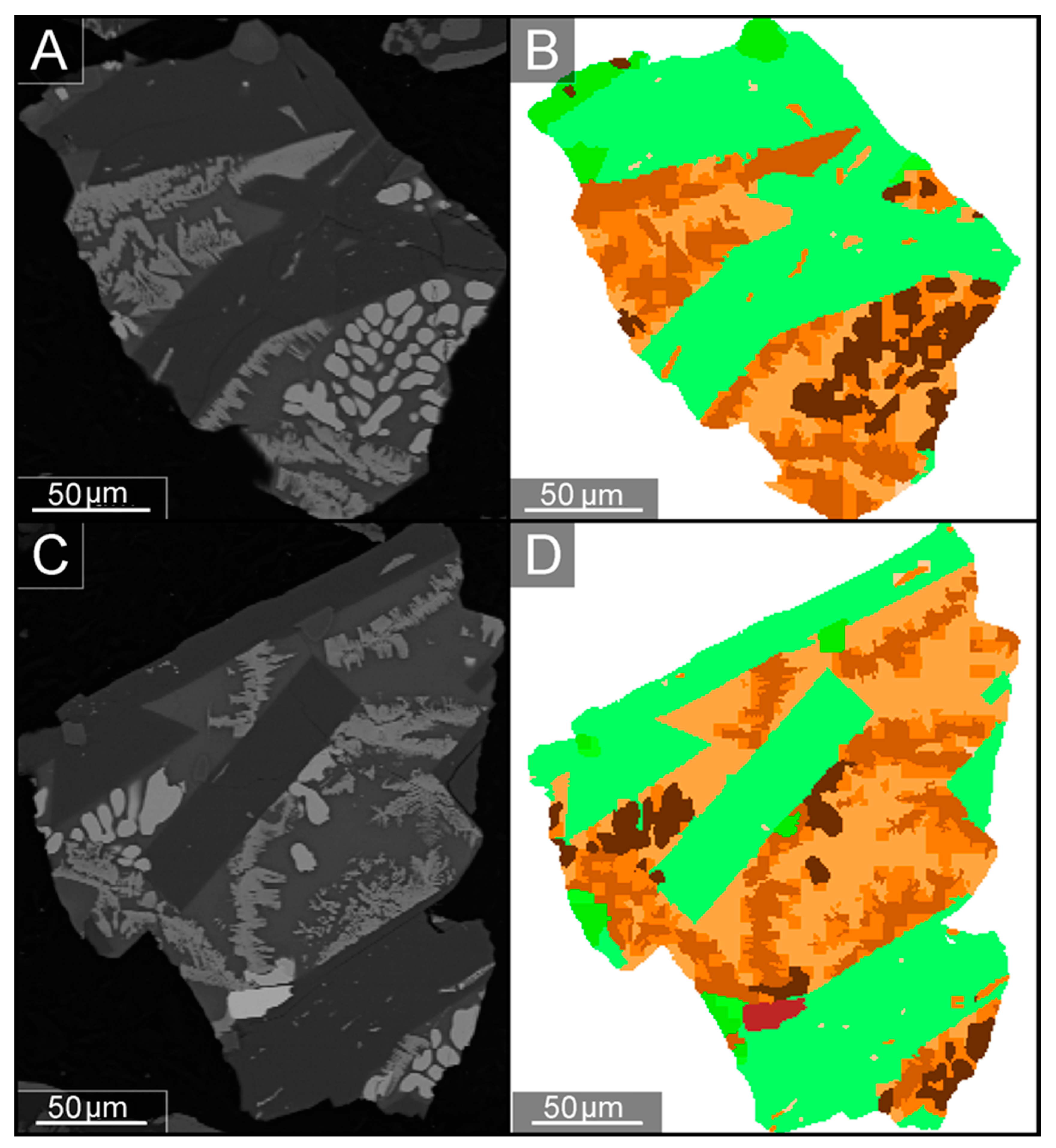

3.2. Results of SEM-Based Mineralogical Analysis

3.3. Other Elements

4. Discussion

5. Conclusions

- The outer amorphous layer of the slag is not suitable for recycling of the metal contents and needs to be minimized.

- The phase structures (e.g., size and shape) showed no differences for sample M (zone 2) and S (zone 3).

- The actual size range of the Cu metal inclusions is too small for mechanical separation processes. The grain size needs to be increased to improve the recyclability; otherwise, these contents need to be lowered in the slag.

- Other elements, e.g., Fe, Sn, Ni, Zn, Pb, and Cr, were not found to be present as pure metals in the slag; rather, they were in other oxide or silicate phases.

- An interdisciplinary approach of different fields (i.e., metallurgy, mineral processing, and analytics) is necessary to improve the recyclability of such complex slag materials.

Author Contributions

Funding

Conflicts of Interest

References

- Worrel, E.; Reuter, M.A. Handbook of Recycling; Elsevier: Waltham, MA, USA, 2014; p. 595. [Google Scholar]

- Hageluken, C. Improving metal returns and eco-efficiency in electronics recycling—A holistic approach for interface optimisation between pre-processing and integrated metals smelting and refining. In Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment, Scottsdale, AZ, USA, 8–11 May 2006. [Google Scholar] [CrossRef]

- Van Schaik, A.; Reuter, M.A. Chapter 22: Material-Centric (Aluminium and Copper) and Product-Centric (Cars, WEEE, TV, Lamps, Batteries, Catalysts) Recycling and DfR Rules. In Handbook of Recycling; Worrel, E., Reuter, M.A., Eds.; Elsevier: Waltham, MA, USA, 2014; pp. 307–378. [Google Scholar]

- Diaz, F.; Flerus, B.; Nagraj, S.; Bokelmann, K.; Stauber, R.; Friedrich, B. Comparative analysis about degradation mechanisms of printed circuit boards (PCBs) in slow and fast pyrolysis: The influence of heating speed. J. Sustain. Metall. 2018, 4, 205–221. [Google Scholar] [CrossRef]

- Borowski, N.; Trentmann, A.; Brinkmann, F.; Stürtz, M.; Friedrich, B. Metallurgical effects of introducing powdered WEEE to a molten slag bath. J. Sustain. Metall. 2018, 4, 233–250. [Google Scholar] [CrossRef]

- Bale, C.W.; Bélisle, E.; Chartrand, P.; Decterov, S.A.; Eriksson, G.; Gheribi, A.E.; Hack, K.; Jung, I.H.; Kang, Y.B.; Melançon, J.; et al. FactSage Thermochemical software and databases, 2010–2016. Calphad 2002, 26, 189–228. [Google Scholar] [CrossRef]

- Obiso, D.; Kriebitzsch, S.; Reuter, M.; Meyer, B. The importance of viscous and interfacial forces in the hydrodynamics of the top-submerged-lance furnace. Metall. Mater. Trans. B 2019, 50, 2403–2420. [Google Scholar] [CrossRef]

- Akashi, M.; Keplinger, O.; Shevchenko, N.; Anders, S.; Reuter, M.A.; Eckert, S. X-ray radioscopic visualization of bubbly flows injected through a top submerged lance into a liquid metal. Metall. Mater. Trans. B 2019, 51, 124–139. [Google Scholar] [CrossRef]

- Sutherland, D.N.; Gottlieb, P. Application of automated quantitative mineralogy in mineral processing. Miner. Eng. 1991, 4, 753–762. [Google Scholar] [CrossRef]

- Fandrich, R.; Gu, Y.; Burrows, D.; Moeller, K. Modern SEM-based mineral liberation analysis. Int. J. Miner. Process. 2007, 84, 310–320. [Google Scholar] [CrossRef]

- Schach, E.; Buchmann, M.; Tolosana-Delgado, R.; Leißner, T.; Kern, M.; van den Boogaart, G.; Rudolph, M.; Peuker, U. Multidimensional characterization of separation processes—part 1: Introducing kernel methods and entropy in the context of mineral processing using SEM-based image analysis. Miner. Eng. 2019, 137, 78–86. [Google Scholar] [CrossRef]

- Buchmann, M.; Schach, E.; Tolosana-Delgado, R.; Leißner, T.; Astoveza, J.; Kern, M.; Möckel, R.; Ebert, D.; Rudolph, M.; van den Boogaart, G.; et al. Evaluation of magnetic separation efficiency on a cassiterite-bearing skarn ore by means of integrative SEM-based image and XRF–XRD data analysis. Minerals 2018, 8, 390. [Google Scholar] [CrossRef]

- Buchmann, M.; Schach, E.; Leißner, T.; Kern, M.; Mütze, T.; Rudolph, M.; Peuker, U.A.; Tolosana-Delgado, R. Multidimensional characterization of separation processes—part 2: Comparability of separation efficiency. Miner. Eng. 2020, 150, 106284. [Google Scholar] [CrossRef]

- Sousa, R.; Simons, B.; Bru, K.; de Sousa, A.B.; Rollinson, G.; Andersen, J.; Martin, M.; Machado Leite, M. Use of mineral liberation quantitative data to assess separation efficiency in mineral processing—Some case studies. Miner. Eng. 2018, 127, 134–142. [Google Scholar] [CrossRef]

- Charikinya, E.; Robertson, J.; Platts, A.; Becker, M.; Lamberg, P.; Bradshaw, D. Integration of mineralogical attributes in evaluating sustainability indicators of a magnetic separator. Miner. Eng. 2017, 107, 53–62. [Google Scholar] [CrossRef]

- Evans, C.L.; Wightman, E.M.; Manlapig, E.V.; Coulter, B.L. Application of process mineralogy as a tool in sustainable processing. Miner. Eng. 2011, 24, 1242–1248. [Google Scholar] [CrossRef]

- Lastra, R. Seven practical application cases of liberation analysis. Int. J. Miner. Process. 2007, 84, 337–347. [Google Scholar] [CrossRef]

- Leißner, T.; Hoang, D.H.; Rudolph, M.; Heinig, T.; Bachmann, K.; Gutzmer, J.; Schubert, H.; Peuker, U.A. A mineral liberation study of grain boundary fracture based on measurements of the surface exposure after milling. Int. J. Miner. Process. 2016, 156, 3–13. [Google Scholar] [CrossRef]

- Reyes, F.; Lin, Q.; Cilliers, J.J.; Neethling, S.J. Quantifying mineral liberation by particle grade and surface exposure using X-ray microCT. Miner. Eng. 2018, 125, 75–82. [Google Scholar] [CrossRef]

- Little, L.; Mainza, A.N.; Becker, M.; Wiese, J.G. Using mineralogical and particle shape analysis to investigate enhanced mineral liberation through phase boundary fracture. Powder Technol. 2016, 301, 794–804. [Google Scholar] [CrossRef]

- Egan, C.K.; Jacques, S.D.; Wilson, M.D.; Veale, M.C.; Seller, P.; Beale, A.M.; Pattrick, R.A.; Withers, P.J.; Cernik, R.J. 3D chemical imaging in the laboratory by hyperspectral X-ray computed tomography. Sci. Rep. 2015, 5, 15979. [Google Scholar] [CrossRef]

- Jacques, S.D.; Egan, C.K.; Wilson, M.D.; Veale, M.C.; Seller, P.; Cernik, R.J. A laboratory system for element specific hyperspectral X-ray imaging. Analyst 2013, 138, 755–759. [Google Scholar] [CrossRef]

- Furat, O.; Leissner, T.; Ditscherlein, R.; Sedivy, O.; Weber, M.; Bachmann, K.; Gutzmer, J.; Peuker, U.; Schmidt, V. Description of ore particles from X-ray microtomography (XMT) images, supported by scanning electron microscope (SEM)-based image analysis. Microsc. Microanal. 2018, 24, 461–470. [Google Scholar] [CrossRef]

- Furat, O.; Leissner, T.; Bachmann, K.; Gutzmer, J.; Peuker, U.; Schmidt, V. Stochastic modeling of multidimensional particle properties using parametric copulas. Microsc. Microanal. 2019, 25, 720–734. [Google Scholar] [CrossRef]

- Reyes, F.; Lin, Q.; Udoudo, O.; Dodds, C.; Lee, P.D.; Neethling, S.J. Calibrated X-ray micro-tomography for mineral ore quantification. Miner. Eng. 2017, 110, 122–130. [Google Scholar] [CrossRef]

- Hanna, R.D.; Ketcham, R.A. X-ray computed tomography of planetary materials: A primer and review of recent studies. Geochemistry 2017, 77, 547–572. [Google Scholar] [CrossRef]

- Ferrara, G.; Preti, U.; Meloy, T.P. Inclusion shape, mineral texture and liberation. Int. J. Miner. Process. 1989, 27, 295–308. [Google Scholar] [CrossRef]

- Cook, N.; Ciobanu, C.; Ehrig, K.; Slattery, A.; Verdugo-Ihl, M.; Courtney-Davies, L.; Gao, W. Advances and opportunities in ore mineralogy. Minerals 2017, 7, 233. [Google Scholar] [CrossRef]

- Lennartsson, A.; Engström, F.; Samuelsson, C.; Björkman, B.; Pettersson, J. Large-Scale WEEE recycling integrated in an ore-based Cu-extraction system. J. Sustain. Metall. 2018, 4, 222–232. [Google Scholar] [CrossRef]

- Anindya, A.; Swinbourne, D.R.; Reuter, M.A.; Matusewicz, R.W. Distribution of elements between copper and FeOx–CaO–SiO2slags during pyrometallurgical processing of WEEE. Miner. Process. Extr. Metall. 2013, 122, 165–173. [Google Scholar] [CrossRef]

- Anindya, A.; Swinbourne, D.R.; Reuter, M.A.; Matusewicz, R.W. Distribution of elements between copper and FeOx–CaO–SiO2slags during pyroprocessing of WEEE: Part 2—Indium. Miner. Process. Extr. Metall. 2013, 123, 43–52. [Google Scholar] [CrossRef]

- Klemettinen, L.; Avarmaa, K.; O’Brien, H.; Taskinen, P.; Jokilaakso, A. Behavior of tin and antimony in secondary copper smelting process. Minerals 2019, 9, 39. [Google Scholar] [CrossRef]

- Avarmaa, K.; Yliaho, S.; Taskinen, P. Recoveries of rare elements Ga, Ge, in and Sn from waste electric and electronic equipment through secondary copper smelting. Waste Manag. 2018, 71, 400–410. [Google Scholar] [CrossRef]

- Chris Pistorius, P.; Kotzé, H. Role of silicate phases during comminution of titania slag. Miner. Eng. 2009, 22, 182–189. [Google Scholar] [CrossRef]

- Sarrafi, A.; Rahmati, B.; Hassani, H.R.; Shirazi, H.H.A. Recovery of copper from reverberatory furnace slag by flotation. Miner. Eng. 2004, 17, 457–459. [Google Scholar] [CrossRef]

- Thyse, E.L.; Akdogan, G.; Olivier, E.J.; O’Connell, J.H.; Neethling, J.H.; Taskinen, P.; Eksteen, J.J. 3D insights into nickel converter matte phases: Direct observations via TEM and FIB SEM tomography. Miner. Eng. 2013, 52, 2–7. [Google Scholar] [CrossRef]

| Scan | Total | Detail |

|---|---|---|

| Source position (mm) | −20 | −14 |

| Detector position (mm) | 160 | 20 |

| Lens | 0.4× | 4× |

| Acceleration voltage (keV) | 110 | 110 |

| Electrical power (W) | 10 | 10 |

| Filter (Zeiss Standard) | HE1 | HE1 |

| Camera binning | 2 | 2 |

| Pixel size (µm) | 7.8 | 2.77 |

| Number of projections | 801 | 2001 |

| Scan angle (°) | 360 | 360 |

| Scan time (hh:mm) | 1:18 | 2:23 |

| GXMAP Parameters | Total |

|---|---|

| Voltage (kV) | 25 |

| Probe current (nA) | 10 |

| Horizontal field width (µm) | 1000 |

| BSE calibration | 253 |

| Resolution (px) | 500 × 500 |

| Pixel size (µm/px) | 2 |

| GXMAP trigger | 25 |

| Step size (px) | 6 |

| Minimum grain size (px) | 4 |

| Slag | SiO2 | Al2O3 | CaO | FexOy | CuO | PbO | Tliq (°C) |

|---|---|---|---|---|---|---|---|

| wt. % | 36 | 31.6 | 19.2 | 22.0 | 5.4 | 0.5 | 1350–1400 |

| Size Fraction (µm) | H (%) | M (%) | S (%) |

|---|---|---|---|

| >250 | 31.9 | 30.0 | 15.2 |

| 125–250 | 30.3 | 22.5 | 23.2 |

| 63–125 | 18.1 | 18.7 | 22.8 |

| <63 | 19.8 | 28.7 | 38.8 |

| Size Fraction (µm) | H (%) | M (%) | S (%) |

|---|---|---|---|

| >250 | 2.9 | 17.9 | 18.1 |

| 125–250 | 2.9 | 18.7 | 18.3 |

| 63–125 | 3.1 | 18.7 | 18.4 |

| <63 | 3.5 | 18.4 | 17.7 |

| Average | 3.1 | 18.4 | 18.1 |

| Size Fraction (µm) | H (%) | M (%) | S (%) |

|---|---|---|---|

| >250 | 0.4 | 7.2 | 8.7 |

| 125–250 | 0.4 | 7.8 | 8.7 |

| 63–125 | 0.5 | 8.0 | 8.6 |

| <63 | 0.6 | 7.7 | 8.4 |

| Average | 0.4 | 7.7 | 8.5 |

| Phase (see Figure 14) | Cu (%) | Fe (%) | Al (%) | Ca (%) | Pb (%) | Si (%) | O (%) | |

|---|---|---|---|---|---|---|---|---|

| a |  | <1 | <1 | 24 | 15 | 0 | 20 | 39 |

| b |  | 15 | <1 | 11 | 4 | 3 | 23 | 37 |

| c |  | 17 | 4 | 12 | 3 | 3 | 23 | 34 |

| d |  | 49 | 19 | 12 | 0 | 0 | 0 | 16 |

| e |  | 100 | - | - | - | - | - | - |

| Content | Al | Fe | Cr | Sn | Pb | Zn | Ni |

|---|---|---|---|---|---|---|---|

| % | 17 | 5 | 2 | 2 | 1 | 1 | 0.5 |

| Element | Cu-Rich (%) | Al-Rich (%) | Other Phases (%) |

|---|---|---|---|

| Al | 29 | 70 | 1 (present as Al metal phase) |

| Fe | 59 | 21 | 20 (present as iron oxide) |

| Cr | 43 | 50 | 7 (distributed between various minor phases) |

| Sn | 30 | - | 70 (present as SnO2) |

| Pb | 99 | - | 1 (distributed between various minor phases) |

| Zn | 21 | 62 | 17 (present as ZnO) |

| Ni | 20 | 78 | 2 (in minor phases) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buchmann, M.; Borowski, N.; Leißner, T.; Heinig, T.; Reuter, M.A.; Friedrich, B.; Peuker, U.A. Evaluation of Recyclability of a WEEE Slag by Means of Integrative X-Ray Computer Tomography and SEM-Based Image Analysis. Minerals 2020, 10, 309. https://doi.org/10.3390/min10040309

Buchmann M, Borowski N, Leißner T, Heinig T, Reuter MA, Friedrich B, Peuker UA. Evaluation of Recyclability of a WEEE Slag by Means of Integrative X-Ray Computer Tomography and SEM-Based Image Analysis. Minerals. 2020; 10(4):309. https://doi.org/10.3390/min10040309

Chicago/Turabian StyleBuchmann, Markus, Nikolaus Borowski, Thomas Leißner, Thomas Heinig, Markus A. Reuter, Bernd Friedrich, and Urs A. Peuker. 2020. "Evaluation of Recyclability of a WEEE Slag by Means of Integrative X-Ray Computer Tomography and SEM-Based Image Analysis" Minerals 10, no. 4: 309. https://doi.org/10.3390/min10040309

APA StyleBuchmann, M., Borowski, N., Leißner, T., Heinig, T., Reuter, M. A., Friedrich, B., & Peuker, U. A. (2020). Evaluation of Recyclability of a WEEE Slag by Means of Integrative X-Ray Computer Tomography and SEM-Based Image Analysis. Minerals, 10(4), 309. https://doi.org/10.3390/min10040309