Lauryl Phosphate Flotation Chemistry in Barite Flotation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Contact Angle Measurements

2.3. Zeta Potential Measurements

2.4. Microflotation Tests

2.5. Molecular Dynamics Simulations

3. Result and Discussion

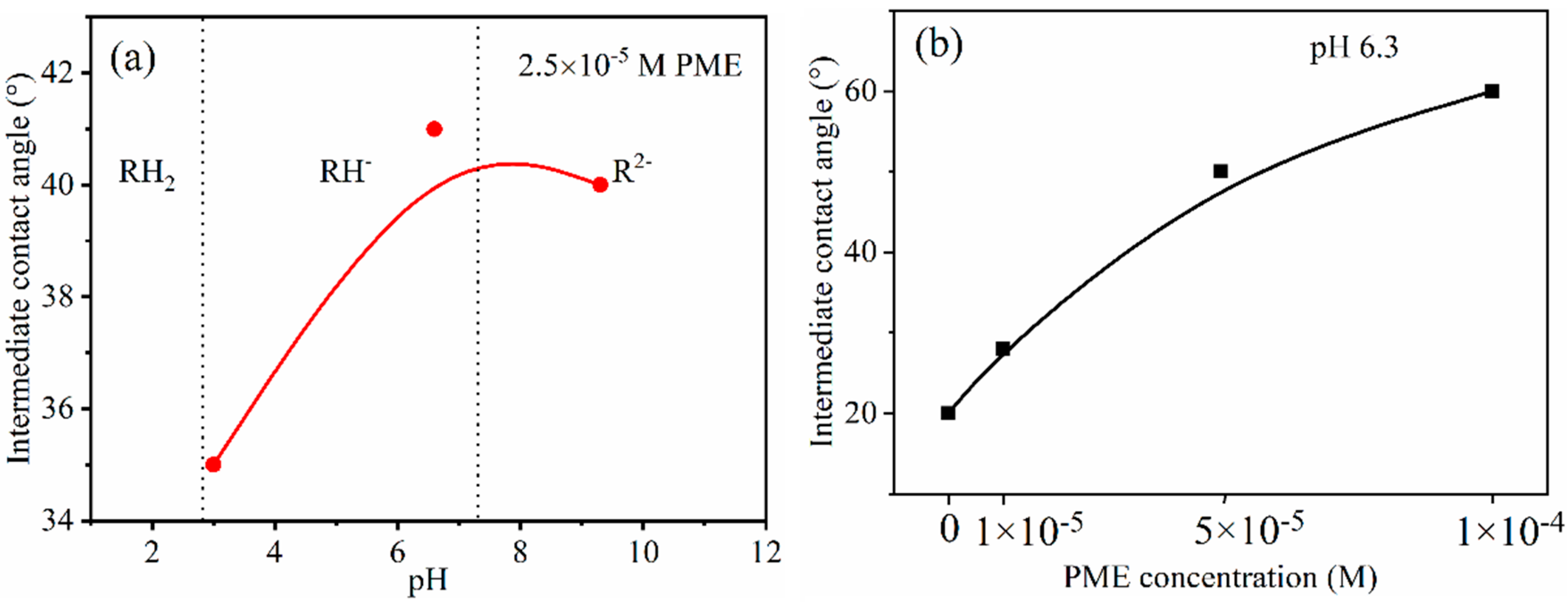

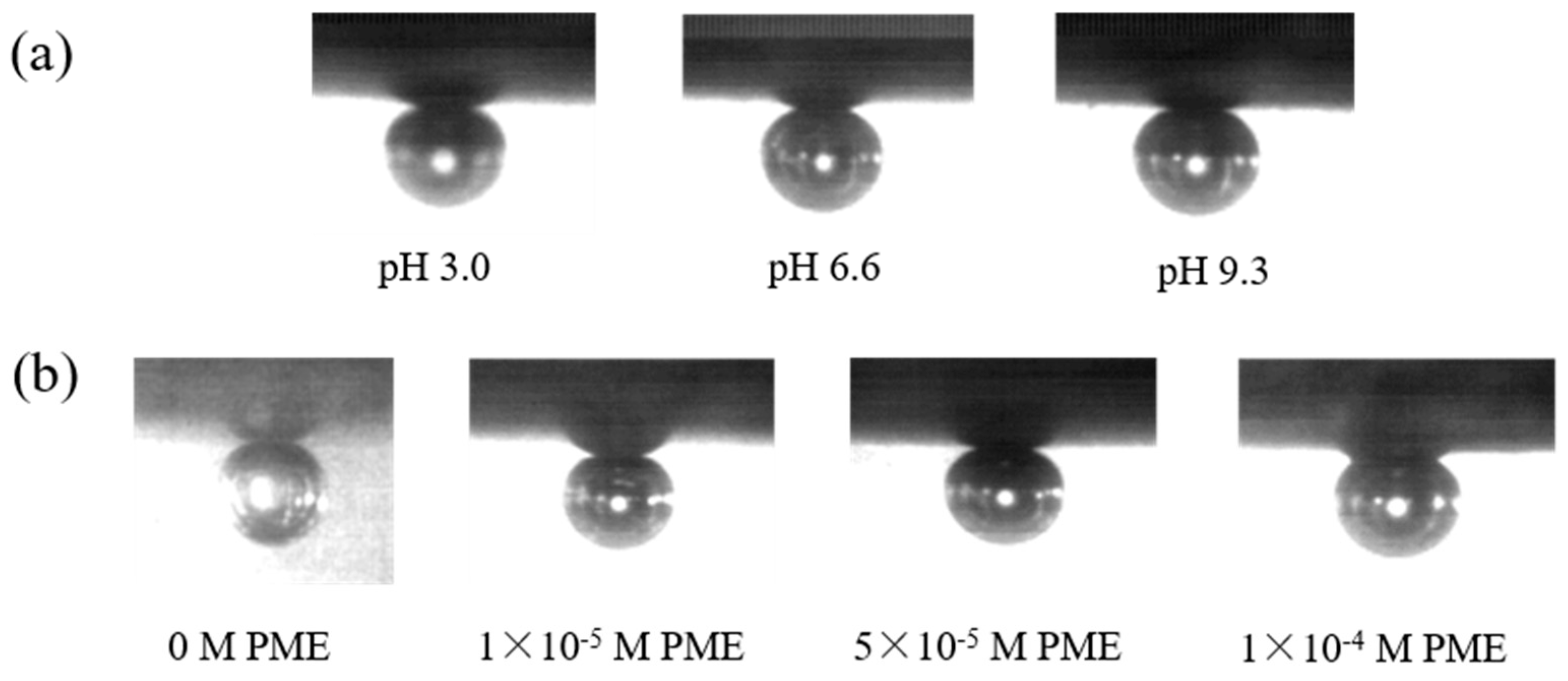

3.1. Contact Angle of Barite with Lauryl Phosphate

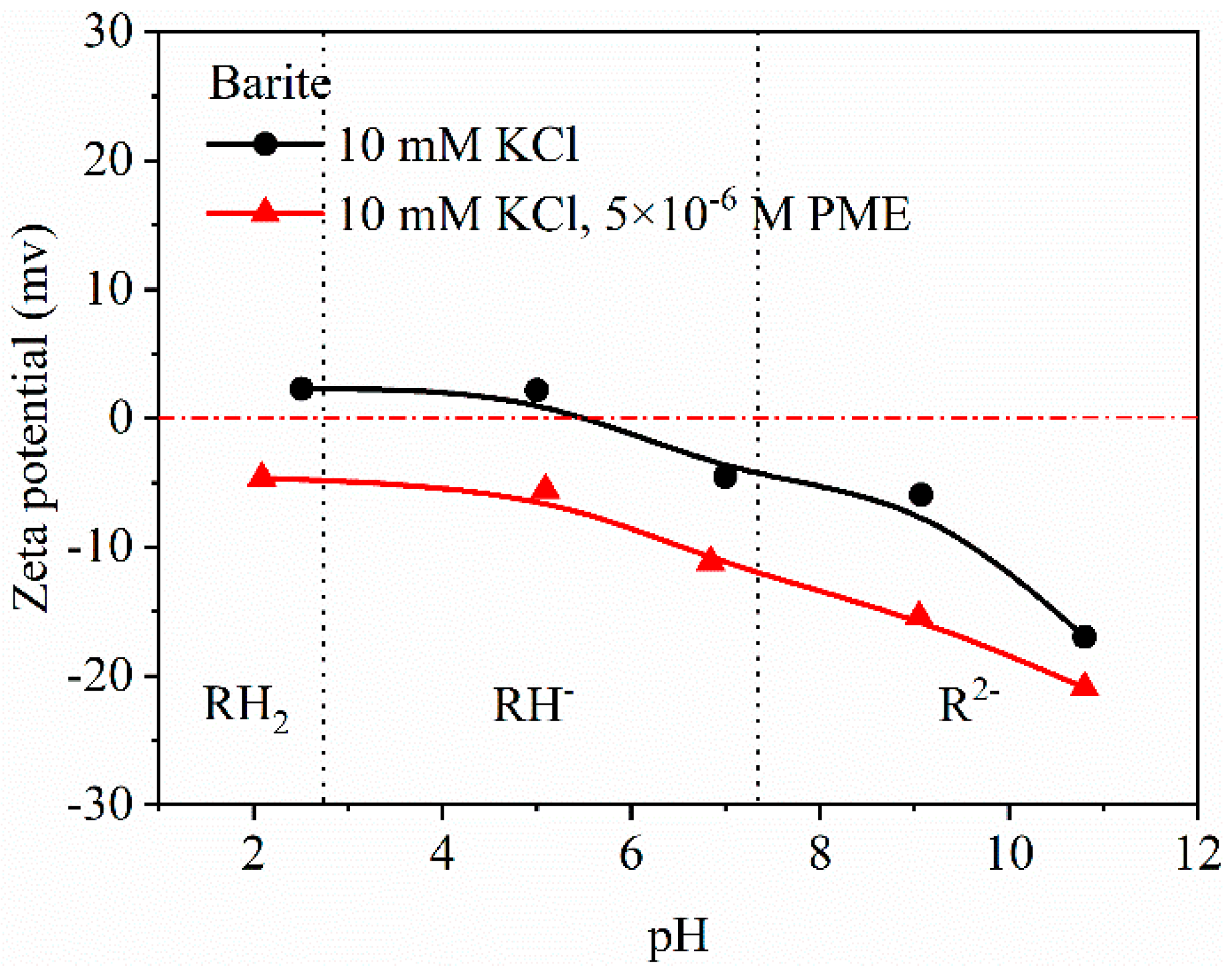

3.2. Zeta Potential of Barite with Lauryl Phosphate

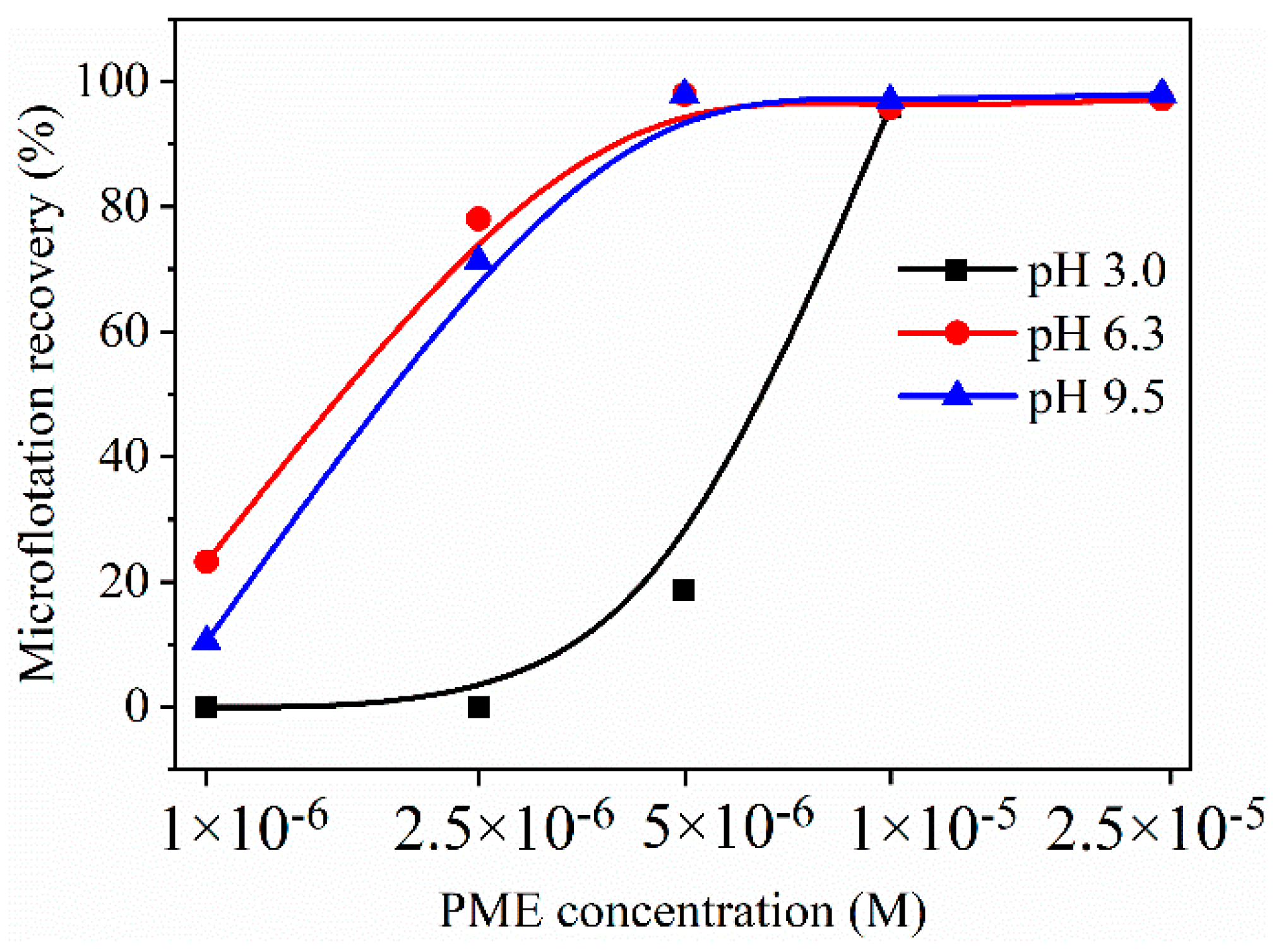

3.3. Barite Flotation with Lauryl Phosphate

3.4. MDS of Lauryl Phosphate Adsorption at the Barite Surface

3.5. Interaction Energy of Lauryl Phosphate Species at the Barite Surface

4. Conclusions

- (1)

- Lauryl phosphate results in higher hydrophobicity of barite in mild and alkaline pH range when compared to acid pH range at low concentration.

- (2)

- A 95% barite flotation recovery can be achieved at a wide pH range using lauryl phosphate as collector with a low usage of 1 × 10−5 M.

- (3)

- The adsorption of anionic lauryl phosphate at the barite surface seems to be chemisorption at pH higher than pH 5.5 and a mixture of physisorption and/or chemisorption at pH less than 5.5.

- (4)

- Lauryl phosphate species replaced water and adsorbed at the barite surface at all pH ranges from interaction energy calculation and molecular dynamics simulations examinations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Notation

| density profiles | |

| N | Moles |

| V | Volume |

| T | Temperature |

| M | atomic mass |

| S | basal surface area |

| D | diffusion coefficients |

| number of diffusive atoms in the simulation cell | |

| mass center positions of the solutes at the time of origin | |

| mass center positions of the solutes at the time of t | |

| ΔE | interaction energy |

| Ecomplex | interaction energies of the optimized mineral surface–reagent complex |

| Emineral surface | interaction energy of mineral surface |

| Ereagent | interaction energy of reagent such as water and lauryl phosphate |

References

- Akkurt, I.; Basyigit, C.; Kilincarslan, S.; Mavi, B. The shielding of γ-rays by concretes produced with barite. Prog. Nucl. Energy 2005, 46, 1–11. [Google Scholar] [CrossRef]

- Sun, S.; Ding, H.; Zhou, H. Preparation of TiO2-coated barite composite pigments by the hydrophobic aggregation method and their structure and properties. Sci. Rep. 2017, 7, 10083. [Google Scholar] [CrossRef]

- Bahl, S.; Lochab, S.P.; Pandey, A.; Kumar, V.; Aleynikov, V.E.; Molokanov, A.G.; Kumar, P. Characterization and luminescence studies of Eu doped Barite nanophosphor. J. Lumin. 2014, 149, 176–184. [Google Scholar] [CrossRef]

- Yekeler, M.; Ulusoy, U. Characterisation of surface roughness and wettability of salt-type minerals: Calcite and barite. Miner. Process. Extr. Metall. 2004, 113, 145–152. [Google Scholar] [CrossRef]

- Gurpinar, G.; Sonmez, E.; Bozkurt, V. Effect of ultrasonic treatment on flotation of calcite, barite and quartz. Miner. Process. Extr. Metall. 2004, 113, 91–95. [Google Scholar] [CrossRef]

- Marinakis, K.I.; Shergold, H.L. Influence of sodium silicate addition on the adsorption of oleic acid by fluorite, calcite and barite. Int. J. Miner. Process. 1985, 14, 177–193. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, Z.; Gao, H.; Zheng, R.; Jin, Y.; Niu, C. Flotation studies of fluorite and barite with sodium petroleum sulfonate and sodium hexametaphosphate. J. Mater. Res. Technol. 2019, 8, 1267–1273. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, H.; Sun, W.; Hu, Y.; Qin, W.; Liu, R. Synergetic effect of the mixed anionic/non-ionic collectors in low temperature flotation of scheelite. Minerals 2017, 7, 87. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Wang, Z.; Miller, J.D. Flotation chemistry features in bastnaesite flotation with potassium lauryl phosphate. Miner. Eng. 2016, 85, 17–22. [Google Scholar] [CrossRef]

- Cao, Q.; Cheng, J.; Wen, S.; Li, C.; Liu, J. Synergistic effect of dodecyl sulfonate on apatite flotation with fatty acid collector. Sep. Sci. Technol. 2016, 51, 1389–1396. [Google Scholar] [CrossRef]

- Guimarães, R.C.; Araujo, A.C.; Peres, A.E.C. Reagents in igneous phosphate ores flotation. Miner. Eng. 2005, 18, 199–204. [Google Scholar] [CrossRef]

- Fuerstenau, D.W. A century of research leading to understanding the scientific basis of selective mineral flotation and design of flotation collectors. Miner. Metall. Explor. 2019, 36, 3–20. [Google Scholar] [CrossRef]

- Seth, V.; Kumar, R.; Arora, S.C.D.; Biswas, A.K. Disodium dodecyl phosphate as a collector in the calcite-apatite mineral system. Trans. Inst. Miner. Metall. 1975, 84, 56–58. [Google Scholar]

- Bulatovic, S.; Wyslouzil, D.M. Process development for treatment of complex perovskite, ilmenite and rutile ores. Miner. Eng. 1999, 12, 1407–1417. [Google Scholar] [CrossRef]

- Srinivas, K.; Sreenivas, T.; Padmanabhan, N.P.H.; Venugopal, R. Studies on the application of alkyl phosphoric acid ester in the flotation of wolframite. Miner. Process. Extr. Metall. Rev. 2004, 25, 253–267. [Google Scholar] [CrossRef]

- Chen, G.L.; Tao, D. Reverse flotation of magnesite by dodecyl phosphate from dolomite in the presence of sodium silicate. Sep. Sci. Technol. 2005, 39, 377–390. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Wang, X.; Miller, J.D. Smithsonite flotation with lauryl phosphate. Miner. Eng. 2020, 147, 106–155. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Miller, J.D. Collector chemistry for bastnaesite flotation—Recent developments. Miner. Process. Extr. Metall. Rev. 2019, 40, 370–379. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Xu, H.; Miller, J.D. Physical chemistry considerations in the selective flotation of bastnaesite with lauryl phosphate. Miner. Metall. Explor. 2017, 34, 116–124. [Google Scholar] [CrossRef]

- Liu, W.; Xu, H.; Wang, Z.; Wang, X. Adsorption features of water molecules and fatty acids at magnesium hydroxide surface from an MDS perspective. Surf. Innov. 2019, 7, 304–316. [Google Scholar] [CrossRef]

- Liu, W.; Xu, H.; Wang, Z.; Wang, X. Simulation of fatty acid adsorption at the magnesia surface. Surf. Innov. 2020, 8, 1–10. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, X.; Liu, W.; Li, E.; Cheng, F.; Miller, J.D. Dispersion behavior and attachment of high internal phase water-in-oil emulsion droplets during fine coal flotation. Fuel 2019, 253, 273–282. [Google Scholar] [CrossRef]

- Liu, W.; Miller, J.D. Higher selectivity of diisobutyl monothiophosphate in the flotation of elemental gold from pyrite. In Proceedings of the 42nd International Precious Metals Institute Annual Conference, San Antonio, TX, USA, 9–12 June 2018. [Google Scholar]

- Gao, Z.; Sun, W.; Hu, Y. New insights into the dodecylamine adsorption on scheelite and calcite: An adsorption model. Miner. Eng. 2015, 79, 54–61. [Google Scholar] [CrossRef]

- Drelich, J.; Wilbur, J.L.; Miller, J.D.; Whitesides, G.M. Contact angles for liquid drops at a model heterogeneous surface consisting of alternating and parallel hydrophobic/hydrophilic strips. Langmuir 1996, 12, 1913–1922. [Google Scholar] [CrossRef]

- Lam, C.N.C.; Wu, R.; Li, D.; Hair, M.L.; Neumann, A.W. Study of the advancing and receding contact angles: Liquid sorption as a cause of contact angle hysteresis. Adv. Colloid Interface 2002, 96, 169–191. [Google Scholar] [CrossRef]

- Delgado, A.V.; González-Caballero, F.; Hunter, R.J.; Koopal, L.K.; Lyklema, J. Measurement and interpretation of electrokinetic phenomena (IUPAC Technical Report). Pure Appl. Chem. 2005, 77, 1753–1805. [Google Scholar] [CrossRef]

- Ergen, G.; Özün, S.; Liu, W. Investigation of the effect of straight-chain xanthates on galena flotation depending on collector concentration and air flow rate (AFR). In Proceedings of the 26th International Mining Congress and Exhibition of Turkey, Belek, Turkey, 16–19 April 2019; Volume 1, pp. 787–794. [Google Scholar]

- Liu, W.; Wang, X.; Xu, H.; Miller, J.D. Lauryl phosphate adsorption in the flotation of bastnaesite, (Ce,La)FCO3. J. Colloid Interface Sci. 2017, 490, 825–833. [Google Scholar] [CrossRef]

- Colville, A.A.; Staudhammer, K. A refinement of the structure of barite. Am. Miner. J. Earth Planet. Mater. 1967, 52, 1877–1880. [Google Scholar]

- Bracco, J.N.; Lee, S.S.; Stubbs, J.E.; Eng, P.J.; Heberling, F.; Fenter, P.; Stack, A.G. Hydration structure of the barite (001)–water interface: Comparison of x-ray reflectivity with molecular dynamics simulations. J. Phys. Chem. C 2017, 121, 12236–12248. [Google Scholar] [CrossRef]

- Case, D.A.; Babin, V.; Berryman, J.T.; Betz, R.M.; Cai, Q.; Cerutti, D.S.; Darden, T.A.; Duke, R.E.; Gohlke, H.; Götz, A.W.; et al. AMBER 14; University of California: San Francisco, CA, USA, 2014. [Google Scholar]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual molecular dynamics. J. Mol. Graph. Model. 1996, 14, 33–38. [Google Scholar] [CrossRef]

- Liu, W.; McDonald, I.; Luther, W.; Wang, X.; Miller, J.D. Bastnaesite flotation chemistry issues associated with alkyl phosphate collectors. Miner. Eng. 2018, 127, 286–295. [Google Scholar] [CrossRef]

- Stack, A.G. Molecular dynamics simulations of solvation and Kink Site formation at the (001) Barite−Water interface. J. Phys. Chem. C 2008, 113, 2104–2110. [Google Scholar] [CrossRef]

- Rappé, A.K.; Casewit, C.J.; Colwell, K.S.; Goddard, W.A., III; Skiff, W.M. UFF, a full periodic table force field for molecular mechanics and molecular dynamics simulations. J. Am. Chem. Soc. 1992, 114, 10024–10035. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Grigera, J.R.; Straatsma, T.P. The missing term in effective pair potentials. J. Phys. Chem. 1987, 91, 6269–6271. [Google Scholar] [CrossRef]

- Veeramasuneni, S.; Drelich, J.; Miller, J.D.; Yamauchi, G. Hydrophobicity of ion-plated PTFE coatings. Prog. Organ. Coat. 1997, 31, 265–270. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, Z.; Gao, H.; Qian, Y.; Zheng, R. Effect of modified starch on separation of fluorite from barite using sodium oleate. Physicochem. Probl. Miner. Process. 2018, 54, 228–237. [Google Scholar]

- Drelich, J.W.; Boinovich, L.; Chibowski, E.; Della Volpe, C.; Hołysz, L.; Marmur, A.; Siboni, S. Contact angles: History of over 200 years of open questions. Surf. Innov. 2019, 8, 3–27. [Google Scholar] [CrossRef]

- Nakayama, K.; Tari, I.; Sakai, M.; Murata, Y.; Sugihara, G. Aggregation behavior of sodium mono-n-dodecyl phosphate surfactant in aqueous media, and function in catalytic activity. I. Multi-step aggregates formation and catalytic activity for hydrolysis of p-nitrophenyl acetate in aqueous solution. J. Oleo Sci. 2004, 53, 247–265. [Google Scholar]

- Lichstein, B.; Woolf, C. Process for removal of phosphates from solutions containing fluoride ions. US Patent 3,755,546, 1973. [Google Scholar]

- Sadowski, Z. The spherical oil agglomeration of barite suspensions in the presence of surfactant and cosurfactant. Colloid Surf. A 1993, 80, 147–152. [Google Scholar] [CrossRef]

- Burkin, A.R. The Chemistry of Hydrometallurgical Processes; D. Van Nostrand Co.: Princeton, NJ, USA, 1972. [Google Scholar]

- Young, C.; Miller, J.D. Thermodynamic evaluation of oleate chemisorption at calcium semi-soluble salt surfaces. In Proceedings of the International Conference on Advances in Materials and Materials Processing, ICAMMP-2002, Kharagpur, India, 1–3 February 2002; Tata McGraw-Hill: New Delhi, India; pp. 793–805. [Google Scholar]

| Number of Molecules | |||||

|---|---|---|---|---|---|

| Na+ | RH2 | RH− | R2− | Water | |

| pH < 2.85 | 6 | 2182 | |||

| 2.85 < pH < 7.35 | 6 | 6 | 2182 | ||

| pH > 7.35 | 12 | 6 | 2182 | ||

| Species | Charge [e] | ε [kcal/mol] | r [Å] | Reference |

|---|---|---|---|---|

| Barium in barite | 2 | 0.364 | 3.703 | [35,36] |

| Sulfur in barite | 1.544 | 0.274 | 4.035 | [35,36] |

| Oxygen in barite | −0.886 | 0.1554 | 3.5536 | [35,37] |

| Water oxygen | −0.8476 | 0.1554 | 3.1659 | [37] |

| Water hydrogen | 0.4238 | 0 | 0 | [37] |

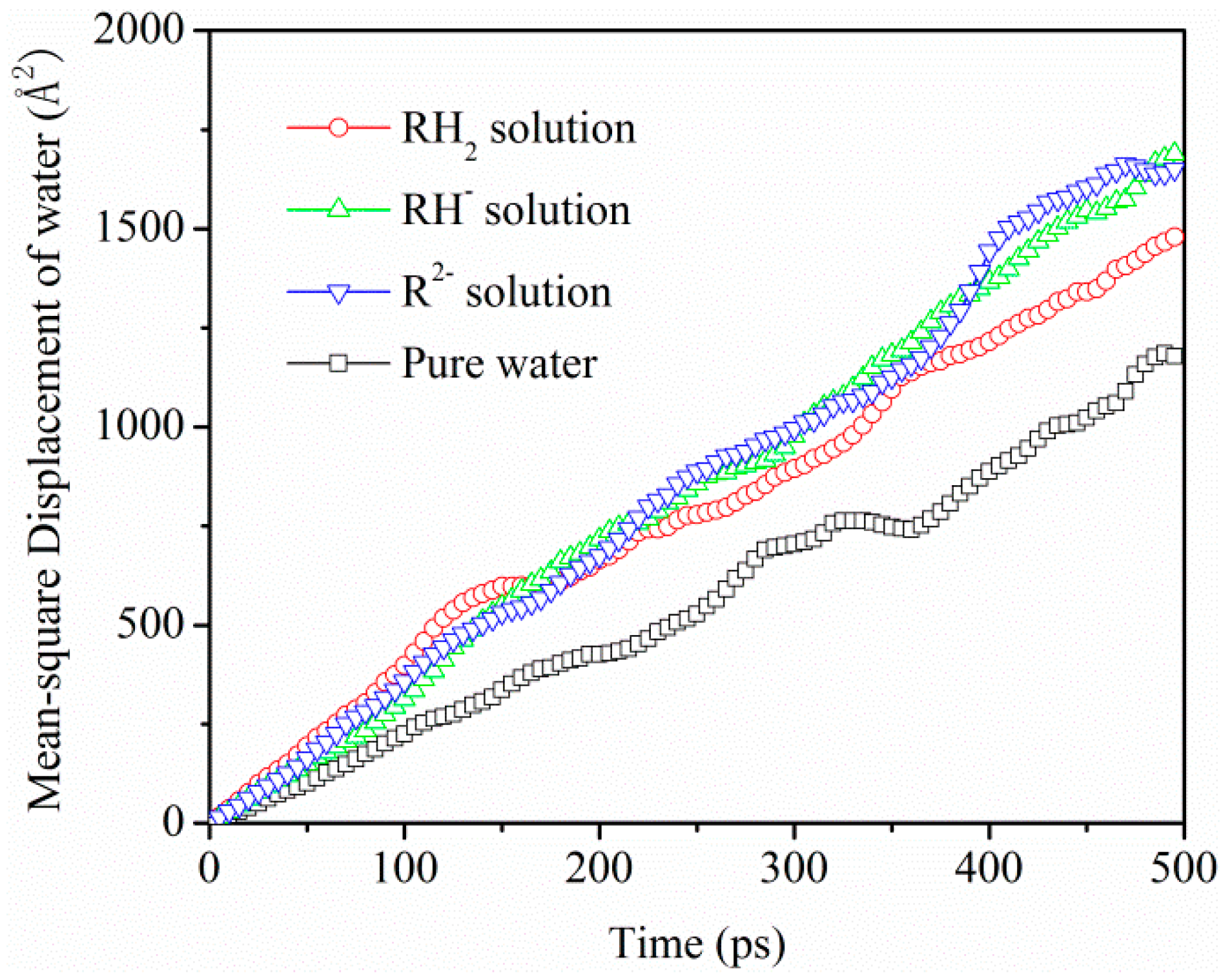

| System | D (10−5 cm2/s) |

|---|---|

| Pure water | 3.84 |

| RH2 solution | 4.71 |

| RH− solution | 5.69 |

| R2− solution | 5.77 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Liu, W.; Wang, X.; Cheng, H.; Cheng, F.; Miller, J.D. Lauryl Phosphate Flotation Chemistry in Barite Flotation. Minerals 2020, 10, 280. https://doi.org/10.3390/min10030280

Lu Y, Liu W, Wang X, Cheng H, Cheng F, Miller JD. Lauryl Phosphate Flotation Chemistry in Barite Flotation. Minerals. 2020; 10(3):280. https://doi.org/10.3390/min10030280

Chicago/Turabian StyleLu, Ying, Weiping Liu, Xuming Wang, Huaigang Cheng, Fangqin Cheng, and Jan D. Miller. 2020. "Lauryl Phosphate Flotation Chemistry in Barite Flotation" Minerals 10, no. 3: 280. https://doi.org/10.3390/min10030280

APA StyleLu, Y., Liu, W., Wang, X., Cheng, H., Cheng, F., & Miller, J. D. (2020). Lauryl Phosphate Flotation Chemistry in Barite Flotation. Minerals, 10(3), 280. https://doi.org/10.3390/min10030280