Grinding Behaviors of Components in Heterogeneous Breakage of Coals of Different Ash Contents in a Ball-and-Race Mill

Abstract

1. Introduction

2. Materials, Equipment and Method

2.1. Materials, Equipment and Grinding Tests

2.2. Quantification of Components in Heterogeneous Grinding Products

3. Results and Discussion

3.1. Grinding Behavior of Components and Mixtures

3.2. Energy Consumed Characterizations of Mixtures and Components

4. Conclusions

- (1)

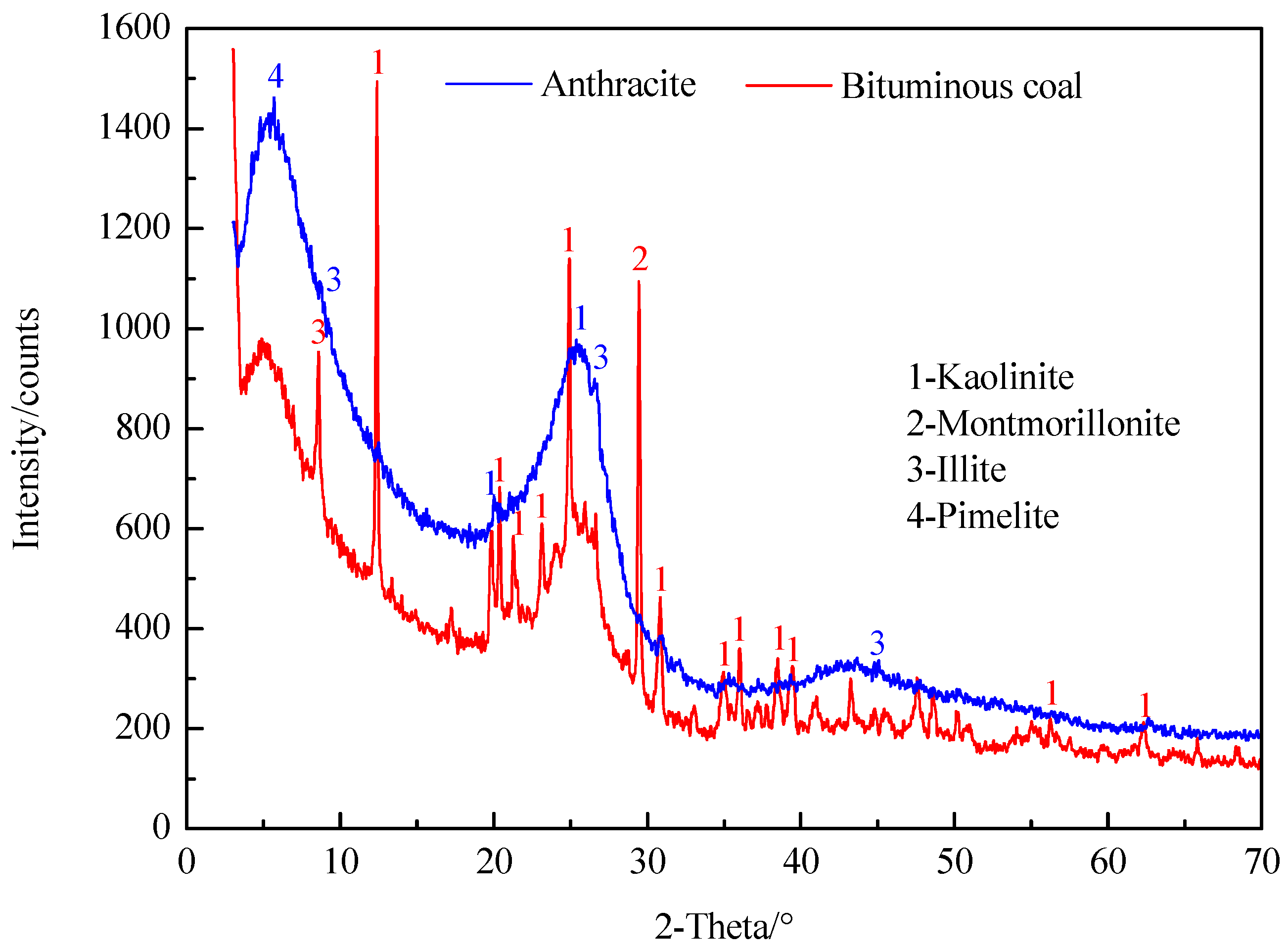

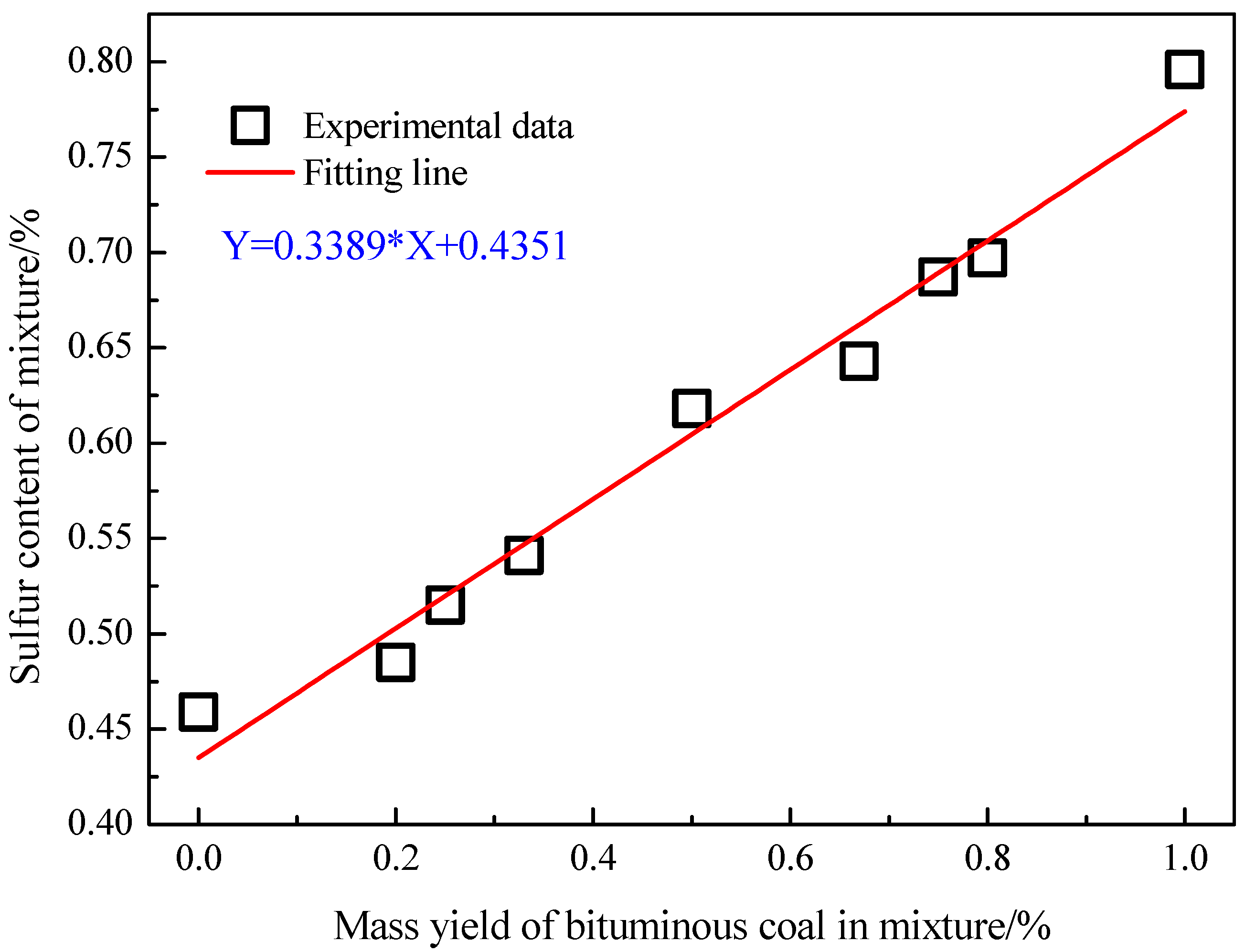

- XRD results show that sulfur in two coals is in organic form, and its content is quantified by XRF. Sulfur contents of mixtures show a linear relation with the mass yield of bituminous coal, which contributes to determining the product fineness t10 of two coals at various grinding conditions and time periods.

- (2)

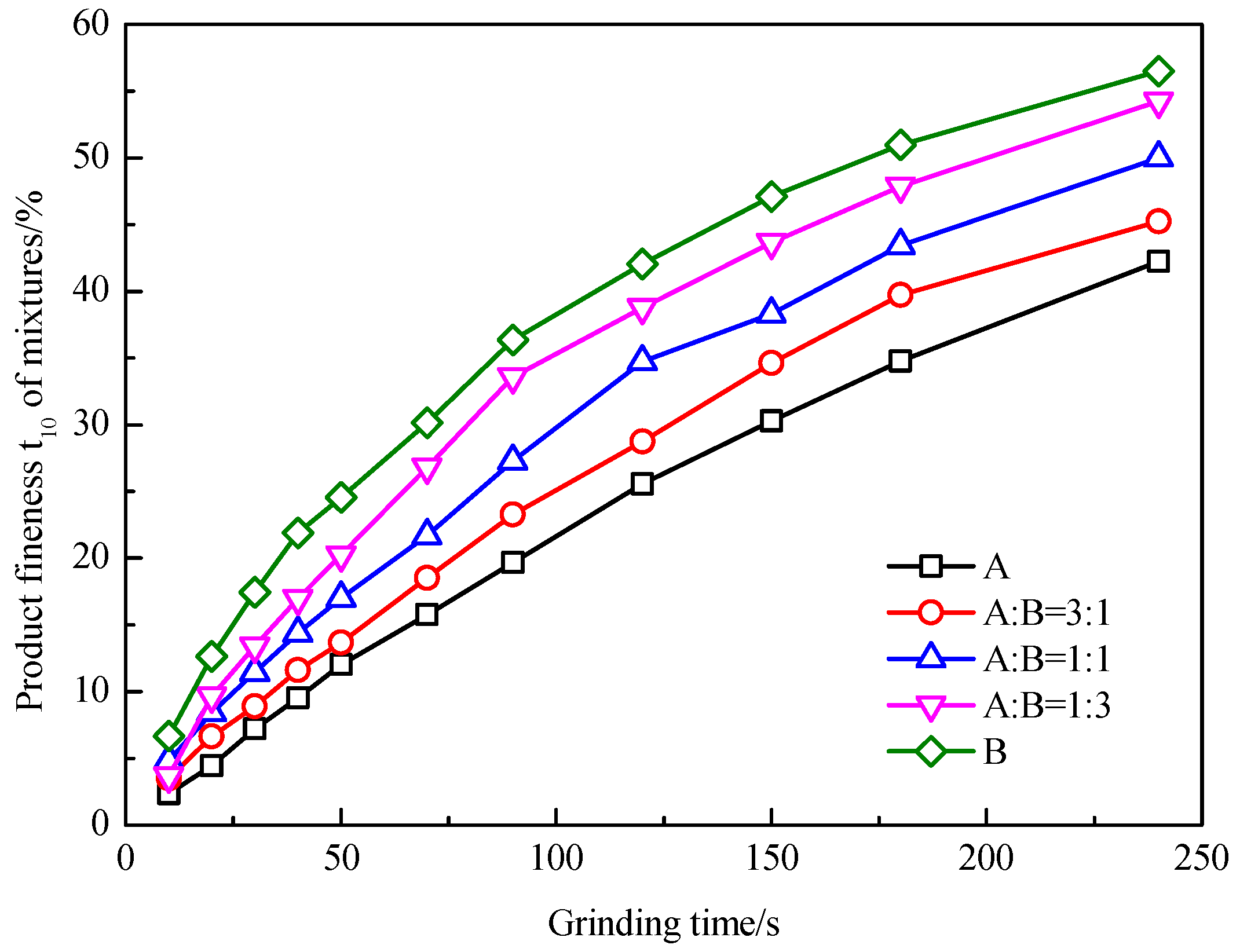

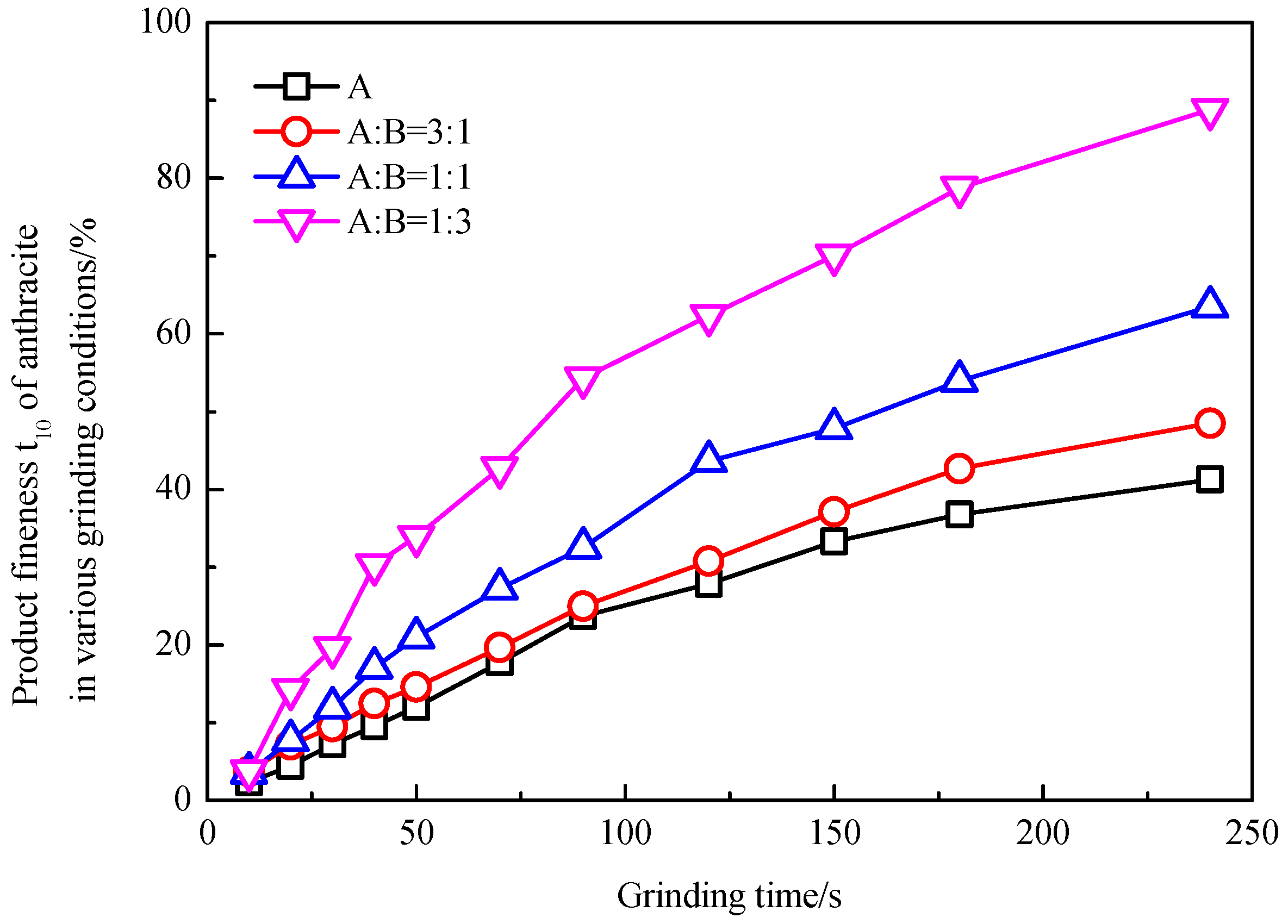

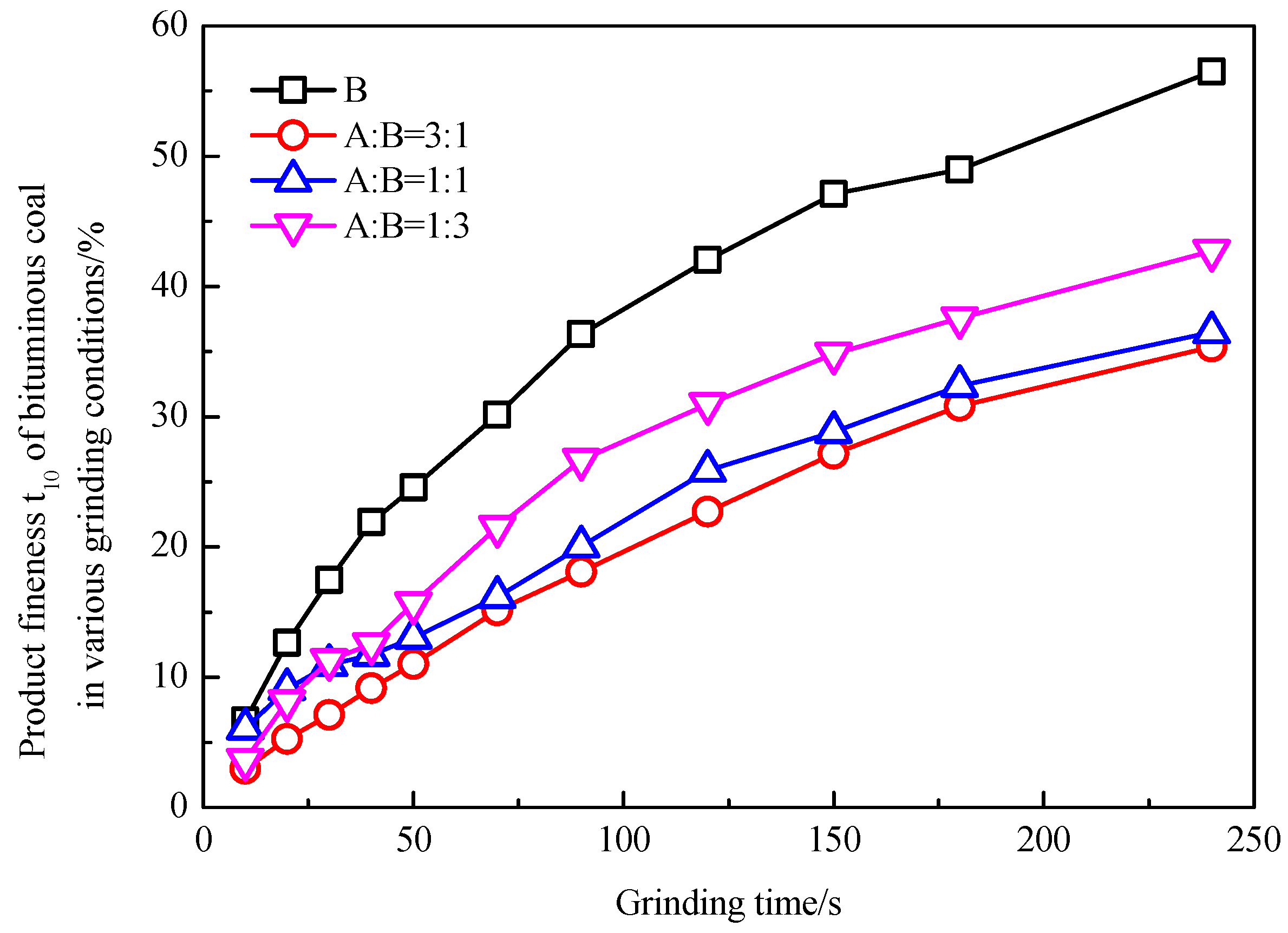

- The breakage rate of the mixture obeys the first-order law. In the mixture breakage, the breakage rate increases with increasing the mass ratio of bituminous coal of the mixture. Compared with the single breakage of anthracite, t10 is improved significantly after mixing with the soft bituminous coal. If the content of anthracite decreases to 25%, t10 is more than twice that of homogeneous grinding, but t10 of bituminous coal is reduced.

- (3)

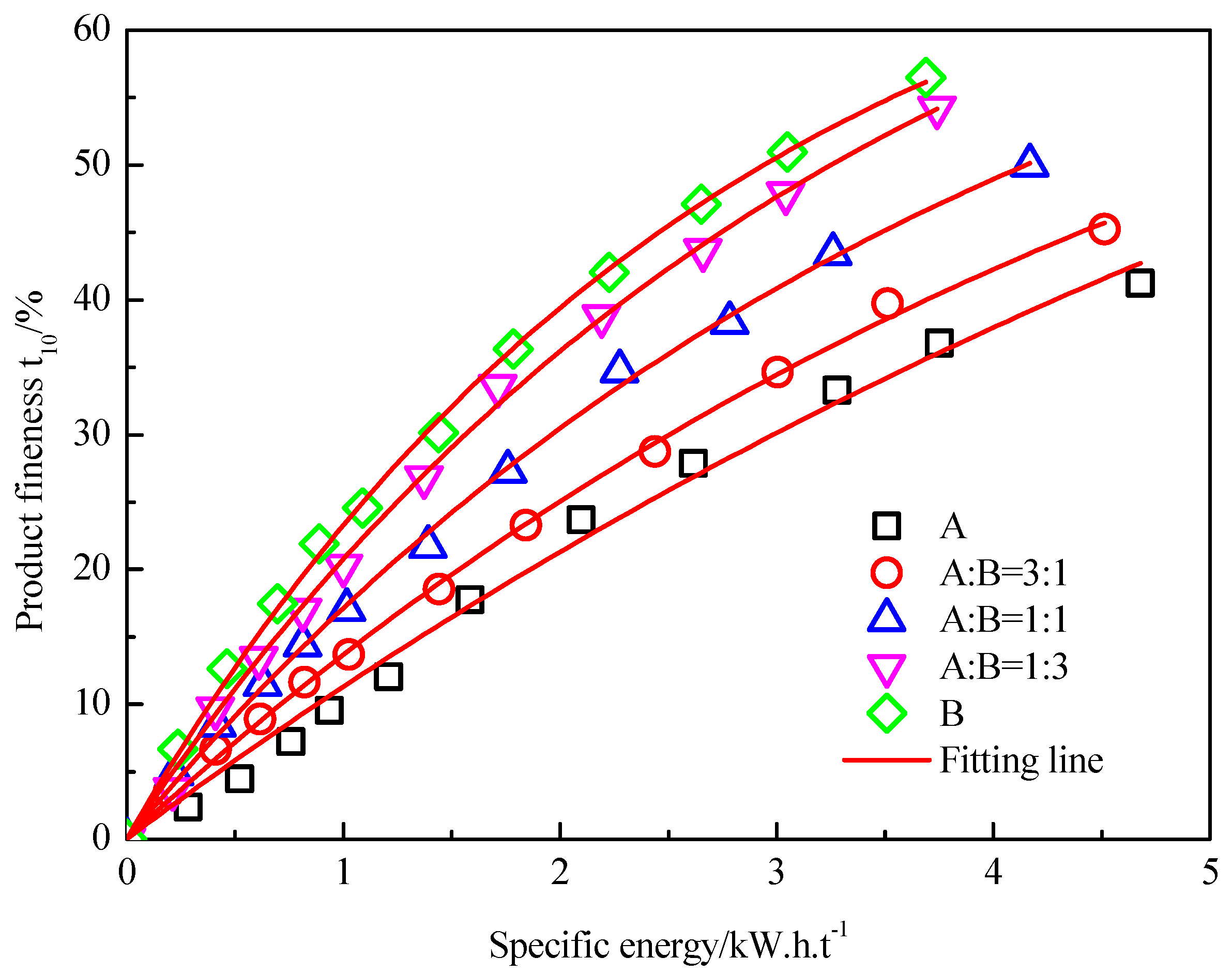

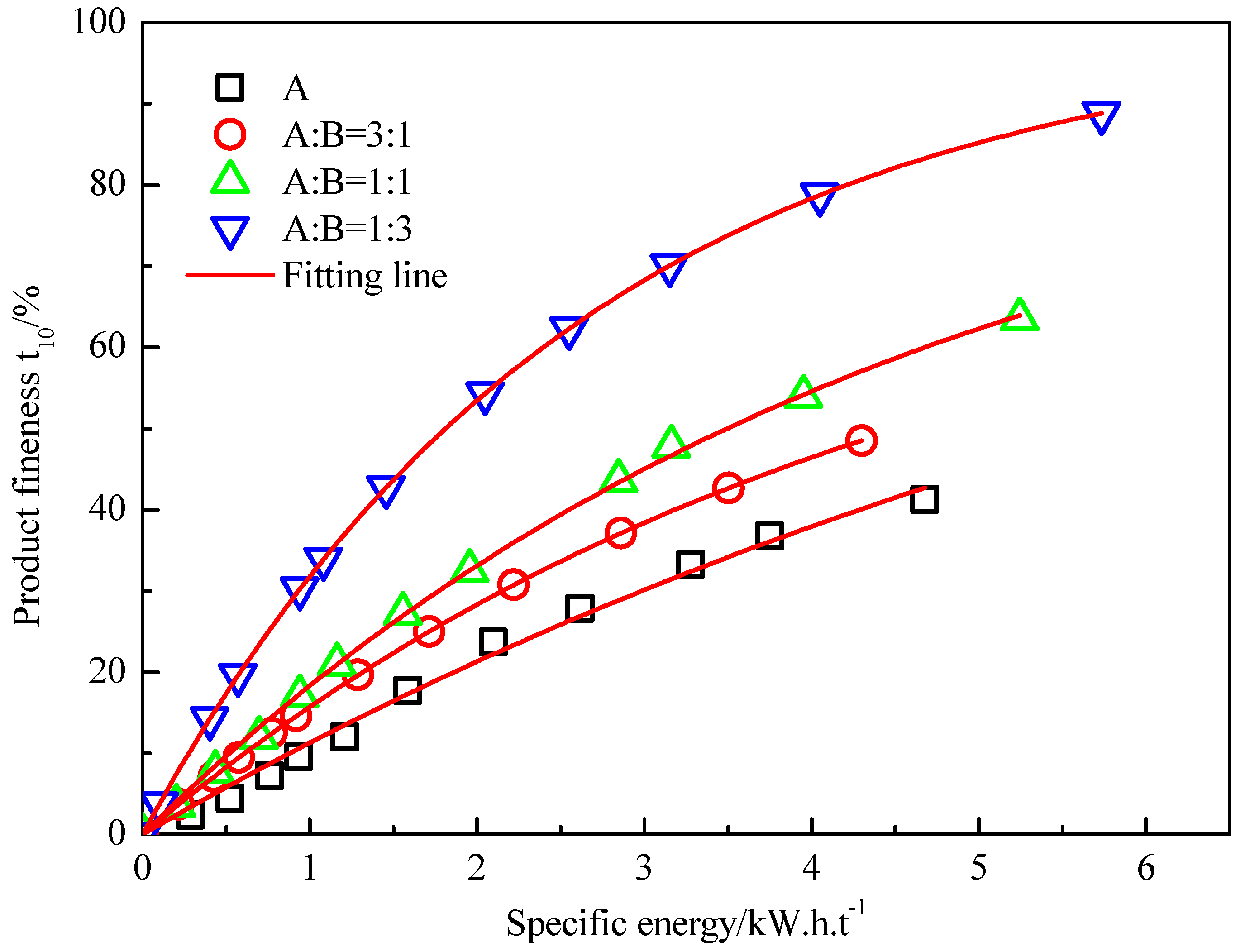

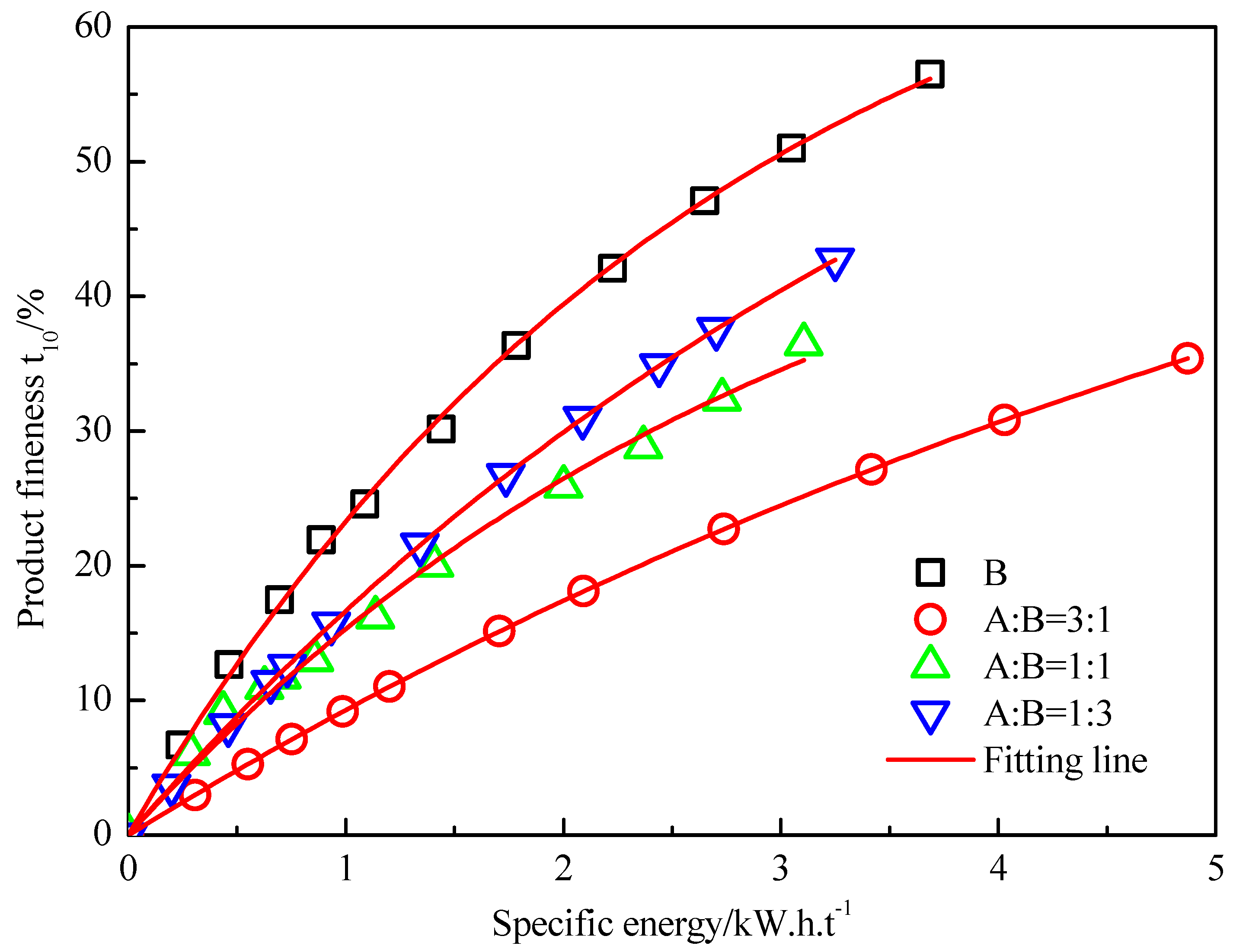

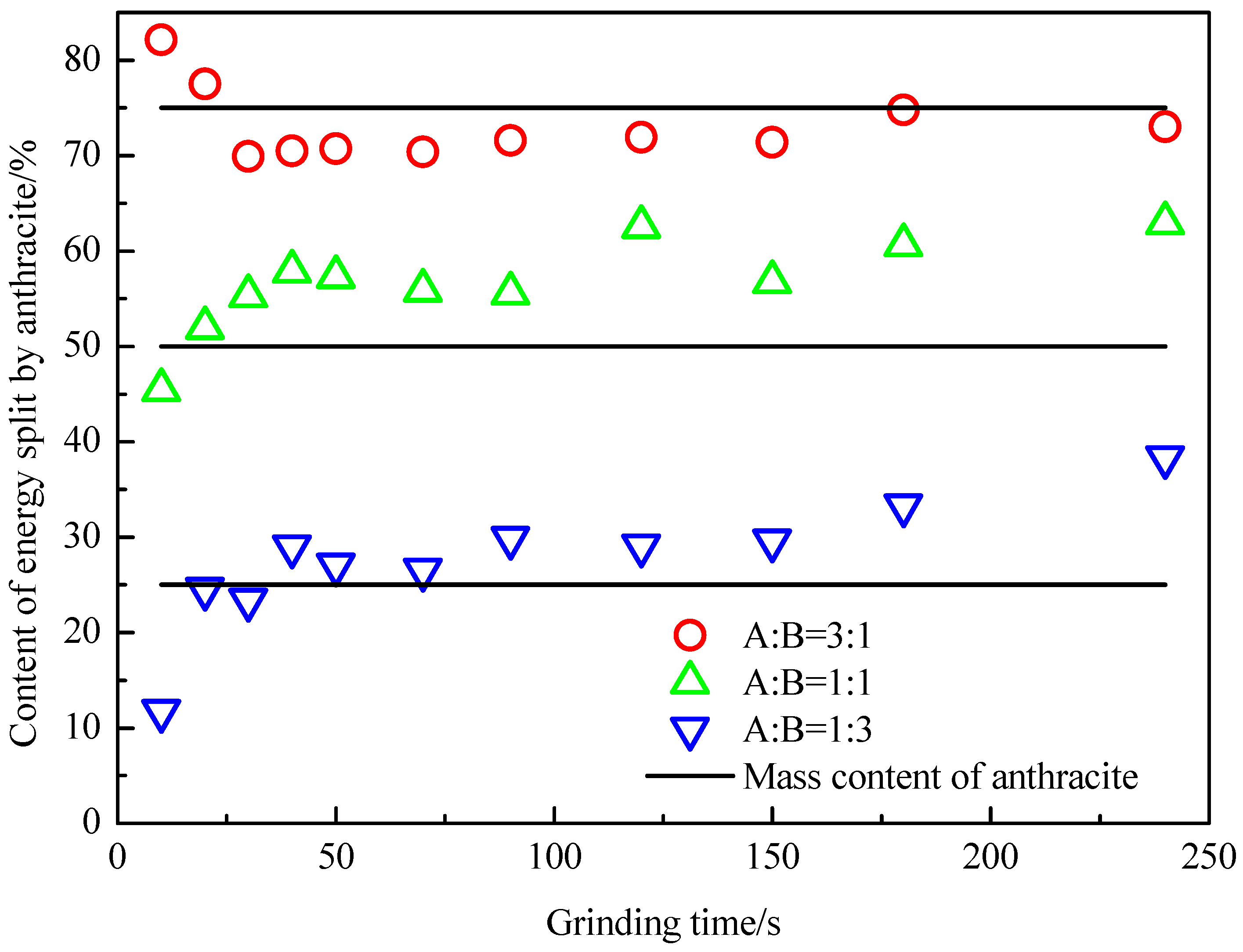

- The classical energy-size reduction model can be applied for the mixture breakage of coals in the Hardgrove mill. Breakage indicator A*b of the mixture increases with adding more soft bituminous coal. Specific energy of the mixture is a little lower than the mass average one of components due to the component interaction in mixture breakage. The relation between t10 and the specific energy of the component indicates that energy efficiency of anthracite grinding increases during the heterogeneous grinding. Added bituminous coal surrounds anthracite particles and improves the grinding phenomenon if compared with the single breakage. Content of energy split by anthracite is bigger than the mass yield of it in the mixture, which indicates the easy transfer of energy to anthracite.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Kim, H.N.; Kim, J.W.; Kim, M.S.; Lee, B.H.; Kim, J.C. Effects of ball size on the grinding behavior of talc using a high-energy ball mill. Minerals 2019, 9, 668. [Google Scholar] [CrossRef]

- Yang, J.; Shuai, Z.; Zhou, W.; Ma, S. Grinding optimization of cassiterite-polymetallic sulfide ore. Minerals 2019, 9, 134. [Google Scholar] [CrossRef]

- Chelgani, S.C.; Parian, M.; Parapari, P.S.; Ghorbani, Y.; Rosenkranz, J. A comparative study on the effects of dry and wet grinding on mineral flotation separation—A review. J. Mater. Res. Technol. 2019, 8, 5004–5011. [Google Scholar] [CrossRef]

- Dündar, H.; Benzer, H. Investigating multicomponent breakage in cement grinding. Miner. Eng. 2015, 77, 131–136. [Google Scholar] [CrossRef]

- Wu, C.; Liao, N.; Shi, G.; Zhu, L. Breakage characterization of grinding media based on energy consumption and particle size distribution: Hexagons versus cylpebs. Minerals 2018, 8, 527. [Google Scholar] [CrossRef]

- Xie, W.; He, Y.; Qu, L.; Sun, X.; Zhu, X. Effect of particle properties on the energy-size reduction of coal in the ball-and-race mill. Powder Technol. 2018, 333, 404–409. [Google Scholar] [CrossRef]

- Shi, F.; Zuo, W. Coal breakage characterization—Part 1: Breakage testing with the JKFBC. Fuel 2014, 117, 1148–1155. [Google Scholar] [CrossRef]

- Hu, Z.-F.; Sun, C.-Y. Effects and mechanism of different grinding media on the flotation behaviors of beryl and spodumene. Minerals 2019, 9, 666. [Google Scholar] [CrossRef]

- Yilmaz, S. A new approach for the testing method of coal grindability. Adv. Powder Technol. 2019, 30, 1932–1940. [Google Scholar] [CrossRef]

- Sato, K.; Meguri, N.; Shoji, K.; Kanemoto, H.; Hasegawa, T.; Maruyama, T. Breakage of coals in ring-roller mills part I. The breakage properties of various coals and simulation model to predict steady-state mill performance. Powder Technol. 1996, 86, 275–283. [Google Scholar] [CrossRef]

- Reichert, M.; Gerold, C.; Fredriksson, A.; Adolfsson, G.; Lieberwirth, H. Research of iron ore grinding in a vertical-roller-mill. Miner. Eng. 2014, 73, 109–115. [Google Scholar] [CrossRef]

- Austin, L.G.; Shah, J.; Wang, J.; Gallagher, E.; Luckie, P.T. An analysis of ball-and-race milling part 1. The hardgrove mill. Powder Technol. 1981, 29, 263–275. [Google Scholar] [CrossRef]

- Austin, L.G.; Luckie, P.T.; Shoji, K. An analysis of ball-and-race milling part II. The bobcock E1.7 mill. Powder Technol. 1982, 33, 113–125. [Google Scholar] [CrossRef]

- Austin, L.G.; Luckie, P.T.; Shoji, K. An analysis of ball-and-race milling part III. Scale-up to industrial. Powder Technol. 1982, 25, 127–134. [Google Scholar] [CrossRef]

- Shi, F. Coal breakage characterization-Part 2: Multi-component breakage modelling. Fuel 2014, 117, 1156–1162. [Google Scholar] [CrossRef]

- Shi, F. A review of the applications of the JK size-dependent breakage model Part 2: Assessment of material strength and energy requirement in size reduction. Int. J. Miner. Process 2016, 157, 36–45. [Google Scholar] [CrossRef]

- Shi, F. A review of the applications of the JK size-dependent breakage model Part 1: Ore and coal breakage characterisation. Int. J. Miner. Process 2016, 155, 118–129. [Google Scholar] [CrossRef]

- Tavares, L.M.; Kallemback, R.D.C. Grindability of binary ore blends in ball mills. Miner. Eng. 2013, 41, 115–120. [Google Scholar] [CrossRef]

- Abouzeid, A.M.; Fuerstenau, D.W. Grinding of mineral mixtures in high-pressure grinding rolls. Int. J. Miner. Process 2009, 93, 59–65. [Google Scholar] [CrossRef]

- Venkataraman, K.S.; Fuerstenau, D.W. Application of the population balance model to the grinding of mixtures of minerals. Powder Technol. 1984, 39, 133–142. [Google Scholar] [CrossRef]

- Cho, H.; Peter, L. Investigation of the Breakage Properties of Components in Mixtures Ground in a Batch Ball-and-Race Mill. Energy Fuels 1995, 9, 53–58. [Google Scholar] [CrossRef]

- Austin, L.G.; Bagga, P.; Celik, M. Breakage properties of some materials in a laboratory ball mill. Powder Technol. 1981, 28, 235–241. [Google Scholar] [CrossRef]

- Xie, W.; He, Y.; Yang, Y.; Shi, F.; Huang, Y.; Li, H.; Wang, S.; Li, B. Experimental investigation of breakage and energy consumption characteristics of mixtures of different components in vertical spindle pulverizer. Fuel 2017, 190, 208–220. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, W.; Zhang, F.; He, Y.; Duan, C.; Wang, S.; Zhu, X. Energy-size reduction of mixtures of anthracite and coking coal in Hardgrove mill. Fuel 2020, 264, 116829. [Google Scholar] [CrossRef]

- Kapur, P.C.; Fuerstenau, D.W. Energy split in multicomponent grinding. Int. J. Miner. Process 1988, 24, 125–142. [Google Scholar] [CrossRef]

- Xie, W.; He, Y.; Ge, Z.; Shi, F.; Yang, Y.; Li, H.; Wang, S.; Li, K. An analysis of the energy split for grinding coal/calcite mixture in a ball-and-race mill. Miner. Eng. 2016, 93, 1–9. [Google Scholar] [CrossRef]

- Shi, F. A review of the applications of the JK size-dependent breakage model part 3: Comminution equipment modelling. Int. J. Miner. Process 2016, 157, 60–72. [Google Scholar] [CrossRef]

| Grinding Time/s | Content of Sulfur/% | ||

|---|---|---|---|

| A:B = 3:1 | A:B = 1:1 | A:B = 1:3 | |

| 10 | 0.507 | 0.648 | 0.687 |

| 20 | 0.502 | 0.618 | 0.649 |

| 30 | 0.503 | 0.597 | 0.650 |

| 40 | 0.502 | 0.573 | 0.623 |

| 50 | 0.503 | 0.565 | 0.632 |

| 70 | 0.504 | 0.561 | 0.639 |

| 90 | 0.501 | 0.564 | 0.637 |

| 120 | 0.502 | 0.561 | 0.638 |

| 150 | 0.502 | 0.563 | 0.638 |

| 180 | 0.501 | 0.563 | 0.635 |

| 240 | 0.501 | 0.559 | 0.635 |

| Breakage Parameters | Mixture Conditions | ||||

|---|---|---|---|---|---|

| A | A:B = 3:1 | A:B = 1:1 | A:B = 1:3 | B | |

| A | 97.63 | 80.24 | 77.44 | 80.77 | 75.68 |

| b | 0.12 | 0.19 | 0.25 | 0.30 | 0.37 |

| A*b | 12.01 | 15.00 | 19.36 | 23.99 | 27.82 |

| Specific Energy/kW.h.t−1 | Measured Data | Mass Average Data | ||||||

|---|---|---|---|---|---|---|---|---|

| Grinding Time/s | A | A:B = 3:1 | A:B = 1:1 | A:B = 1:3 | B | A:B = 3:1 | A:B = 1:1 | A:B = 1:3 |

| 10 | 0.28 | 0.20 | 0.22 | 0.21 | 0.24 | 0.27 | 0.26 | 0.25 |

| 20 | 0.52 | 0.41 | 0.42 | 0.41 | 0.46 | 0.51 | 0.49 | 0.48 |

| 30 | 0.76 | 0.62 | 0.63 | 0.61 | 0.70 | 0.74 | 0.73 | 0.71 |

| 40 | 0.94 | 0.82 | 0.81 | 0.81 | 0.89 | 0.92 | 0.91 | 0.90 |

| 50 | 1.21 | 1.03 | 1.01 | 1.00 | 1.09 | 1.18 | 1.15 | 1.12 |

| 70 | 1.59 | 1.44 | 1.39 | 1.37 | 1.44 | 1.55 | 1.51 | 1.48 |

| 90 | 2.10 | 1.84 | 1.76 | 1.71 | 1.78 | 2.02 | 1.94 | 1.86 |

| 120 | 2.61 | 2.44 | 2.28 | 2.19 | 2.23 | 2.52 | 2.42 | 2.32 |

| 150 | 3.28 | 3.00 | 2.78 | 2.66 | 2.65 | 3.12 | 2.96 | 2.81 |

| 180 | 3.75 | 3.51 | 3.26 | 3.04 | 3.05 | 3.58 | 3.40 | 3.22 |

| 240 | 4.68 | 4.51 | 4.17 | 3.74 | 3.69 | 4.43 | 4.18 | 3.94 |

| Specific Energy/kW.h.t−1 | Mixture Conditions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grinding Time/s | A:B = 3:1 | A:B = 1:1 | A:B = 1:3 | |||||||||

| A | B | Calculated Mixture | Measured Mixture | A | B | Calculated Mixture | Measured Mixture | A | B | Calculated Mixture | Measured Mixture | |

| 10 | 0.22 | 0.31 | 0.24 | 0.20 | 0.20 | 0.29 | 0.25 | 0.22 | 0.10 | 0.20 | 0.17 | 0.21 |

| 20 | 0.43 | 0.55 | 0.46 | 0.41 | 0.44 | 0.44 | 0.44 | 0.42 | 0.40 | 0.46 | 0.45 | 0.41 |

| 30 | 0.58 | 0.75 | 0.62 | 0.62 | 0.69 | 0.63 | 0.66 | 0.63 | 0.57 | 0.65 | 0.63 | 0.61 |

| 40 | 0.77 | 0.99 | 0.82 | 0.82 | 0.94 | 0.71 | 0.82 | 0.81 | 0.94 | 0.73 | 0.78 | 0.81 |

| 50 | 0.92 | 1.20 | 0.99 | 1.03 | 1.16 | 0.86 | 1.01 | 1.01 | 1.08 | 0.93 | 0.97 | 1.00 |

| 70 | 1.29 | 1.71 | 1.39 | 1.44 | 1.56 | 1.14 | 1.35 | 1.39 | 1.46 | 1.34 | 1.37 | 1.37 |

| 90 | 1.71 | 2.09 | 1.81 | 1.84 | 1.96 | 1.41 | 1.68 | 1.76 | 2.05 | 1.74 | 1.81 | 1.71 |

| 120 | 2.22 | 2.74 | 2.35 | 2.44 | 2.85 | 2.00 | 2.42 | 2.28 | 2.55 | 2.09 | 2.20 | 2.19 |

| 150 | 2.86 | 3.42 | 3.00 | 3.00 | 3.16 | 2.37 | 2.76 | 2.78 | 3.15 | 2.44 | 2.62 | 2.66 |

| 180 | 3.50 | 4.03 | 3.63 | 3.51 | 3.95 | 2.73 | 3.34 | 3.26 | 4.05 | 2.70 | 3.04 | 3.04 |

| 240 | 4.30 | 4.87 | 4.44 | 4.51 | 5.25 | 3.11 | 4.18 | 4.17 | 5.73 | 3.25 | 3.87 | 3.74 |

| Breakage Parameters | Anthracite | Bituminous Coal | ||||||

|---|---|---|---|---|---|---|---|---|

| Single | A:B = 3:1 | A:B = 1:1 | A:B = 1:3 | Single | A:B = 3:1 | A:B = 1:1 | A:B = 1:3 | |

| A | 97.6257 | 78.721 | 94.2295 | 99.958 | 75.684 | 73.043 | 56.1382 | 81.387 |

| b | 0.12305 | 0.223 | 0.21653 | 0.383 | 0.3676 | 0.136 | 0.3024 | 0.229 |

| A*b | 12.01 | 17.55 | 20.40 | 38.28 | 27.82 | 9.93 | 16.98 | 18.64 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, J.; Lu, Q.; Zhao, Z.; Wang, X.; Zhang, Y.; Wang, J.; Li, B.; Xie, W.; Sun, X.; Zhu, X. Grinding Behaviors of Components in Heterogeneous Breakage of Coals of Different Ash Contents in a Ball-and-Race Mill. Minerals 2020, 10, 230. https://doi.org/10.3390/min10030230

Duan J, Lu Q, Zhao Z, Wang X, Zhang Y, Wang J, Li B, Xie W, Sun X, Zhu X. Grinding Behaviors of Components in Heterogeneous Breakage of Coals of Different Ash Contents in a Ball-and-Race Mill. Minerals. 2020; 10(3):230. https://doi.org/10.3390/min10030230

Chicago/Turabian StyleDuan, Jin, Qichang Lu, Zhenyang Zhao, Xin Wang, Yuxin Zhang, Jue Wang, Biao Li, Weining Xie, Xiaolu Sun, and Xiangnan Zhu. 2020. "Grinding Behaviors of Components in Heterogeneous Breakage of Coals of Different Ash Contents in a Ball-and-Race Mill" Minerals 10, no. 3: 230. https://doi.org/10.3390/min10030230

APA StyleDuan, J., Lu, Q., Zhao, Z., Wang, X., Zhang, Y., Wang, J., Li, B., Xie, W., Sun, X., & Zhu, X. (2020). Grinding Behaviors of Components in Heterogeneous Breakage of Coals of Different Ash Contents in a Ball-and-Race Mill. Minerals, 10(3), 230. https://doi.org/10.3390/min10030230